5G millimeter wave antenna and manufacturing method thereof

A manufacturing method and millimeter-wave technology, applied to antennas, antenna arrays, devices for manufacturing antenna arrays, etc., can solve problems such as difficult processing costs, complex structural design, reduced efficiency of microstrip patch antennas, and poor processing accuracy and etching accuracy. To achieve the effect of ensuring plasticizing quality and plasticizing ability, reducing surface roughness and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0051] The following is attached Figure 1-4 Explanation of reference signs:

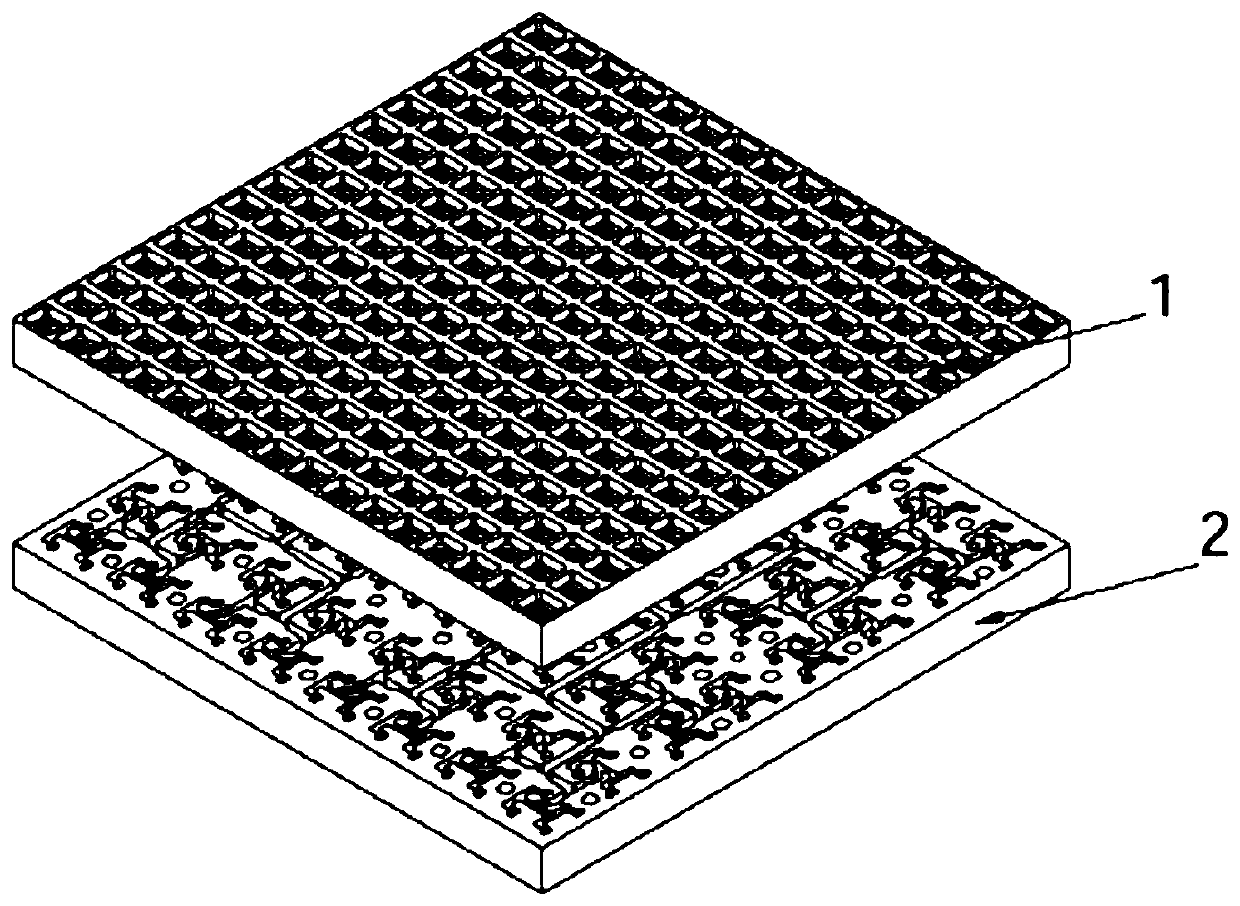

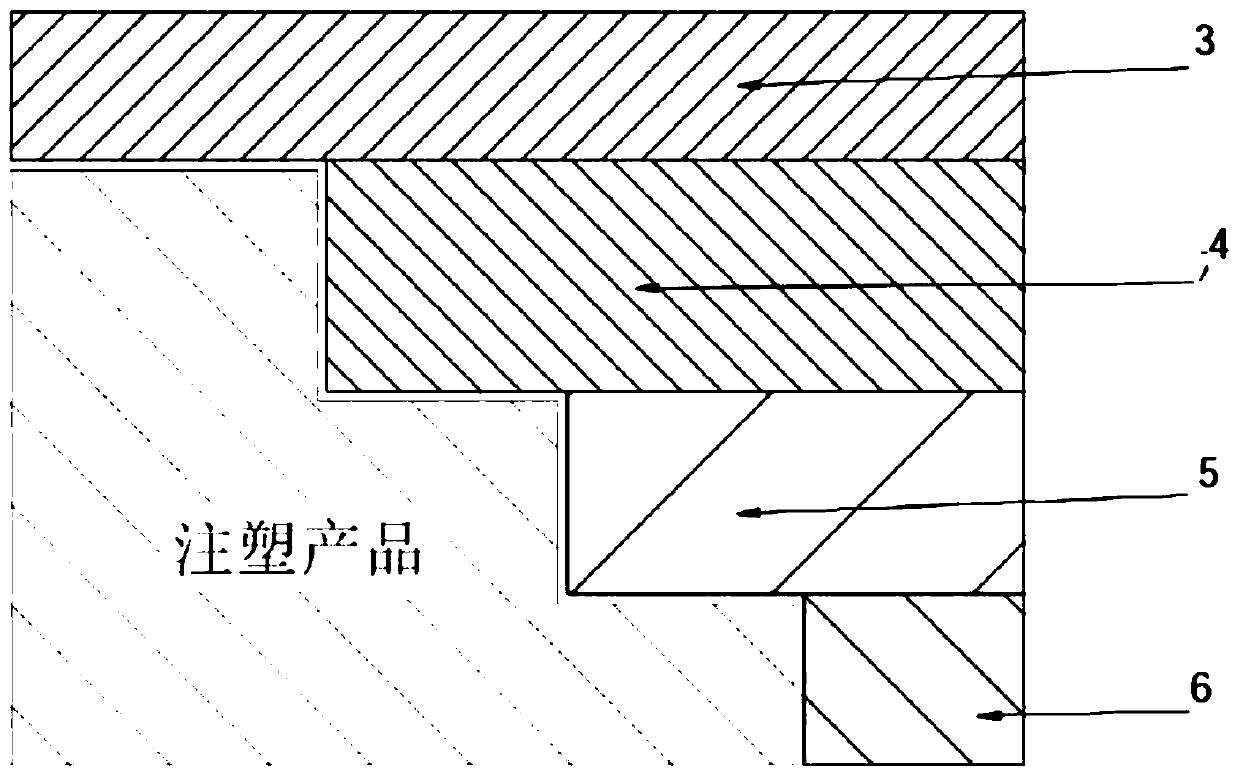

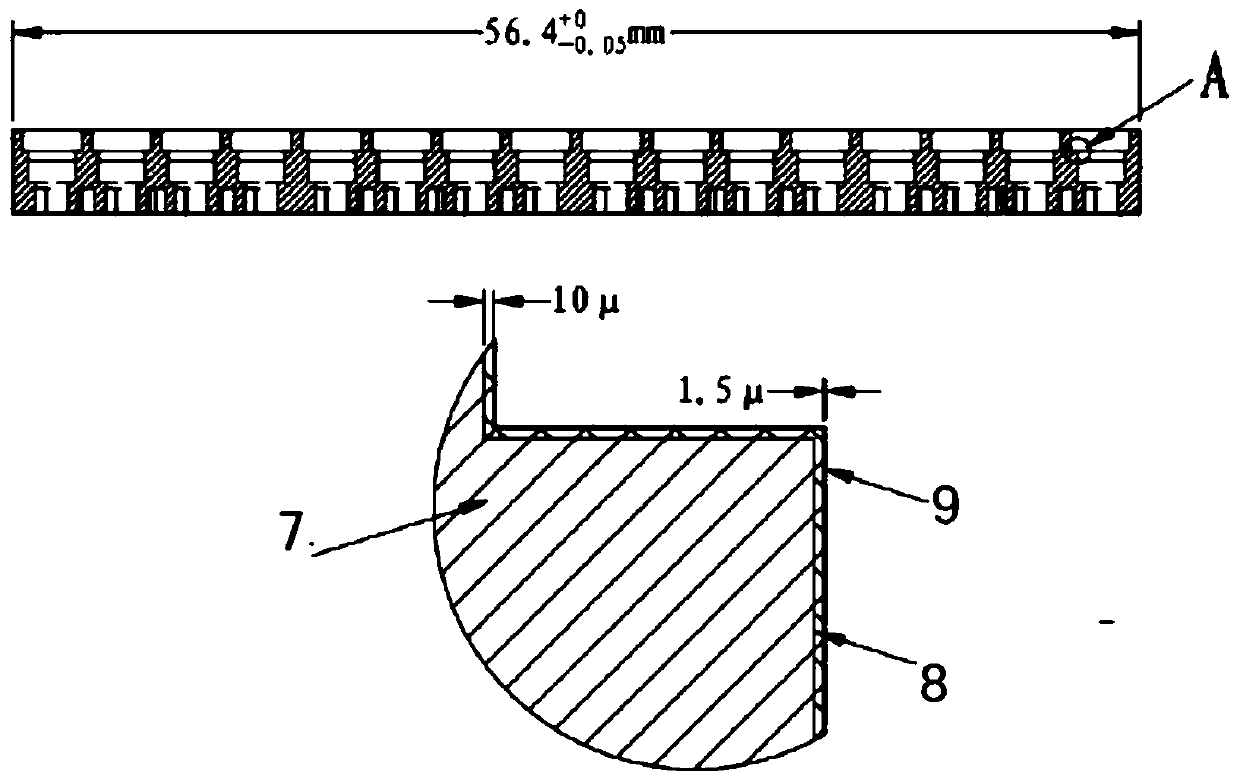

[0052] 1 is feed network + radiation layer; 2 is feed network layer; 3 is mold; 4 is mold insert 1; 5 is mold insert 2; 6 is mold insert 3; 7 is LCP substrate; 8 is UV Coating layer; 9 is a metal plating layer.

[0053] (1) Injection molding

[0054] The plastic particles for injection molding are selected from LCP VECTRA series E130I; the mold is made of mold steel with a hardness not lower than HRC65°, and the rear mold is processed by high-speed CNC with a spindle speed of not lower than 30,000r / min. The corners ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com