3D concrete printing device and method for building automatic reinforcement

A 3D printing and construction automation technology, which is applied in clay preparation devices, construction materials processing, construction, etc., can solve problems such as difficult cleaning of nozzles and pipes, rough and uneven printing surfaces, and easy clogging of concrete, so as to avoid clogging and resist tension. Enhanced strength, avoid rough and uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

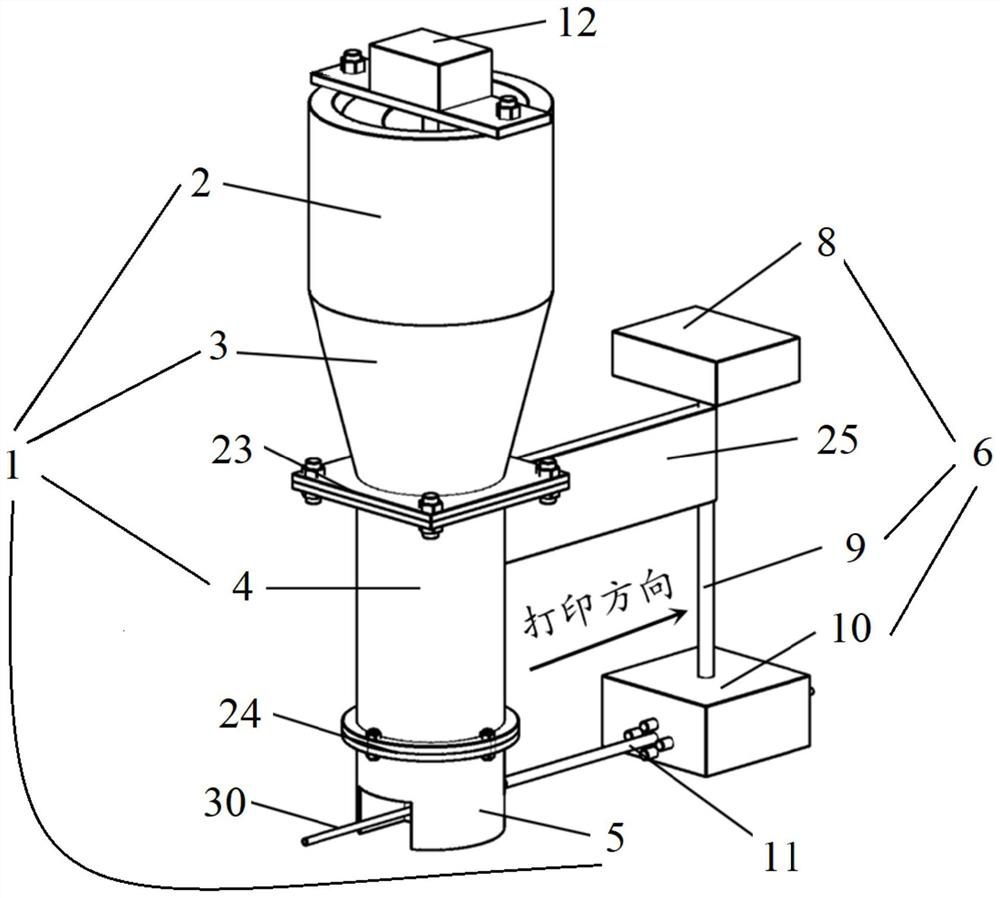

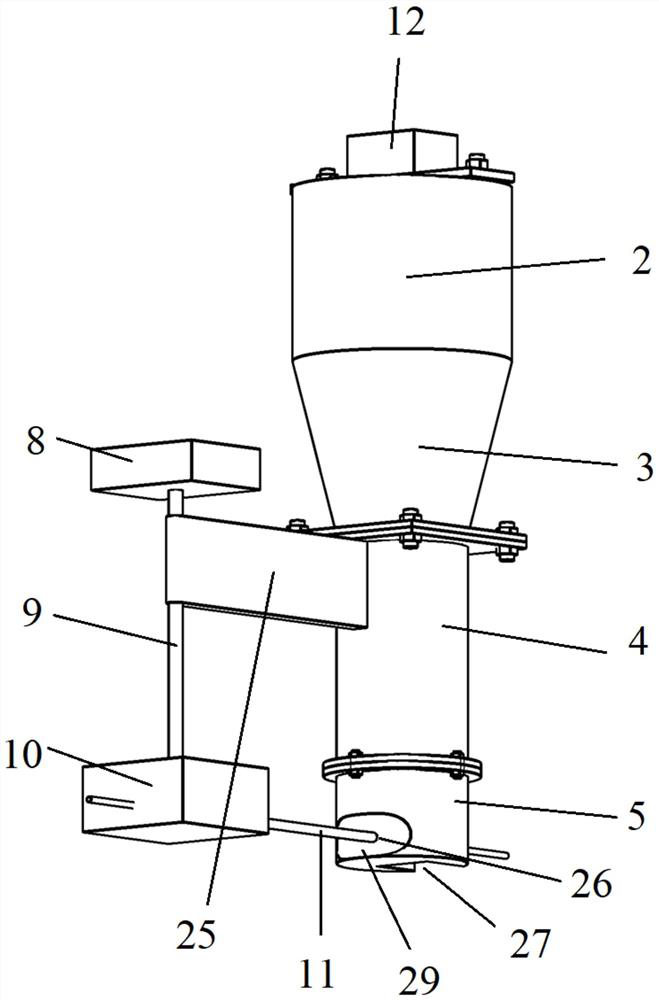

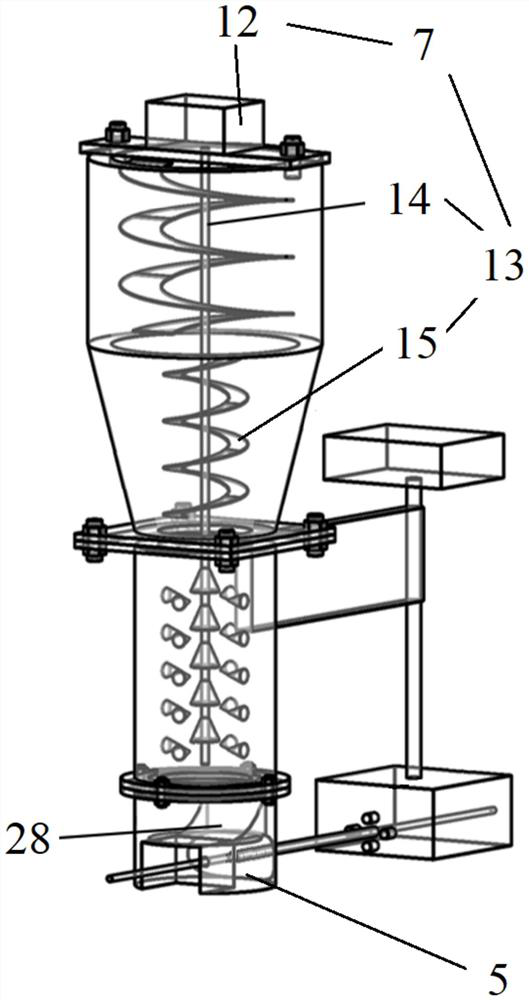

[0046] Comply with the above technical solutions, such as Figure 1 ~ Figure 4 As shown, this embodiment provides a 3D printing concrete device for building automatic reinforcement, including a concrete sprinkler device 1, and the concrete sprinkler device 1 includes a sequentially connected material barrel 2, a mixing drum 3, and a feeding channel 4 and nozzle 5, also includes the reinforcement device 6 that is connected with concrete sprinkler device 1, and described reinforcement device 6 is connected with nozzle 5, is all provided with in the described barrel 2, mixing drum 3, feed channel 4 Stirring Conveyor 7.

[0047] The concrete enters the mixing drum 3, the feeding channel 4 and the nozzle 5 from the material barrel 2, and is evenly stirred in the material barrel 2, the mixing tube 3, and the material transferring channel 4, and then is sprayed out from the nozzle 5, and the reinforcement device 6 is used to give the printed Insert steel bars 30 into the concrete, a...

Embodiment 2

[0070] Comply with the above technical solutions, such as Figure 5 As shown, this embodiment provides a 3D printing concrete printing method for building automatic reinforcement, which is carried out by using the 3D printing concrete device for building automatic reinforcement described in Example 1.

[0071] Including the following steps:

[0072] Step 1: Pour the material components in the printed concrete into the barrel 2, and after being fully stirred evenly by the barrel 2, the mixing barrel 3 and the material transfer channel 4, extrude it from the specially designed nozzle 5 to form a long strip printing layer;

[0073] Step 2: While the nozzle 5 is extruding the printed concrete, the steel bar 30 has passed through the steel bar channel 11 of the wire extruder 10 to the beginning of the printing layer. Under the action of the connecting block 25, the nozzle device 1 and the reinforcement device 6 The whole moves toward the printing direction, so as to realize the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com