Oversize and precise horizontal winding machine

A horizontal winding machine, super-sized technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of low winding efficiency, composite material winding machine can not be applied to super-sized and high-precision products, etc., to achieve high precision Winding accuracy, accurate centering and winding, and the effect of improving the efficiency of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

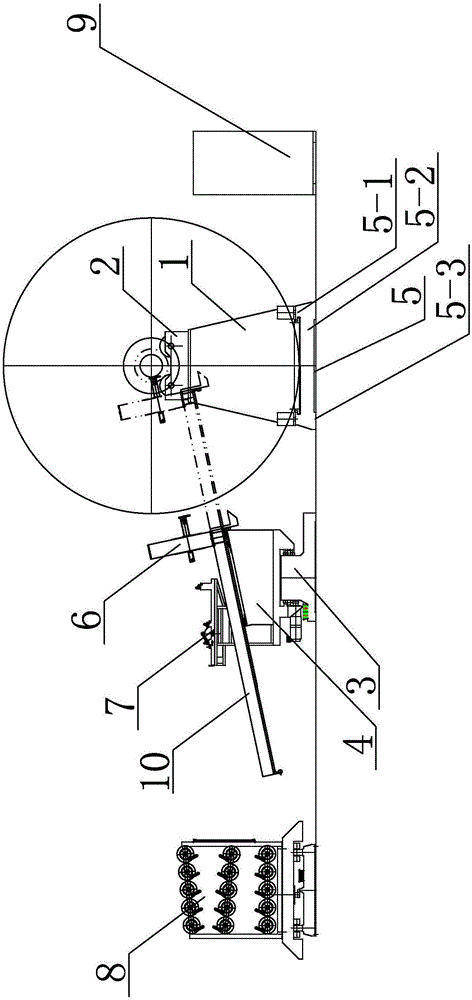

[0021] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment. A super-large precision horizontal winding machine in this embodiment includes a horizontal bed head 1, a horizontal bed tail 2, a horizontal bed 3, a winding trolley system 4, a ground rail 5, and a deflected yarn delivery system 6. , follow-up dipping system 7, follow-up creel system 8, control cabinet 9 and outrigger mechanism 10, the ground rail 5 is installed on the horizontal ground, and the horizontal bed head 1 and horizontal bed tail 2 are respectively installed in the length direction of the ground rail 5 The horizontal bed 3 is installed on the horizontal ground on one side of the ground rail 5, the winding trolley system 4 is installed on the horizontal bed 3, the outrigger mechanism 10 is installed on the winding trolley system 4, and the deflection spinning system 6 is installed on the winding trolley system 4, and the deflecting yarn-spitting system 6 is installed ob...

specific Embodiment approach 2

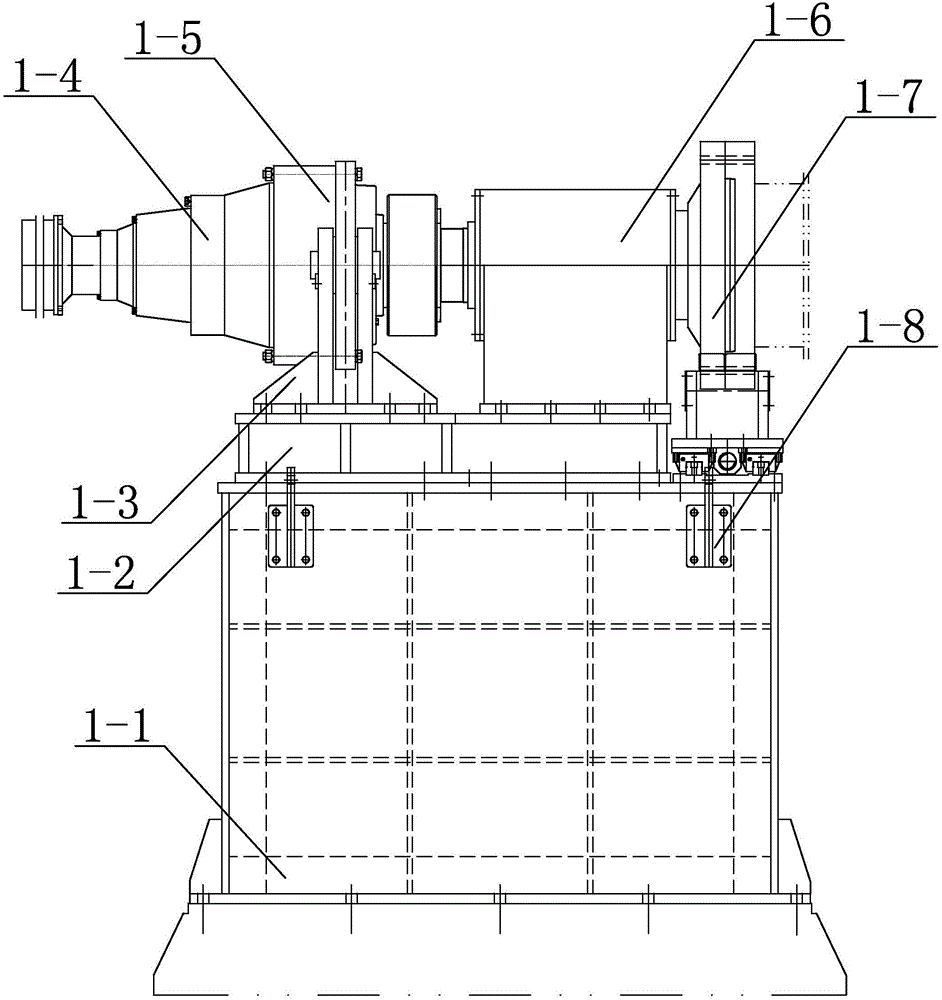

[0031] Specific implementation mode two: combination figure 1 and 2 Describe this embodiment, the horizontal head of a bed 1 of this embodiment comprises head of a bed box body 1-1, connecting support 1-2, torque arm support 1-3, head of a bed servo motor 1-4, head of a bed reducer 1-5, drive mechanism 1-6, support mechanism 1-7 and bedside hook 1-8, bedside box 1-1 is installed vertically on the floor rail 5, connecting support 1-2 is installed on the bedside On the box body 1-1, the torque arm support 1-3 is installed on the connection support 1-2, the bedside reducer 1-5 is installed on the torque arm support 1-3, the bedside reducer 1-5 The input end is connected with the bedside servo motor 1-4, the output end of the bedside reducer 1-5 is connected with the driving mechanism 1-6, and the lower part of the driving mechanism 1-6 is supported by being installed on the bedside box body 1-1 Mechanism 1-7 supports, and bedside suspension hook 1-8 is installed in the both sid...

specific Embodiment approach 3

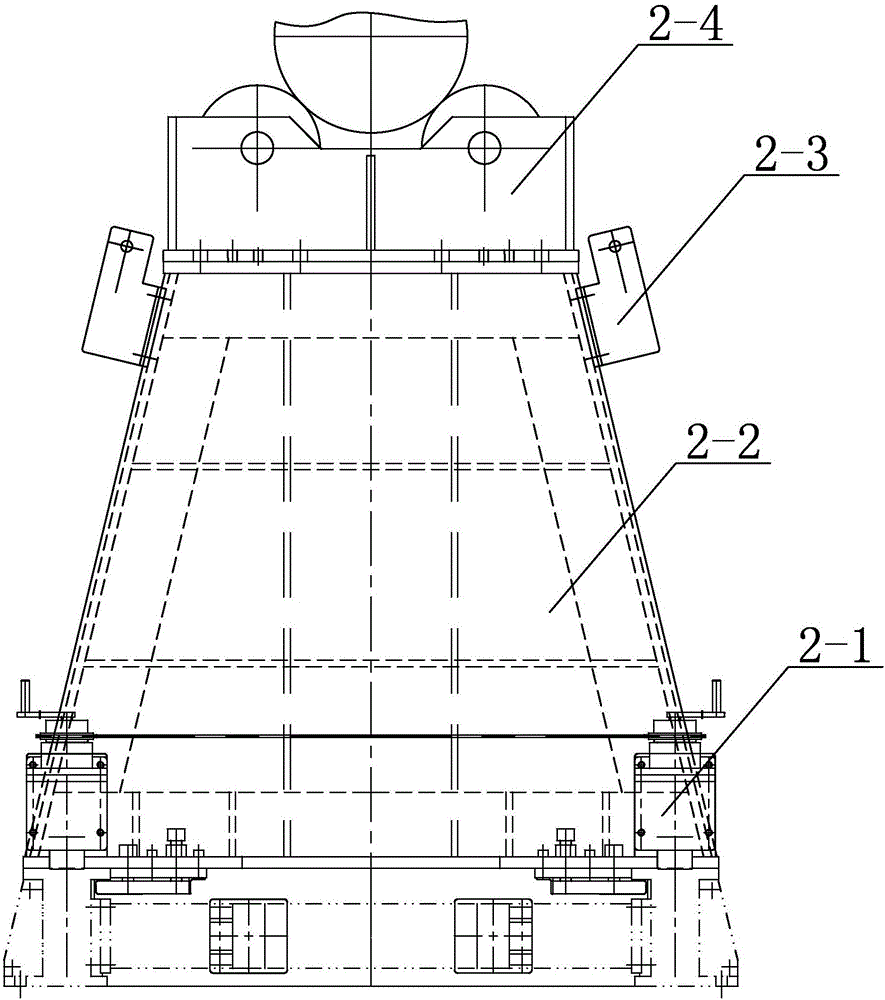

[0034] Specific implementation mode three: combination figure 1 and image 3 Describe this embodiment, the horizontal bed end 2 of this embodiment comprises road wheel assembly 2-1, tailstock lower box 2-2, bed end hook 2-3 and supporting roller assembly 2-4, road wheel assembly 2-1 is installed on both sides of the lower end of the tailstock lower box 2-2, the bed end hook 2-3 is installed on both sides of the upper end of the tailstock lower box 2-2, and the roller support assembly 2-4 is installed on the tailstock The upper end of lower casing 2-2. Such setting ensures the installation rigidity and torsional rigidity of the horizontal bed end 2, and the position of the horizontal bed end 2 can be adjusted according to the size of the workpiece, so as to realize convenient and accurate centering and clamping when the workpiece is loaded and unloaded. , the other composition and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com