Electrolyte, preparation method for same and high-voltage lithium ion battery

An electrolyte and lithium salt technology, applied in the field of lithium-ion battery preparation, can solve the problems of few types and single effects, and achieve the effects of reducing dissolution, inhibiting deposition and reduction, and improving interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

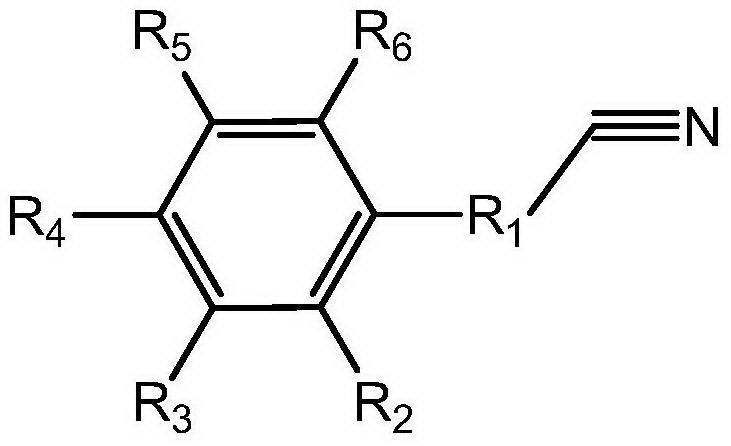

Method used

Image

Examples

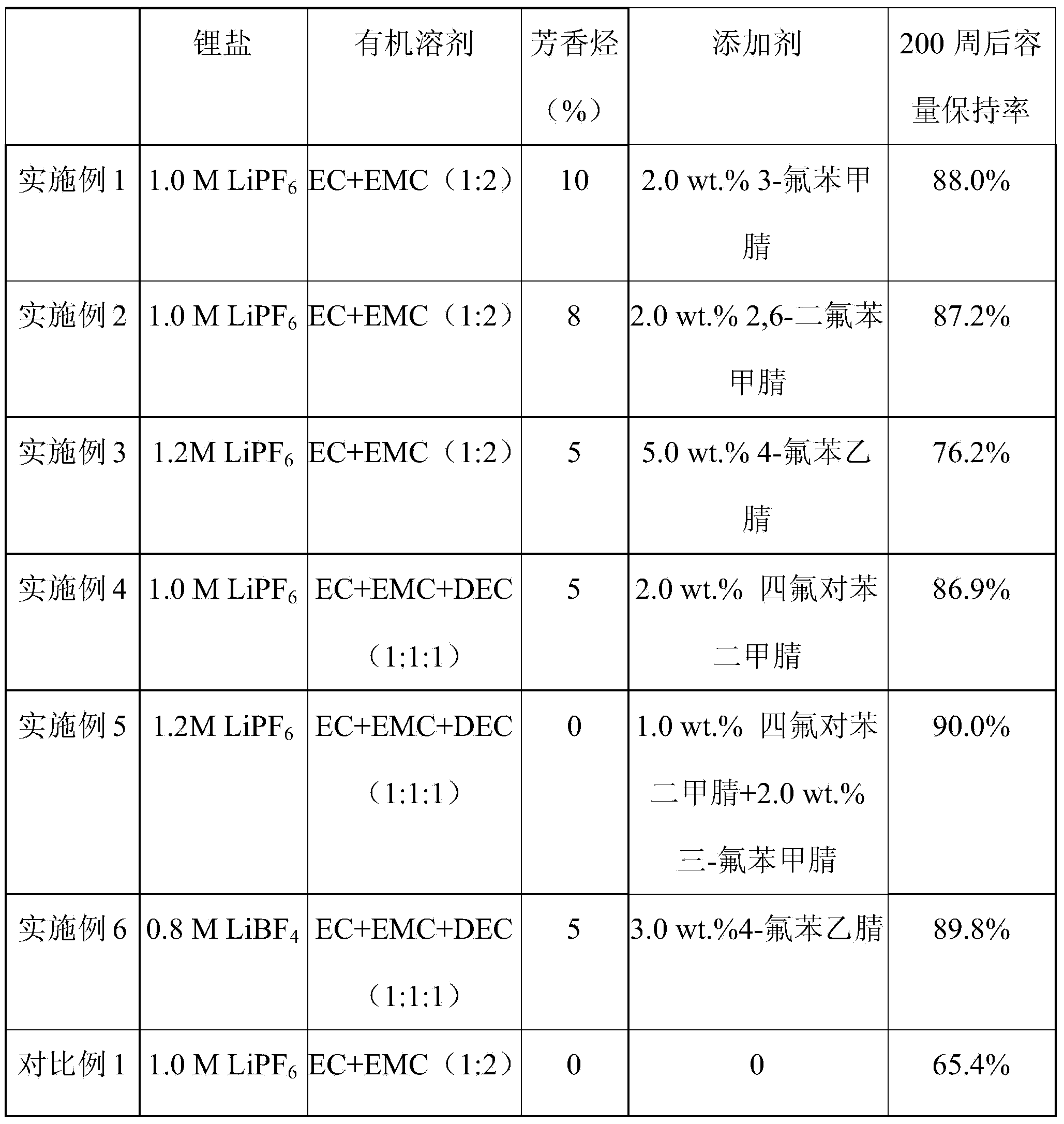

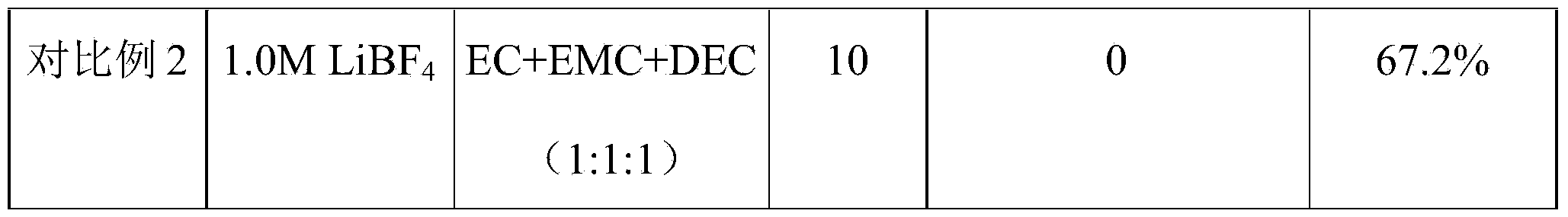

Embodiment 1

[0031] A high-voltage lithium-ion battery electrolyte, mainly comprising organic solvents, conductive lithium salts and additives, said organic solvents are composed of cyclic carbonate solvents (ethylene carbonate EC), aromatic hydrocarbon solvents (fluorobenzene FB), linear carbonic acid The composition of ester solvent (ethyl methyl carbonate EMC), the weight ratio of EC and linear carbonate is EC:EMC=1:2, and the dosage of FB is 10.0wt.%. The conductive lithium salt LiPF 6 Concentration in organic solvent is 1.0mol / L, and described common additive is the vinylene carbonate of 1.0wt.% consumption and the propane sultone that consumption is 1.0wt.%, and described additive is 3-fluorobenzyl Nitrile The dosage is 2.0wt.%.

[0032] The preparation method of electrolyte is:

[0033] (1) Mix the organic solvents in proportion and use them Molecular sieve, calcium hydride, lithium hydride purification, impurity removal, water removal;

[0034] (2) Dissolving the conductive ...

Embodiment 2

[0039] A high-voltage lithium-ion battery electrolyte, mainly comprising organic solvents, conductive lithium salts and additives, said organic solvents are composed of cyclic carbonate solvents (ethylene carbonate EC), aromatic hydrocarbon solvents (fluorobenzene FB), linear carbonic acid The composition of ester solvent (ethyl methyl carbonate EMC), the weight ratio of EC and linear carbonate is EC:EMC=1:2, and the dosage of FB is 8.0wt.%. The conductive lithium salt LiPF 6 The concentration in the organic solvent is 1.0mol / L, and the commonly used additives are vinylene carbonate in an amount of 1.0wt.% and propane sultone in an amount of 1.0wt.%, and the additives are 2,6-di Fluorobenzonitrile The dosage is 2.0wt.%.

[0040] The preparation method of electrolyte is:

[0041] (1) Mix the organic solvents in proportion and use them Molecular sieve, calcium hydride, lithium hydride purification, impurity removal, water removal;

[0042] (2) Dissolving the conductive li...

Embodiment 3

[0047] A high-voltage lithium-ion battery electrolyte mainly includes organic solvents, conductive lithium salts and additives, and the organic solvents are composed of cyclic carbonate solvents (ethylene carbonate EC), linear carbonate solvents (ethyl methyl carbonate EMC) It is composed of aromatic hydrocarbon solvent (fluorobenzene FB), the weight ratio of EC and linear carbonate is EC:EMC=1:2, and the dosage of FB is 5.0wt.%. The conductive lithium salt LiPF 6 Concentration in organic solvent is 1.0mol / L, and described common additive is the vinylene carbonate of 1.0wt.% consumption and the propane sultone that consumption is 1.0wt.%, and described additive is 4-fluorophenylacetonitrile The dosage is 5wt.%.

[0048] The preparation method of electrolyte is:

[0049] (1) Mix the organic solvents in proportion and use them Molecular sieve, calcium hydride, lithium hydride purification, impurity removal, water removal;

[0050] (2) Dissolving the conductive lithium salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com