Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Suppress flatulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-voltage electrolyte and high-voltage lithium ion battery

InactiveCN105119014AReduce oxidative decompositionImprove high temperature performanceSecondary cellsElectrolytic agentOrganic solvent

The invention discloses a high-voltage electrolyte and a lithium ion battery. The high-voltage electrolyte comprises a non-aqueous organic solvent, an electrolyte salt, a conventional high-voltage electrolyte additive and a functional additive. The functional additive has a general chemical formula of AXB or AB. The electrolyte functional additive is added into the conventional high-voltage electrolyte additive so that the high-voltage electrolyte is prepared. The lithium ion battery containing the high-voltage electrolyte comprises a positive pole and a negative pole. In the lithium ion battery, the additives in the high-voltage electrolyte can produce synergism, can form interfacial films on surfaces of the positive and negative poles, can inhibit electrode surface reaction activity, can reduces electrolyte oxidation decomposition and can effectively inhibit Qi distention so that lithium ion battery high temperature performances, cycle performances at a normal temperature under normal pressure, and a service life are improved and lithium separation in the lithium ion battery working at a low temperature is reduced.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

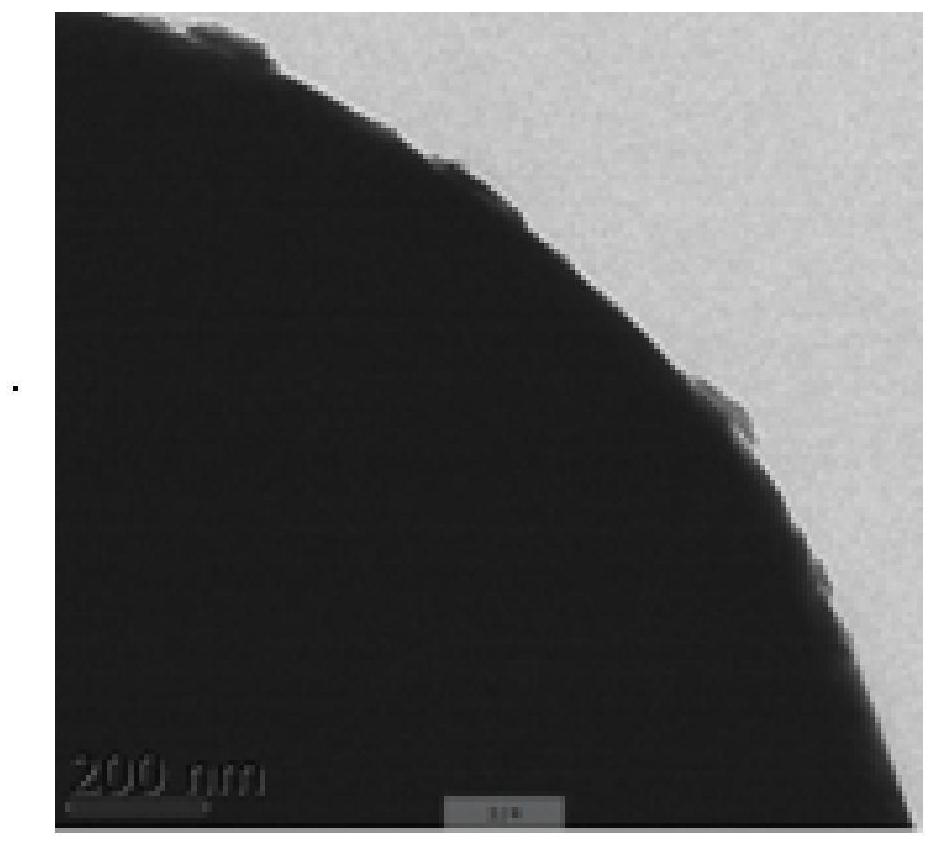

Shape-controllable nano lithium titanate composite and preparation method thereof and lithium ion battery

InactiveCN105870437AImprove conductivity and stabilitySuppress flatulenceCell electrodesSecondary cellsLithium carbonateCarbon source

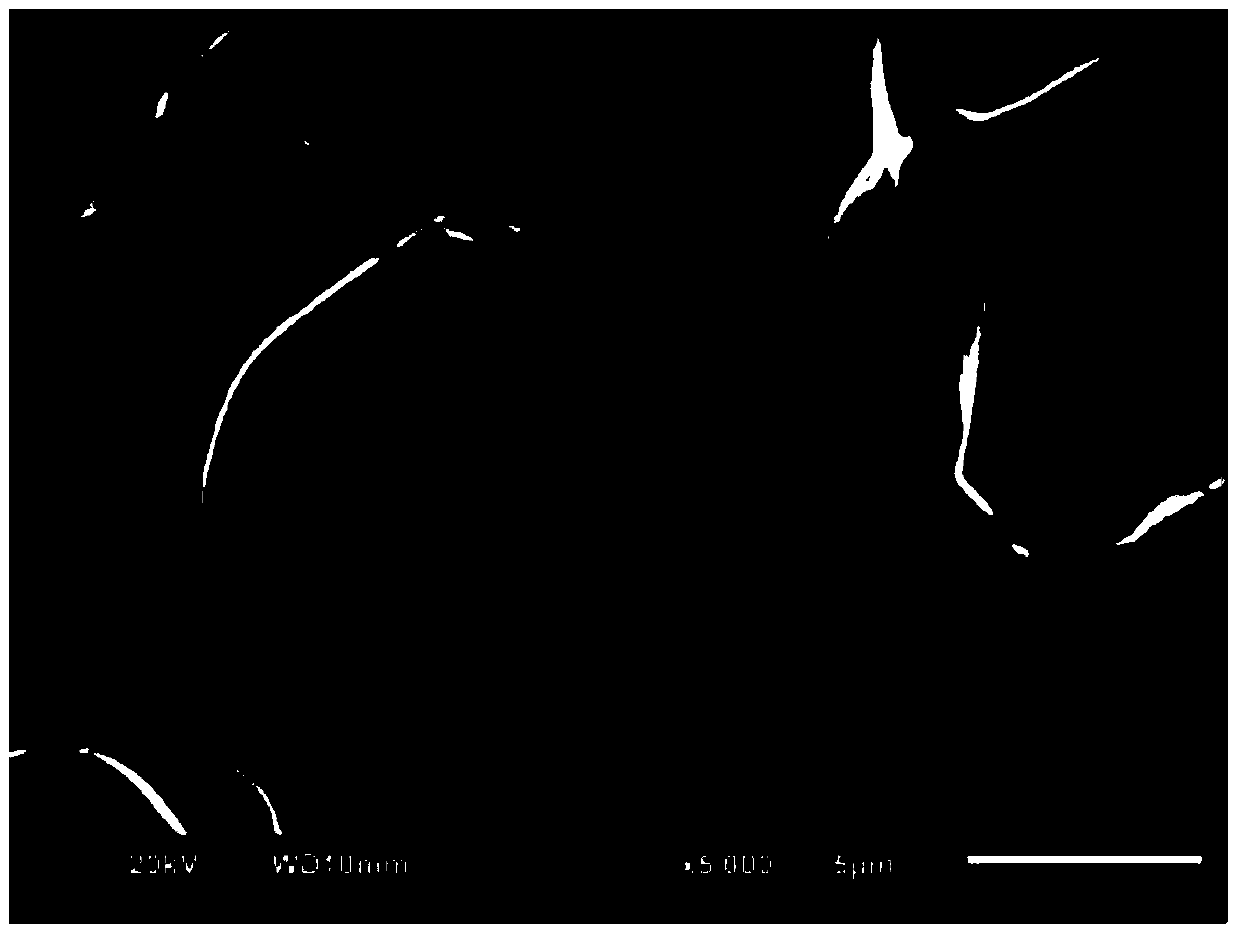

The invention relates to shape-controllable nano lithium titanate composite and a preparation method thereof and a lithium ion battery. The preparation method includes (1) uniformly mixing a lithium source and a titanium source, sintering and cracking all mixtures to obtain a precursor of lithium titanate composite; (2) adding the precursor of lithium titanate composite into dispersion media that is then added with organic carbon source, grinding until particle size of the precursor of lithium titanate composite in all mixtures reaches the nano scale, and obtaining lithium titanate composite pulp; (3) drying, cracking and sintering the lithium titanate composite pulp to obtain the product. Through grinding the precursor of lithium titanate composite to the nano scale and adjusting the second sintering process, particle size of the product can be effectively controlled and particle shape can be so changed. In addition, with doping, carbon wrapping, and oxide wrapping, composite modification of the lithium titanate composite can be realized. Therefore, performance about capacity, magnification, cycling and so on of the lithium titanate is optimized.

Owner:北京泰和九思科技有限公司

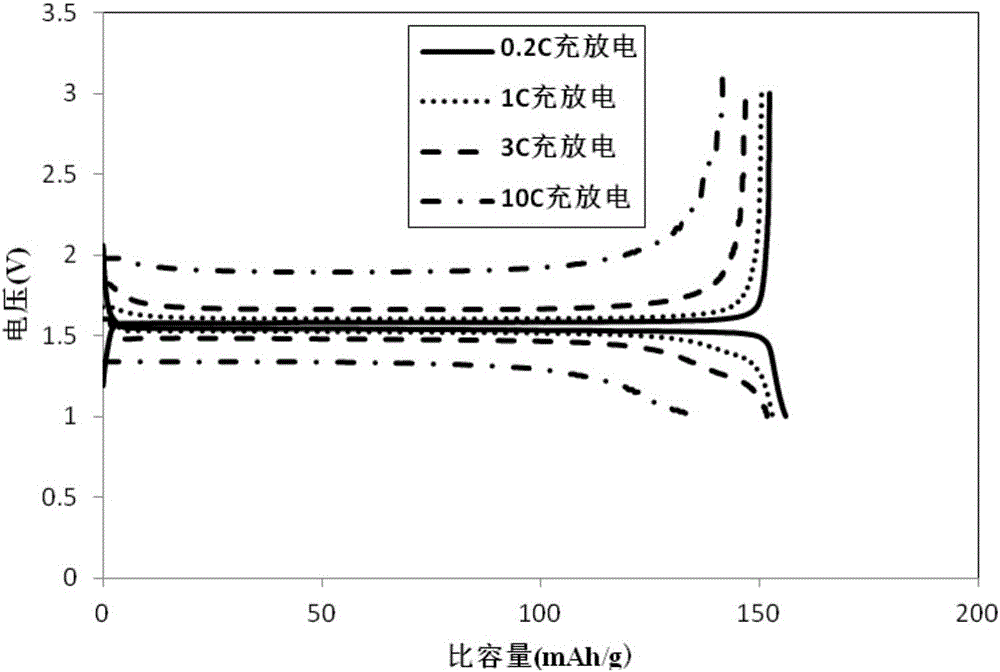

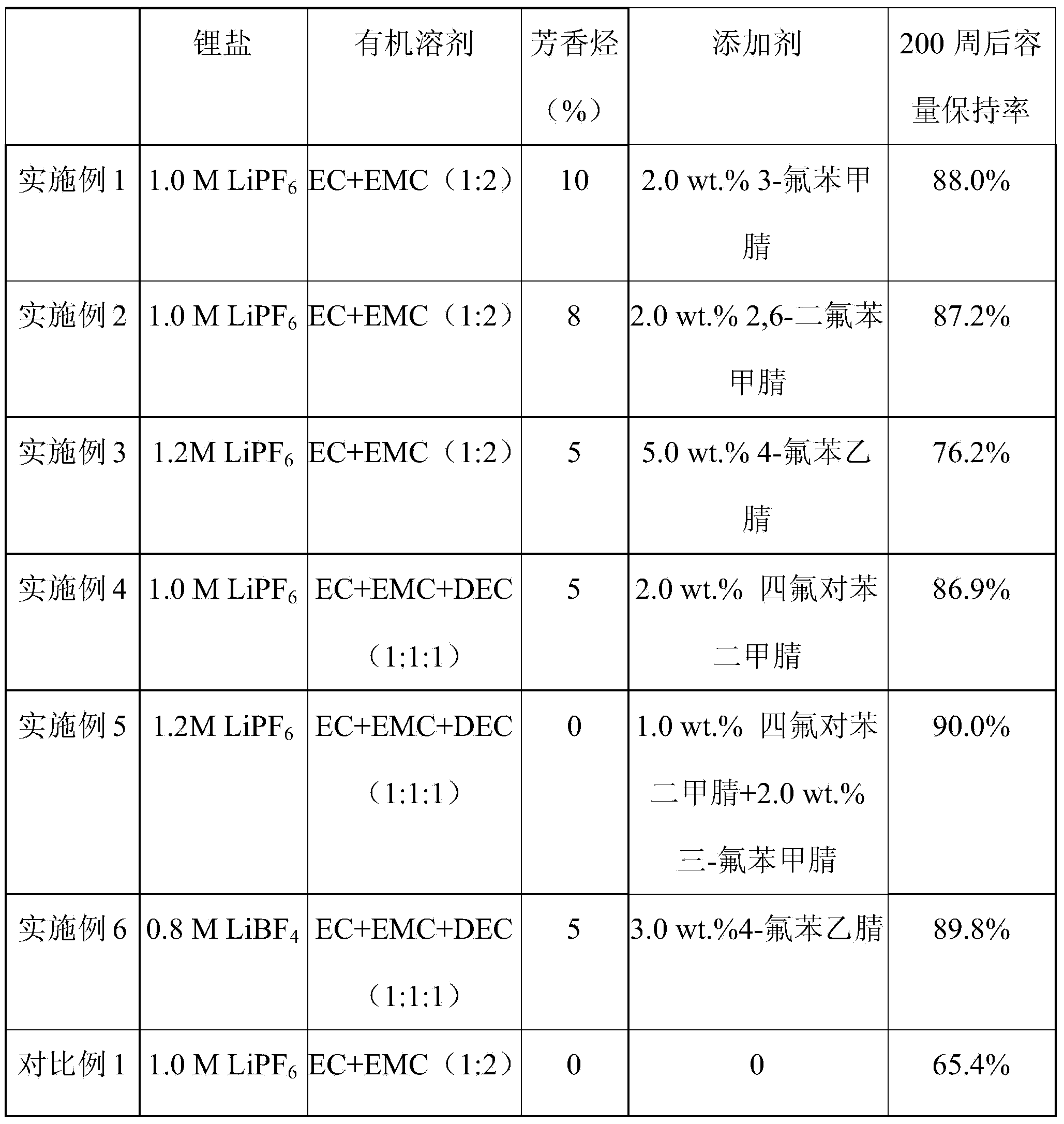

Electrolyte, preparation method for same and high-voltage lithium ion battery

ActiveCN104051786AReduce polarizationImprove interface propertiesElectrolyte accumulators manufactureOrganic solventDecomposition

The invention discloses electrolyte, a preparation method for the same and a high-voltage lithium ion battery. The electrolyte mainly comprises an organic solvent, conductive lithium salt and an additive, wherein the organic solvent is prepared from more than one of a cyclic carbonate solvent, an aromatic hydrocarbon solvent and a linear solvent; the concentration of the conductive lithium salt in the organic solvent is 0.8 to 1.5mol / L; the using amount of the additive is 0.1 to 10.0 percent based on the weight of the organic solvent, and the additive is a halogenated cyanophenyl compound. After the additive is added into the electrolyte, a polymer film can be formed on the surface of each of a positive electrode and a negative electrode, so that the interface impedance of the electrodes / electrolyte is reduced, the decomposition of the electrolyte on the surface of an electrode material is suppressed, and the prolonging of cycle life of the high-voltage lithium ion battery (higher than 4.4V), the improvement of high / low-temperature performance of the high-voltage lithium ion battery and the suppression of gas expansion of the battery are facilitated.

Owner:GUANGZHOU TINCI MATERIALS TECH

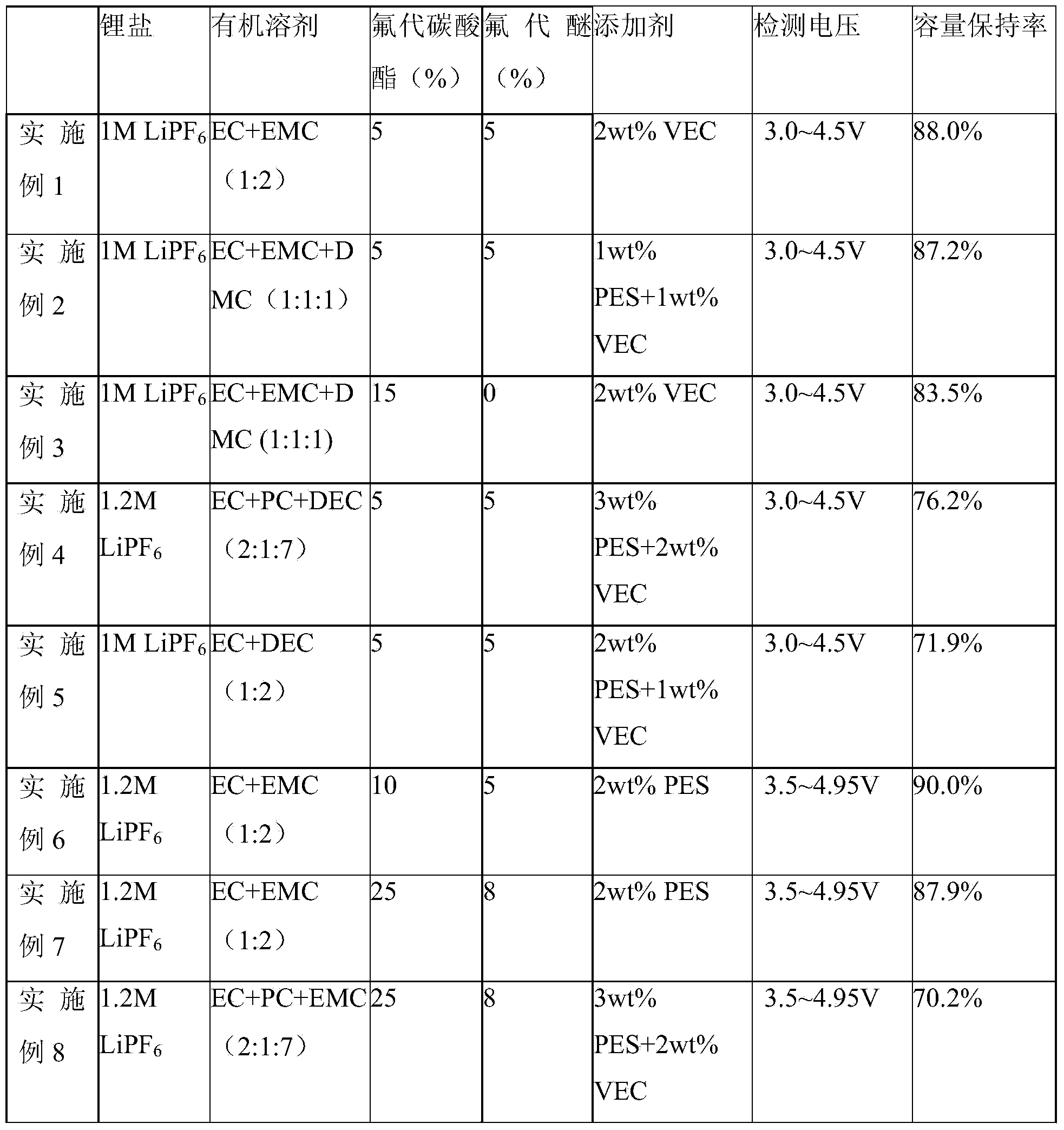

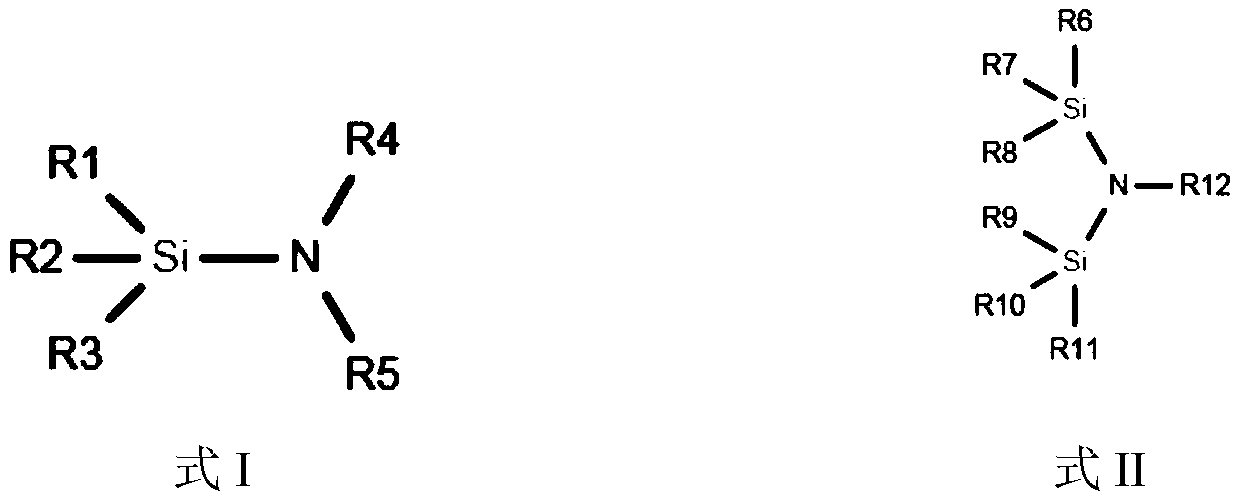

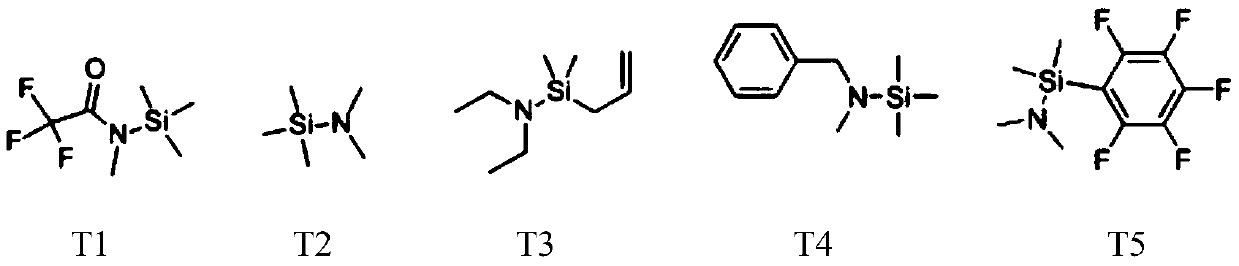

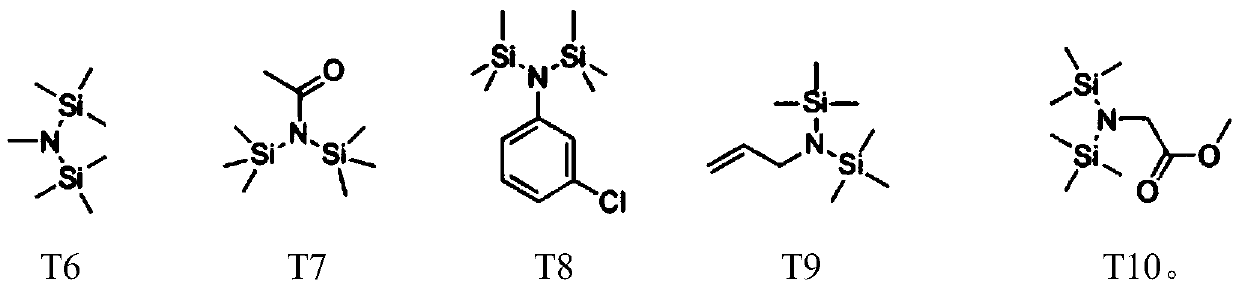

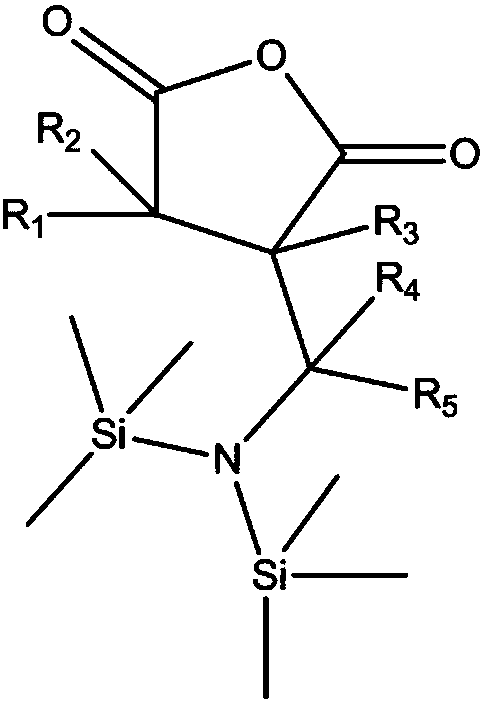

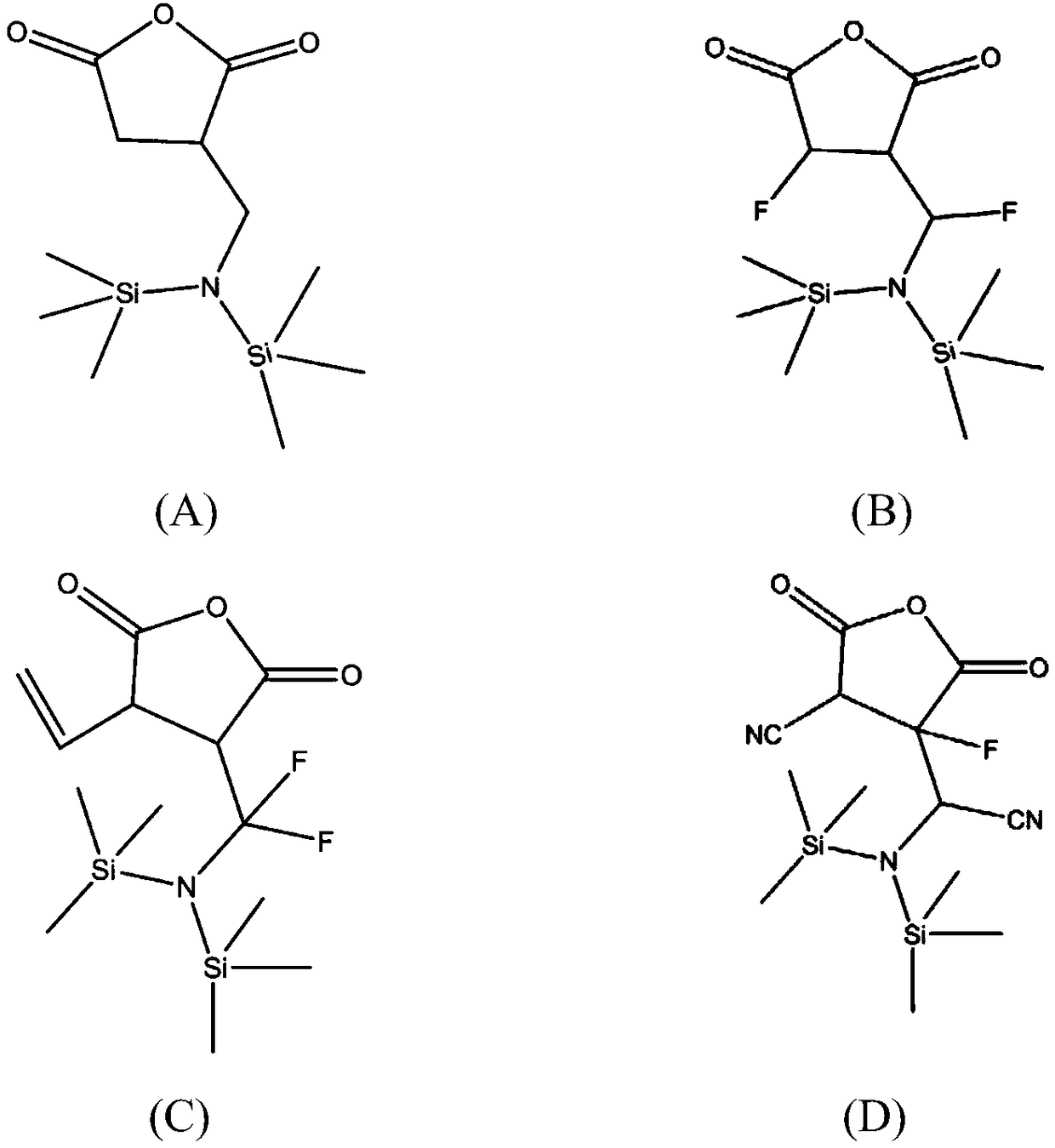

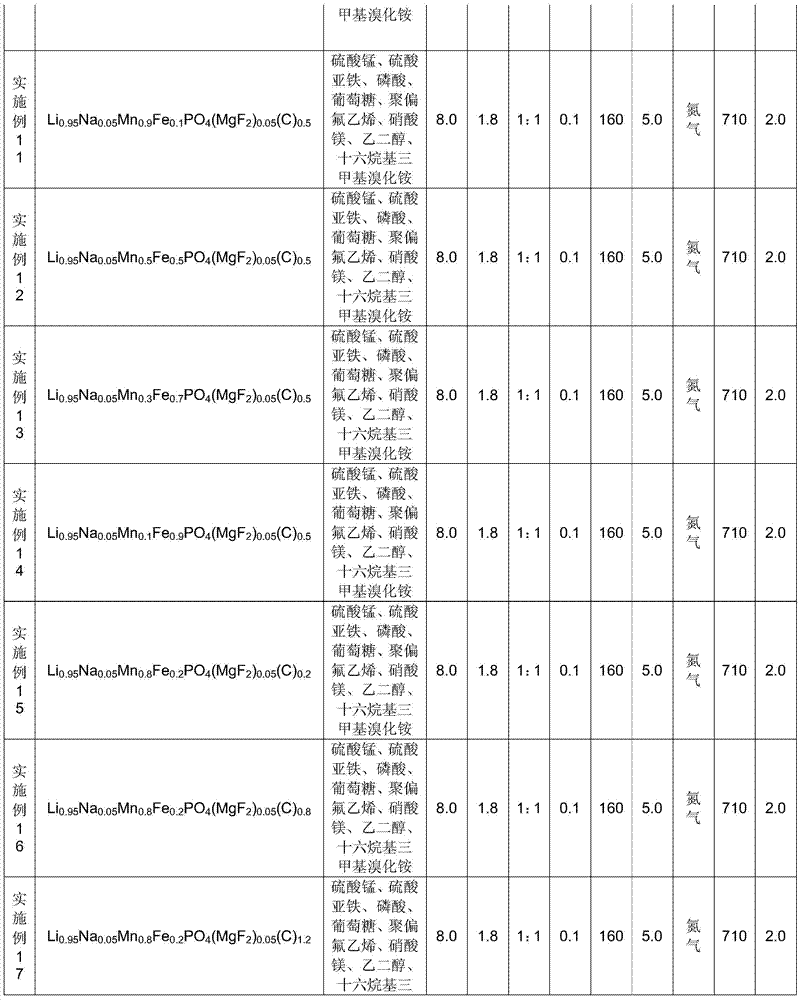

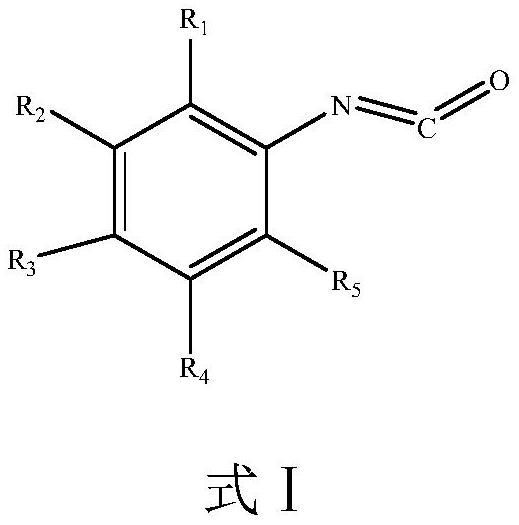

Electrolyte applicable to silicon carbon negative and lithium ion battery comprising electrolyte

ActiveCN109873205AImproved reversible capacity performanceImprove cycle performanceSecondary cells servicing/maintenanceHigh temperature storageSodium-ion battery

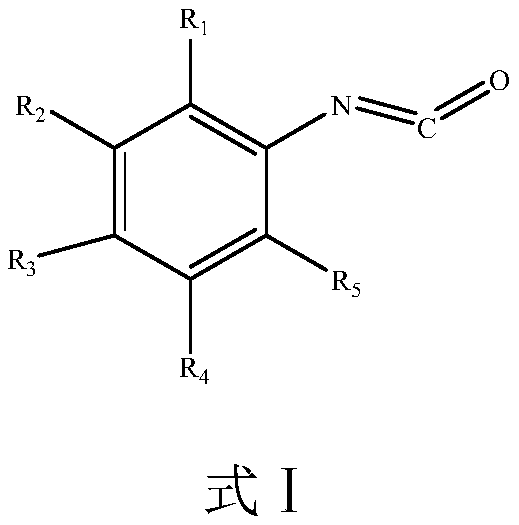

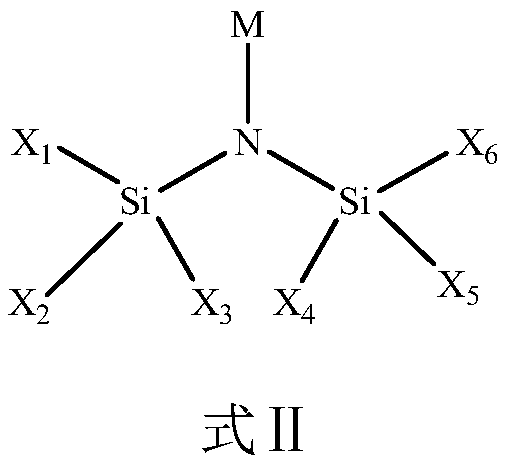

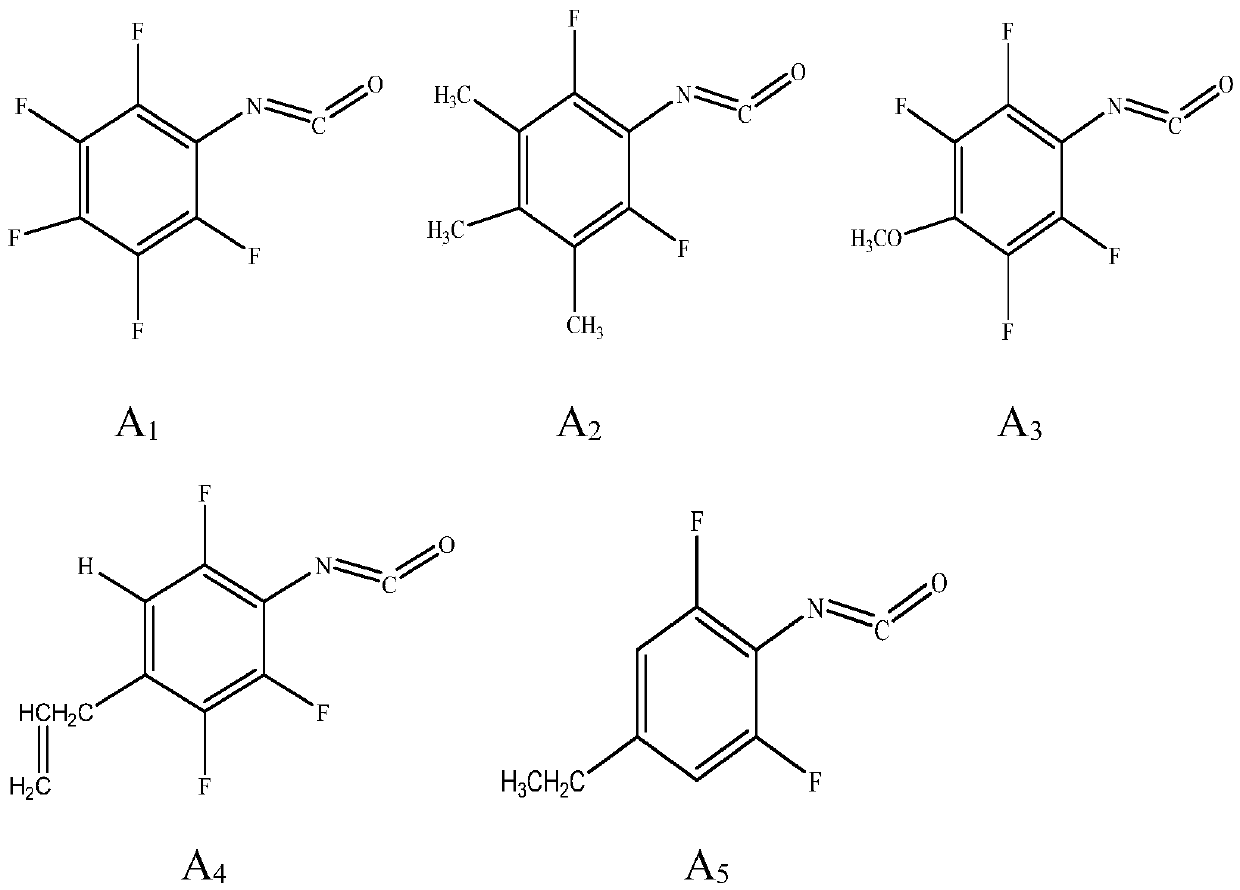

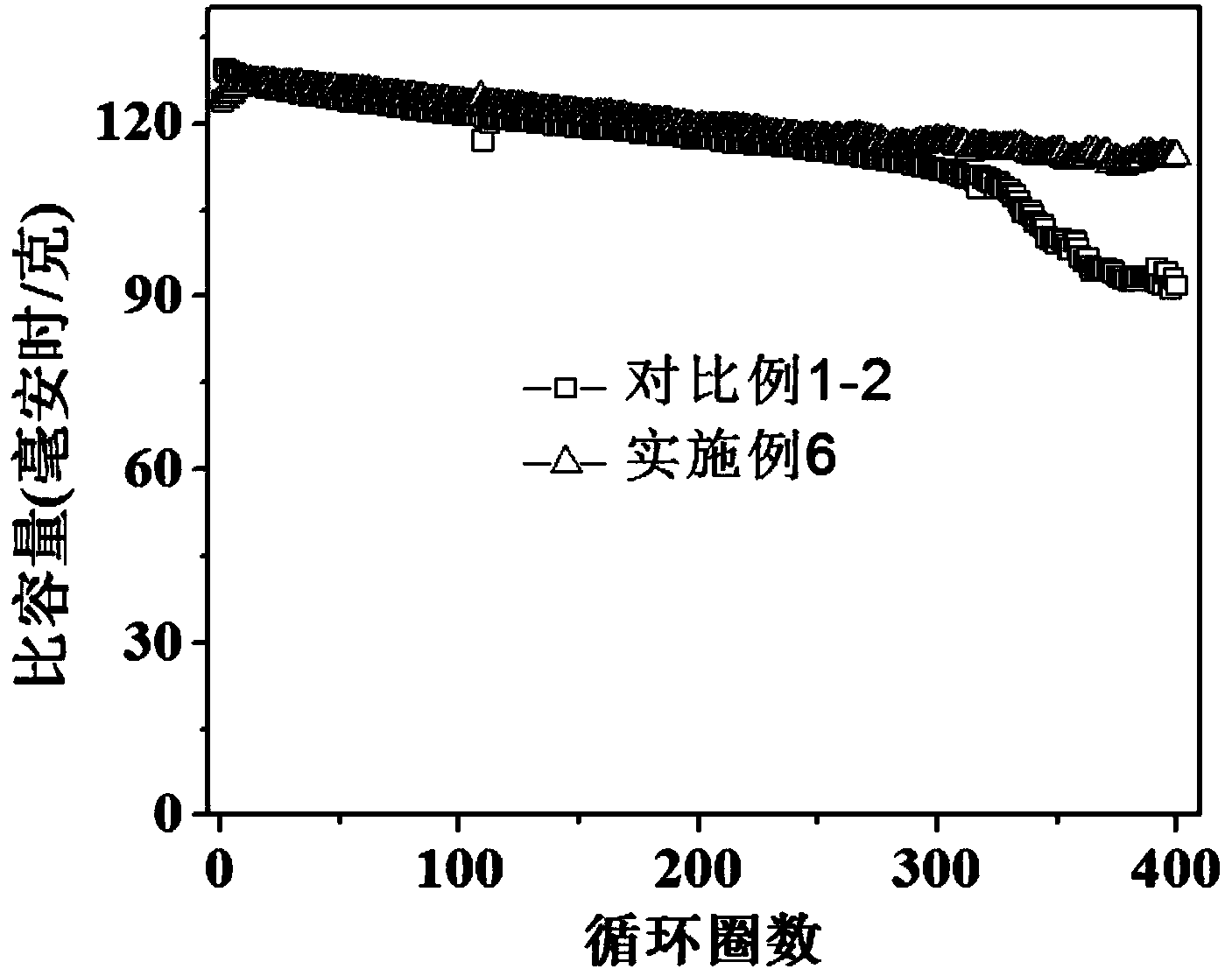

The invention belongs to the technical field of a lithium ion battery, and particularly relates to an electrolyte applicable to a silicon carbon negative and a lithium ion battery comprising the electrolyte. The electrolyte comprises an electrolyte lithium salt, a non-aqueous organic solvent and an additive. Wherein the additive comprises a negative film formation additive, a fluorine-substitutedphenyl isocyanate compound additive with a formula I structure and a dosilane nitrogen-based compound additive. Compared with the prior art, the actual discharging capability, the cycle stability andthe high-temperature storage performance of a silicon carbon negative electrode lithium ion battery are effectively improved by means of a synergic effect generated by combined application of variousadditives, gas generation is prevented, the problems of volume expansion and pole plate pulverization of the battery during the charge-discharge process are solved very well, and meanwhile, the electrolyte is compatible with relatively good high- and low-temperature performance.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

High-voltage lithium ion battery electrolyte, preparation method and application of electrolyte

InactiveCN103956517AReduce decompositionImprove high voltage performanceFinal product manufactureElectrolyte accumulators manufactureOrganic solventSolvent

The invention discloses high-voltage lithium ion battery electrolyte, a preparation method and application of electrolyte. The high-voltage lithium ion battery electrolyte comprises an organic solvent, conductive lithium salt and a functional additive, wherein the organic solvent is prepared from a cyclic carbonate solvent, a fluoro solvent and a linear carbonic ester solvent, the content of the fluoro solvent in the high-voltage lithium ion battery electrolyte is 0.1-40wt.%, the content of the functional additive is 0.01-5wt.%, and the concentration of the conductive lithium salt in the organic solvent is 0.8-1.5mol / L. According to the high-voltage lithium ion battery electrolyte, the interfacial property of the anode and the cathode of the battery and the electrolyte can be improved, and the stability of the electrolyte can be improved, so that the cycle life of the high-voltage lithium ion battery is prolonged, the high-temperature property of the high-voltage lithium ion battery is improved and the working voltage of the high-voltage lithium ion battery is increased to be above 4.5V.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Non-aqueous electrolyte and lithium ion battery containing same

The present invention provides a non-aqueous electrolyte and a lithium ion battery containing the same, and belongs to the technical field of electrolyte research. The non-aqueous electrolyte comprises a non-aqueous organic solvent, a conductive lithium salt and an additive, the additive comprises based on the total weight of the electrolyte: 0.1-5% of an anode film formation additive, 0.1-10% ofa cathode film formation additive and 0.1-5% of a gas expansion inhibition additive, wherein the anode film formation additive comprises at least one of vinyl-vinylene carbonate, 4-Fluoro-1,3-dioxolan-2-one, Ethylene Sulfate, 1,3-propanesultone and vinylene carbonate; and the cathode film formation additive is at least one of nitriles, phosphate compounds and a boracic-like compound. The side reaction of the electrolyte and the electrode material in the storage and cyclic process of the battery is reduced, the battery gas expansion is inhibited so as to the storage and cycle lives of the battery are obviously improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Lithium ion battery electrolyte suitable for NCM811 and SiO-C material system and preparation method

ActiveCN110600804AImprove cycle performancePromote circulationSecondary cellsDifluorophosphateSolid state electrolyte

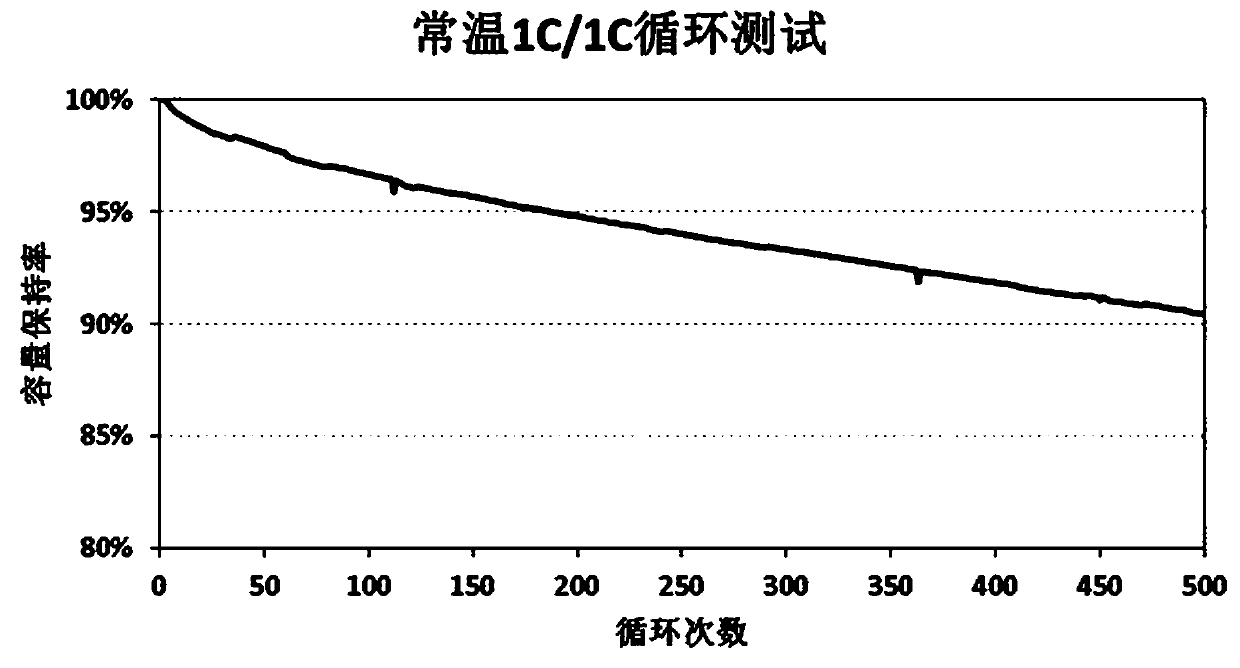

The invention discloses a lithium ion battery electrolyte suitable for a NCM811 and SiO-C material system and a preparation method. In the electrolyte of the present invention, an organic solvent composed of ethyl methyl carbonate, diethyl carbonate, and ethylene carbonate, a lithium salt composed of lithium hexafluorophosphate and lithium difluorophosphate, and an additive composed of vinylene carbonate, fluoroethylene carbonate, ethylene sulfate, and 1,3-propane sultone are compounded in a certain proportion, and cooperate to react, during a lithium ion battery cycle, on the surface of NCM811 and SiO-C and form a stable solid electrolyte protective film to prevent direct contact between the electrolyte and NCM811 and SiO, thereby reducing the side reactions between the electrode and theelectrolyte, and reducing the phase transition and volume change of the material, and further improving the cycling performance of the lithium ion battery. Experimental results show that by using theelectrolyte of the present invention, the lithium ions of the NCM811 and SiO-C material system has a capacity retention rate of more than 90% after 500 cycles of 1C / 1C at room temperature, and has excellent cycle performance.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Method for wrapping lithium cobalt oxide serving as anode material of lithium ion secondary battery through wet method

InactiveCN104009223ASuppress flatulenceImprove poor cycle performanceCell electrodesSecondary cellsLithiumThermal treatment

The invention discloses a method for wrapping lithium cobalt oxide serving as an anode material of a lithium ion secondary battery through a wet method. According to the method for wrapping the lithium cobalt oxide serving as the anode material of the lithium ion secondary battery through the wet method, a soluble metal salt solution is added to the lithium cobalt oxide serving as the anode material, then stirring is conducted, the surface of the lithium cobalt oxide serving as the anode material is completely and evenly wrapped in a layer of corresponding metallic oxide after thermal treatment is conducted, in this way, the circulation performance of the lithium ion secondary battery at high voltage is effectively improved, and the expansion degree of the lithium ion secondary battery is reduced.

Owner:北京盟固利新材料科技有限公司

Non-aqueous electrolyte and lithium titanate battery

ActiveCN103401021ASuppress flatulenceImprove cycle performanceSecondary cellsCharge dischargeSolvent

The invention relates to non-aqueous electrolyte. The non-aqueous electrolyte comprises lithium salt, solvent and additives, wherein the additives include an additive A and an additive B, the mass percent of the additive A in the electrolyte is 0.01 to 10 percent, the mass percent of the additive B in the electrolyte is 0.01 to 10 percent, the structural formula of the additive A is as follows (which is specified in the description), R1, R2 and R3 are respectively an alkyl group of C1 to C3, and R4 is a linear-chain or branch-chain alkyl group of C1 to C5; the chemical formula of the additive B is CH3O(CH2CH2O)mCH3, and m is an integer of 1 to 6. By improving the non-aqueous electrolyte, the electrolyte can remarkably inhibit the inflation problem of the lithium titanate battery, so that the battery adopting the lithium titanate as a negative electrode has good cyclicity and magnification charging-discharging property.

Owner:轻工业化学电源研究所 +1

Electrolyte and lithium ion battery using same

ActiveCN105119019APromote circulationReduce flammabilitySecondary cells servicing/maintenanceCarbon numberAlkylphosphate

The invention relates to an electrolyte. The electrolyte comprises lithium salt, nonaqueous solvent and an additive; the additive is cycloalkene represented in the general formula (I) or the general formula (II), wherein R1 represents one of an alkyl phosphate group, a fluorinated phosphate group and a phosphazene group, R2 represents an alkyl group with the carbon number of 1-12, or an alkoxy carbanyl group with the carbon number of 1-12, or an alkyl sulfonyl group with the carbon number of 1-12 or an alkenyl group with the carbon number of 1-12, and all hydrogen atoms in the R2 substituent group are replaced by halogen atoms. When the electrolyte is used for manufacturing a lithium ion battery, stable interface films can be formed on the surfaces of the positive electrode and the negative electrode, so that reaction activity of the surfaces of the electrodes is restrained, oxygenolysis of the electrolyte is reduced, gas expansion is effectively restrained, then the safety performance and the cycling performance under high voltage particularly the high-temperature cycling performance of the lithium ion battery are improved, and the service life of the lithium ion battery is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

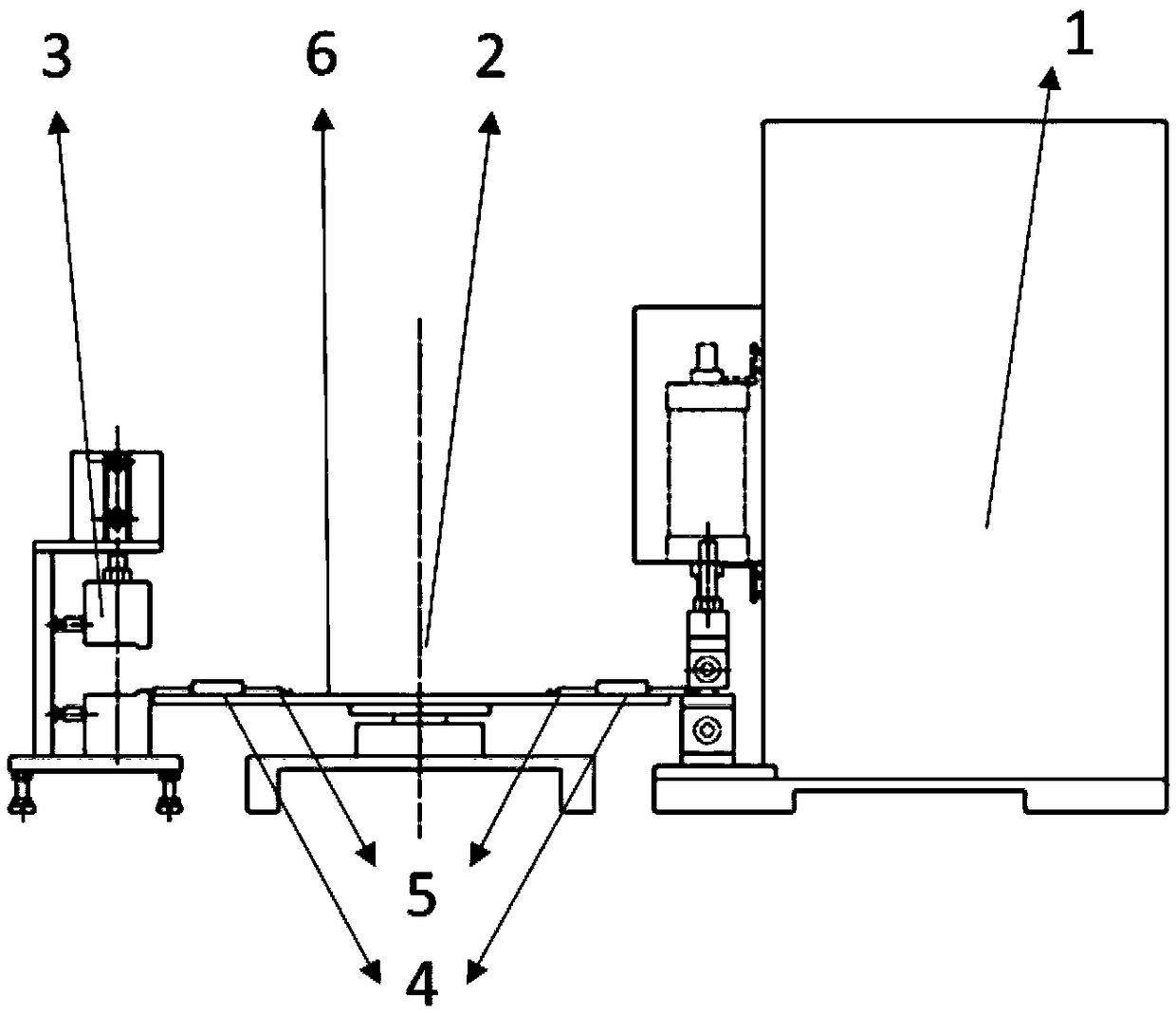

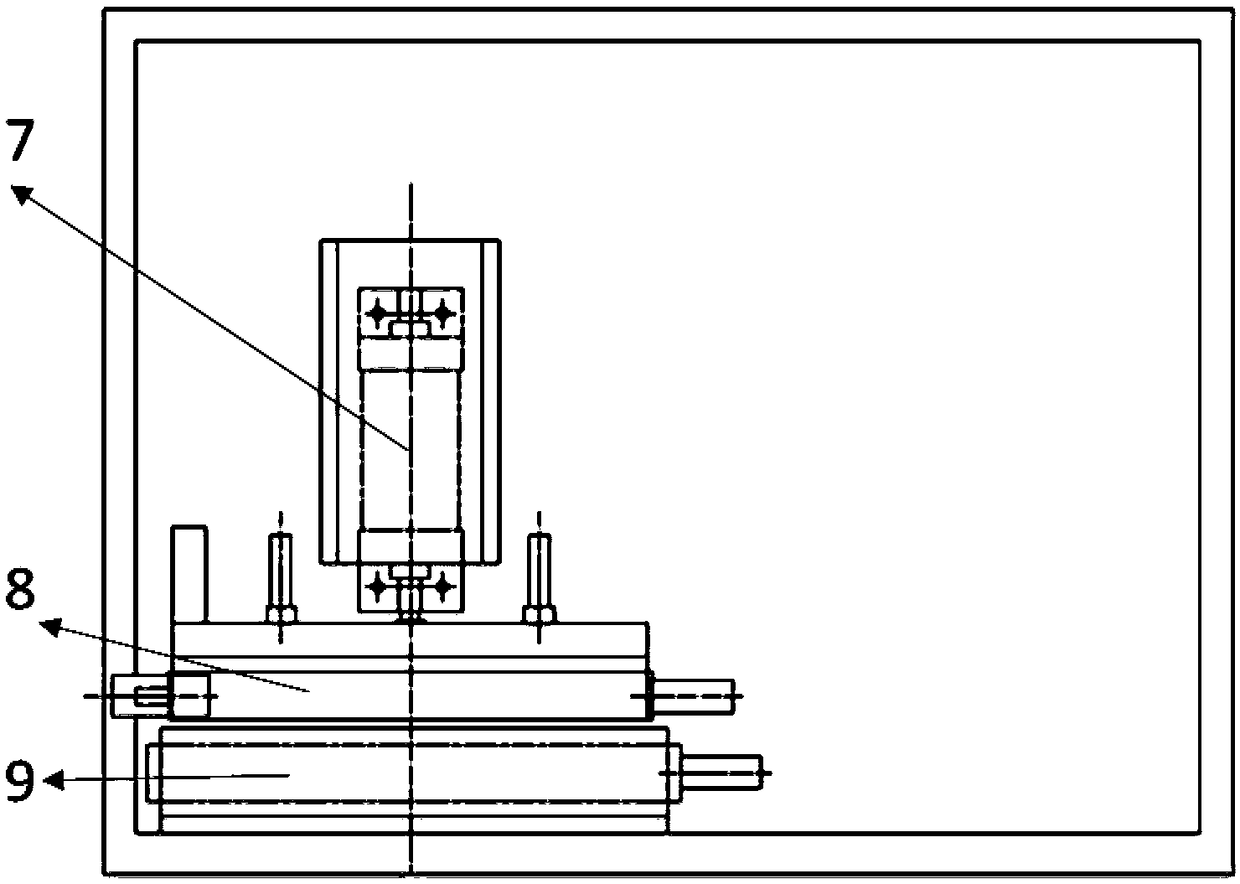

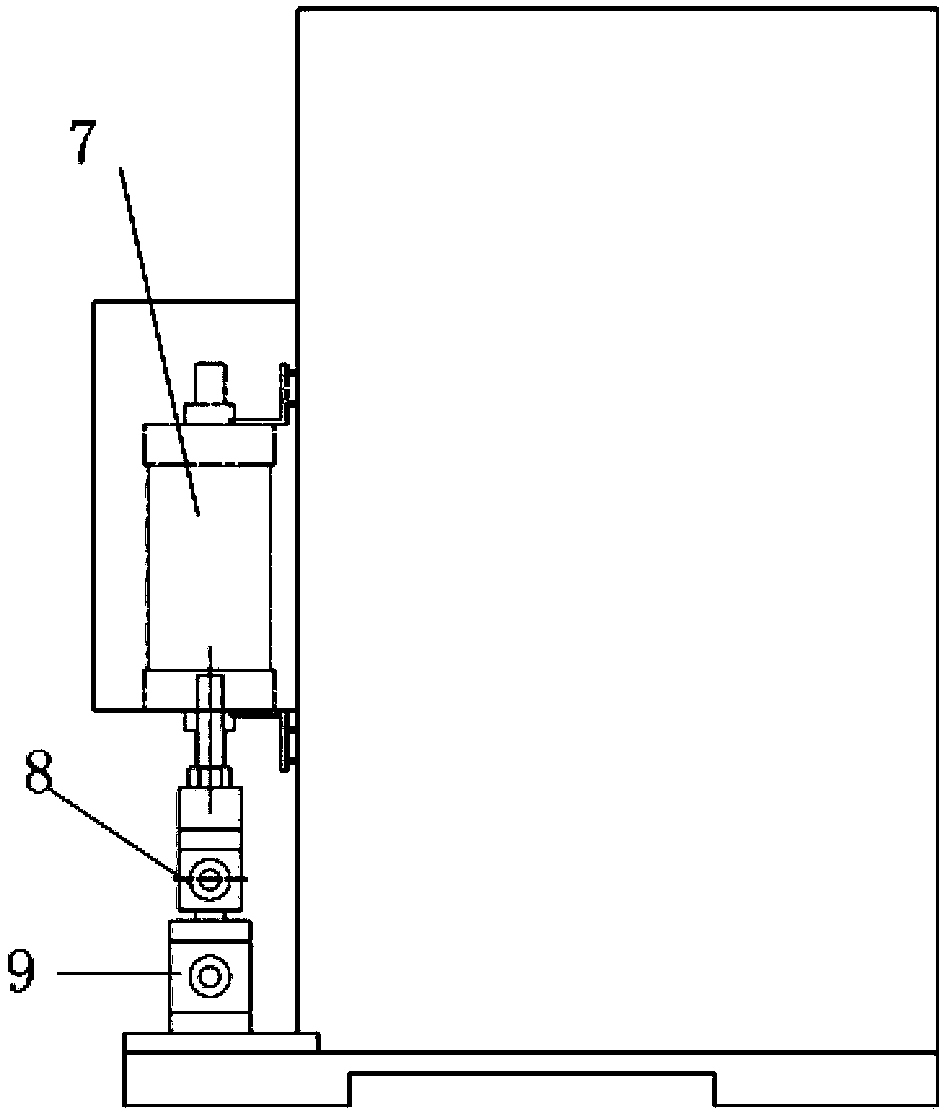

Encapsulating method and device of lithium ion battery

ActiveCN108923070AHigh temperature resistantMoisture-proofFinal product manufactureElectrolyte accumulators manufactureEngineeringLithium-ion battery

The invention discloses an encapsulating method and device of a lithium ion battery. The method and device realize heating encapsulating of a lithium ion battery and then fast cooling. The device comprises a heat encapsulating unit, a transmission structure and a cold encapsulating unit. The heat sealing unit heats and encapsulates a cell, and the treated cell is conveyed into the cold encapsulating unit through the transmission structure and then is cooled and encapsulated. The encapsulating method and device shorten the adjustment time from heat encapsulating to cold encapsulating, preventswaste of resources and time and improves the production efficiency. The method and device can effectively suppress the flatulence of the lithium ion battery, prolong the storage time of the battery, and greatly improve the cycle life and safety of the lithium ion battery.

Owner:北京英耐时新能源科技有限公司 +1

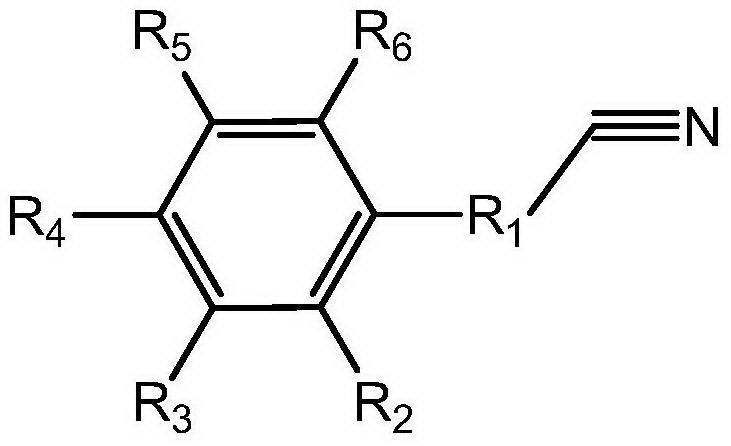

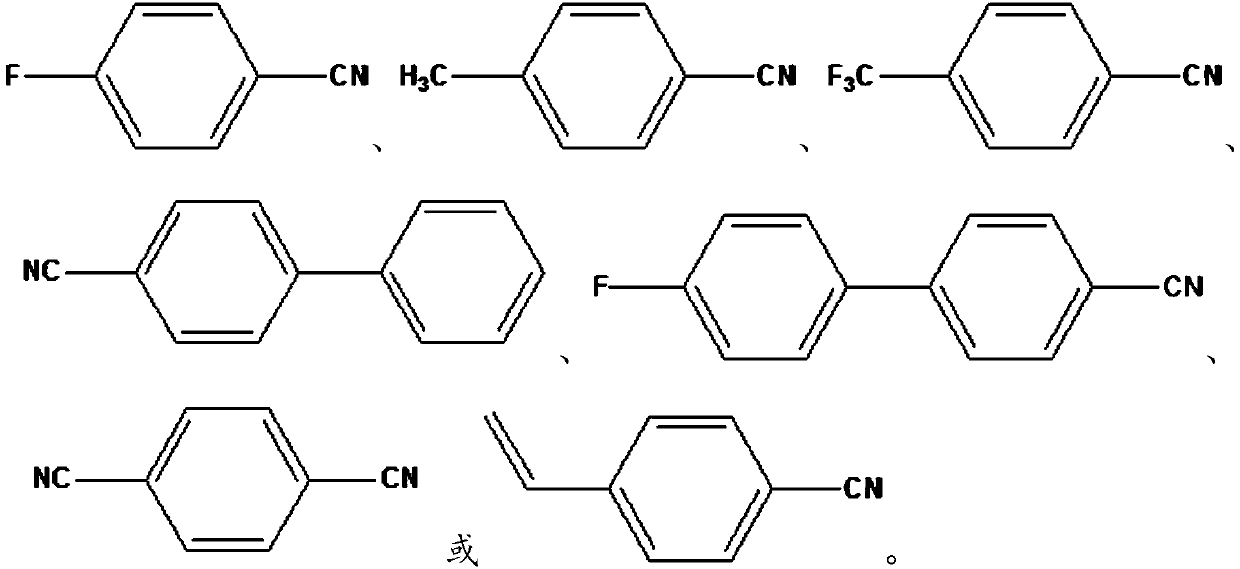

Lithium secondary battery electrolyte and lithium secondary battery thereof

The invention relates to lithium secondary battery electrolyte and a lithium secondary battery thereof. The lithium secondary battery electrolyte comprises an organic solvent, conductive lithium salt,a benzonitrile compound and additives, the benzonitrile compound has a structure as shown in a formula I, and R is any one of F, substituted or unsubstituted C1-6 alkyl, substituted or unsubstitutedC6-26 aryl, C1-4 nitrile groups and C1-6 alkenyl. The benzonitrile compound as shown in the structural formula (I) is added into the electrolyte, transition metal ions can be combined, positive electrode material surfaces are improved, decomposition of the electrolyte is inhibited, bloating is further inhibited, and the high-temperature performance of the battery is improved. By adding the lithium-containing additives, the low-temperature performance of the battery can be improved, and the cycling performance of the battery can be remarkably improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

Lithium titanate-titanium dioxide composite material formed in situ and preparation method thereof

ActiveCN106910879AImprove conductivityHigh specific capacityCell electrodesSecondary cellsLithium hydroxideAqueous sodium hydroxide

The invention discloses a lithium titanate-titanium dioxide composite material formed in situ and a preparation method thereof. The lithium titanate-titanium dioxide composite material is composed of three layers from interior to exterior, wherein the innermost layer is lithium titanate; the middle layer is titanium dioxide; and the outermost layer is carbon. The preparation method comprises the following steps: adding titanium dioxide into an aqueous solution of sodium hydroxide and carrying out a hydrothermal reaction; then adding a product of the previous step into an acid solution, carrying out ion substitution, then carrying out centrifugation to obtain a solid, adding the solid into a lithium hydroxide solution, then carrying out uniform mixing and adding the obtained mixture into a hydro-thermal reaction vessel for a reaction; and carrying out centrifugation again, subjecting a collected solid to primary roasting so as to obtain lithium titanate, adding an organic carbon source, and carrying out ball milling and secondary roasting successively so as to obtain the lithium titanate-titanium dioxide composite material formed in situ. The lithium titanate-titanium dioxide composite material has a core-shell structure, can inhibit bloating of a product and enables the product to have good safety performance and structural stability.

Owner:TIANJIN B&M SCI & TECH

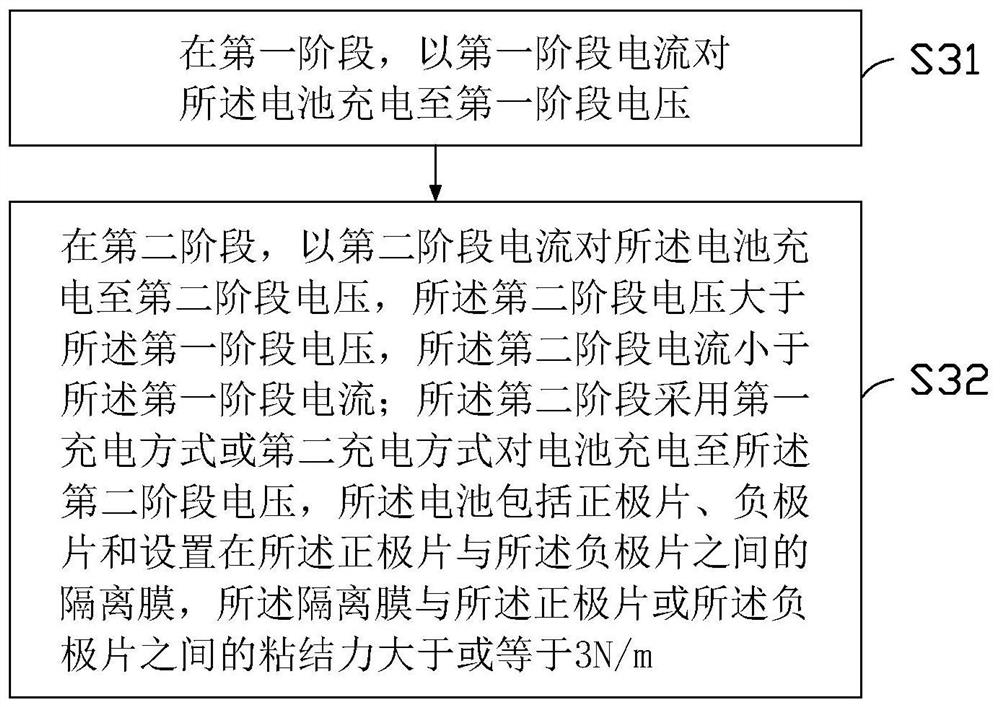

Method for improving battery cycle performance and electronic device

ActiveCN112106248AShorten the timeImprove cycle performanceFilm/foil adhesivesCells structural combinationElectrical batteryProcess engineering

The invention provides a method for improving the cycle performance of a battery, the method is applied to the battery, the battery comprises a positive plate, a negative plate and an isolating membrane arranged between the positive plate and the negative plate, the adhesive force between the isolating membrane and the positive plate or the negative plate is greater than or equal to 3N / m, and themethod comprises the following steps: in a first stage, separating the positive plate and the negative plate from each other; charging the battery with the first-stage current to a first-stage voltage; and in a second stage, charging the battery to a second-stage voltage with a second-stage current, the second-stage voltage being greater than the first-stage voltage, and the second-stage current being less than the first-stage current. The invention further provides an electronic device. According to the method provided by the invention, the cycle performance of the battery in a high-temperature environment can be remarkably improved.

Owner:NINGDE AMPEREX TECH

Original coal and stock oil composition for needle coke and for electricity storing carbon material

ActiveCN101331082AImprove cycle characteristicsSimplified washing operationsElectrolytic capacitorsSpecial form destructive distillationBoiling pointPetroleum

A stock oil composition as a stock oil for production of needle coke or for production of an active carbon for electric double layer capacitor electrode, comprising a first heavy oil of 300 DEG C or higher initial boiling point, 12 mass percent or less asphaltene contents, 50 mass percent or more saturated contents and 0.3 mass percent or less sulfur contents as obtained by vacuum distillation ofpetroleums as residual oil and a second heavy oil of 150 DEG C or higher initial boiling point and 0.5 mass percent or less sulfur contents as obtained by fluid catalytic cracking of hydrocarbon oil.

Owner:NIPPON OIL CO LTD +1

Non-aqueous electrolyte for inhibiting sodium-ion battery swelling as well as preparation method and application thereof

InactiveCN108288730ASuppress flatulenceImprove Coulombic efficiencyFinal product manufactureSecondary cells servicing/maintenanceSodium tetrafluoroborateSodium-ion battery

The invention discloses non-aqueous electrolyte for inhibiting sodium-ion battery swelling as well as a preparation method and application thereof. The non-aqueous electrolyte comprises a sodium salt,an organic solvent and a first functional additive, wherein the molecular formula of the first functional additive is R1R2R3C3H3O3S; the content of the first functional additive in the non-aqueous electrolyte is 0.001-30wt%; the sodium salt refers to one or more of sodium hexafluorophosphate, sodium tetrafluoroborate, sodium hexafluoroarsenate, sodium borate dioxalate, sodium ditrifluoromethyl sulfonamide, sodium trifluoromethanesulfonate, sodium difluorosulfonimide or sodium perchlorate; the organic solvent refers to one or more of cyclic carbonate, chain linear carbonate, carboxylic ester or cyclic lactone.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

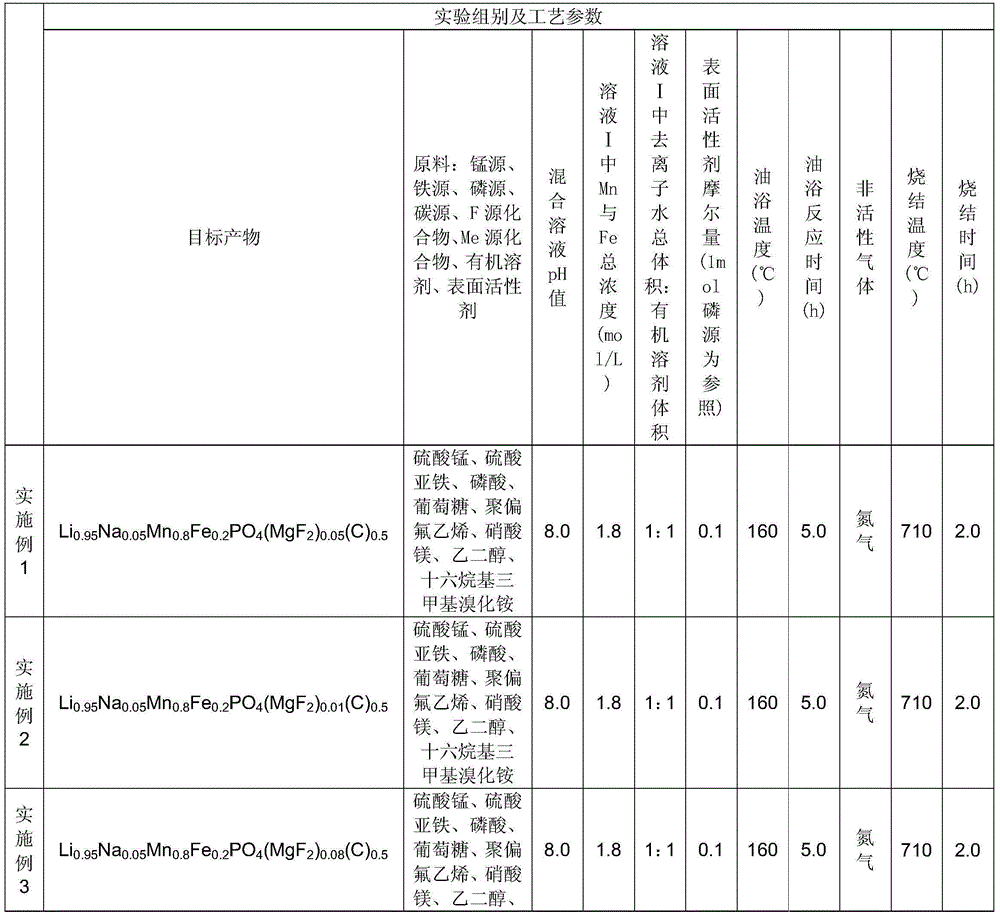

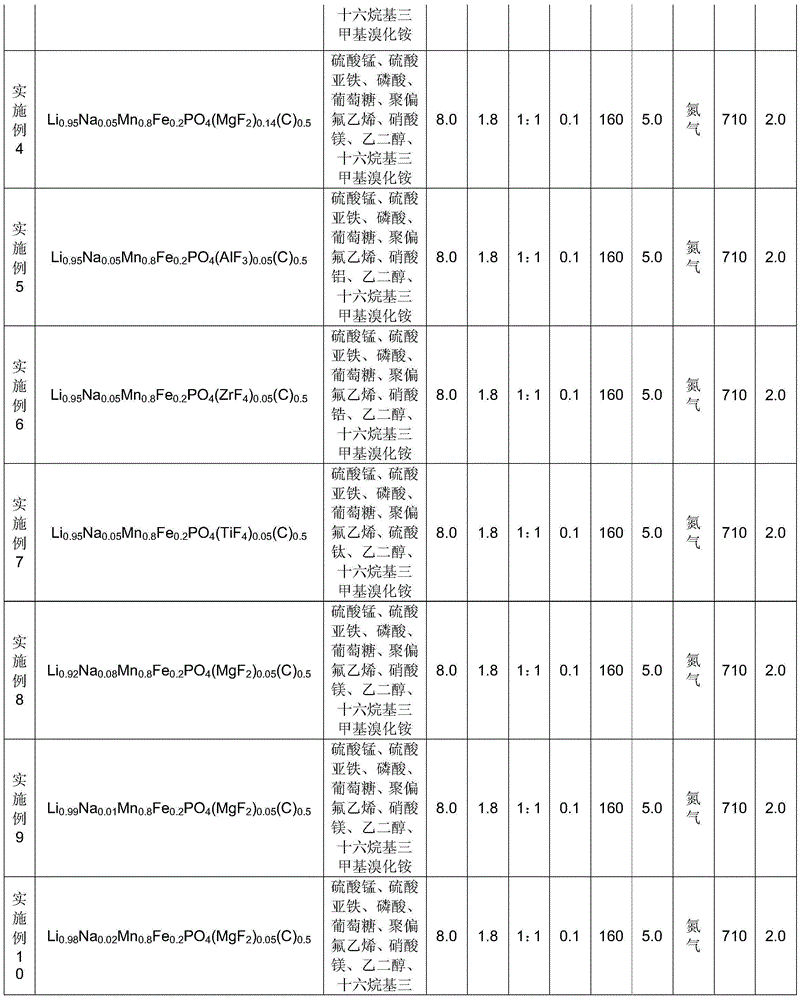

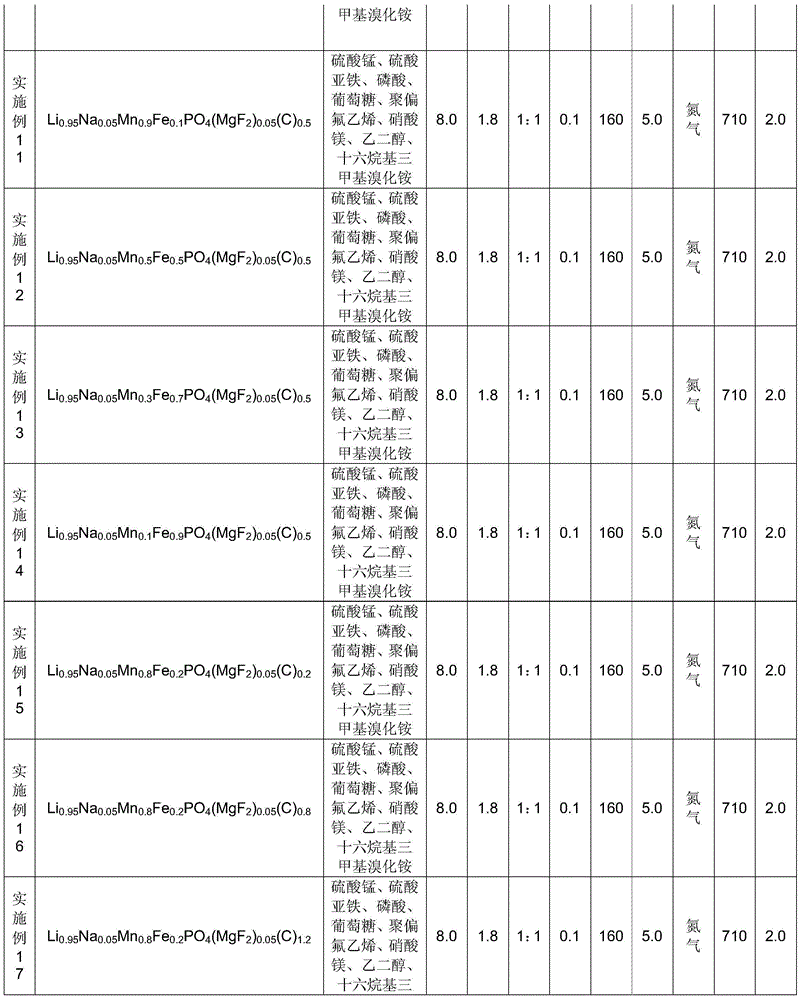

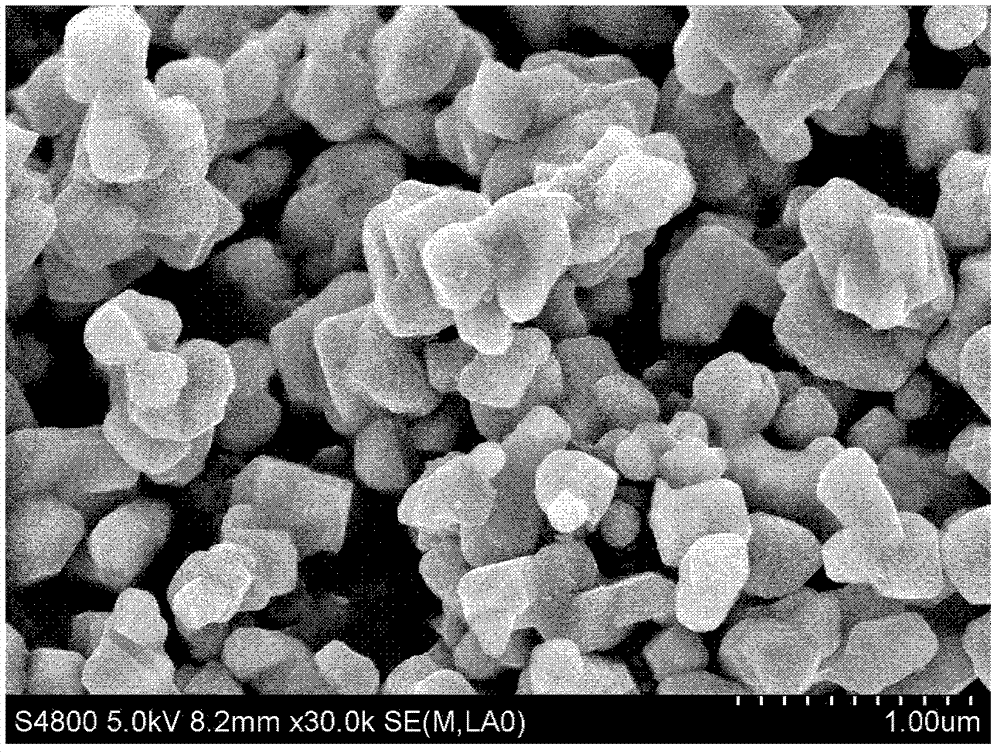

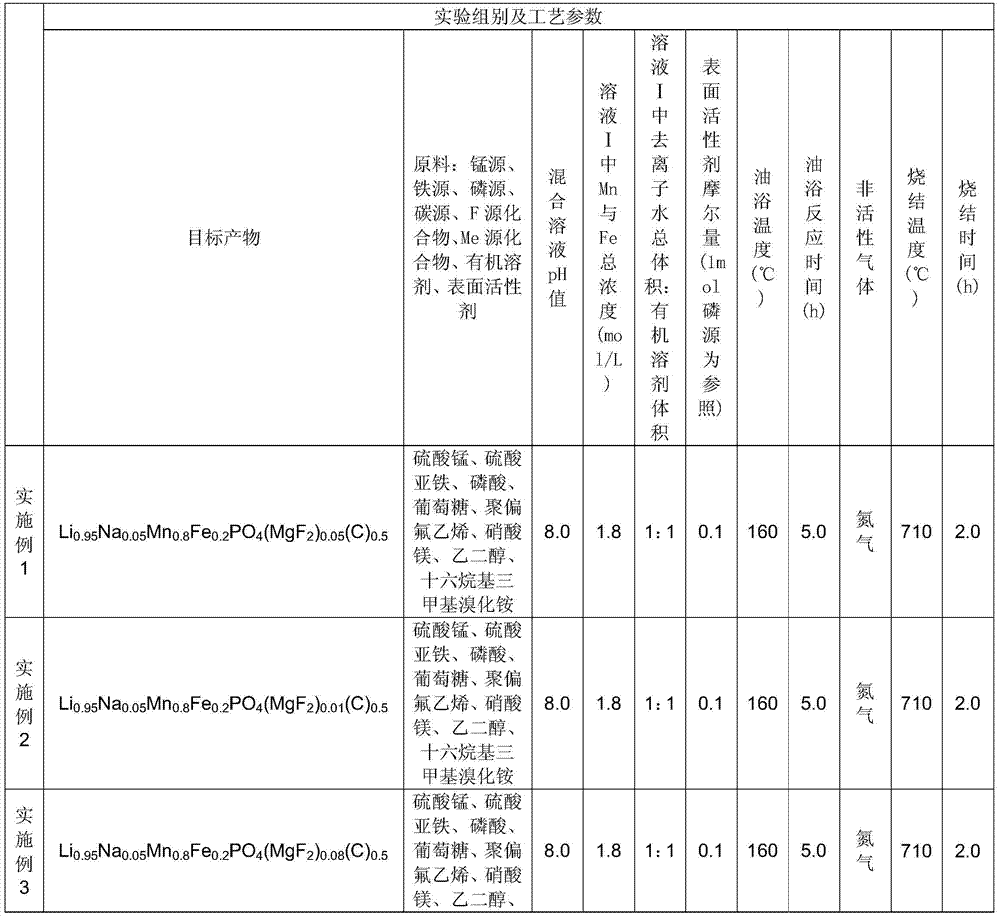

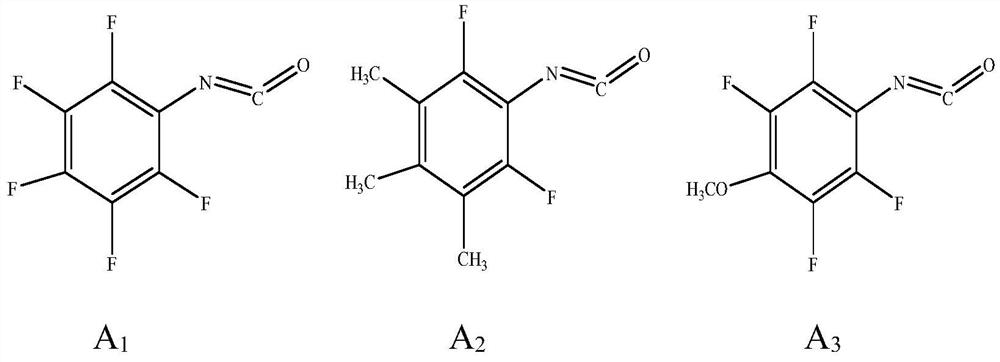

Positive electrode material of lithium ion battery and preparation method thereof

ActiveCN104953118AThe lattice structure is stableIncrease the diffusion rate of lithium ionsCell electrodesSecondary cellsElectrical batteryLithium electrode

The invention provides a positive electrode material of a lithium ion battery. The chemical formula of the positive electrode material is Li(1-a)NaaMnxFe(1-x)PO4(MeFy)b(C)c, wherein a is more than 0 and smaller than or equal to 0.08, b is more than 0 and smaller than 0.15, c is more than 0 and smaller than 1.5, b+c is smaller than 1.5, x is more than or equal to 0.1 and smaller than or equal to 0.9, MeFy is at least one of AlF3, TiF4, MgF2, ZrF4, MoF6 and NbF4; the positive electrode material is of a core-shell structure, and sequentially comprises a Na<+> bulk phase doped Li(1-a)NaaMnxFe(1-x)PO4 inner core layer, a middle transitional layer containing metal fluoride MeFy, and a carbon coverage layer positioned on the surface. The invention also provides a preparation method of the positive electrode material. According to the positive electrode material, the electric conductivity is improved, the bloating of the positive electrode material is effectively inhibited, the cycle life of the battery is prolonged, and the high-temperature storage property of the battery is improved.

Owner:QINGHAI CONTEMPORARY AMPEREX TECH

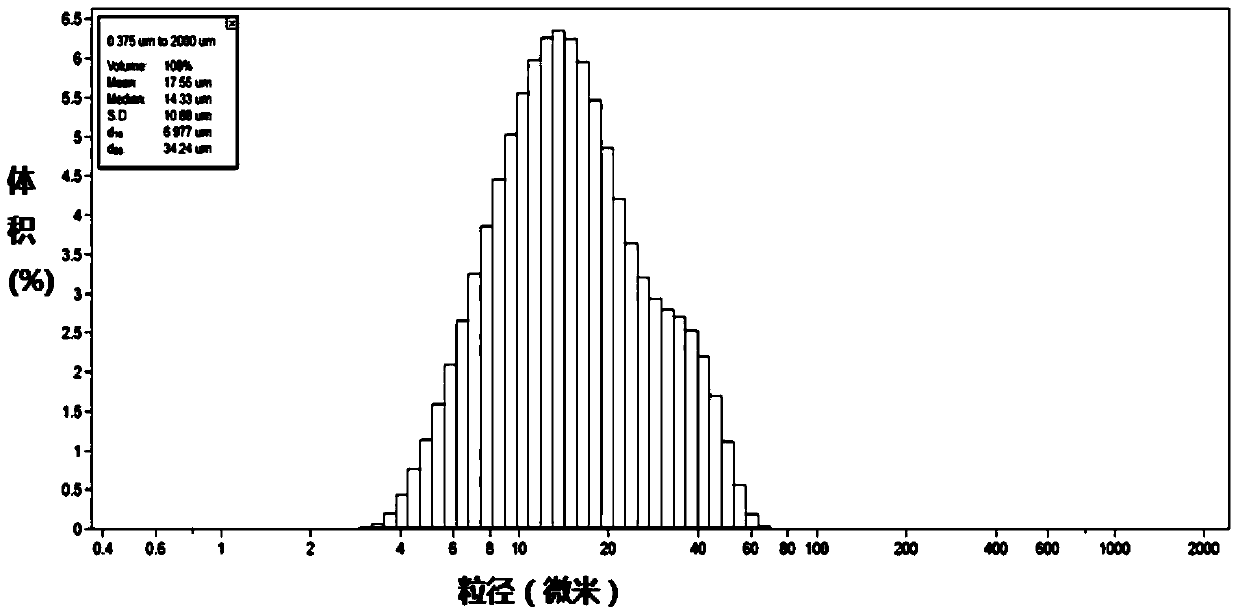

Preparation method of aluminum-oxide-coated nano lithium titanate composite material

ActiveCN102376947BImproved magnification performanceImprove cycle performanceCell electrodesFree coolingRoom temperature

The invention discloses a preparation method of aluminum-oxide-coated nano lithium titanate composite material, which comprises the steps of: adding aluminum salt solution into prepared Li4Ti5O12 suspending liquid under the stirring condition, wherein the adding quantity of the aluminum salt solution is in accordance with the molar ratio as follows: Ti: Al=5: x, and x=0.01-0.55; simultaneously, adding a right amount of ammonia water, and adjusting the pH value to be 8-10; stirring for reaction for 30-50 minutes, and standing still for about 6 hours; after filtering, washing and drying, obtaining precursor of the aluminum-oxide-coated nano lithium titanate composite material; and finally, sintering the obtained precursor of the aluminum-oxide-coated nano lithium titanate composite materialat 400-600 DEG C for 4-10 hours, naturally cooling to be room temperature, and obtaining the aluminum-oxide-coated nano lithium titanate composite material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

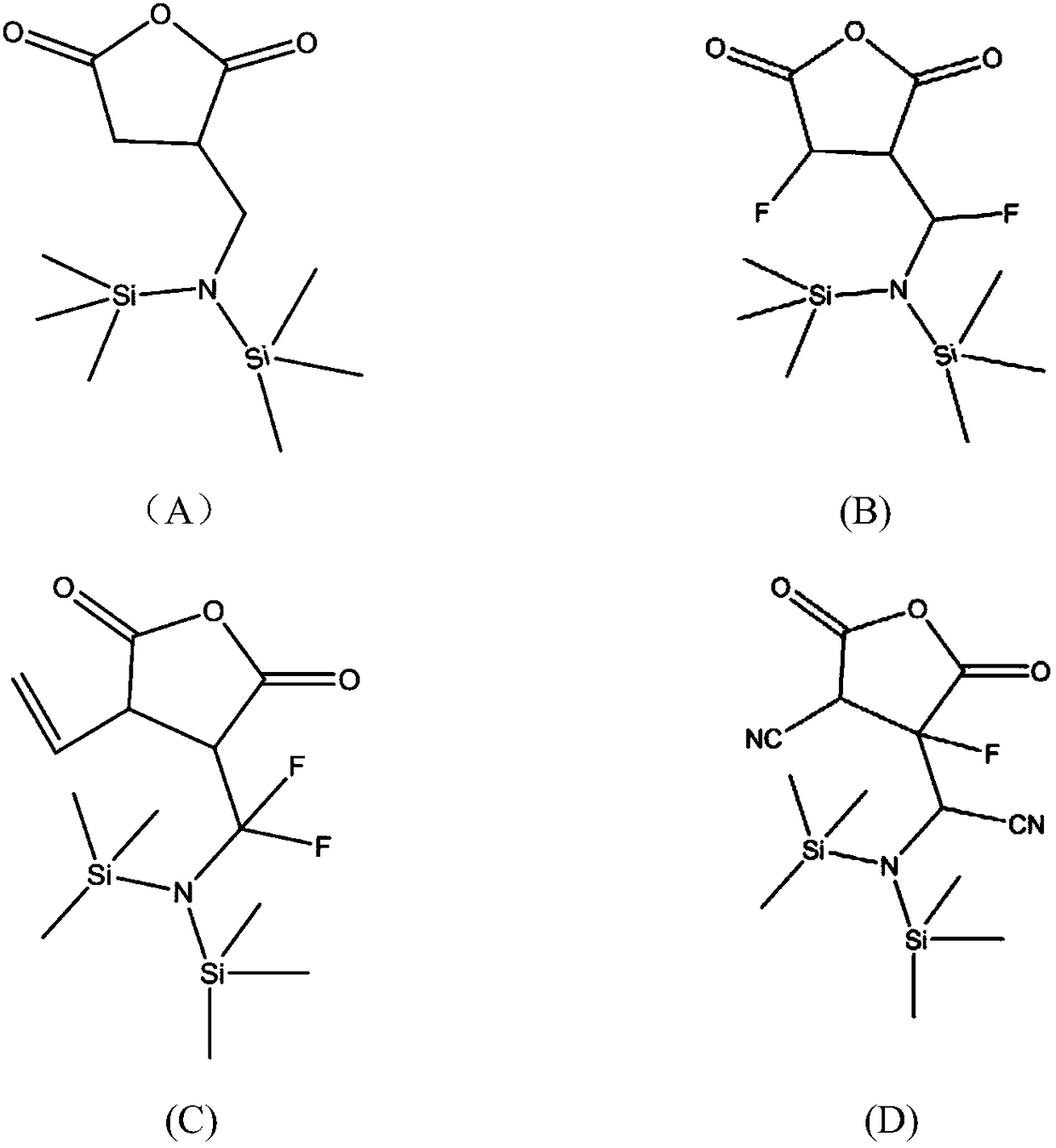

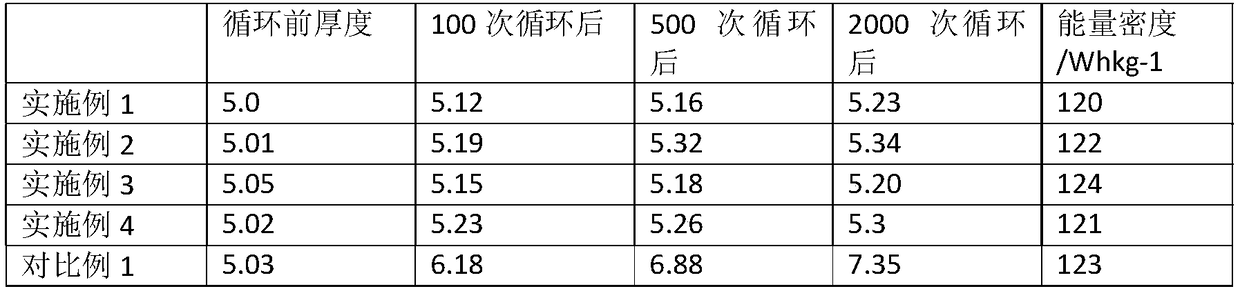

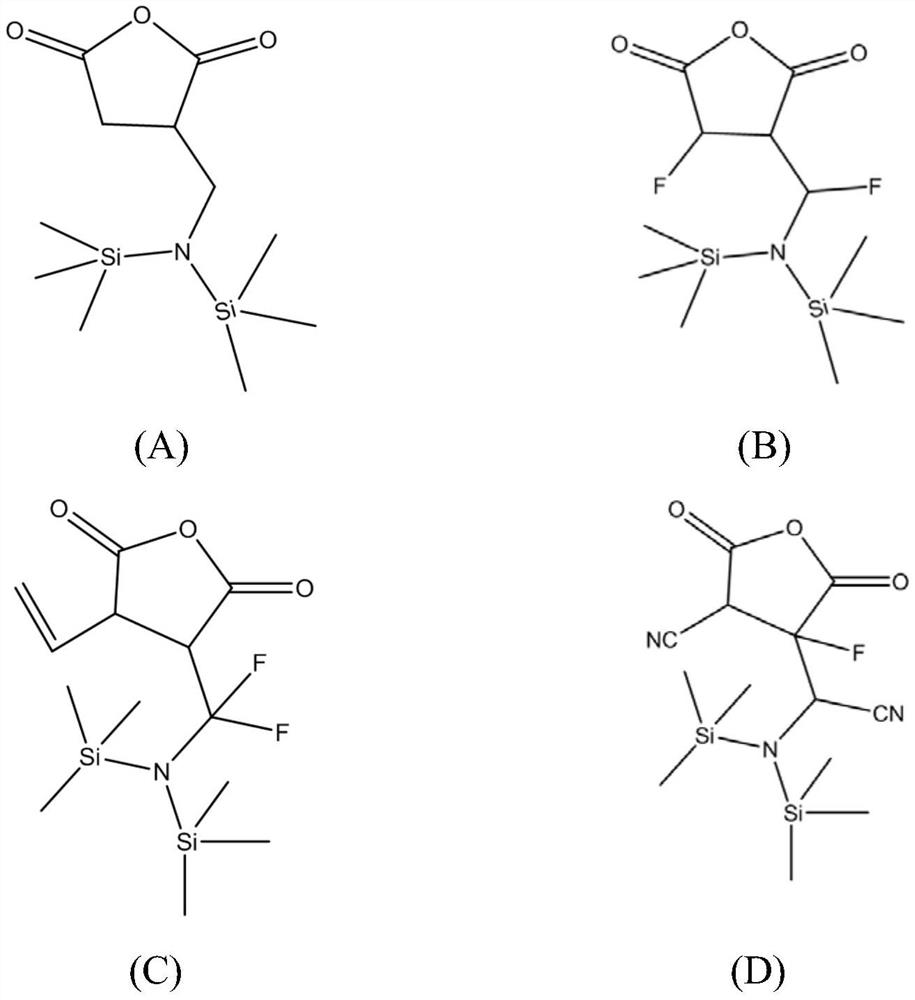

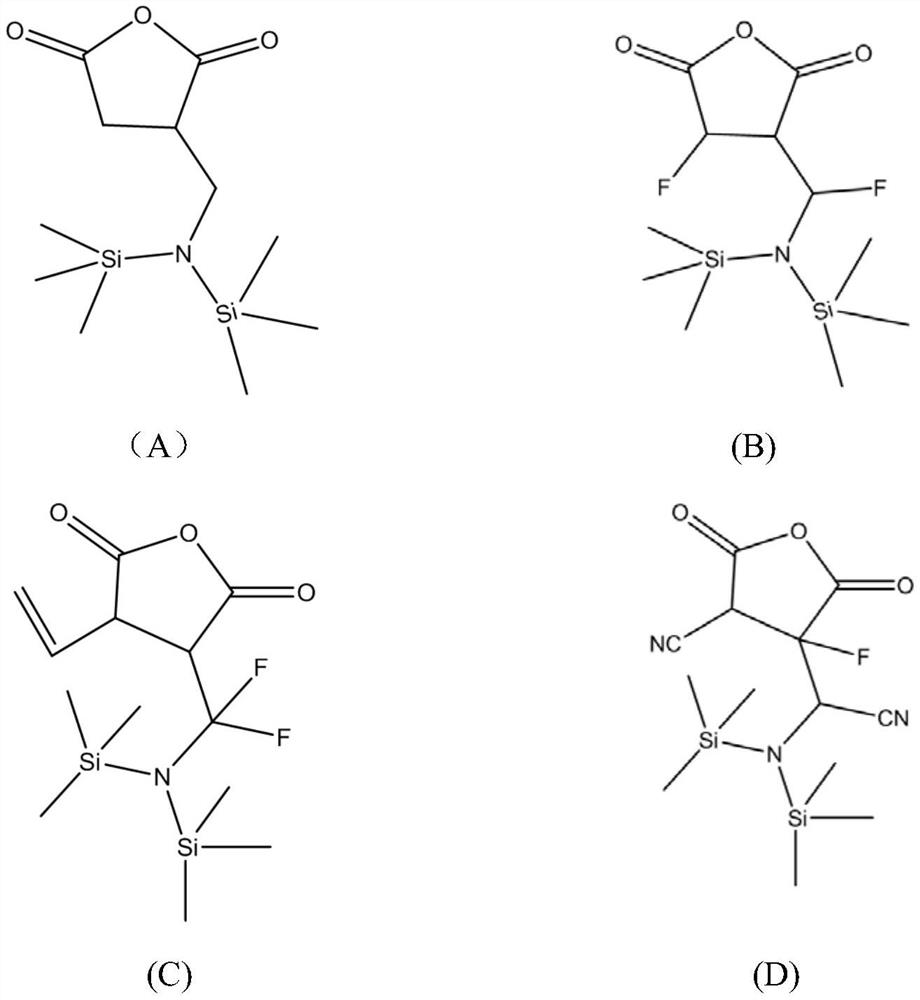

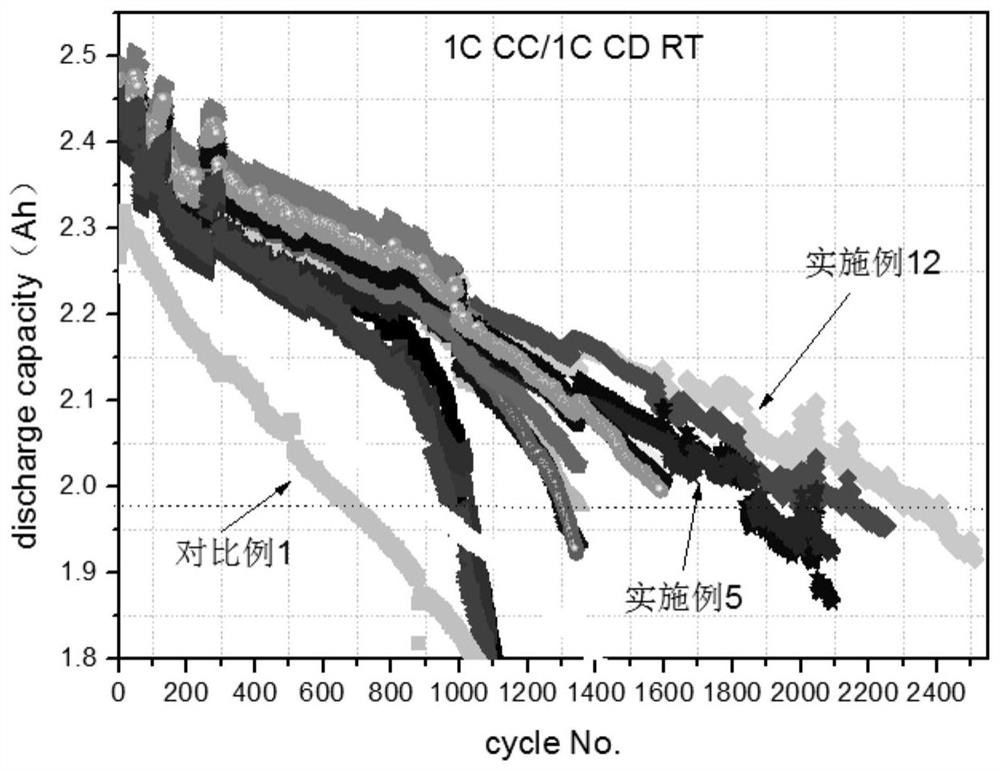

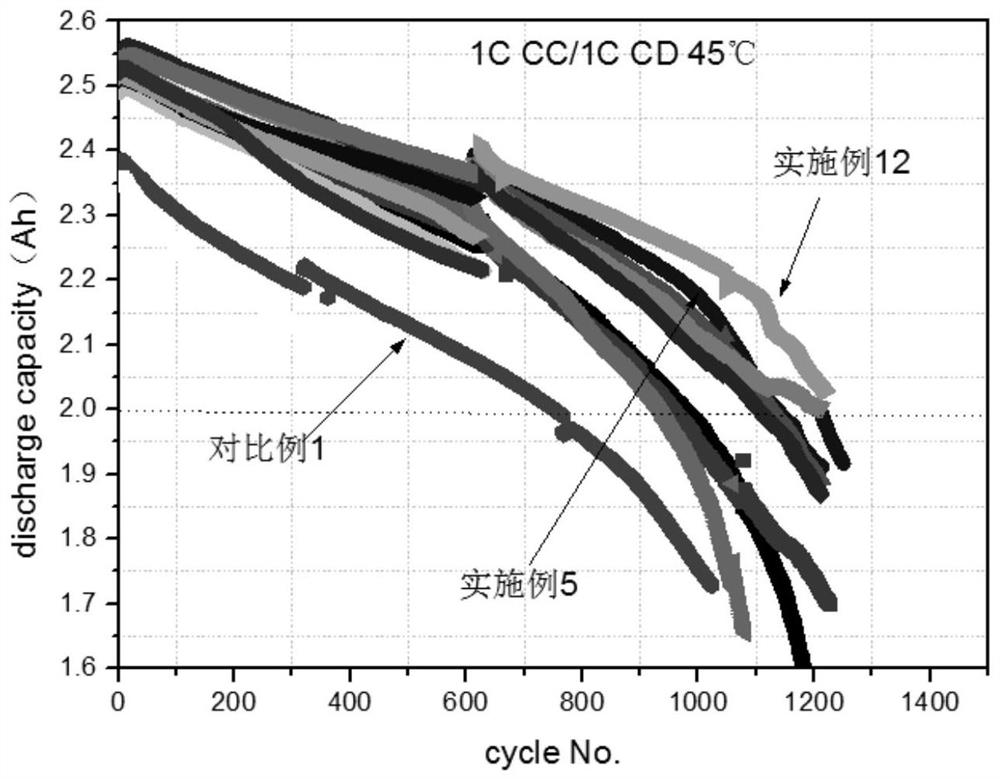

A battery electrolyte and a lithium ion battery containing the electrolyte

ActiveCN109148957ASuppress flatulenceImprove performanceSecondary cellsOrganic electrolytesLithium-ion batteryAcid anhydride

A battery electrolyte A lithium ion battery containing the electrolyte is also disclosed, As that acid anhydride derivative additive is added into the battery electrolyte, At the same time, the acid anhydride derivative additive contains O, N, Si, F and has good compatibility with the positive and negative electrode materials when it is used as the electrolyte additive, which can effectively inhibit the gas expansion of the battery and improve the high-temperature cycling performance of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

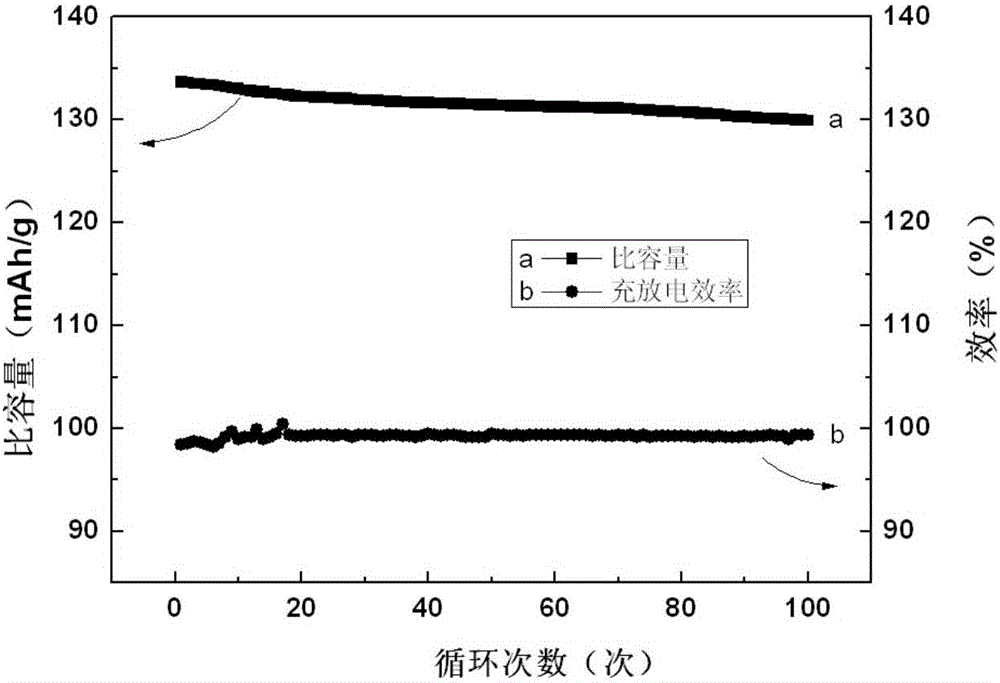

A kind of preparation method of composite material coating lithium nickel manganese oxide

ActiveCN105374997BPurePromote crystallizationCell electrodesSecondary cellsAir atmospherePolyethylene glycol

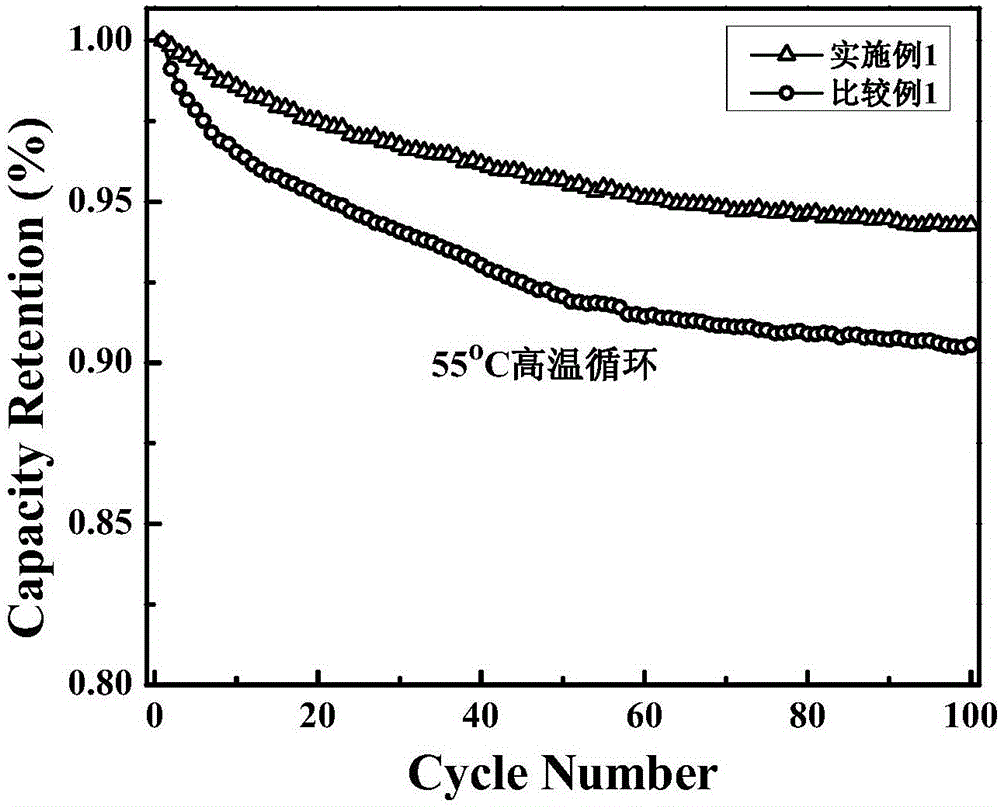

The invention discloses a preparation method for a nickel lithium manganate coated composite material. The preparation method comprises the following steps of adding a composite solution of a calcium salt, a zircon salt and a titanium salt into a pure-phase nickel lithium manganate precursor suspension liquid, simultaneously adding polyethylene glycol (PEG) as a dispersing agent and citric acid as a complexing agent, adjusting pH with ammonia water, carrying out mechanical stirring and constant-temperature waterbath reaction, taking out and ageing the composite solution, and carrying out filtering, washing and drying to obtain a Cao-ZrO2-TiO2 coated nickel lithium manganate precursor, wherein the composite solution is prepared from Li, Ca, Zr and Ti according to the ratio of 2:x:x:x, and x is equal to (0.01-0.1); and carrying out calcination and annealing processing in an air atmosphere to obtain the CaO-ZrO2-TiO2 coated nickel lithium manganate composite material. The material obtained according to the preparation method is pure in phase, well crystallization is achieved, the process is simple, continuous industrial production is easily realized, moreover, the initial discharging specific capacity at 0.2C reaches over 130mAh / g, and the cycle capacity retention rate at 0.2C after rate of 100 times is over 97%.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Novel compound additive for producing high-strength carbon-graphite material and preparation method of carbon-graphite material

The invention discloses a novel compound additive for producing a high-strength carbon-graphite material and a preparation method of the carbon-graphite material. The novel compound additive is a mixture of rare-earth metal powder or a rare-earth compound and a boron compound, wherein the two substances are mixed at a mass ratio ranging from (1 to 1) to (1 to 5); the rare-earth compound is selected from one or more of a rare-earth organic compound and a rare-earth inorganic compound; the boron compound is selected from one or more of a boron organic compound and a boron inorganic compound.

Owner:EAST CHINA UNIV OF SCI & TECH

Lithium titanate material, preparation and application thereof

ActiveCN108155372AAchieve effective compoundingSuppress flatulenceHybrid capacitor electrodesCell electrodesGraphiteGraphene

The invention relates to a modified lithium titanate material. The modified lithium titanate material is prepared by mixing lithium titanate powder with fluorinated graphene and / or fluorinated graphite at mass ratio of 100-1 to 1-4. The modified lithium titanate material can be used as an electrode material in a lithium titanate battery or a lithium titanate capacitor. The modified lithium titanate material is capable of effectively restraining the swelling problem of the lithium titanate battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lithium titanate coated positive electrode material for power battery and preparation method

InactiveCN109713270AGood effectImprove cycle performanceCell electrodesSecondary cellsPower batteryGraphene

The invention belongs to the technical field of technical lithium batteries, and provides a lithium titanate coated positive electrode material for a power battery and a preparation method. The methodcomprises the following steps: mixing a positive electrode material precursor with graphene oxide, performing heating to form a positive electrode material precursor coated with graphene oxide hydrogel, adding butyl titanate, performing reaction with a lithium source, and performing coating in a graphene oxide hydrogel grid to prepare the lithium titanate coated positive electrode material. Comparing with a material prepared through a traditional method, the prepared lithium titanate coated positive electrode material can effectively inhibit the gas expansion caused by contact between lithiumtitanate and an electrolyte because the surface of the positive electrode active material is uniformly coated with the formed graphene oxide / lithium titanate composite material. Meanwhile, the preparation process is simple, the process is easy to control, and the lithium titanate-coated positive electrode material has a good prospect in large-scale industrial production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Novel composite additive for producing low-resistance high-strength graphite as well as preparation method of graphite material

The invention discloses a novel composite additive for producing low-resistance high-strength graphite as well as a preparation method of the graphite material. The composite additive is a mixture of rare-earth metal powder or a rare-earth compound with titanium metal powder or a titanium compound, wherein the mass ratio of the two substances is (1:1)-(1:5) when the two substances are mixed; the rare-earth compound is selected from one or more of rare-earth organic compounds and rare-earth inorganic compounds; and the titanium compound is selected from one or more of titanium organic compounds and titanium inorganic compounds.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of electrolytic solution and its preparation method and a kind of high-voltage lithium-ion battery

ActiveCN104051786BReduce polarizationImprove interface propertiesElectrolyte accumulators manufactureOrganic solventInterface impedance

The invention discloses electrolyte, a preparation method for the same and a high-voltage lithium ion battery. The electrolyte mainly comprises an organic solvent, conductive lithium salt and an additive, wherein the organic solvent is prepared from more than one of a cyclic carbonate solvent, an aromatic hydrocarbon solvent and a linear solvent; the concentration of the conductive lithium salt in the organic solvent is 0.8 to 1.5mol / L; the using amount of the additive is 0.1 to 10.0 percent based on the weight of the organic solvent, and the additive is a halogenated cyanophenyl compound. After the additive is added into the electrolyte, a polymer film can be formed on the surface of each of a positive electrode and a negative electrode, so that the interface impedance of the electrodes / electrolyte is reduced, the decomposition of the electrolyte on the surface of an electrode material is suppressed, and the prolonging of cycle life of the high-voltage lithium ion battery (higher than 4.4V), the improvement of high / low-temperature performance of the high-voltage lithium ion battery and the suppression of gas expansion of the battery are facilitated.

Owner:GUANGZHOU TINCI MATERIALS TECH

A kind of battery electrolyte and lithium ion battery containing the electrolyte

ActiveCN109148957BSuppress flatulenceImprove performanceSecondary cellsOrganic electrolytesElectrolytic agentPhysical chemistry

The invention discloses a battery electrolyte, and also discloses a lithium-ion battery containing the electrolyte. By adding acid anhydride derivative additives to the battery electrolyte, the problem of flatulence of the battery can be improved. At the same time, the acid anhydride derivative The additive contains O, N, Si, F and other elements. When it is used as an electrolyte additive, it has good compatibility with positive and negative electrode materials, which can effectively inhibit battery flatulence and improve battery high-temperature cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Electrolyte and lithium ion battery

PendingCN114171791AImprove cycle performanceSuppress flatulenceSecondary cells servicing/maintenanceComposite electrolytesElectrolytic agentHigh energy

The invention discloses an electrolyte suitable for an NCM system and a battery. The electrolyte comprises an organic solvent, electrolyte lithium salt and additives, and the additives comprise ethylene sulfate accounting for 0.1%-10% of the total mass of the electrolyte, succinic anhydride accounting for 0.1%-5% of the total mass of the electrolyte, ethyoxyl (pentafluoro) cyclotriphosphazene accounting for 0.1%-15% of the total mass of the electrolyte and diphenyl carbonate accounting for 0.01%-5% of the total mass of the electrolyte. The electrolyte and the battery provided by the invention not only have excellent electrochemical performance at normal temperature and high temperature, but also are obviously improved in the aspects of overcharge and flame retardance; therefore, the material has a wide application prospect in batteries of high-energy density systems in the future.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Lithium-ion battery cathode material and preparation method thereof

ActiveCN104953118BStructural stabilityIncreased diffusion rateCell electrodesSecondary cellsHigh temperature storagePhysical chemistry

The invention provides a positive electrode material of a lithium ion battery. The chemical formula of the positive electrode material is Li(1-a)NaaMnxFe(1-x)PO4(MeFy)b(C)c, wherein a is more than 0 and smaller than or equal to 0.08, b is more than 0 and smaller than 0.15, c is more than 0 and smaller than 1.5, b+c is smaller than 1.5, x is more than or equal to 0.1 and smaller than or equal to 0.9, MeFy is at least one of AlF3, TiF4, MgF2, ZrF4, MoF6 and NbF4; the positive electrode material is of a core-shell structure, and sequentially comprises a Na<+> bulk phase doped Li(1-a)NaaMnxFe(1-x)PO4 inner core layer, a middle transitional layer containing metal fluoride MeFy, and a carbon coverage layer positioned on the surface. The invention also provides a preparation method of the positive electrode material. According to the positive electrode material, the electric conductivity is improved, the bloating of the positive electrode material is effectively inhibited, the cycle life of the battery is prolonged, and the high-temperature storage property of the battery is improved.

Owner:QINGHAI CONTEMPORARY AMPEREX TECH

A kind of electrolytic solution suitable for silicon carbon negative electrode and lithium ion battery comprising the electrolytic solution

ActiveCN109873205BImproved reversible capacity performanceImprove cycle performanceSecondary cells servicing/maintenanceElectrolytic agentOrganosolv

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Original coal and stock oil composition for needle coke and for electricity storing carbon material

ActiveCN101331082BSimplified washing operationsSmall coefficient of thermal expansionHybrid capacitor electrodesSpecial form destructive distillationPetroleum oilElectric double-layer capacitor

A stock oil composition as a stock oil for production of needle coke or for production of an active carbon for electric double layer capacitor electrode, comprising a first heavy oil of 300 DEG C or higher initial boiling point, 12 mass percent or less asphaltene contents, 50 mass percent or more saturated contents and 0.3 mass percent or less sulfur contents as obtained by vacuum distillation ofpetroleums as residual oil and a second heavy oil of 150 DEG C or higher initial boiling point and 0.5 mass percent or less sulfur contents as obtained by fluid catalytic cracking of hydrocarbon oil.

Owner:NIPPON OIL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com