Preparation method of high-strength, anti-cracking and anti-seismic concrete

A concrete, high-strength technology, applied in the field of seismic concrete preparation, high-strength, and crack resistance, can solve problems such as difficulty in meeting construction requirements, and achieve the effects of not easy cracking, enhanced strength, and improved compressive strength and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

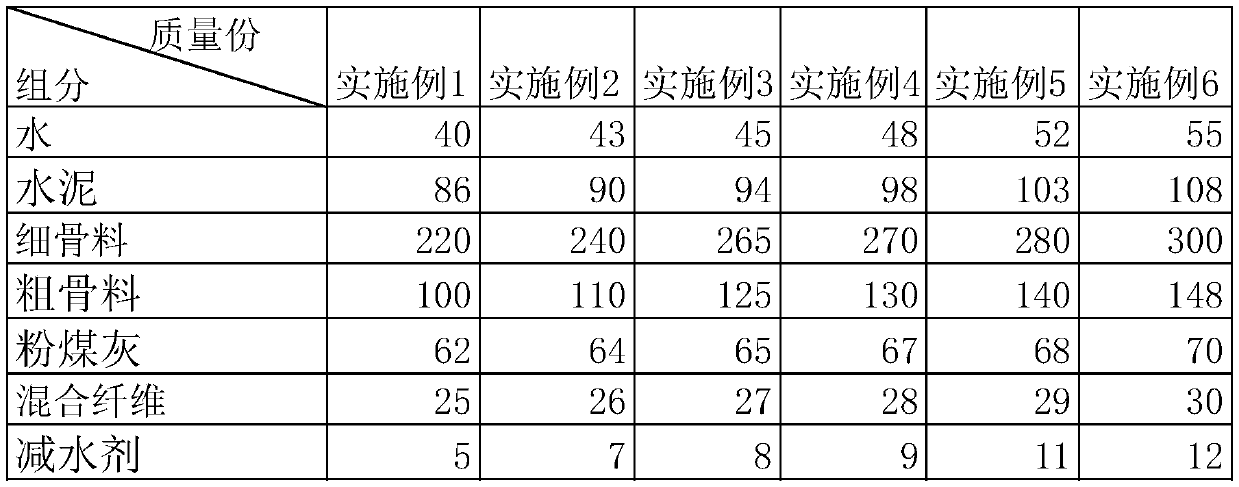

[0039] The preparation method of high-strength, crack-resistant, and earthquake-resistant concrete. The components and mass parts of the high-strength, crack-resistant, and earthquake-resistant concrete are shown in Table 1.

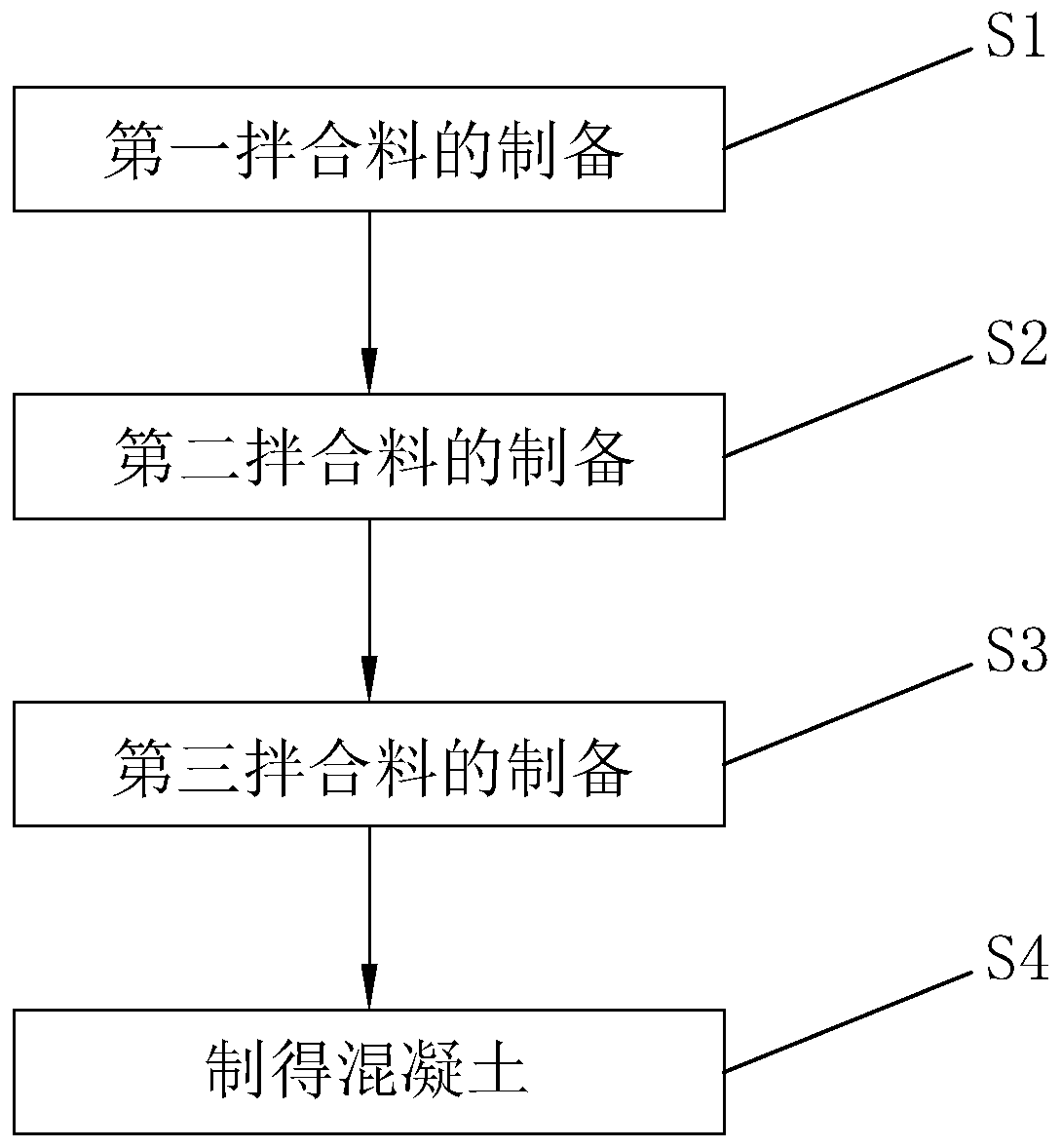

[0040] The preparation of high-strength, crack-resistant, and earthquake-resistant concrete includes the following steps:

[0041] S1. Preparation of the first mixture: In a stirring tank, add corresponding parts by mass of water and cement, and stir to prepare the first mixture. The stirring speed is 100 r / min, and the stirring time is 5 minutes. In this step, the stirring tank can be a cement mixer, but not limited to a cement mixer.

[0042] S2. Preparation of the second mixture: add corresponding parts by mass of water reducer and mixed fibers to the first mixture while stirring, and stir evenly to obtain the second mixture.

[0043] S3. Preparation of the third mixture: In the gravel mixer, under normal temperature conditions, add the corresponding...

Embodiment 2

[0046] The difference between the preparation method of high-strength, crack-resistant, and earthquake-resistant concrete and that of Example 1 is that the components and mass parts of the high-strength, crack-resistant, and earthquake-resistant concrete are shown in Table 1.

[0047] The preparation of high-strength, crack-resistant, and earthquake-resistant concrete includes the following steps:

[0048] S1. Preparation of the first mixture: In a stirring tank, add corresponding parts by mass of water and cement, and stir to prepare the first mixture. The stirring speed is 120 r / min, and the stirring time is 7 minutes. In this step, the stirring tank can be a cement mixer, but not limited to a cement mixer.

[0049]S2. Preparation of the second mixture: add corresponding parts by mass of water reducer and mixed fibers to the first mixture while stirring, and stir evenly to obtain the second mixture.

[0050] S3. Preparation of the third mixture: In the gravel mixer, under n...

Embodiment 3

[0054] The difference between the preparation method of high-strength, crack-resistant, and earthquake-resistant concrete and that of Example 2 is that the components and mass parts of the high-strength, crack-resistant, and earthquake-resistant concrete are shown in Table 1.

[0055] The preparation of high-strength, crack-resistant, and earthquake-resistant concrete includes the following steps:

[0056] S1. Preparation of the first mixture: In a stirring tank, add corresponding parts by mass of water and cement, and stir to prepare the first mixture. The stirring speed is 150 r / min, and the stirring time is 8 minutes.

[0057] S2. Preparation of the second mixture: add corresponding parts by mass of water reducer and mixed fibers to the first mixture while stirring, and stir evenly to obtain the second mixture.

[0058] S3. Preparation of the third mixture: In the gravel mixer, under normal temperature conditions, add the corresponding mass parts of coarse aggregate and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com