A high-precision and lightweight triangular antenna panel and its manufacturing method

An antenna panel, triangular technology, applied in the direction of antenna, electrical components, etc., can solve the problems of easy generation of glue tumor, poor glue and air bubbles, difficult to control the overall accuracy of the structure, waste of manpower and equipment resources, etc., to reduce production raw materials, improve Installation accuracy and installation efficiency, and the effect of improving bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

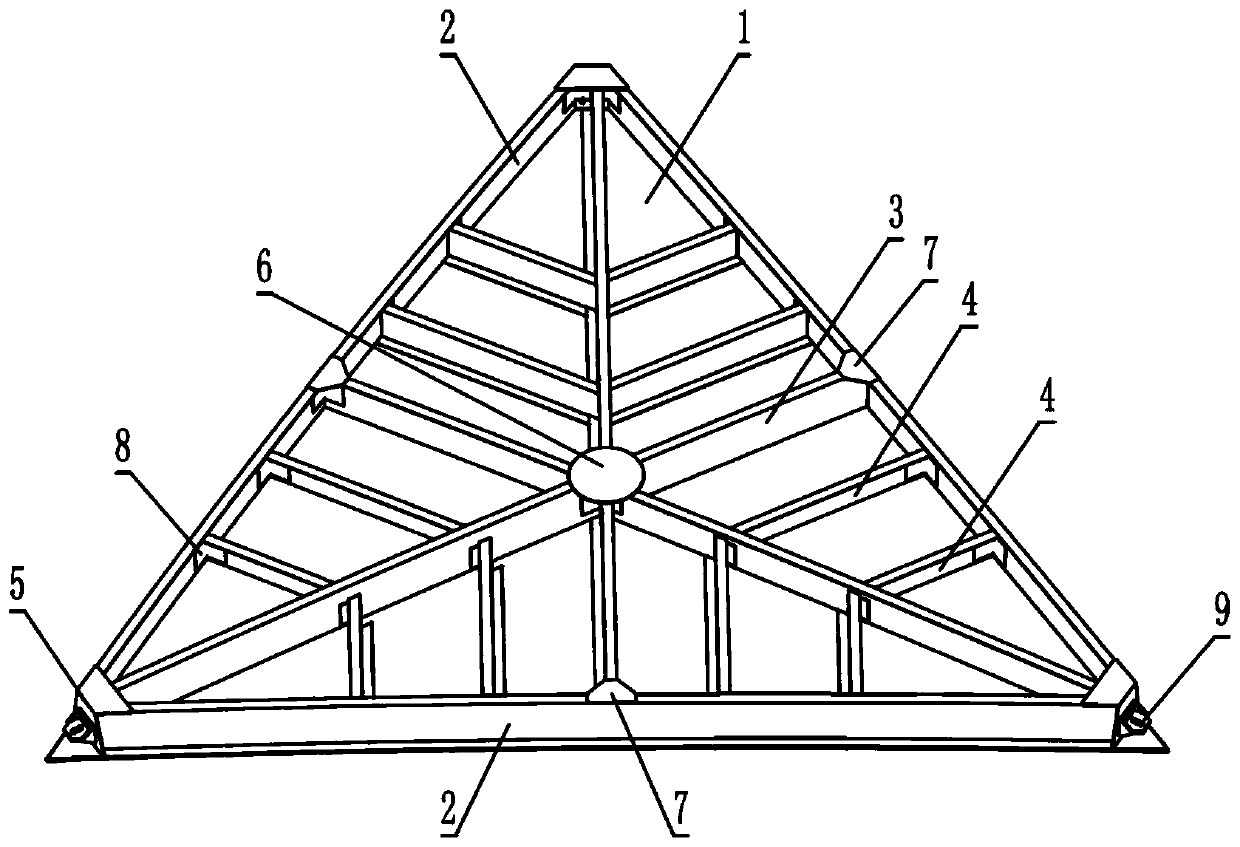

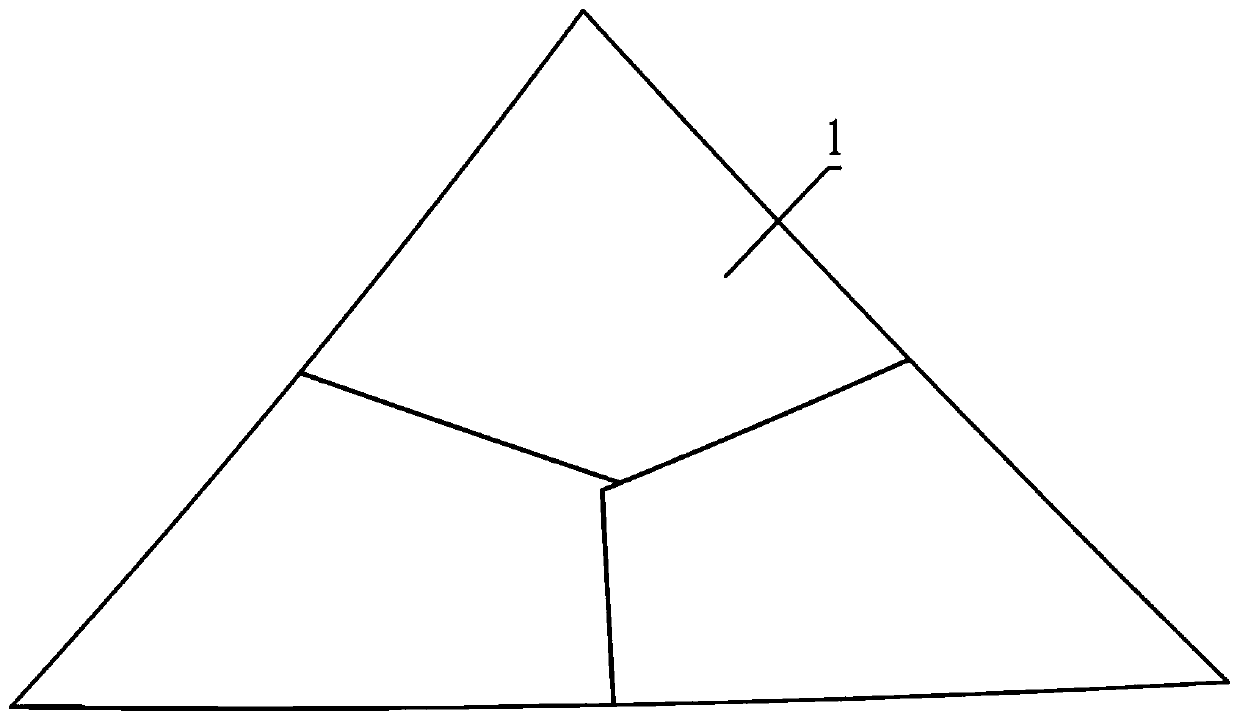

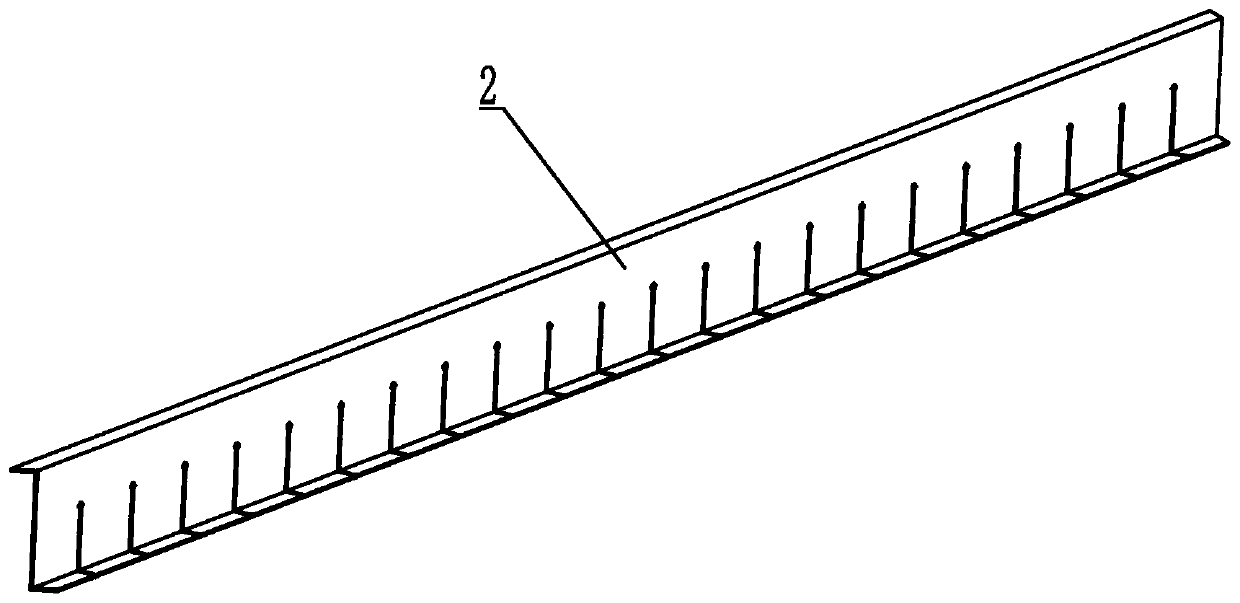

[0051] Such as Figure 1 to Figure 6 As shown, a triangular antenna panel includes a skin 1, a main side rib 2, a central rib 3, an auxiliary rib 4, a corner rib 5, a central connecting plate 6, an edge connecting plate 7, a corner piece 8 and a support 9; The skin 1 is triangular, and three main side ribs 2 are arranged on the three side directions of the convex surface of the skin 1; the central rib 3 is located on the midline of the three main side ribs 2; the auxiliary ribs 4 are distributed on both sides of the central rib 3 and The main side ribs 2 are vertical; the corner ribs 5 are arranged at the intersection of the main side ribs 2; the central connecting plate 6 is located at the intersection of the three central ribs 3; the edge connecting plate 7 is located at the midpoint of the three main side ribs 2 and connected to the central ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com