Organic silicon slag slurry treatment method

A technology for organosilicon slurry and treatment methods, which is applied in the direction of separation methods, chemical instruments and methods, mixers with rotating stirring devices, etc., and can solve the problems of failure to achieve sufficient stirring of organic silicon slurry, treatment efficiency, etc. The insulation effect is not involved in other issues, so as to increase the utilization rate of energy, improve the service life, and improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

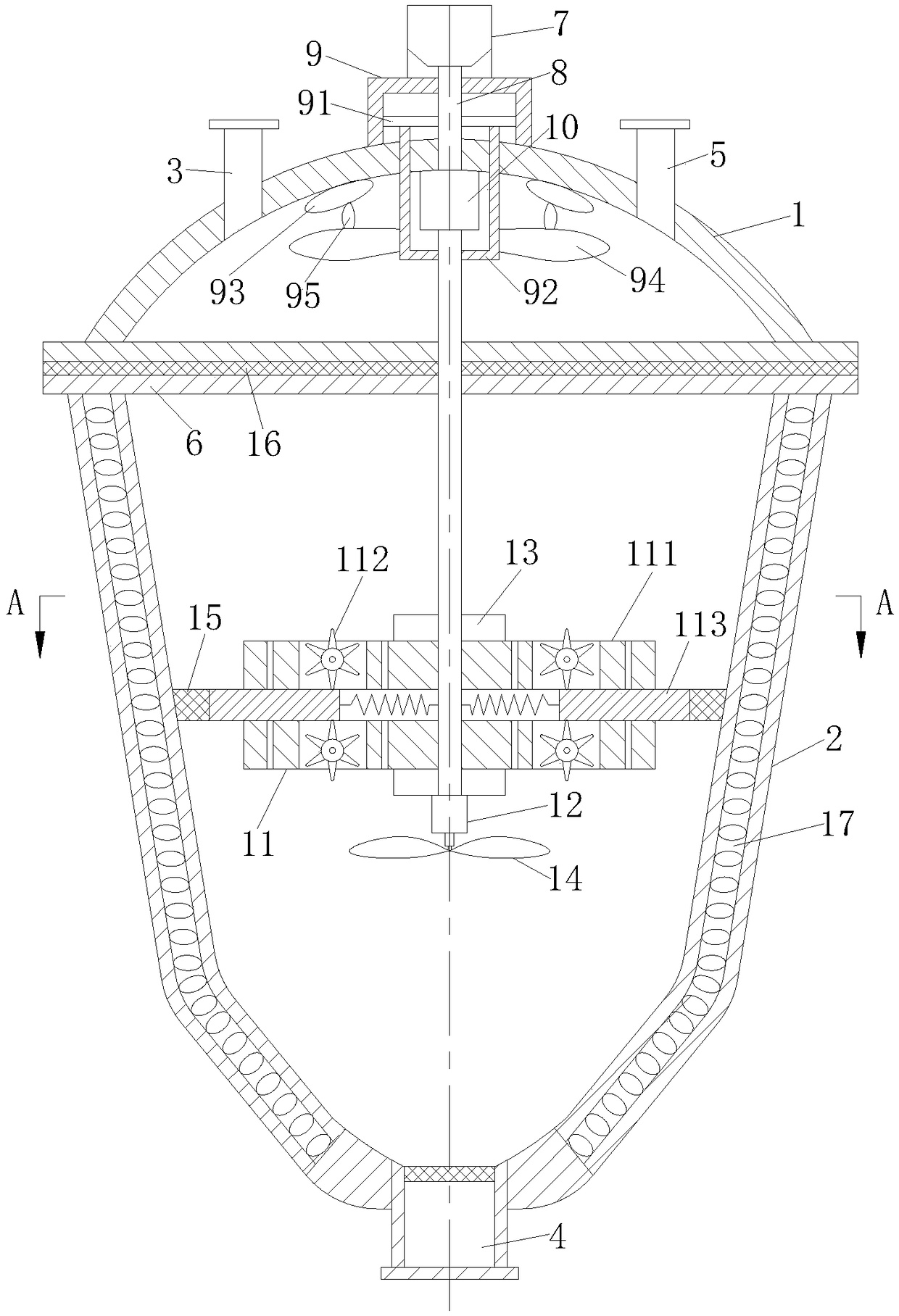

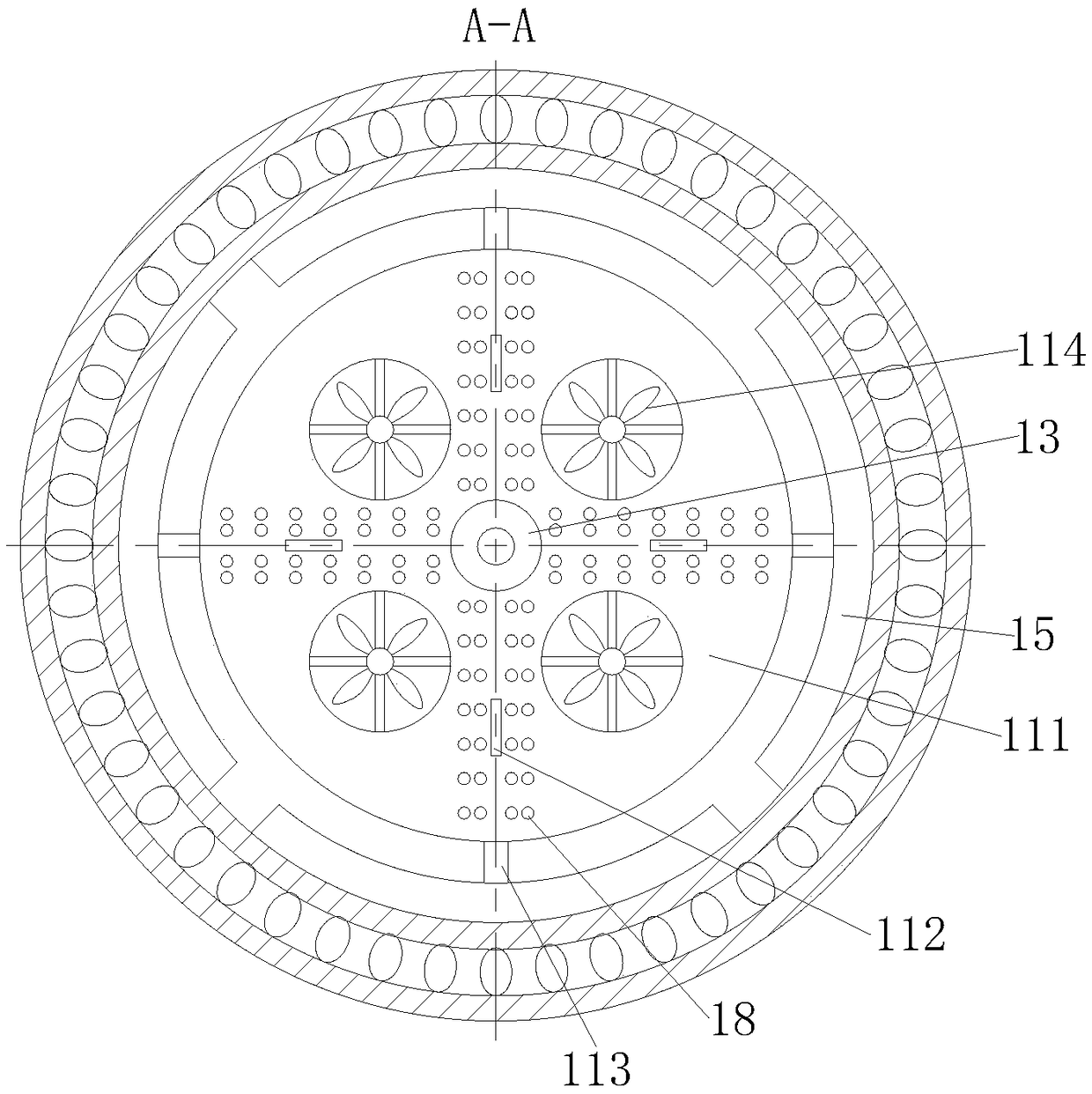

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

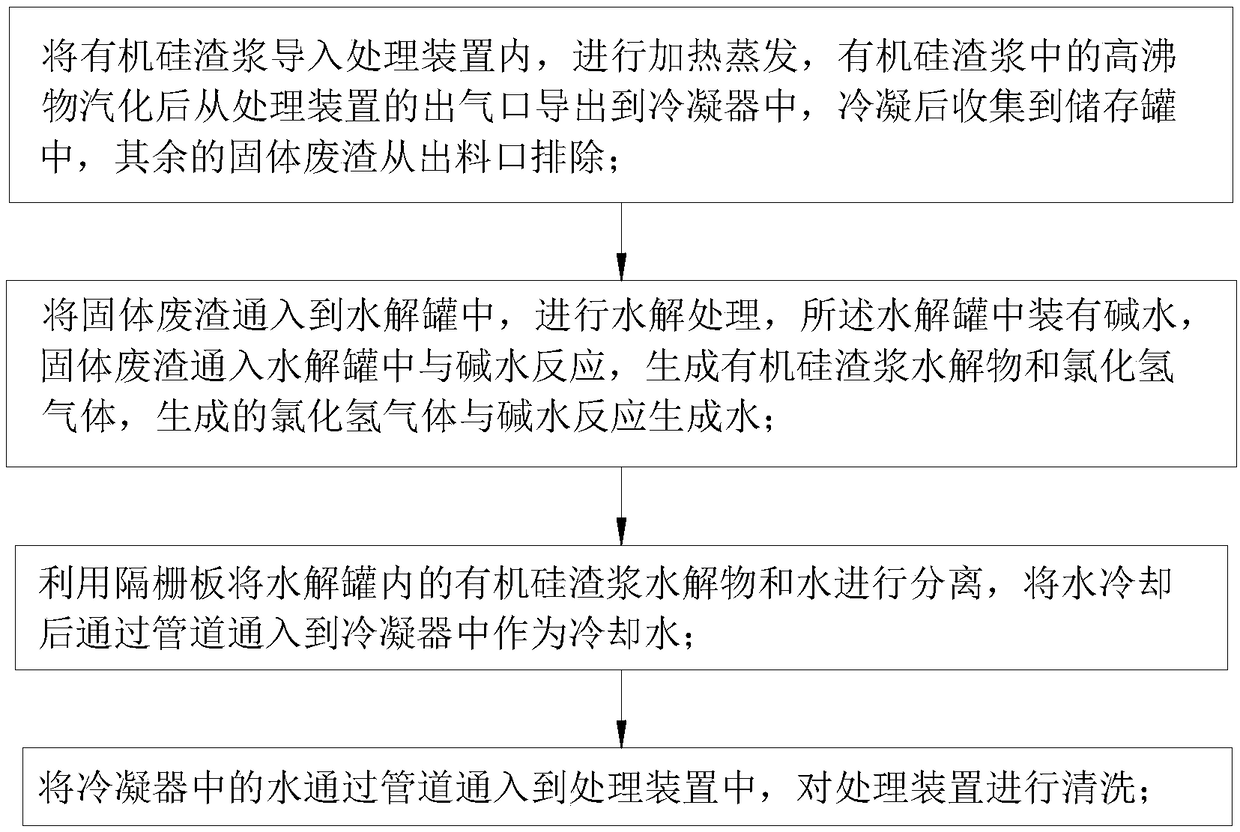

[0028] like Figure 1 to Figure 3 Shown, a kind of organic silicon slurry processing method of the present invention, the method step is as follows:

[0029] S1: Lead the organic silicon slurry into the treatment device for heating and evaporation. After the high boilers in the organic silicon slurry are vaporized, they are exported from the gas outlet of the treatment device to the condenser, and collected into the storage tank after condensation. The rest of the solids The waste residue is discharged from the discharge port;

[0030] S2: Pass the solid waste residue in S1 into a hydrolysis tank for hydrolysis treatment. The hydrolysis tank is filled with alkaline water, and the solid waste residue is passed into the hydrolysis tank to react wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com