Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Stir well stir well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation for promoting plant to root

InactiveCN102210305APromote germinationImprove cold resistanceBiocidePlant growth regulatorsDiseaseTree root

The invention relates to a preparation for promoting a plant to root. The preparation comprises sodium indolebutyrate, Nafusaku, diatomite, talcpowder and the like. The preparation is characterized by comprising 2 to 5 grams of sodium indolebutyrate, 0.5 to 2 grams of Nafusaku, 450 to 500 grams of diatomite, 450 to 500 grams of talcpowder and 0.5 to 1.5 grams of monopotassium phosphate, wherein the talcpowder adopts 300-mesh granules; and the Nafusaku is a broad-spectrum plant growth conditioner, has the effects of adjusting growth, promoting rooting, sprouting and blooming, preventing flowers and fruits from falling off, forming seedless fruits, promoting prematurity, increasing yield and the like, and can improve drought resistance, cold resistance, disease resistance, saline alkali resistance and dry hot wind resistance of the plant. The preparation is prepared by the following steps of: mixing 2 to 5 grams of the sodium indolebutyrate, 0.5 to 2 grams of the Nafusaku and 0.5 to 1.5 grams of the monopotassium phosphate; stirring the mixture completely and uniformly for later use; adding the mixture into 450 to 500 grams of the diatomite and mixing uniformly; adding the mixture into 450 to 500 grams of the talcpowder and mixing; and stirring the mixture completely and uniformly to prepare powdered preparation. The preparation is diluted by 400 to 600 folds and then is poured into the periphery of a tree root system. The preparation is convenient to use, saves using amount and has quick response, so the preparation is a high-efficiency and environment-friendly preparation.

Owner:TIANJIN LVDONG PLANT NUTRITION TECH DEV

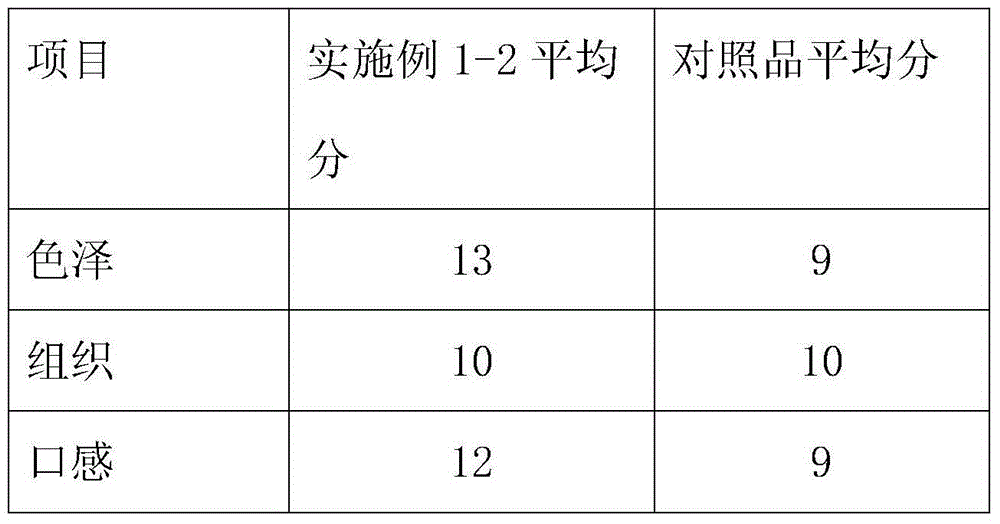

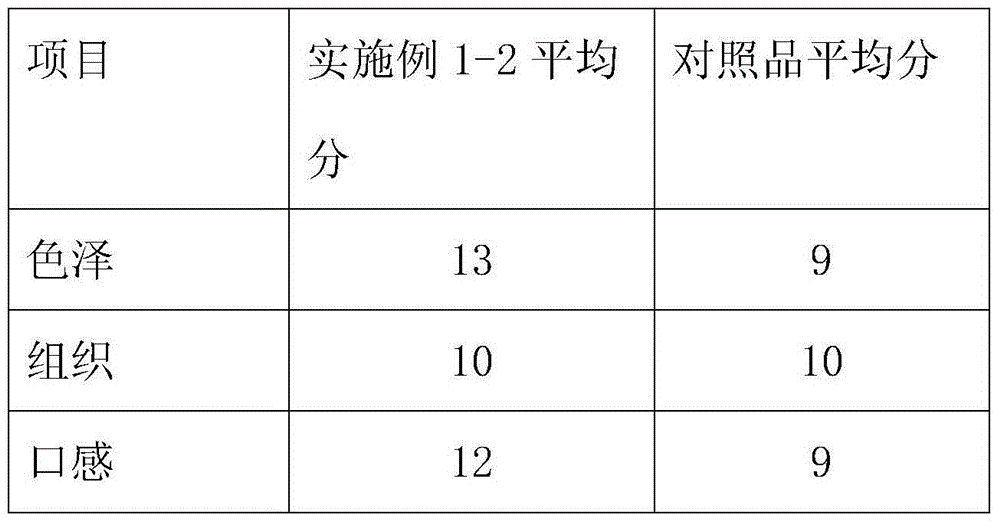

Process of making preserved vanilla-Roselle calyx

The present invention relates to process of making preserved vanilla-roselle. The making process includes the following steps: 1. preparing materials including sugar, fresh roselle in 2 times of the sugar and natural vanilla tincture in 0.5-1.5 % roselle weight; 2. boiling roselle pulp in water solution of sugar; 3. adding vanilla tincture into hot roselle and sugar solution via stirring a soaking for 1-2 days, fishing out roselle and draining sugar liquid; and 4. stoving the roselle in a stove at 50-60 deg.c to water content not more than 25 %. The preserved vanilla-roselle has scented smell, unique taste, several health functions and high nutritious value.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI

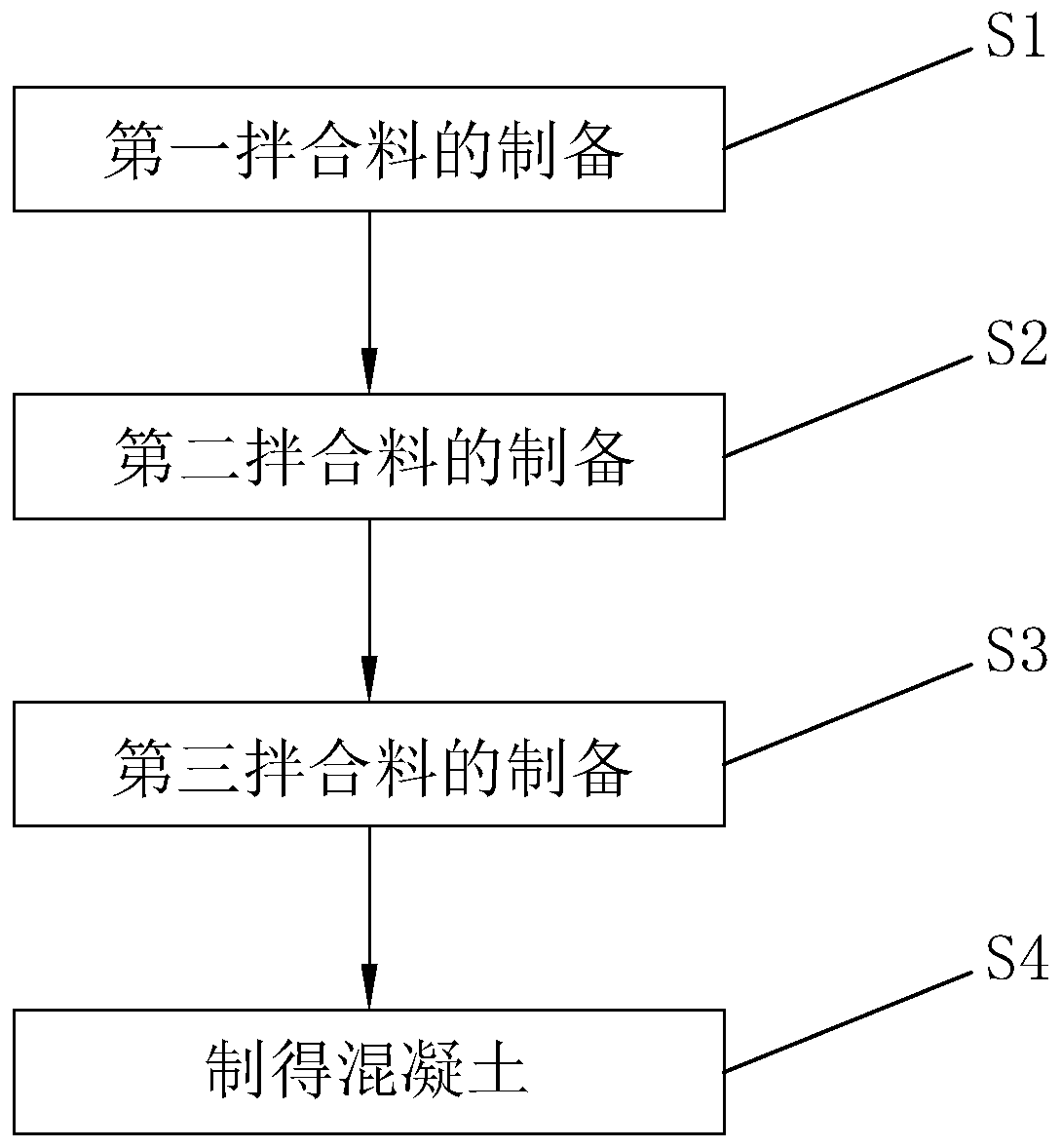

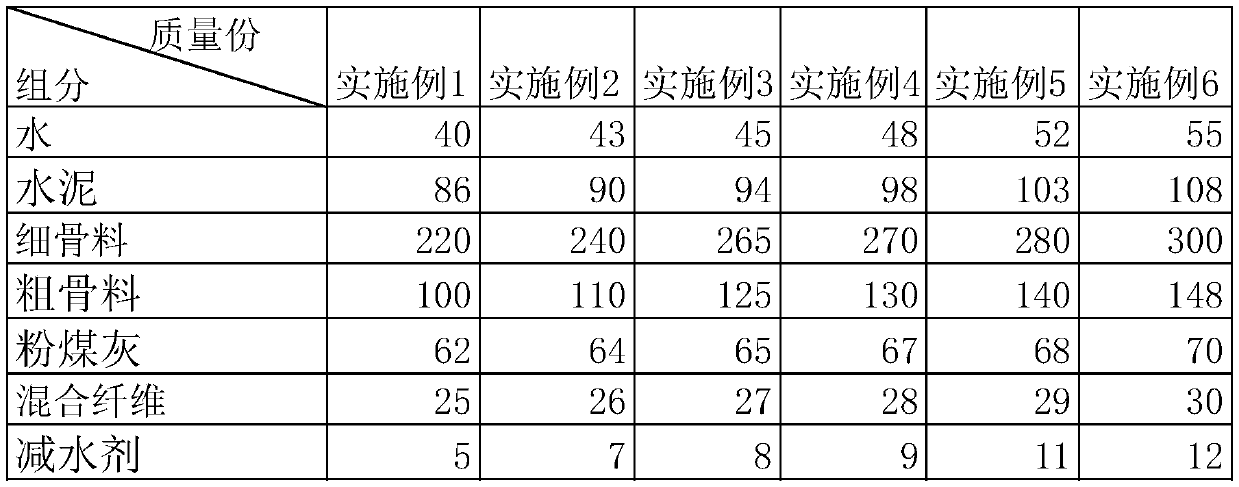

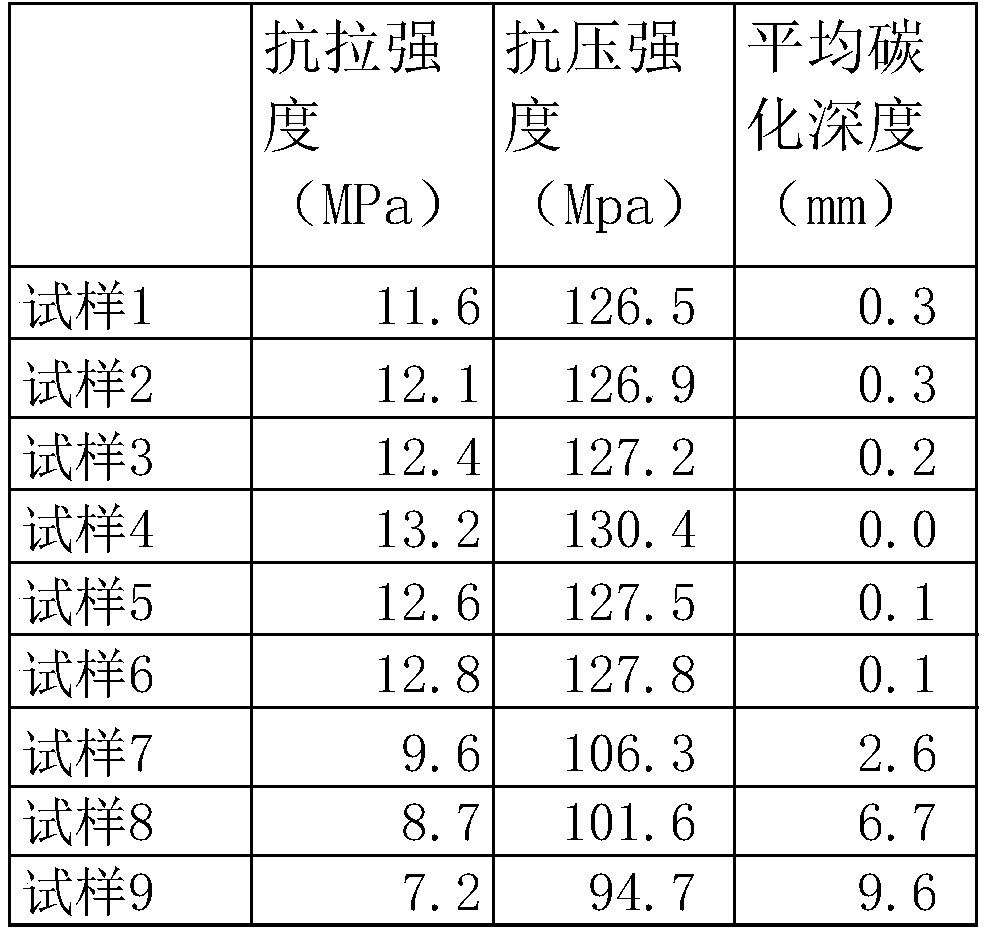

Preparation method of high-strength, anti-cracking and anti-seismic concrete

The invention relates to the field of concrete preparation, in particular to a preparation method of high-strength, anti-cracking and anti-seismic concrete, which comprises the following components inparts by mass: 40 to 55 parts of water, 86 to 108 parts of cement, 220 to 300 parts of fine aggregate, 100 to 148 parts of coarse aggregate, 62 to 70 parts of fly ash, 25 to 30 parts of mixed fibersand 5 to 12 parts of a water reducing agent. The preparation method of the high-strength, anti-cracking and anti-seismic concrete comprises the following steps: S1, preparing a first mixture, S2, preparing a second mixture, S3, preparing a third mixture, and S4, preparing concrete. The concrete has the advantage that the compressive strength of the concrete is improved.

Owner:广东承沐建设工程有限公司

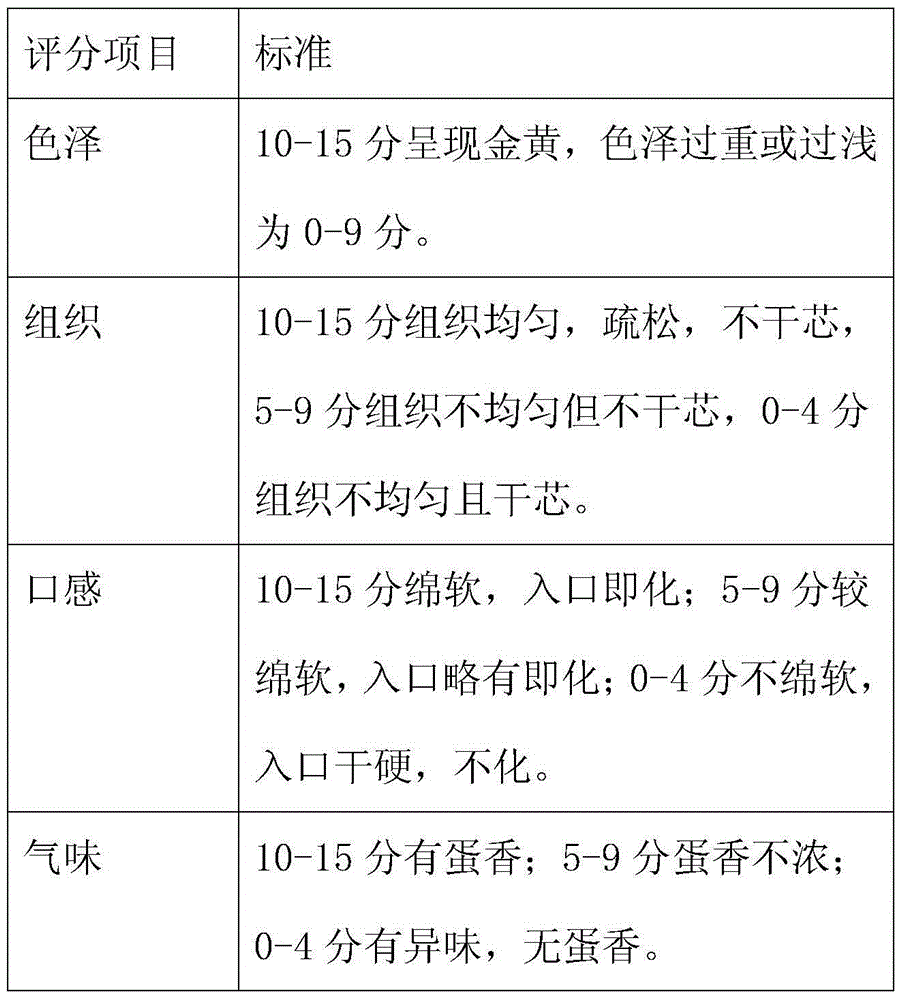

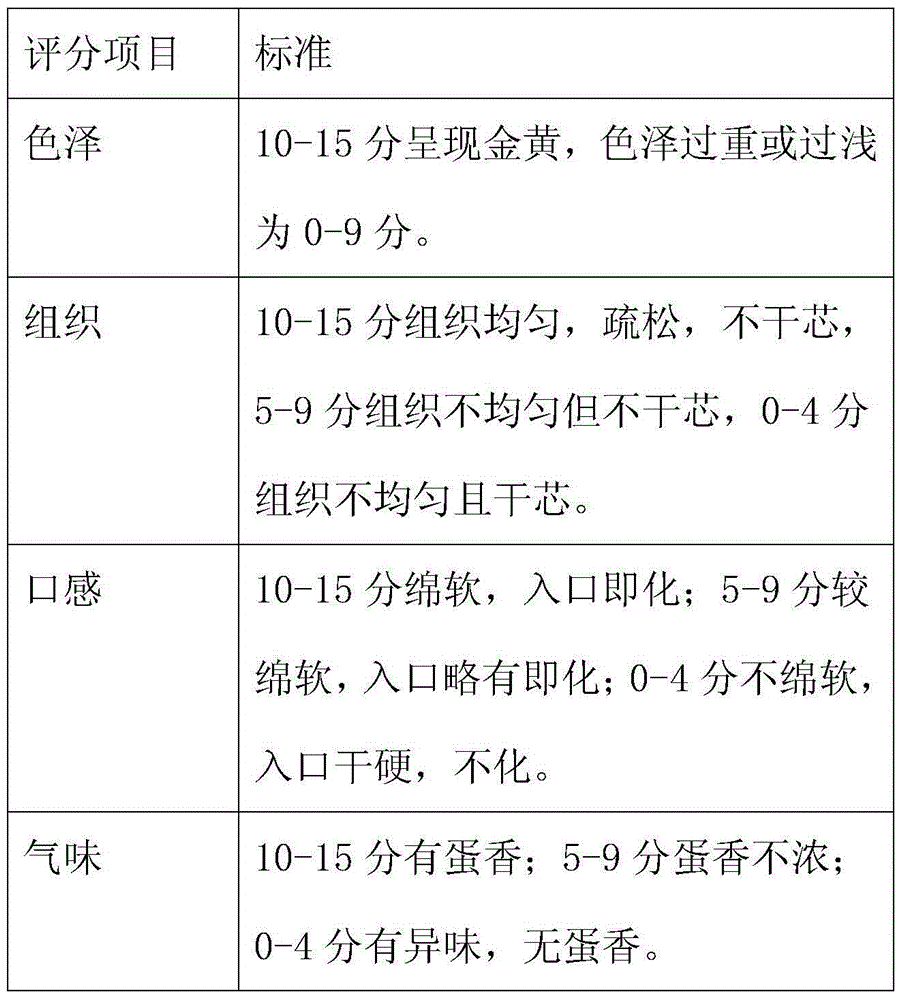

Production process of French type crispy cakes

The invention provides a production process of French type crispy cakes. The French type crispy cakes are prepared according to the steps as follows: a mixture of grease, white granulated sugar, salt and water is heated to 90-110 DEG C; then wheat flour is added into the mixture, and the mixture and the wheat flour are mixed fully to the temperature of 45-65 DEG C; an egg liquid is added for three times, and then stirring is performed until a paste is smooth, and the blank temperature is 40-60 DEG C; the stirred paste is poured into a crispy cake extruder and extruded into strips; the strips are baked at the tunnel oven temperature of 170-260 DEG C for 17-30 min; and baked semi-finished products are cut into strips, and the strips and a syrup are mixed, stirred and transmitted to a forming machine for cutting and forming. According to the production process of the French type crispy cakes, a braking processing technology and a physical mixing manner are adopted, no artificial addition colors and preservatives are caused, the egg content reaches up to 30%-40%, the nutritional values of products are increased, the golden luster is increased, a coagulation function is realized, and eggs are used as swelling agents, so that sizes of the products are increased, and the products are sweet and mellow in custard, crispy and agreeably sweet in taste; and added wheat flour cannot produce a burning smell, and the overall taste of the French type crispy cakes is improved.

Owner:NANJING HONGSENLIN FOOD

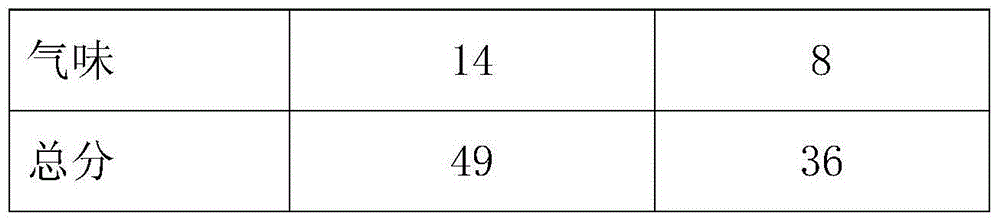

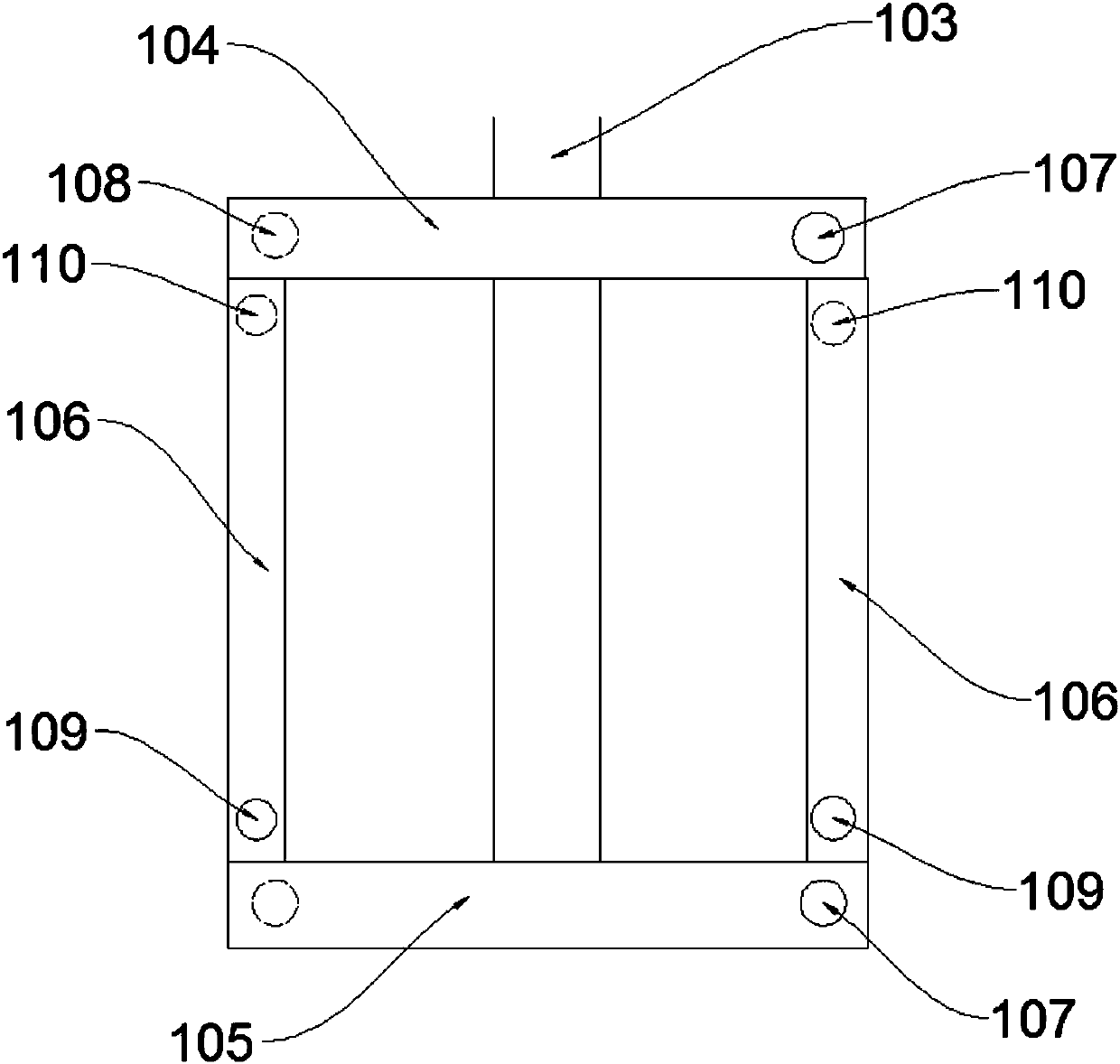

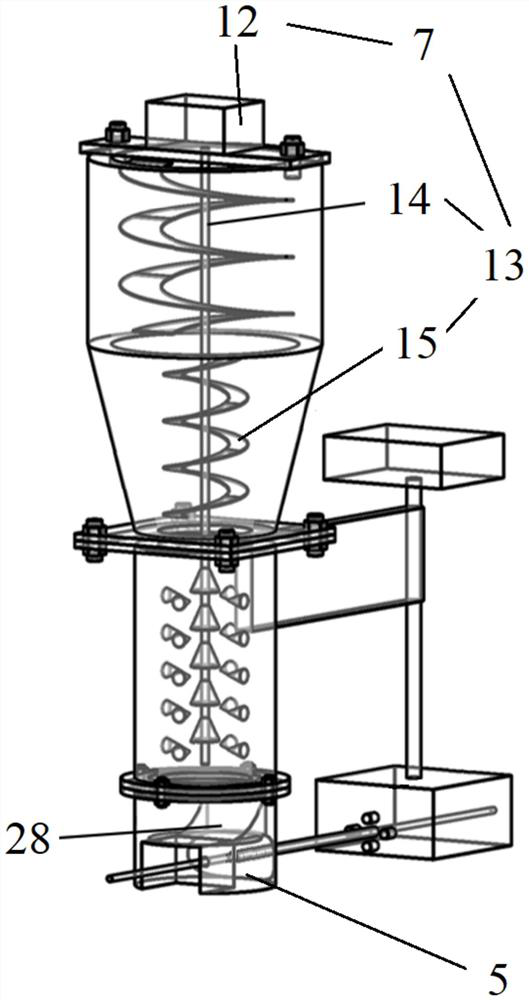

Fermentation reactor integrating functions of stirring and crusting breaking and stirring crust-breaking method

ActiveCN103396942AImprove gas production efficiencyImprove gas production performanceBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryProduction rate

The invention relates to a fermentation reactor integrating functions of stirring and crusting breaking and a stirring crust-breaking method, and the problems in the prior art are solved that an anaerobic reactor is low in gas production rate and low in gas productivity during fermentation. The fermentation reactor comprises a digester, a heat tracing band, a heat-insulation layer and a protective layer; the fermentation reactor also comprises a digester upper cover, a first stirrer with a frequency converter, a charge level indicator, a second stirrer with a frequency converter and a third stirrer with a frequency converter; the digester upper cover is buckled on the digester; the protective layer, the outer side wall of the digester is successively sleeved by the heat-insulation layer and the heat tracing band from outside to inside; the inner side wall of the digester is provided with a feed inlet; and the first stirrer with the frequency converter and the third stirrer with the frequency converter are disposed on the digester; the second stirrer with the frequency converter is disposed on the bottom inner wall of the digester. The fermentation reactor integrating the functions of stirring and crusting breaking is applied to the field of full-mixing anaerobic fermentation.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Processing technology for boron carbide neutron absorber

The invention relates to a process for preparing a neutron absorber for absorbing stray neutrons, and in particular relates to a processing technology for a boron carbide neutron absorber which is wide in raw material sources, low in processing cost and simple in process and can be applied in a collimator for effectively absorbing the stray neutrons. The processing technology comprises the following steps: 1), selecting raw materials; 2) selecting moulds; 3) stirring the raw materials; 4) pressurizing and mold-filling; 5) curing and molding; 6) demolding and molding. The boron carbide neutron absorber has easily-available raw materials, is simple in processing steps and low in cost; cold press molding is generally adopted, and the difficulty in the molding process is avoided; the molding or curing time can be greatly shortened on the premise of hot press, the curing speed is increased, and the yield is improved; moreover, according to the boron carbide neutron absorber prepared by processing, the good neutron absorption can be realized, and therefore, the processing technology for boron carbide neutron absorber is suitable for industrial development and can bring long-term economic benefit.

Owner:DONGGUAN UNIV OF TECH +8

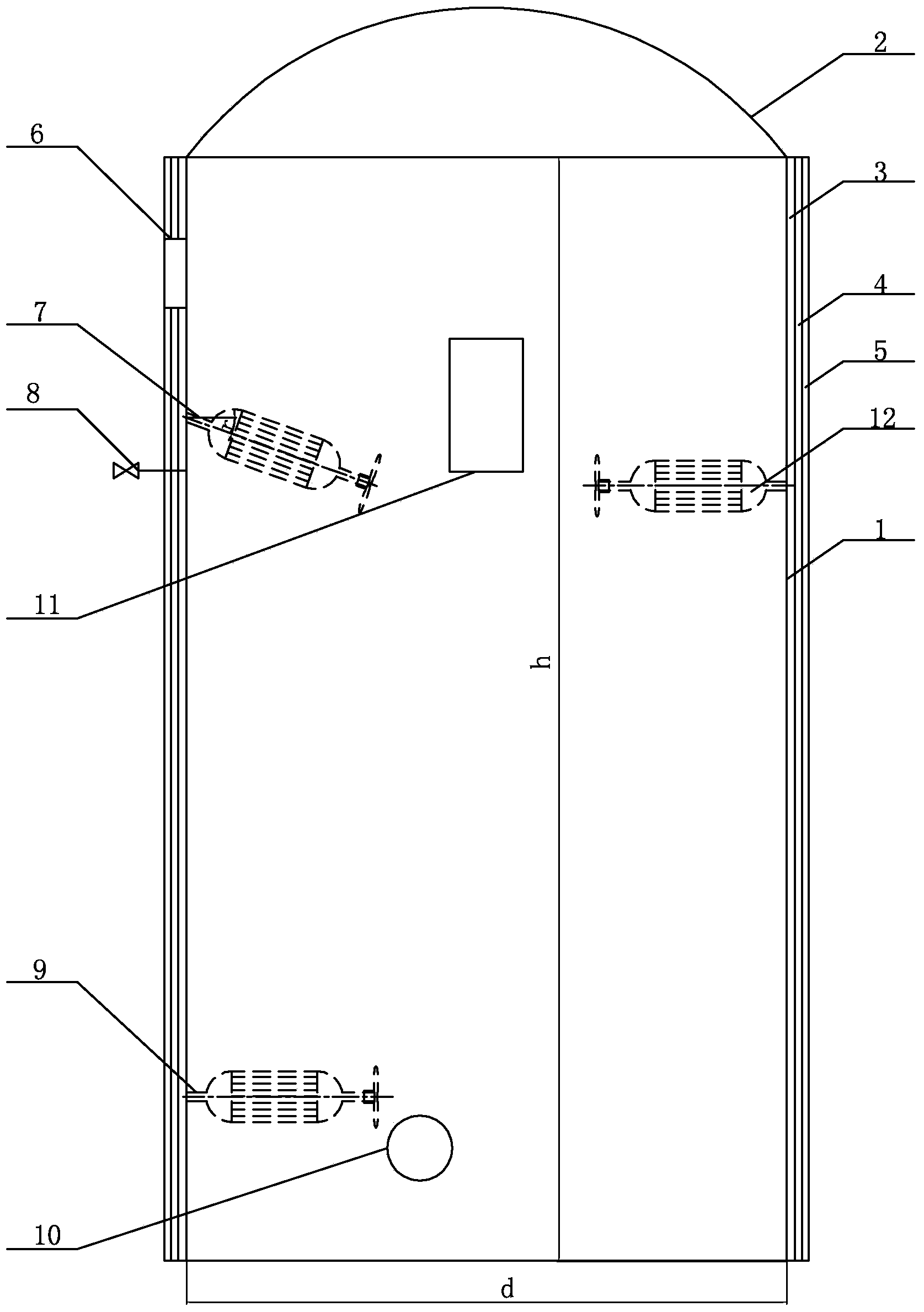

Oblique irrigation apparatus used for growth of blueberries

InactiveCN108934375AAvoid wastingAvoid harmRotary stirring mixersTransportation and packagingWater sourceEngineering

The invention discloses an oblique irrigation apparatus used for growth of blueberries, which includes a water tank and a branch pipe. A water valve is arranged below the water tank. A shutoff valve is installed at the left-lower side of the water valve. A fertilizing barrel is arranged under the shutoff valve. A motor is installed on the top of the fertilizing barrel. A stirring shaft is connected at the lower side of the motor. Stirring blades are arranged on the surface of the stirring shaft. A main pipe is connected to the right side of the shutoff valve. A filter is arranged on the outerside of the main pipe. An electromagnetic valve is disposed on the right side of the filter. A support is disposed under the filter. A pressure regulator is arranged on the outer side of the branch pipe which is located at the right-lower side of the main pipe. The water tank supplies water to the whole irrigation apparatus and the water valve is used for controlling the water source for preventing waste. Meanwhile, after irrigation is finished, the water valve can be closed timely. The fertilizing barrel is used for accommodating a fertilizer required in growth of blueberries.

Owner:安徽徽王农业有限公司

Fertilizer special for edible mushroom

The fertilizer specially for edible mushroom is composite mixed fertilizer comprising organic material and inorganic material, and consists of organic matter 20-61 wt%, azophoska 6-21 wt%, trace elements 1.5-2.8 wt% and water and impurity 30-58 wt%. The production process includes crushing the material, mixing in stirrer, and packing. The special fertilizer can meet the requirement of edible mushroom in N, P, K, Ca, S, trace elements and organic matter, and can raise the yield and quality of edible mushroom.

Owner:马春安

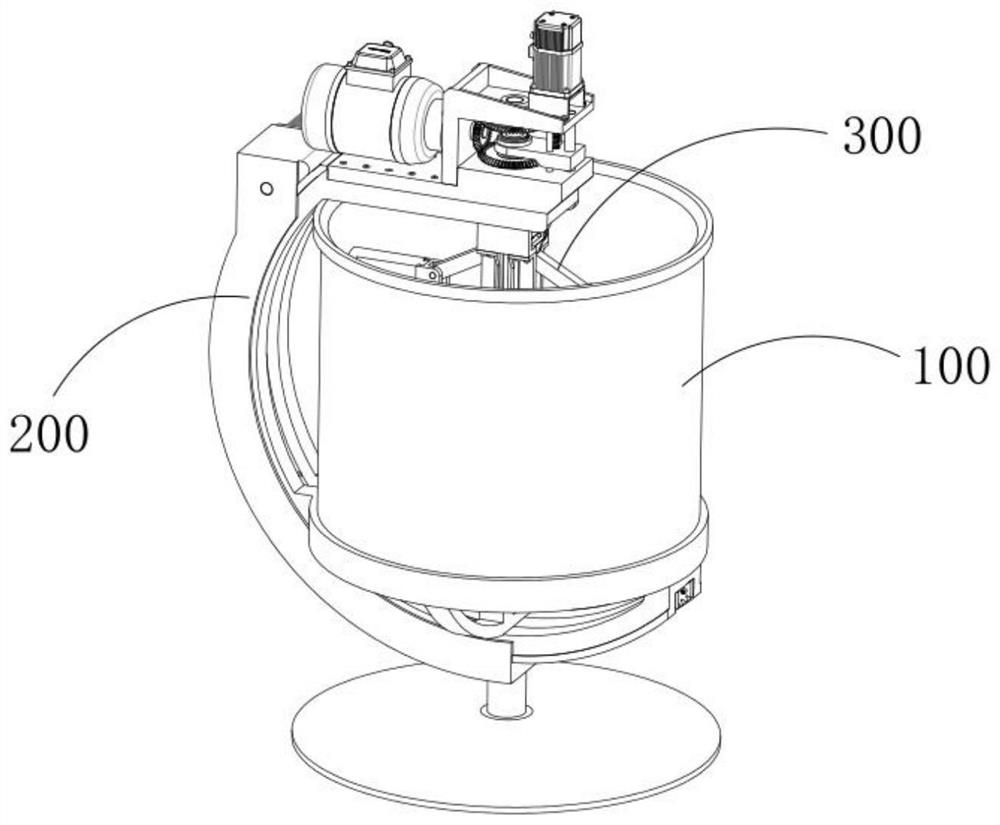

Different-direction stirring and mixing method for chemical raw materials

ActiveCN110652906AReduce labor intensityGood mixing effectRotary stirring mixersTransportation and packagingProcess engineeringBLENDER/MIXER

The invention discloses a different-direction stirring and mixing method for chemical raw materials. The method comprises the following steps: sequentially putting to-be-stirred materials into a stirring tank by an operator; fully and uniformly stirring the obtained inner ring mixture by using an inner ring stirring part; fully and uniformly stirring the obtained outer ring mixture by an outer stirring part during the stirring of the inner ring mixture with the inner stirring part; stopping running of a different-direction stirring mechanism after the mixture is fully and uniformly stirred, turning on an automatic pouring mechanism to make the stirring tank obliquely arranged in order to pour out the uniformly stirred mixture in the stirring tank, reversely running the automatic pouring mechanism to recover the stirring tank to the original position, and performing the next round of mixture stirring. The whole mixture discharging process is fully automatic without manual operation of workers, so the labor intensity of the workers is greatly reduced; and the inner ring and outer ring different-direction stirring mode is adopted, so the mixture can be fully and evenly stirred, and the stirring effect is good.

Owner:重庆安盛钾业有限公司

Automatic slag splashing control method and system for converter

ActiveCN112981033AHigh viscosityHigh melting pointManufacturing convertersProcess efficiency improvementSlagControl system

The invention discloses an automatic slag splashing control method and system for a converter, and belongs to the technical field of converter slag splashing furnace protection. The control method comprises the steps that firstly, final slag conditions are classified according to the end point oxygen content, the end point carbon content and the residual manganese yield range in molten steel; secondly, according to different final slag conditions, slag adjusting materials with the corresponding weights are selectively added into the converter to adjust the viscosity of the slag, and the content of magnesium oxide in the final slag is made to be 10%-15%; and thirdly, corresponding slag splashing gun position curves are selected according to different final slag conditions, and the control system is used for carrying out automatic slag splashing operation. The automatic slag splashing control method and system have the beneficial effects that the slag adjusting materials with corresponding weights are added according to the different final slag conditions for slag adjusting, the corresponding slag splashing gun positions are automatically selected, the automatic slag splashing operation is completed, and the slag splashing operation is standardized. The labor intensity of workers is lowered, the slag splashing time is shortened, the nitrogen consumption is reduced, and the furnace profile can be more stable to maintain.

Owner:新余钢铁股份有限公司

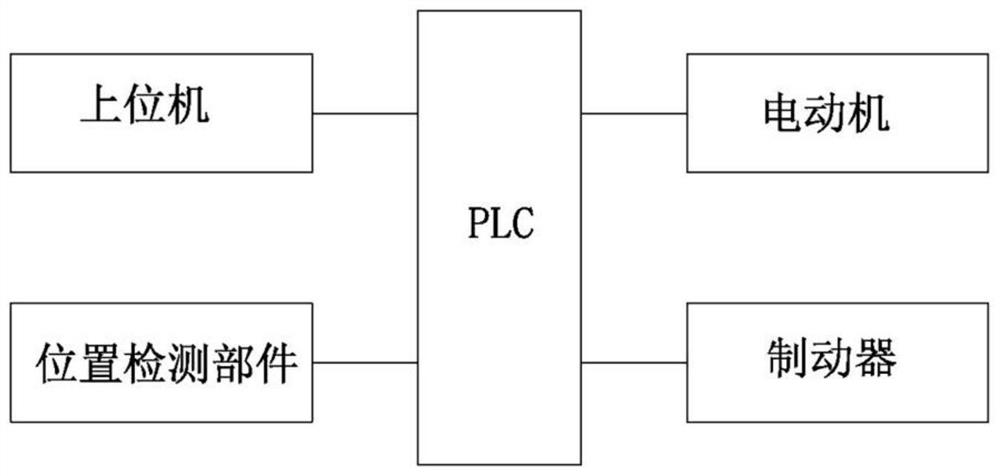

Industrial liquid filling robot

InactiveCN107839913AEasy to produceHigh degree of automationLiquid materialLiquid storage tankBottle

The invention discloses an industrial liquid filling robot which is arranged above a conveyor belt for conveying filling bottles. The industrial liquid filling robot comprises a rack, a plurality of liquid storage tanks, a liquid mixing tank and a plurality of filling mechanisms, wherein the rack is arranged at one side of the conveyor belt; a first stirring mechanism is arranged in each liquid storage tank; the liquid mixing tank communicates with each liquid storage tank through a first pipeline, and a second stirring mechanism is arranged in the liquid mixing tank; each filling mechanism isconnected with the liquid mixing tank through a second pipeline with a one-way valve, so that liquid only can enter a quantitative filling barrel from the liquid mixing tank; and of the bottom of each filling mechanism is equipped with a vertical downward filling tube, and an outlet end of the filling tube extends to a bottleneck of each filling bottle, so that continuous filling of liquid is realized. The industrial liquid filling robot can realize direct mixing and filling of various liquids, is high in degree of automation, does not need a great deal of manual-assisted filling, and has excellent filling capacity for liquids.

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

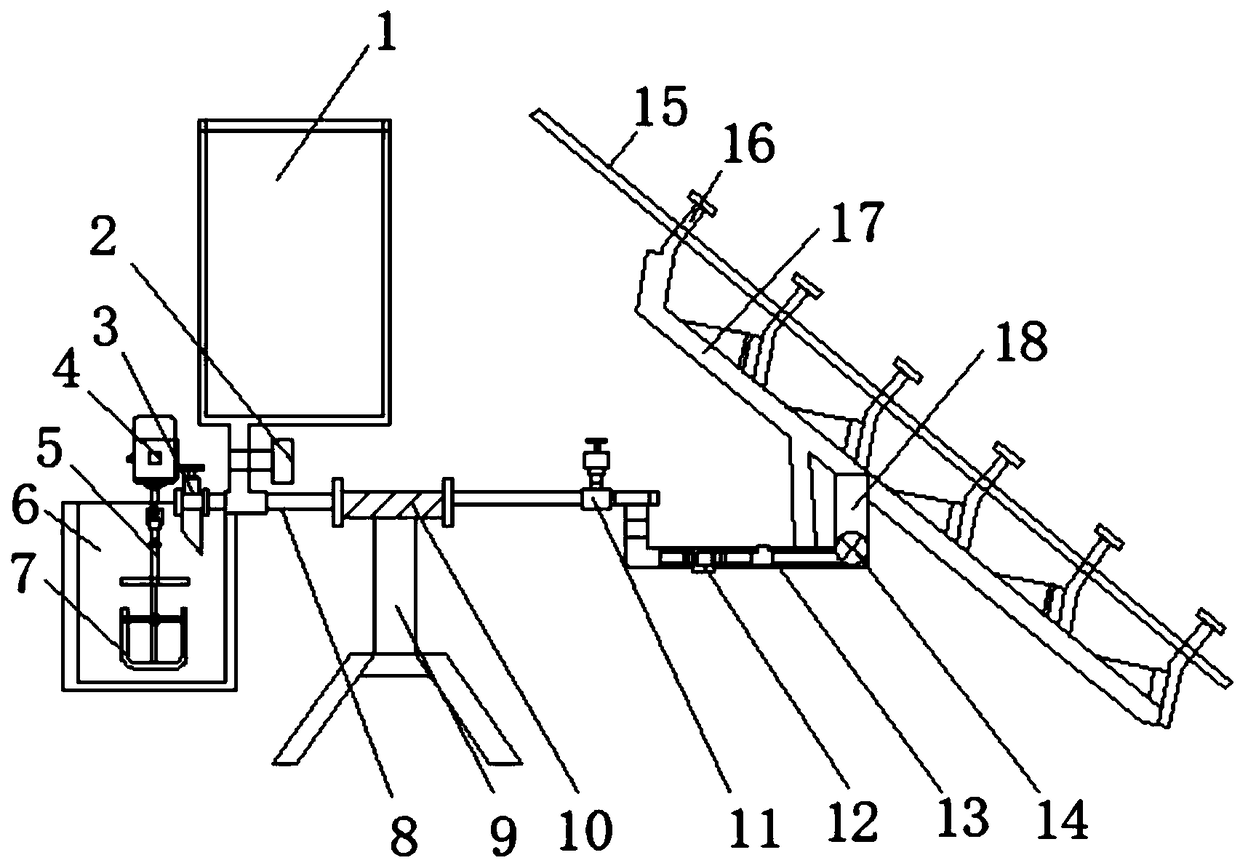

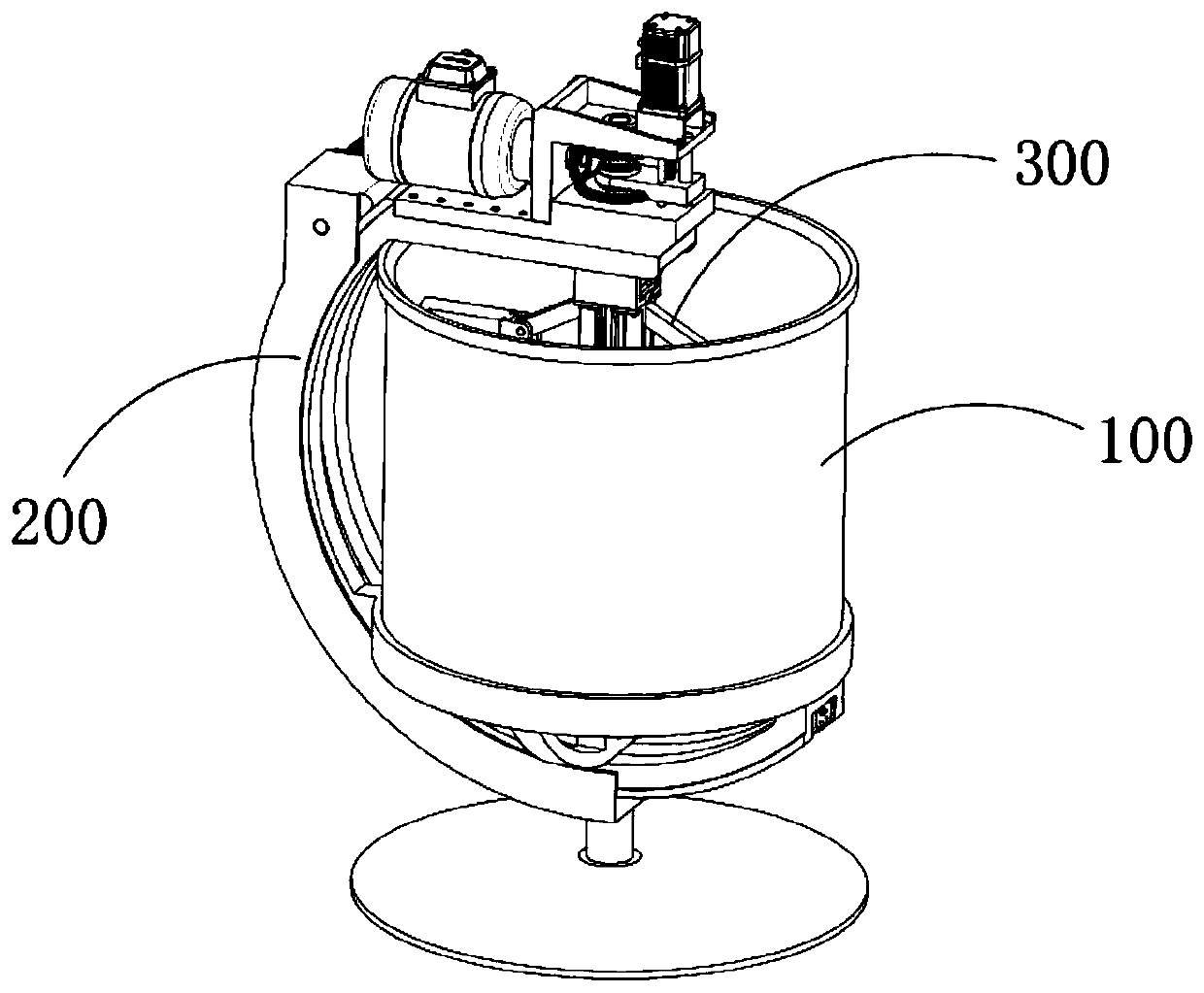

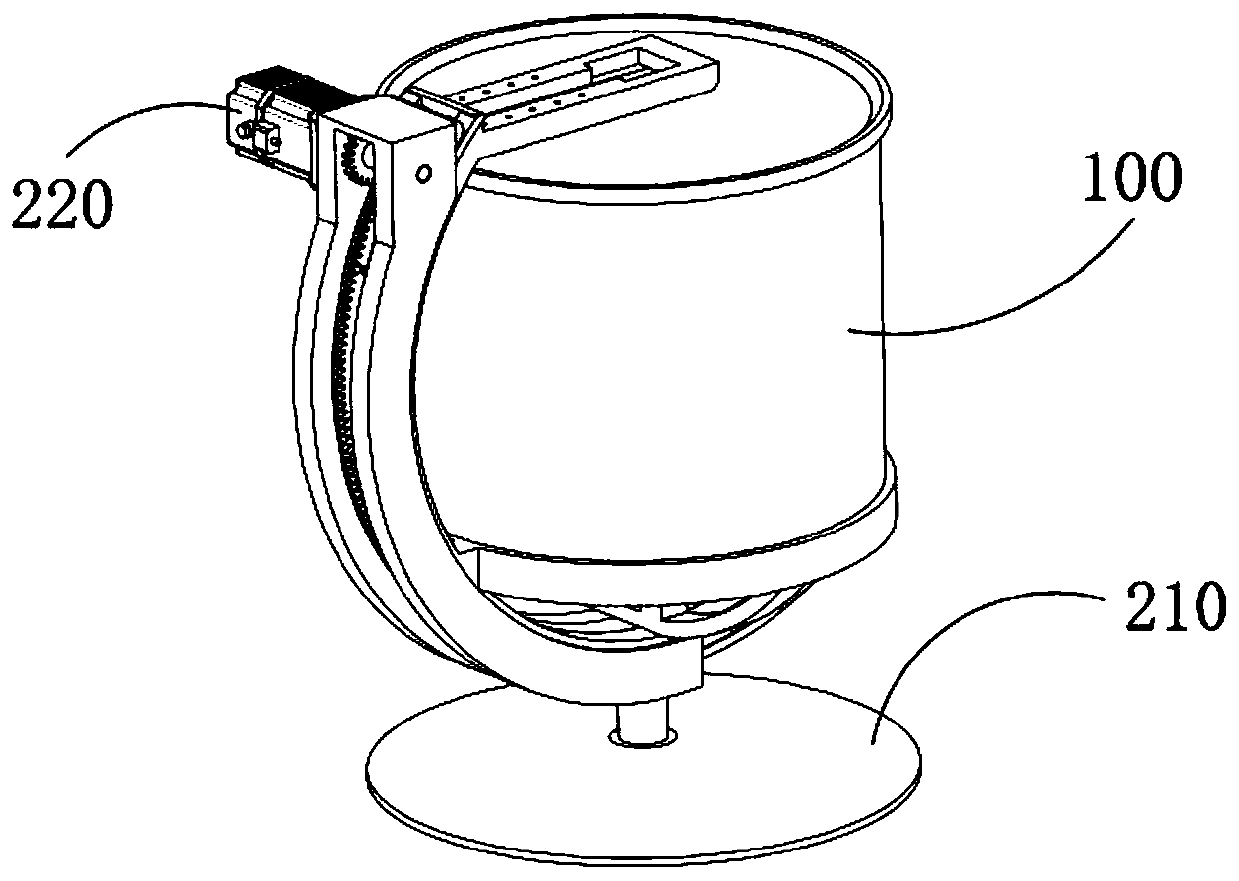

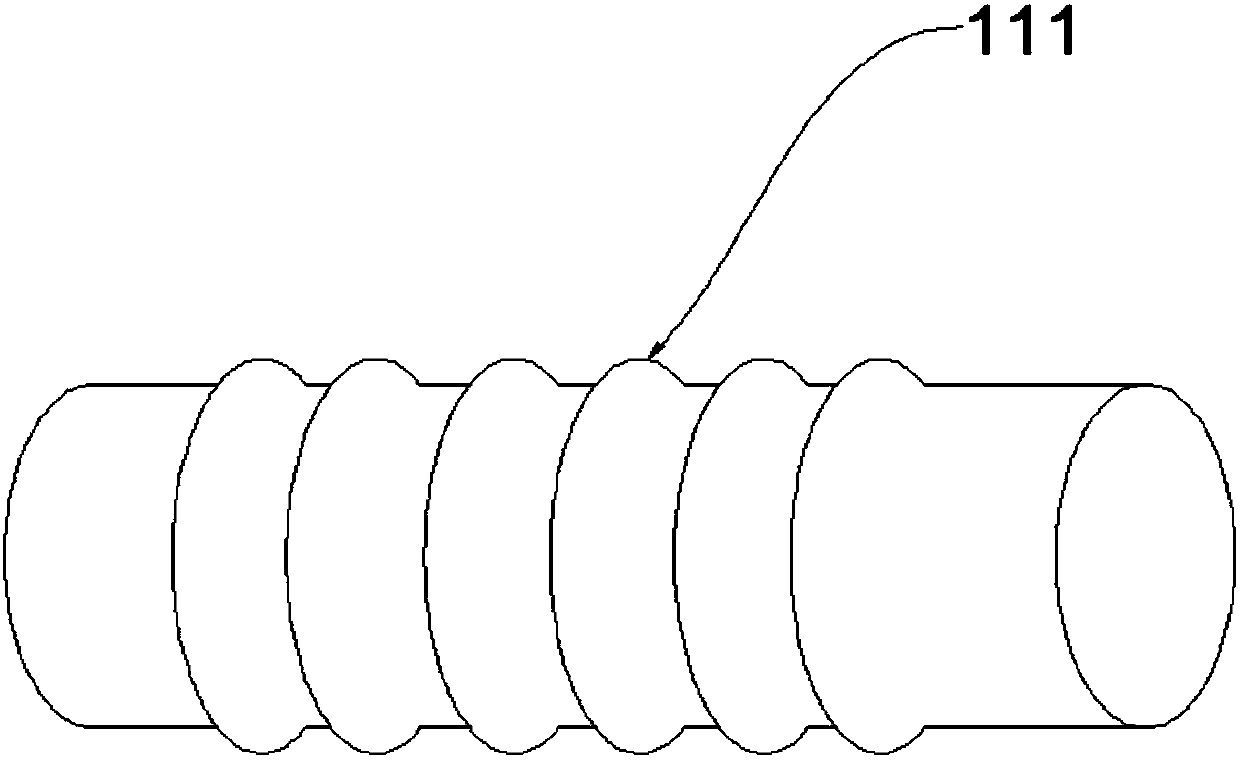

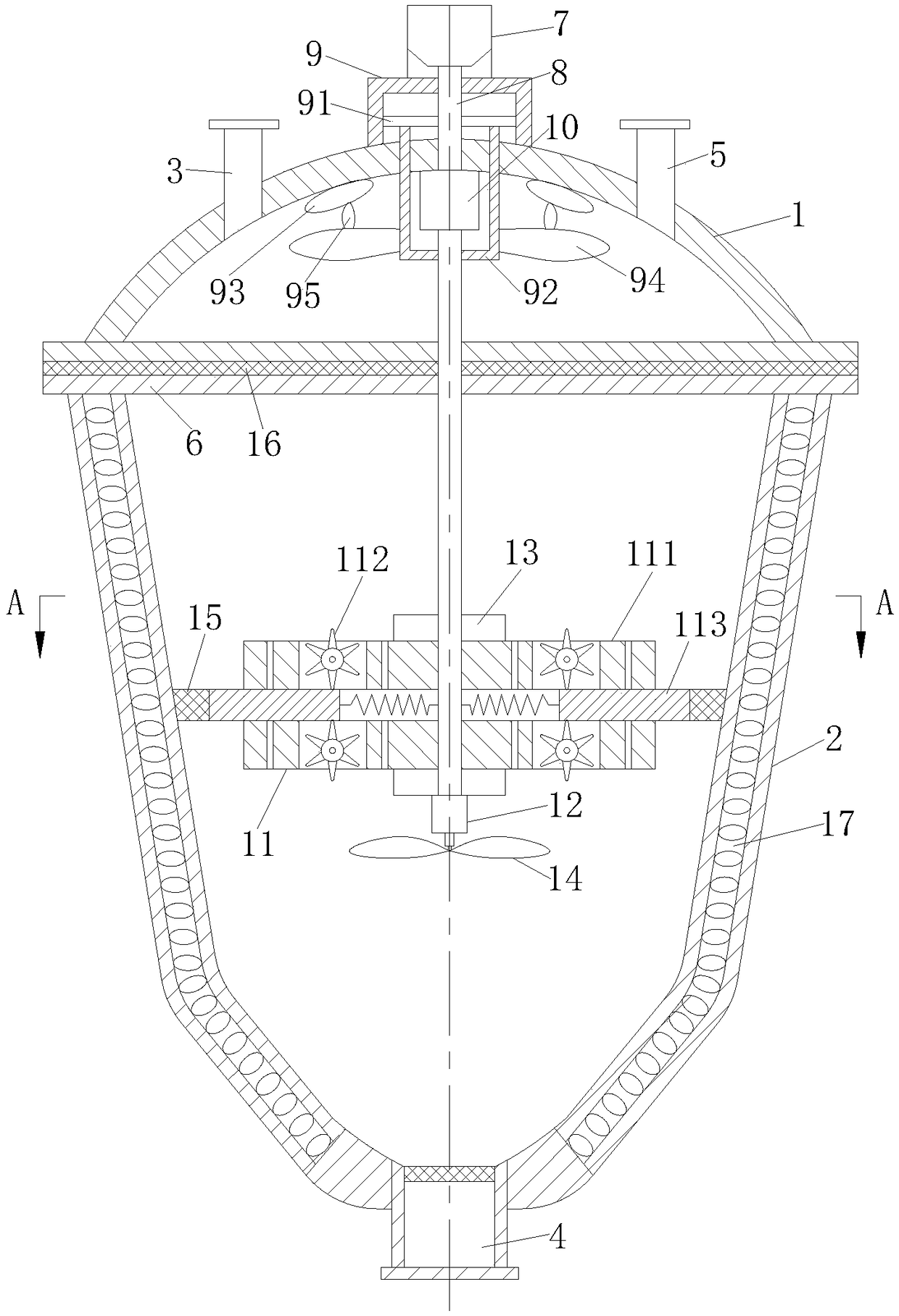

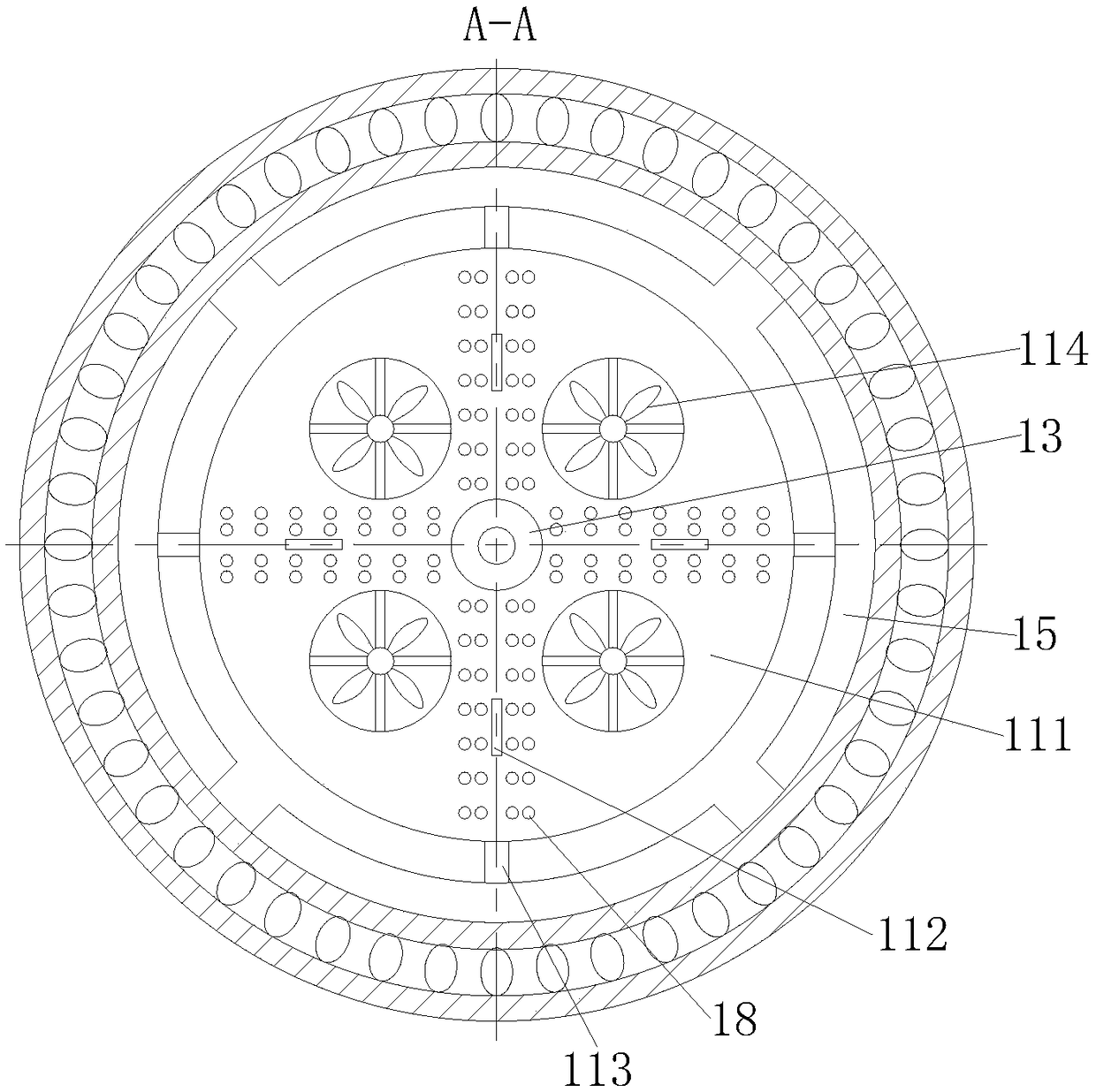

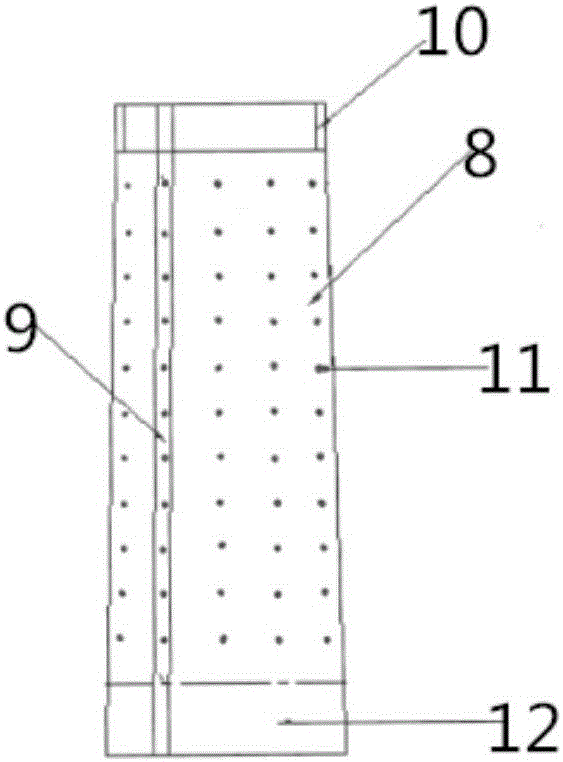

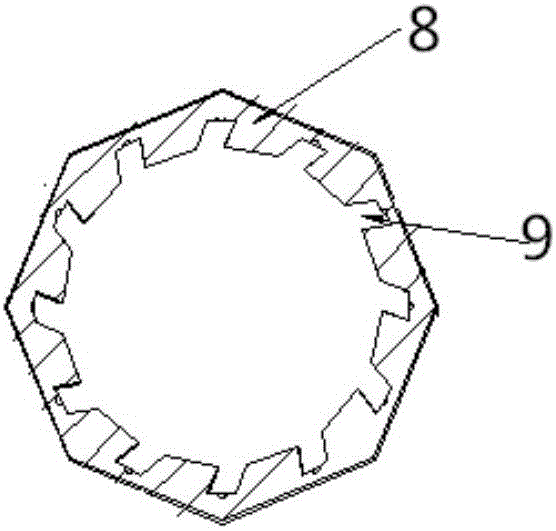

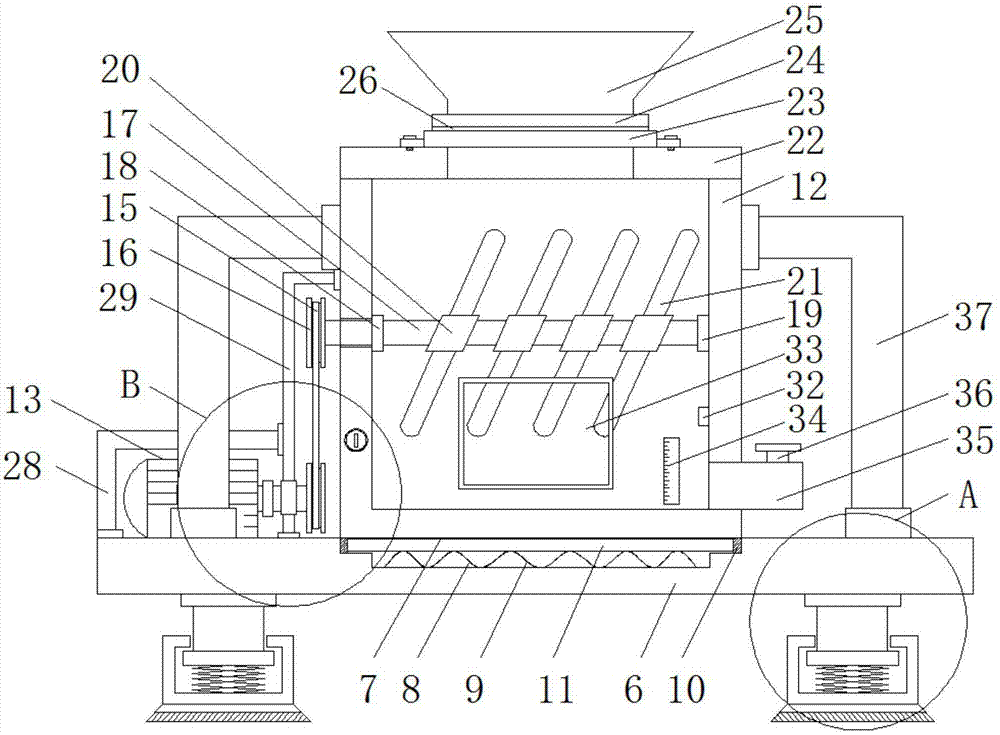

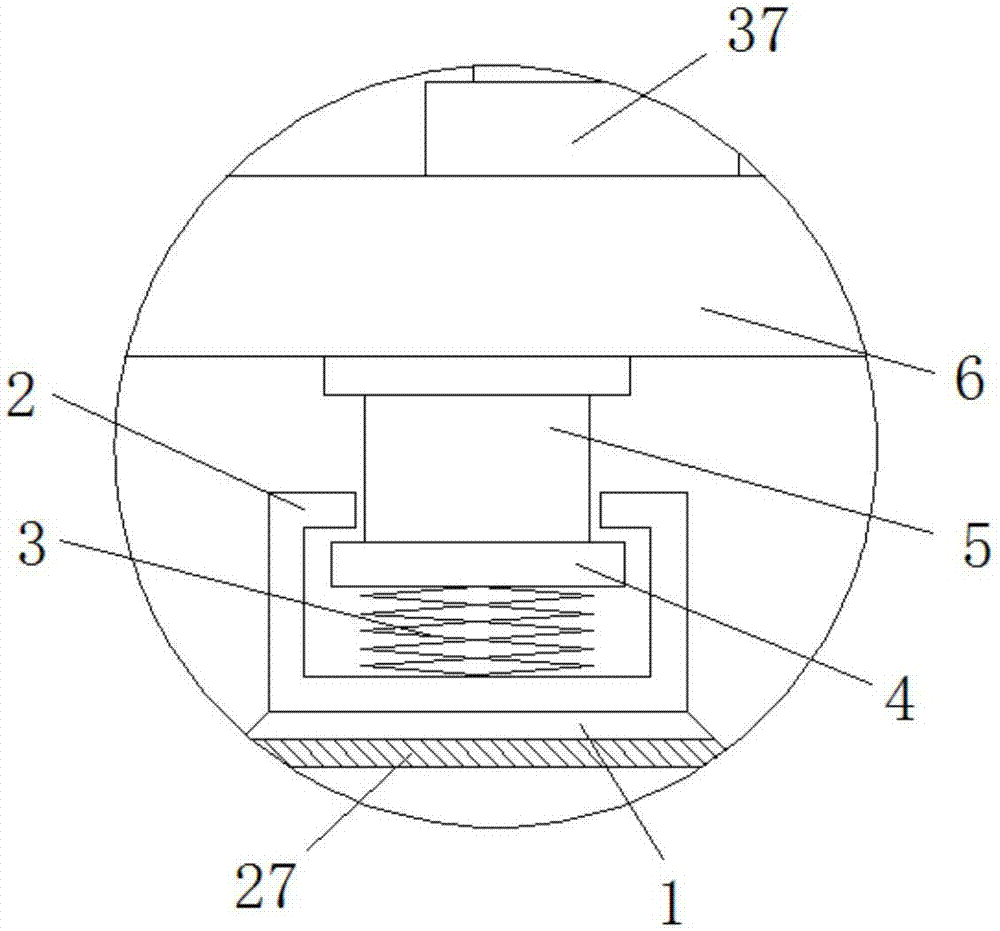

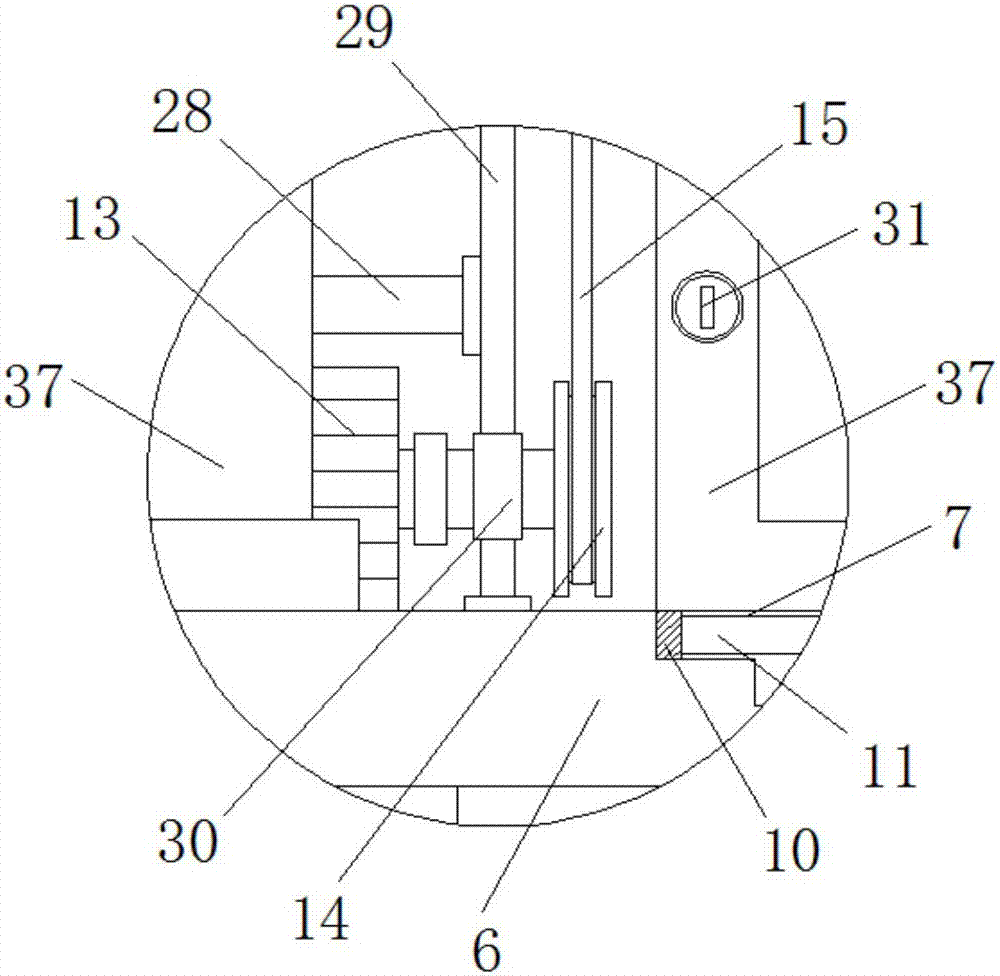

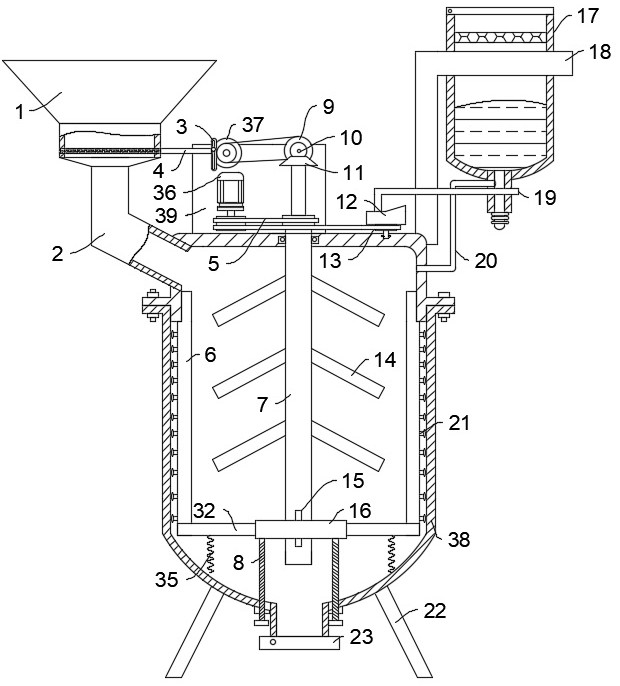

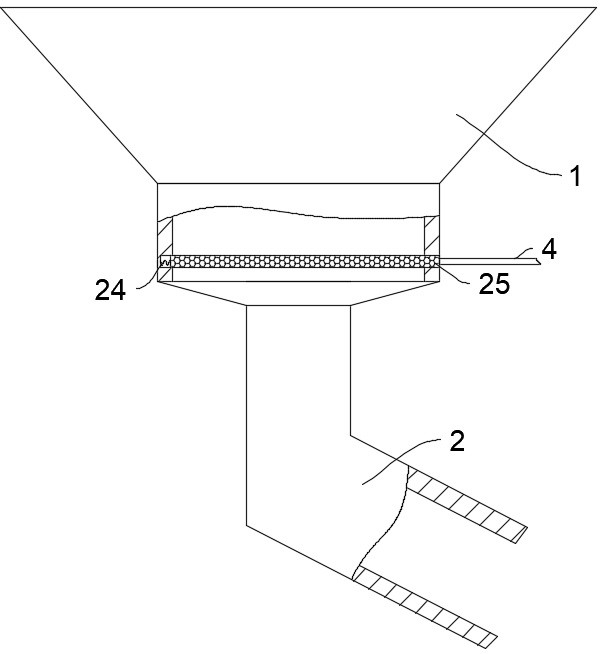

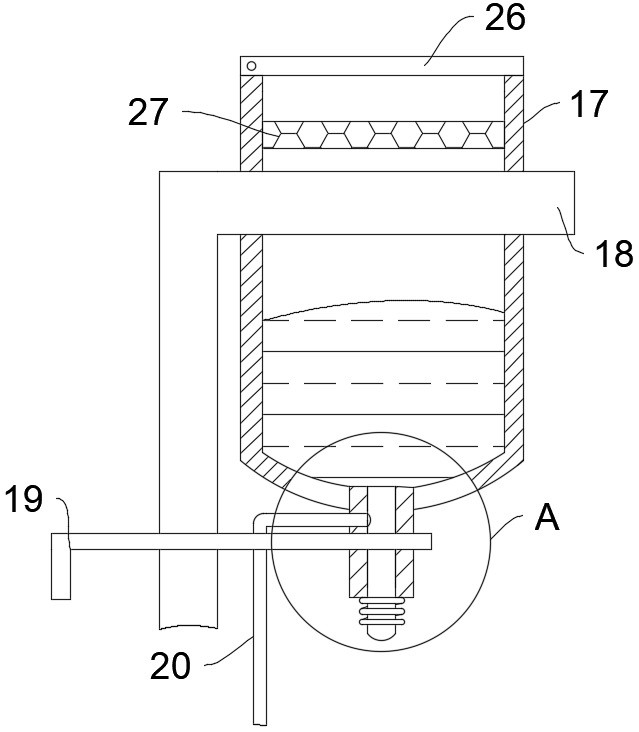

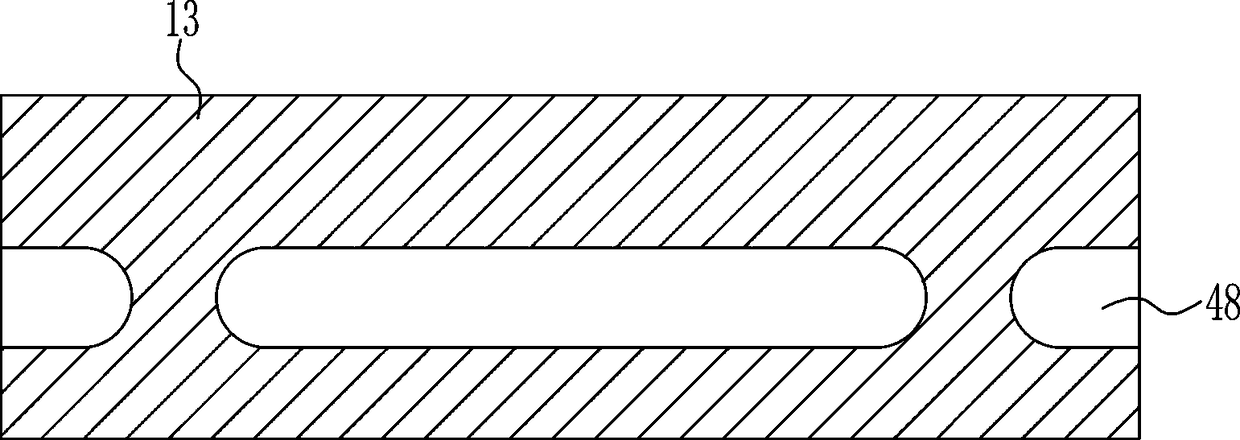

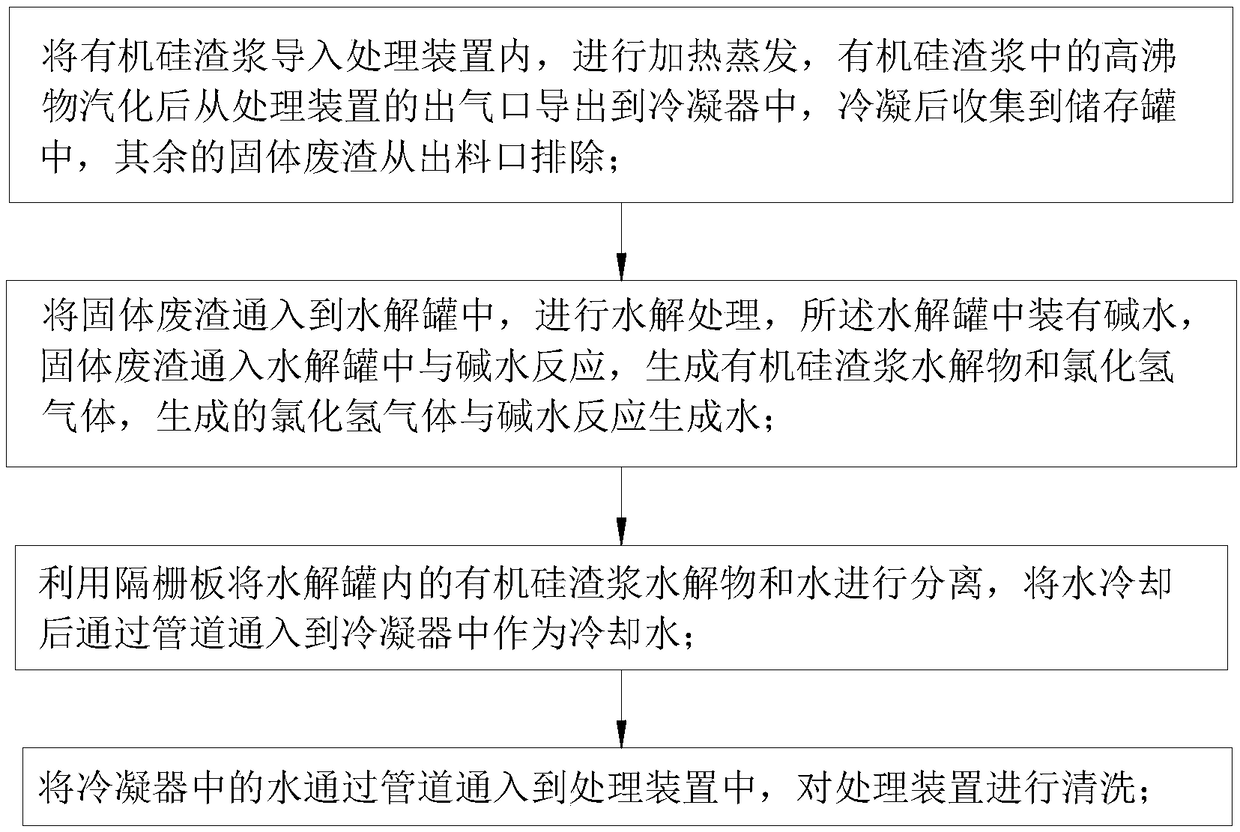

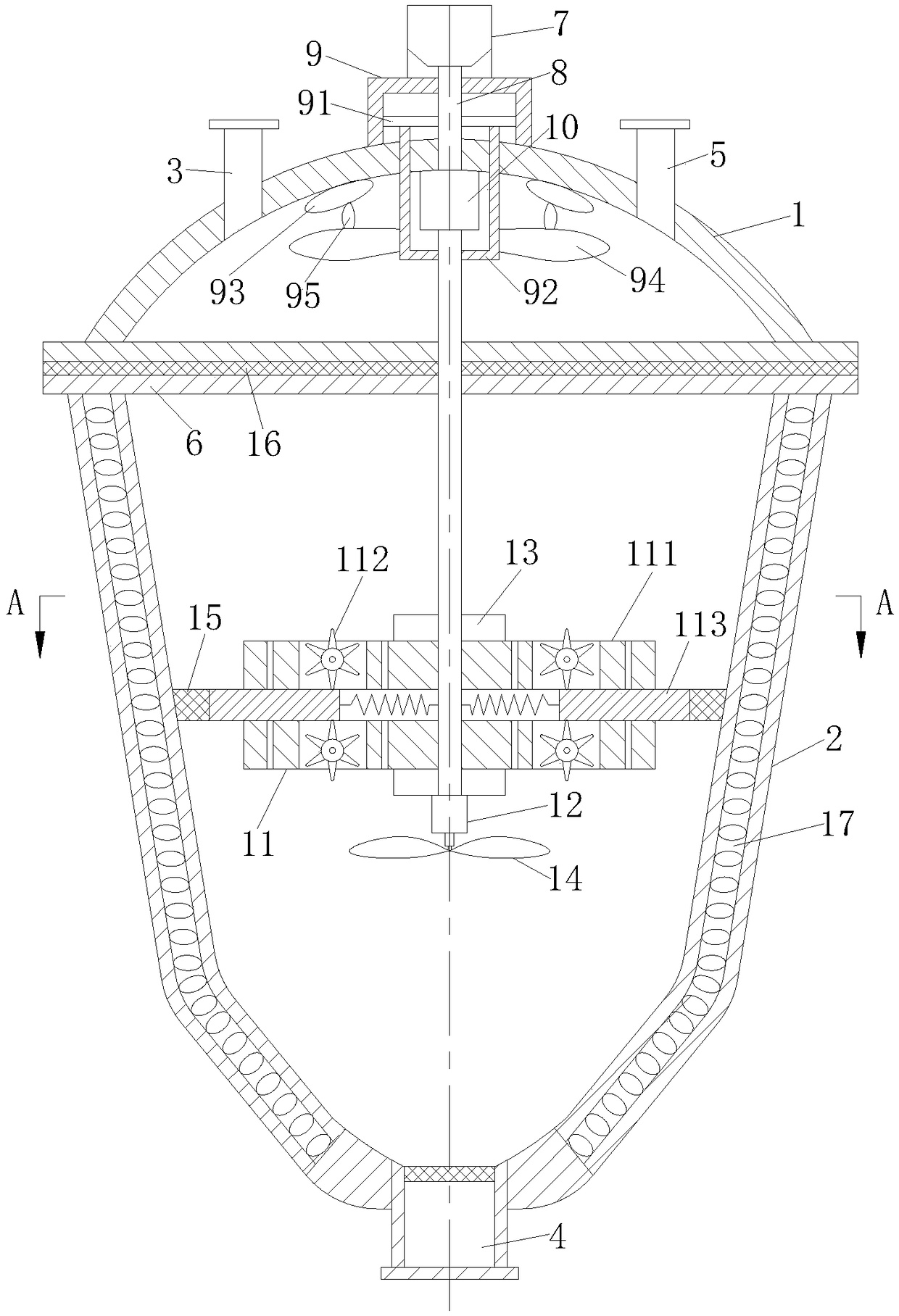

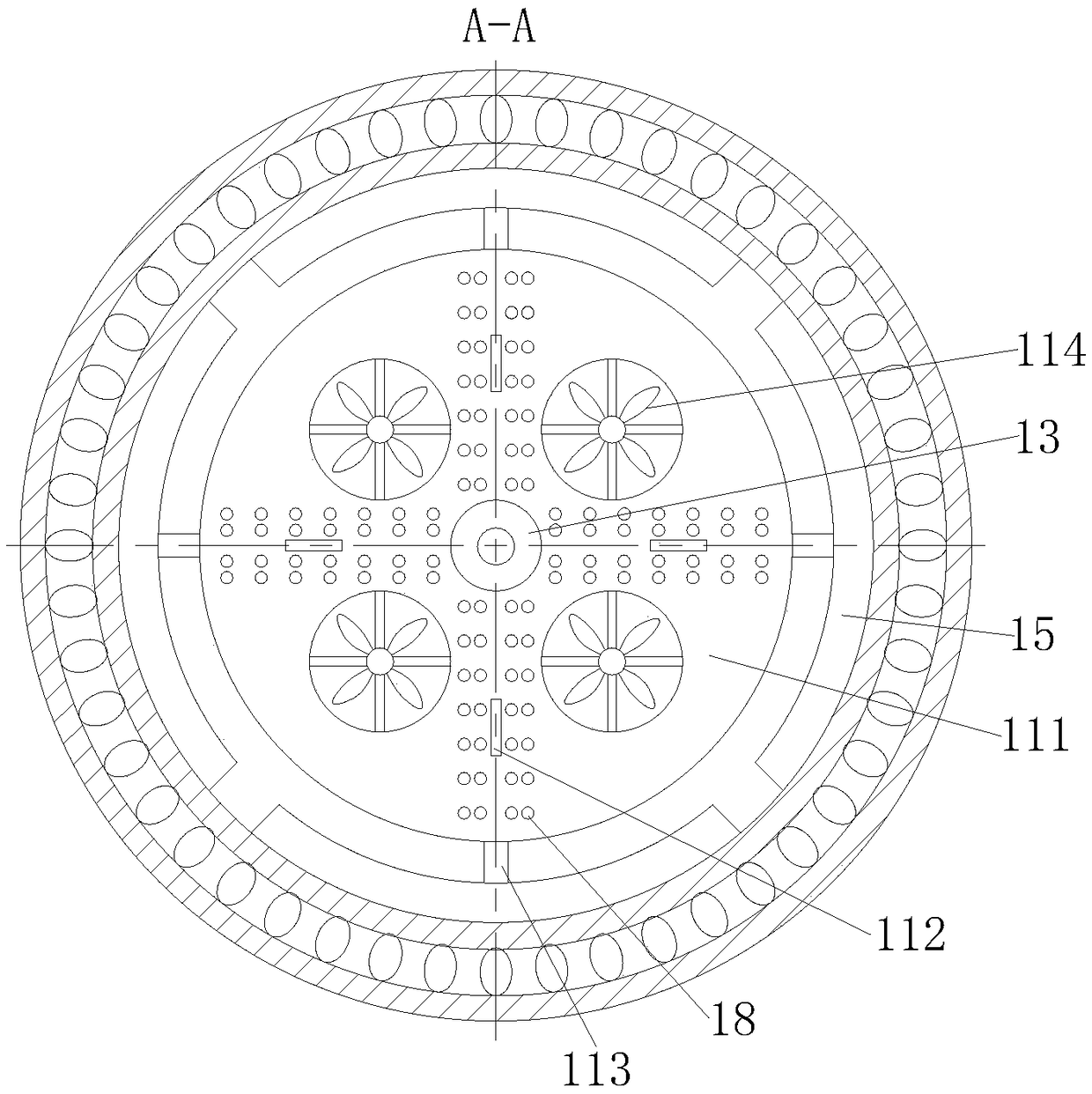

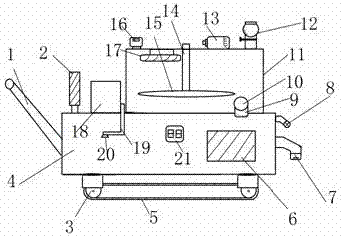

Silicone residue slurry treatment device

ActiveCN109157852AStir wellStir well stir wellEvaporator accessoriesEvaporator regulation/controlBiochemical engineeringEvaporation

The invention belongs to the technical field of silicone production and in particular discloses a silicone residue slurry treatment device. The silicone residue slurry treatment device comprises a tank cover, a tank body, a feeding hole, a discharging hole and an air outlet, wherein the feeding hole and the air outlet are formed in the tank cover; the tank cover and the tank body are connected bya flange; the tank body is conical; the discharging hole is formed in the bottom of the tank body; a controller is arranged on the outer side of the tank body; the motor is arranged on a mounting bracket; the output shaft of the motor is connected with a rotating shaft; the middle of the supporting rod is fixedly connected onto the rotating shaft; the top of the support frame is fixedly connectedonto the supporting rod; the bottom of the rotating shaft is fixedly connected with a cylinder I; a telescopic rod of the cylinder I penetrates through the bottom of the support frame and is connectedwith a stirring module. According to the silicone residue slurry treatment device disclosed by the invention, the stirring module is driven to rotate by the cylinder I, and silicone residue slurry inthe tank body is stirred in a top-and-down reciprocating manner, so that the silicone residue slurry is fully stirred, and the evaporation efficiency of the device is improved.

Owner:淮北亚荣科技有限公司

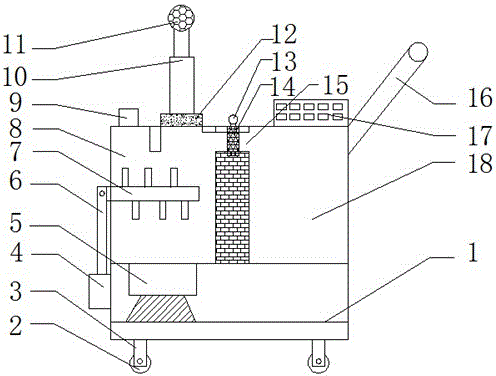

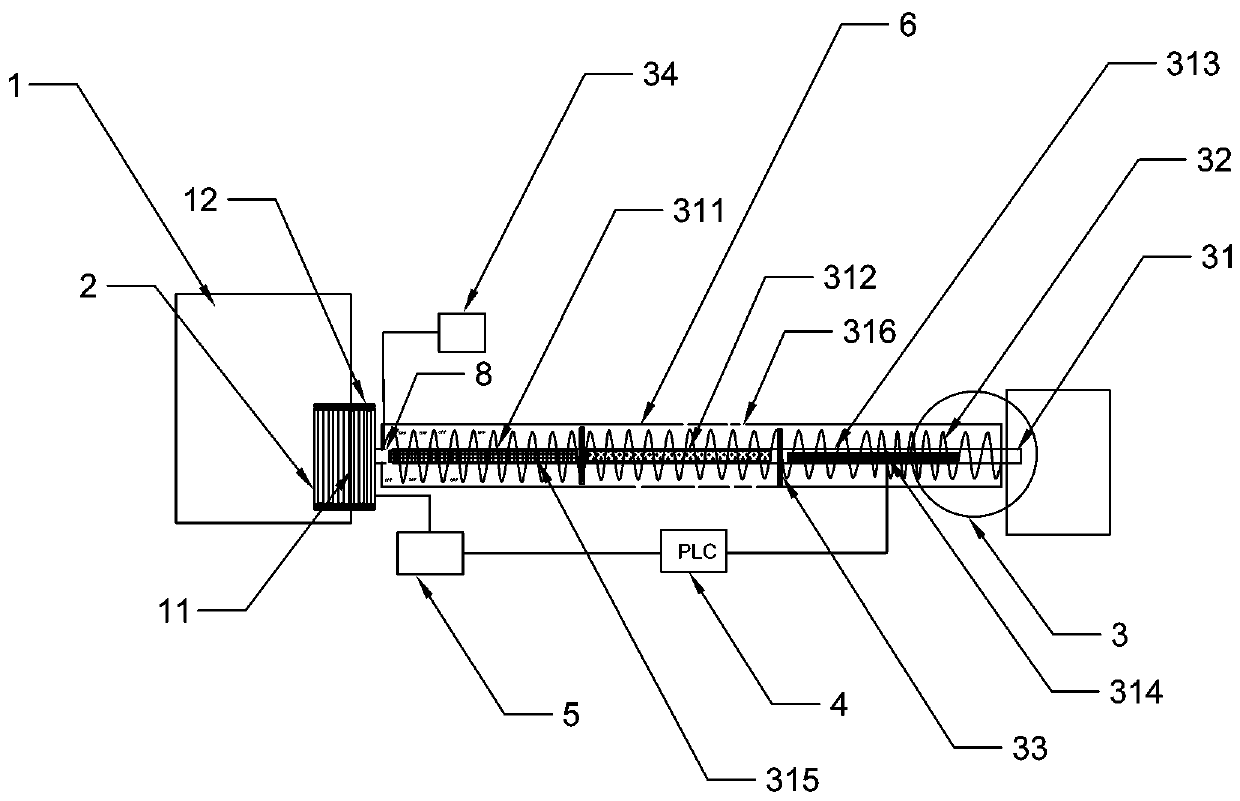

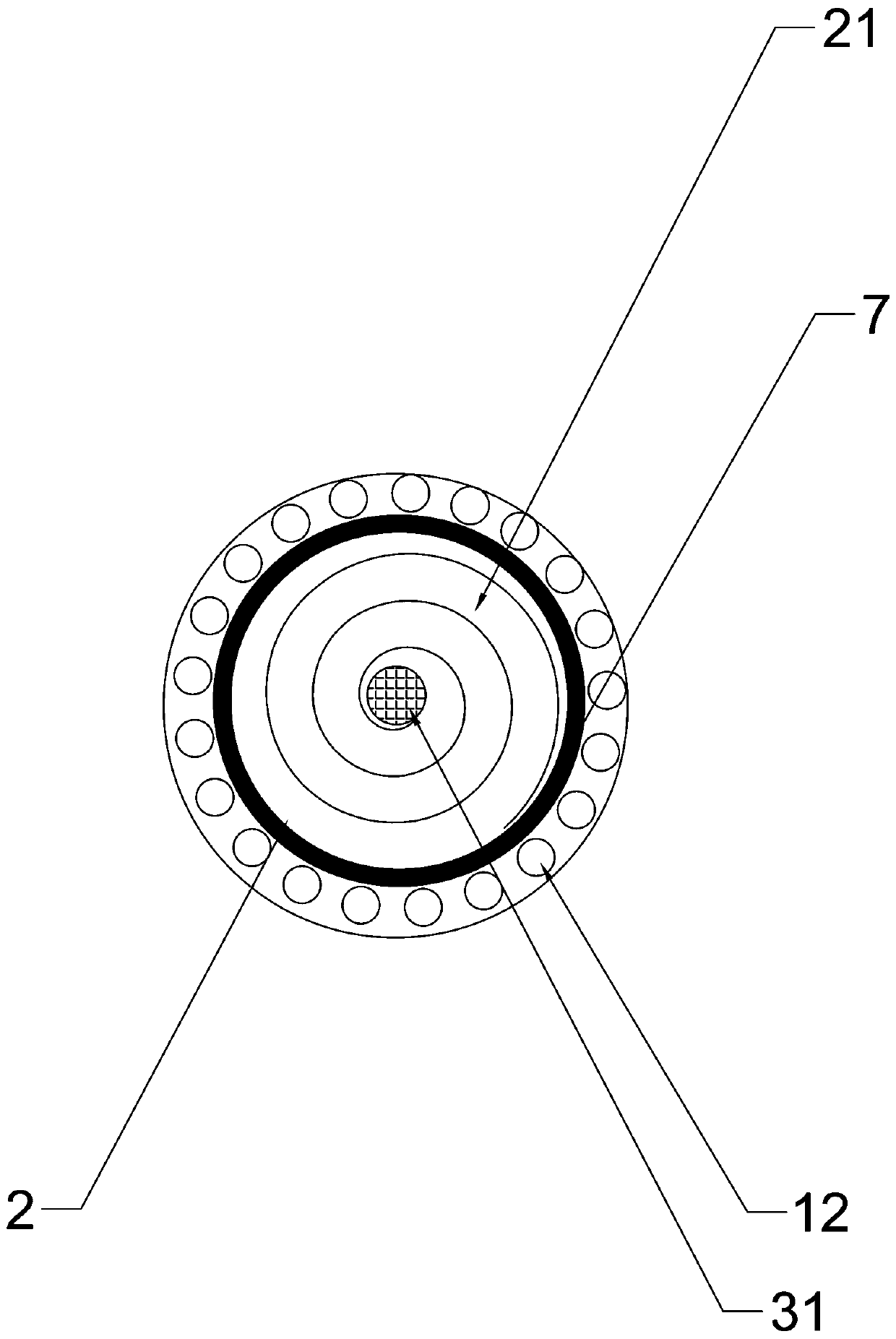

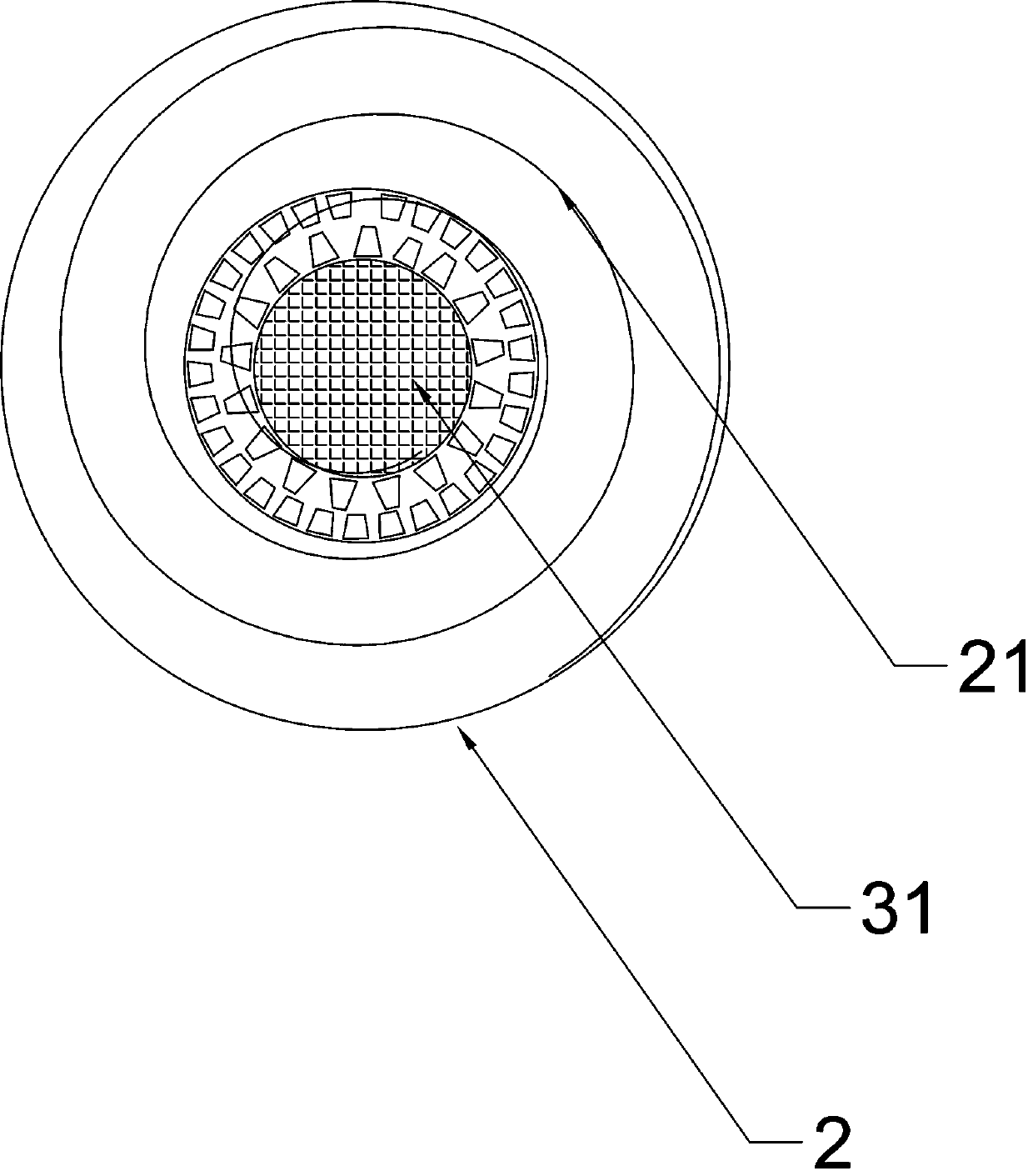

Industrial gas ultralow-nitrogen energy-saving spiral combustion head and combustor

The invention discloses an industrial gas ultralow-nitrogen energy-saving spiral combustion head and belongs to the technical field of gas combustion devices. The spiral combustion head comprises an outer cylindrical wall; an inner cylindrical wall is sleeved inside the outer cylindrical wall; the outer cylindrical wall and the inner cylindrical wall are connected into an integrated structure through a spiral bulge; air outlet holes are uniformly distributed in the bottom of the inner cylindrical wall; a fire outlet hole is formed in the top of the outer cylindrical wall; and the bottom of the outer cylindrical wall is provided with a combustion head connecting section. The invention also discloses a combustor comprising the spiral combustion head. By using the spiral combustion head disclosed by the invention, a flame rotates in a fixed direction, so that the heat exchange efficiency is increased, and the utilization ratio of heat energy is increased; meanwhile the combustion speed of the flame is stabilized, so that flame lifting and backfire are avoided; by using the combustor comprising the spiral combustion head, the radiated heat energy can be increased, so that a nitrogen reducing effect is achieved; and air and gases are sufficiently and uniformly stirred in a mixing pipe, so that an air / fuel ratio approaching to a theoretical value is achieved.

Owner:江苏弗雷姆环境科技有限公司

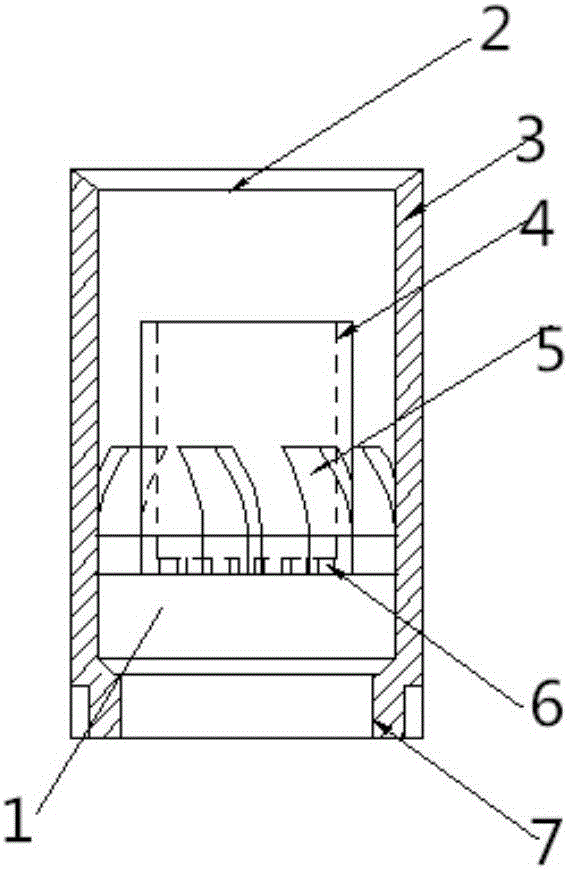

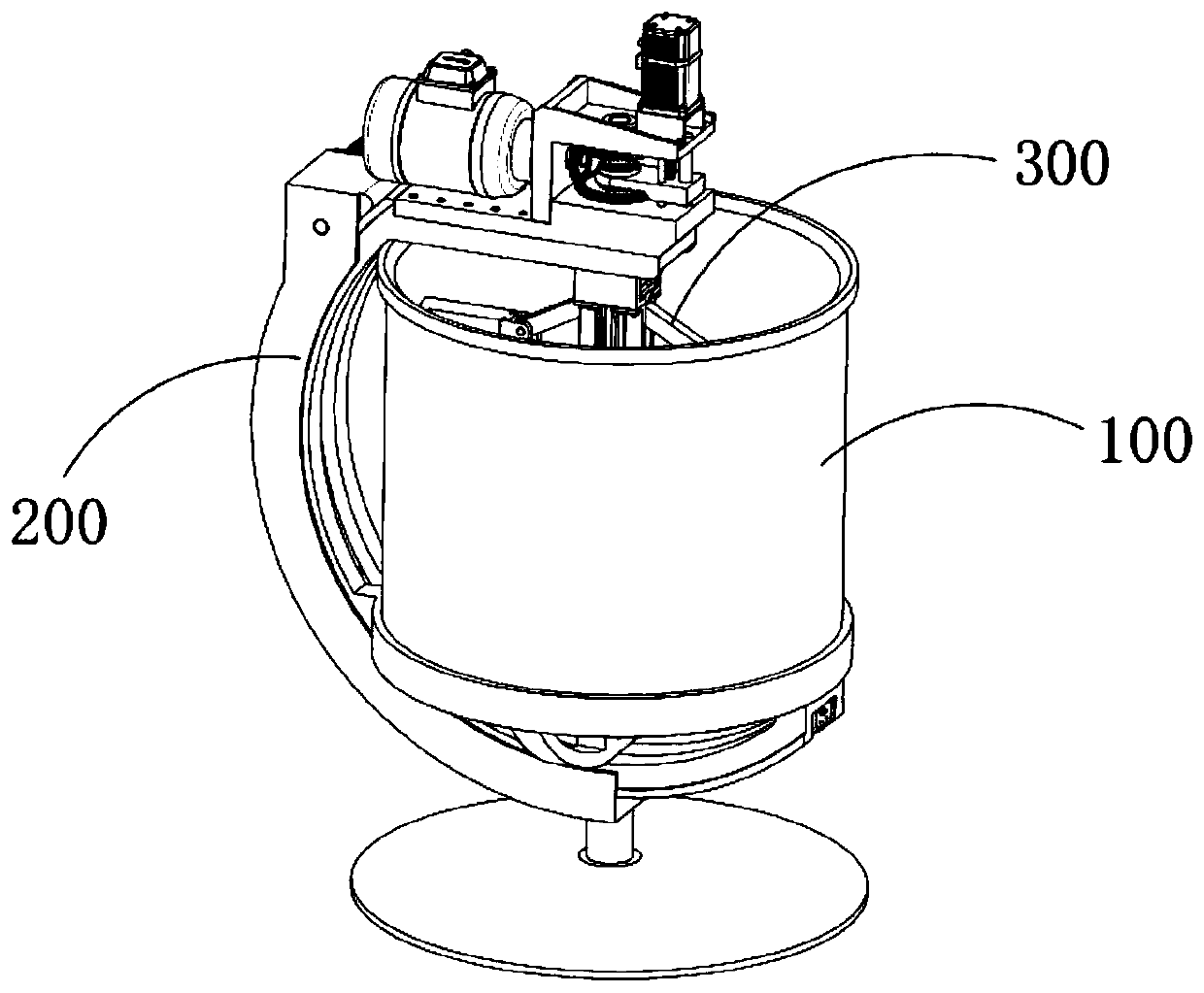

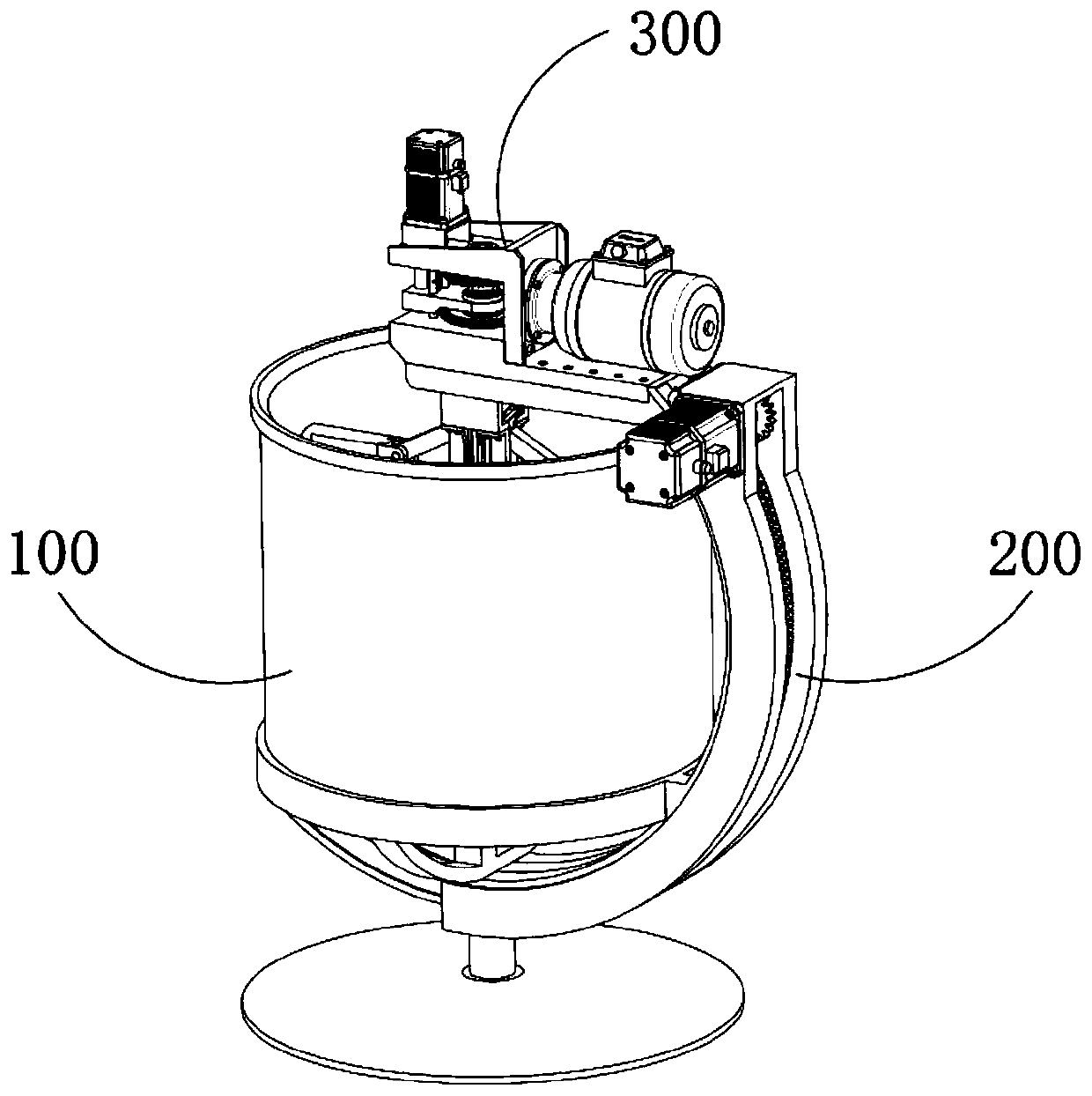

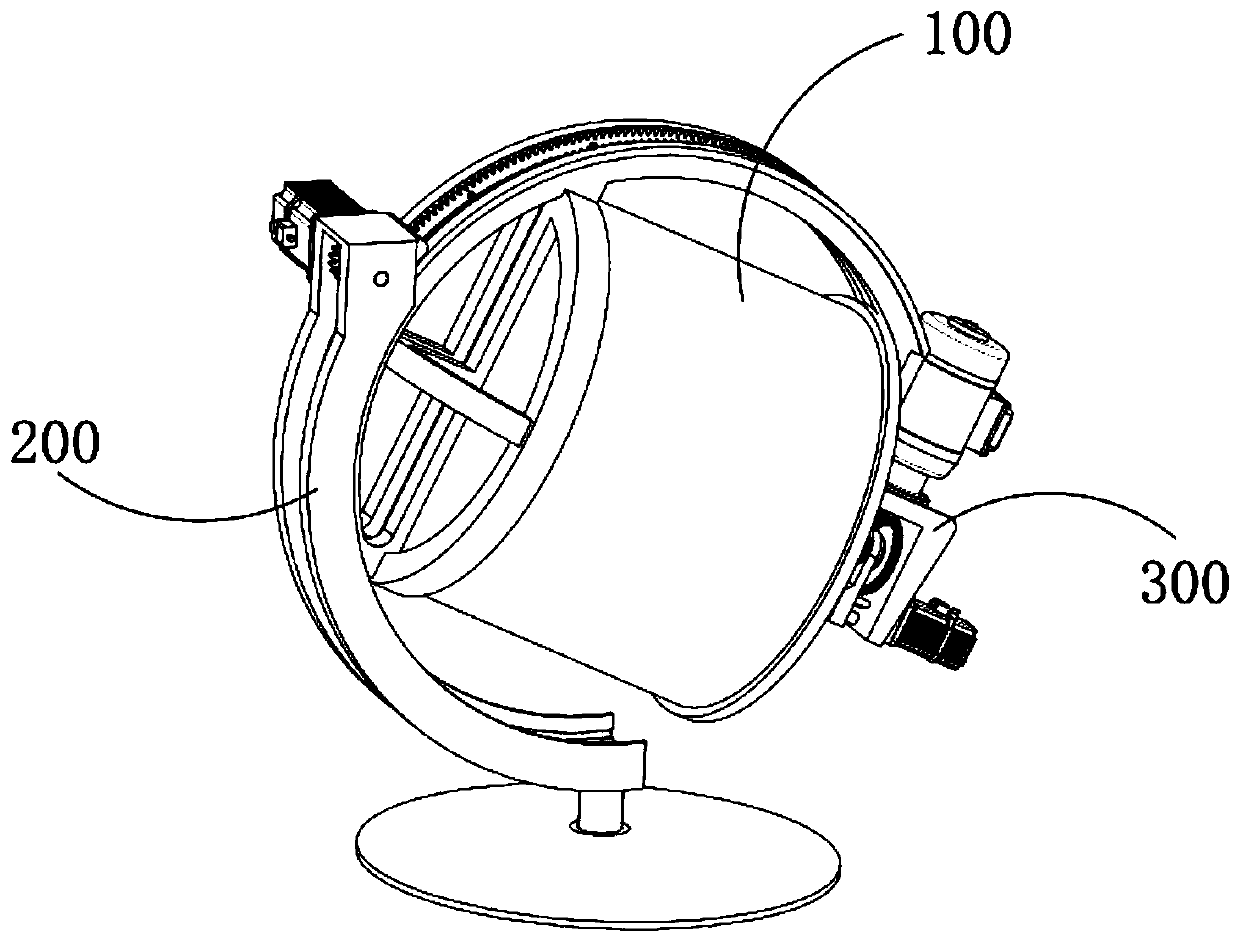

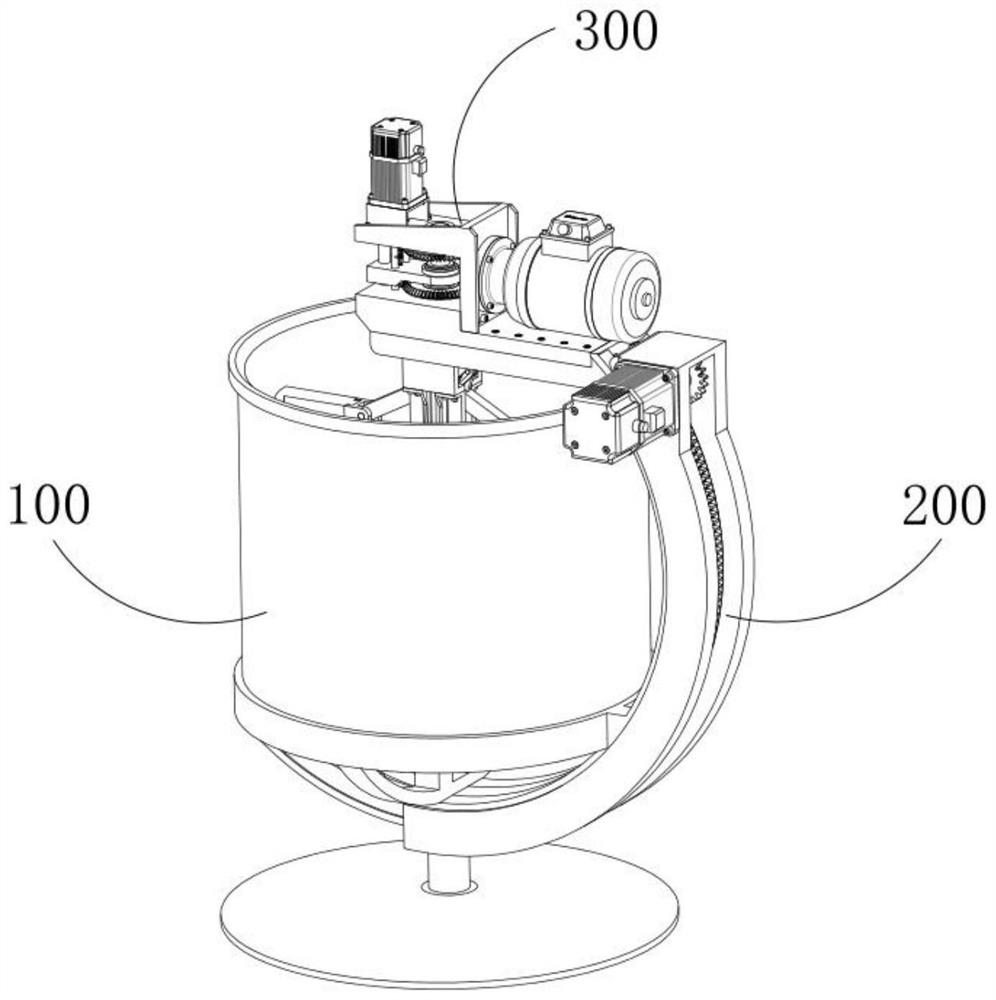

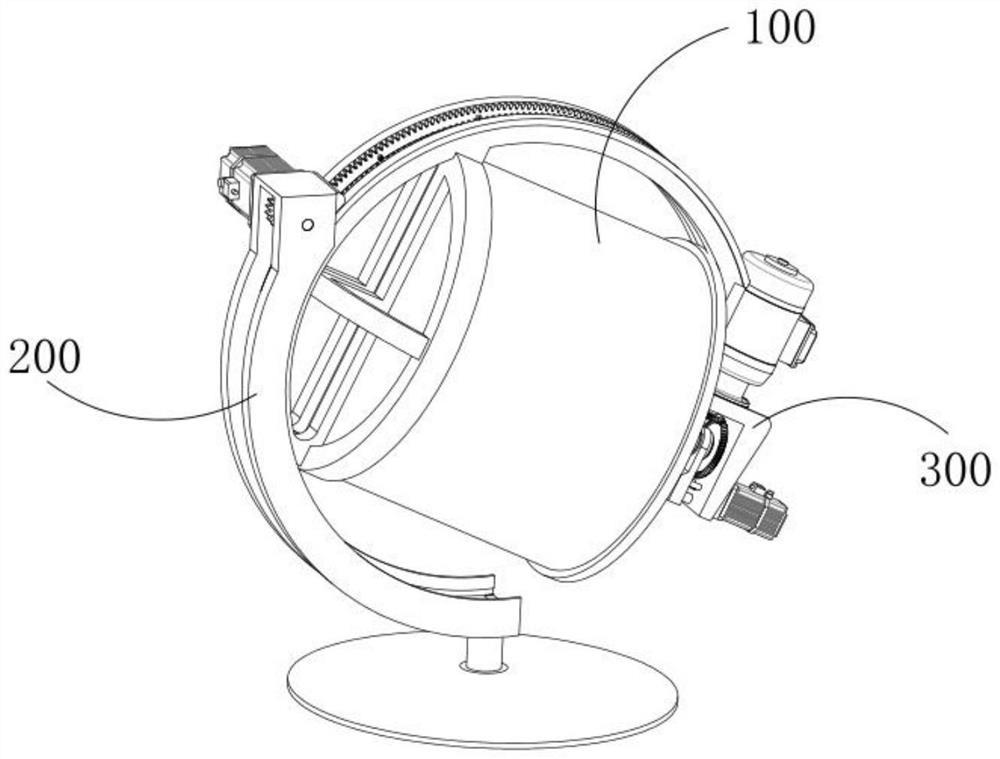

Coaxial opposite-direction self-unloading stirring equipment for promoting uniform mixing of chemical raw materials

ActiveCN110585967AStir wellStir well stir wellShaking/oscillating/vibrating mixersTransportation and packagingEngineeringUltimate tensile strength

Owner:山西瑞峰百合化工有限公司

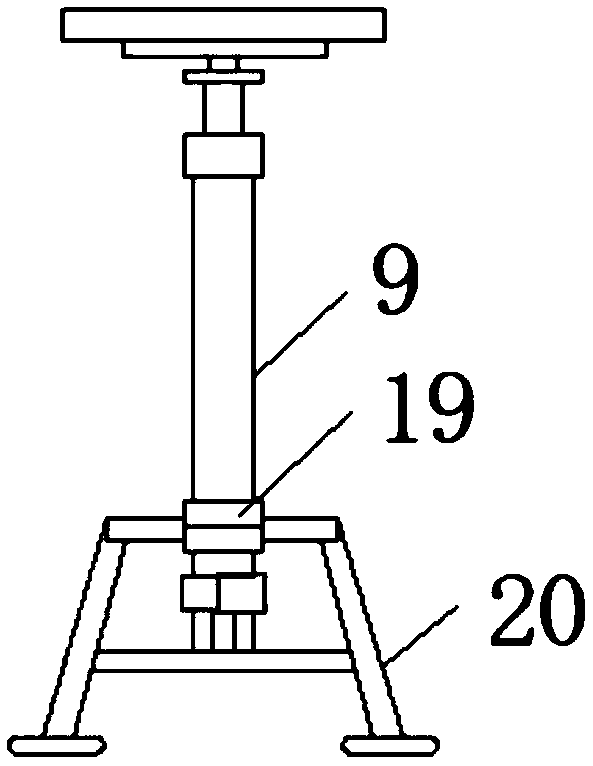

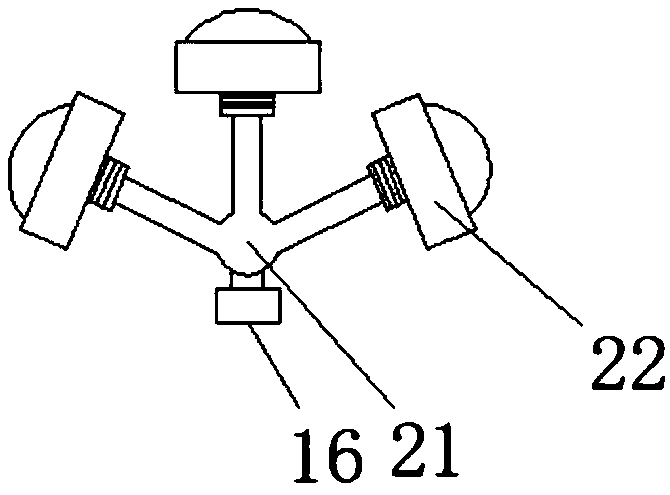

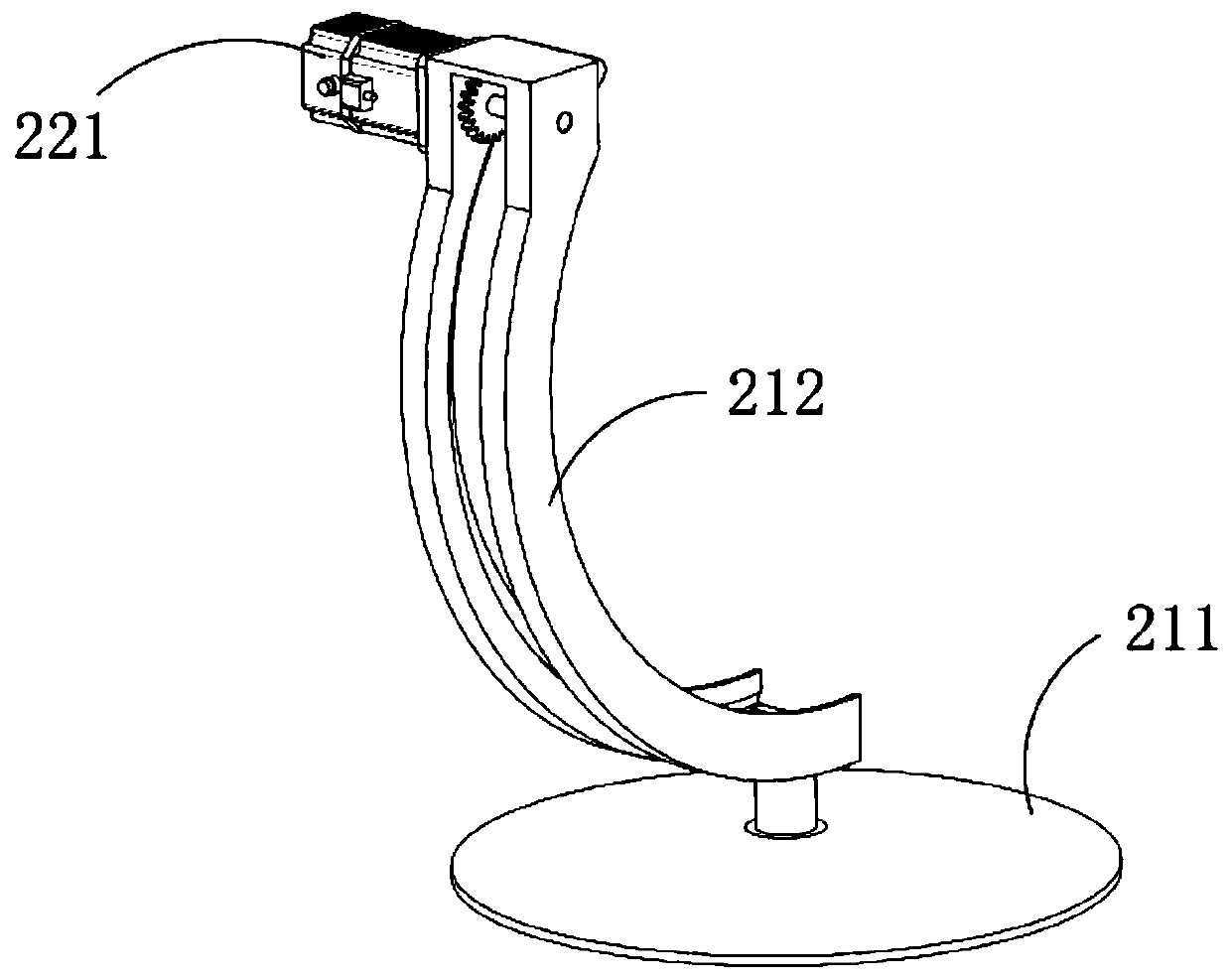

Stable pulping and stirring robot

InactiveCN107537354AGuaranteed stabilityReduce vibration amplitudeRotary stirring mixersMixer accessoriesPulp and paper industryCushion

Owner:吴莉锋

Production process of aluminum-titanium alloy AlTi10

The invention discloses a production process of aluminum-titanium alloy AlTi10. The production process comprises the steps of placing an aluminum ingot with the content of larger than 99.70% into an electric furnace, and heating to 1250 DEG C; adding sponge titanium or titanium scraps until the aluminum ingot is completely molten, wherein the mass ratio of the aluminum ingot to the sponge titanium or the titanium scraps is 100:11; uniformly stirring through a magnetic stirrer; adding lithium aluminum tetrahydride, and standing for reacting; adding a leveling agent to stand before sampling, and then, carrying out low-power analysis and component analysis; and casting and molding after the assay is approved. Power low-ebb operation is adopted in the production process disclosed by the invention, so that energy sources are saved, and the production cost is reduced; manpower work can be replaced with magnetic stirring equipment, so that materials can be sufficiently and uniformly stirred, the labor intensity of a worker can be reduced, the production period can be shortened, and the production efficiency can be increased; and the titanium content of the casting product AlTi10 can be up to 9-11% which is twice as much as the content of titanium produced by using the old national standard, and no segregation is caused.

Owner:铜山县超特有色金属添加剂厂

Intelligent air-spraying system for fruit tree planting

InactiveCN106561616AReasonable structural designEasy to operateInsect catchers and killersFruit treeSprayer

The invention discloses an intelligent air-spraying system for fruit tree planting. The intelligent air-spraying system for fruit tree planting comprises a sprayer body. A spray lance is arranged on the right side of a liquid inlet, a flow control valve is mounted below the spray lance, a nozzle is arranged above the spray lance, a driving motor is arranged on the left lower side of the sprayer body, the driving motor is in transmission connection to a stirring rod through a transmission rod, an air compressor is arranged on the inner right side of the sprayer body, an air inlet is formed in the upper left side of the air compressor, a pressure adjusting valve is mounted on the air inlet, a pressure gauge is arranged above the pressure adjusting valve, the flow control valve is electrically connected to a control device through a wire, and a push rod is arranged on the upper right side of the sprayer body. The intelligent air-spraying system for fruit tree planting has the advantages of being reasonable in structural design, simple to operate, good in spraying effect, convenient and practical and the like, and meanwhile, the spraying efficiency can be improved to a great extent, human and material resources are saved, and the intelligent air-spraying system for fruit tree planting can be generally popularized and used.

Owner:王守祥

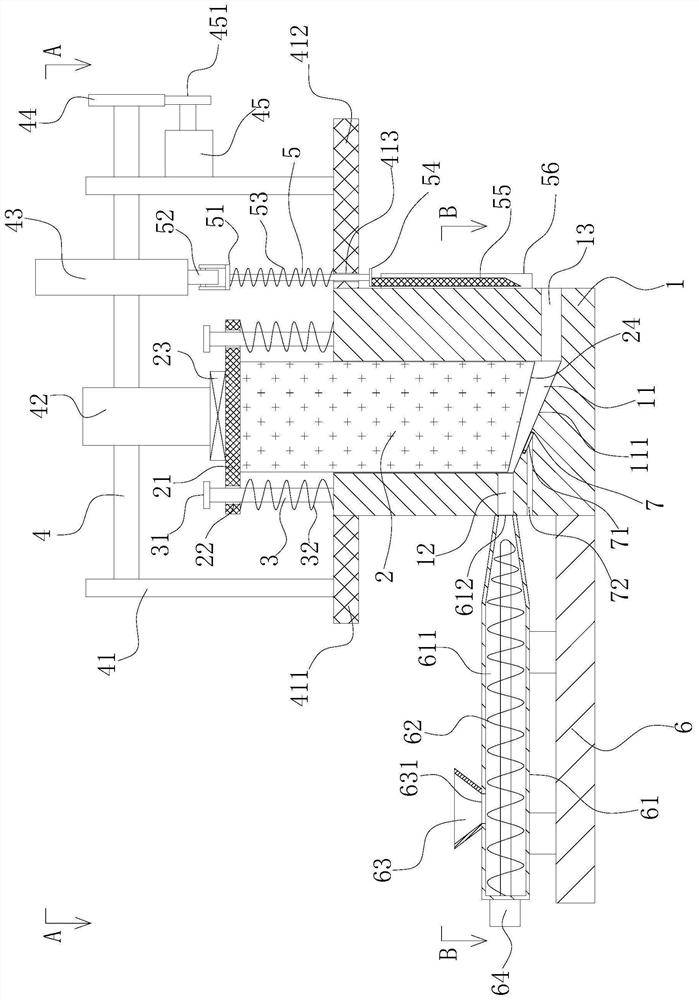

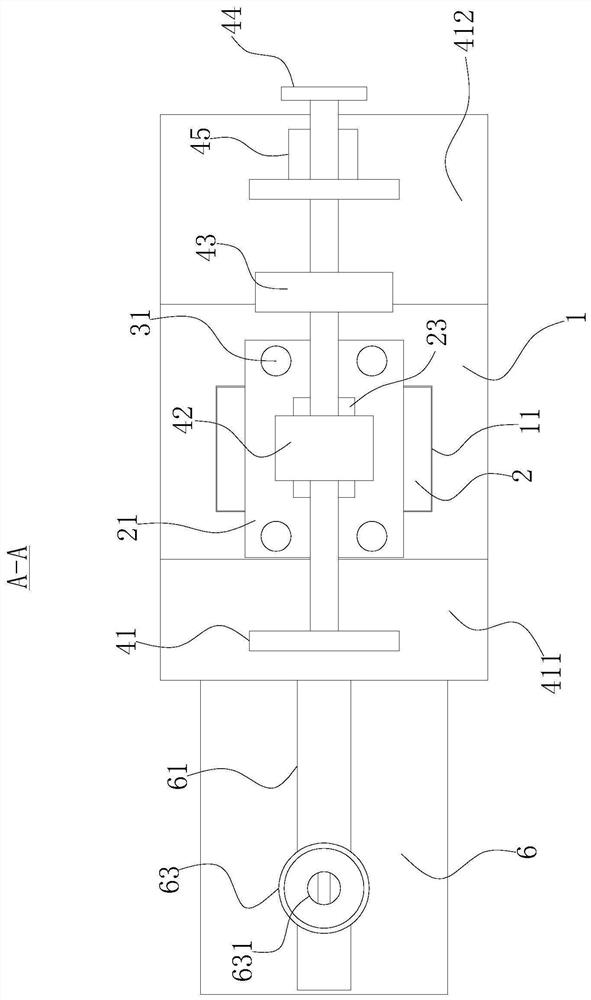

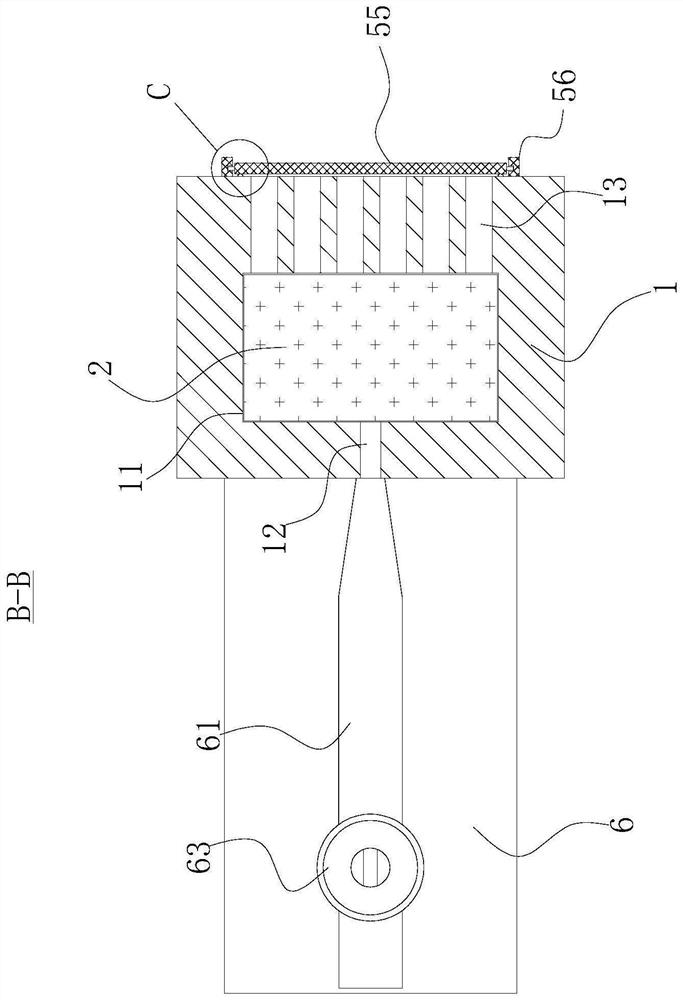

Fish ball making device and using method thereof

InactiveCN113349237AEasy to operateQuality improvementMeat processingStructural engineeringMechanical engineering

The invention provides a fish ball making device and a using method thereof, and belongs to the technical field of food equipment. The fish ball making device comprises a pressure bearing block, an extrusion block, a feeding hole, a plurality of discharging holes, a feeding mechanism, a driving mechanism and a cutting mechanism, wherein an extrusion groove is formed in the upper side surface of the pressure bearing block; the extrusion block is arranged in the extrusion groove in an up-down sliding manner; the feeding hole is horizontally formed in the left side surface of the pressure bearing block; the feeding hole communicates with the bottom of the left side wall of the extrusion groove; the discharging holes are sequentially and horizontally formed in the right side surface of the pressure bearing block at intervals; the discharging holes communicate with the bottom of the right side wall of the extrusion groove; the feeding mechanism can inject fish ball raw materials into the feeding hole; the driving mechanism can drive the extrusion block to slide up and down; and the cutting mechanism can cut off fish ball strips extending out of the discharging holes. The fish ball making device can quickly make fish balls, and the making efficiency and the quality of the fish balls are improved.

Owner:ZHEJIANG INT MARITIME COLLEGE

Concrete stirring device

PendingCN112405842AStir well stir wellMain properties improvedSievingScreeningElectric machineryWater pipe

The invention discloses a concrete stirring device, and relates to the technical field of concrete processing. The concrete stirring device comprises a stirring tank body, wherein the bottom of the stirring tank body is fixedly connected with support legs, the middle position of the bottom of the stirring tank body is fixedly connected with a discharge door, and the two sides of the bottom of thestirring tank body are fixedly connected with return springs. According to the concrete stirring device, a water tank is arranged on one side of the top of the stirring tank body, a water distributionblock is arranged at the bottom of the water tank, a water distribution pipe is slidably connected to the bottom of the water distribution block in the vertical direction through the return springs,a driving folding rod is fixedly connected to the middle of the water distribution pipe, a connecting hole is formed in the side, close to the position above the driving folding rod, of the water distribution pipe, a main motor drives an end cam to rotate through a third belt transmission structure, the end cam forces the driving folding rod to intermittently drive the connecting hole in one sideof the top of the water distribution pipe to communicate with the top of a water inlet pipe, and at the moment, the water tank can intermittently provide water required by a stirring process for the stirring tank body through the water distribution pipe and the water inlet pipe, so that concrete is fully and uniformly stirred, and the main property of the concrete is greatly improved.

Owner:关艳玲

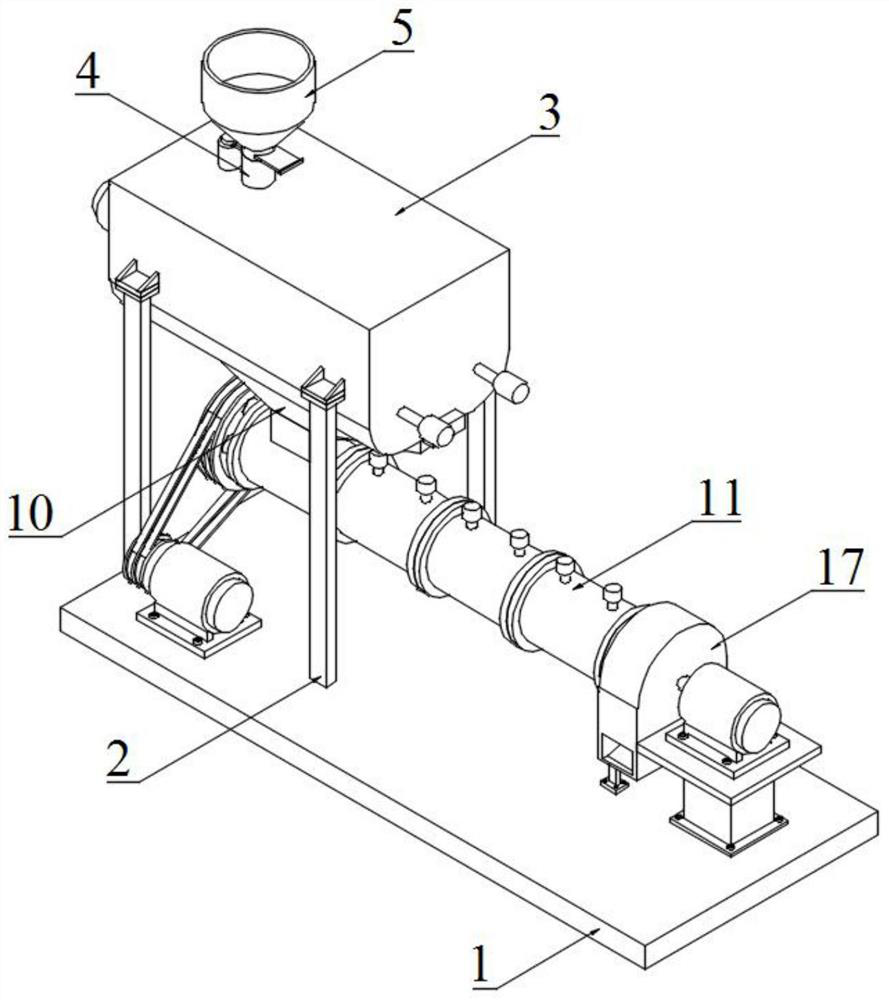

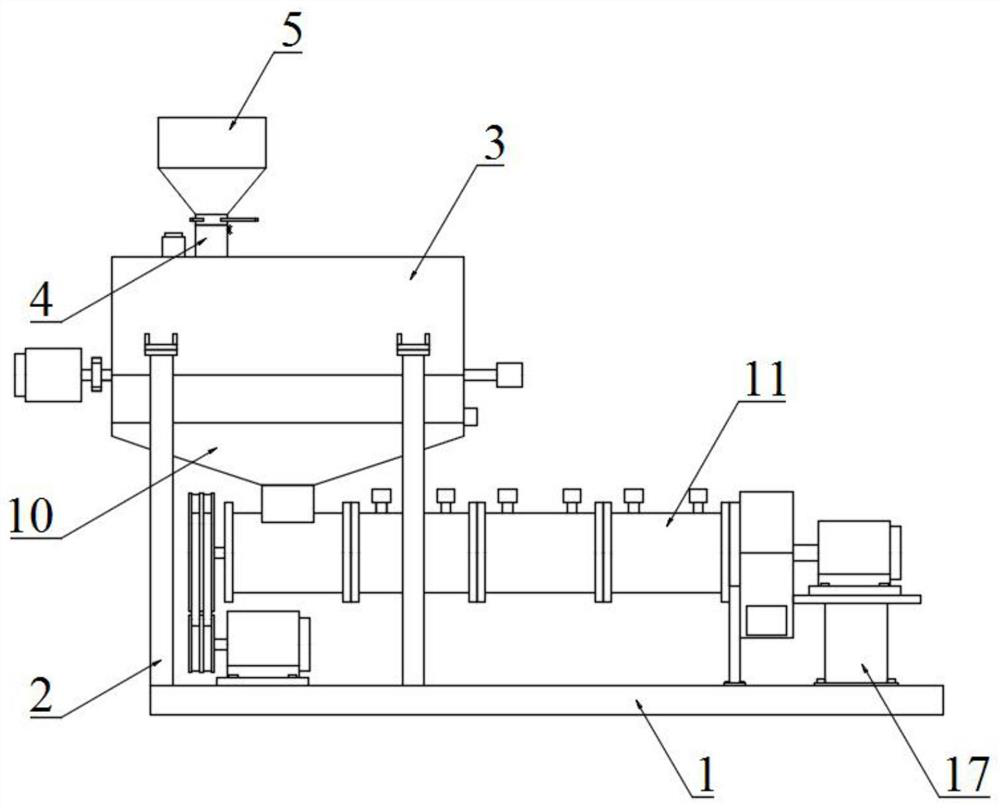

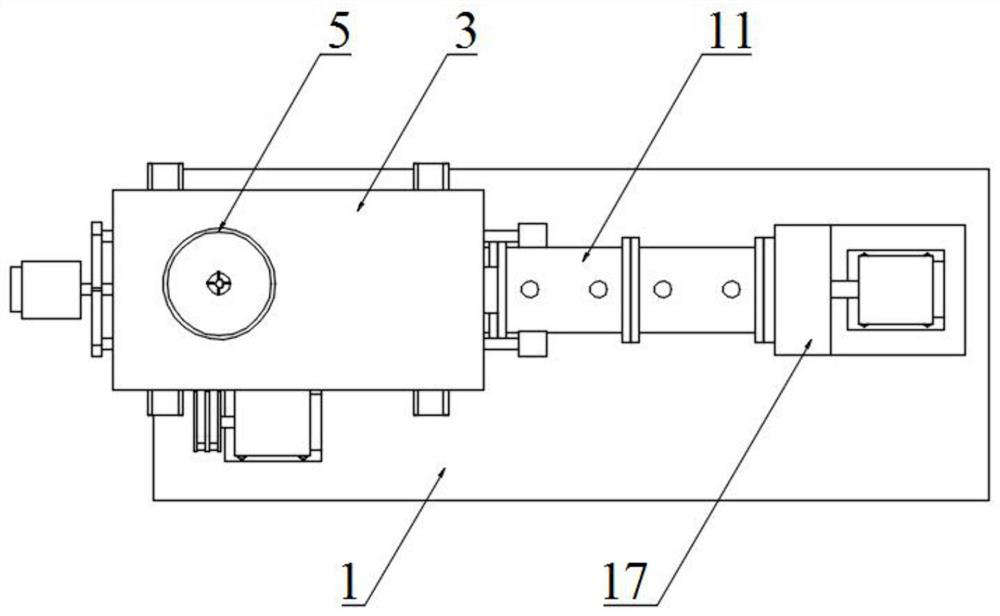

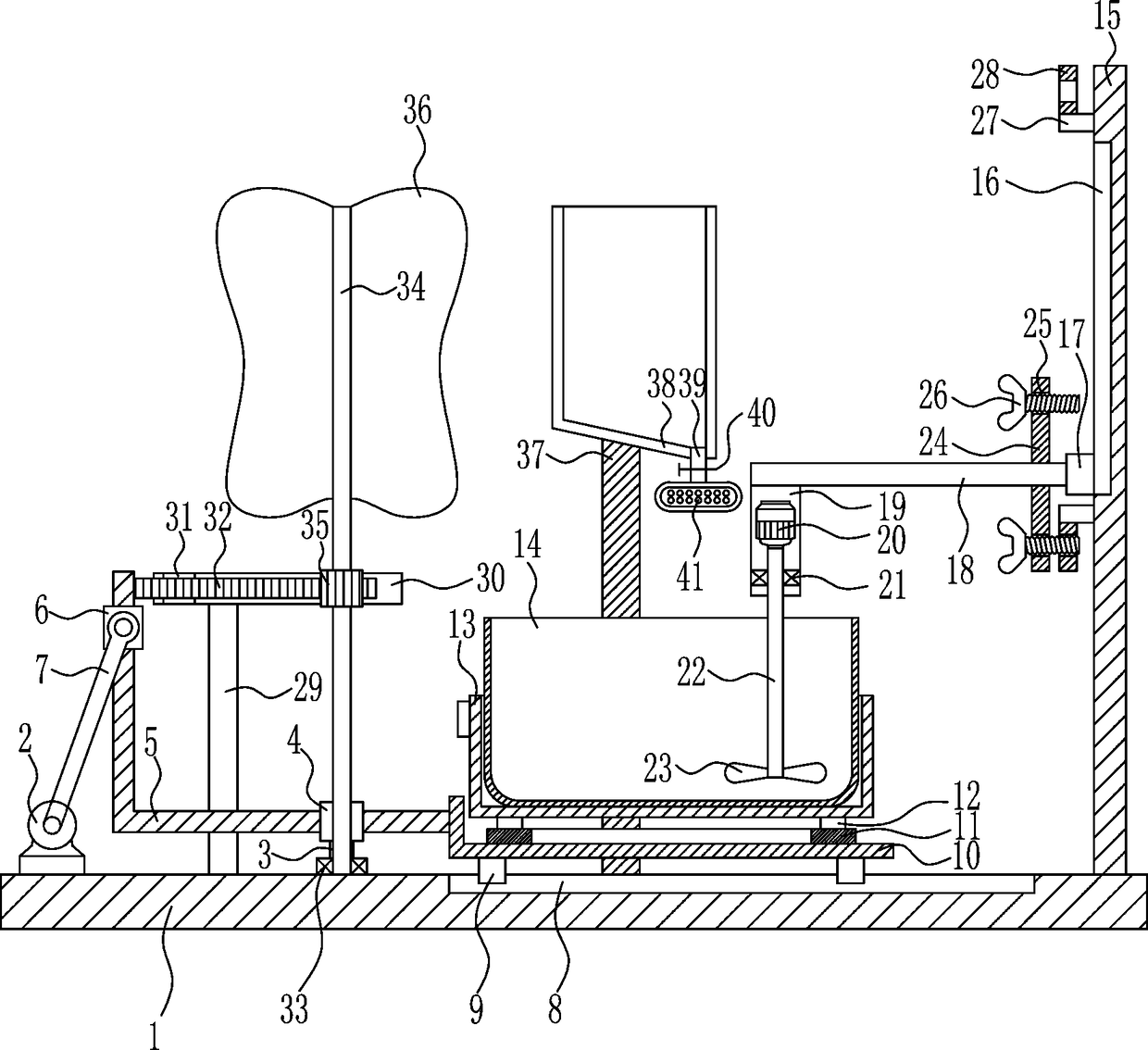

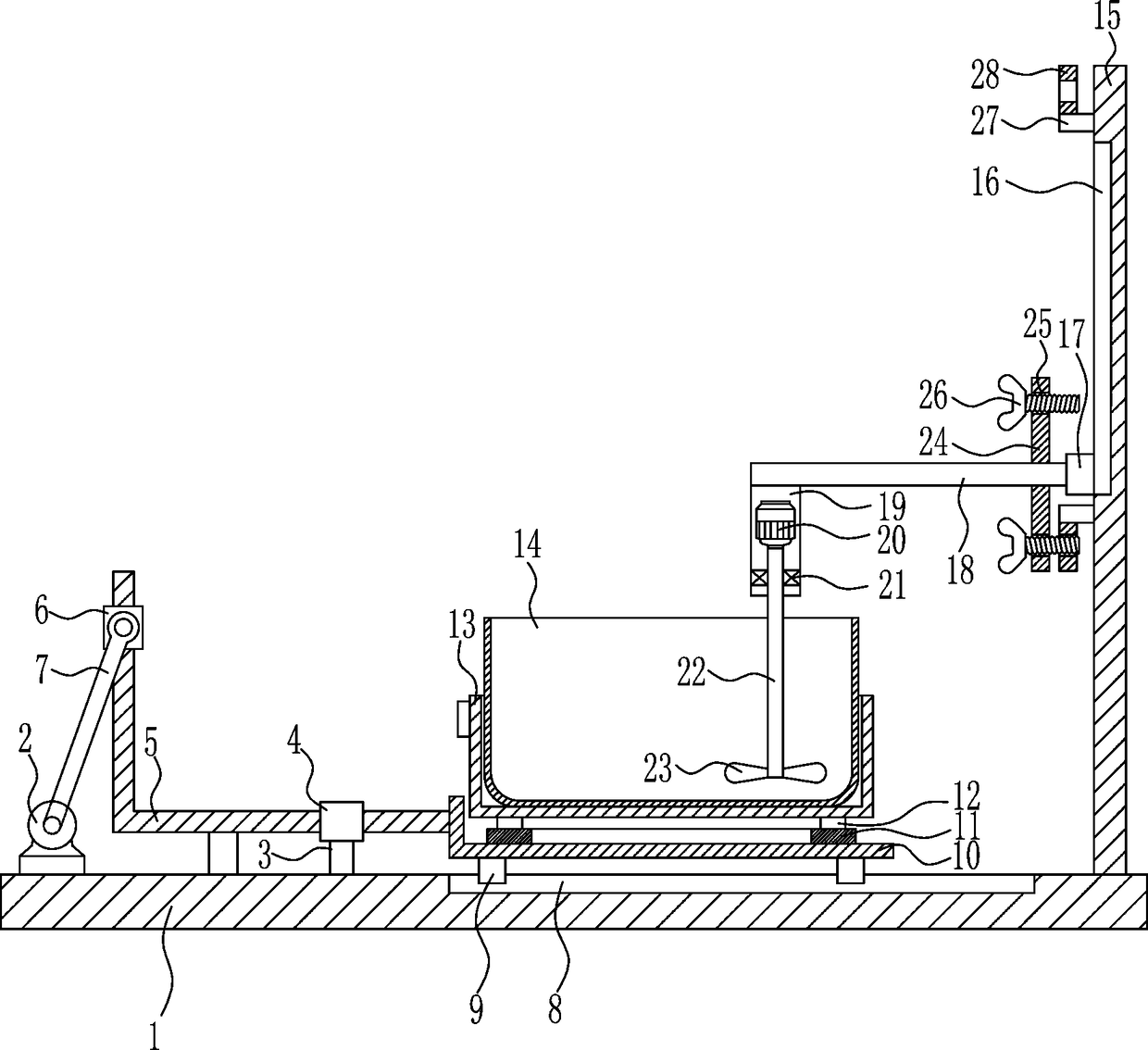

Cat food capable of improving immunity of cats and production device thereof

PendingCN112369526APromote growth and developmentImprove your own resistanceFeeding-stuffAnimal feeding stuffBiotechnologyAnimal science

The invention discloses cat food capable of improving cat immunity and a production device of the cat food. The cat food is prepared from the following raw materials in parts by weight: 100-150 partsof corn flour, 40-60 parts of chicken, 30-50 parts of fishbone dust, 15-20 parts of vegetable oil, 10-15 parts of milk powder, 1-5 parts of compound amino acid, 1-3 parts of compound vitamin and 10-20parts of traditional Chinese medicine extract. The cat food production device comprises a base, a supporting frame is fixedly installed on the left side of the top of the base, a conditioning box isfixedly installed on the top of the supporting frame, a feeding pipe is fixedly installed on the top of the conditioning box, a feeding hopper is detachably installed at the upper end of the feeding pipe, and a discharging hopper is fixedly installed in the middle of the bottom of the conditioning box; a puffing extrusion mechanism is arranged below the conditioning box and the puffing extrusion mechanism comprises a feeding pipe, a puffing pipe and an extrusion pipe which are connected in sequence; and the cutting mechanism is fixedly arranged at the top of the base corresponding to the extrusion pipe. According to the cat food, non-specific immunity of organisms is stimulated through the traditional Chinese medicine extracts, the autoimmunity of cats is enhanced, the raw materials can befully mixed through the cat food production device, meanwhile, the cat food is in a closed environment during production, and the quality of the produced cat food is effectively improved.

Owner:ANHUI UNIV OF SCI & TECH

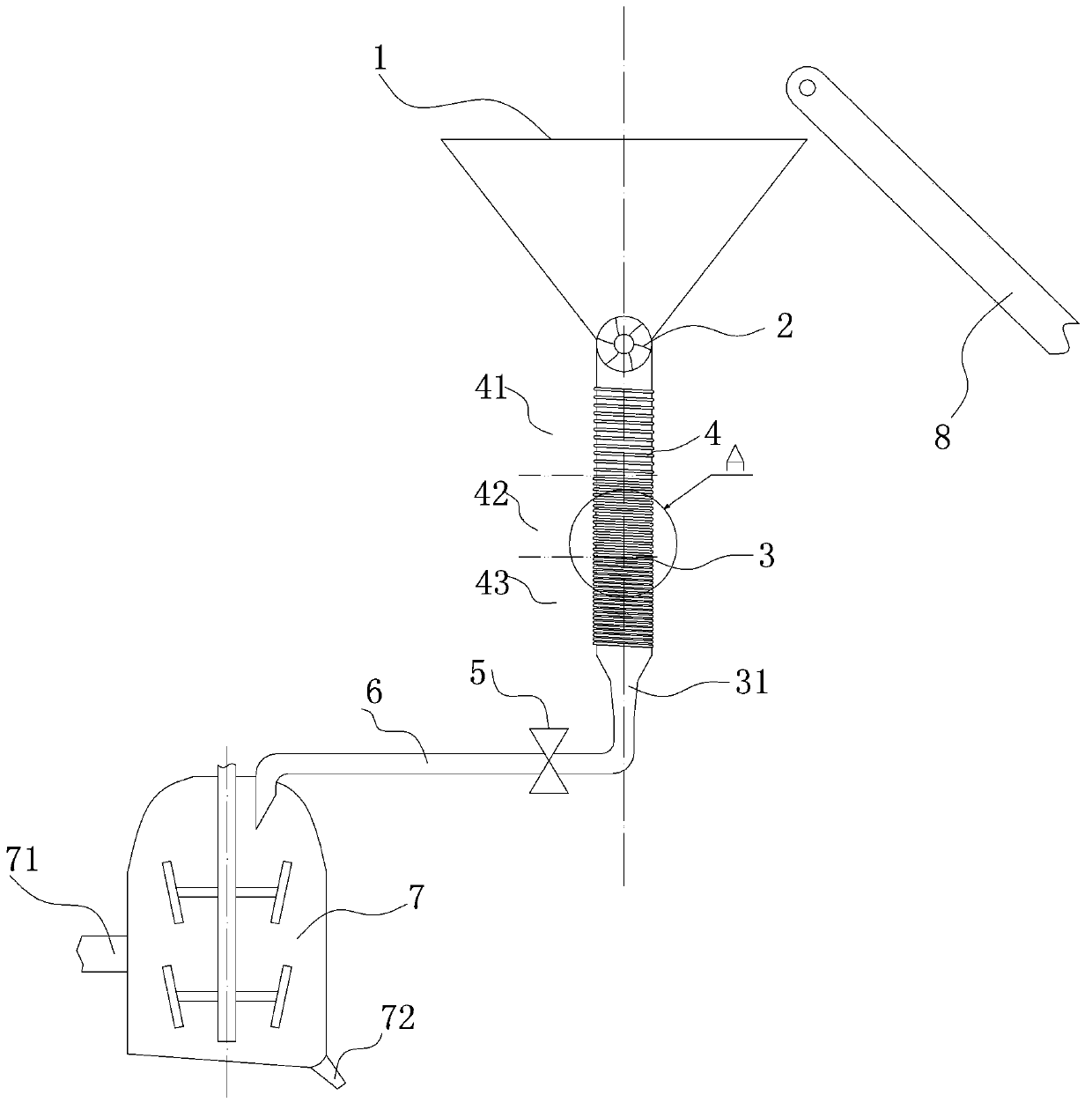

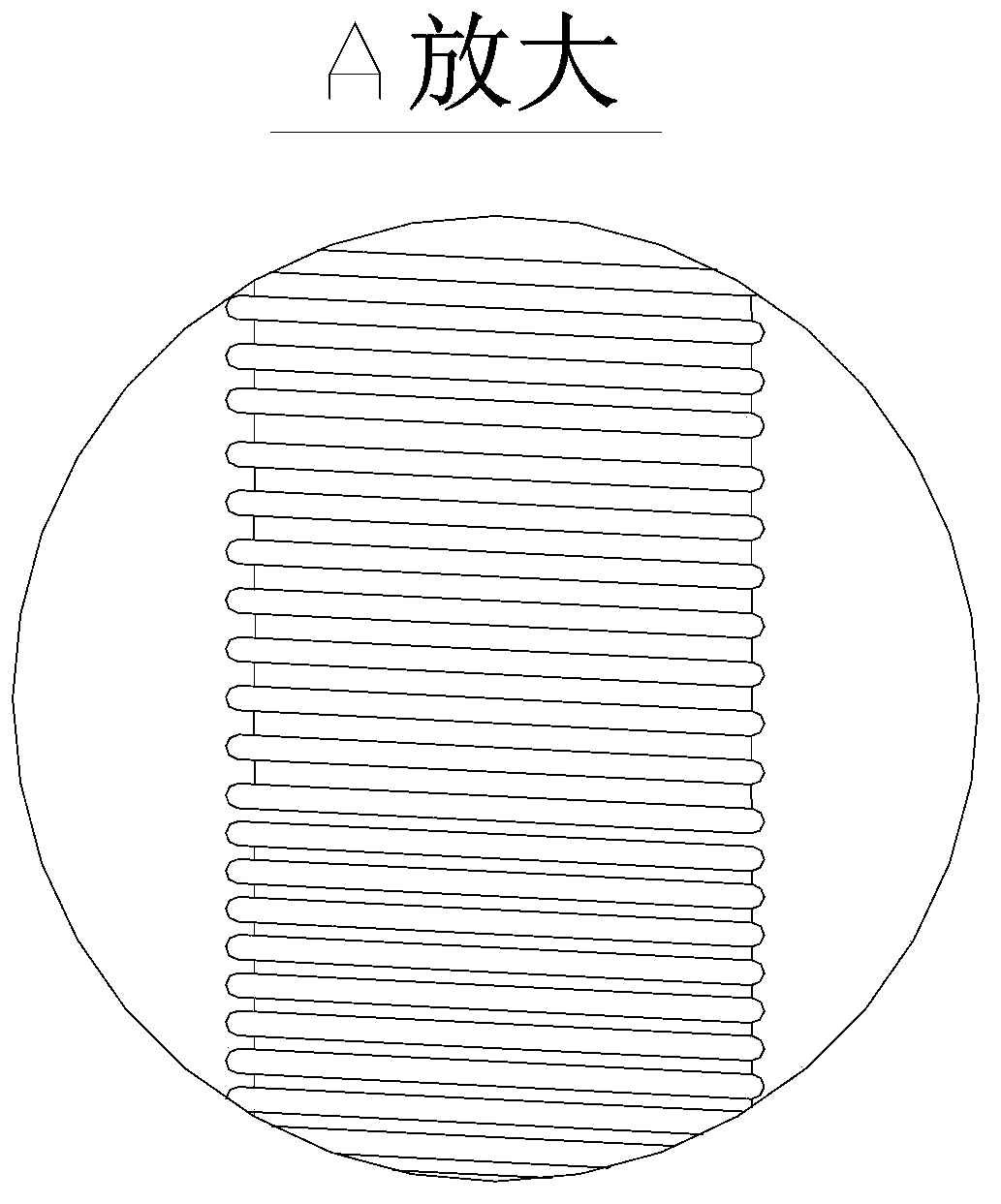

Automatic heating device for special polyethylene wax for marking of road

InactiveCN103962061AReduce coal consumptionStir wellHeat treatmentsRotary stirring mixersTemperature controlProduction line

The invention discloses an automatic heating device for special polyethylene wax for marking of a road, and relates to an automated heating and transmission device for the special polyethylene wax for marking of the road.. The automatic heating device can greatly improve thermal efficiency, save energy, reduce emission and reduce air pollution. The automatic heating device comprises a conveyor belt, and also a feed hopper, a feeder, an iron heating pipeline, an electromagnetic coil and a fluid-state matter conveying pipe, wherein an outlet of the conveyor belt is communicated with an upper hopper port of the feed hopper, a lower hopper port of the feed hopper is connected with a feed port of the heating pipeline, and the feeder is arranged at the feed port of the heating pipeline; the electromagnetic coil is wound on the outer surface of the heating pipeline; and an inlet of the conveying pipe is connected with a discharge port of the heating pipeline. According to the automatic heating device disclosed by the invention, as an electromagnetic heating mode convenient for heating temperature control and having high thermal effectiveness is adopted, the coal consumption caused by heating of coal is greatly reduced, 3 / 4 of the energy can be saved, and manpower can be also greatly saved by adopting an automated assembly line. By adopting a stirring kettle, liquefied special polyethylene wax can be fully and uniformly stirred and fully mixed.

Owner:YANGZHOU JINXIANGSU CHEM MATERIALS FACTORY

Foam concrete stirring device and method

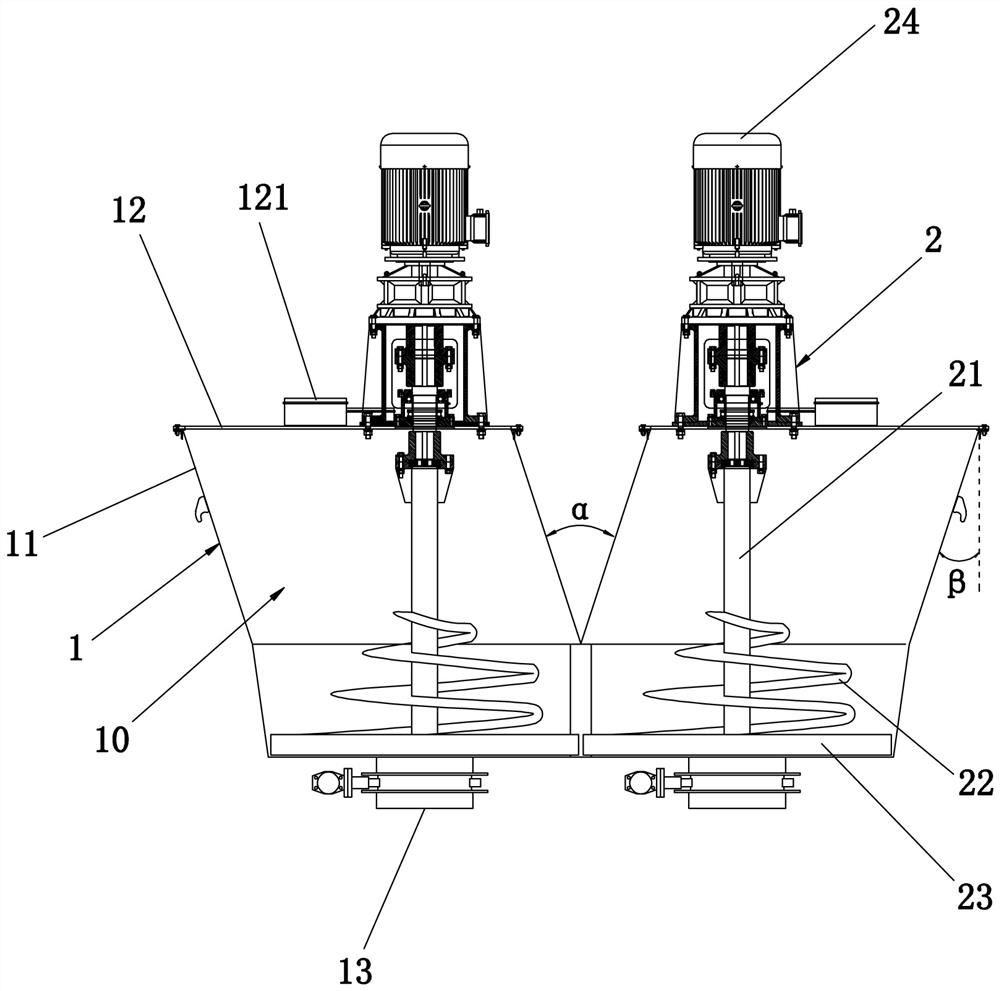

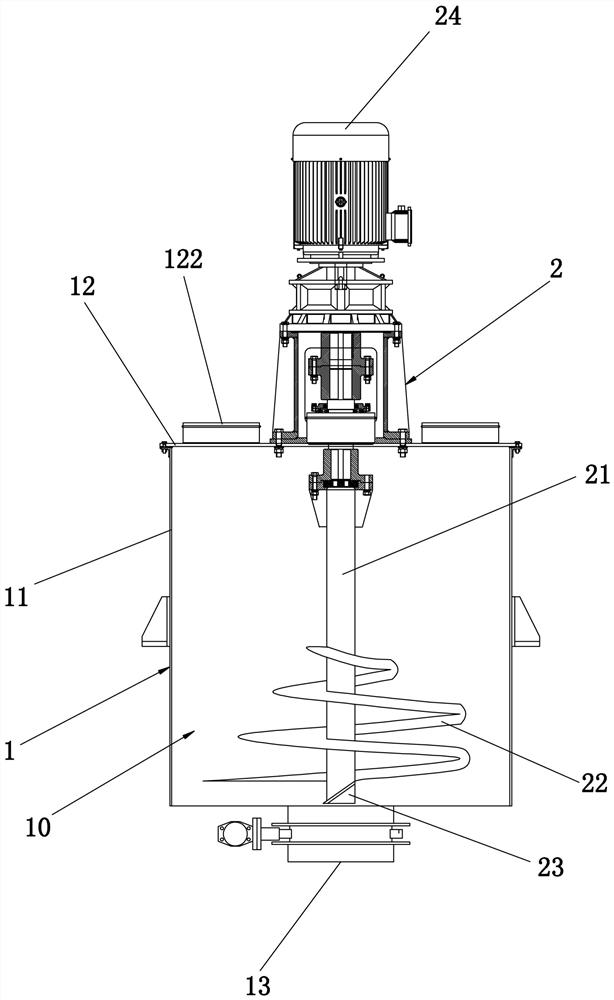

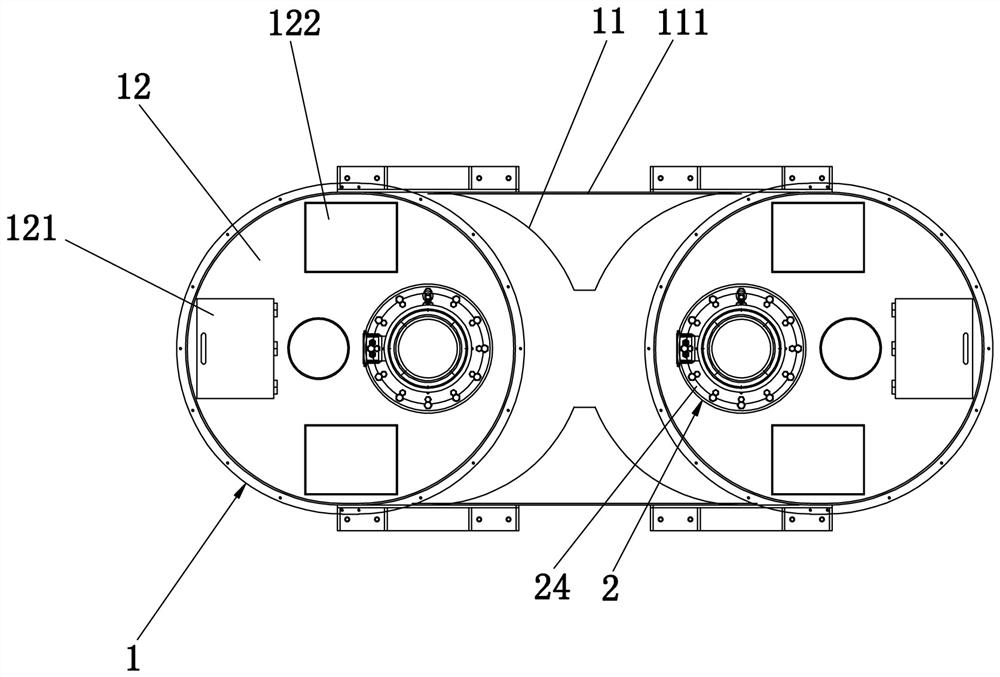

PendingCN111941642AImprove stirring efficiencyEnsure specific gravityHollow article cleaningCement mixing apparatusManufacturing engineeringFoam concrete

The invention discloses a foam concrete stirring device and method, and relates to the technical field of stirring equipment. The foam concrete stirring device comprises a stirring tank and stirrers,wherein the stirring tank is provided with a stirring space with a V-shaped structure, and the stirrers are arranged on the two sides of the stirring space respectively; and each stirrer is provided with a stirring shaft with stirring blades, and the stirrers are used for pressing slurry while stirring the slurry, so that the slurry is rolled upwards along the side wall of the stirring tank. According to the foam concrete stirring device and method, the internal structure of the stirring tank is optimized, a single mode of horizontal stirring of an existing stirring shaft is changed, so that the slurry can be rolled upwards along the side wall of the stirring tank while horizontally rotating, three-dimensional stirring is realized, the stirring efficiency is effectively improved, it is ensured that the slurry is uniformly stirred and fully mixed and the specific gravity of the slurry is uniform, breakage or perforation of bubbles in a foaming process is avoided, and the quality of foamconcrete is effectively improved.

Owner:福建雄辉科技有限公司

Coaxial and counter-rotating self-unloading mixing equipment to promote uniform mixing of chemical raw materials

ActiveCN110585967BStir wellStir well stir wellShaking/oscillating/vibrating mixersTransportation and packagingBLENDER/MIXERProcess engineering

Owner:山西瑞峰百合化工有限公司

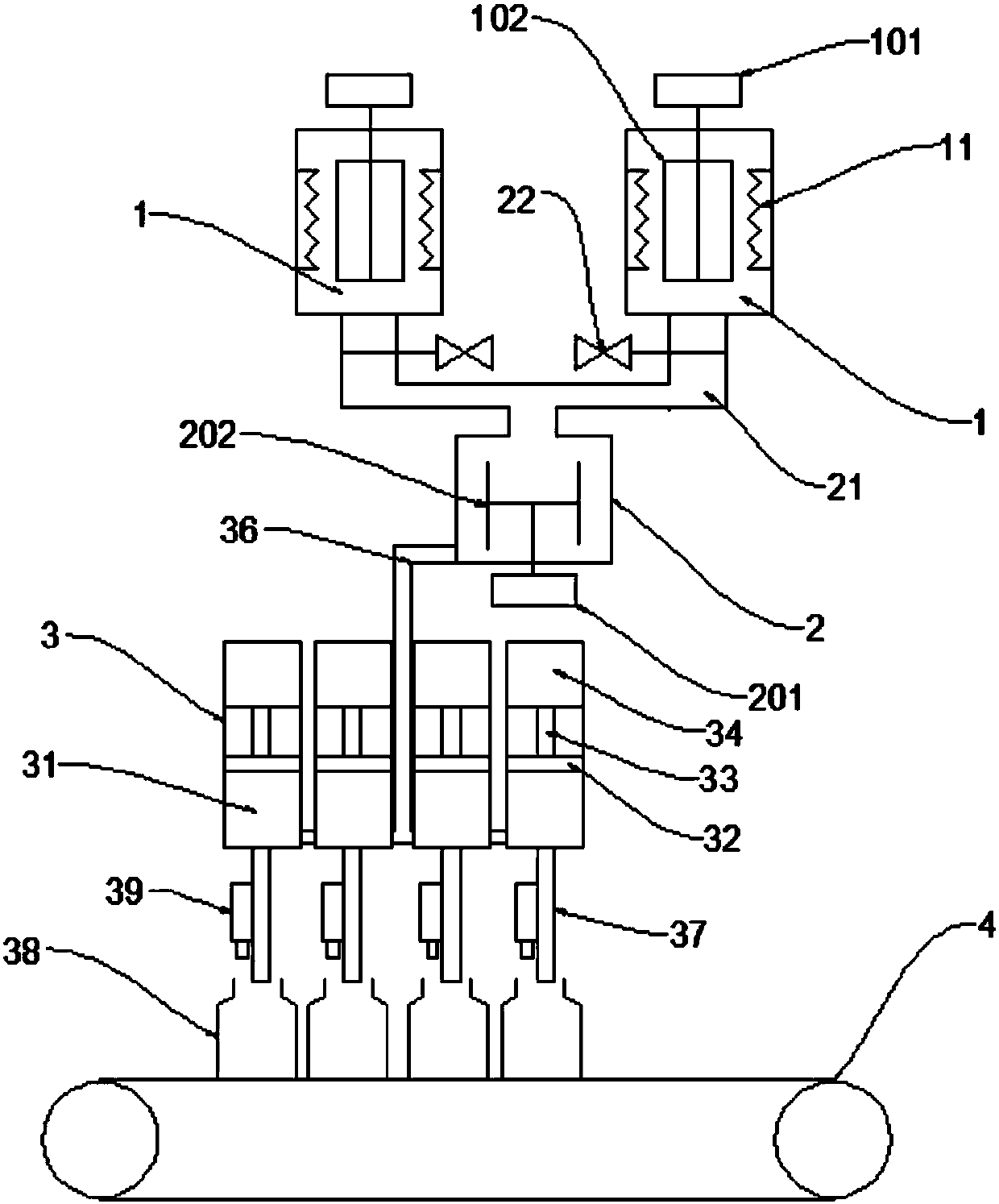

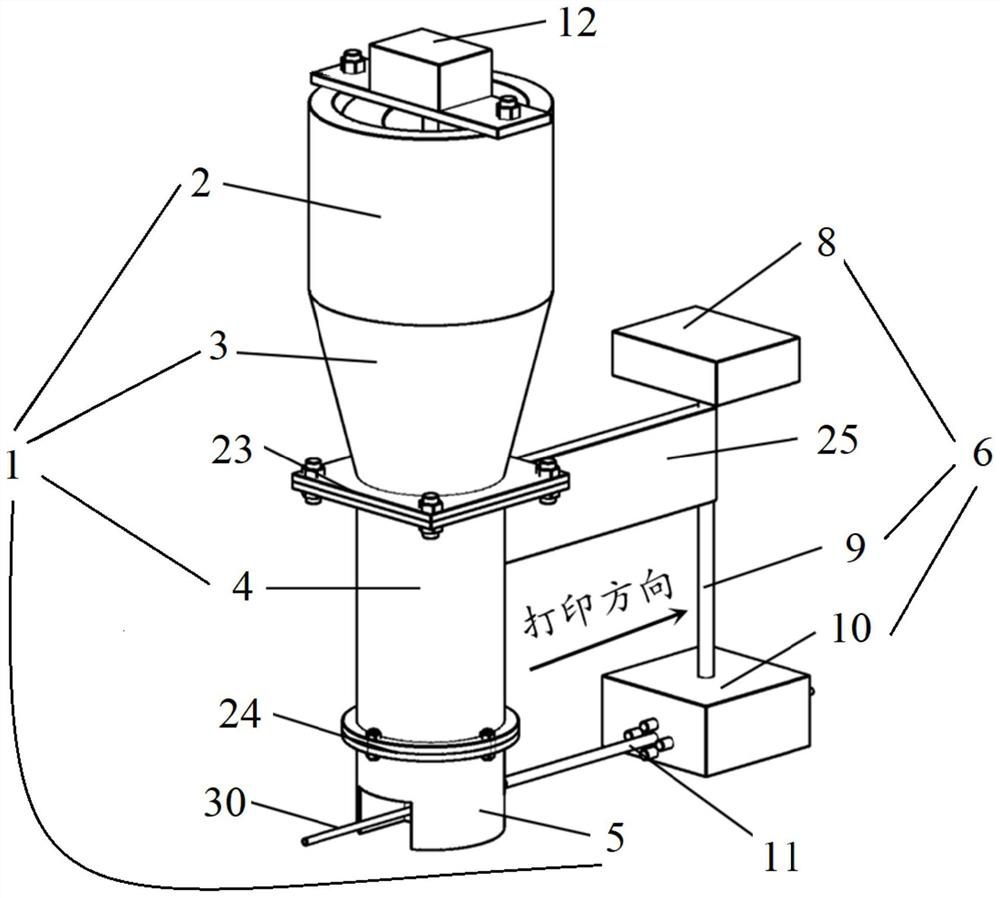

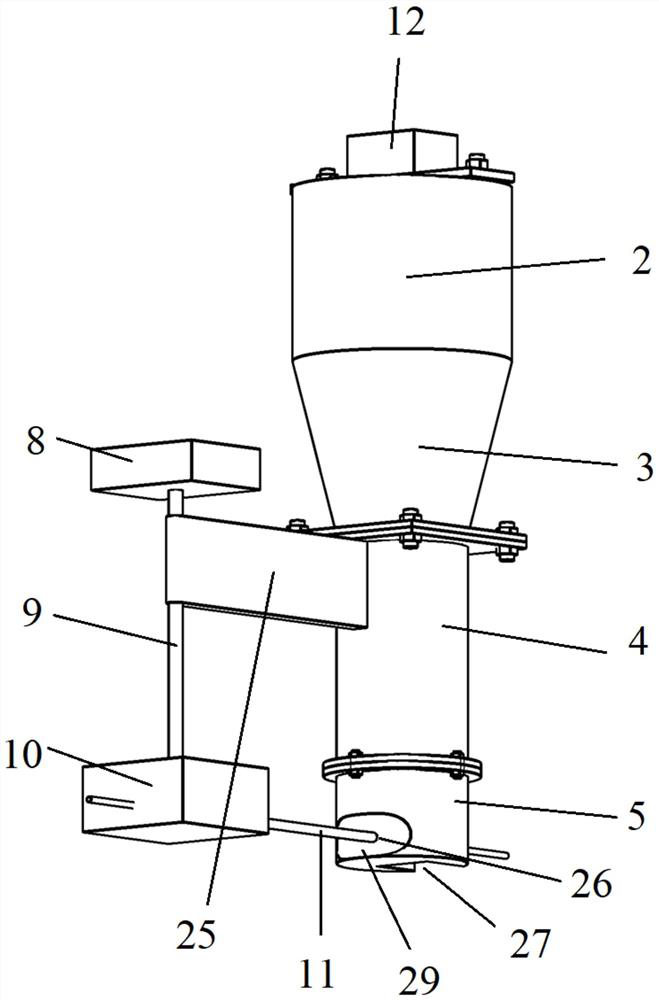

3D concrete printing device and method for building automatic reinforcement

ActiveCN112412043AHigh tensile strengthAutomatically and accurately embedBuilding material handlingCement mixing apparatus3d printSprayer

The invention provides a 3D printing concrete device for building automatic reinforcement. The 3D printing concrete device comprises a concrete sprayer device, the concrete sprayer device comprises acharging barrel, a stirring barrel, a material conveying channel and a nozzle which are connected in sequence, the 3D printing concrete device further comprises a reinforcement device connected with the concrete sprayer device, and the reinforcement device is connected with the nozzle; and stirring and conveying devices are arranged in the charging barrel, the stirring barrel and the material conveying channel. By arranging the reinforcement device, steel bars are added in the concrete printing process, so that the tensile strength of a concrete printing component is enhanced; and conveying blades, stirring blades and conical rotating blades are sequentially arranged on a rotating rod, conical protruding parts which protrude outwards are arranged on the periphery of the inner wall of the material conveying channel, the conical protruding parts and the conical rotating blades are arranged in a staggered mode, under the combined action, printed concrete can be fully and evenly stirred, the rheological requirement of the printed concrete is met, and therefore blocking of a pipeline or the nozzle in the printing process is avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Slurry mixing device for construction site

ActiveCN108527656AWon't gatherStir wellCement mixing apparatusLiquid ingredients supply apparatusPulp and paper industrySpeed reduction

The invention relates to a mixing device, in particular to a slurry mixing device for a construction site. The invention aims at solving the technical problem of providing a slurry mixing device for aconstruction site which can sufficiently and uniformly stir the slurry in the mechanical stirring process and can prevent people from breathing a great amount of pungent smells. The slurry mixing device for the construction site comprises a bottom plate and a speed reduction motor; and the upper left side of the bottom plate is provided with the speed reduction motor and a supporting rod, the speed reduction motor is disposed on the left of the supporting rod, the upper end of the supporting rod is provided with a guide sleeve, and a movable frame is arranged in the guide sleeve in a slidingmanner. By adopting the slurry mixing device, a mechanized stirring process can be achieved, sufficiency and uniformity in stirring can be realized, and people can be prevented from inhaling a great amount of pungent smells; and the mixing box continuously moves left and right, so that a rotating stirring blade can sufficiently stir the powdery raw material and liquid in the mixing box, when the powdery raw material and liquid are mixed, the peculiar smell and pungent smell can be scattered, and the odor is difficult to gather.

Owner:无锡开源建设工程有限公司

Organic silicon slag slurry treatment method

PendingCN109260815AStir wellStir well stir wellShaking/oscillating/vibrating mixersRotary stirring mixersSlagReciprocating motion

The invention belongs to the technical field of production of organic silicon, and in particular relates to an organic silicon slag slurry treatment method. A treatment device used in the method comprises a tank cover, a tank body, a feeding hole, a discharge hole and a gas outlet, wherein the tank cover is provided with the feeding port and the gas outlet; the tank cover is connected with the tank body by means of a flange; the bottom of the tank body is provided with the discharge hole; a controller is arranged at the outer side of the tank body; a motor is installed on an installing support, and an output shaft of the motor is connected with a rotating shaft; the middle parts of support rods are fixedly connected with the rotating shaft; the top of a support frame is fixedly connected with the support rods; the bottom of the rotating shaft is fixedly connected with a cylinder No. 1, and a telescopic rod of the cylinder No. 1 passes through the support frame and is connected with a stirring module. When the treatment device is in use, organic silicon slag slurry in the tank body is stirred in a way of up and down reciprocating motion while the stirring module is driven to rotateby means of the cylinder No. 1, so that the organic silicon slag slurry is fully stirred, the evaporation efficiency of the device is increased, and the effective treatment of the organic silicon slagslurry is realized.

Owner:褚成亮

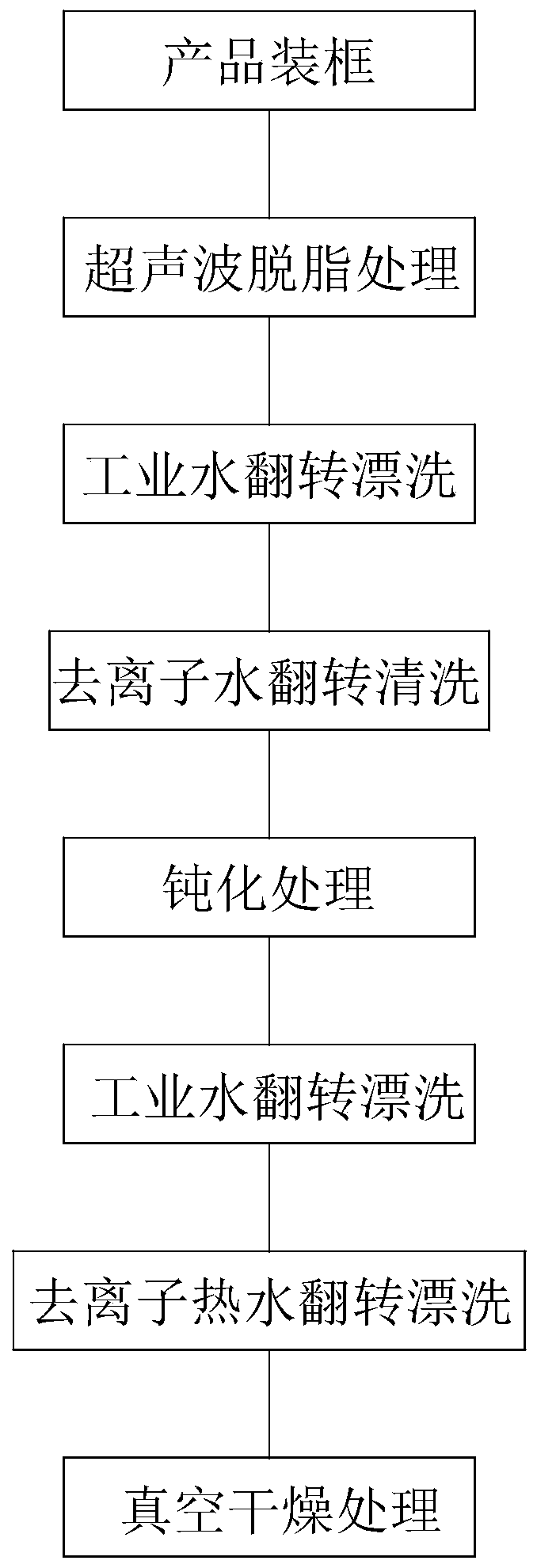

Surface treatment method for Audi C8 base structural member

ActiveCN110863210AGuaranteed cleaning effectReduce pollutionMetallic material coating processesCleaning using liquidsMetallurgyEnergy consumption

The invention discloses a surface treatment method for an Audi C8 base structural member. The surface treatment method comprises the four steps that the base structural member is framed, and ultrasonic degreasing treatment and overturning cleaning treatment are conducted on the base structural member in the frame; the cleaned base structural member is transferred into a passivation tank, and overturning passivation treatment is conducted; overturning spraying rinsing treatment is conducted on the passivated base structural member; and vacuum drying treatment is conducted on the cleaned base structural member. The surface treatment method is good in treatment effect, convenient to operate and low in energy consumption, energy is saved, and the production time is shortened.

Owner:四川众兴汽车零部件有限公司

Metering and transporting device for transporting alternative fuel into kiln tail

PendingCN110631358AEasy to reinforceIncrease concentrationSolid fuel pretreatmentRotary drum furnacesGear driveEngineering

The invention provides a metering and transporting device for transporting alternative fuel into a kiln tail. The metering and transporting device is characterized in that the metering and transporting device comprises is provided with a SRF material storage bin, a rotating discharge mechanism and a spiral which is provided with a rotating shaft and a rotating chain; the side end of the SRF material storage bin is provided with a discharge port, and a part of the rotating discharge mechanism is embedded in the discharge port through a bearing; and the rotating discharging mechanism is providedwith a vortex feeding channel and a gear connected with the rotating shaft in a toothing manner. The rotary discharging mechanism is rotated, and the SRF rotates to enter the center of the rotating discharging mechanism from the outside to the inside along the vortex feeding channel and the SRF can be transported to the rotating chain, an at the same time, the rotating discharge mechanism is driven by the gear to make the spiral rotate, and the SRF continues rotating along the rotating chain until the kiln tail.

Owner:长兴智博新材料科技有限公司

Production process of French type crispy cakes

Owner:NANJING HONGSENLIN FOOD

Efficient easily stirring and cleaning sprinkler

InactiveCN107130554AEasy to pushEasy to walkTransportation and packagingRotary stirring mixersImpellerWater storage tank

The invention discloses an efficient easily stirring and cleaning sprinkler which comprises a pushing handle, a guide wheel, a trolley, a camera, a floodlight, a nozzle, a drug conveying pipe, a water storage tank, a water inlet pipe, a motor, a rotating shaft, an impeller and an ultraviolet lamp, wherein the pushing handle is arranged on one side of the trolley; the guide wheel is arranged at the bottom end of the trolley; a crawler belt is sleeved on the guide wheel; a display device is arranged on the trolley; the camera and the floodlight are arranged at the front end of the trolley; a storage battery is arranged in the trolley; a water storage tank is arranged on the trolley; the drug conveying pipe is arranged on the two sides of the water storage tank; the nozzle is arranged at an outlet end of the drug conveying pipe; a water inlet pipe is arranged at the top end of the water storage tank; the rotating shaft is arranged in the water storage tank; an impeller is arranged on the rotating shaft; the motor is arranged on the water storage tank; the ultraviolet lamp is arranged in the water storage tank. The efficient easily stirring and cleaning sprinkler can fully and uniformly stir the cleaning agent with water, can avoid the bacteria propagated in the water storage tank or the influence of the residue of the used cleaning agent on the effect of the cleaning effect, has a simple structure, is convenient in use and is beneficial to popularization.

Owner:宿迁洁丽环保设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com