Foam concrete stirring device and method

A foamed concrete and mixing device technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of uneven mixing, poor mixing effect, bubble burst, etc., so as to improve the mixing effect and improve the mixing effect. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

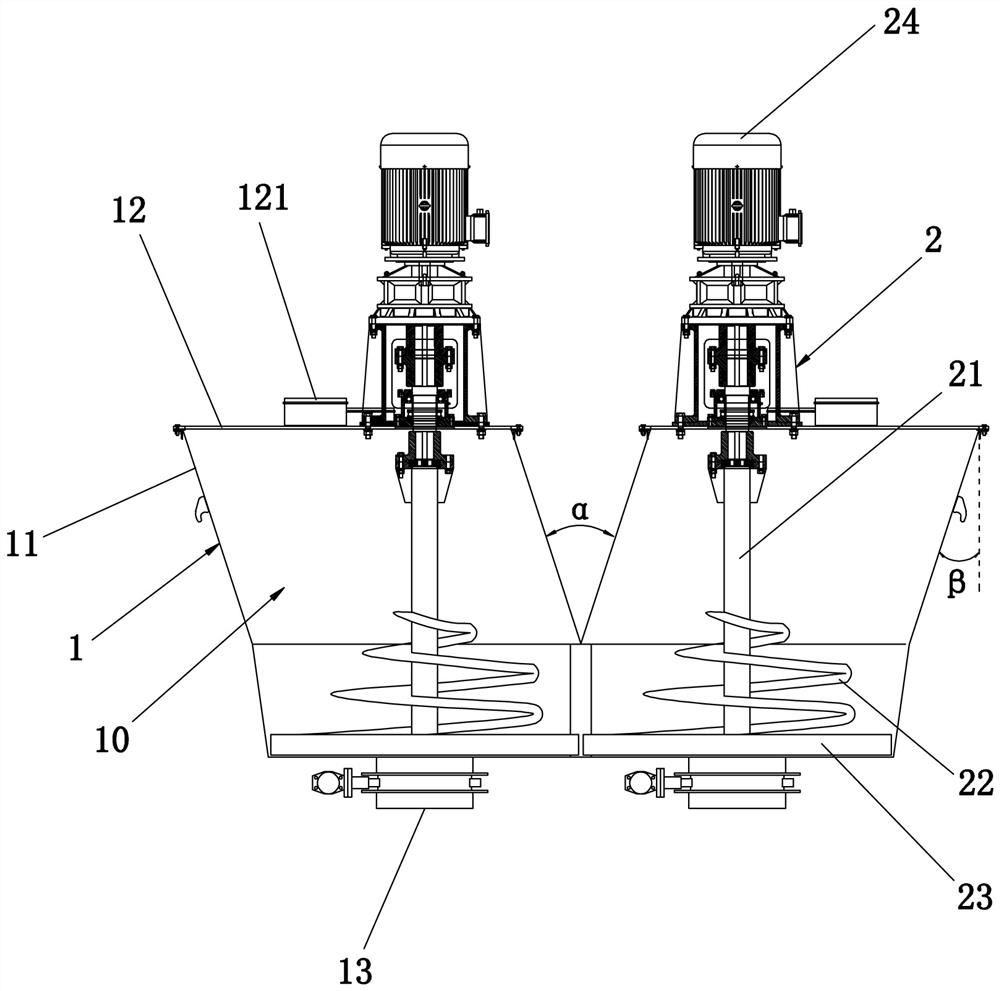

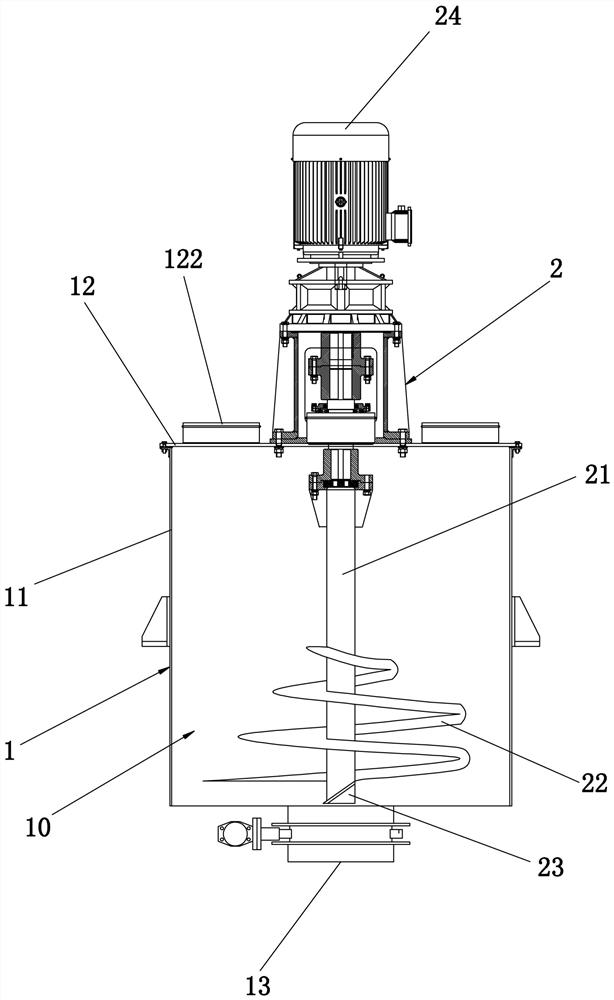

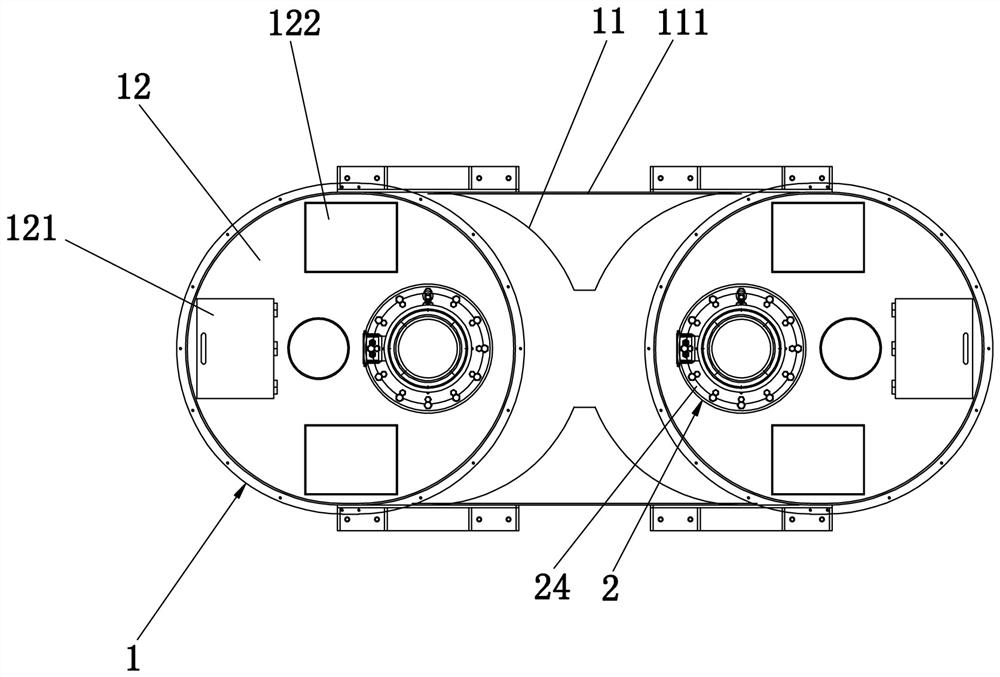

[0029] refer to Figure 1 to Figure 3 , a foam concrete mixing device, comprising a mixing tank 1 and an agitator 2; the mixing tank 1 has a mixing space 10 of V-shaped structure, and is respectively provided with an agitator 2 on both sides of the mixing space 10; the agitator 2 is provided with a belt The stirring shaft 21 of the stirring blade 22 is used to press down the slurry while stirring the slurry, so that the slurry rolls upward along the side wall of the stirring tank 1 . The present invention optimizes the design of the internal structure of the stirring tank 1, and changes the single mode of horizontal stirring of the existing stirring shaft 21, so that the slurry will roll upward along the side wall of the stirring tank 1 while rotating horizontally, thereby realizing three-dimensional Stirring effectively improves the mixing efficiency, ensures that the slurry is evenly and fully mixed, and then ensures that the specific gravity of the slurry is uniform, avoidi...

Embodiment 2

[0041] refer to Figure 1 to Figure 4 , different from Embodiment 1, the scraper 23 in this embodiment is preferably two arc-shaped scrapers arranged symmetrically in the center, thereby improving the scraping effect and lateral stirring effect of the scraper 23 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com