A method of making a piezoelectric ultrasonic transducer

An ultrasonic transducer, piezoelectric ultrasonic technology, applied in the direction of the fluid using vibration, etc., to achieve the effect of overcoming shrinkage deformation, overcoming high viscosity and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

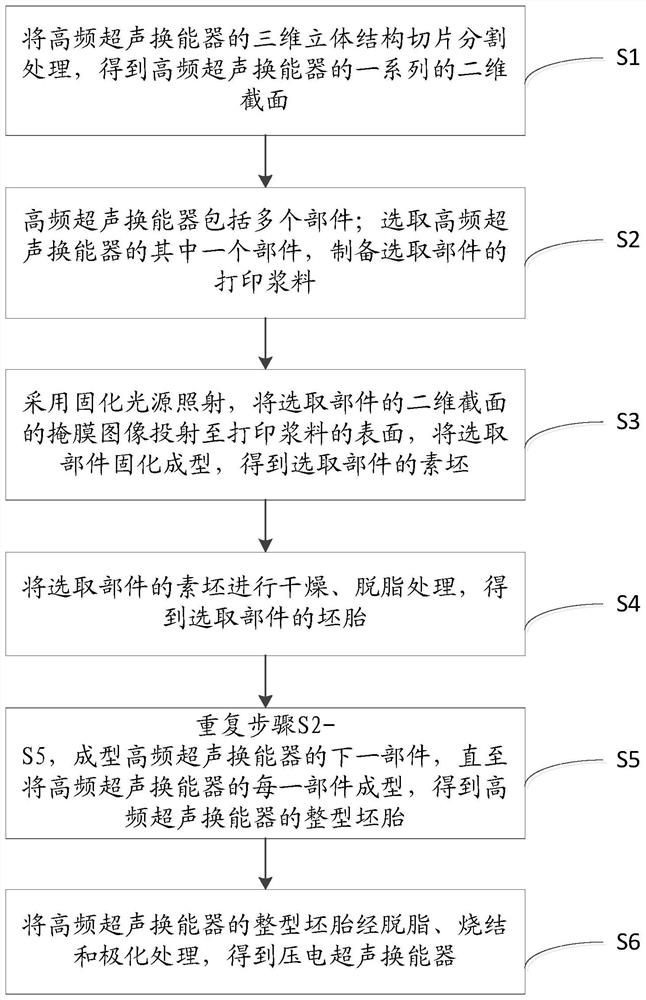

[0033] see figure 1 , is a flow chart of the method for manufacturing the piezoelectric ceramic transducer provided in this embodiment. It includes steps S1-S6:

[0034] S1: Slicing and segmenting the three-dimensional structure of the high-frequency ultrasonic transducer to obtain a series of two-dimensional cross-sections of the high-frequency ultrasonic transducer.

[0035] Specifically, in this step, computer software such as AutoCAD is used to slice and segment the three-dimensional structure of the high-frequency ultrasonic transducer to obtain a series of two-dimensional cross-sections of the high-frequency ultrasonic transducer.

[0036] S2: The high-frequency ultrasonic transducer includes a plurality of components; select one of the components of the high-frequency ultrasonic transducer, and prepare a printing paste for the selected component.

[0037] This step is used to prepare the printing paste, adding the solid powder into the photocuring agent solution to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com