Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "To achieve high precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

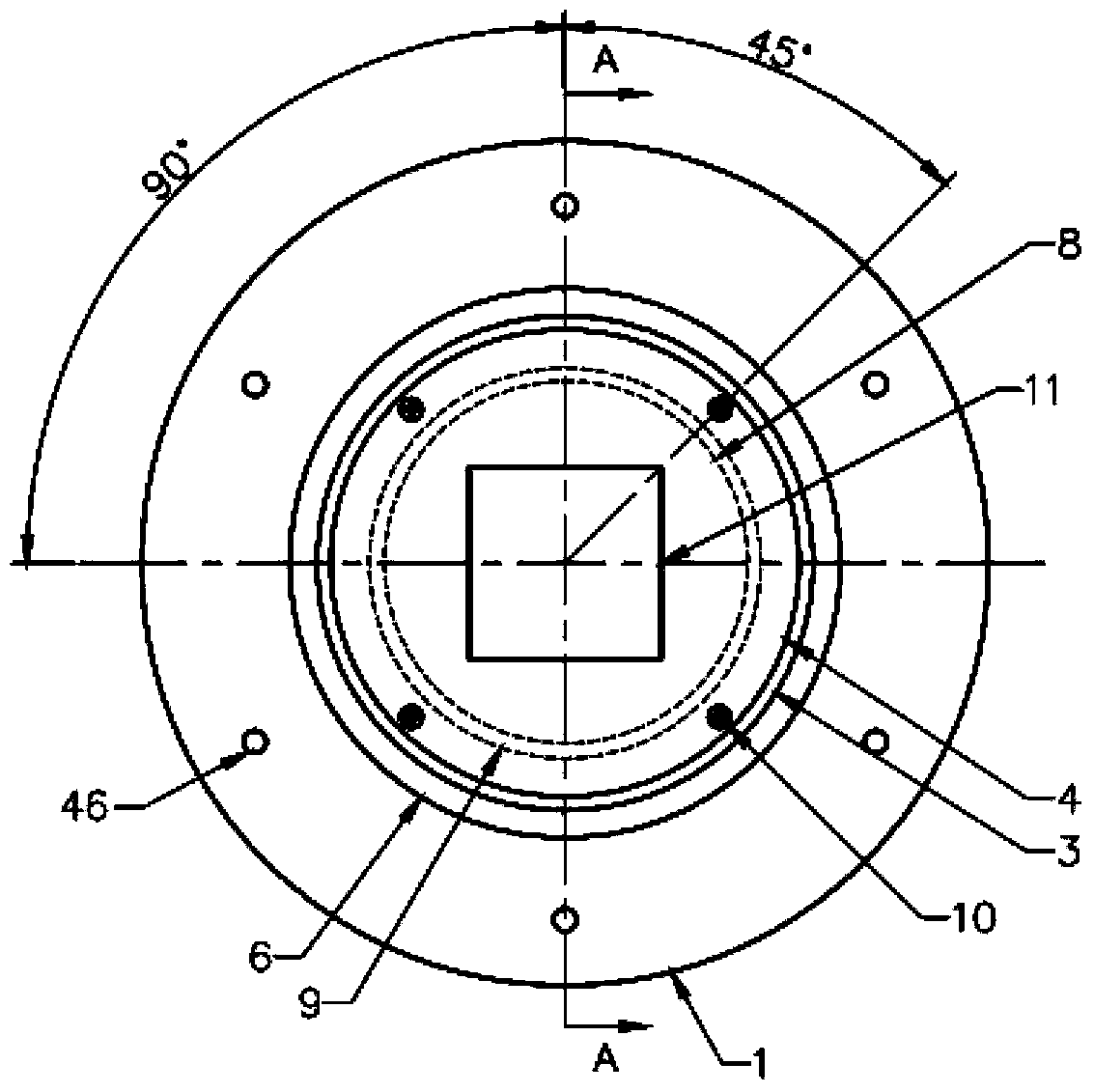

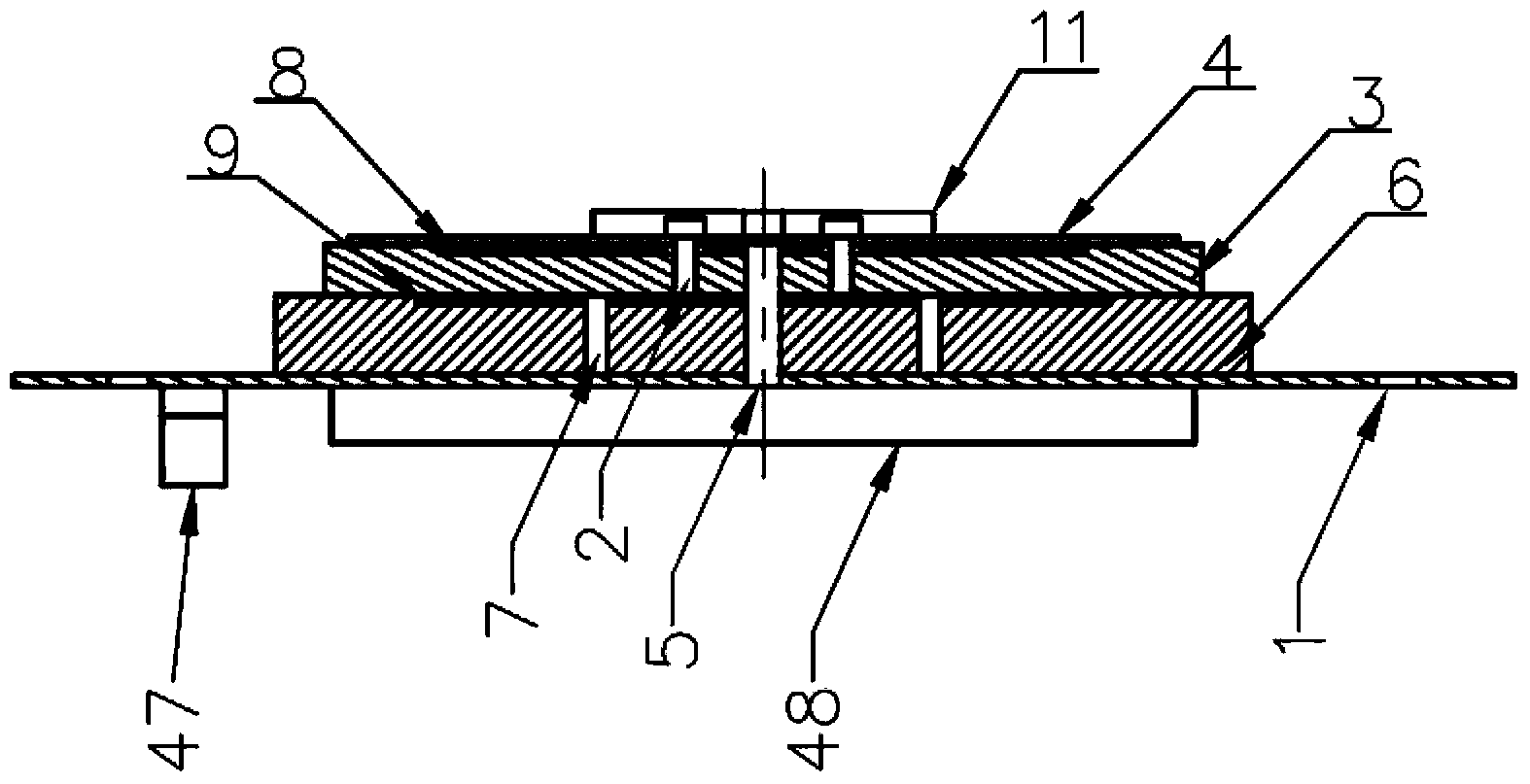

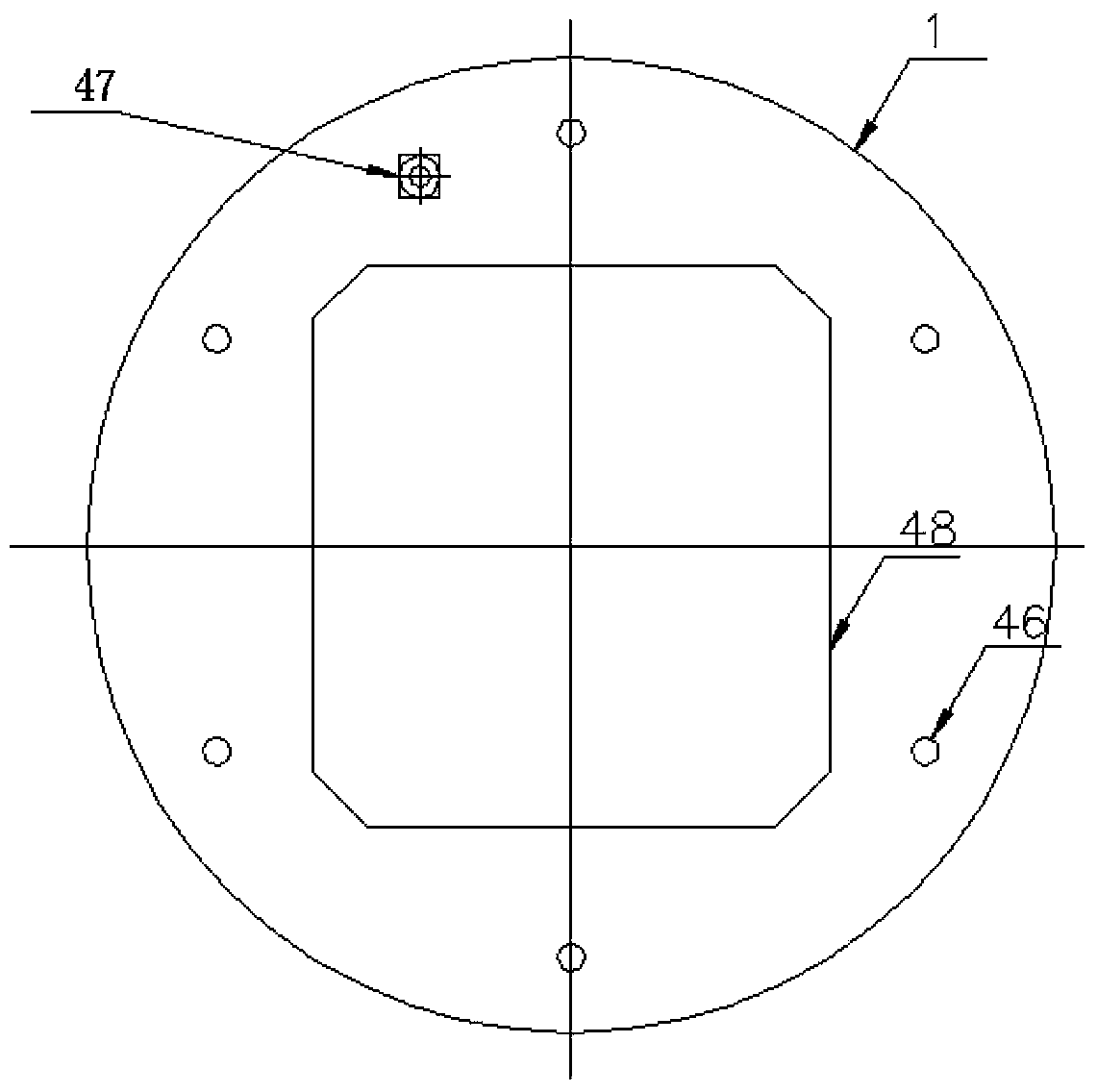

Antenna device and receiving system

ActiveCN103474766AHigh phase stabilityHigh bandwidthSimultaneous aerial operationsRadiating elements structural formsLow noiseMedia layer

An antenna device comprises a reflecting plate, a top shielding cover arranged on one side of the reflecting plate, a first frequency band feed network, a substrate, a first frequency band radiating face, a first frequency band medium layer, a second frequency band radiating face, a second frequency band medium layer, at least one first frequency band feed probe, a second frequency band feed probe, a second frequency band feed network arranged on the other side of the reflecting plate and a low-noise amplifying circuit. The top shielding cover is fixed on the substrate, the first frequency band radiating face is connected to the first frequency band feed network through the first frequency band feed probe, the second frequency band radiating face is larger than the first frequency band radiating face and positioned on the second frequency band medium layer, the second frequency band radiating face is connected to the second frequency band feed network through a second frequency band feed probe, and the first frequency band feed network and the second frequency band feed network are connected with the low-noise amplifying circuit. The invention further provides a receiving system. By means of the antenna device and the receiving system, mutual interference between all frequency points is avoided, the phase stability of an antenna is improved, and the measuring accuracy is improved.

Owner:HARXON CORP

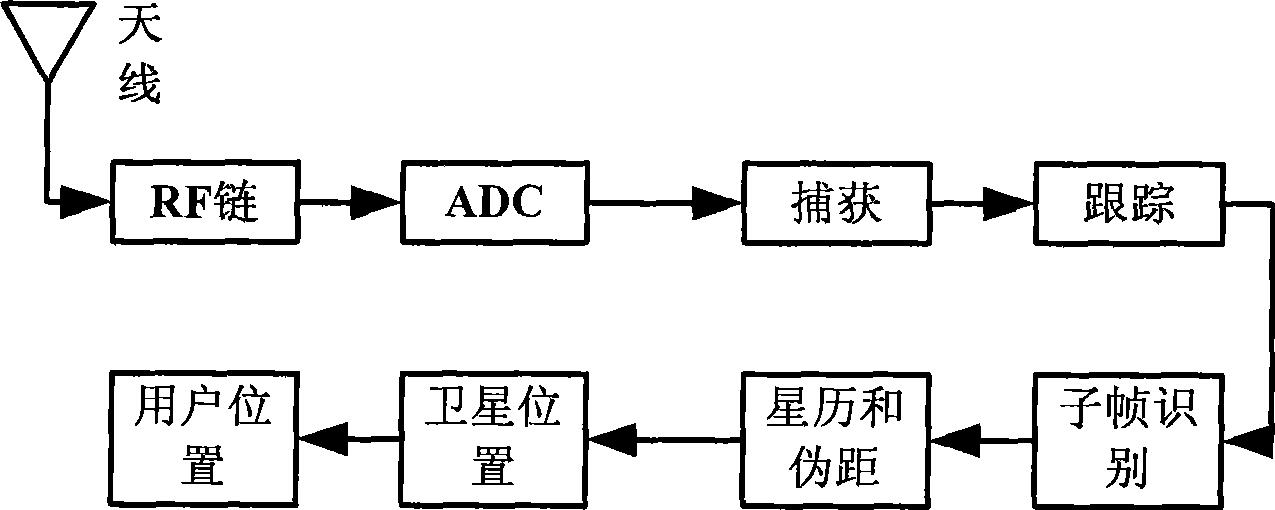

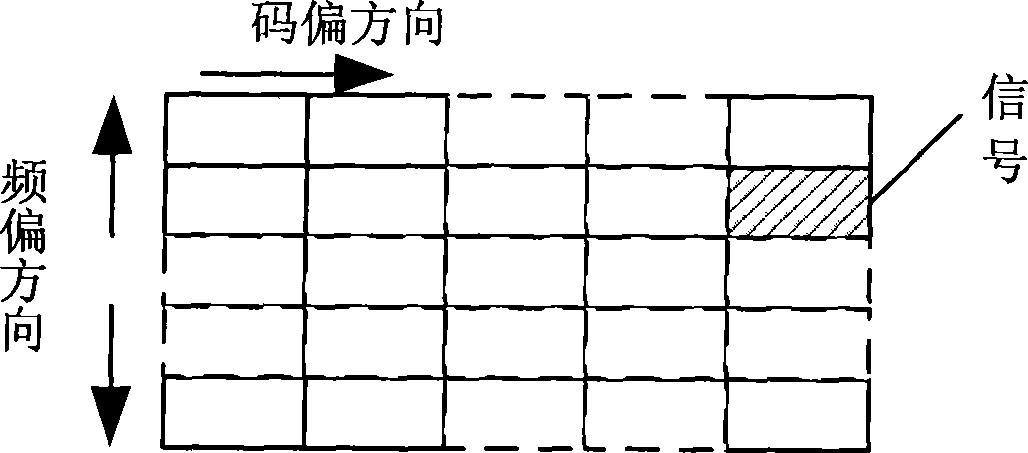

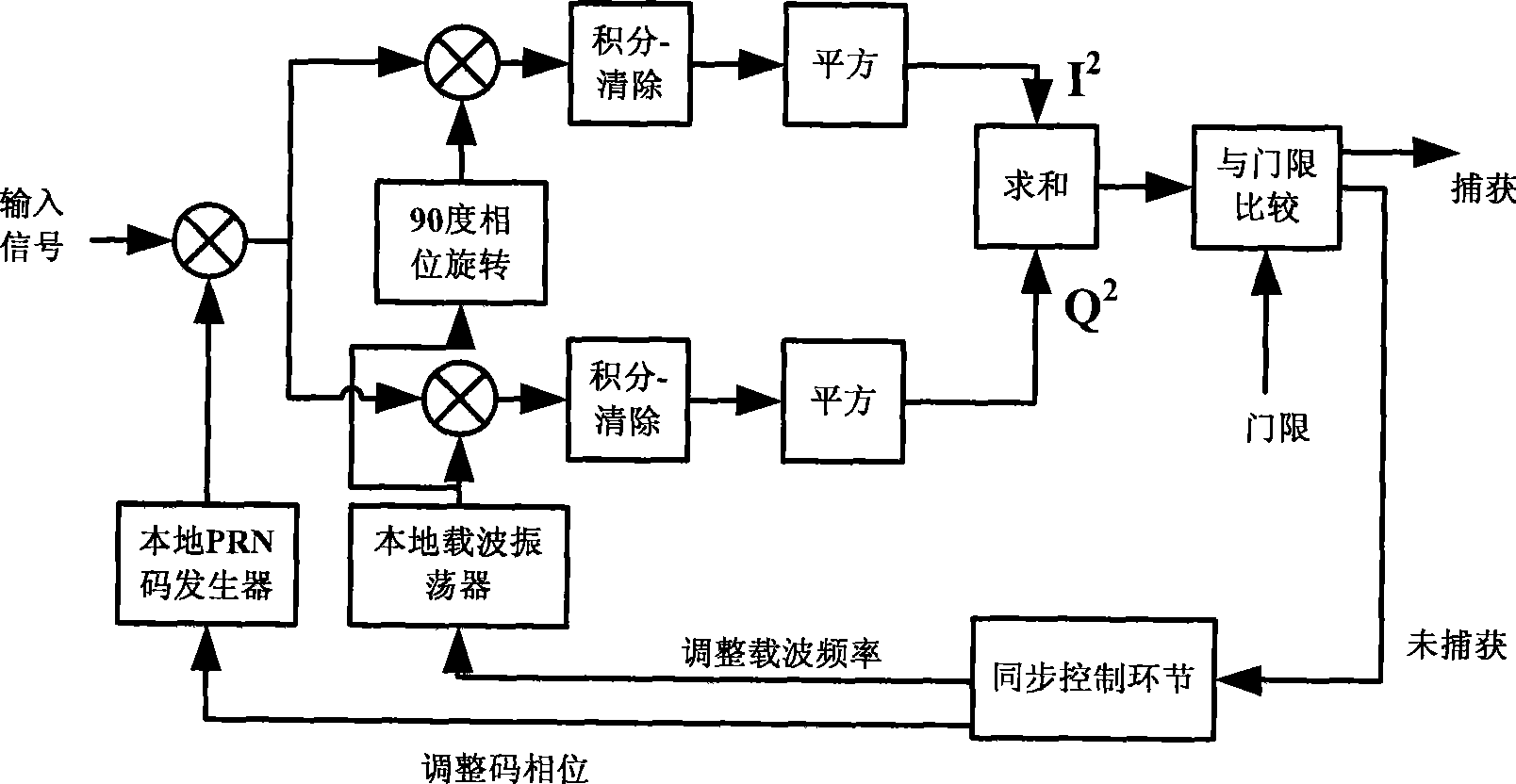

Method for capturing C/A code signal of GPS

InactiveCN101464508AImprove capture performanceAchieve high precisionPosition fixationSatellite radio beaconingCarrier signalSatellite

The invention discloses a method for acquiring the C / A code signals of a GPS in the GPS communication technical field. The method comprises a rough acquisition process and a precise acquisition process. The rough acquisition process comprises the following steps: searching a plurality of parallel satellites set by a system and obtaining a rough code phase and carrier frequency by using code phase search based on FFT; and the precise acquisition process comprises the following steps: setting a precise acquisition carrier frequency step according to the code phase and the carrier frequency obtained from rough acquisition and determining the search scope of precise acquisition; and removing the correlation between input signals and local carrier signals influenced by the code phase and comparing a correlation value and a resetting threshold value to determine whether satellite signals can be really acquired. Compared with the prior GPS acquiring method, the invention improves the acquisition performance of GPS signals, ensures the GPS fast acquisition, and simultaneously achieves the high-accuracy requirements of the GPS acquisition.

Owner:许军

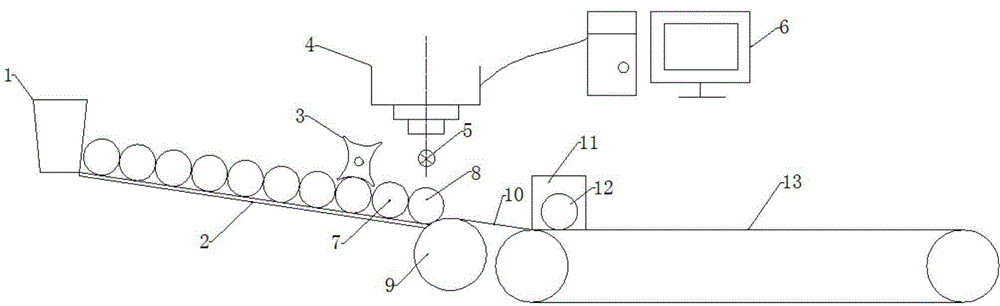

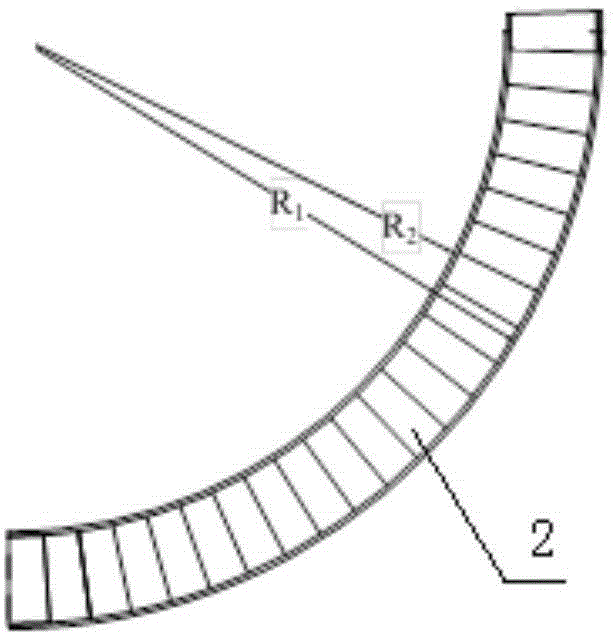

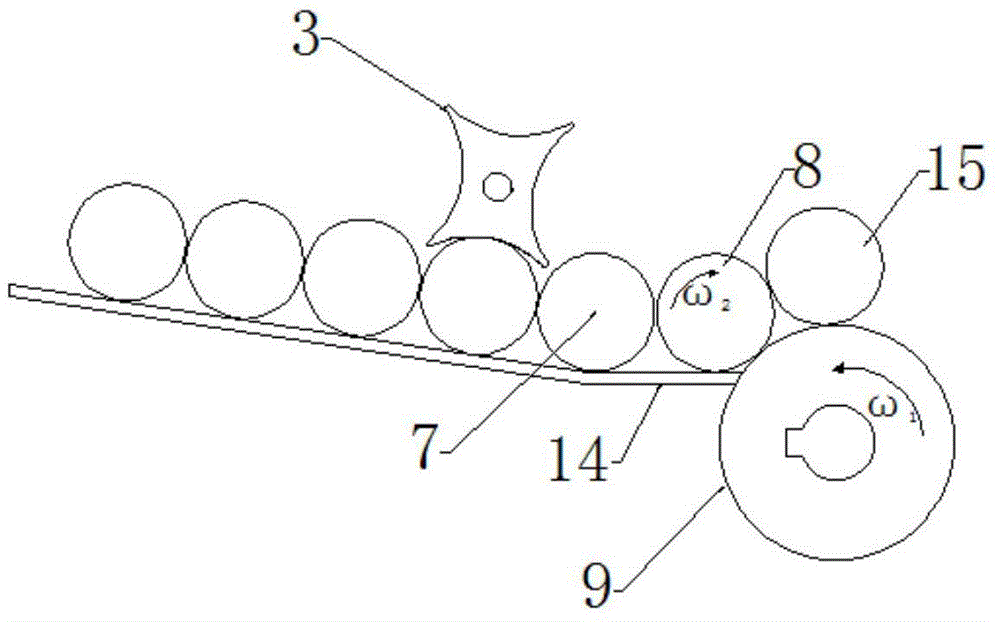

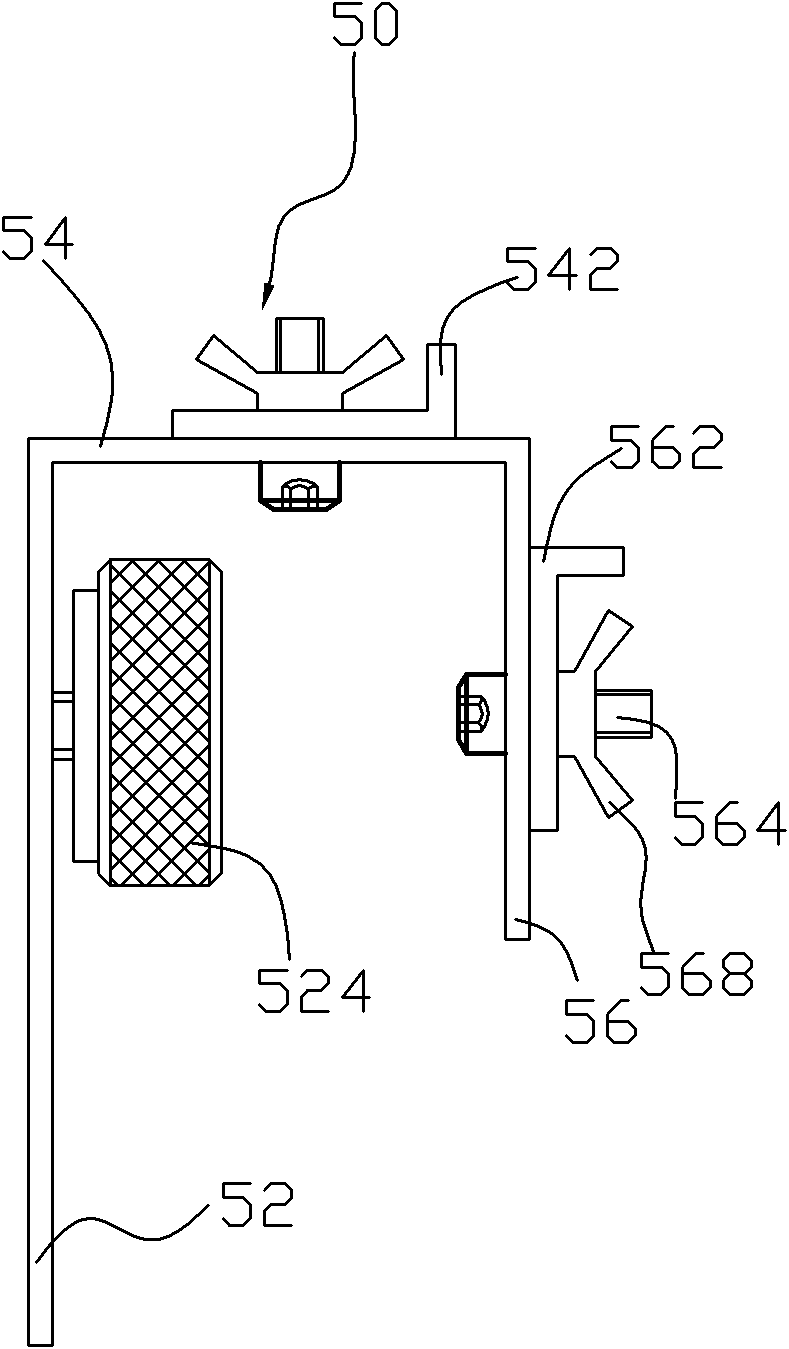

Device and method for detecting defects on surface of conical bearing roller

InactiveCN104089960AImplement automatic detectionRealize automation requirementsMaterial analysis by optical meansEngineeringPersonal computer

The invention discloses a device and a method for detecting defects on the surface of a conical bearing roller, belongs to the technical field of photoelectric detection, and aims to solve the problems of inaccuracy in artificial detection, injury to human eyes, low detection efficiency and high cost. According to the invention, a feed hopper of the device is arranged at the inlet end of a material passage, and a drive plate close to the upper part of the outlet end of the material passage intermittently drives the conical bearing roller; the inlet end of a detection table is connected with the outlet end of the material passage, a friction wheel is arranged at the outlet end of the detection table, the friction wheel is matched with the conical bearing roller at the outlet end of the detection table, and the friction wheel is connected with a conveying belt through a baffle; a charge coupled device (CCD) camera is arranged above the outlet end of the detection table, a light source is arranged between the CCD camera and the detected conical bearing roller, and an ejection device is arranged at one end, connected with the baffle, of the conveying belt. According to the method, an image of the surface of the detected conical bearing roller is acquired in real time through the CCD camera and transmitted to an industrial personal computer to judge whether defects exit, and the industrial personal computer controls the ejection device to eject the conical bearing roller with defects.

Owner:CHANGCHUN UNIV OF SCI & TECH

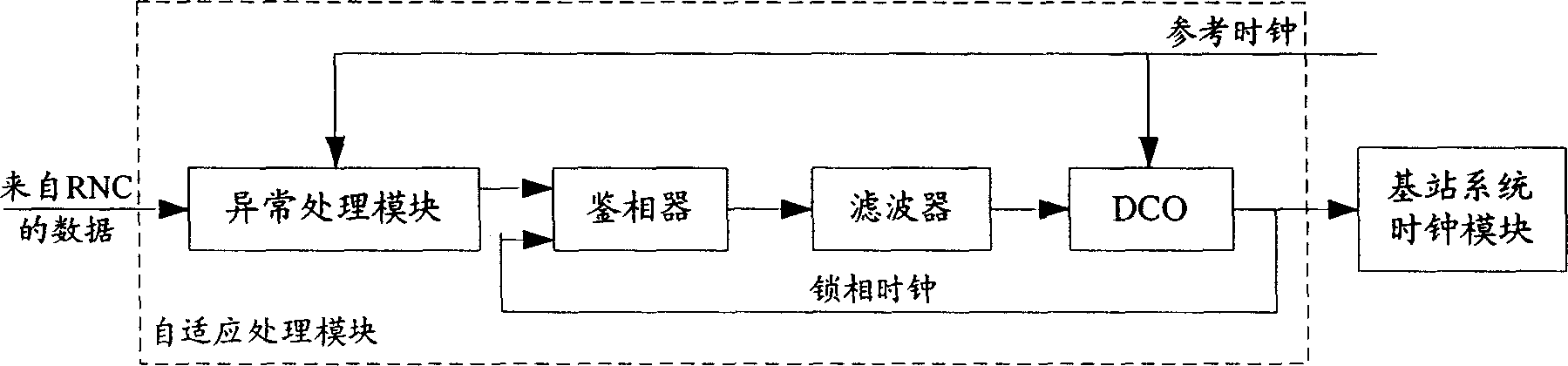

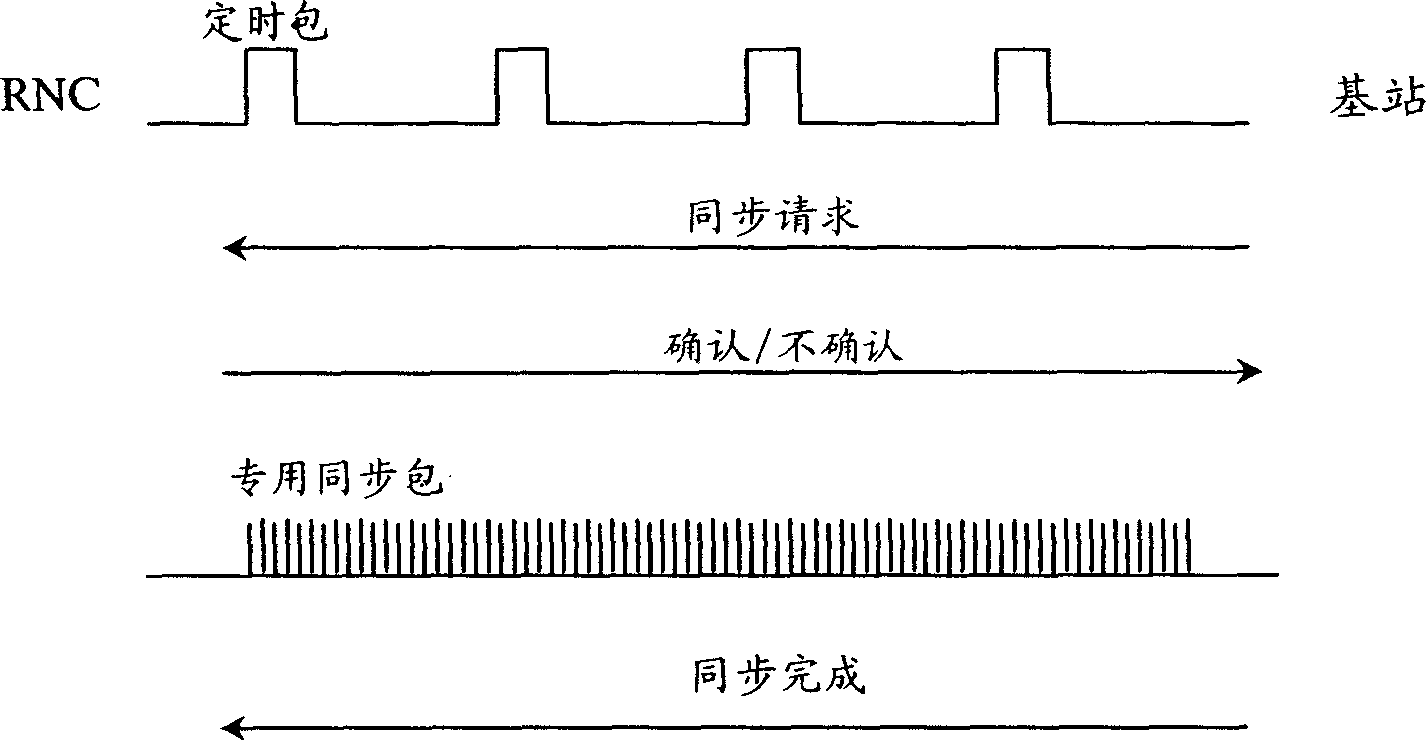

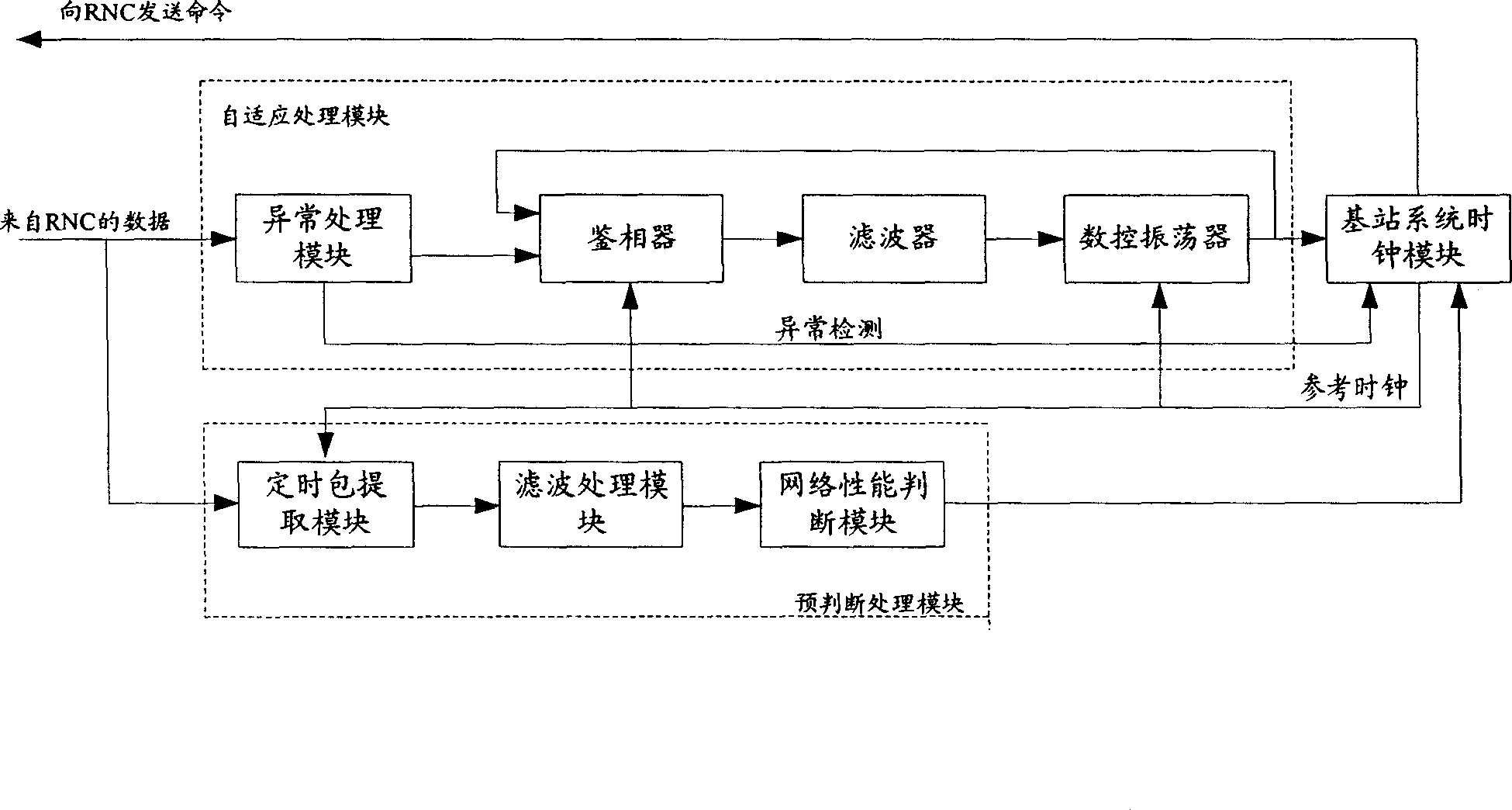

Clock reference device and method for IP network transmission base station

InactiveCN1878054AAchieving Clock ConvergenceFast Clock ConvergenceSynchronisation signal speed/phase controlSelf adaptiveClock signal

The invention discloses a clock reference device and method in the IP network transmission base station between sending end and clock mode of base station system, which contains at least self-adaptive disposal mode to receive the synchronous clock signal of base station from sending end through IP network, wherein the mode traces and disposes the clock signal to clock mode of base station system, which adjusts system clock of base station. The invention can generate to adjust clock frequency of base station system, which reduces cost to realize clock synchronization of base station.

Owner:HUAWEI TECH CO LTD

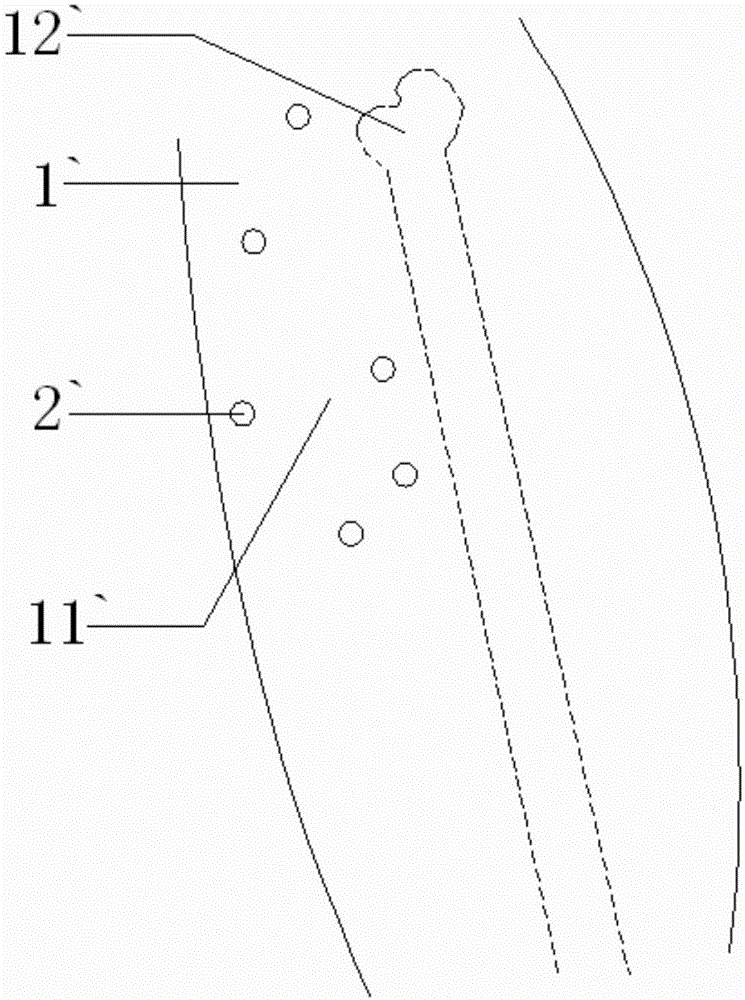

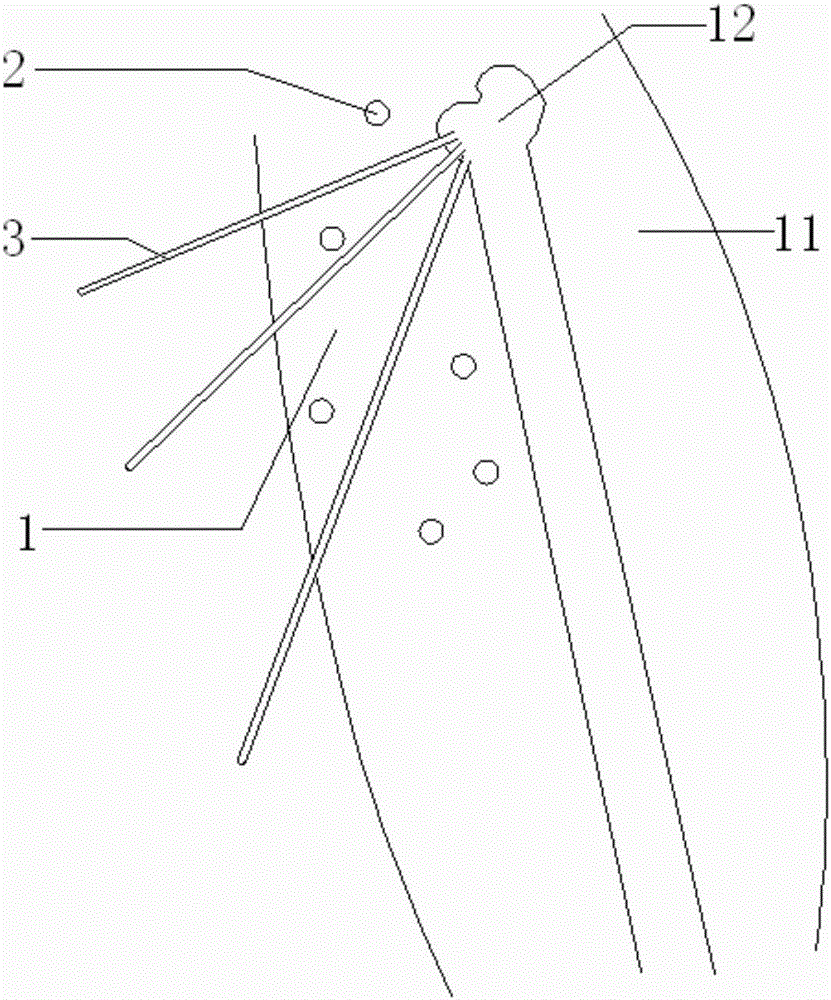

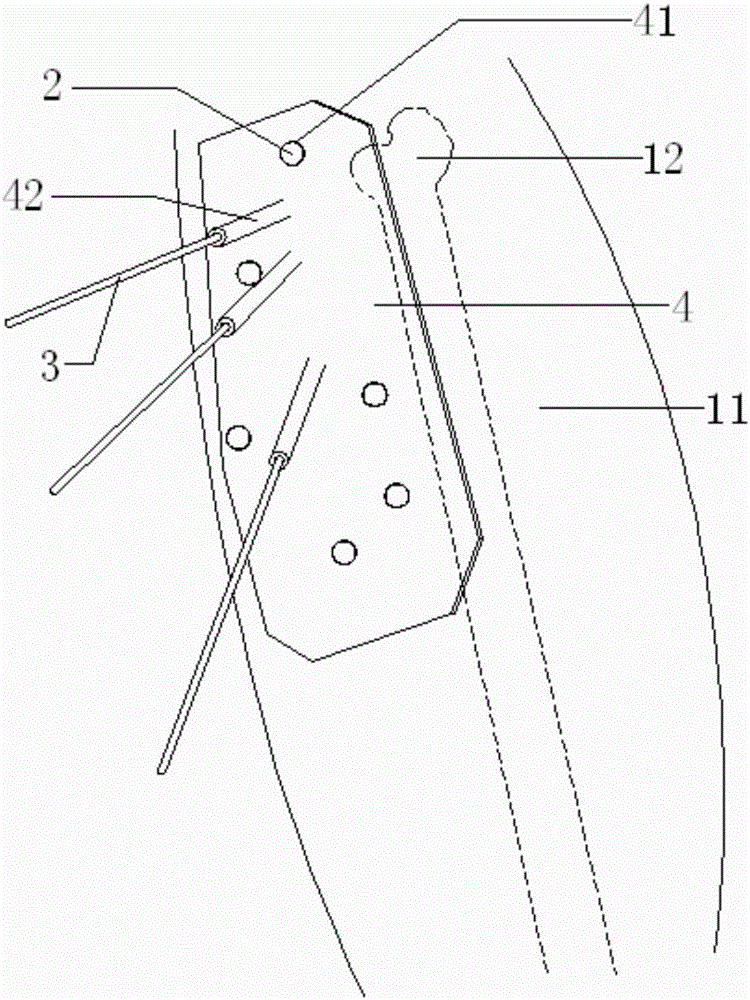

Percutaneous navigation guide board combined with body position fixation device and preparation method thereof

PendingCN106618755ARapid designCorrectly designedInstruments for stereotaxic surgeryComputed tomographySkin surface

The invention provides a preparation method for a percutaneous navigation guide board combined with a body position fixation device, pertaining to the field of medical instruments. The method comprises the following steps: (1) utilizing the body position fixation device; (2) fixing a marker to the skin surface corresponding to a required surgical spot of a human body, which is used for fixing the navigation guide board; (3) utilizing CT scanning technology to scan the required surgical spot to obtain spatial position data of a human body dissecting structure; (4) inputting CT scanning spatial position data into a computer and carrying out digital and three-dimensional reconstruction; (5) simulating operations in the virtual three-dimensional structure and virtually inserting needles / nails on the virtual skin surface where markers are located; (6) fitting the navigation guide board on the virtual skin surface, wherein the navigation guide board is closely attached to the skin surface and can be used for virtual needle / nail insertion adapted to the virtual markers and the navigation guide board has guide pipelines; (7) inputting data of the above virtual guide board into a 3D printer, wherein the 3D printer obtains the percutaneous needle / nail-inserting navigation guide board which can be used in combination with the body position fixation device.

Owner:BEIJING DITAN HOSPITAL CAPITAL MEDICAL UNIV

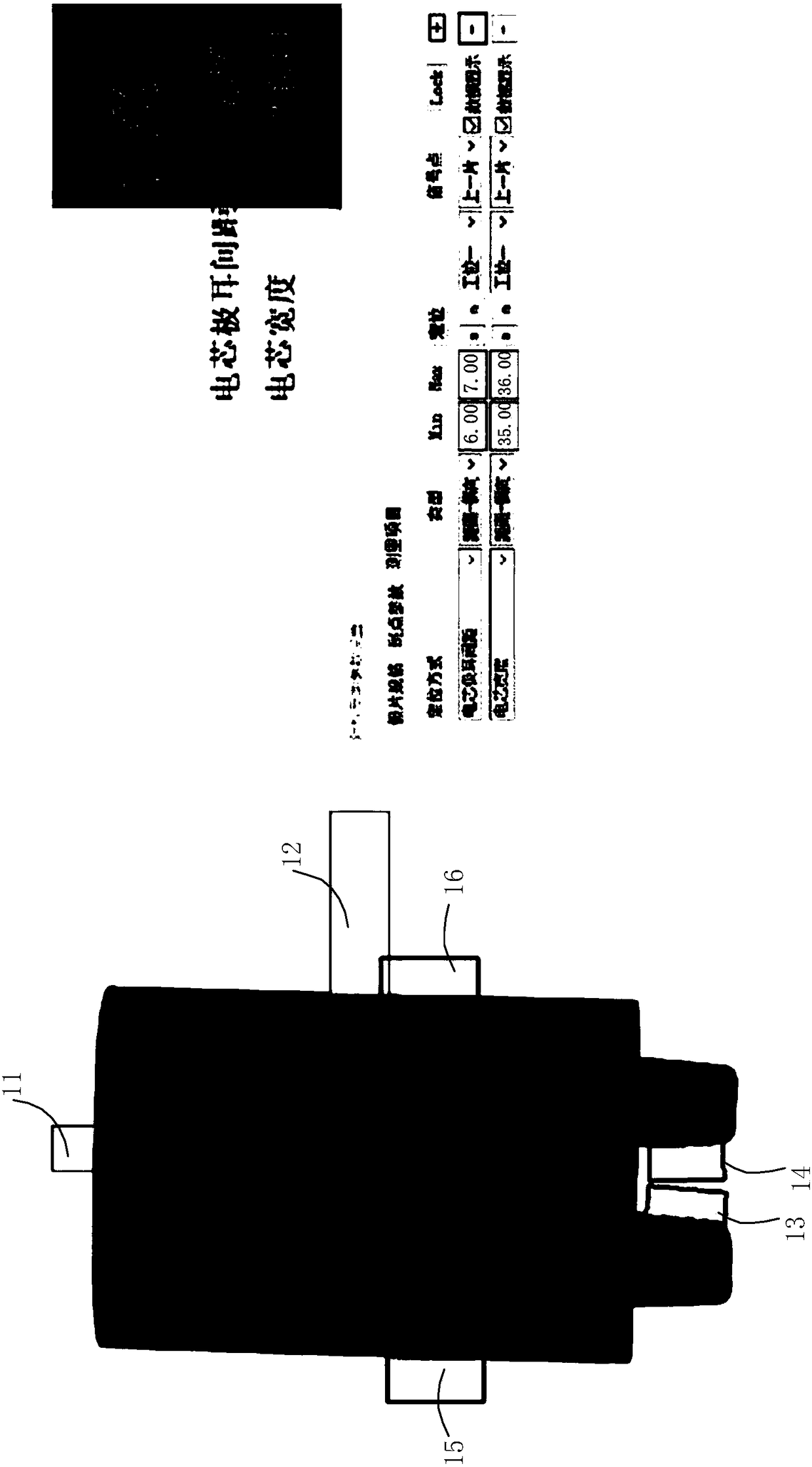

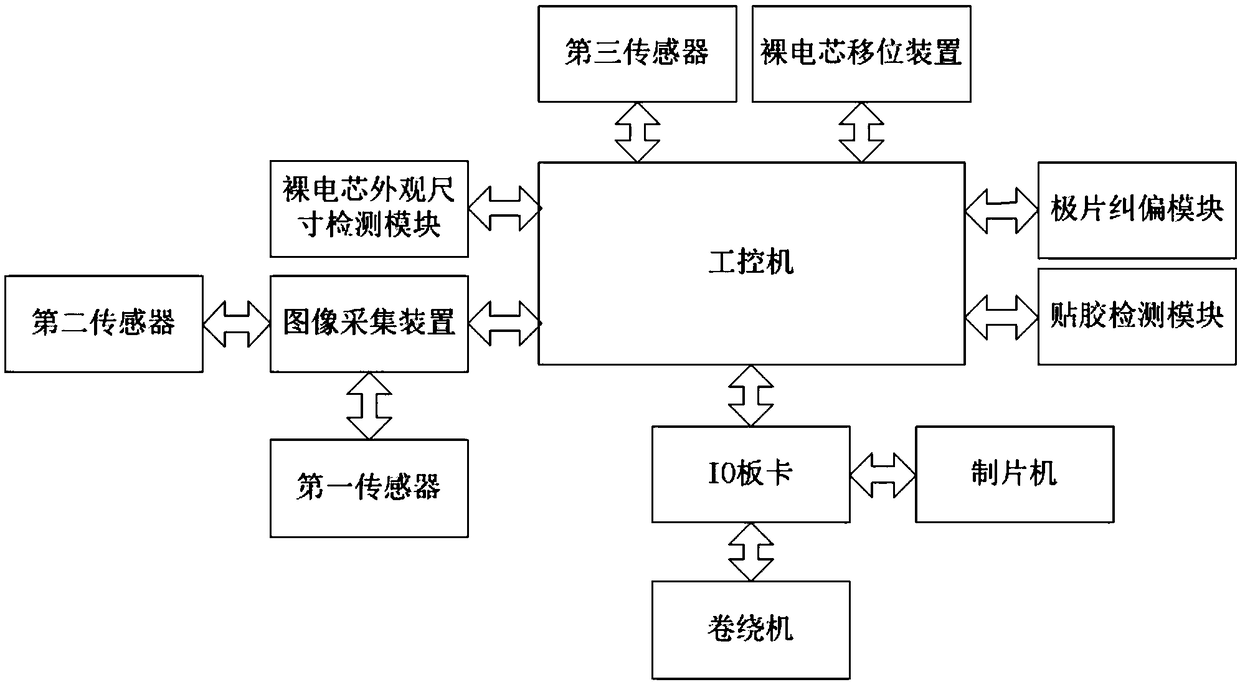

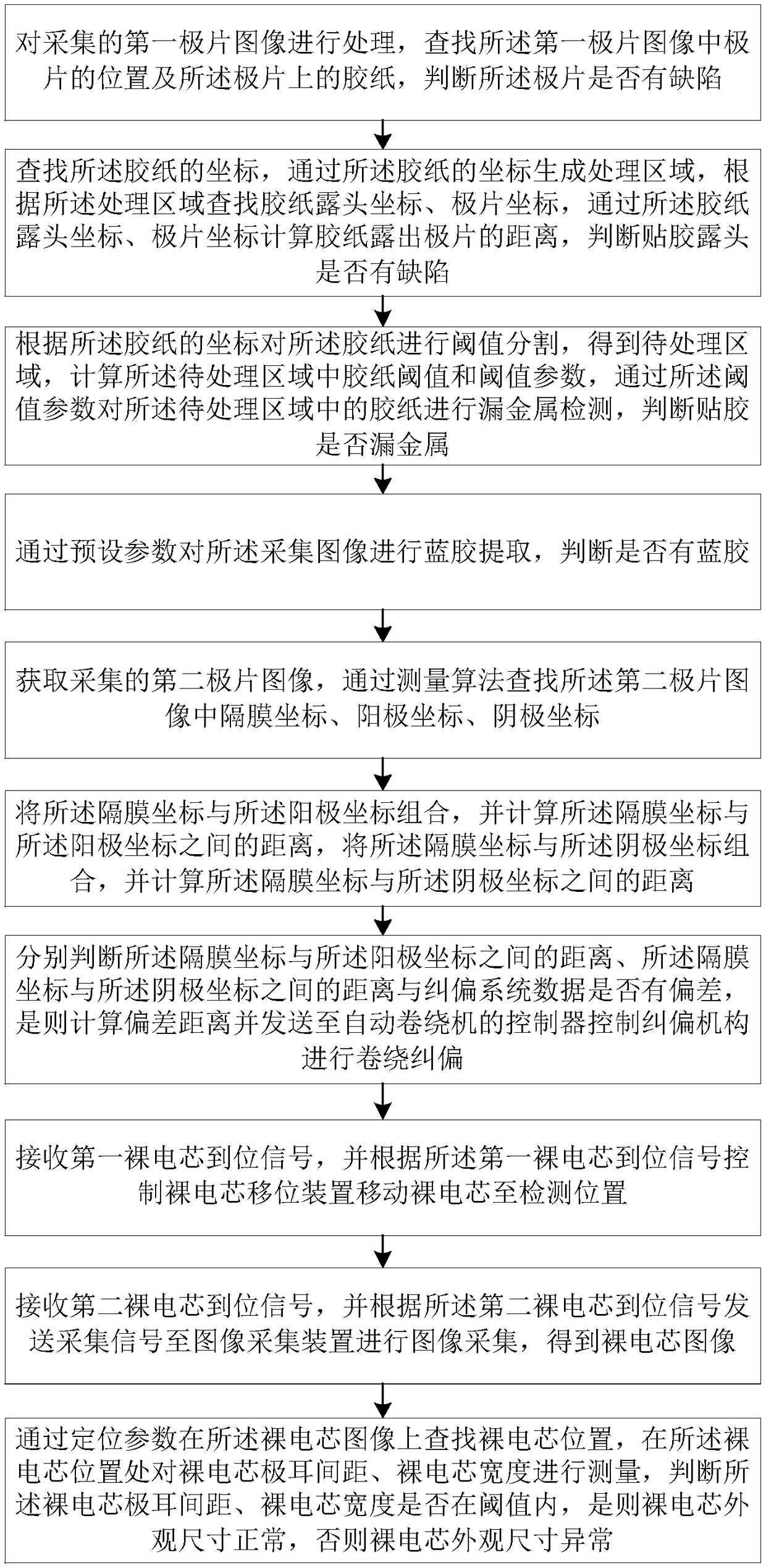

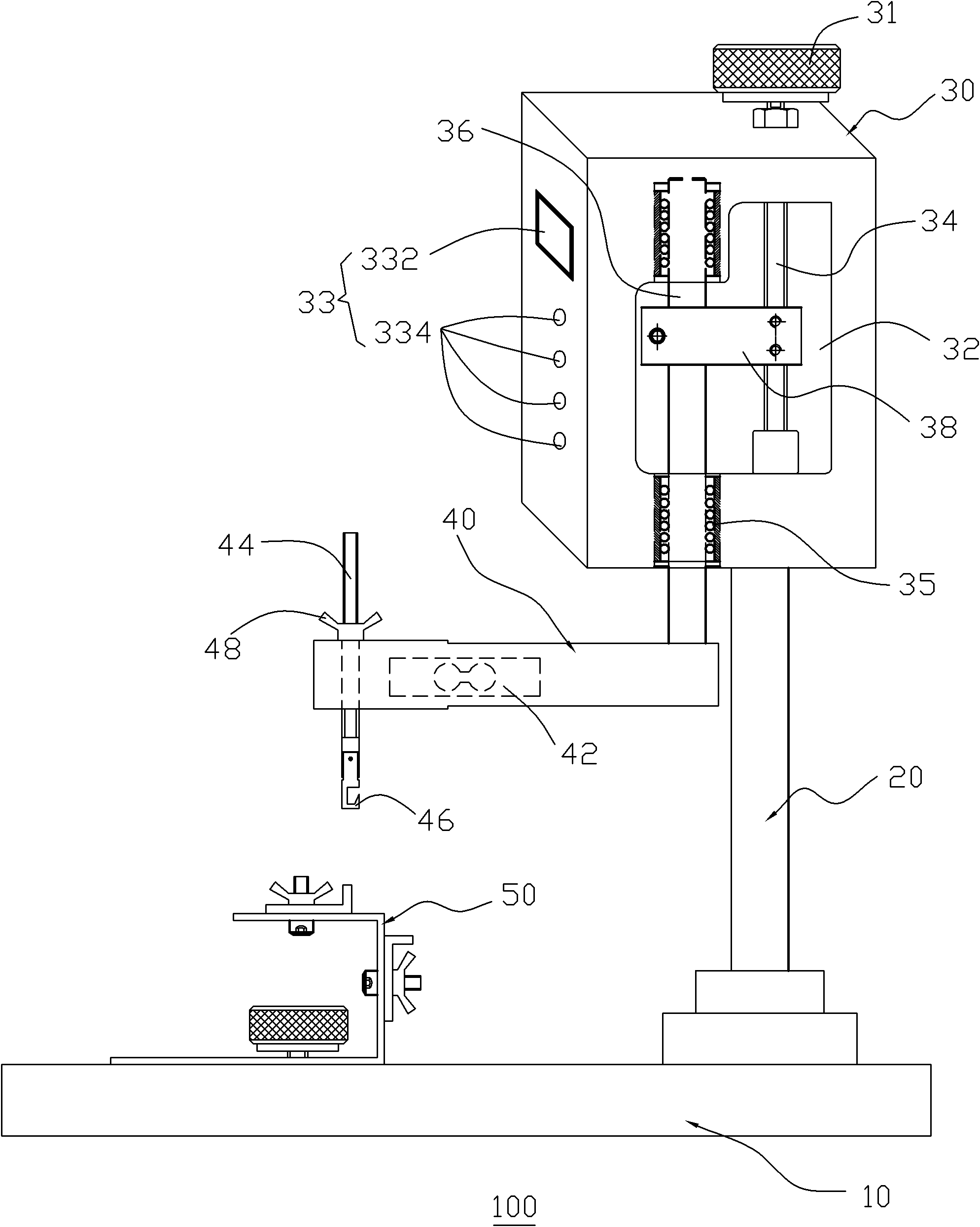

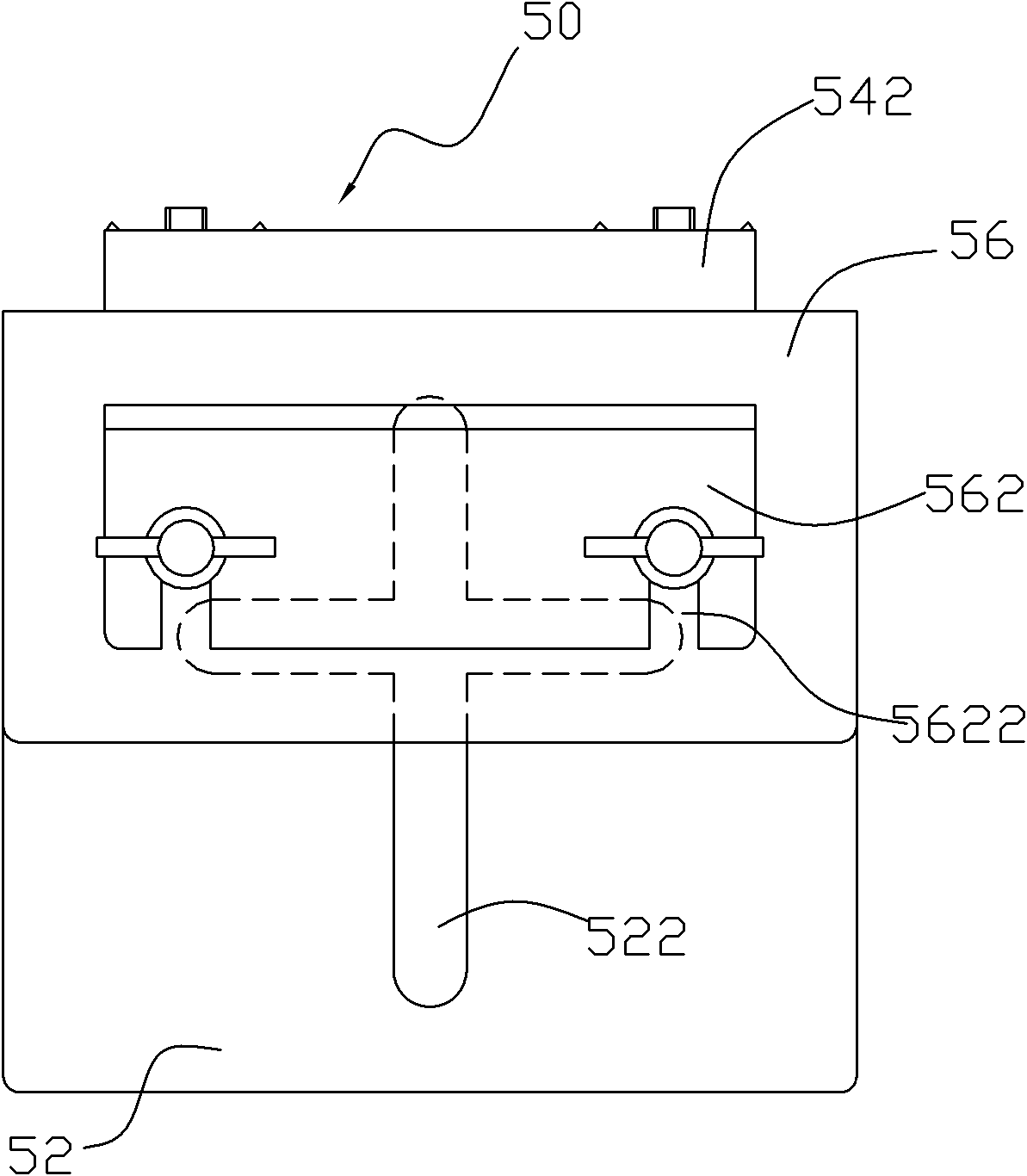

Pole piece producing and winding defect full-function detection method and system, device and medium

ActiveCN109358064ASolve the problem of glue defectsImprove efficiencyFinal product manufactureOptically investigating flaws/contaminationEngineeringPole piece

The invention provides a pole piece producing and winding defect full-function detection method. The pole piece producing and winding defect full-function detection method comprises the steps of detecting of the position of a pole piece, measuring of the size, detecting of the adhering defects, detecting of a blue adhesive tape, finding of the coordinates of the parameters, calculating of the coordinate distance, correcting of the pole piece, receiving of a position signal, collecting of a bare cell image and detecting of the apparent size of a bare cell. The invention relates to an electronicdevice and a readable storage medium for performing a pole piece producing and winding defect full-function detection method. The invention further relates to a pole piece producing and winding defect full-function detection system. According to the pole piece producing and winding defect full-function detection method, the electronic device, the readable storage medium and the pole piece producing and winding defect full-function detection system, the automatic detection of the position of the pole piece, the adhesive tape on the pole piece, the adhered exposed head, the adhered leakage metal and the blue adhesive tape is realized, and the detected image is analyzed, the distance between the anode and the cathode of the pole piece, the distance between the anode and the diaphragm are detected, automatic detection of the appearance size of bare cells is carried out, and the huge demand and high quality requirements of consumers for lithium batteries can be met.

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH

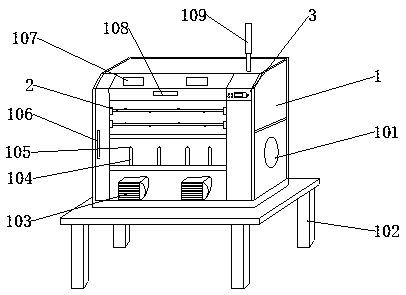

Microscopic welding micro-tensile measuring instrument

ActiveCN102128746AShorten working distanceTo achieve high precision requirementsMaterial strength using tensile/compressive forcesElectricityMeasuring instrument

The invention relates to a microscopic welding micro-tensile measuring instrument, which comprises a base, a support column arranged on the base, a frame arranged on the top of the support column, a workpiece chuck capable of moving up and down relative to the frame and a workbench which is arranged on the base and corresponds to the workpiece chuck, wherein a tension conducting structure with a pull rod is arranged in the frame; the pull rod extends out of the bottom of the frame and is fixed with the workpiece chuck; and a tension sensor is arranged inside the workpiece chuck, and is electrically connected with a tension display device. In the microscopic welding micro-tensile measuring instrument, the new photoelectric technology and mechanical technology of the tension sensor are combined, so that the tension sensor becomes a new measuring instrument which combines optics, mechanics and electronics; and the tension sensor is arranged on the workpiece chuck, so that the friction and various resistances which are caused by driving the workpiece chuck to move up and down are prevented, the measuring accuracy of tension is improved, and the measurement on the tension of small workpieces is realized.

Owner:GUANGZHOU MICRO WELDING EQUIP

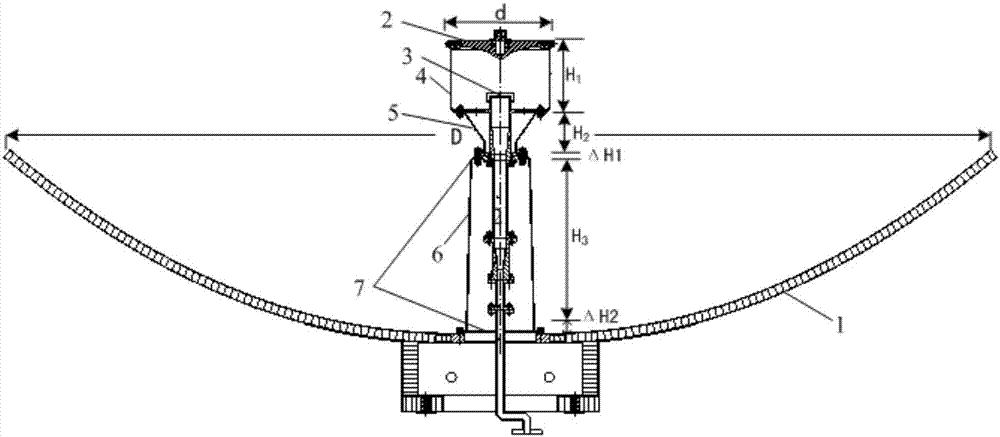

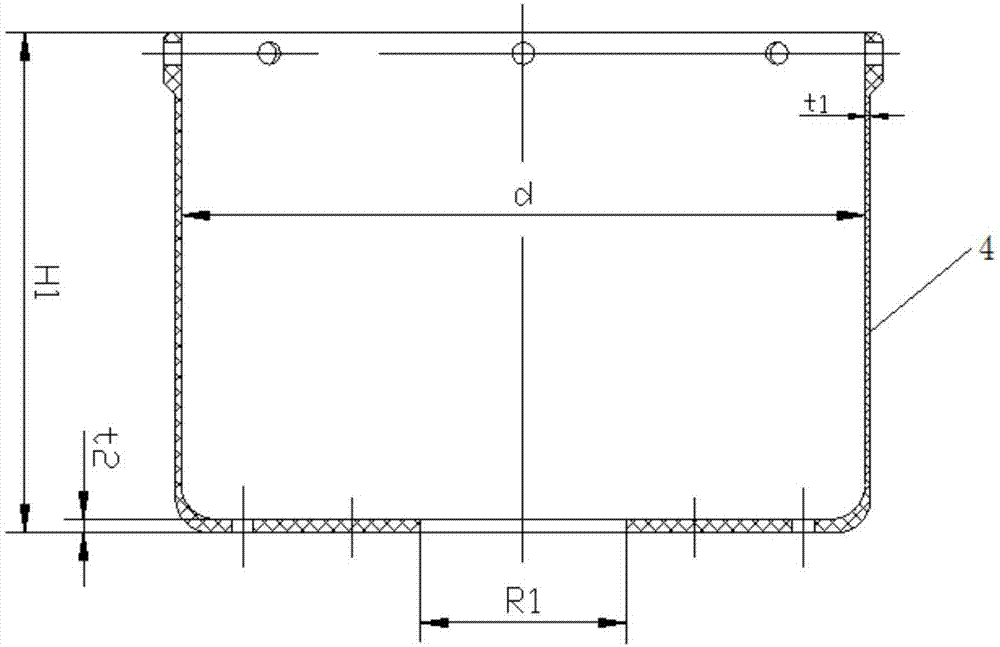

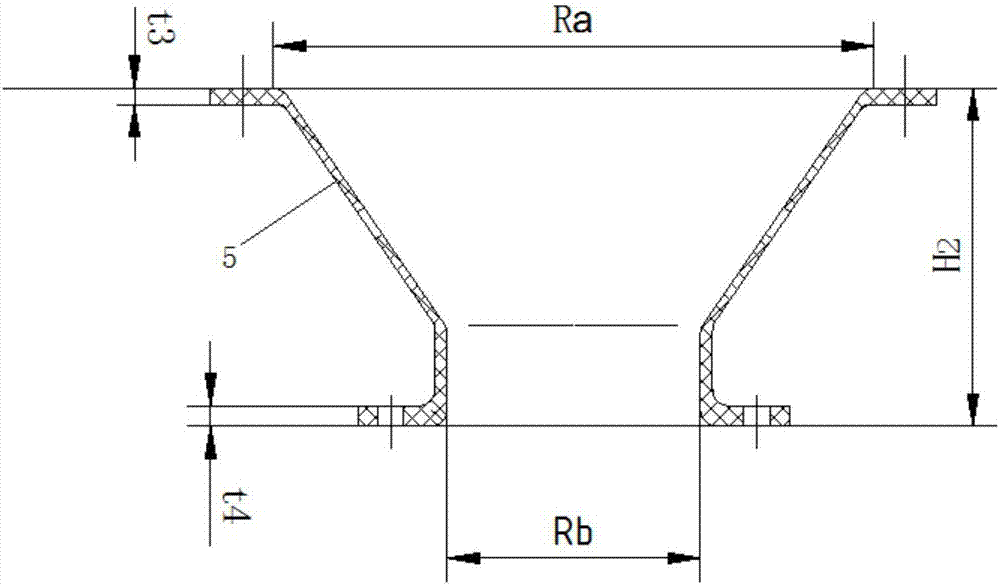

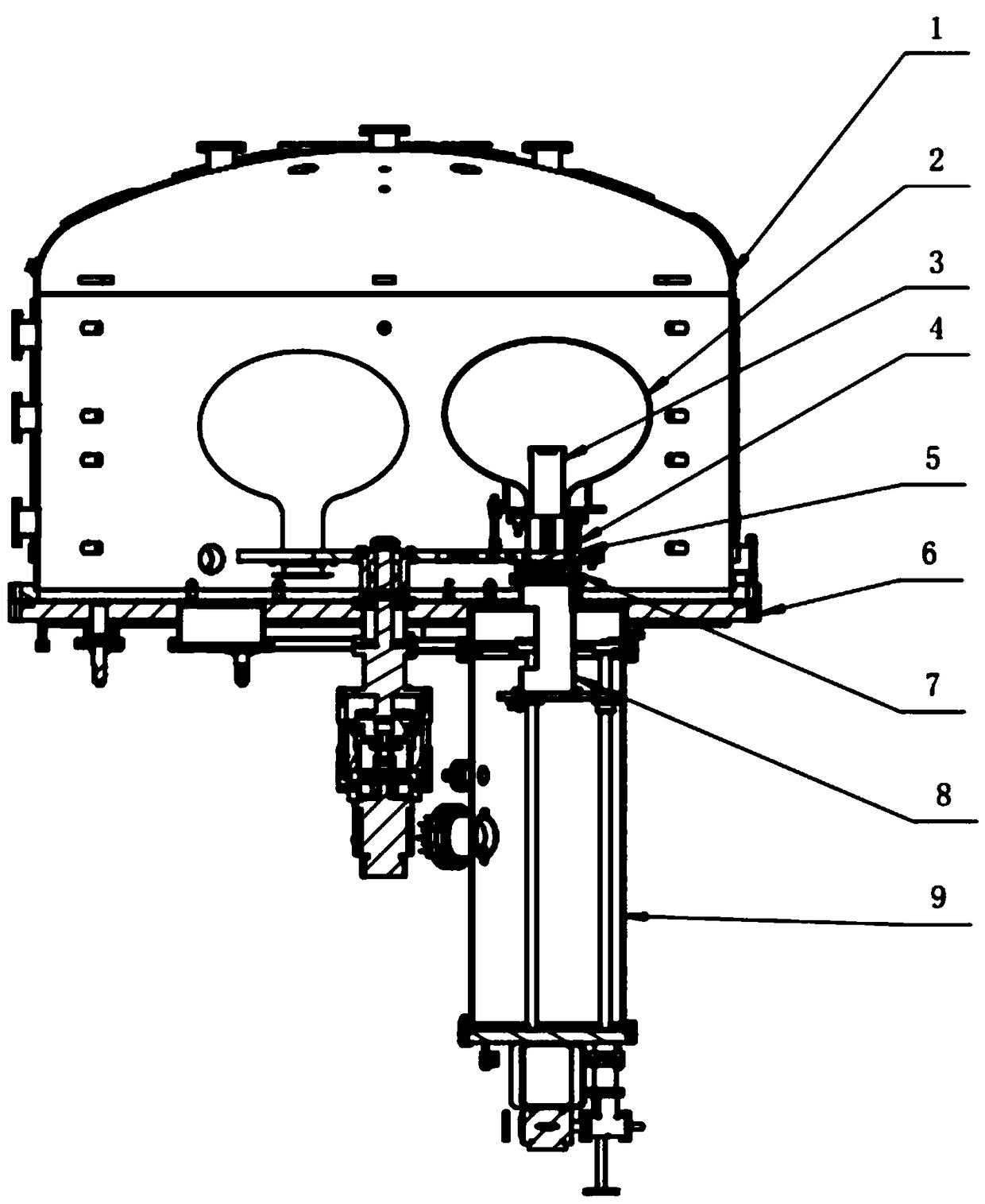

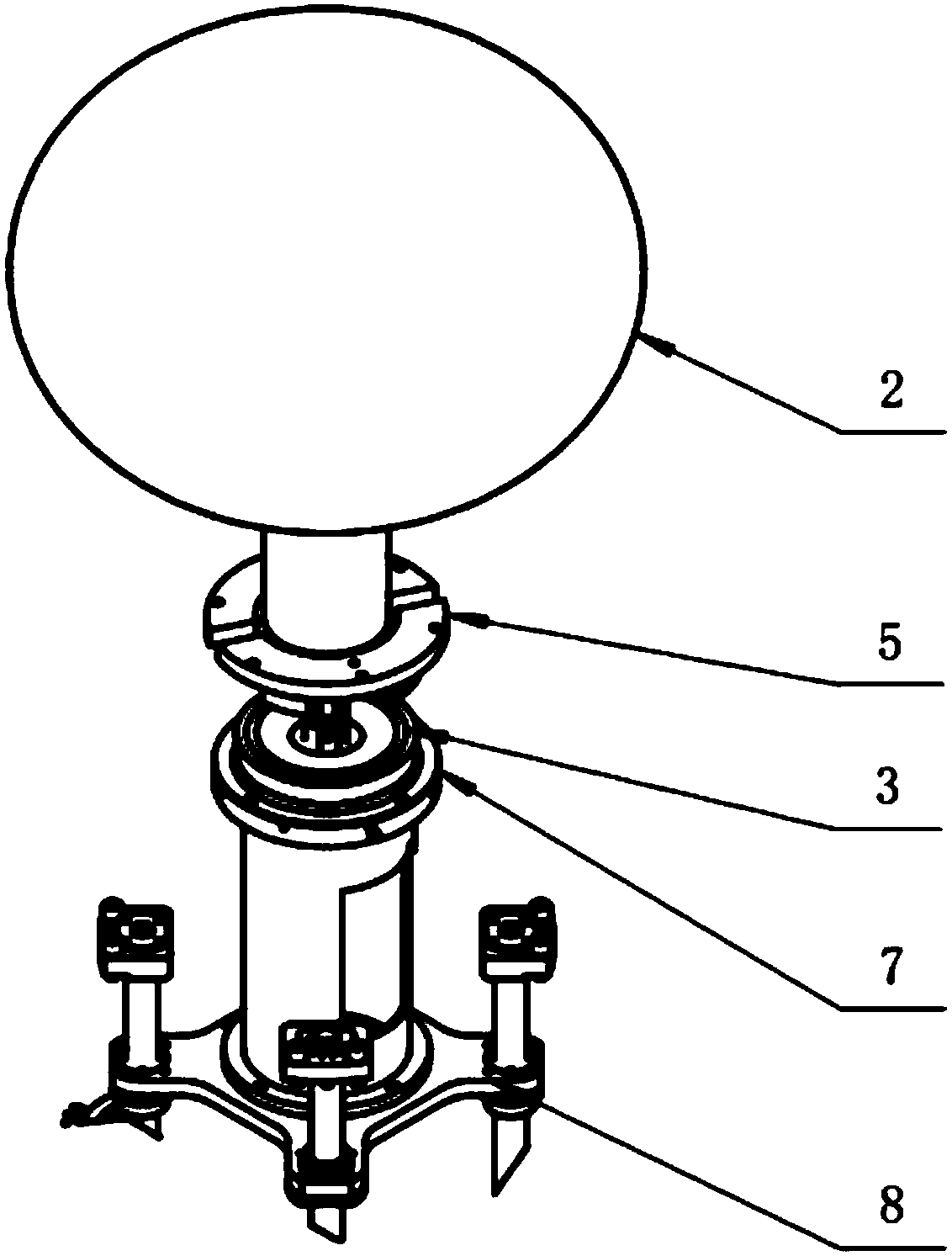

Novel auxiliary reflecting face supporting satellite borne ring focus antenna

ActiveCN106961000AReduce occlusionReduced scattering effectWaveguide hornsAntenna supports/mountingsSatelliteElectrical and Electronics engineering

The invention discloses a novel auxiliary reflecting face supporting satellite borne ring focus antenna comprising a main reflecting face, an auxiliary reflecting face, a feed source assembly, a cylinder medium cover, a round platform medium cover, adjusting pads and a central support cover, wherein the feed source assembly is mounted on a central support bucket; after the cylinder medium cover is firmly connected with the auxiliary reflecting face in a fixed manner, the cylinder medium cover and the auxiliary reflecting face are connected with the round platform medium cover in a fixed manner via screws; the cylinder medium cover, the auxiliary reflecting face and the round platform medium cover are jointly mounted on the central support bucket, adjusting pads are added between the central support bucket and the round platform medium cover and between the central support bucket and the main reflecting face, and the central support bucket is finally fixed on the main reflecting face. According to the satellite borne ring focus antenna disclosed in the invention, a large aperture antenna is enabled to be advantaged by high assembling precision, high antenna efficiency, reliable structure, convenient debugging operation, low cost and the like; the large aperture antenna is particularly suitable for being used as the satellite borne ring focus antenna.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

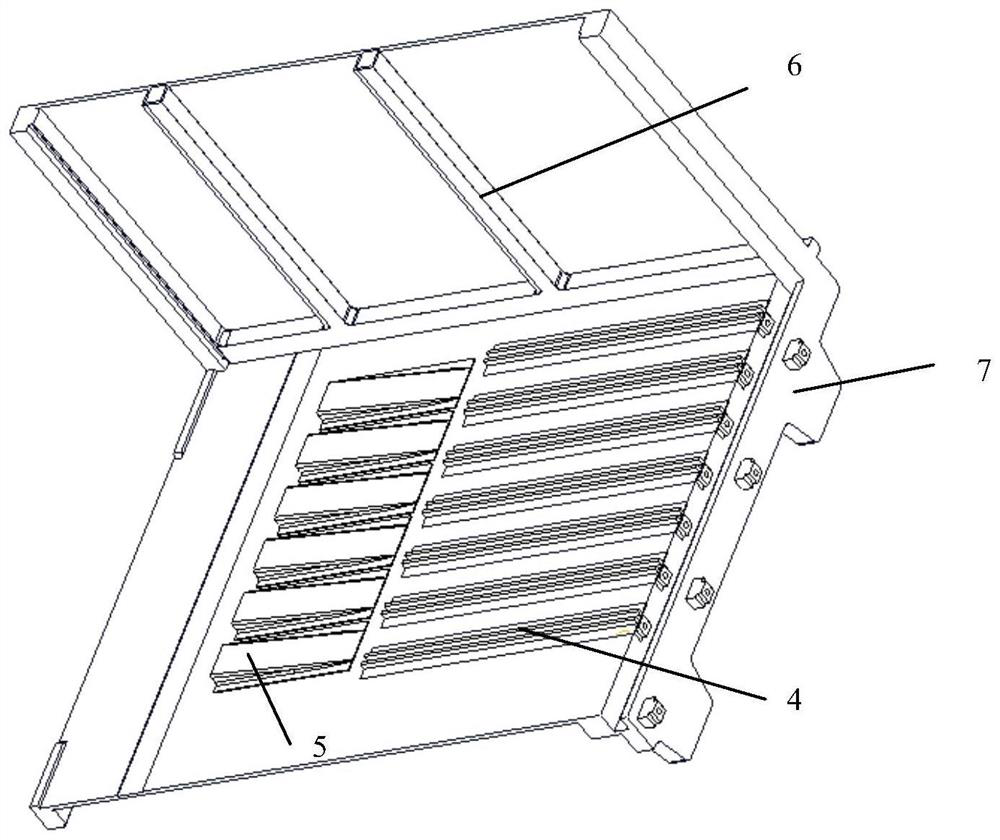

Light carbon fiber case integral forming manufacturing method

ActiveCN111113951APrecise positioningMultiple installation interfacesDomestic articlesCoatingsFiberCarbon fibers

The invention discloses a light carbon fiber case integral forming manufacturing method. The light carbon fiber case integral forming manufacturing method comprises the following contents of pre-formation of guide rails and wedge-shaped parts; implementation of threaded installation holes, wherein the threaded installation holes are implemented through metal embedded parts, bottom installation holes are pre-machined in the metal embedded parts, and the metal embedded parts are precisely positioned on the forming surface of a case die through the pre-machined bottom installation holes; pre-formation of side face installation beams; case body lay-up; machining; surface metallization on the inner surface and the outer surface of the case body; and surface three-proofing treatment. According to the light carbon fiber case integral forming manufacturing method, reasonable split design is carried out, the guide rails, the wedge-shaped parts and side face connecting beams are pre-formed and then assembled with the case body die, overall case body lay-up and autoclave co-curing formation are carried out, the manufacturing difficulty is lowered, and the overall rigidity requirement of the case body is also ensured; many printed board assemblies need to be installed in the case body, a power supply component needs to be installed outside the case body, installation interfaces are many, the positions are compact, the high-precision requirement for installation positions and dimensions is met through the embedded part precise positioning technology, and the connecting strength is ensured.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

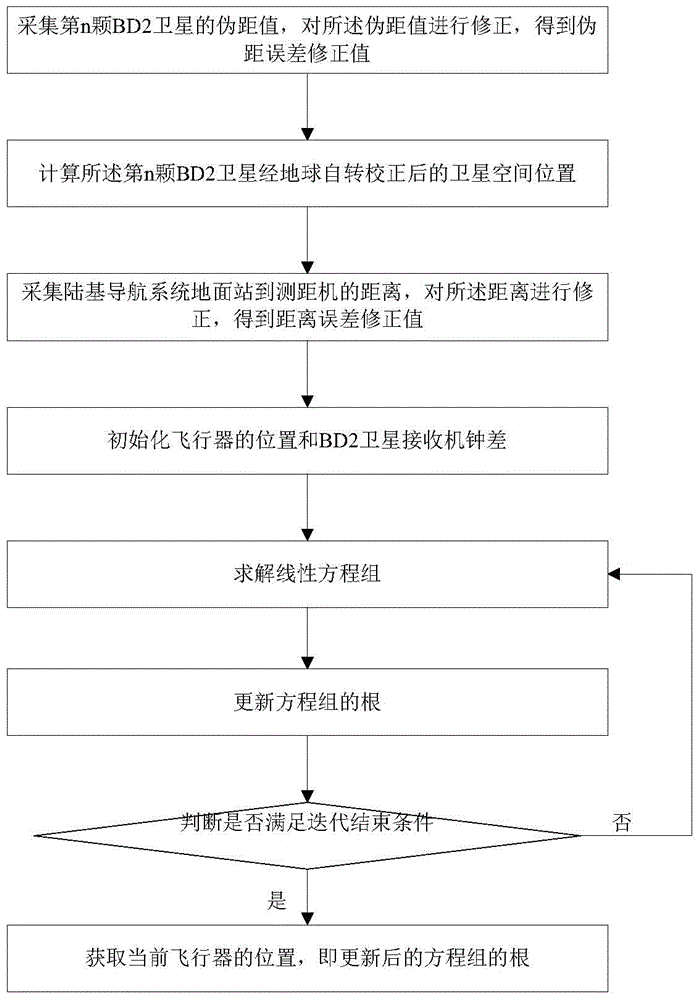

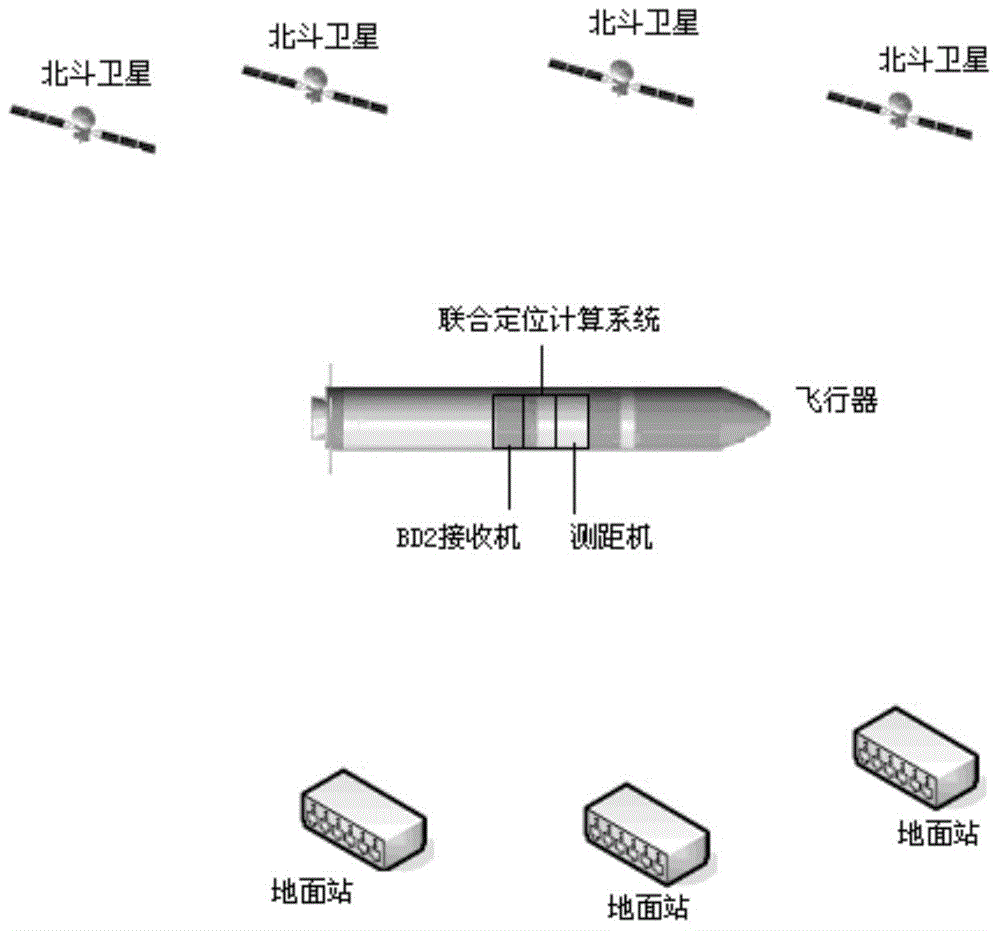

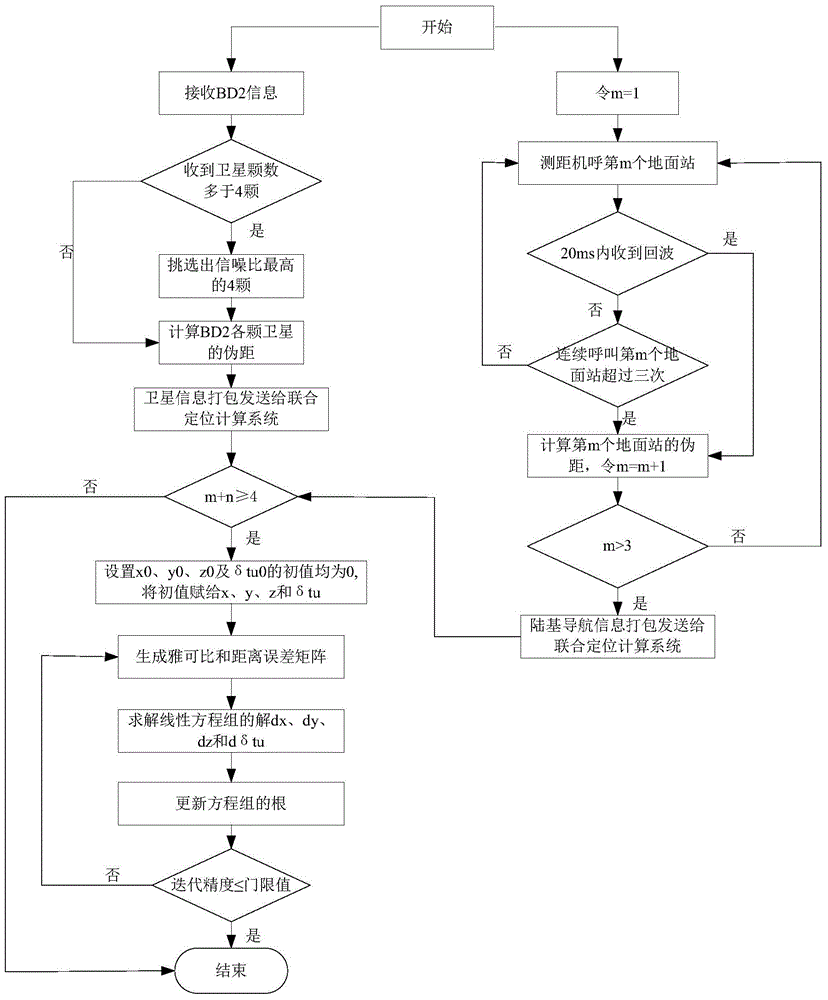

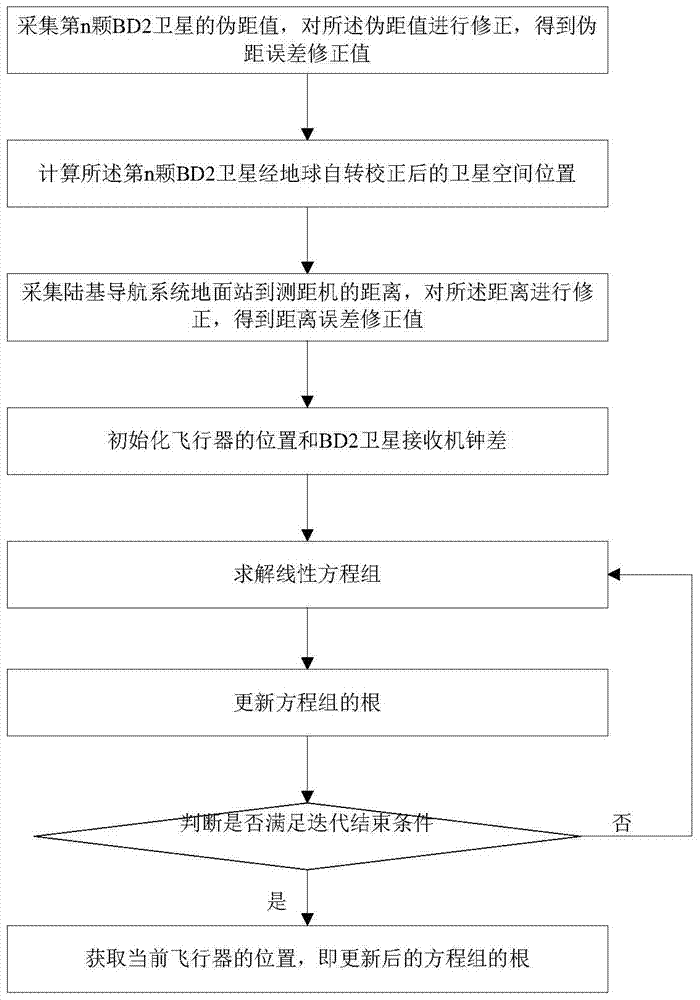

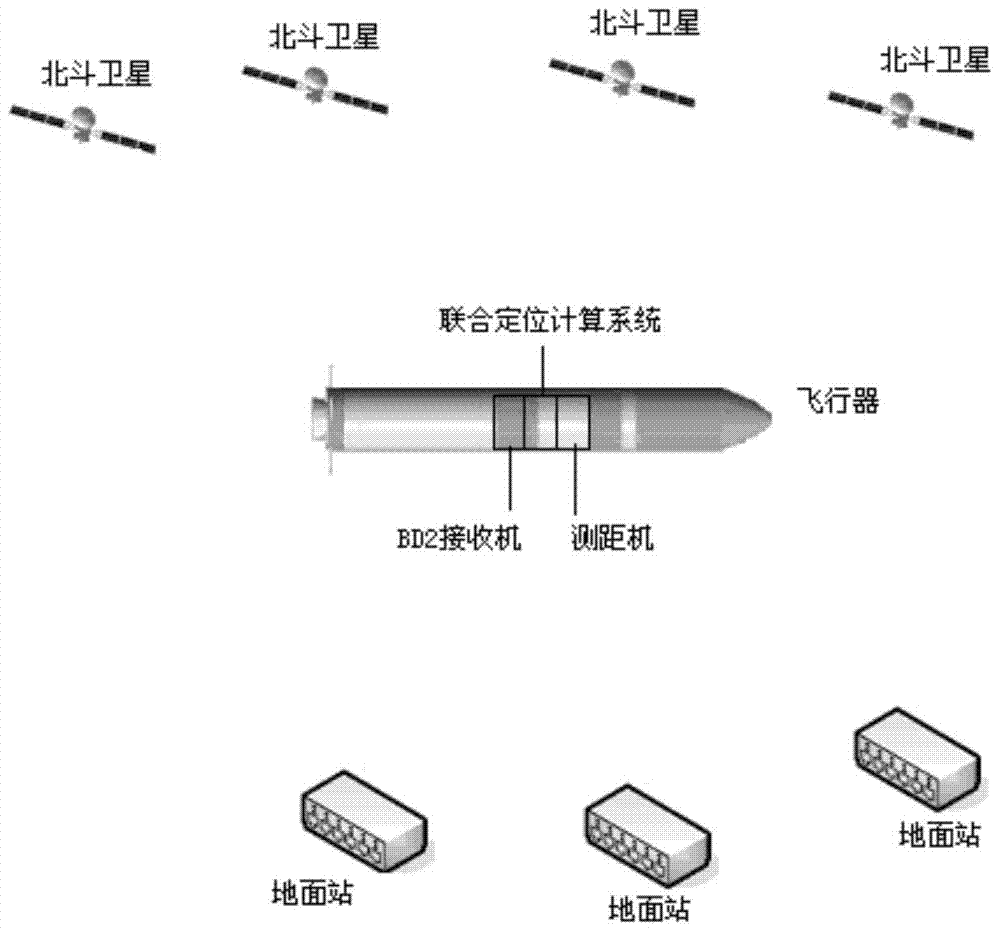

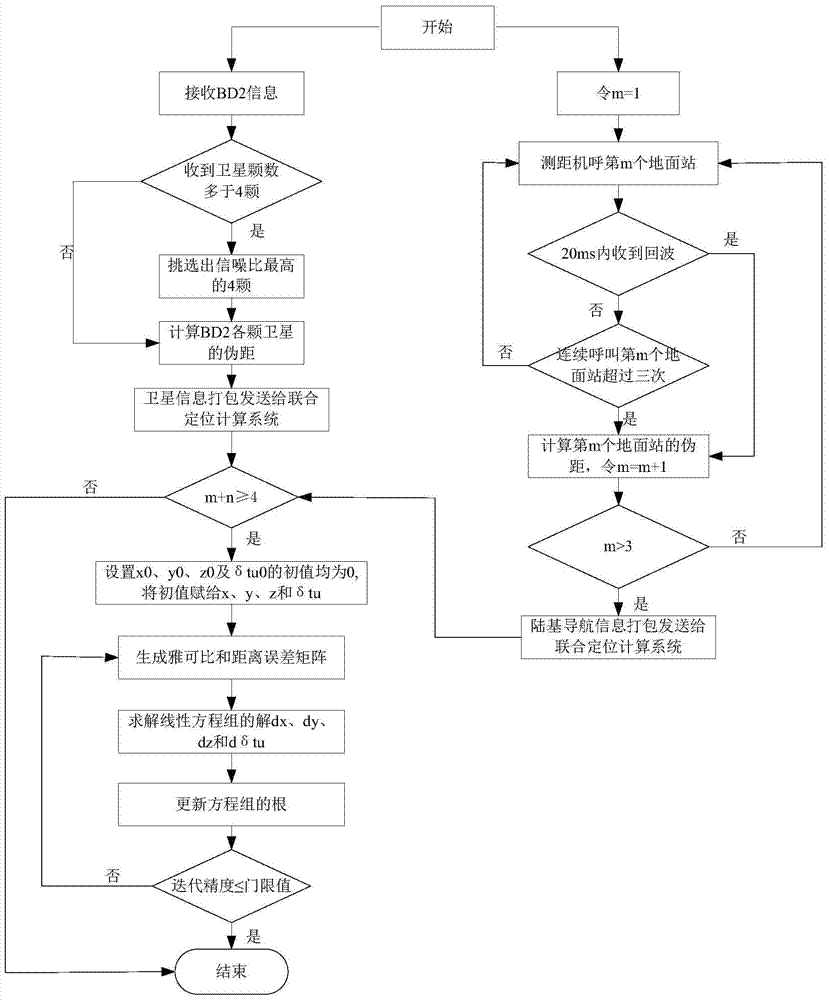

Combined positioning method and system based on BD2 and ground-based navigation system

ActiveCN104931992AMake up for the shortcomings of insufficient positioning accuracyOvercome the disadvantage of limited navigation rangeSatellite radio beaconingEarth's rotationNavigation system

The invention discloses a combined positioning method and system based on BD2 and a ground-based navigation system, and the method comprises the steps: S1, collecting and correcting a pseudo-range value of a BD2 satellite; S2, calculating the spatial position of the BD2 satellite after earth rotation correction; S3, collecting and correcting the distance from a ground station of the ground-based navigation system to a distance measurement machine; S4, initializing the position of an aircraft and a clock error of a satellite receiver; S5, building and solving a corresponding linear equation group; S6, updating the roots of the linear equation group; S7, judging whether the iteration is ended or not: calculating an iteration threshold value delta, and enabling the calculation result obtained at step S6 to serve as the current position of the aircraft and enabling the iteration to be ended if the delta is not greater than a preset threshold value; or else, repeatedly carrying out step S5-S7 till the iteration is ended. The invention also provides a system achieving the above method. The method and system can greatly improving the positioning precision of a system, are not dependent on GPS resources, can be used during wartime, and are high in reliability.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

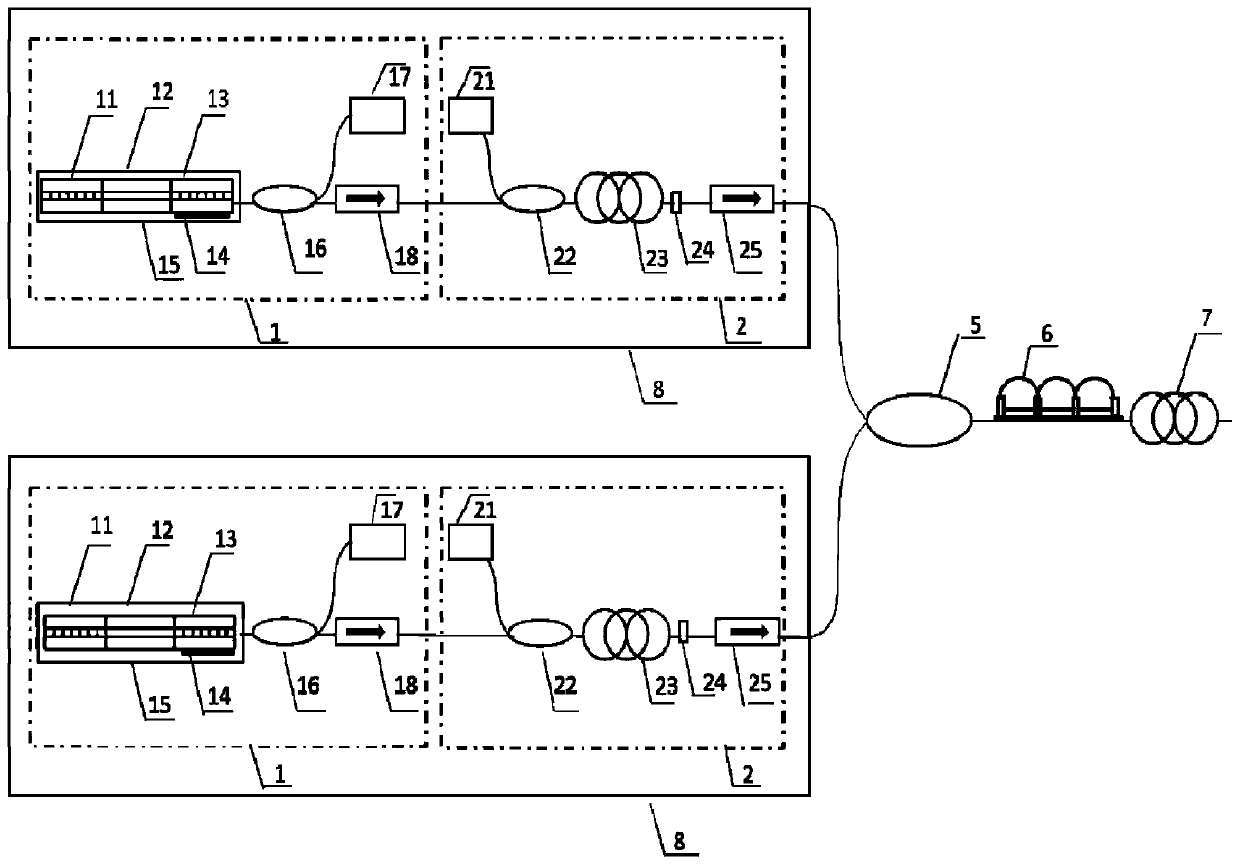

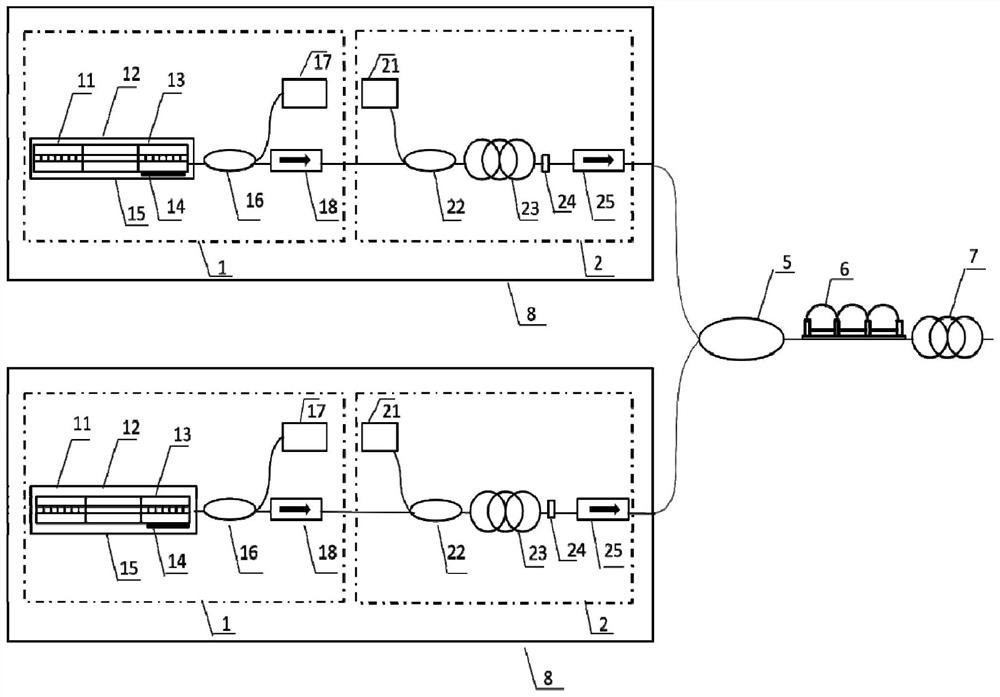

Wide-range high-precision narrow-linewidth optical fiber laser with adjustable linewidth

ActiveCN110867718AHigh precisionAchieve a wide rangeActive medium shape and constructionLine widthGain

The invention discloses a wide-range high-precision narrow-linewidth optical fiber laser with an adjustable linewidth, which comprises two laser emitting devices, a wave combiner, a polarization controller and a nonlinear optical fiber. A tunable single-frequency laser seed source generates single-frequency optical fiber laser, an optical fiber amplifier amplifies the power of the single-frequencyoptical fiber laser, the wave combiner combines the two single-frequency optical fiber laser beams subjected to power amplification into one laser beam, the polarization controller adjusts the polarization state of the combined laser beam, and the nonlinear optical fiber is used for controlling the linewidth of the output laser. The power ratio of the two paths of laser beams injected into the nonlinear optical fiber is adjusted, and therefore, the gain in the nonlinear optical fiber is changed, the output laser linewidth is further controllable, the narrow-linewidth optical fiber laser finally has the advantages of being flexible and controllable in linewidth, large in adjusting range, high in linewidth adjusting precision and the like, and the narrow-linewidth optical fiber laser can beapplied to the aspects of an optical wavelength division multiplexing system, coherent combination, spectrum combination, gravitational wave detection and the like.

Owner:SOUTH CHINA UNIV OF TECH

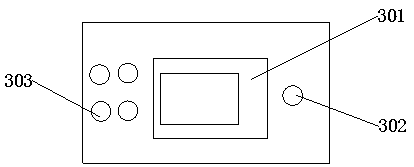

High-precision textile machine

InactiveCN108103644AEasy to operateHigh precisionLoomsAuxillary apparatusEngineeringMechanical engineering

The invention discloses a high-precision textile machine which comprises a textile machine body. Supporting legs are arranged at the lower end of the textile machine body. The upper surfaces of the supporting legs are fixedly connected with the outer surface of the bottom of the textile machine body. A winding rod is arranged in the textile machine body and closely welded to the textile machine body. The high-precision textile machine has the advantages of being plentiful in function and high in operation intelligence and precision; a thermometer is installed on the left side of the textile machine body and embedded in the textile machine body, temperature measurement is conducted in real time, the thermometer is used for judging whether cooling needs to be conducted in the machine body ornot, operation is easy, and the good temperature environment in the machine body is ensured; meanwhile, an installation control key is arranged on the upper surface of the intelligent controller, themachine is accurately controlled by the control key to run, errors can not easily happen, the precision of various data is improved, and the high precision requirement is met.

Owner:SUZHOU DANFANG TEXTILE R & D

A manufacturing method for integral molding of lightweight carbon fiber chassis

ActiveCN111113951BReduce weightObvious weight loss effectDomestic articlesCoatingsFiberCarbon fibers

The invention discloses a manufacturing method for the integral molding of a lightweight carbon fiber chassis, comprising the following contents: preforming guide rails and wedge-shaped parts; realizing threaded mounting holes; realizing threaded mounting holes through metal embedded parts, on the metal embedded parts Pre-processing the installation bottom hole, using the pre-processing installation bottom hole to accurately position on the molding surface of the cabinet mold; pre-forming the side mounting beam; cabinet layering; machining; surface metallization on the internal and external surfaces; surface three-proof. The present invention conducts reasonable split design, preforms guide rails, wedge-shaped parts, and side connecting beams, and then assembles them with box molds to carry out overall box laying and autoclave co-curing molding, which not only reduces manufacturing difficulty, but also ensures The overall rigidity requirements of the box body; more printed board components need to be installed inside the box body, power supply components need to be installed outside the box body, there are many installation interfaces, and the location is compact. Through the precise positioning technology of embedded parts, the high precision requirements of the installation position size are realized. , to ensure the connection strength.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

A narrow linewidth fiber laser with wide range and high precision linewidth adjustable

ActiveCN110867718BHigh precisionAchieve a wide rangeActive medium shape and constructionLine widthGain

Owner:SOUTH CHINA UNIV OF TECH

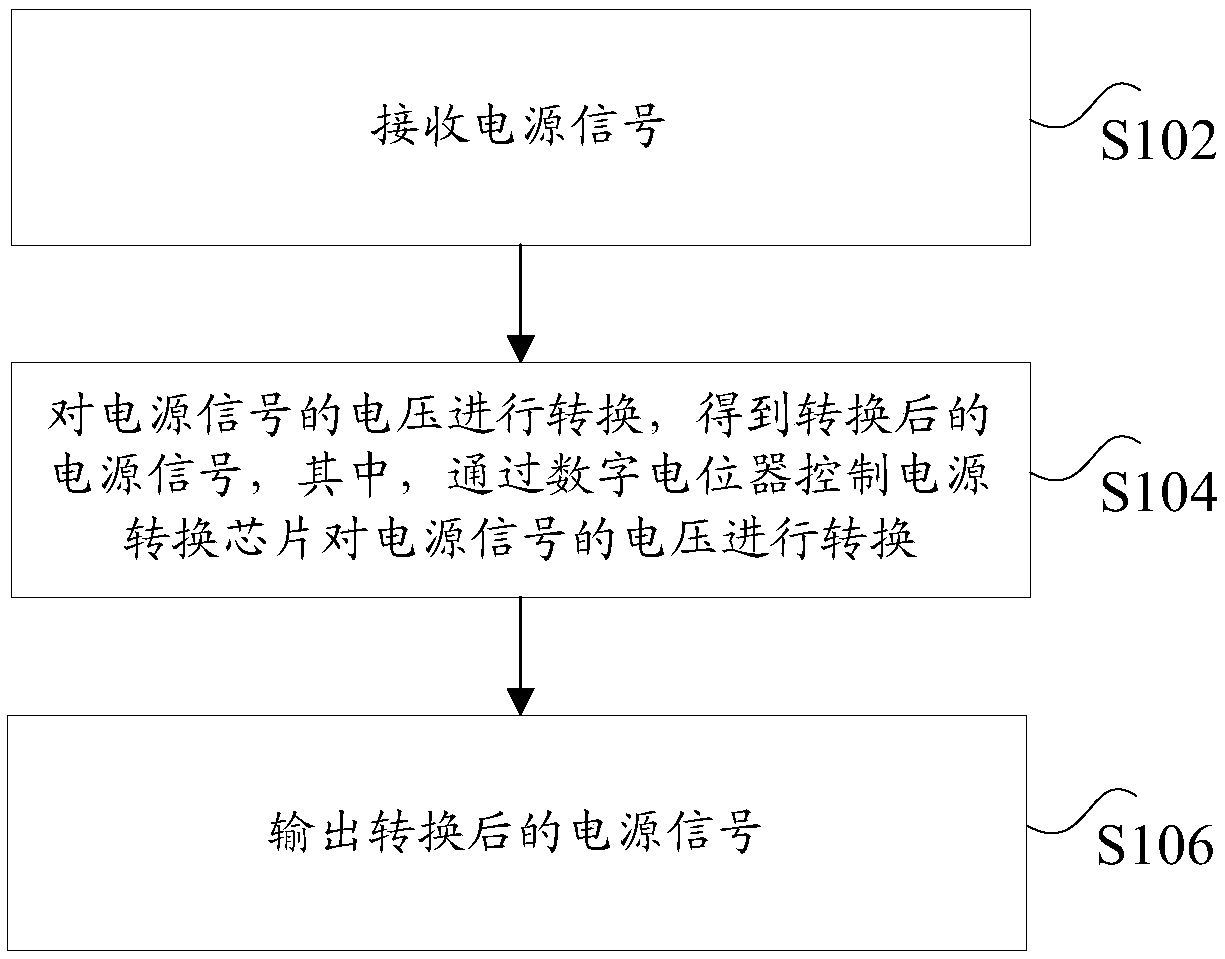

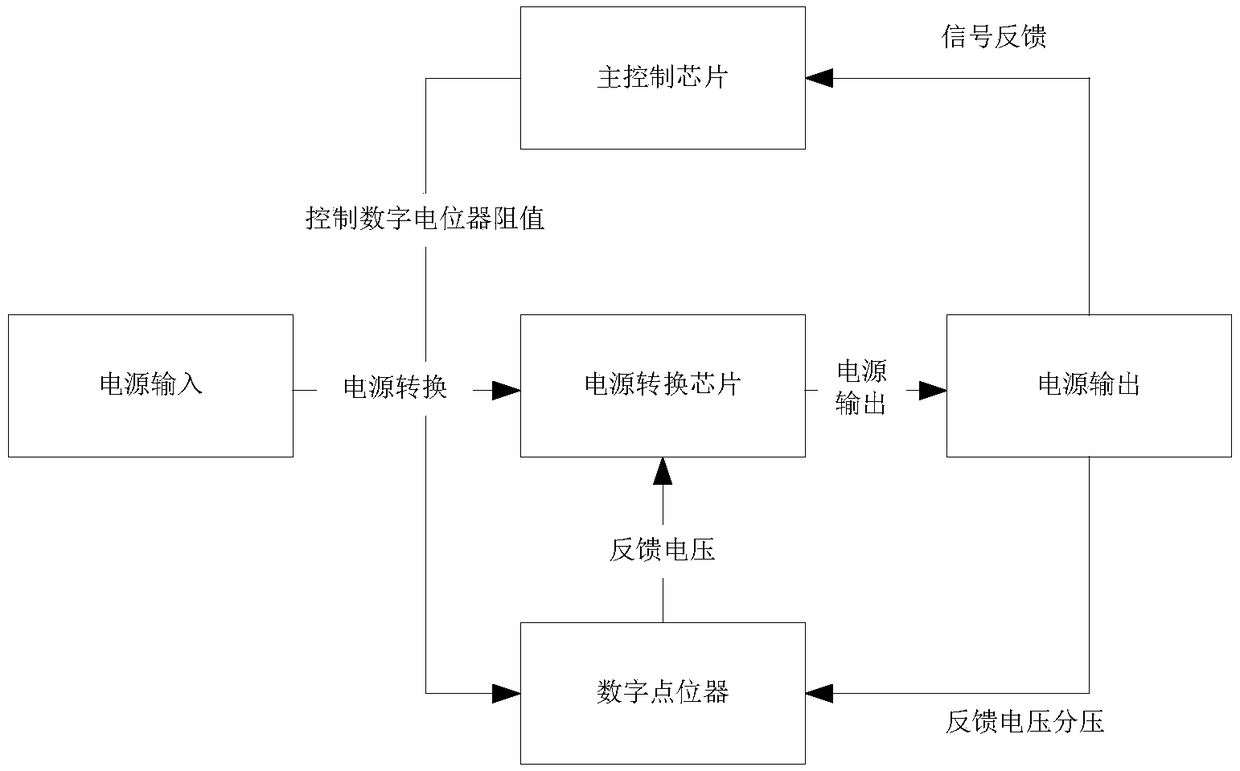

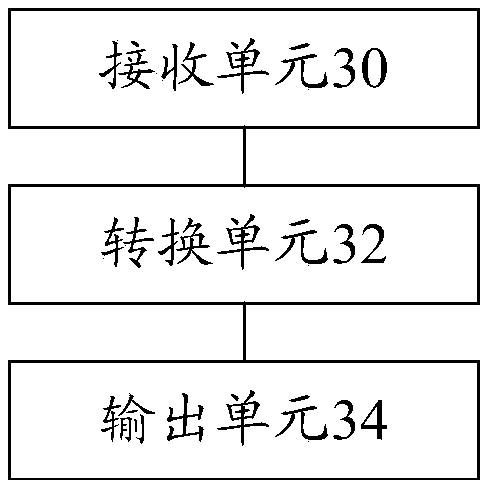

Control method, device and system of power supply voltage

InactiveCN109189144ATo achieve the purpose of precise controlMeet high precision requirementsElectric variable regulationDigital potentiometerEngineering

The invention discloses a control method, device and system of power supply voltage. The method comprises the following steps: receiving a power supply signal; converting the voltage of the power supply signal to obtained a converted power supply signal, wherein a digital potentiometer controls a power supply conversion chip to convert the voltage of the power supply signal; and outputting the converted power supply signal. The technical problem that a high-precision requirement on the voltage by precise equipment cannot be satisfied since the adjusting precision on the power supply voltage islow in the related technology is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

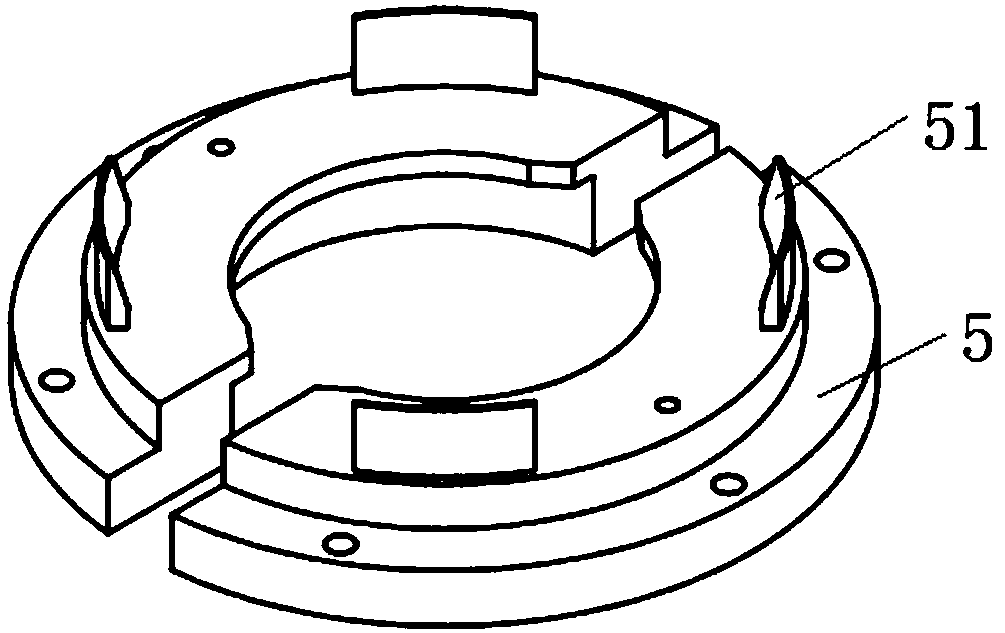

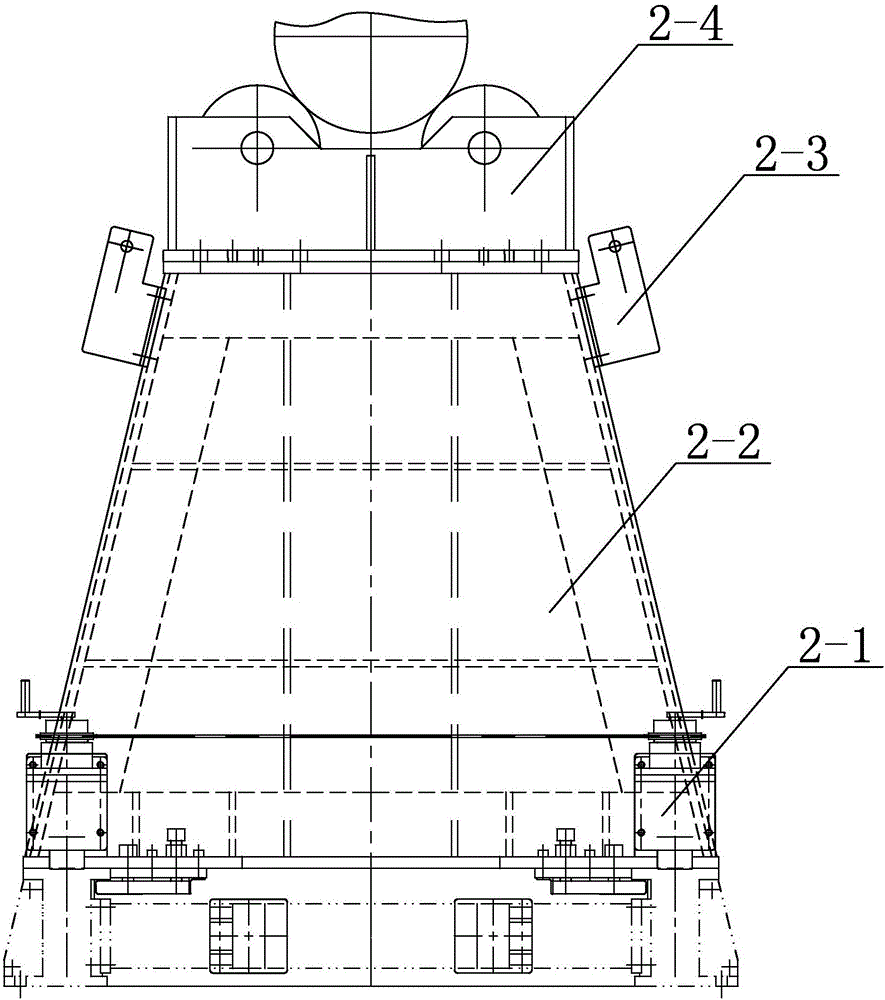

Multi-station automatic centering device under high-temperature and high-vacuum environment

ActiveCN108666189ATo achieve high precision requirementsCold cathode manufactureKovarMechanical engineering

The invention discloses a multi-station automatic centering device under a high-temperature and high-vacuum environment. The multi-station automatic centering device under the high-temperature and high-vacuum environment comprises a main vacuum cavity, wherein the main vacuum cavity is arranged on a cavity bottom disc, a bearing rotation positioning mechanism is arranged in the main vacuum cavity,a main shaft of the bearing rotation positioning mechanism penetrates out of the main vacuum cavity and is fixed on the cavity bottom disc, three stations are arranged on the bearing rotation positioning mechanism and are used for placing workpieces, the workpieces are fixed on the bearing rotation positioning mechanism by workpiece fixtures, guide blocks are arranged on the workpiece fixtures, an MCP assembly tray is arranged below the main vacuum cavity, an MCP assembly is borne on the MCP assembly tray and comprises a lower kovar disc, and an MCP lifting mechanism is arranged below the MCPassembly tray and is arranged in an MCP cavity. The multi-station automatic centering device has the beneficial effects that initial centering of a three-station workpiece is achieved by the bearingrotation positioning mechanism, and automatic centering is achieved by the characteristic that an adjustment bottom disc in the MCP assembly tray can freely slide in the support adjustment disc in a horizontal direction by 360 degrees and by the geometric sizes of the guidance bottoms of the workpiece fixtures.

Owner:北京中科科美科技股份有限公司

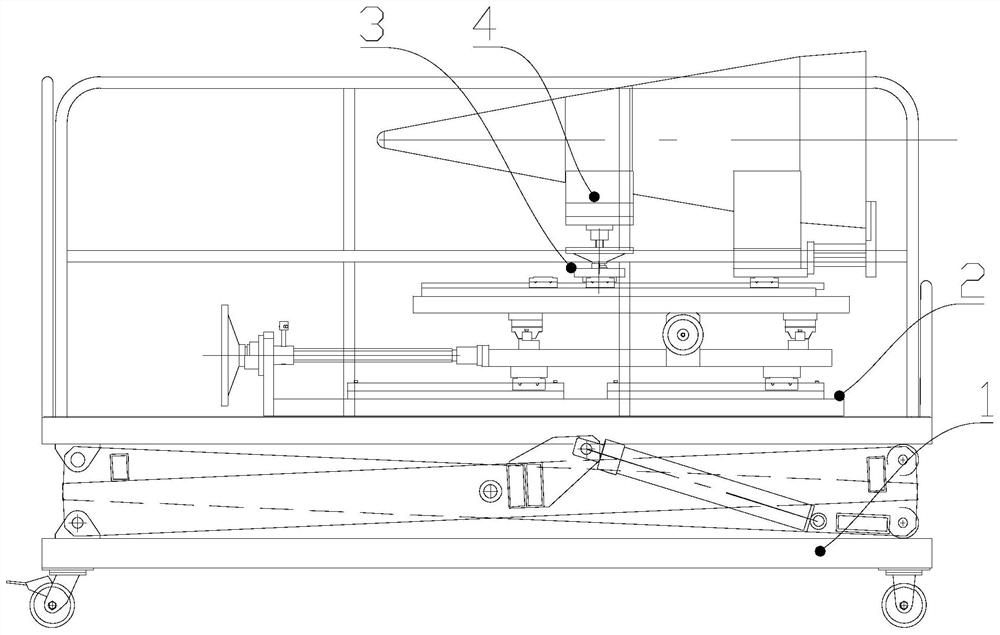

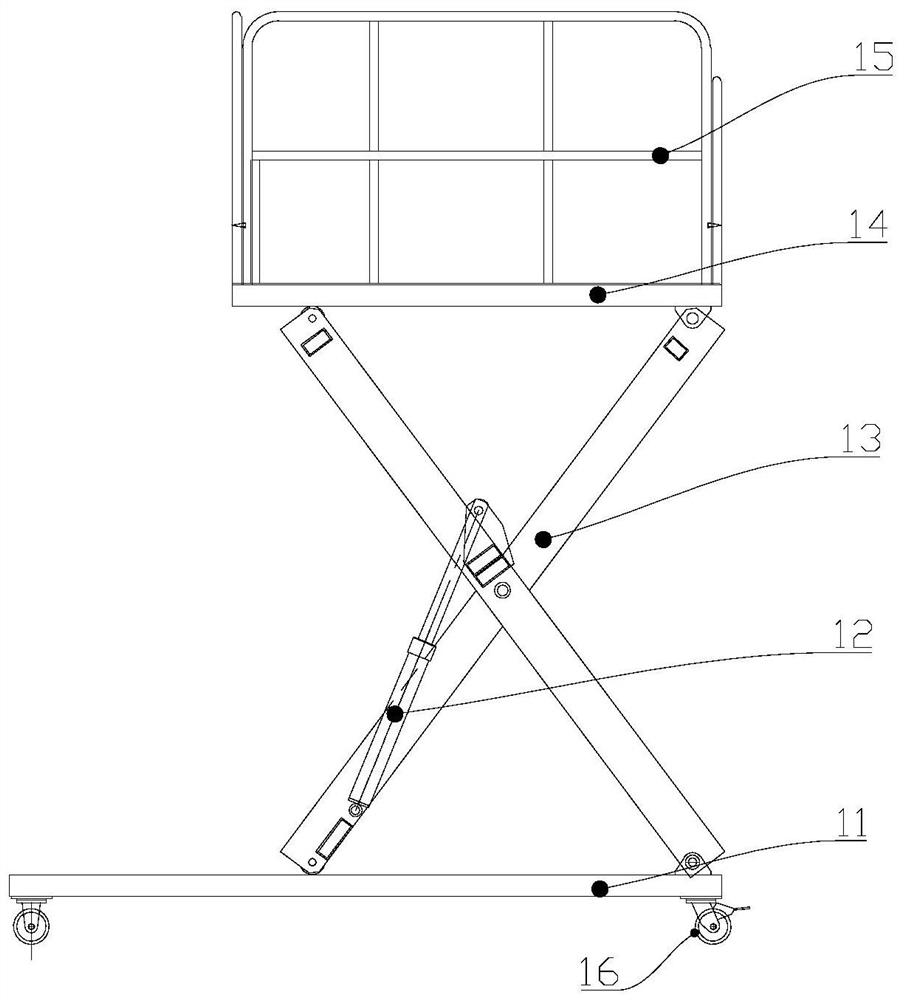

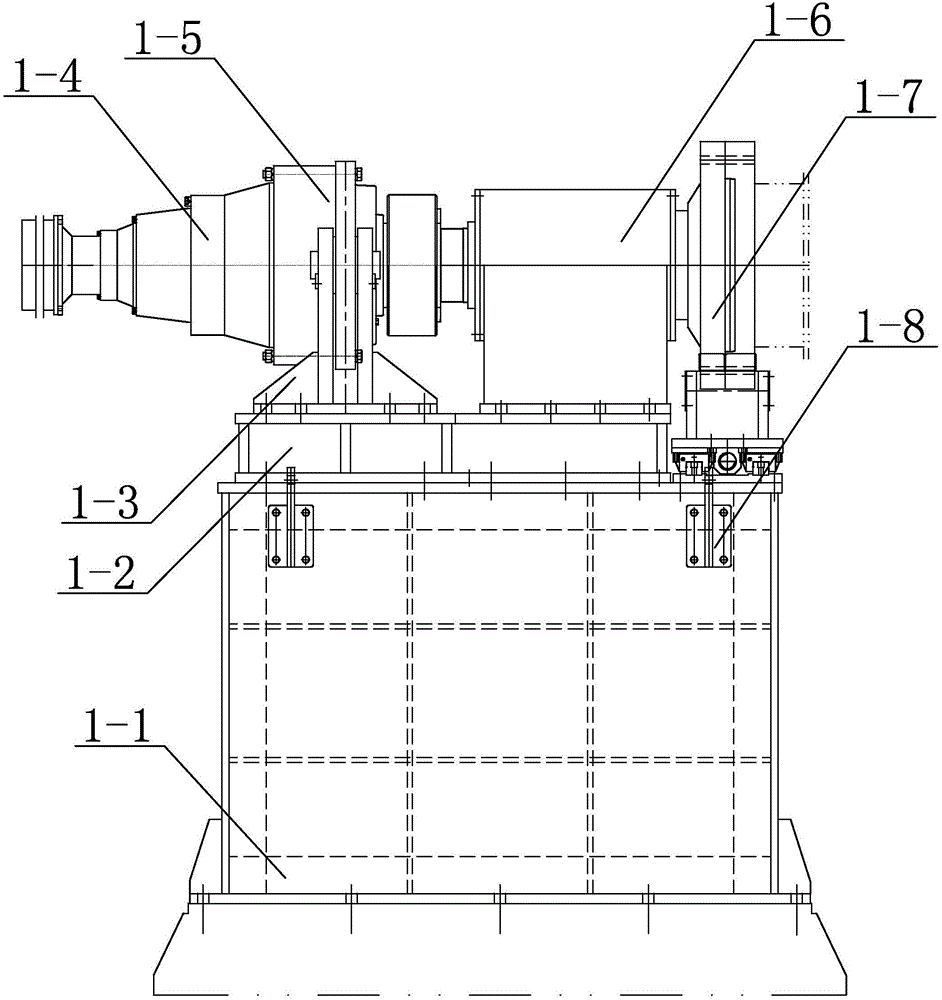

Large missile-borne radar radome erecting platform

ActiveCN113814928AHigh precision requirementsAdaptableAntenna adaptation in movable bodiesWork holdersRadar antennasControl theory

The invention provides a large missile-borne radar radome erecting platform. The platform comprises a lifting mechanism, a coarse adjustment mechanism matched with the lifting mechanism, a fine adjustment mechanism matched with the coarse adjustment mechanism and a mounting mechanism matched with the fine adjustment mechanism; a radome can be fixed to the mounting mechanism; the lifting mechanism can drive the coarse adjustment mechanism to change the height, the coarse adjustment mechanism can drive the fine adjustment mechanism to adjust the position in the horizontal plane, and the fine adjustment mechanism can drive the mounting mechanism to change the height. Rapid coarse adjustment of the position of the radome is achieved through the lifting mechanism and the coarse adjustment mechanism, the radome is moved to the designated position, then accurate adjustment of the position is conducted through the fine adjustment mechanism, the high-precision requirement for head cover matching can be met, the matched mounting mechanism can be replaced according to the type of the radome, the adaptability is high, and the equipment cost is obviously reduced.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

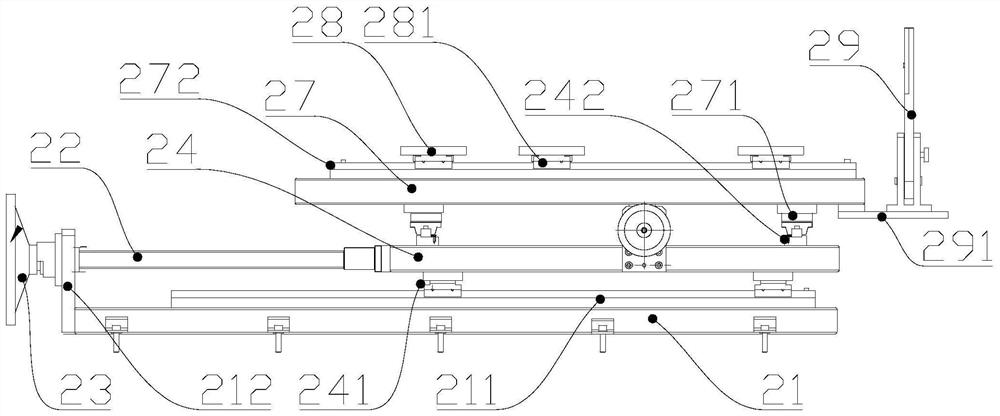

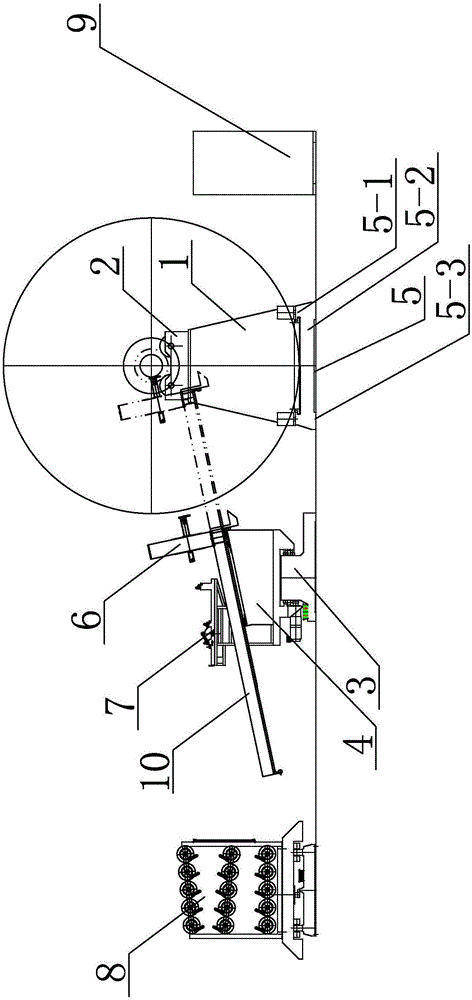

Oversize and precise horizontal winding machine

InactiveCN106273385AFulfill production needsTo achieve high precision requirementsDomestic articlesYarnWinding machine

The invention discloses an oversize and precise horizontal winding machine, relates to a winding machine, and aims at solving the problems that an existing composite material winding machine cannot be suitable for oversize and high-precision products and is low in winding efficiency. A ground rail is installed on the horizontal ground, a horizontal machine tool head and a horizontal machine tool tail are installed at the two ends, in the length direction, of the ground rail respectively, and a horizontal machine tool body is installed on the portion, on one side of the ground rail, of the horizontal ground; a winding car system is installed on the horizontal machine tool body, a deflected yarn spraying system is installed on the winding car system, a follow-up gum dipping system is installed on the winding car system, a follow-up creel system is installed at one side of the horizontal machine tool body, and a control cabinet is located at one side of the horizontal machine tool body and controls rotation of a spindle and the motion and working states of the follow-up creel system, the winding car system, the deflected yarn spraying system and the follow-up gum dipping system. The oversize and precise horizontal winding machine is used for winding oversize and high-precision pipe fittings.

Owner:HARBIN COMPOSITE EQUIP

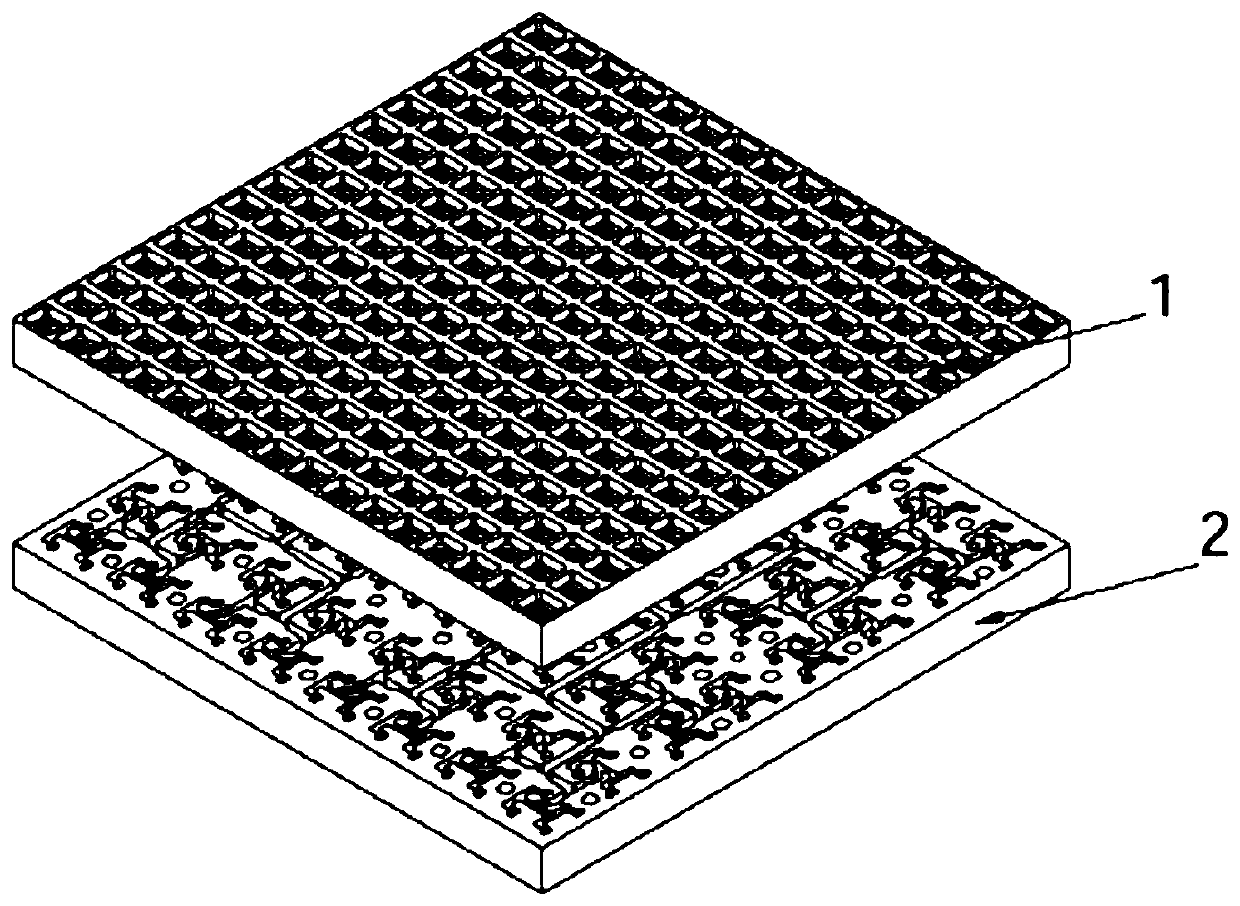

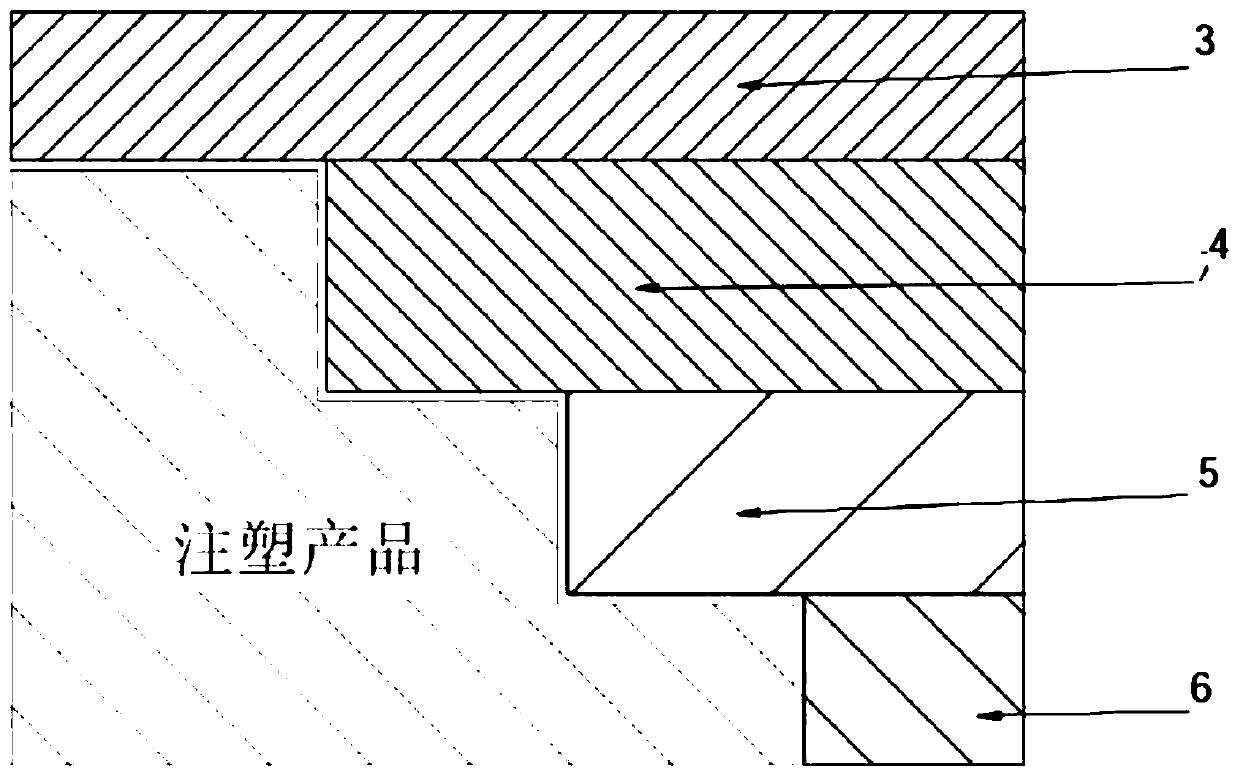

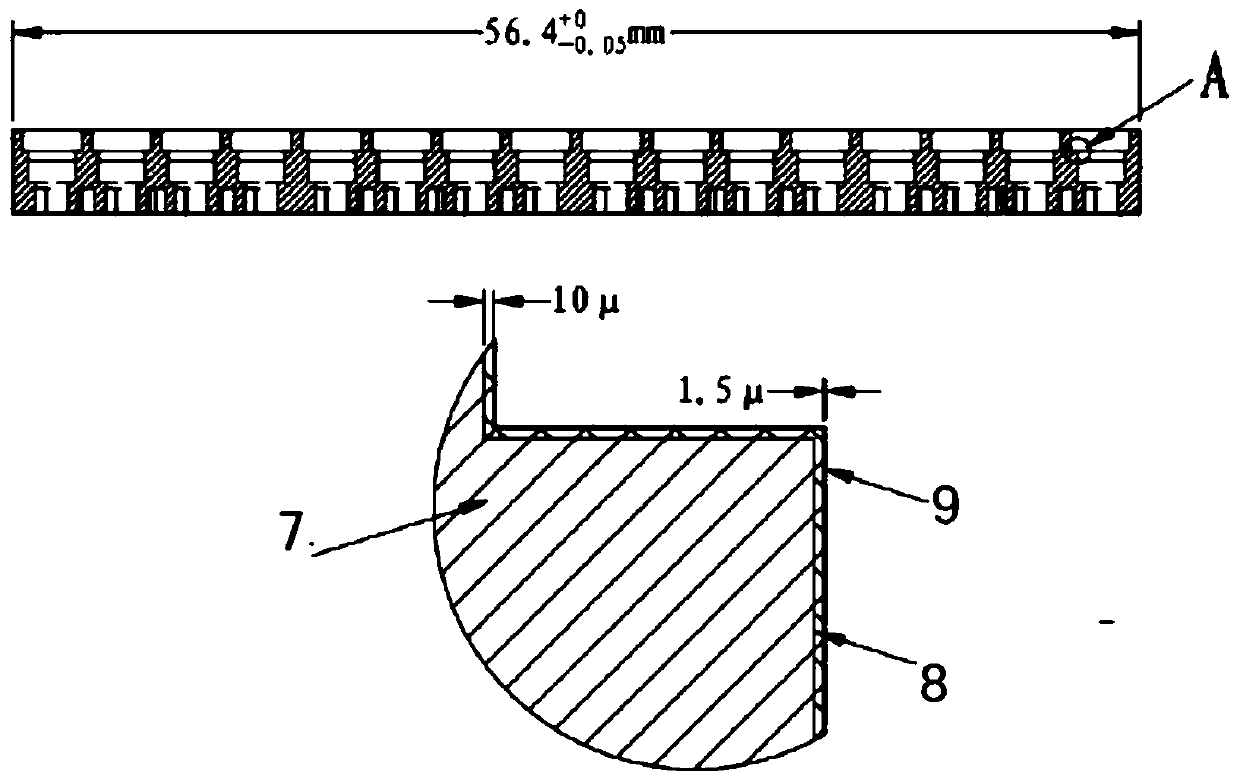

5G millimeter wave antenna and manufacturing method thereof

ActiveCN111180904AMaintain dimensional accuracyMaintain dimensional stabilityRadiating elements structural formsAntenna arrays manufactureMillimetre waveMillimeter wave antennas

The invention relates to a manufacturing method of a millimeter wave array antenna. The method comprises the following steps: a plastic base material of an antenna fragmentation model is obtained through an injection molding method; and metallization treatment is carried out on the surface of the plastic base material. According to the millimeter wave array antenna processing method, the manufacturability of the product is improved, and batch production is facilitated; the millimeter wave antenna cost is reduced, the product weight is reduced, and the transportation and installation difficultyand cost are reduced.

Owner:深圳市聚慧达科技有限公司

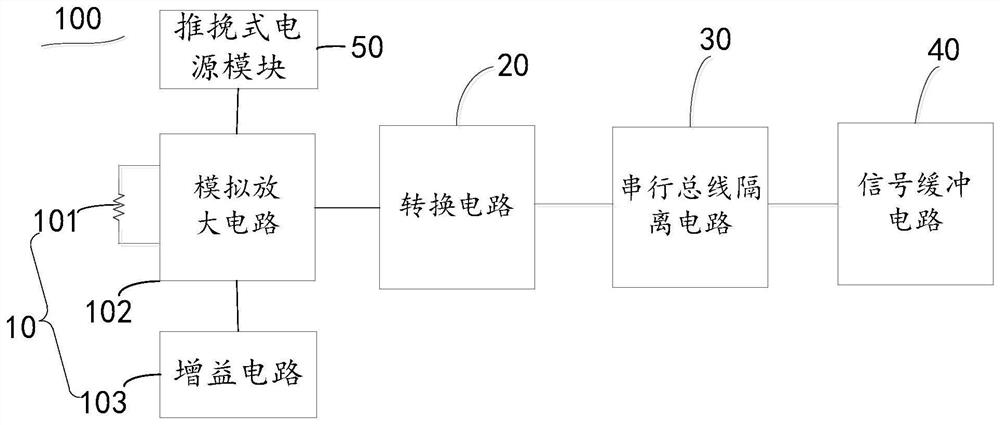

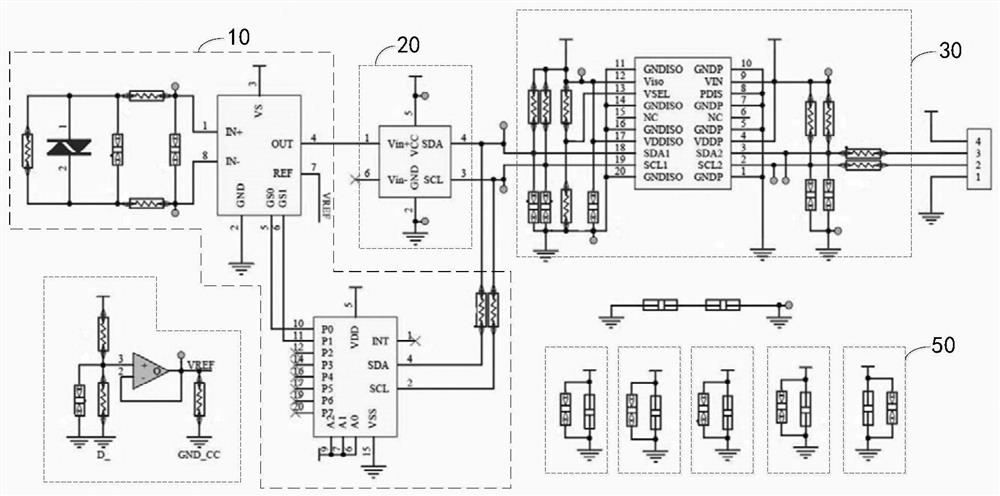

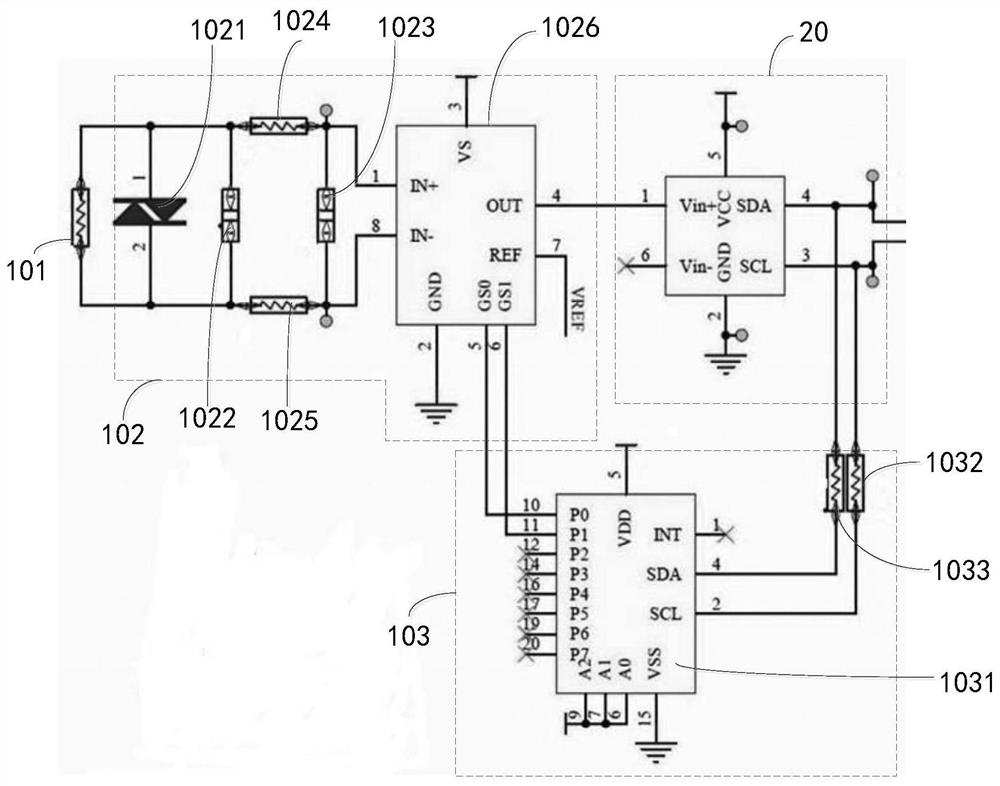

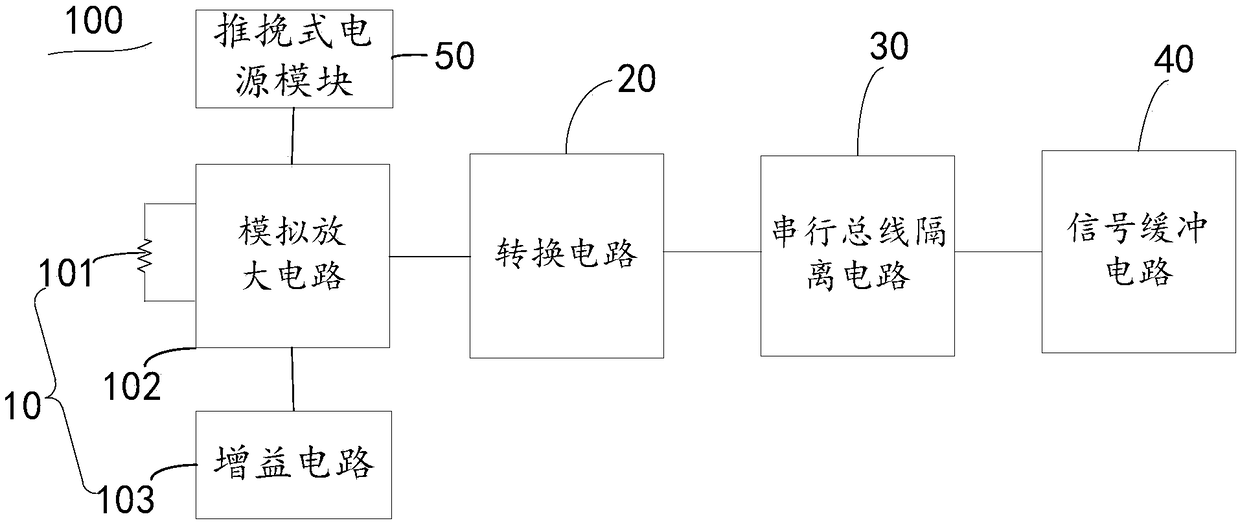

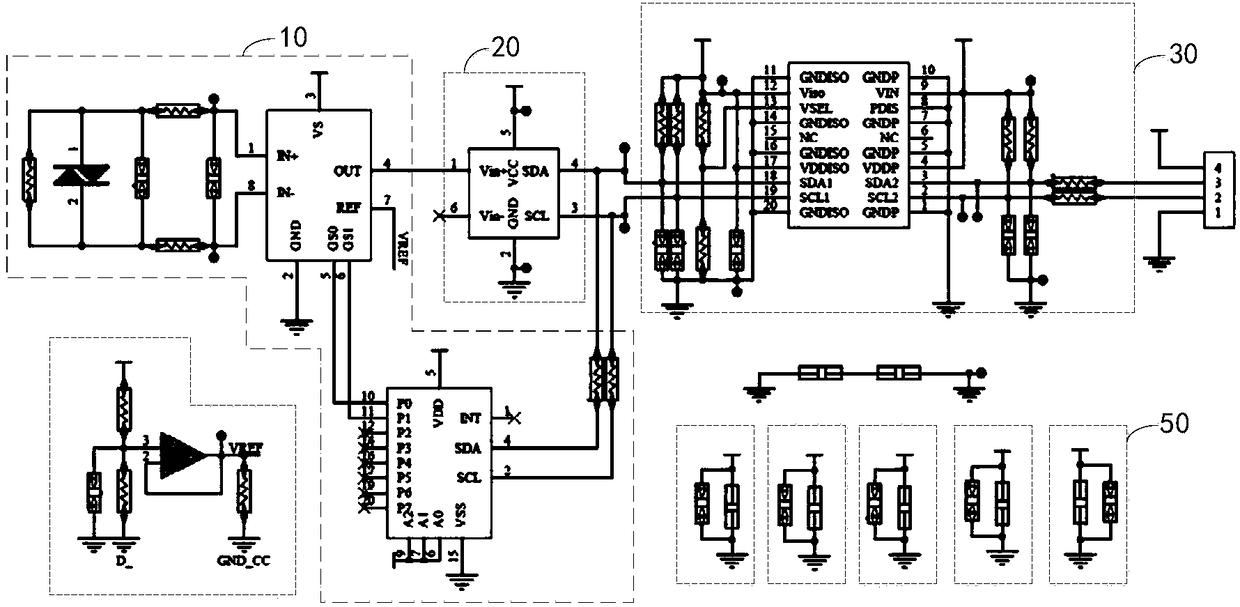

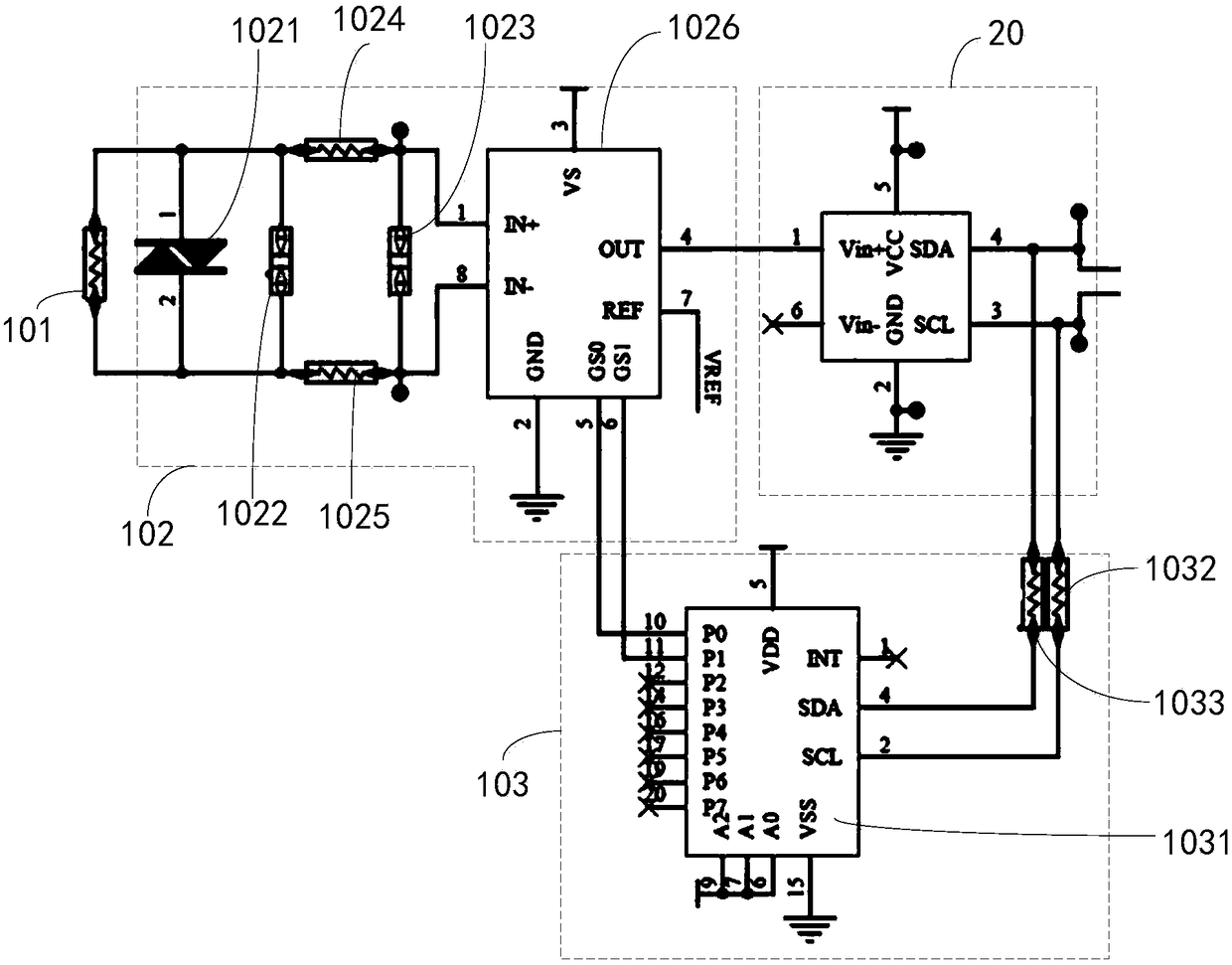

A current sampling circuit

ActiveCN108445285BTo achieve high precision requirementsReduce manufacturing costMeasurement using digital techniquesHemt circuitsControl theory

The invention relates to a battery management system, and discloses a current sampling circuit. The current sampling circuit comprises a collecting circuit, a switching circuit, a serial bus separation circuit and a signal buffering circuit; the collecting circuit is used for collecting a simulated current signal; the input end of the switching circuit is connected with the output end of the collecting circuit, and the switching circuit is used for switching the simulated current signal to a digital current signal; the input end of the serial bus separation circuit is connected with the outputend of the switching circuit, and the serial bus separation circuit is used for switching the digital current signal to a serial current signal conforming to a serial bus protocol; and the input endof the signal buffering circuit is connected with the output end of the serial bus separation circuit, the signal buffering circuit is used for buffering output of the serial current signal, the high-precision requirement of current sampling is achieved, and meanwhile, the production cost is lowered.

Owner:SHENZHEN POWEROAK NEWENER

Machine box panel machining method

InactiveCN103495843ATo achieve high precision requirementsDuplicating/marking methodsMetal casingsMachiningDesign data

The invention discloses a machine box panel machining method which includes the following steps that CNC carving is adopted on a metal surface of a machine box panel according to design data and apertures and the shape are carved. The CNC machining rotation speed is set to be the machining speed of 1000-30000r / min. Chamfered counter bores are formed in the machine box panel which undergoes oxidation character printing.

Owner:昆山纯柏精密五金有限公司

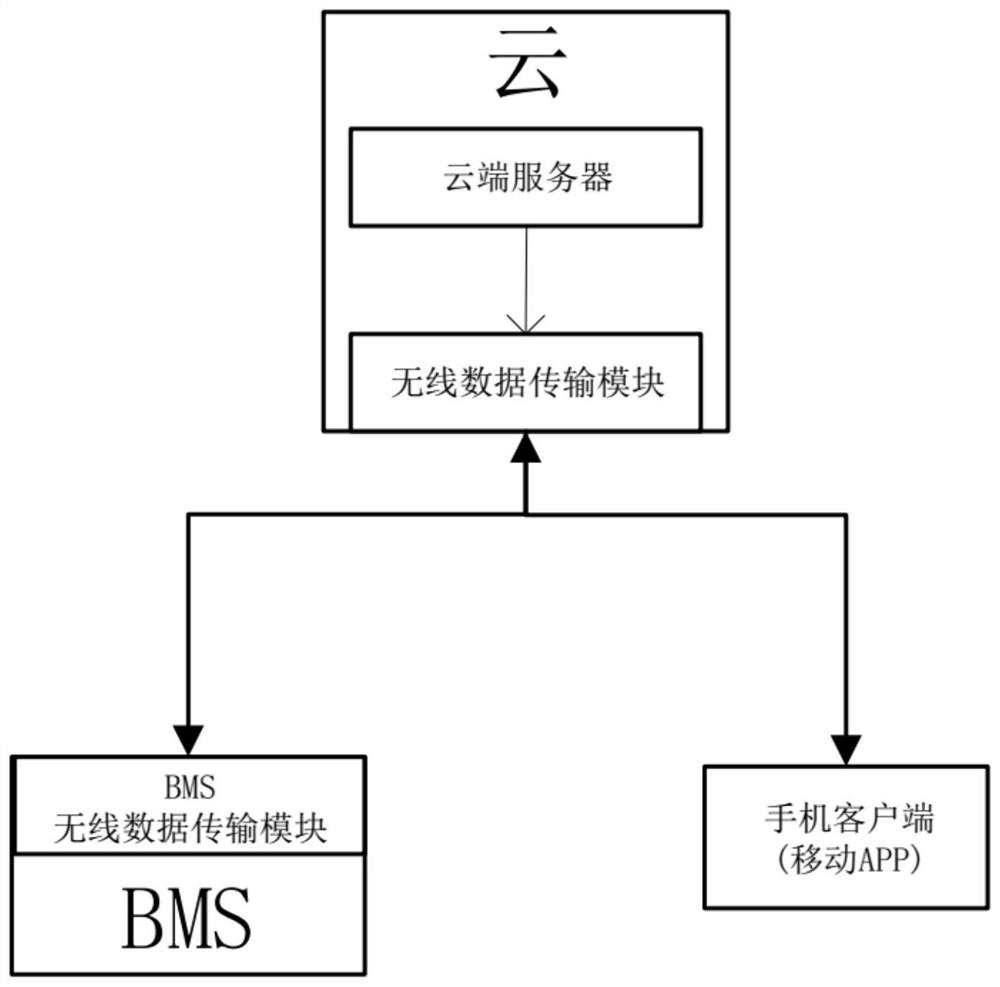

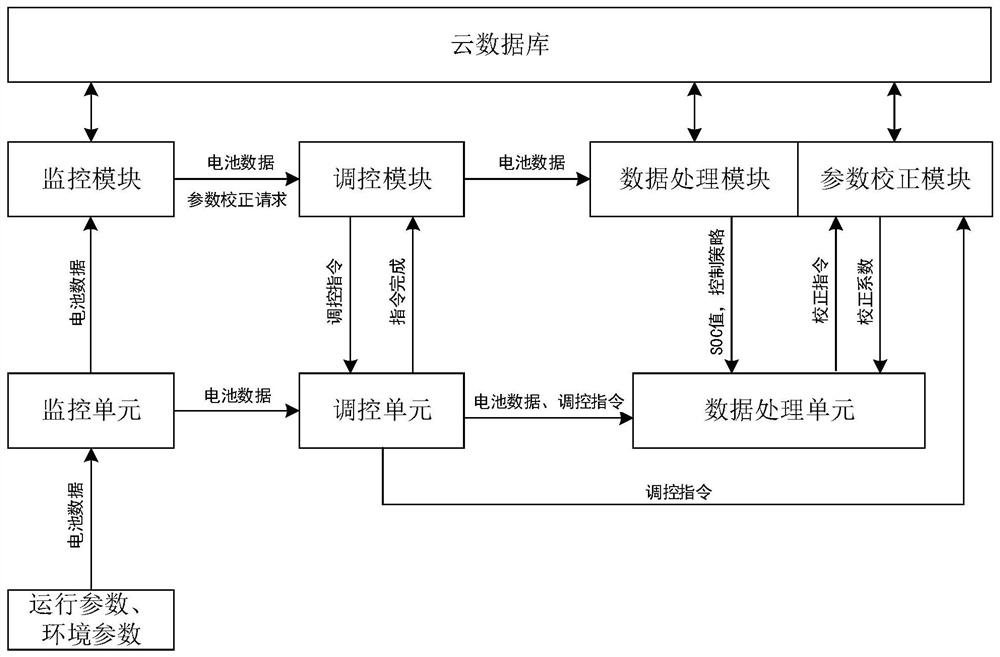

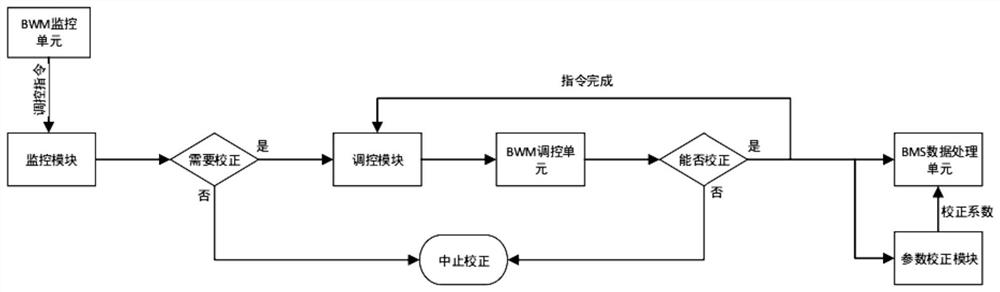

Intelligent battery SOC management system and method based on cloud platform

ActiveCN110749827BIncrease computing speedImprove calculation accuracyElectrical testingComputer scienceBattery cell

The utility model discloses an intelligent battery SOC management system and method based on a cloud platform. The system comprises a BMS system configured to collect operation parameters of a batterymodule and environmental parameters of the current equipment and upload the operation parameters and the environmental parameters to the cloud server, calculate a SOC value of the battery module according to the operation parameters of the battery module, receive a regulation and control instruction and a new correction coefficient issued by the cloud server, and correct the calculated SOC value;and a cloud server configured to receive the operation parameters of the battery module and the environmental parameters of the current equipment acquired by the BMS system, analyze and process the operation parameters and the environmental parameters, and establish a corresponding operation parameter and environmental parameter database, and judge whether the battery SOC parameters need to be re-corrected according to the operation parameters, issue the regulation and control instruction to the BMS system if the battery SOC parameters need to be re-corrected, re-adjust the correction coefficients according to the operation parameters of the battery module and historical operation parameter information thereof to obtain new correction coefficients, and issue the new correction coefficients to the BMS system.

Owner:元山(济南)电子科技有限公司

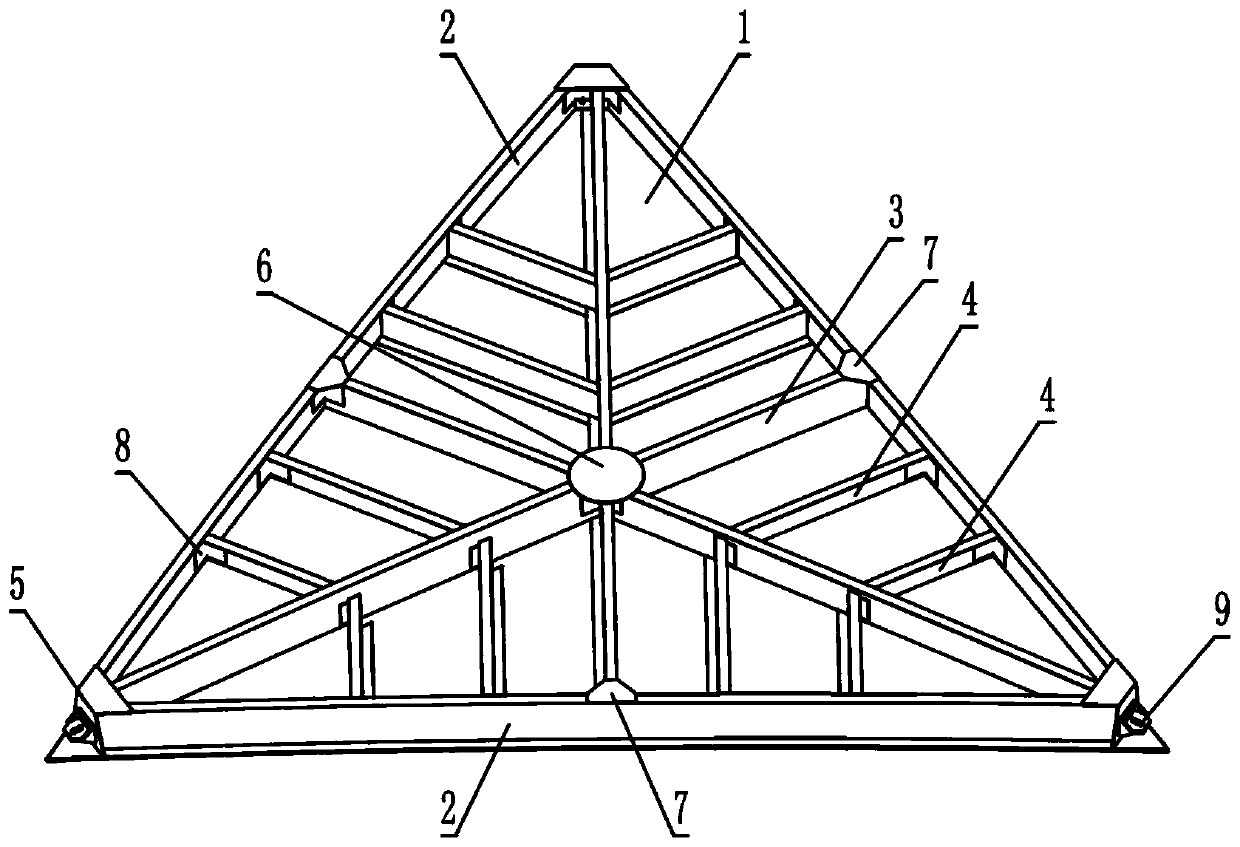

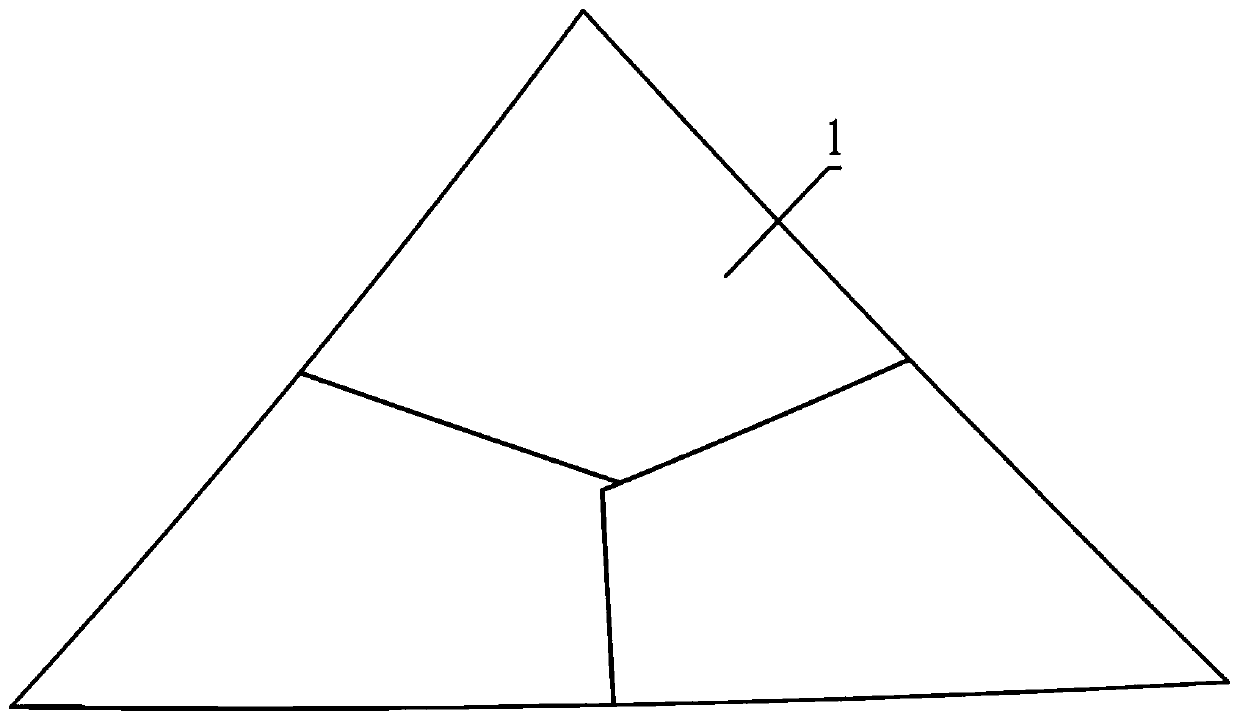

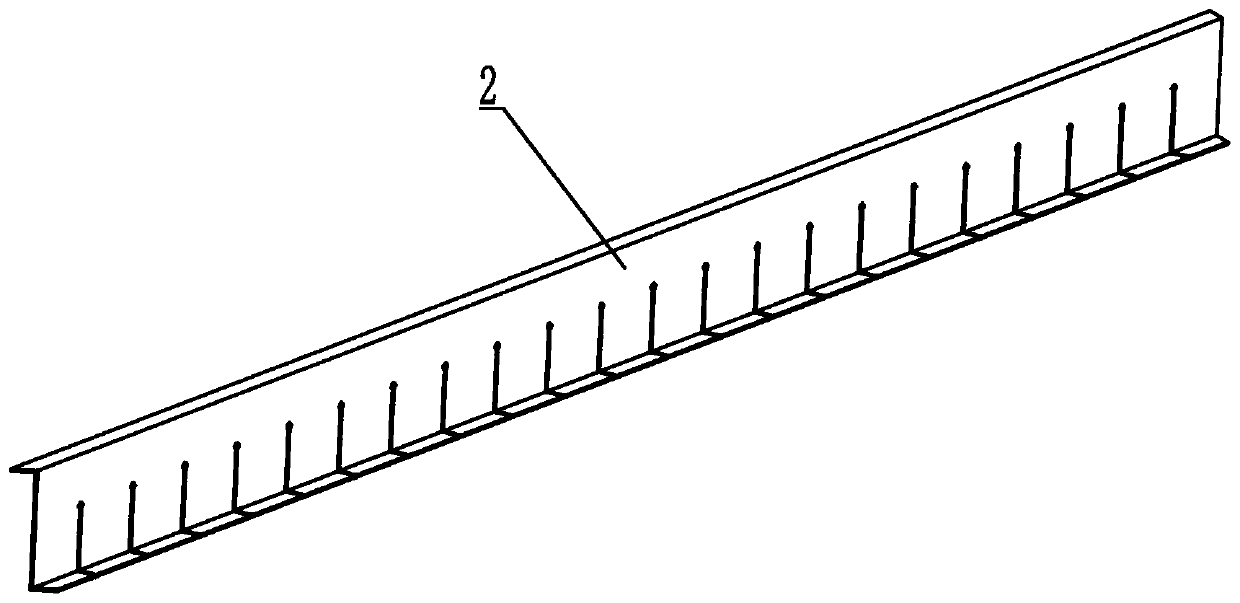

A high-precision and lightweight triangular antenna panel and its manufacturing method

ActiveCN108666762BAvoid deformationImprove installation accuracyAntennasHigh volume manufacturingManufacturing technology

The invention discloses a high-precision light-weight triangular antenna panel and a manufacturing method, relates to the design and manufacturing technologies of high-precision reflector antenna panels in the fields such as communication, measurement and control and radio astronomy, and aims to provide the antenna panel which is high in precision, light in weight and low in cost and is applicablefor batch production. The antenna panel comprises a skin, main side ribs, center ribs, auxiliary ribs, angle ribs, a center connecting plate, an edge connecting plate, angle supports and a support, wherein the skin is triangular; three main side ribs are arranged in the directions of three sides of the convex side of the skin; the center ribs are positioned on the center lines of the three main side ribs; the auxiliary ribs are distributed on two sides of the center ribs and are vertical to the main side ribs; the angle ribs are arranged at the intersection of the main side ribs; the center connecting plate is positioned at the intersection of the three center ribs; and vacuum negative pressure adsorption forming is adopted. The antenna panel is particularly applicable to designing and manufacturing panels of offset reflector antennas or circular symmetry reflector antennas which are high in precision and produced in batches.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

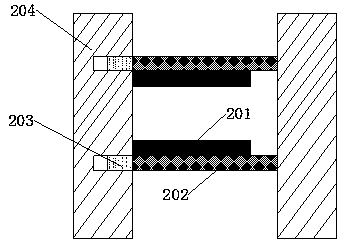

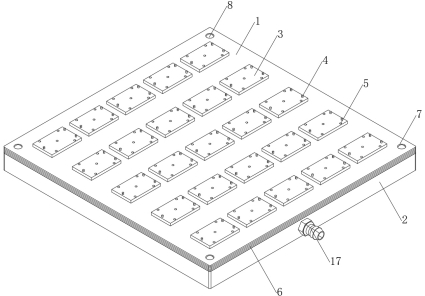

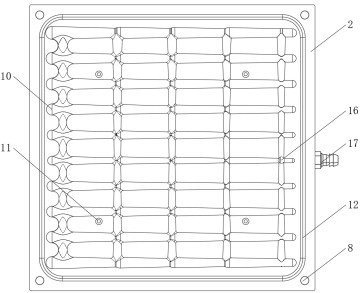

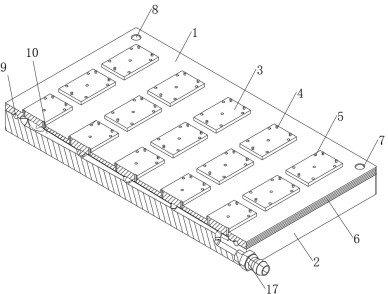

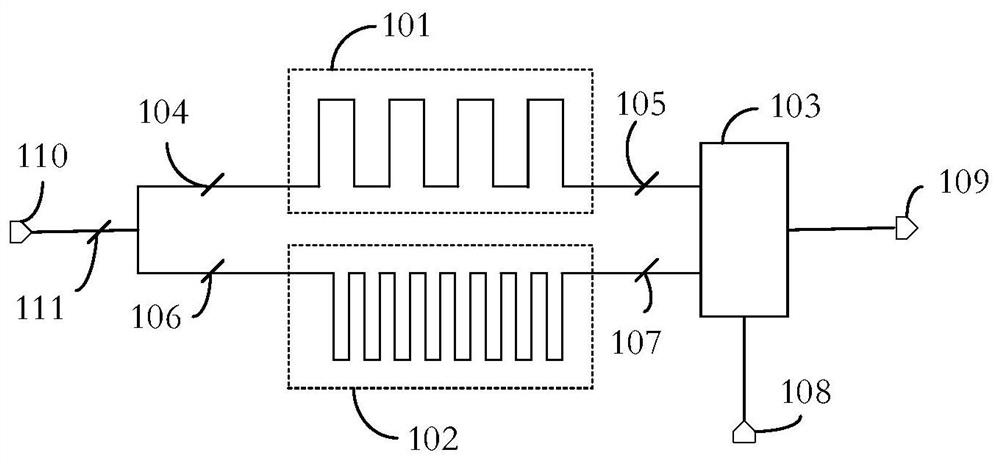

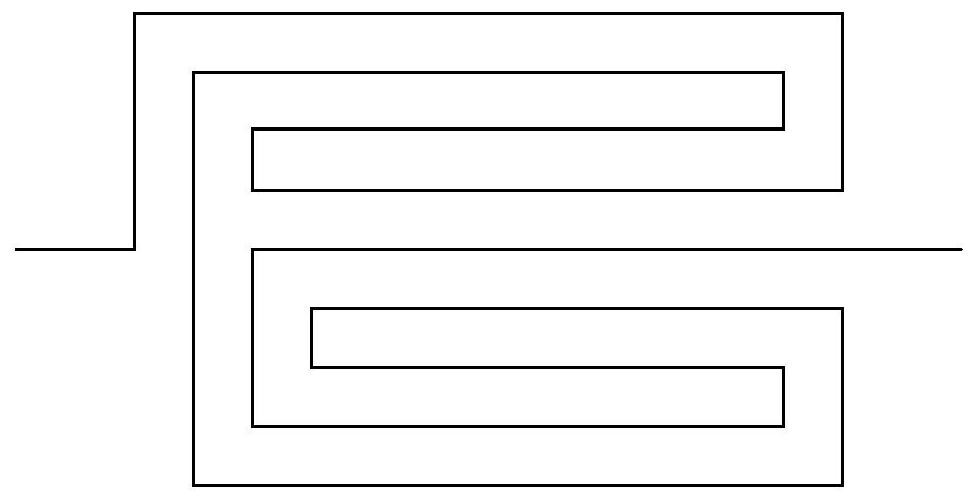

Low-pressure-difference steady-state vacuum chuck based on stepped conical flow channel

ActiveCN114883240APrevent movementGuaranteed uptimeSemiconductor/solid-state device manufacturingMachining processTop cap

The invention discloses a low-pressure-difference steady-state vacuum chuck based on a stepped conical runner, and belongs to the technical field of tool clamps, the low-pressure-difference steady-state vacuum chuck comprises a top cover and a base, the top of the top cover is fixedly connected with a plurality of bosses, the top of each boss is fixedly connected with the bottoms of a plurality of limiting columns, each boss is further provided with a plurality of air suction holes, and the air suction holes are communicated with the bottom of the top cover. Each air suction hole penetrates through the boss and the top cover, an anti-skid layer is arranged on the side wall of the top cover, and a plurality of positioning holes are formed in the position, close to the anti-skid layer, of the top of the top cover; the top cover and the base are kept relatively stable through cooperation of the positioning holes formed in the top cover and the positioning pins fixedly connected to the base, the top cover and the base are further kept stable through cooperation of the pressing grooves formed in the bottom of the top cover and the sealing strips and the annular grooves, relative movement of the top cover and the base in the chip machining process is avoided, and the chip machining quality is improved. The bottom of the air suction hole is always communicated with the diversion trench, so that the vacuum chuck can operate stably.

Owner:中科领航医疗科技有限公司

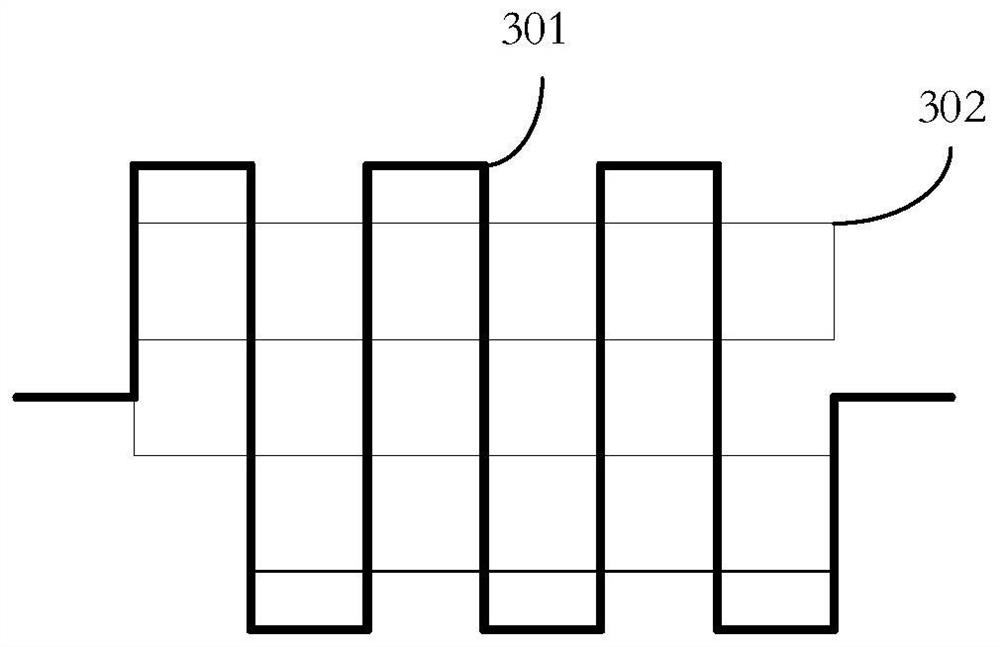

Delay circuit

PendingCN114584112ATo achieve high precision requirementsPulse manipulationSoftware engineeringWire wrap

A delay circuit includes a first buffer, a second buffer, a wire, and a selector. The first buffer is configured to buffer an input signal to generate the first intermediate signal. The second buffer is used for buffering the input signal to generate the second intermediate signal. The winding is used for delaying the first intermediate signal to generate a delayed signal. The selector is configured to select the delayed signal or the second intermediate signal as an output signal. According to the invention, high-precision time sequence delay can be realized by adjusting the winding length.

Owner:SHANGHAI CAMBRICON INFORMATION TECH CO LTD

Current sampling circuit

ActiveCN108445285ATo achieve high precision requirementsReduce manufacturing costMeasurement using digital techniquesPower flowEngineering

The invention relates to a battery management system, and discloses a current sampling circuit. The current sampling circuit comprises a collecting circuit, a switching circuit, a serial bus separation circuit and a signal buffering circuit; the collecting circuit is used for collecting a simulated current signal; the input end of the switching circuit is connected with the output end of the collecting circuit, and the switching circuit is used for switching the simulated current signal to a digital current signal; the input end of the serial bus separation circuit is connected with the outputend of the switching circuit, and the serial bus separation circuit is used for switching the digital current signal to a serial current signal conforming to a serial bus protocol; and the input endof the signal buffering circuit is connected with the output end of the serial bus separation circuit, the signal buffering circuit is used for buffering output of the serial current signal, the high-precision requirement of current sampling is achieved, and meanwhile, the production cost is lowered.

Owner:SHENZHEN POWEROAK NEWENER

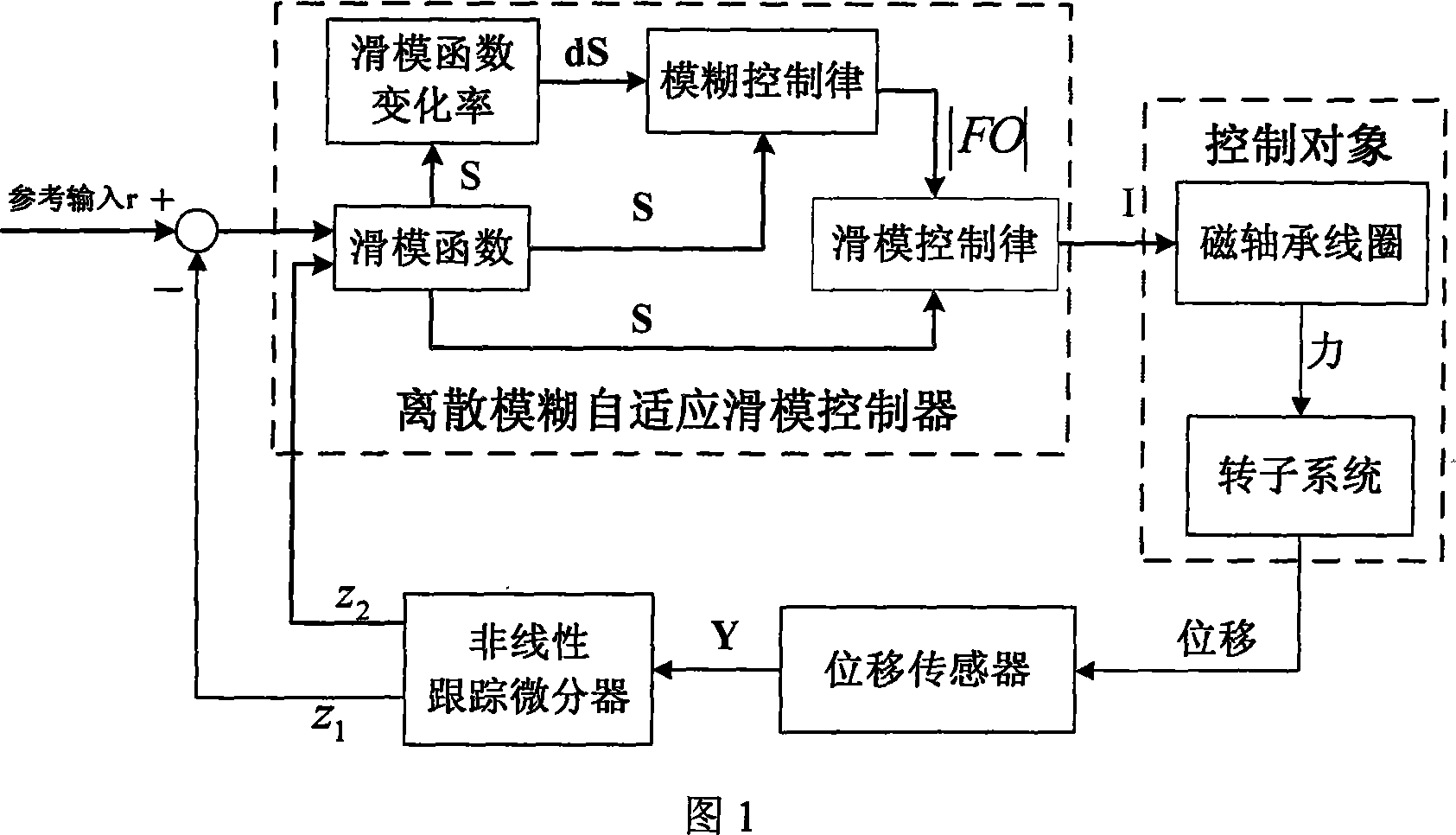

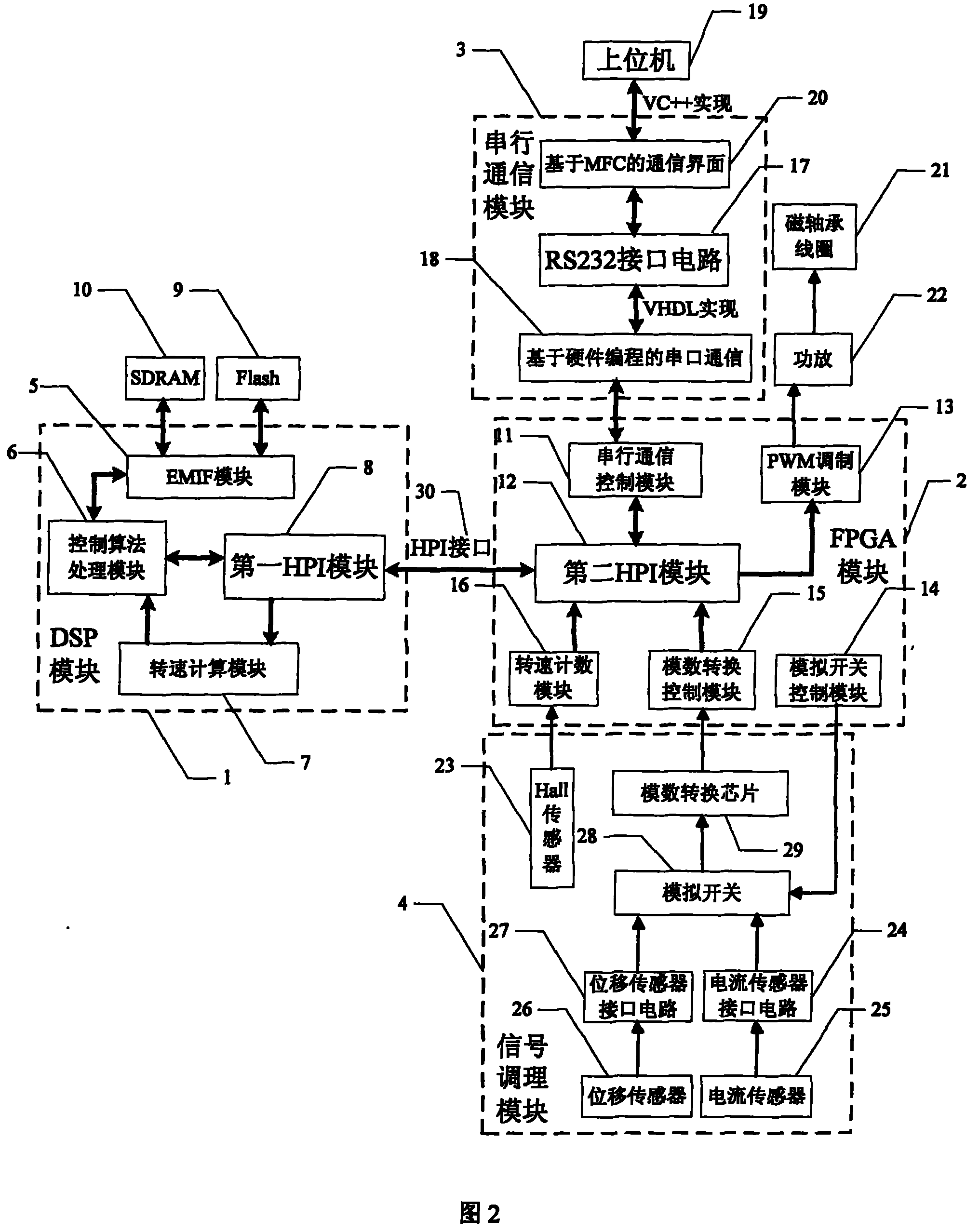

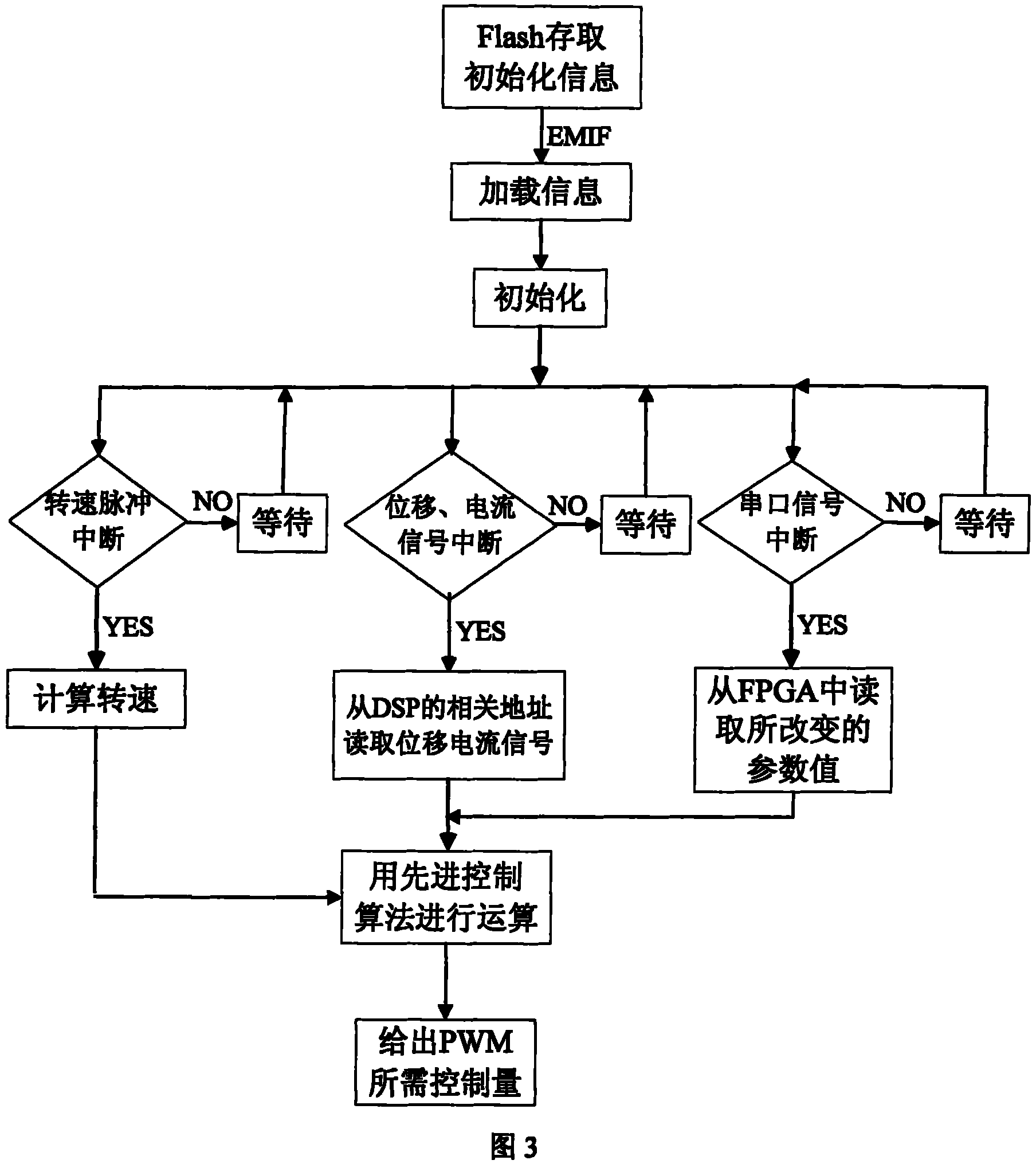

Integrated digital control system for high temperature superconducting magnetic suspension energy accumulation flywheel magnetic bearing

An integrated high temperature superconduct magnetic suspension energy storage flywheel magnetic bearing digital control system is provided, which comprises a DSP module, a FPGA module, a serial communication module and a signal modulation module. Wherein, the DSP module realizes the treatment of advanced control arithmetic and the calculation of rotate speed; the FPGA module accomplishes the sampling of displacement and electric current signal, counting of rotate speed and PWM modulation of the control extent; a control electric current for the magnetic bearing loop is generated via a power amplifier to realize the high precision control of the high temperature superconduct magnetic suspension energy storage flywheel magnetic bearing system. In addition, the serial communication module realizes the real time communication between a upper position machine and FPGA; the signal modulation module offsets, amplifies and filter the collected displacement and electric current signal as wellas outputs the result to FPGA module. Therefore, the digital control system in the invention does not only realizes outstanding computation capacity and high communication speed, but also assures thereal time communication between the upper position machine and FPGA, thereby further enhancing the control precision for the high temperature superconduct magnetic suspension energy storage flywheel magnetic bearing system.

Owner:BEIHANG UNIV

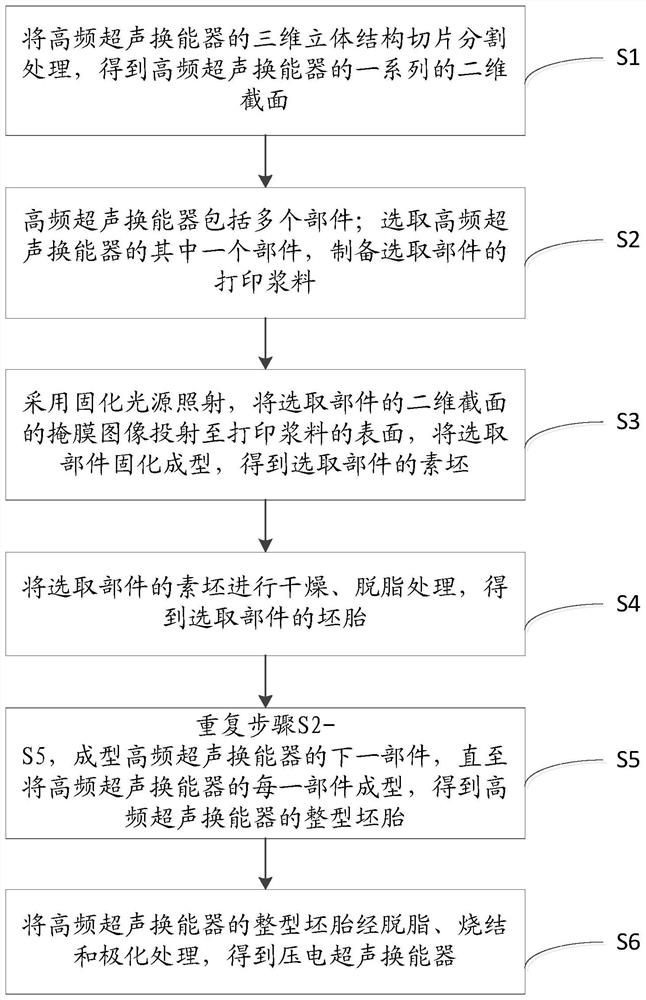

A method of making a piezoelectric ultrasonic transducer

ActiveCN108906560BComplete structureImprove performanceMechanical vibrations separationUltrasonic sensorTransducer

The invention discloses a method of manufacturing a piezoelectric ultrasonic transducer. The method comprises the following steps: S1, segmenting a slice of a three-dimensional structure of a high frequency ultrasonic transducer to obtain a series of two-dimensional sections of the high frequency ultrasonic transducer; S2, as the high frequency ultrasonic transducer comprises a plurality of parts,selecting one of the parts of the high frequency ultrasonic transducer to prepare printing slurry of the selected part; S3, irradiating the part with a curing light source, projecting a mask image ofthe two-dimensional section of the selected part to the surface of the printing slurry, and curing and forming the selected part to obtain a biscuit of the selected part; S4, drying and degreasing the biscuit of the selected part to obtain a blank of the selected part; and S5, repeating S2-S5, and forming a next part of the high frequency ultrasonic transducer till every part of the high frequency ultrasonic transducer is formed to obtain a whole blank of the high frequency ultrasonic transducer. The method provided by the invention meets a high precision demand in manufacturing the ultrasonic transducer, and the work efficiency is improved greatly.

Owner:广州联声电子科技有限公司

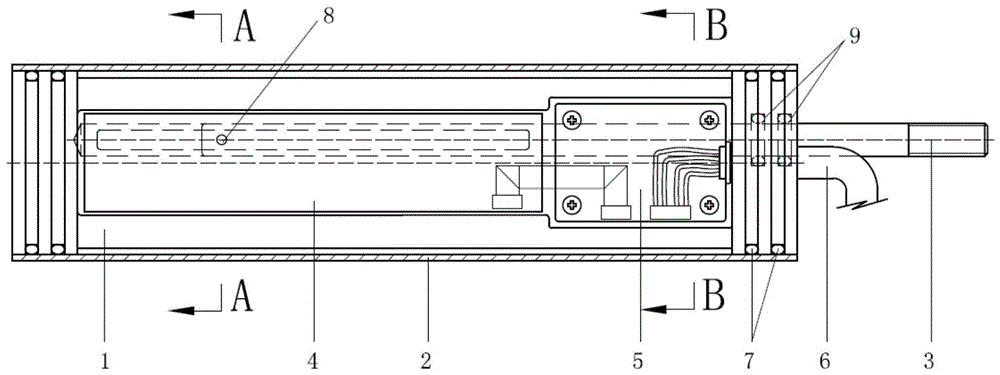

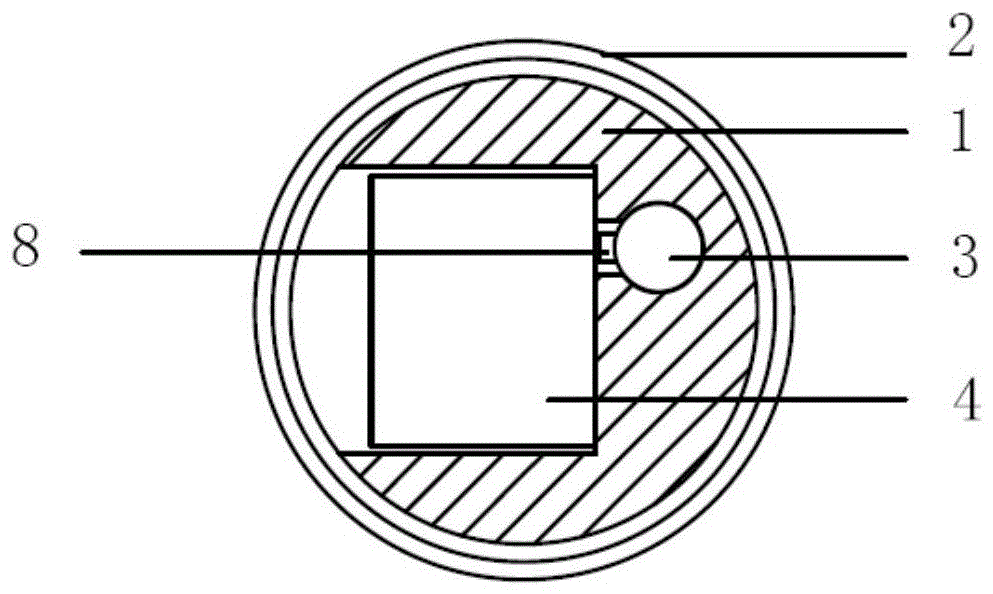

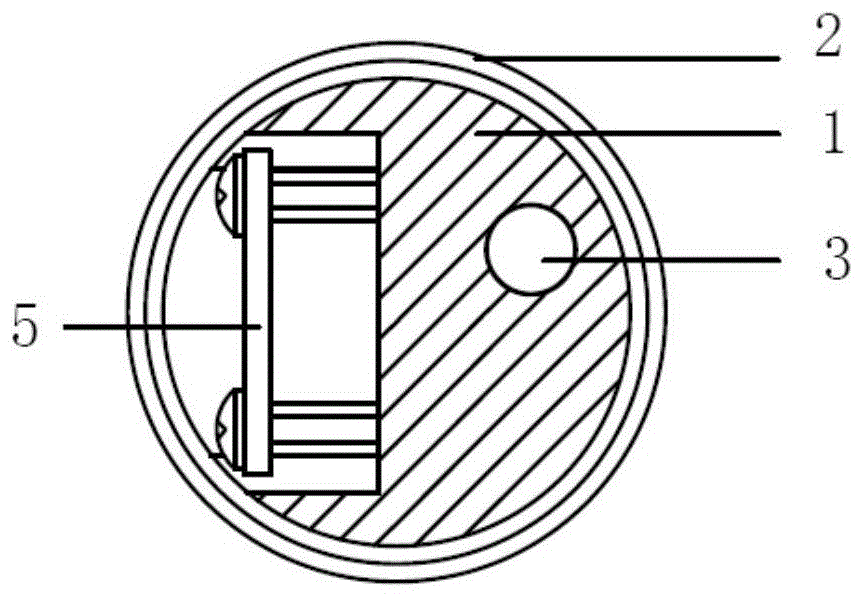

photoelectric displacement sensor based on cis

The invention provides a CIS-based photoelectric displacement sensor. The CIS-based photoelectric displacement sensor comprises an outer protective barrel, a sensor core, a displacement slide bar, a CIS contact type image sensor, a measurement control circuit board and a cable, wherein the sensor core, the CIS contact type image sensor and the measurement control circuit board are all packaged in the outer protective barrel, a slit is formed between a mounting groove and a slideway in the length direction of the sensor core, the mounting groove and the slideway are formed in the sensor core, the mounting groove is communicated with the slideway through the slit, one part of the displacement slide bar slides in the slideway, the other part of the displacement slide bar stretches out of the outer protective barrel from the slideway, the CIS contact type image sensor mounted in the mounting groove receives reflected light of the displacement slide bar through the slit, converts the reflected light into voltage signals, outputs the voltage signals to the measurement control circuit board and leads the voltage signals out of the outer protective barrel through the cable. The photoelectric displacement sensor is concise in structure, high in precision, high in working reliability and stability and suitable for popularization and application of small and medium-range displacement monitoring in engineering monitoring.

Owner:CHINA GEOKON INSTR

A joint positioning method and system based on bd2 and ground-based navigation system

ActiveCN104931992BMake up for the shortcomings of insufficient positioning accuracyOvercome the disadvantage of limited navigation rangeSatellite radio beaconingEarth's rotationLand based

The invention discloses a combined positioning method and system based on BD2 and a ground-based navigation system, and the method comprises the steps: S1, collecting and correcting a pseudo-range value of a BD2 satellite; S2, calculating the spatial position of the BD2 satellite after earth rotation correction; S3, collecting and correcting the distance from a ground station of the ground-based navigation system to a distance measurement machine; S4, initializing the position of an aircraft and a clock error of a satellite receiver; S5, building and solving a corresponding linear equation group; S6, updating the roots of the linear equation group; S7, judging whether the iteration is ended or not: calculating an iteration threshold value delta, and enabling the calculation result obtained at step S6 to serve as the current position of the aircraft and enabling the iteration to be ended if the delta is not greater than a preset threshold value; or else, repeatedly carrying out step S5-S7 till the iteration is ended. The invention also provides a system achieving the above method. The method and system can greatly improving the positioning precision of a system, are not dependent on GPS resources, can be used during wartime, and are high in reliability.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com