Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Solve the problem of black smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

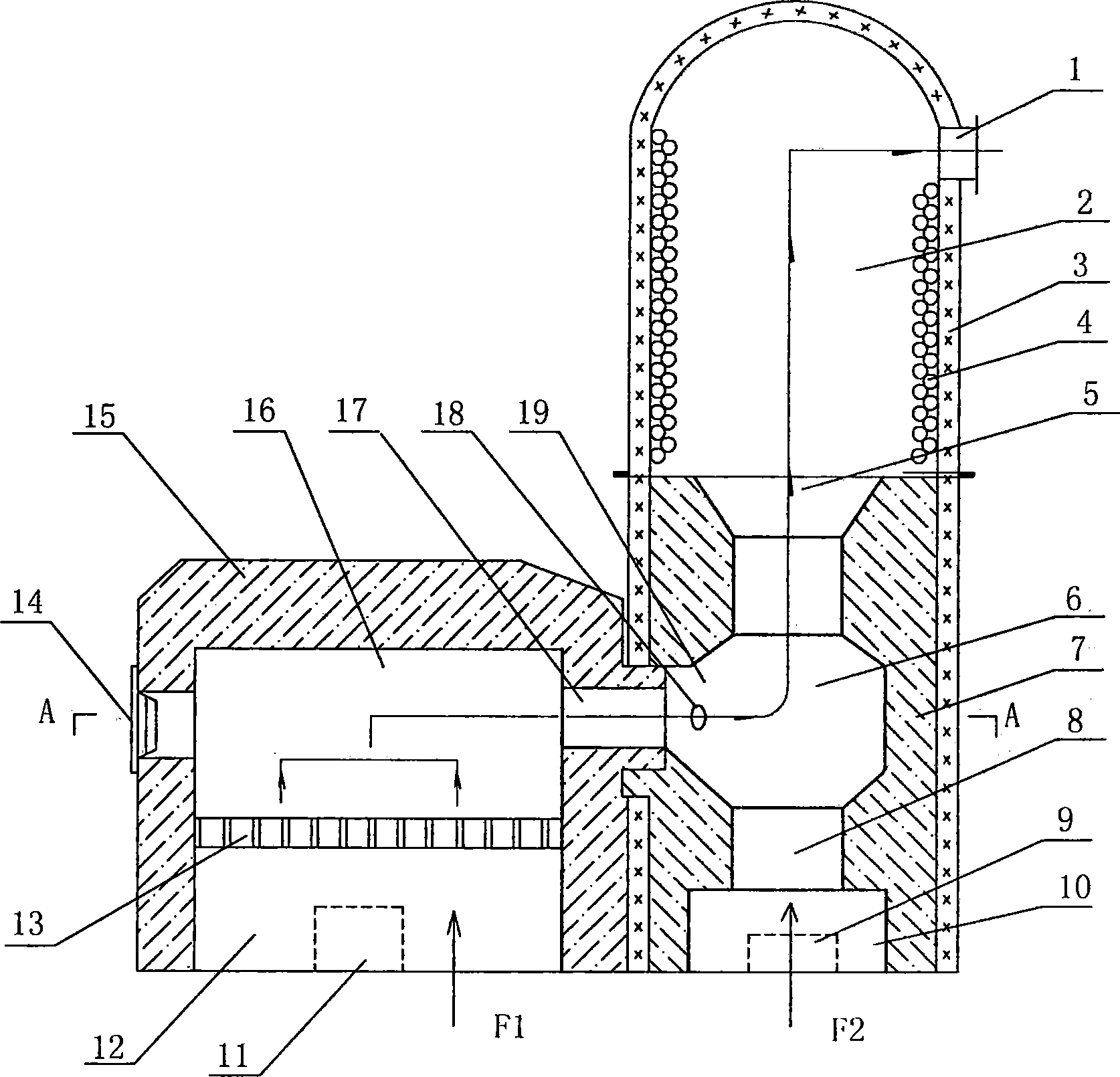

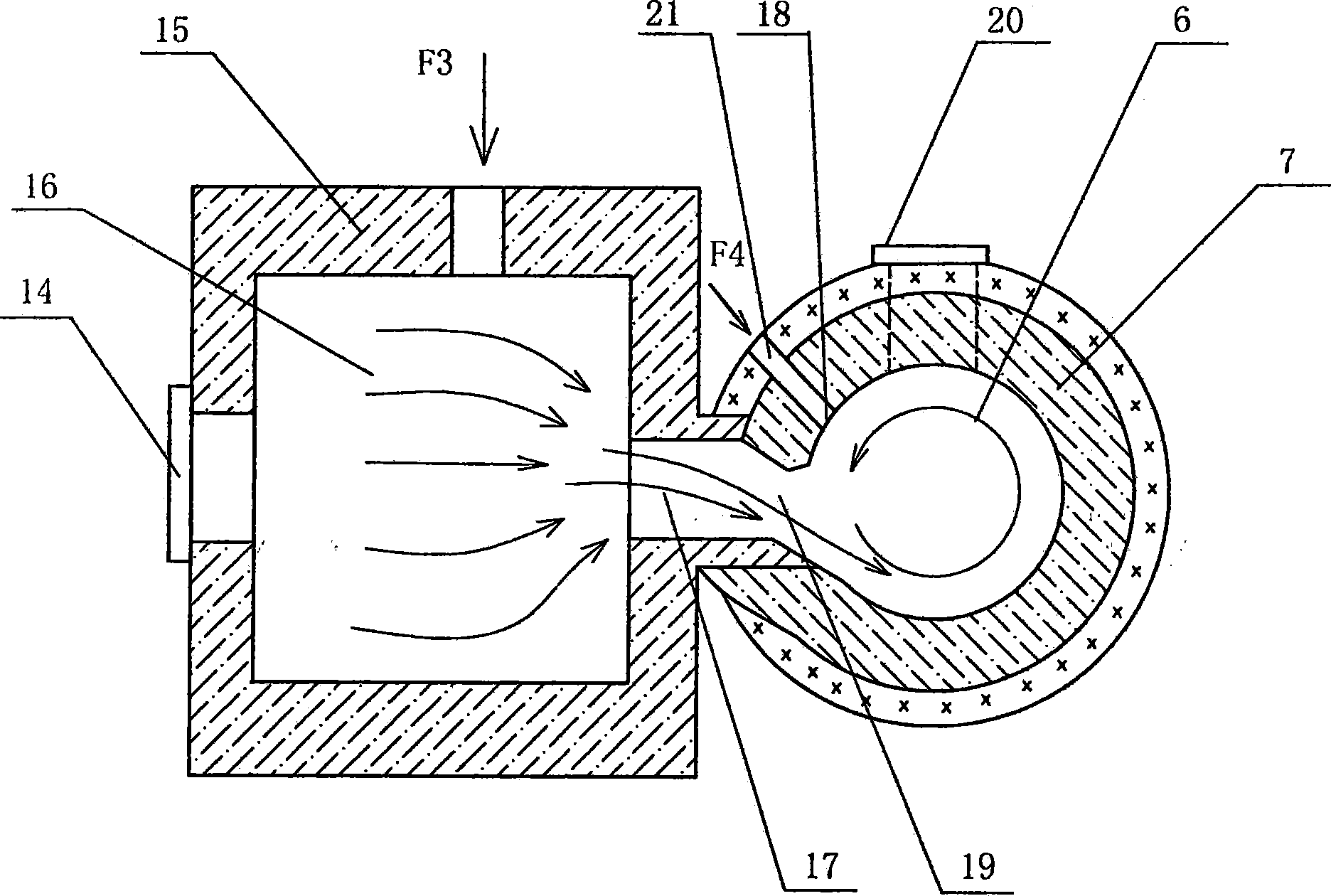

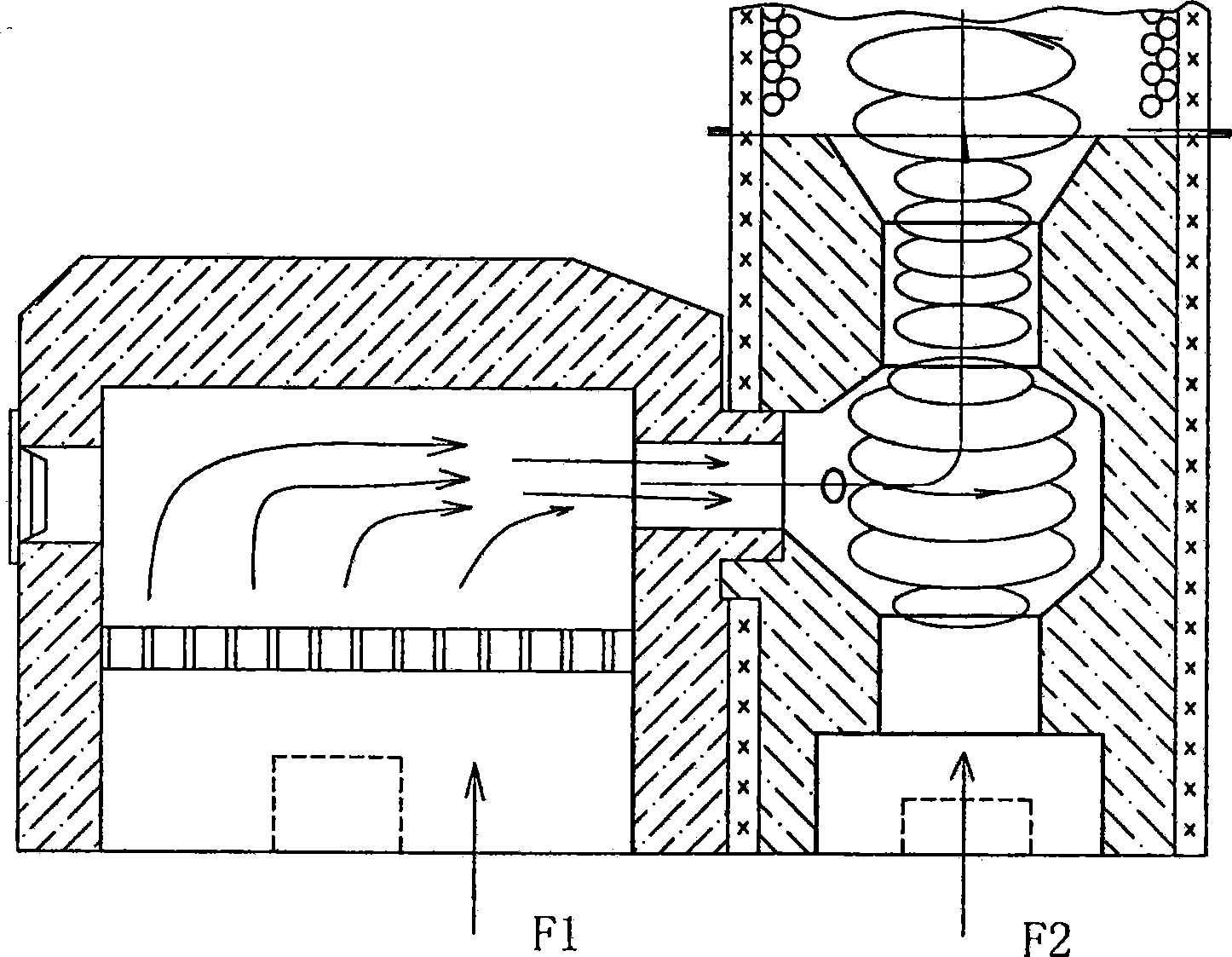

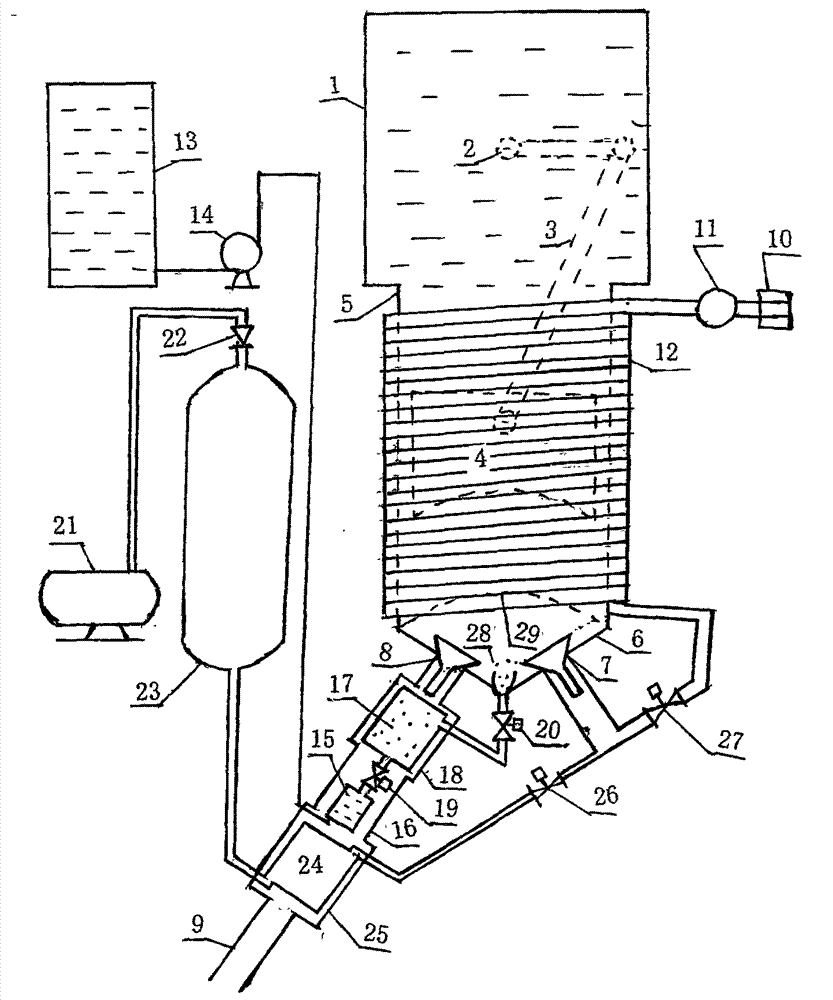

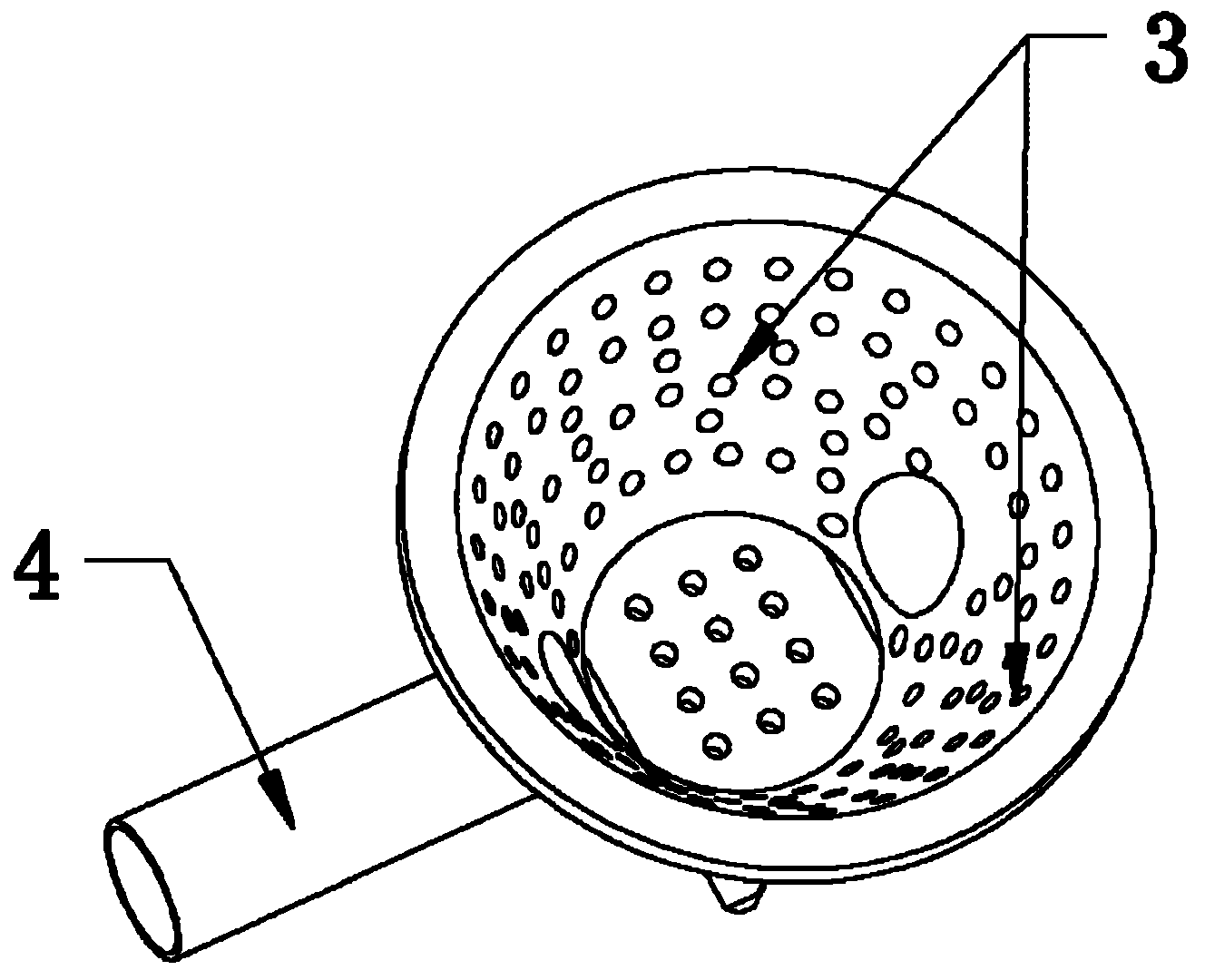

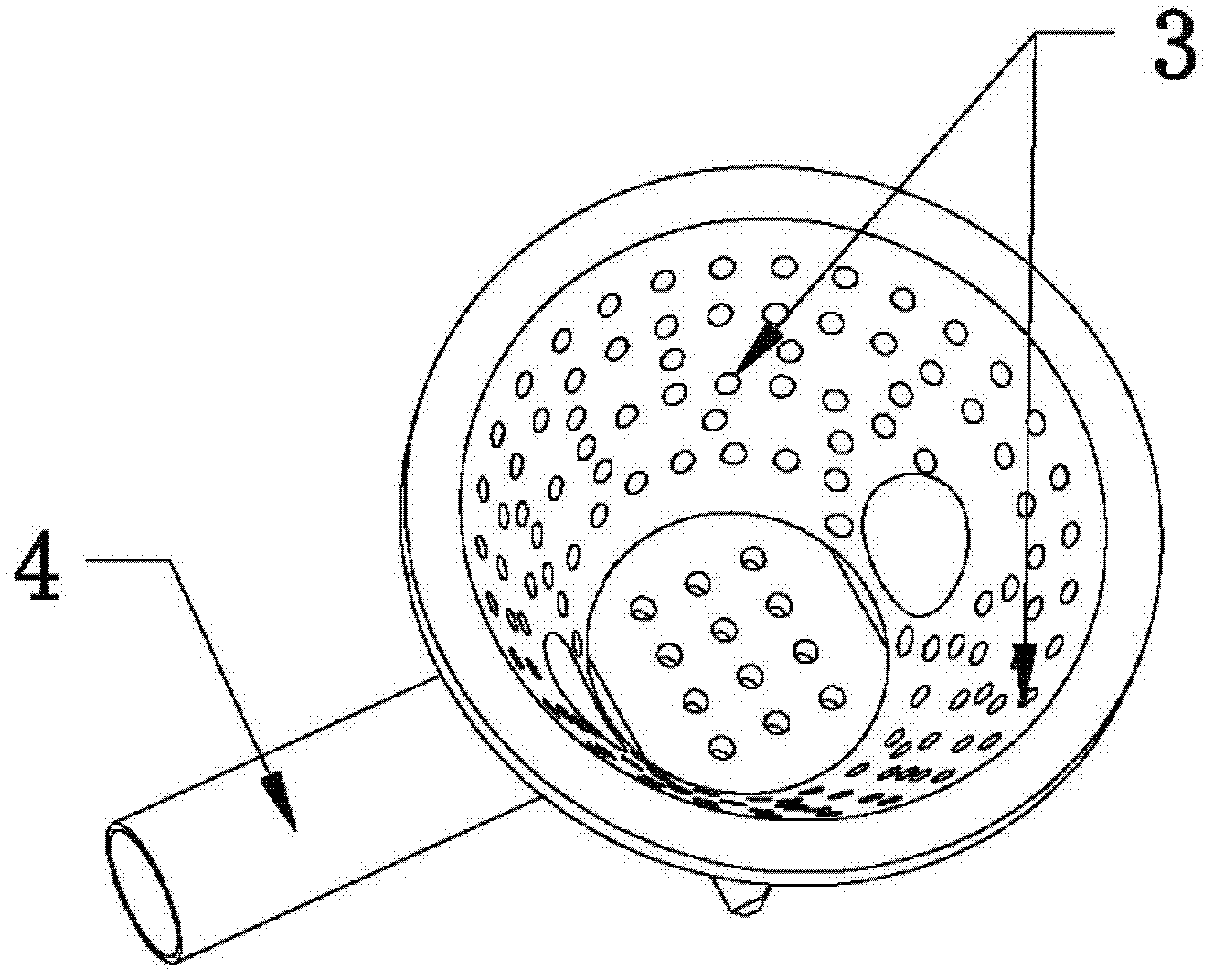

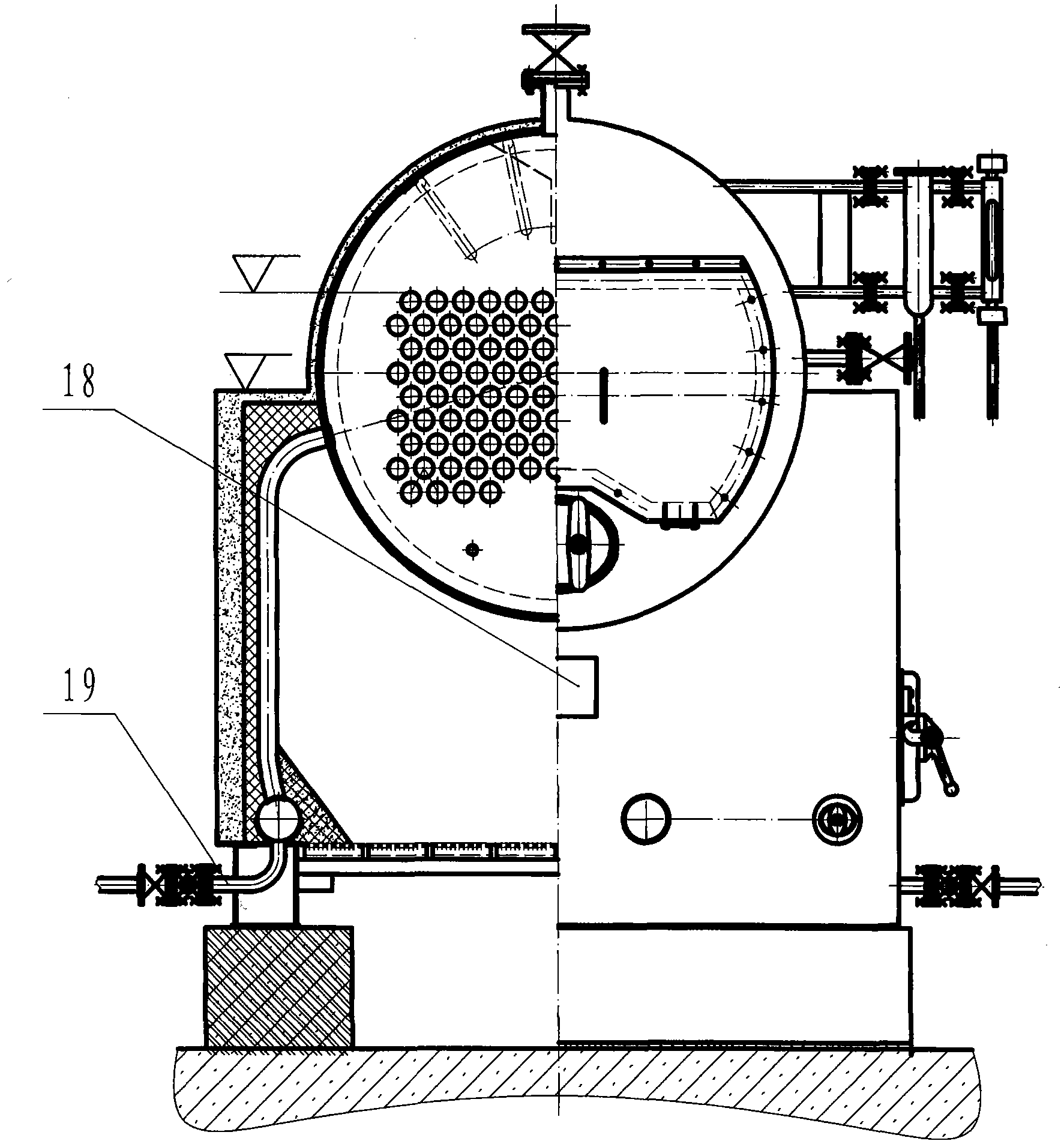

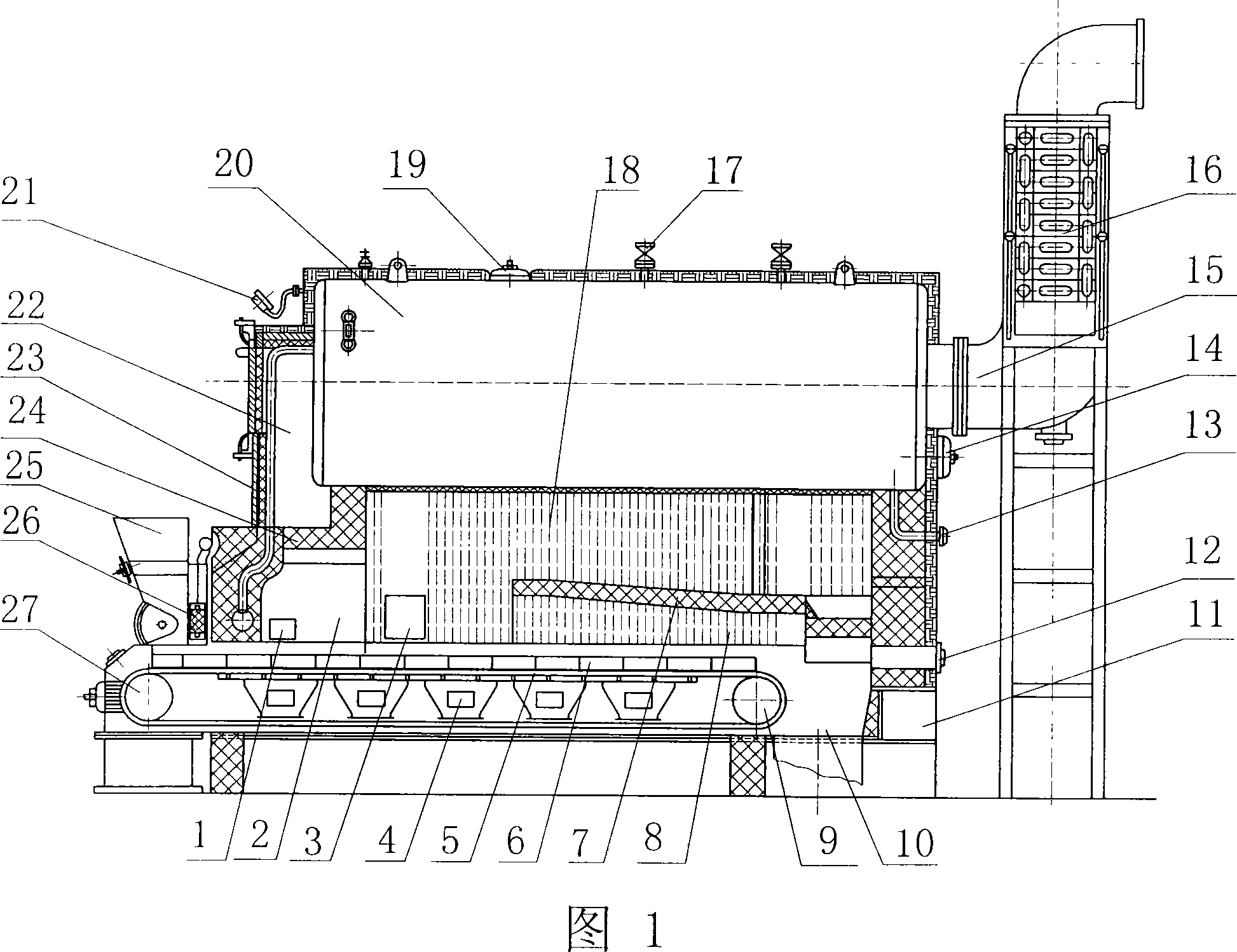

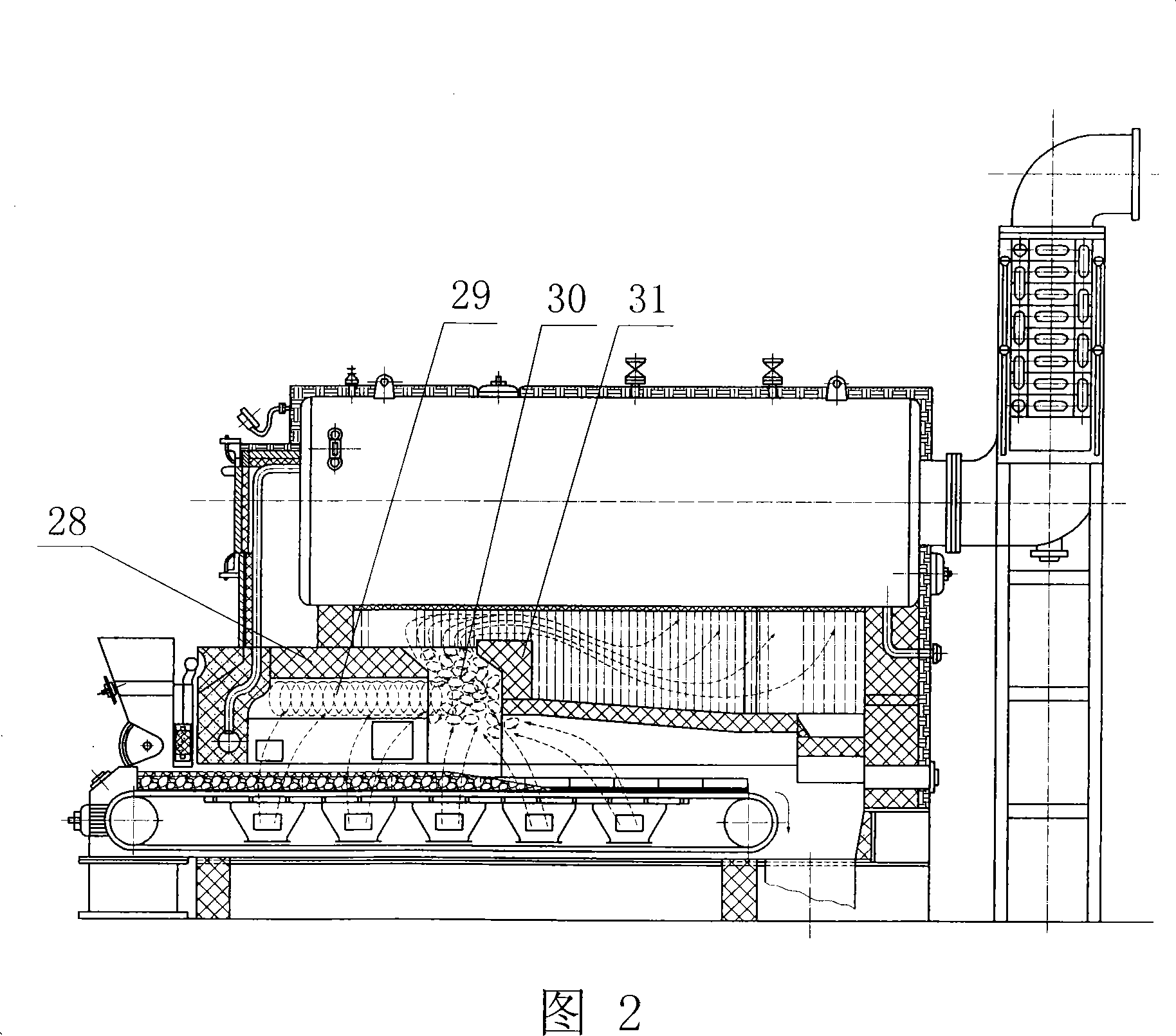

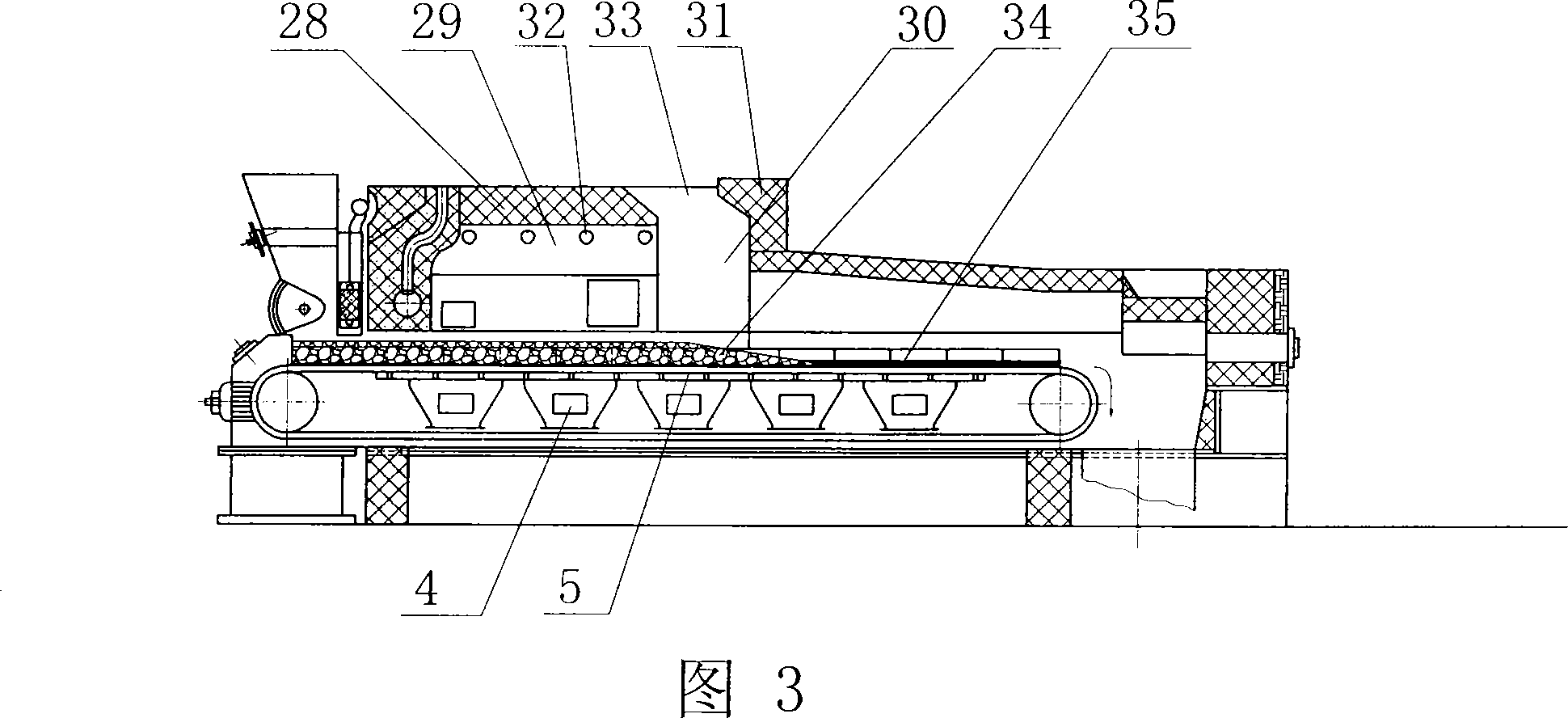

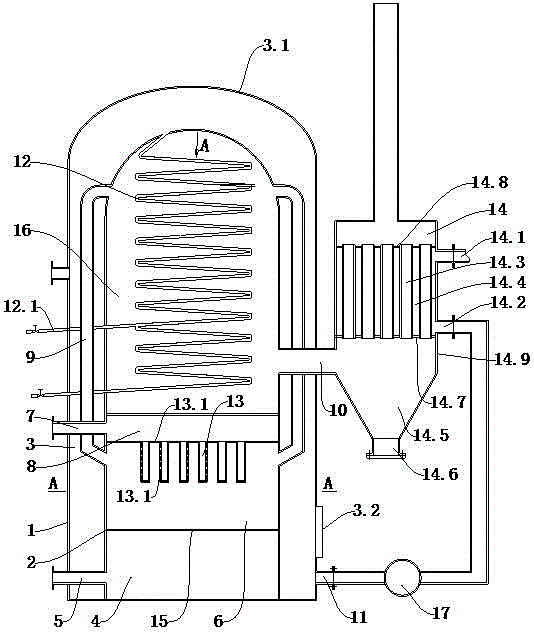

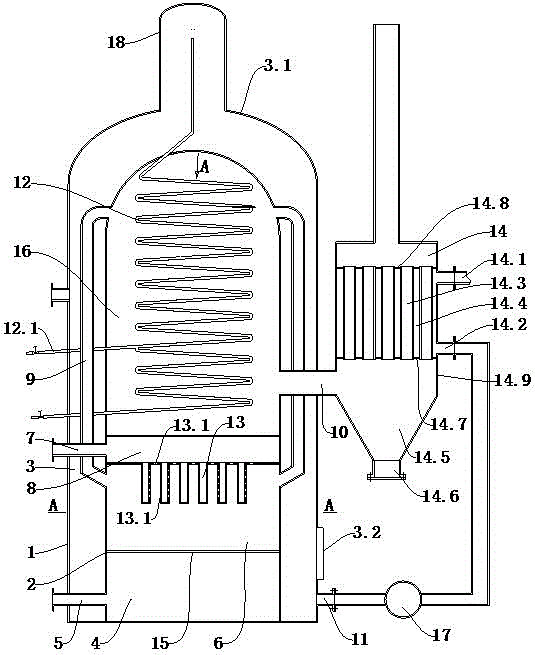

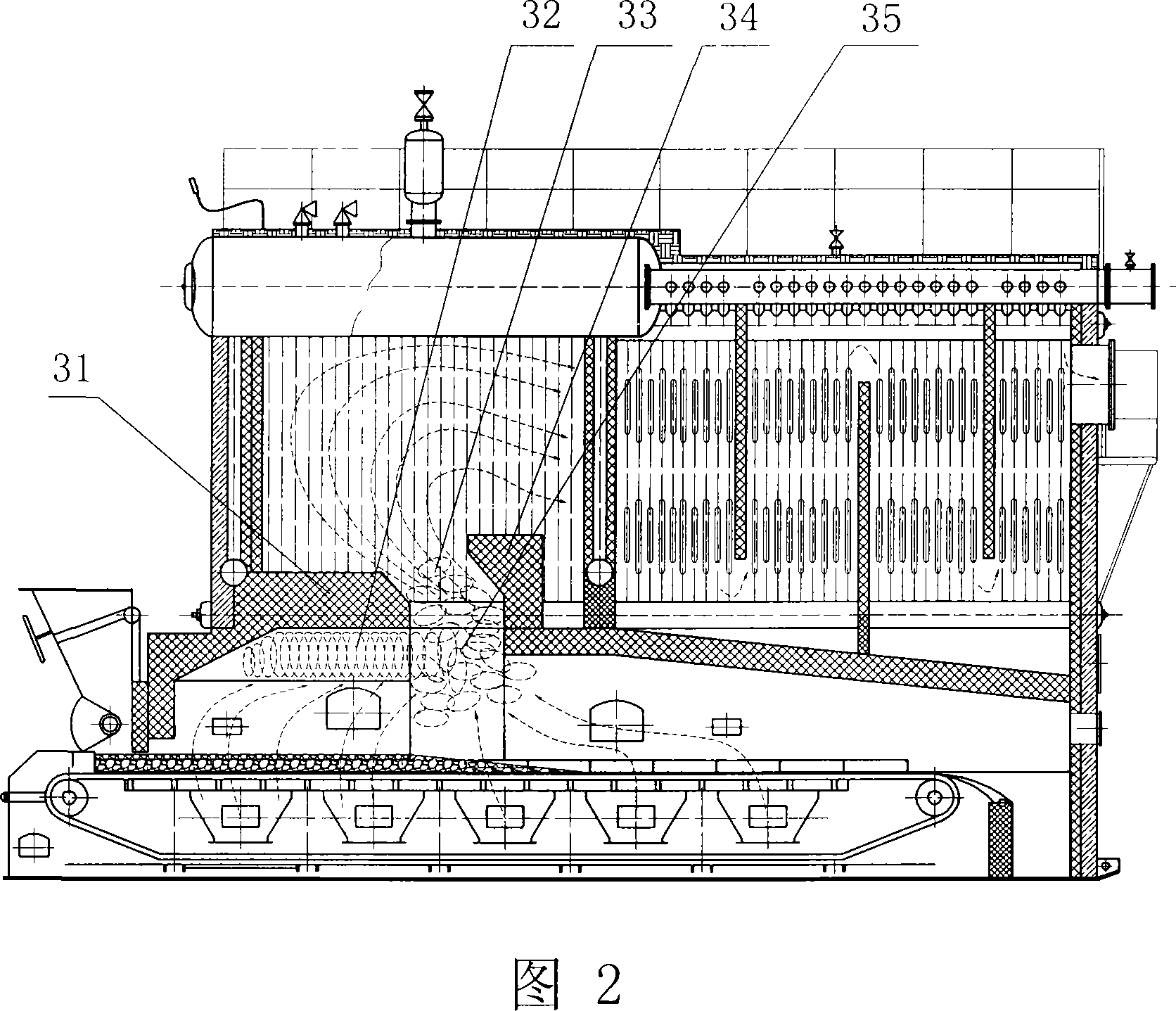

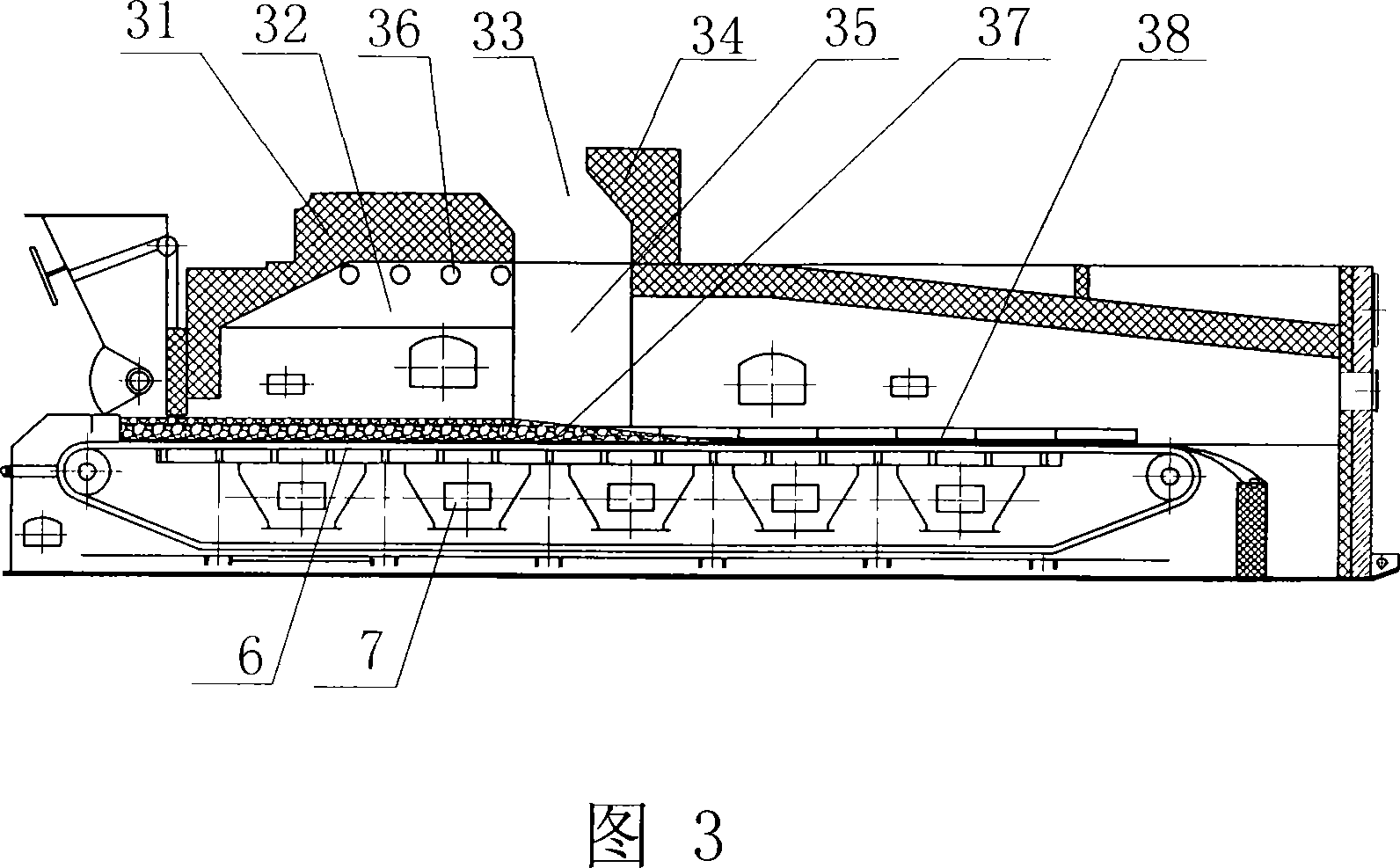

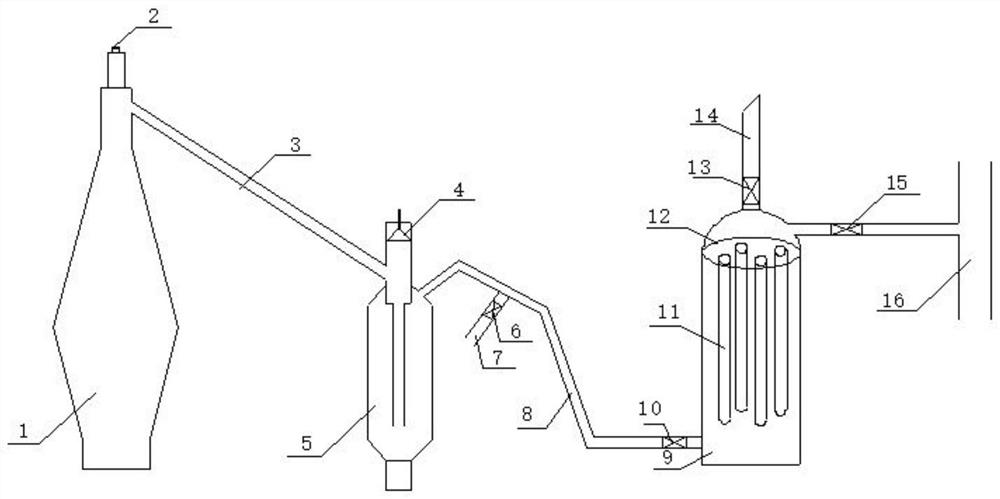

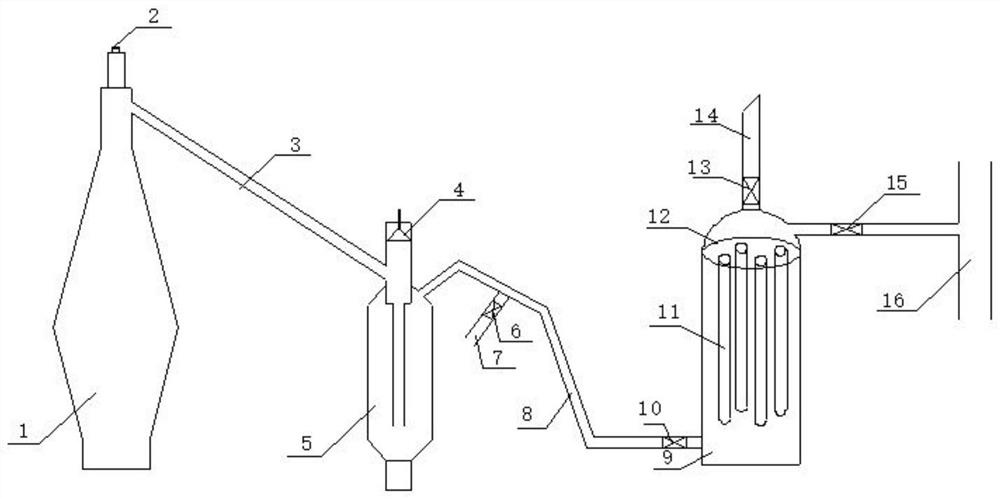

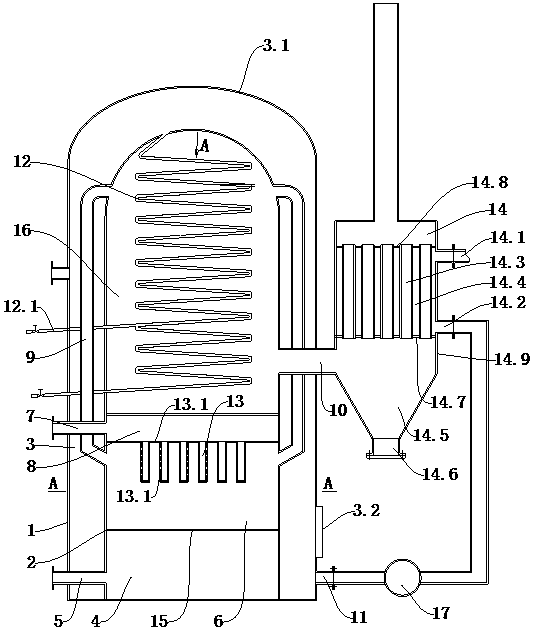

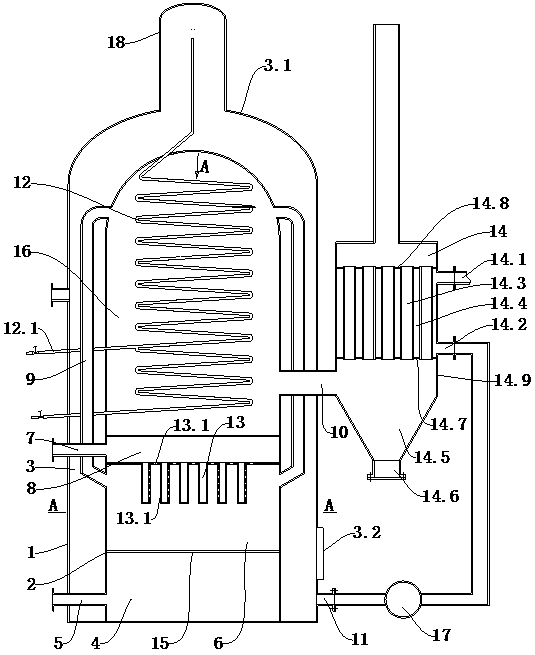

Industrial boiler for burning bio-briquettes

ActiveCN101818891AEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

Owner:ZHEJIANG JINGUO BOILER

Converter bedding face repairing material and use method thereof

The invention relates to a converter bedding face repairing material and a use method of the converter bedding face repairing material. According to the technical scheme, the converter bedding face repairing material is composed of a component A and a component B; the component A is formed by mixing raw materials including 40-65 wt% of magnesia particles, 10-20 wt% of forsterite particles, 5-15 wt% of magnesia fine powder, 10-15 wt% of fused quartz fine powder, 2-5 wt% of quartz fine powder, 5-10 wt% of silicon carbide micro powder, 0.5-2 wt% of alpha-Al2O3 micro powder and 1-3 wt% of magnesia rich spinel micro powder, and additional raw materials including 0.05-0.15 wt% of organic fibers and 0.1-1 wt% of borax; the component B is formed by mixing thermally conductive silicone grease, organosilicon compounds and waste engine oil by a mass ratio of 1: 1: (3-5). When the converter bedding face repairing material is used, the component A and the component B are mixed by a mass ratio of 1: (0.04-0.08), are stirred to be in a plastic flowing shape and are fed into a hopper to be thrown into a converter, the converter body is shaken rapidly, and the repaired part is paved with the repairing material. The converter bedding face repairing material has the advantages of being good in high-temperature self-flowing performance, short in sintering time, long in service life and environmentally friendly.

Owner:WUHAN UNIV OF SCI & TECH

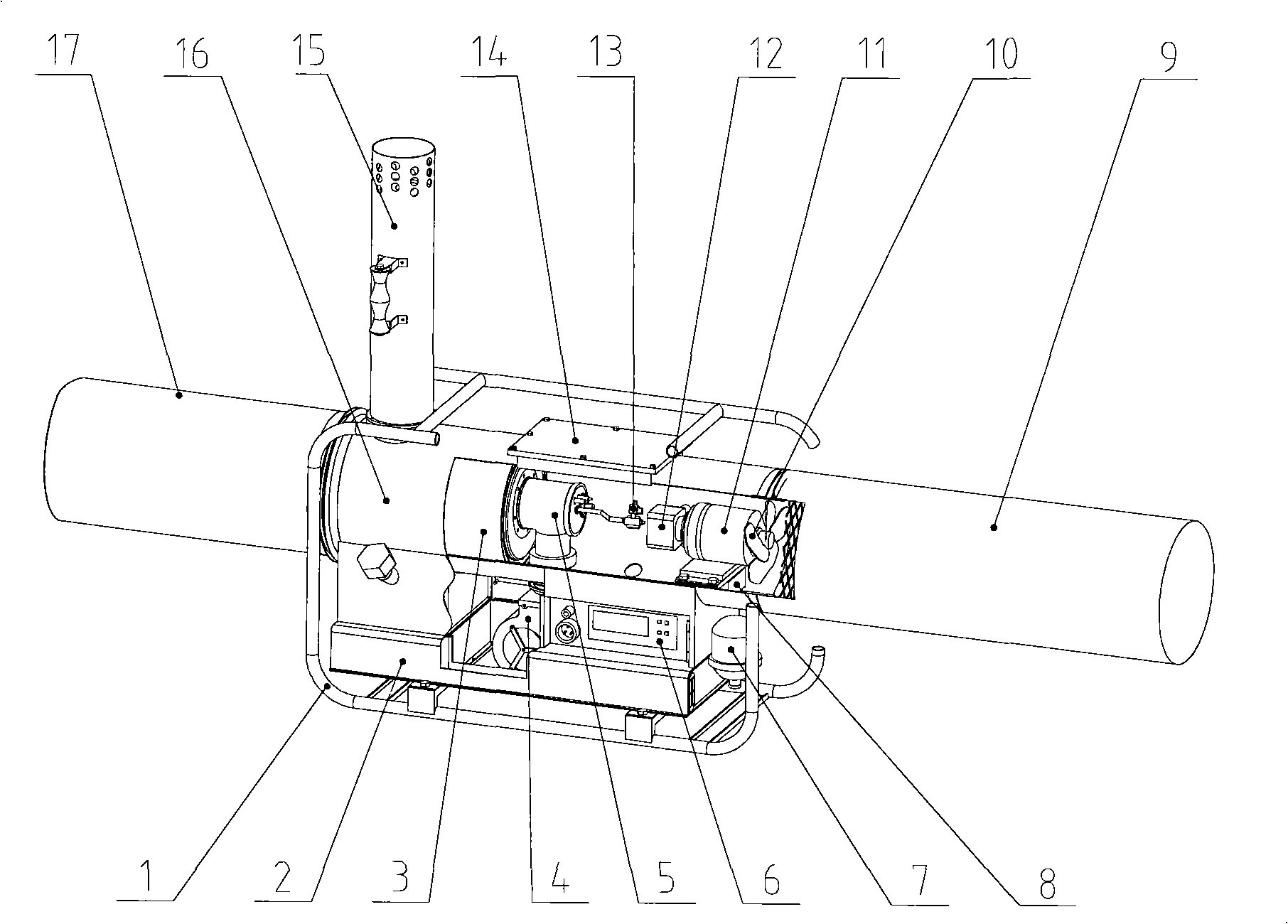

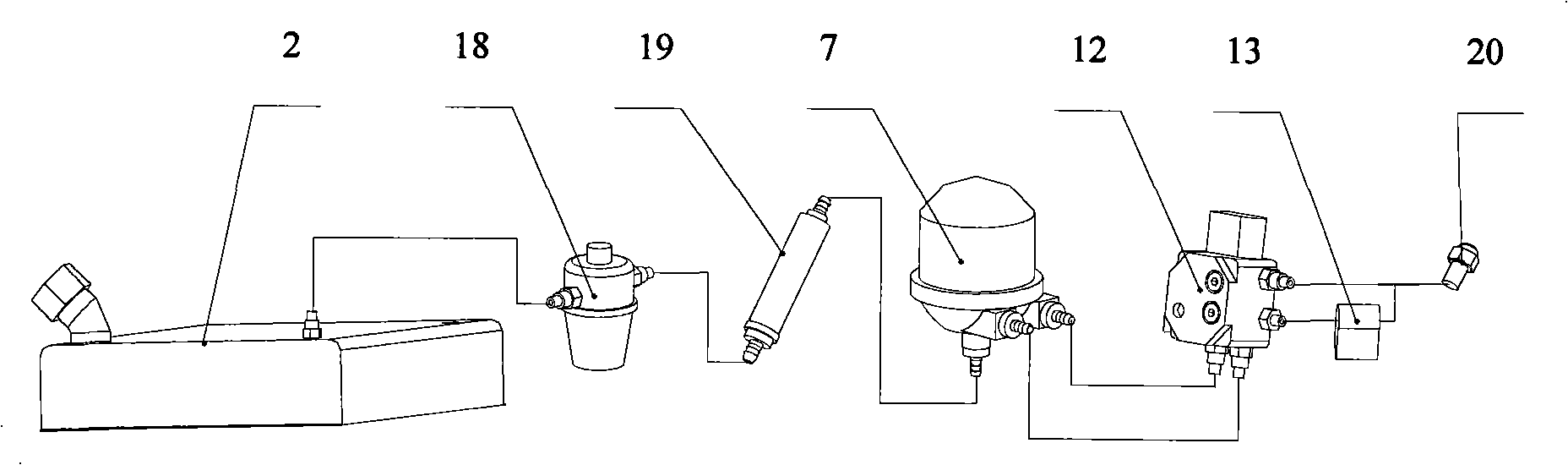

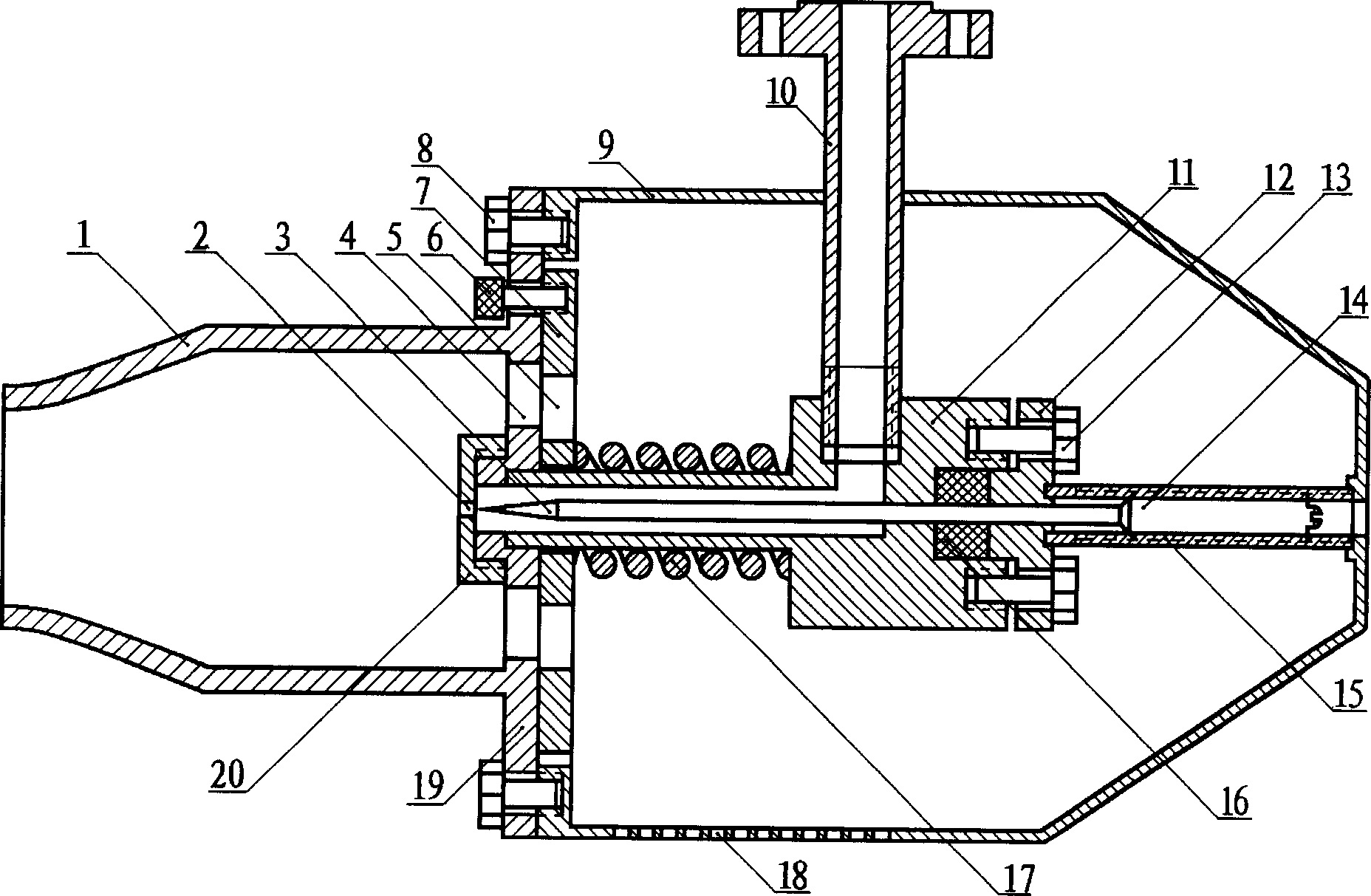

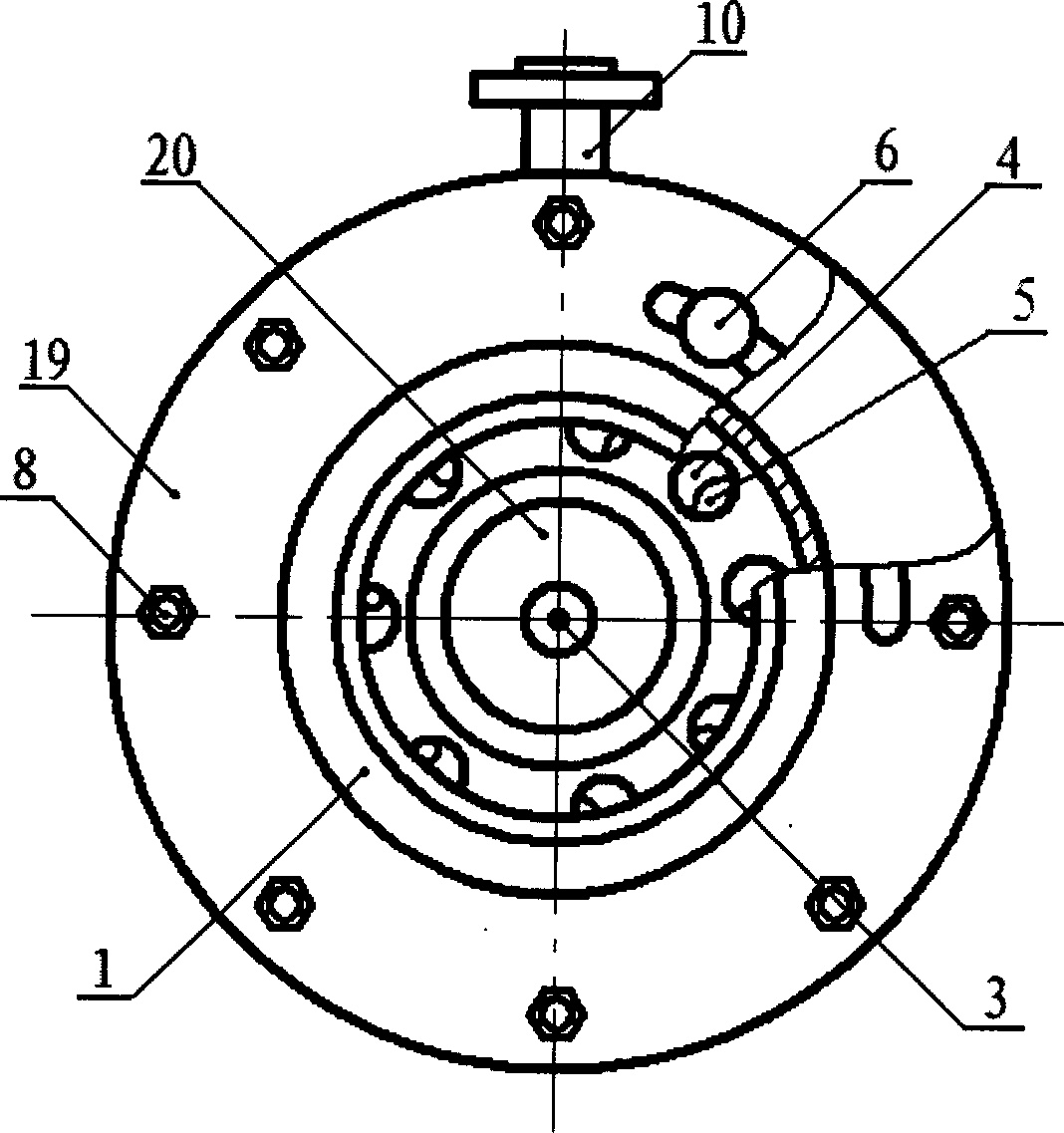

Portable fuel heater unit

The invention discloses a portable fuel heater unit. The bottom of a frame is fixed with a fuel tank, the middle of the fuel tank is fixed with a combustion fan, the frame is provided with a controller, the side is provided with a flow control valve, the heater unit is fixed with a cylinder body close to the upper part, the inner part of the cylinder is axially sequentially provided with a combustion chamber and a heat exchanger which are connected with a combustion system, the combustion is connected with a normally open solenoid valve of a fuel supply system through a fuel pipe and is connected with a fuel pump through a fuel pipe, one end of a motor is connected with the fuel pump, the other end of the motor is connected with a heat exchange fan, the motor is fixed in the cylinder body, the controller is connected with an ignition transformer, and flue pipes are inserted into outlets of the combustion chamber and the heat exchanger.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

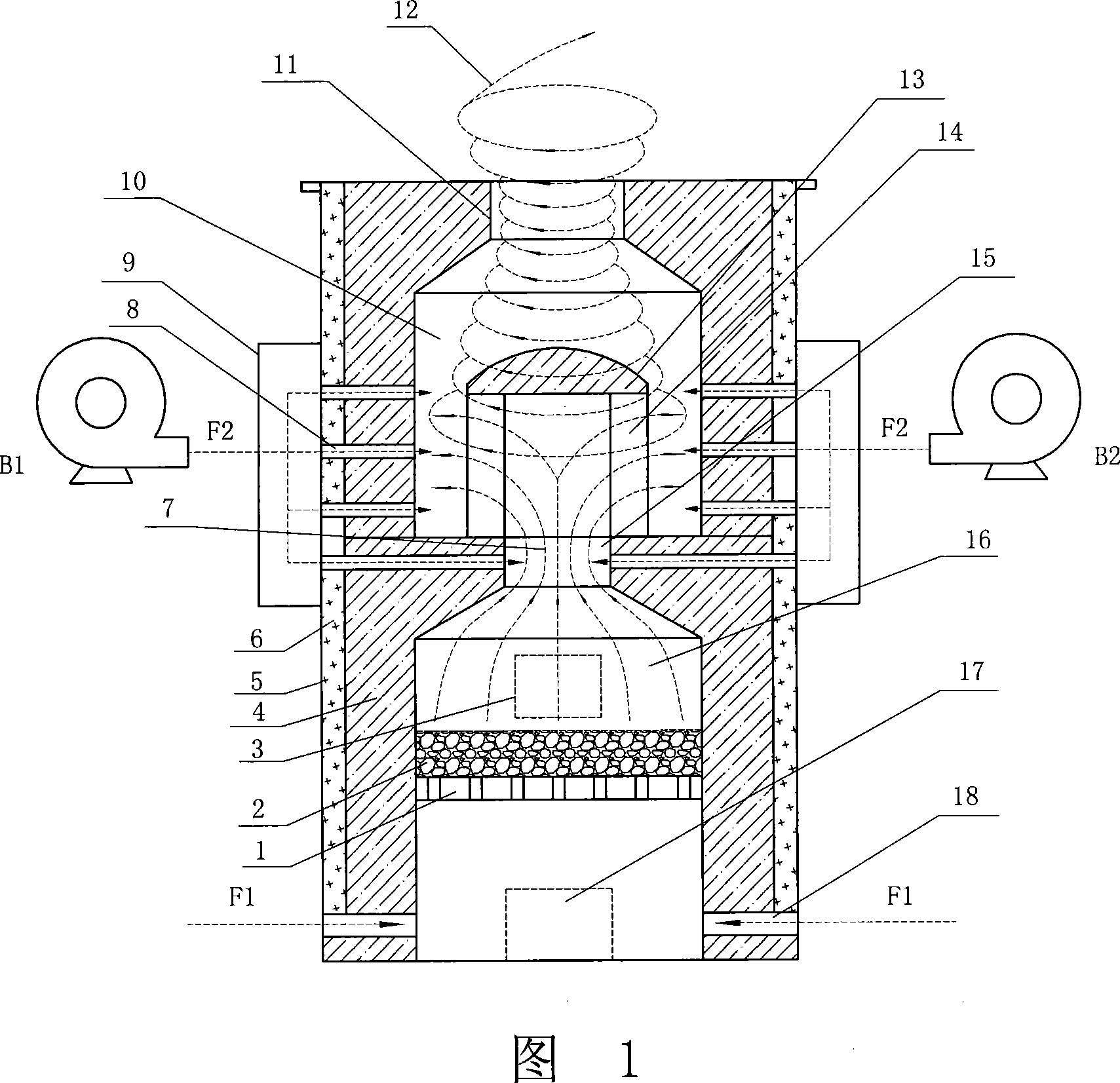

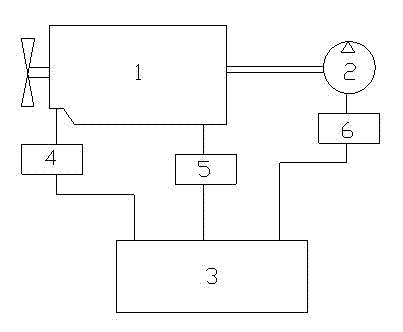

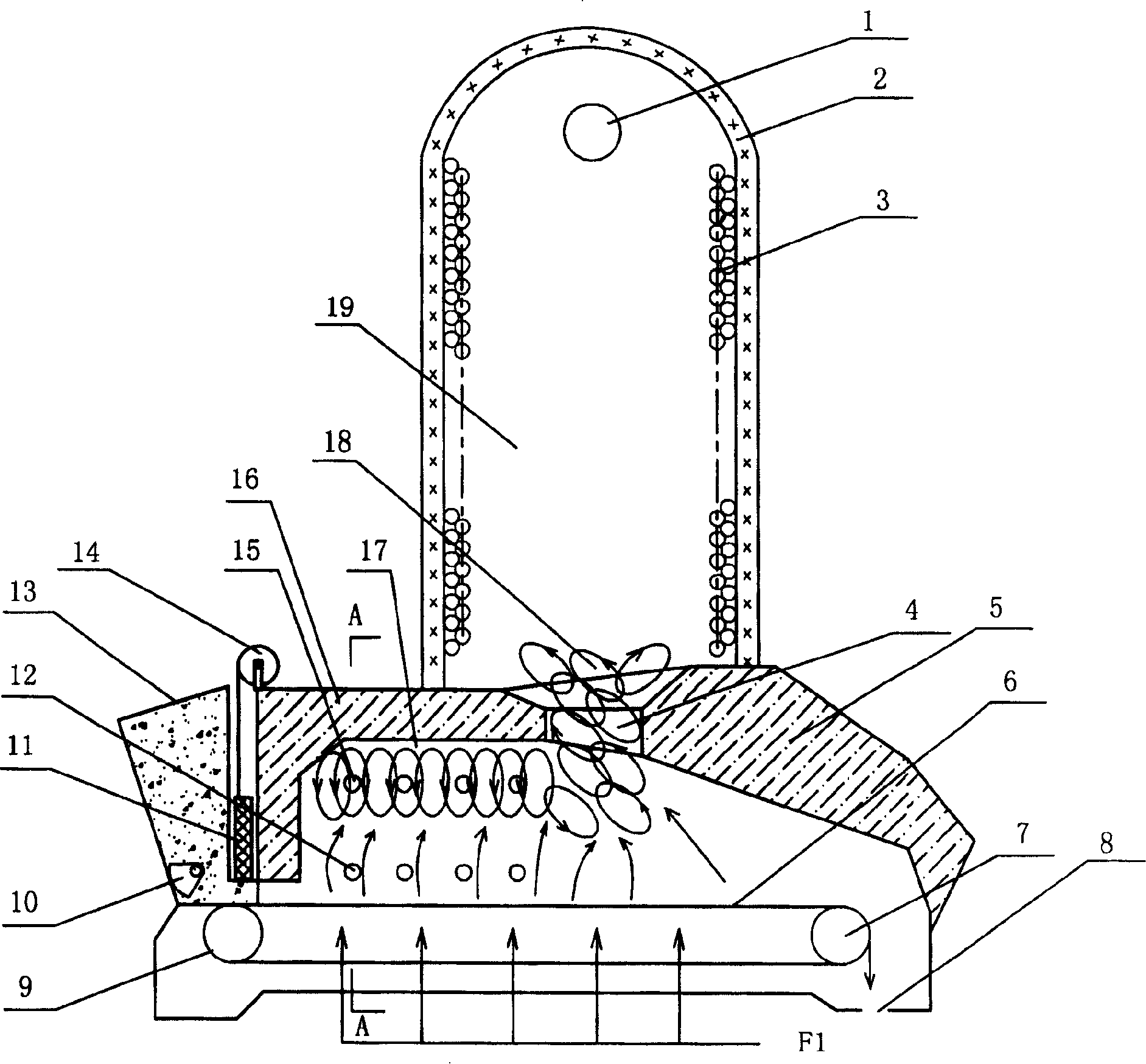

Pure smokeless, coal saving type heat transfer oil stove with external combustion and inner rotational flow

InactiveCN1873320AConvenient for centralized processingNo pollution in the processSolid fuel combustionCombustion apparatusCycloneCombustion

The present invention relates to a pure smokeless coal-saving type external-combustion internal-cyclone heat-conducting oil-fired boiler. It is characterized by that the upper portion of its furnace body is heating zone, the interior of furnace body of heating zone is equipped with heat-conducting oil pipe, the top portion of said heating zone is equipped with a draught fan, the lower portion of said furnace body is coal-burning zone, said coal-burning zone is equipped with a coal-burning device, its coal-burning device includes coal-burning combustion device outside of furnace body and cyclone combustion device in the furnace body, said coal-burning combustion device includes coal-adding mouth. Besides, said invention also provides the concrete structure of said cyclone combustion device. Said invention can completely solve the problem of discharging black smoke by burning coal, and can save coal resource and raise heat efficiency.

Owner:王树洲

Flow guiding bevel-type pure smokless combustion device

InactiveCN101021311AReasonable structureSolve the black smoke of coal burningSolid fuel combustionCasings/liningsCoalProduct gas

The present invention relates to a flow-inducing conical type pure smokeless combustion equipment. It is characterized by that its combustion furnace cavity is placed over the fire grate, under the fire grate an ash chamber is set, the top portion of said combustion furnace cavity is equipped with a high-temperature flue gas outlet, over the high-temperature flue gas outlet a secondary combustion furnace cavity is set, in the secondary combustion furnace cavity a flow-inducing cone is set, said flow-inducing cone is correspondent to the high-temperature flue gas outlet, said flow-inducing cone is formed from longitudinally peripherally-distributed high-temperature flue gas flow-inducing plates and top cover positioned in the top portion of flow-inducing plate, on the secondary combustion furnace cavity a secondary combustion-supporting air hole is set, and the top portion of said secondary combustion furnace cavity is equipped with a high-temperature gas outlet.

Owner:王树洲

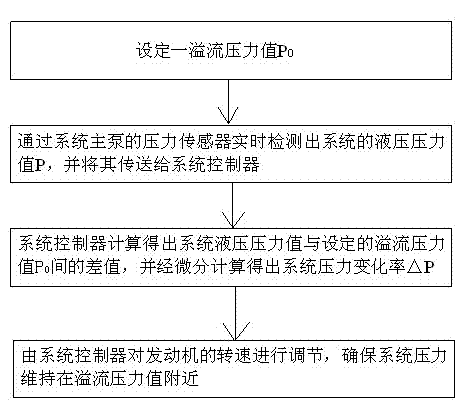

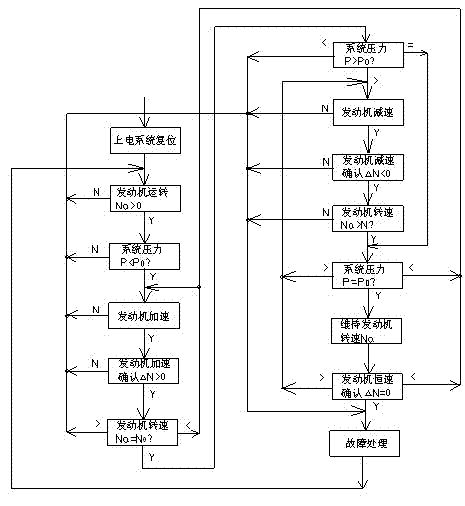

Control method for reducing oil consumption of excavator engine

InactiveCN102251546AReduce fuel consumptionEnergy savingSoil-shifting machines/dredgersAutomatic controlSystem pressure

The invention discloses a control method for reducing oil consumption of an excavator engine. The method comprises the following steps of: setting an overflow pressure value P0; detecting the hydraulic pressure value P of a system in real time through a pressure sensor of a main pump of the system, and transmitting the hydraulic pressure value P to a system controller; calculating the difference between the hydraulic pressure value P of the system and the set overflow pressure value P0 by the system controller, and obtaining system pressure change rate delta P by differential calculation; andadjusting the revolving speed of the engine by the system controller, ensuring that the system pressure is maintained nearby the overflow pressure value so as to fulfill the purposes of reducing the overflow rate and reducing the oil consumption of the engine. By the control method for reducing the oil consumption of the excavator engine, the output power of a hydraulic pump can be automatically controlled according to the work load of an excavator, so that the output power of the hydraulic pump is matched with the power required by the actual work of the excavator, the oil consumption of theexcavator is reduced and the energy is saved.

Owner:SANY HEAVY MACHINERY

Compression ignition engine and low-pressure low-temperature ignition and exhaust pollution elimination method

InactiveCN104763527ASolve the problem of ignition at low pressure and low temperatureSolve white smokeInternal combustion piston enginesThermal treatment of fuelEngineeringAlloy

The invention discloses a compression ignition engine and a low-pressure low-temperature ignition and exhaust pollution elimination method. The compressed air in a compressed air package is heated through a compressed air electric heater or the waste heat exhausted from the engine, the heated compressed air is fed into a cylinder in the stating process of the engine or the air suction stroke during acceleration, and accordingly the temperature of the compressed air in the cylinder at the beginning of the power stroke is improved and accordingly the injected vaporized fuel is easy to ignite. The lower concentration of injected vaporized fuel can be ignited under the 400 DEG C and can be fully burnt due to a honeycomb three-way catalytic alloy net which is arranged in the cylinder. The hot air inside a cylinder air-cooled coil pipe can be fed into the cylinder through a booster fan in the process of normal operation of the engine. The high-temperature fuel heated through a liquid fuel electric heater or a liquid fuel exhaust heater enters a vaporizing chamber to be vaporized and the vaporized fuel in the vaporizing chamber continues to be heated through a vaporized fuel infrared electric light wave heater or a vaporized fuel exhaust heater. Accordingly, the compression ratio can be reduced.

Owner:张英华

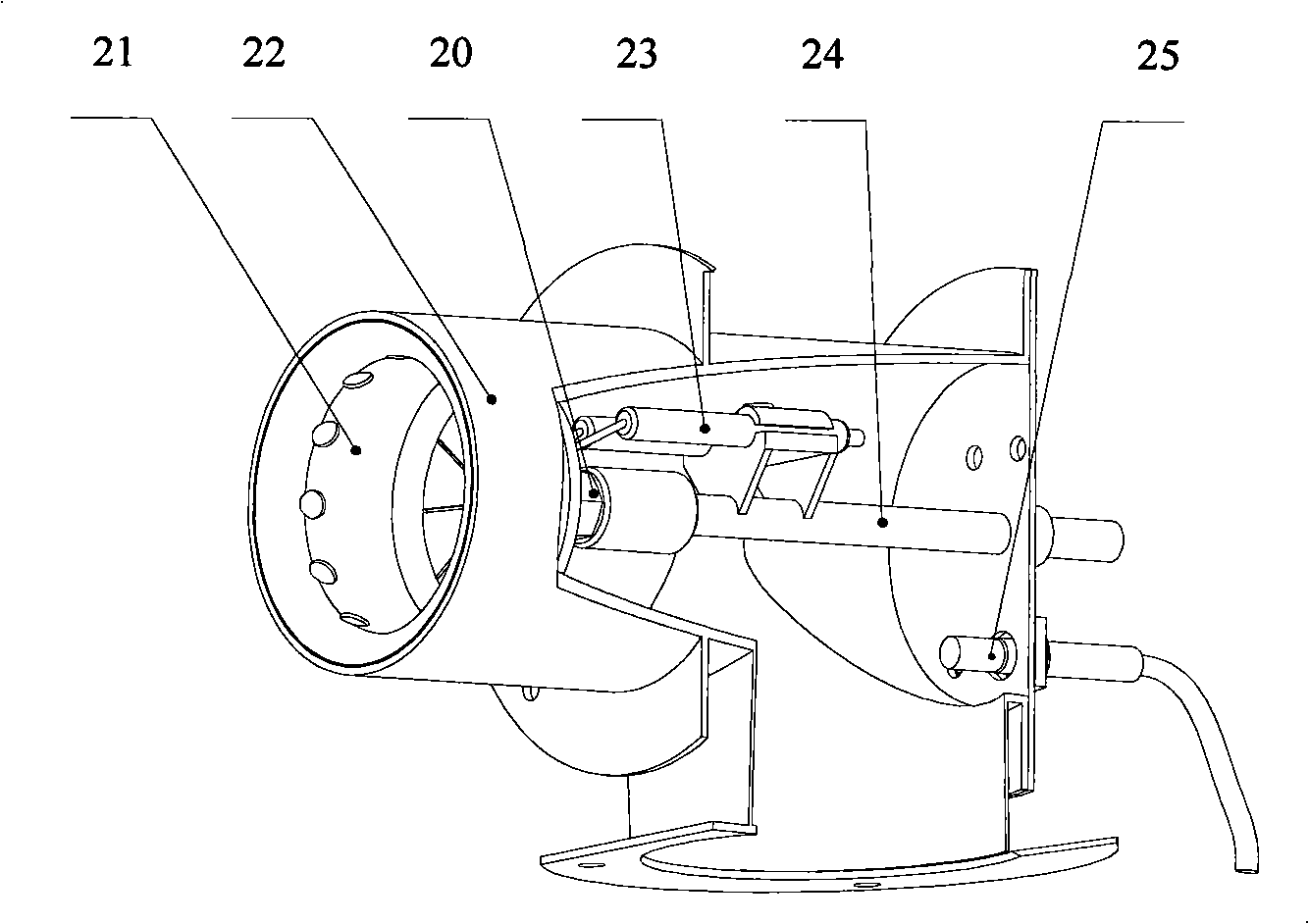

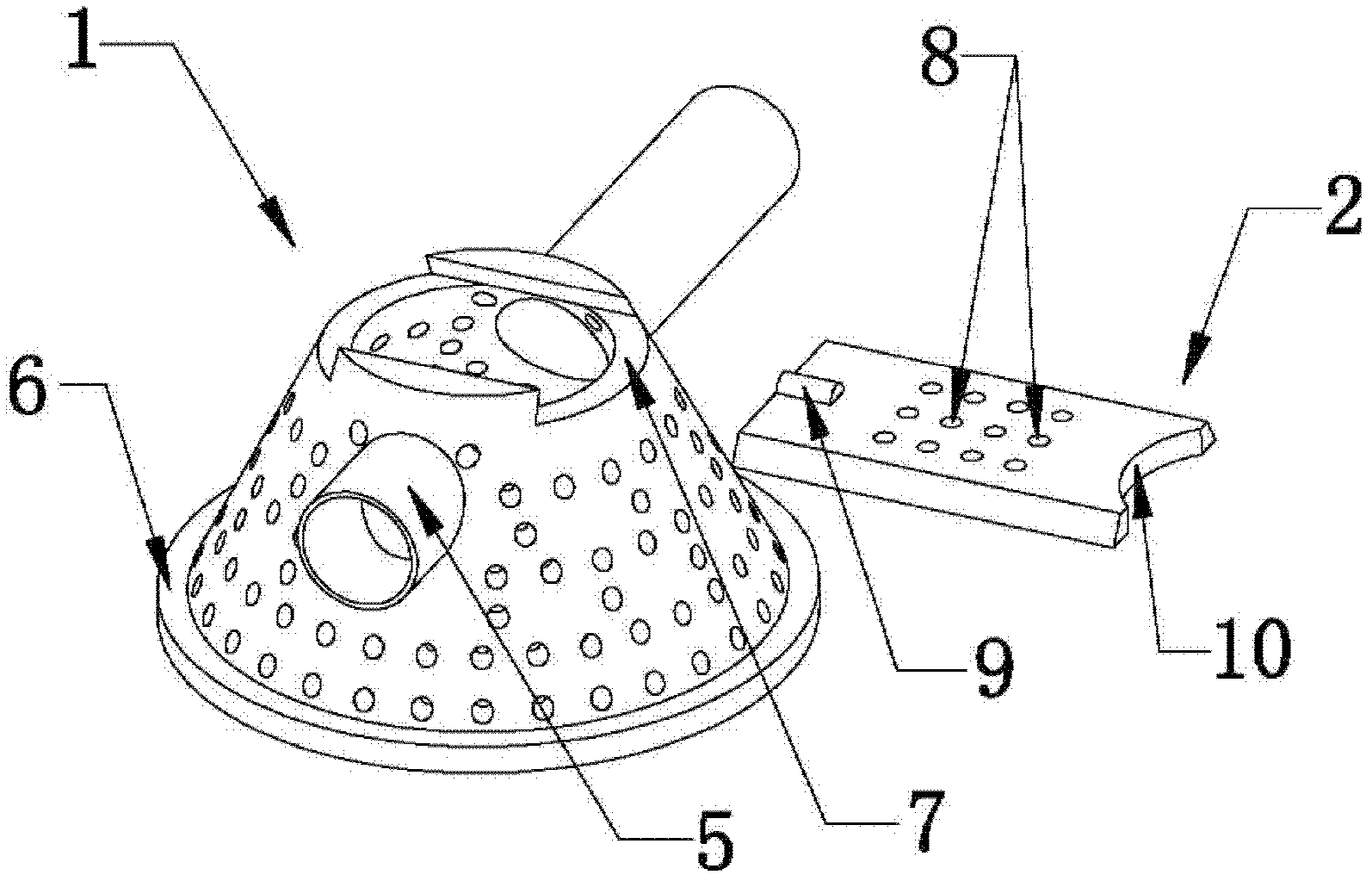

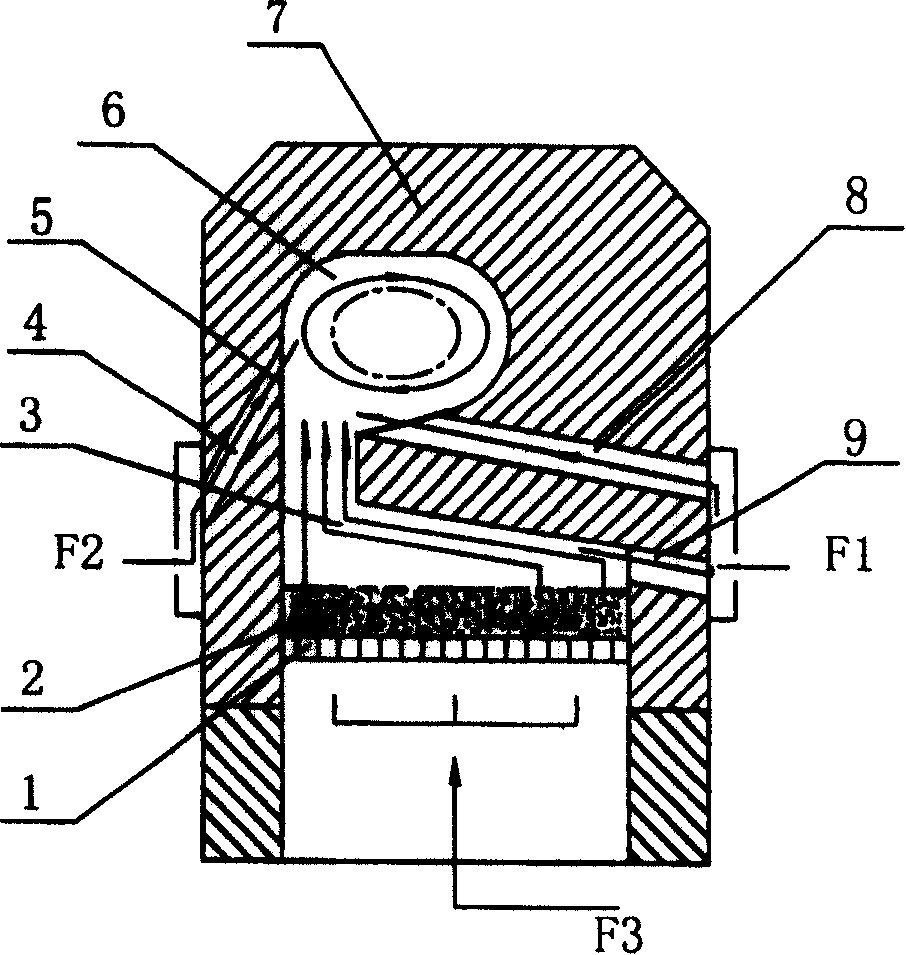

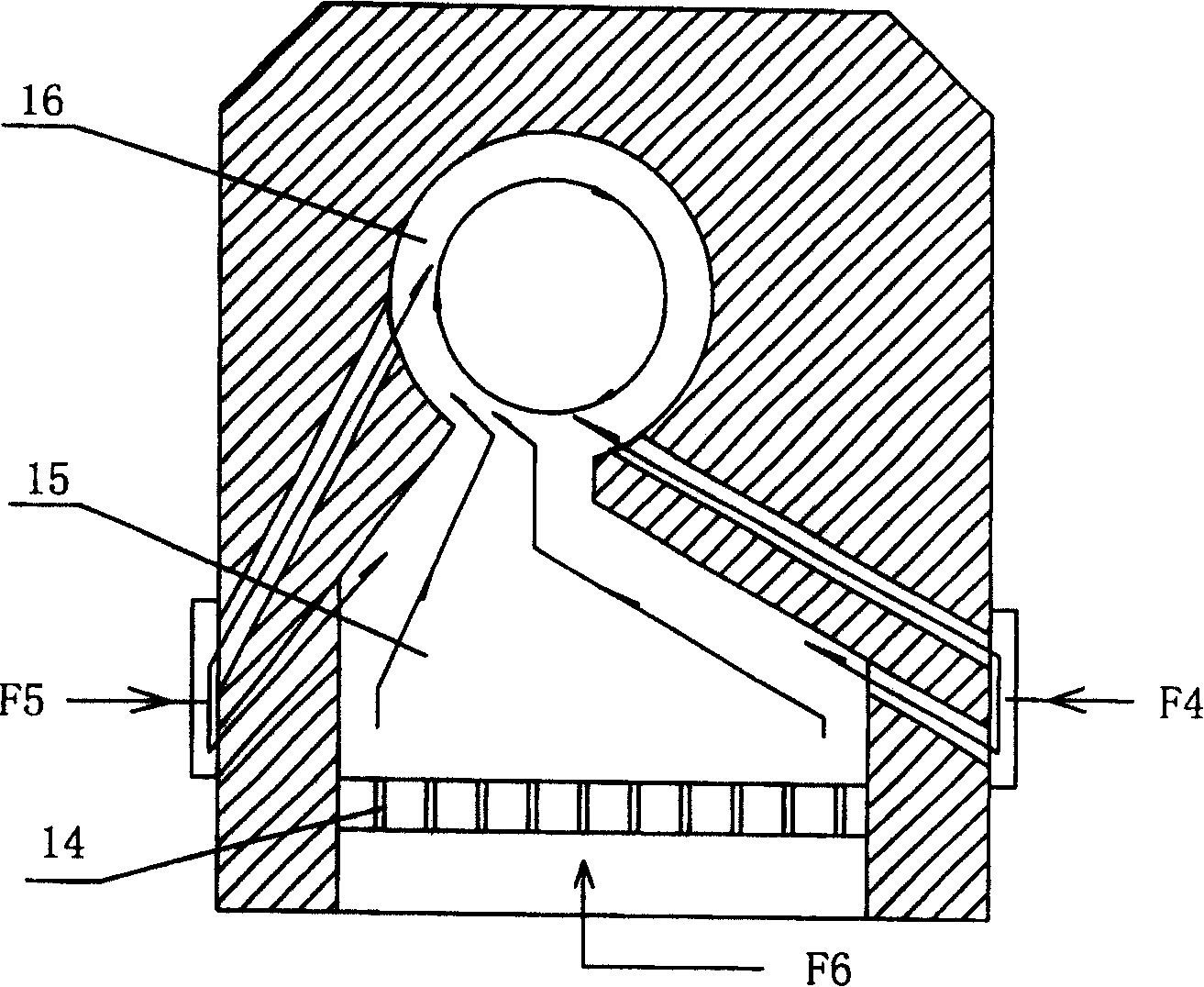

Grate for biomass particle environment-friendly boiler

The invention discloses a grate for a biomass particle environment-friendly boiler, which comprises a grate and a valve, wherein the grate body is movably connected with the valve; the grate body is in a taper shape and a plurality of vent holes A are uniformly distributed on the grate; one end of a side wall of the grate is provided with a long pipe for ignition and the other end of the side wall is symmetrically provided with a short pipe for ventilation; and a large orifice end of the grate body is circularly provided with a support block, a small orifice end is provided with a cavity of which the shape and the size are matched with the shape and the size of the valve, and a plurality of vent holes B are uniformly arranged on the valve. The problems that biomass particles in the prior art are hard to ignite and cannot burn fully, black smoke is easy to generate and fuel residue is inconvenient to remove and wash are effectively solved through the grate for the biomass particle environment-friendly boiler.

Owner:田和东

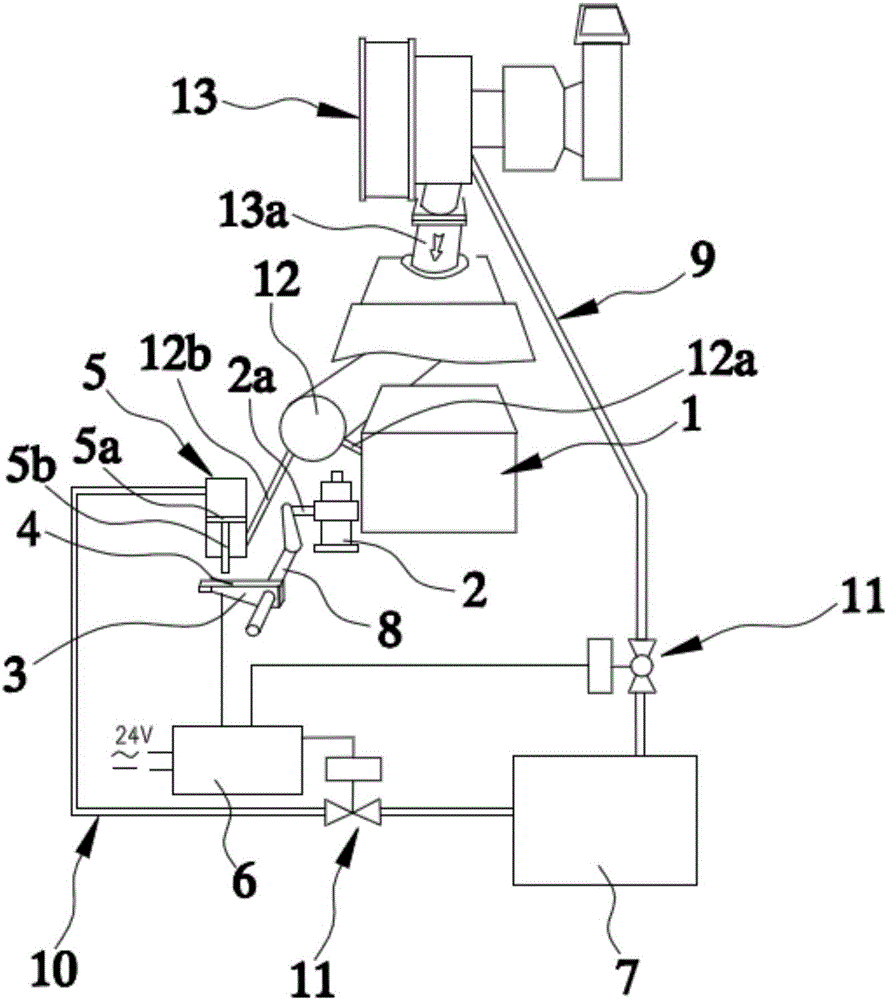

Air-fuel ratio adjustment system with parking function

PendingCN106837573AReduce dirtIncrease profitElectrical controlMachines/enginesSolenoid valveDieseling

The invention discloses an air-fuel ratio adjustment system with a parking function. The air-fuel ratio adjustment system comprises an engine, a fuel injection pump, an adjustment arm, a switch piece, a cylinder, a controller and a compressed air system. A fuel injection rack is mounted on one side of the fuel injection pump, and the fuel injection rack is connected with the adjustment arm through a connecting rod mechanism. The switch piece is mounted on the adjustment arm and the adjustment arm is provided with a signal sensor. The cylinder is arranged on the upper portion of the adjustment arm, and an inner cavity of the cylinder is provided with a piston and a piston rod. The compressed air system is provided with a first air connection pipe, a second air connection pipe and corresponding solenoid valves mounted on the air connection pipes correspondingly. The first air connection pipe communicates a main air inlet pipe, and an engine air inlet pipe and a cylinder air inlet pipe are mounted on the both sides of the main air inlet pipe correspondingly. The second air connection pipe connected to the compressed air system communicates with the upper end of the cylinder. According to the air-fuel ratio adjustment system with the parking function, the problem that black smoke is generated due to the insufficient combustion of the fuel in of the starting and sudden loading process of a diesel engine can be solved, and the emergency parking function of the engine can be realized.

Owner:CHONGQING PUSH MECHANISM

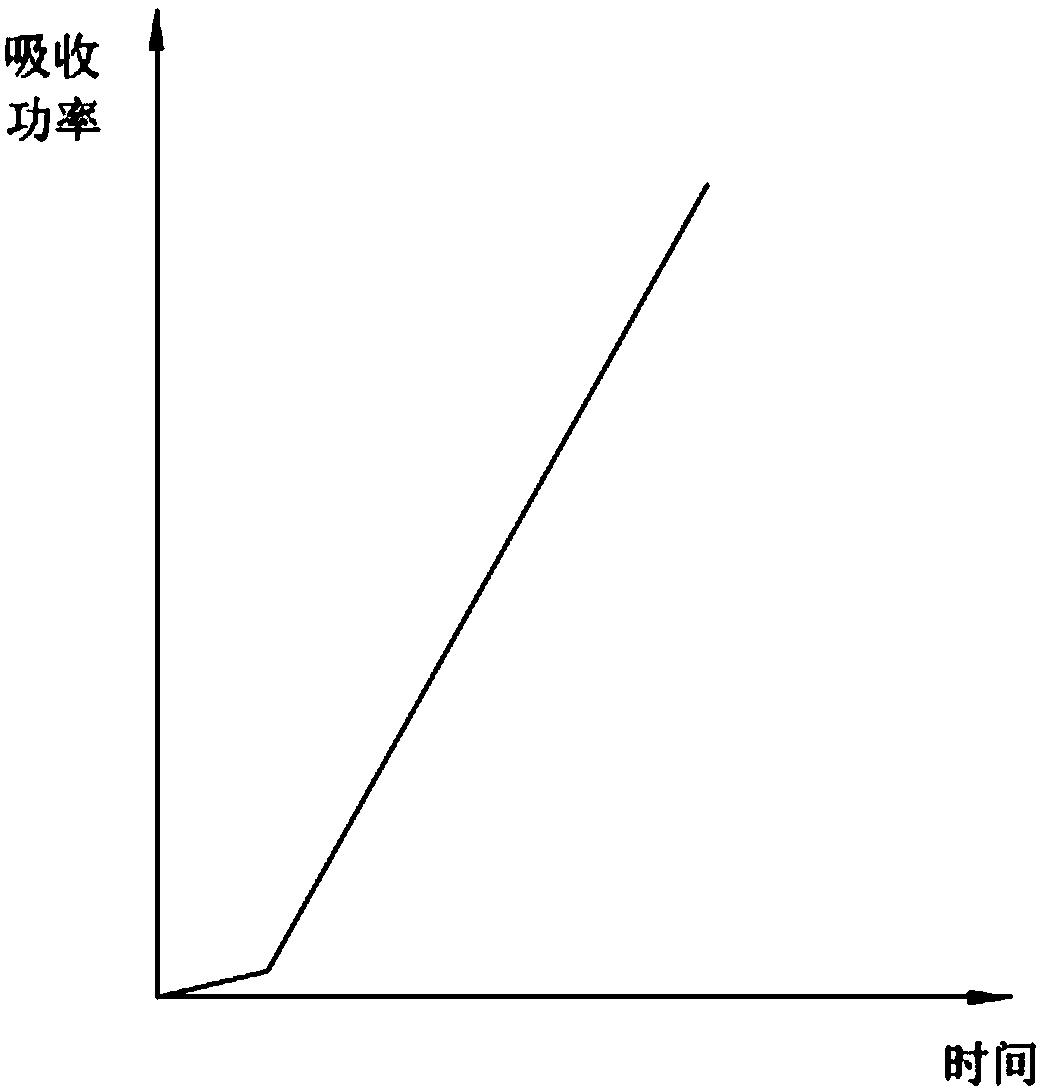

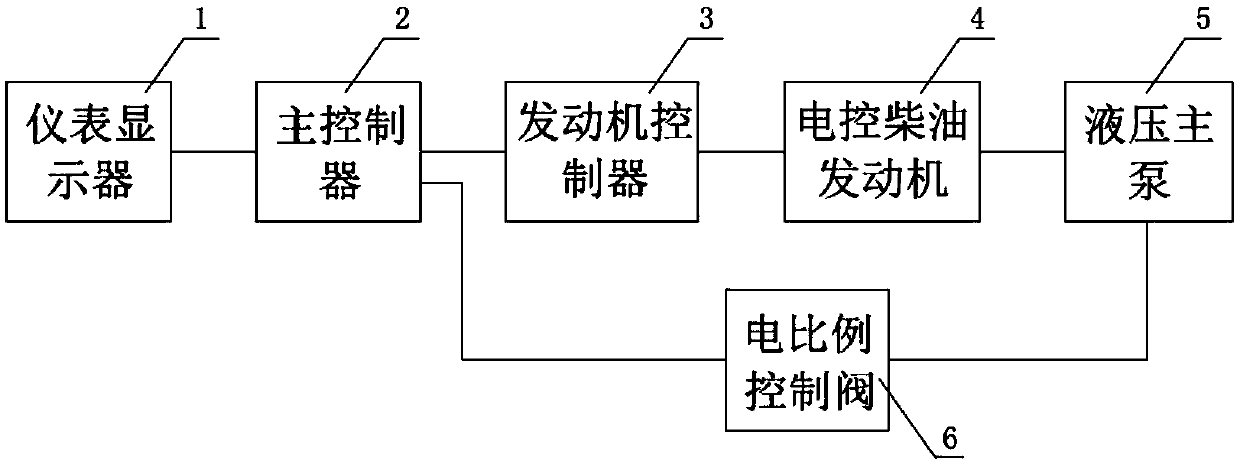

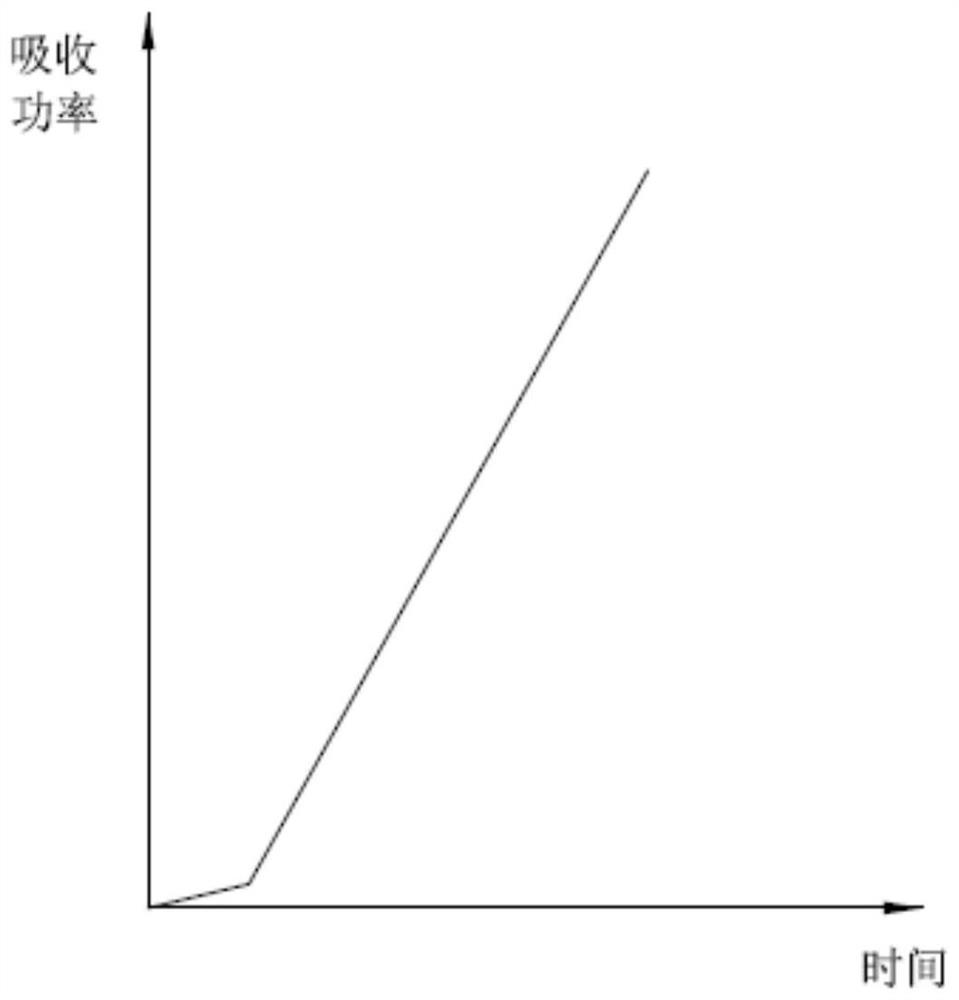

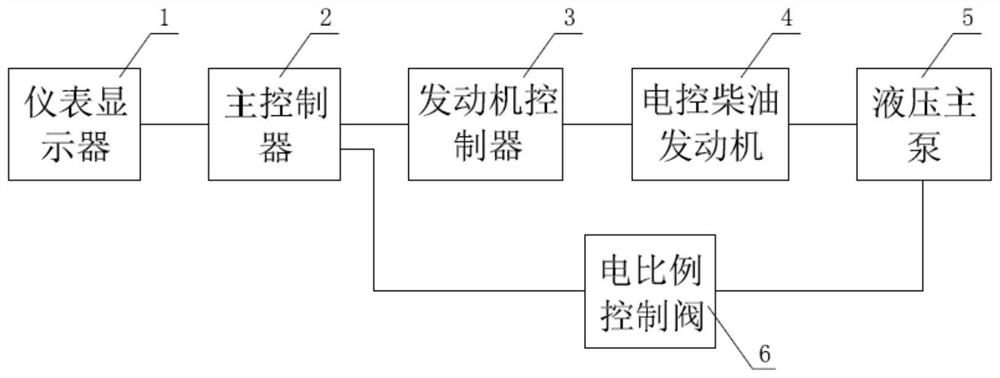

Method for preventing failure during engineering machine starting

ActiveCN109611224AReduce loadSolve the problem of black smokeEngine controllersPositive-displacement liquid enginesProportional controlDiesel engine

The invention discloses a method for preventing failure during engineering machine starting. The starting process is divided into two stages, specifically, in the first stage, a main controller controls the absorption power of a hydraulic main pump through an electric proportional control valve to be increased to 3-10% of the target power of the hydraulic main pump at the rate k1; in the second stage, the main controller controls the absorption power of the hydraulic main pump through the electric proportional control valve to be increased to the target power of the hydraulic main pump at therate k2; and the first stage is the former 0.6-1s of the starting process, and the rate k2 is 2-6 times of the rate k1. In the starting process, the absorption power of the hydraulic main pump is controlled to be matched with the power of a diesel engine, the load of the diesel engine in the initial stage of starting is reduced, thus the diesel engine can be started normally, and the problem of black smoke during load starting of the diesel engine is avoided; and a starting control system of an engineering machine does not need to be transformed, and the transformation cost is saved.

Owner:CHTC JOVE HEAVY IND

Environment friendly and energy-saving heavy oil additive

ActiveCN101705123AImprove performanceExtended shelf lifeLiquid carbonaceous fuelsCombustionOil additive

The invention discloses an environmental priendly and energy-saving heavy oil additive which comprises the following components in parts by weight: 8-20 parts of ampholyticsurfactant, 10-35 parts of cosurfactant, 10-20 parts of combustion improver, 20-35 parts of stablizing dispersant, 3-15 parts of corrosion inhibitor and 20-50 parts of water. The heavy oil additive greatly dilutes the viscosity of heavy oil, improves the flowability of the heavy oil, ensures that the heavy oil can be burnt completely, eliminates dark smoke, effectively reduces the pollution to the environment, ensures high watering rate of the heavy oil and long stable phase of the heavy oil and saves fuel resources. In addition, during combustion, an oil nozzle can not coke easily, thereby the maintenance frequency of the oil nozzle is greatly reduced, and the fuel cost and the maintenance expense of boilers and other combustion equipment are reduced.

Owner:SHANDONG TAIDE NEW ENERGY

Smokeless, coal saving type heat transfer oil stove with large mechanical fire grate

InactiveCN1873322ANo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving large-size mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that said furnace body has heating zone and hot gas supply zone, the interior of furnace body of heating zone is equipped with heat-absorbing tube bank, the bottom portion of heating zone is equipped with a hot gas inlet, and the top portion of said heating zone is equipped with a draught fan; the hot gas supply zone possesses a coal-burning device, said coal-burning device has a combustion furnace cavity, meachinical fire grate, coal-adding device and high-temperature gas outlet. Said invention also provides the concrete structure of said furnace cavity. Said invention is simple in structure and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

Automatic helical feeding combustion boiler

InactiveCN102062391AEmission reductionIncrease temperatureSolid fuel combustionCombustion apparatusCombustion chamberPropeller

The invention discloses an automatic helical feeding combustion boiler which comprises a boiler body and a boiler wall. The automatic helical feeding combustion boiler is characterized in that a helical propeller is arranged at a boiler feeding hole, the outer end of the helical propeller is connected with a motor and a feeding device, the feeding device is arranged on the top surface of the helical propeller, the inner end of the helical propeller is arranged at a combustion chamber feeding hole, the bottom surface of a combustion chamber is provided with a fire grate, and fuel is arranged on the top surface of the fire grate. The invention has the advantages that the fuel directly combusts on the fire grate and stays for a long time, thus the ventilating combustion-supporting effect is good, the fuel is saved, boiled water and steam are rapidly obtained, and the temperature of a hearth reaches above 1150 DEG C; and the heat efficiency is high, emission of smoke, harmful gases SO2, NOx and the like is reduced, and various indexes and energy-saving indexes are greatly superior to the standard specified in China.

Owner:何忠海

Method for melting copper through line frequency furnace

ActiveCN105274354AImprove airtightnessImprove energy savingProcess efficiency improvementIngotShaft furnace

The invention discloses a method for melting copper through a line frequency furnace. The method comprises the following steps that 1, a waste copper piece and waste are subjected to primary treatment; 2, screening is carried out; 3, classification is carried out; 4, accessories are fed into furnaces, wherein the accessory I, the accessory II and the accessory III are fed into the shaft furnace, the open-hearth furnace and the line frequency cored copper melting copper to be refined, and a product I, a product II and a product III are obtained; 5, the product I and the product II are transported to a copper continuous casting and rolling unit for casting treatment, a steel rod is obtained, and the product III is placed in a pig casting machine to be machined and treated, and a copper ingot is obtained; and 6, the steel rod in the step 5 is drawn, and a qualified copper piece is obtained. The method for melting copper through the line frequency furnace achieves energy saving and is environmentally friendly, and manufactured steel is good in quality.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

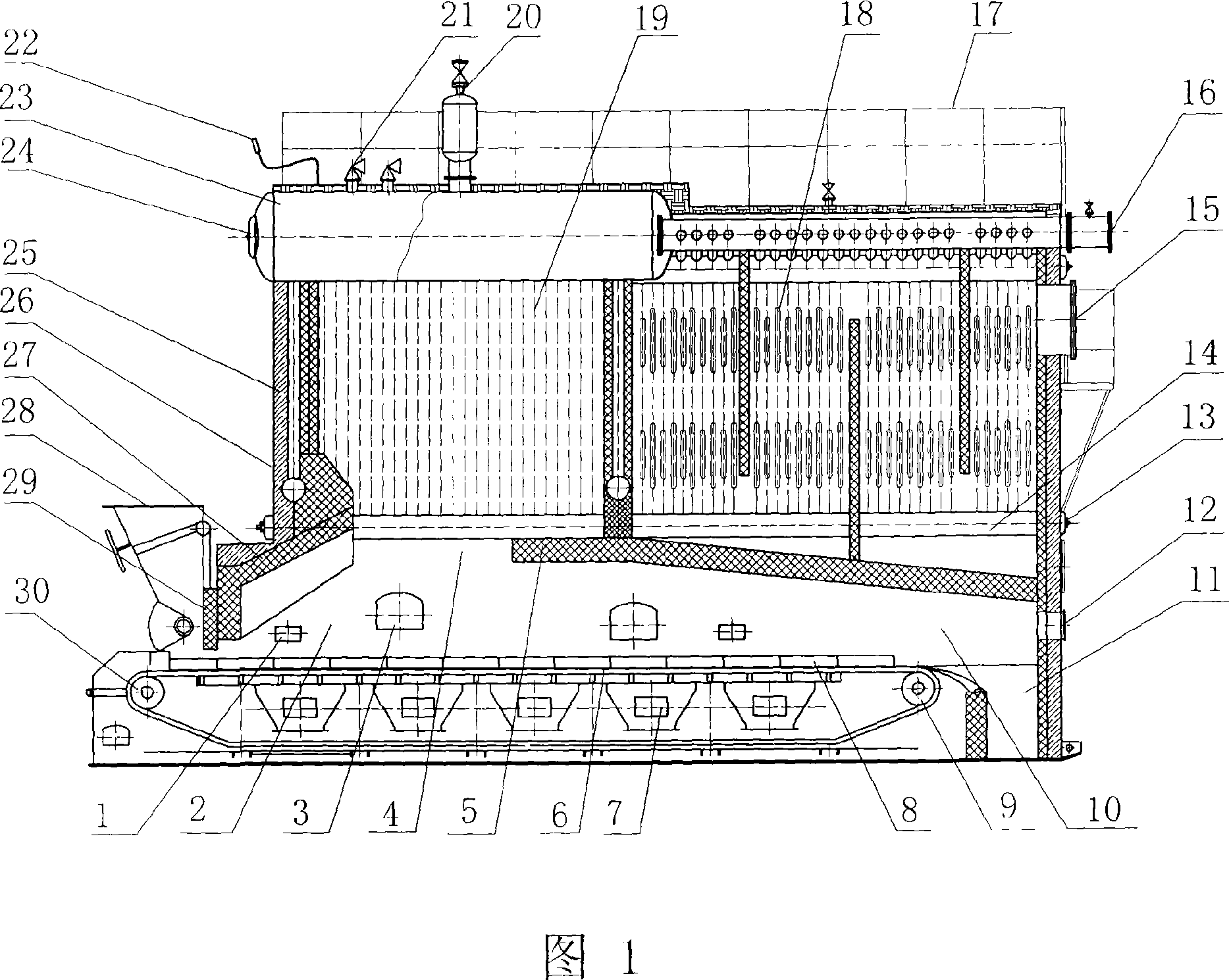

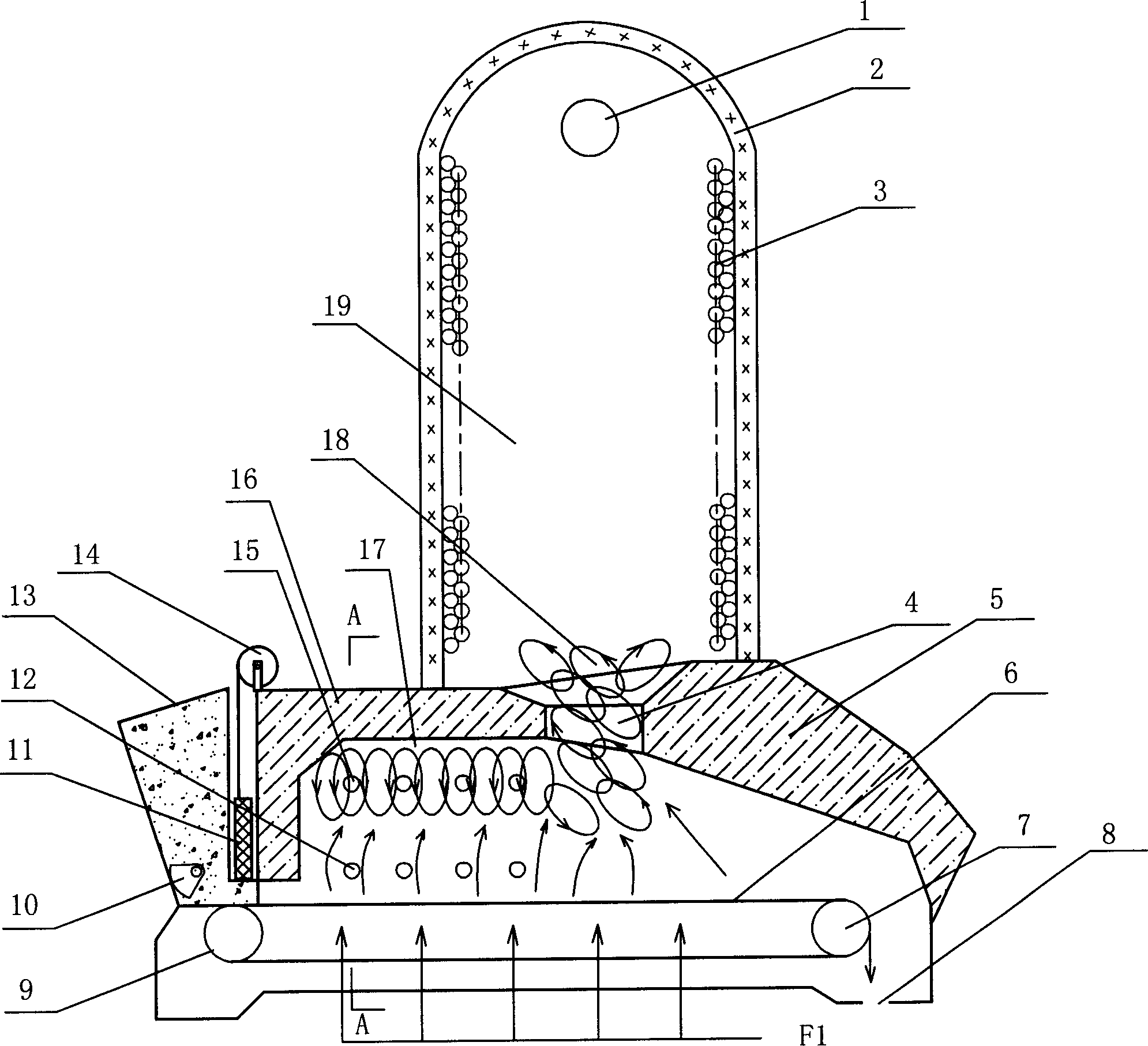

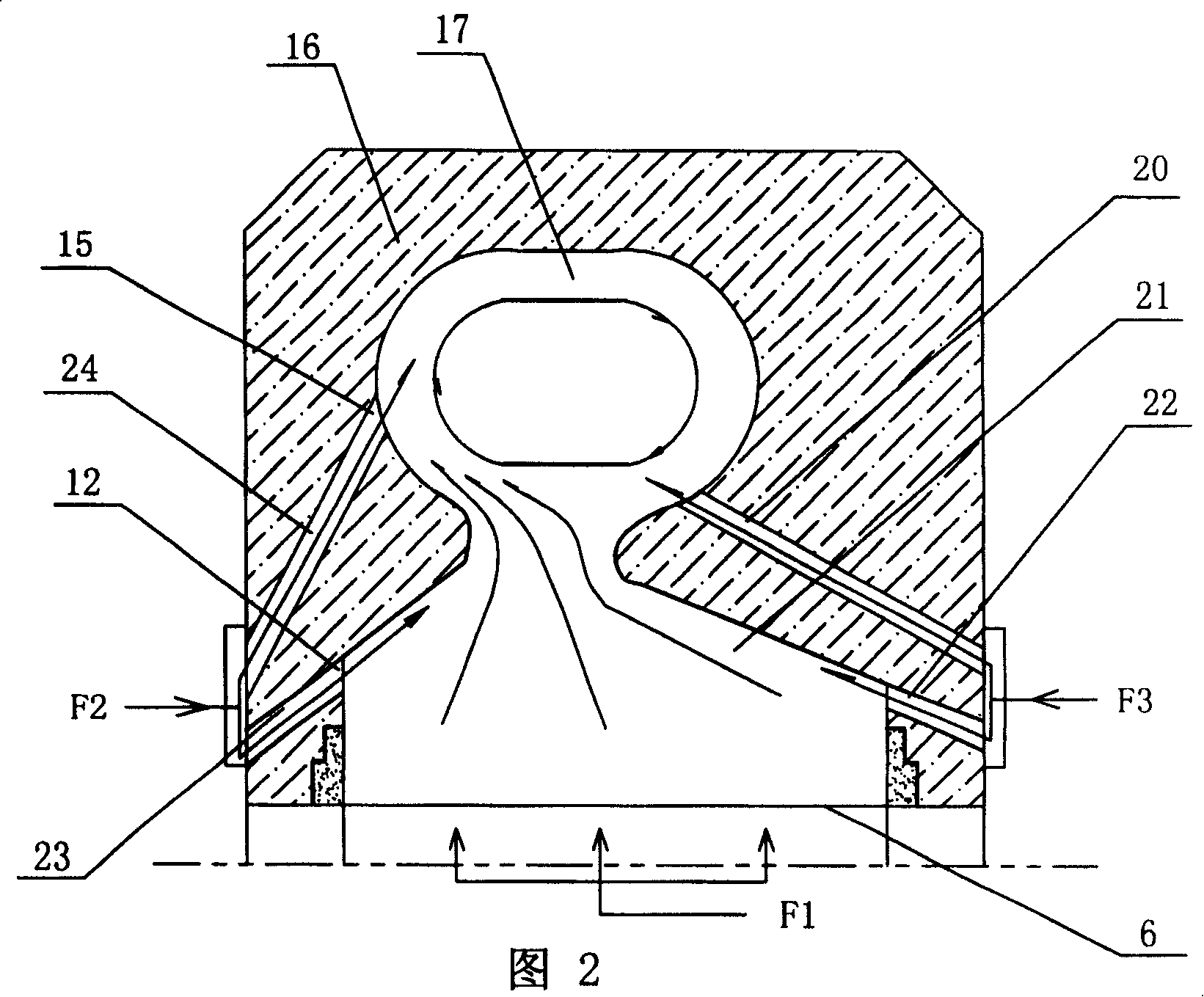

Single-spiral flow smokeless steam boiler with chain grates

InactiveCN101074773ASolve the problem of black smokeSimple structureSolid fuel combustionCasings/liningsCombustionEngineering

This invention relates to a single-chain grate swirl pure smoke-free hot water boiler which belongs to thermal equipment. It includes the shell, water wall, drum and lower coal-fired device. The coal-fired device includes the coal installation; the chain stove arranges upper coal, the stokehold push and pushes behind the stove. Front furnace chamber is composed between the stokehold arch and the chain stove row. Queen furnace chamber is composed between pushes behind the stove and the chain stove row. The top of the front furnace chamber's surface form the arch by the whorl stream burning. The oblique tones wall of the furnace chamber matches the combustion-supporting place with draught that leads to the front furnace. The combustion-supporting place with draught is tangent with the front furnace chamber top arch, and the back of furnace chamber is connected in the front burning hot gas outlet. The structure is simple reasonable, and low cost, full combustion, high thermal efficiency, low energy consumption, solved black smoke fouling problems, protection of the environment.

Owner:王树洲

Boiler

ActiveCN105927956AAvoid pipe burstImprove energy utilizationSteam generation using pressureIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention discloses a boiler which comprises an outer wall and an inner wall. The outer wall and the inner wall are sealed to form a water storage cavity; a steam chamber is arranged at the top of the water storage cavity; a slagging cavity, a combustion chamber, an air cavity and a high-temperature cavity are sequentially arranged in the inner wall from bottom up; the air cavity communicates with an upper air inlet; the slagging cavity communicates with a lower air inlet; a plurality of ventilating ducts communicating with the air cavity are arranged in the combustion chamber; a plurality of air spouts are formed in the side walls of the ventilating ducts; a plurality of fire tubes are uniformly arranged in the water storage cavity; the bottoms of the fire tubes communicate with the combustion chamber; the tops of the fire tubes communicate with the top of the high-temperature cavity; the bottom of a smoke pipe penetrates through the outer wall and the inner wall, and the smoke pipe discharges smoke out of the boiler. The boiler effectively avoids pipe explosion and is high in energy utilization ratio.

Owner:平原通元商贸有限公司

Single-spiral flow smokeless hot-water boiler of chain fire grated

InactiveCN101074800ASolve the problem of black smokeSimple structureWater heatersCombustionEngineering

This invention relates to a single-chain grate swirl pure smoke-free steam boiler which belongs to thermal equipment. It includes the shell, the upper part of the flag -pipe group, waterwall, drum and lower coal-fired device. The coal-fired device includes coal installation; the chain stove arranges upper coal, the stokehold push and pushes behind the stove. Front furnace chamber is composed between the stokehold arch and the chain stove row. Queen furnace chamber is composed between pushes behind the stove and the chain stove row. The top of the front furnace chamber's surface form the arch by the whorl stream burning. The oblique tones wall of the furnace chamber matches the combustion-supporting place with draught that leads to the front furnace. The combustion-supporting place with draught is tangent with the front furnace chamber top arch, and the back of furnace chamber is connected in the front burning hot gas outlet. The structure is simple reasonable, and low cost, full combustion, high thermal efficiency, low energy consumption, solved black smoke fouling problems, protection of the environment.

Owner:王树洲

Smokeless, coal saving type horizontal heat transfer oil stove with mechanical fire grate

InactiveCN1873323ANo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving horizontal mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that the upper portion of said furnace body is heating zone, the lower portion of said furnace body is hot gas supply zone, the interior of furnace body of heating zone is equipped with a heat-conducting oil pipe, the bottom portion of heating zone has a hot gas inlet, the top portion of heating zone is equipped with a draught fan; the hot gas supply zone has a coal-burning device, said coal-burning device possesses combustion furnace cavity, mechanical fire grate, coal-adding device and high-temperature gas outlet. Besides, said invention also provides the concrete structure of said combustion furnace cavity. Said invention is simple in structure, and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

Smokeless, coal saving type horizontal heat transfer oil stove with mechanical fire grate

InactiveCN100402923CNo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving horizontal mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that the upper portion of said furnace body is heating zone, the lower portion of said furnace body is hot gas supply zone, the interior of furnace body of heating zone is equipped with a heat-conducting oil pipe, the bottom portion of heating zone has a hot gas inlet, the top portion of heating zone is equipped with a draught fan; the hot gas supply zone has a coal-burning device, said coal-burning device possesses combustion furnace cavity, mechanical fire grate, coal-adding device and high-temperature gas outlet. Besides, said invention also provides the concrete structure of said combustion furnace cavity. Said invention is simple in structure, and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

Coal gas treatment method for eliminating black smoke from top of blast furnace

ActiveCN112251552ASolve the problem of black smokeEliminate black smoke phenomenonBlast furnace detailsDust arrestersThermodynamicsDust control

The invention discloses a coal gas treatment method for eliminating black smoke from the top of a blast furnace. According to the method, under the condition that no equipment is added, the problem that black smoke is emitted from the top of the blast furnace in the damping down and reblowing processes of the blast furnace is solved by changing a coal gas treatment operation program and utilizingan existing dry dedusting coal gas purification system. Specifically, according to the method, in the damping down and reblowing processes of the blast furnace, under the condition that the interior of the furnace is still under positive pressure, a blow-off valve at the top of the furnace is not opened, coal gas is introduced into a cloth bag dedusting box, the coal gas is dedusted through the dedusting function of a cloth bag, and then clean coal gas is discharged through a blow-off pipe of a cloth bag deduster, so that the phenomenon that black smoke is emitted from the top of the furnace in the damping down and reblowing processes is completely eliminated.

Owner:NANJING IRON & STEEL CO LTD

Combustion-supporting dust remover for coal-fired boiler

InactiveCN1800716AImprove fullnessRaise the combustion temperatureNon-combustible gases/liquids supplyEngineeringSoot

The invention relates to a coal boiler burning-auxiliary dust cleaner which can fully burn the coal and solve the black smoke problem of chimney with energy-saving effect and reducing the soot Ringlemann less than 1 level. It comprises an ejection cylinder, an ejector, wind adjusting gate, a steam three-through, a case, a steam adjusting rod and a steam pipe connected to the steam division cylinder via pipeline. It is characterized in that: the steam three-through is mounted inside the case; the ejection cylinder is mounted at the front end of case; the wall of case has cooling wind hole; one end of steam three-through is connected to the steam pipe while another end is connected to the ejection cylinder; the back end face of ejection cylinder is the flange, which has a wind inlet, and its center has a ejector; and the ejector has a nozzle. The invention can apply variable coal boilers with environment-friendly and energy-saving effects.

Owner:朴世鹤

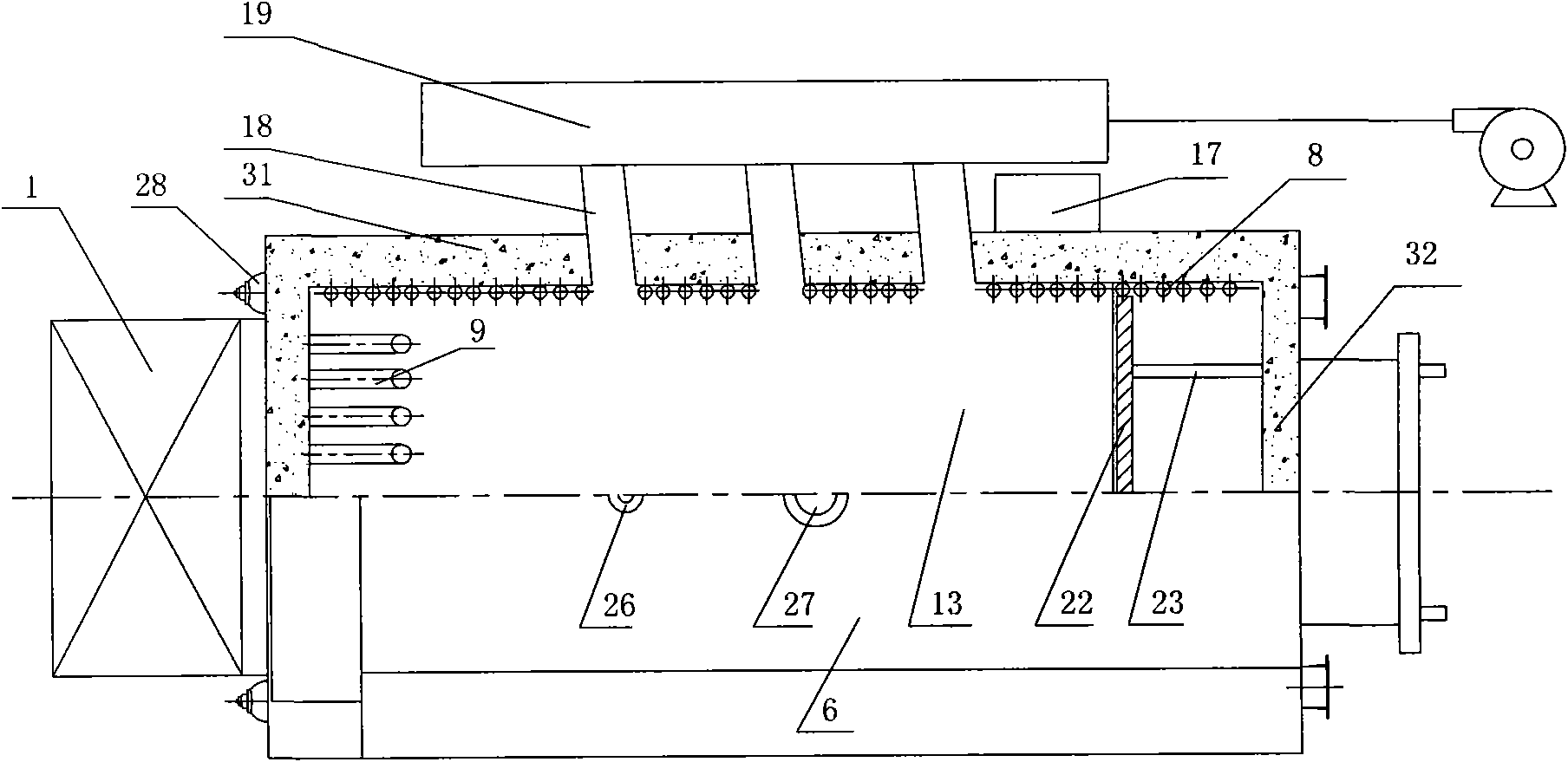

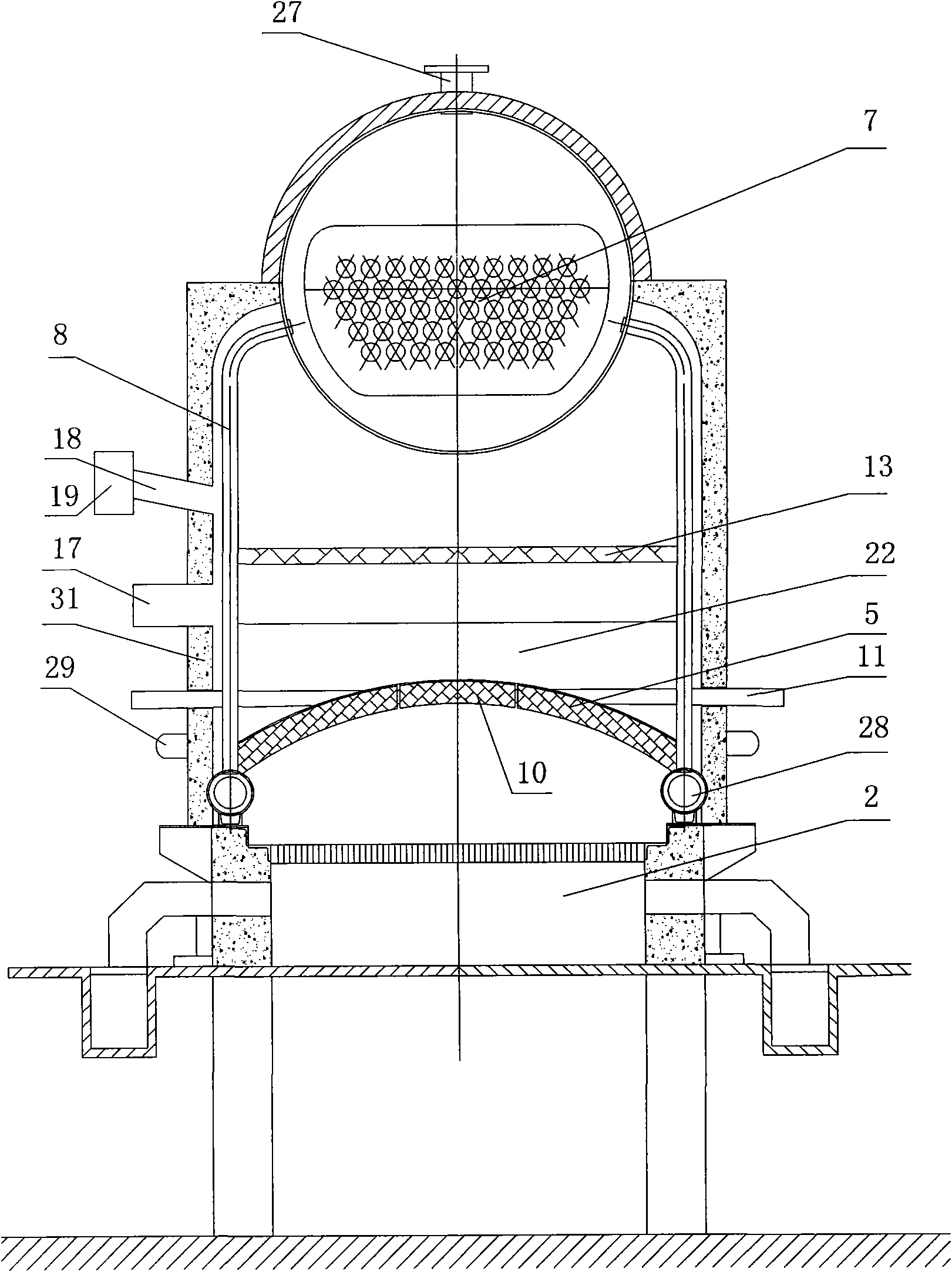

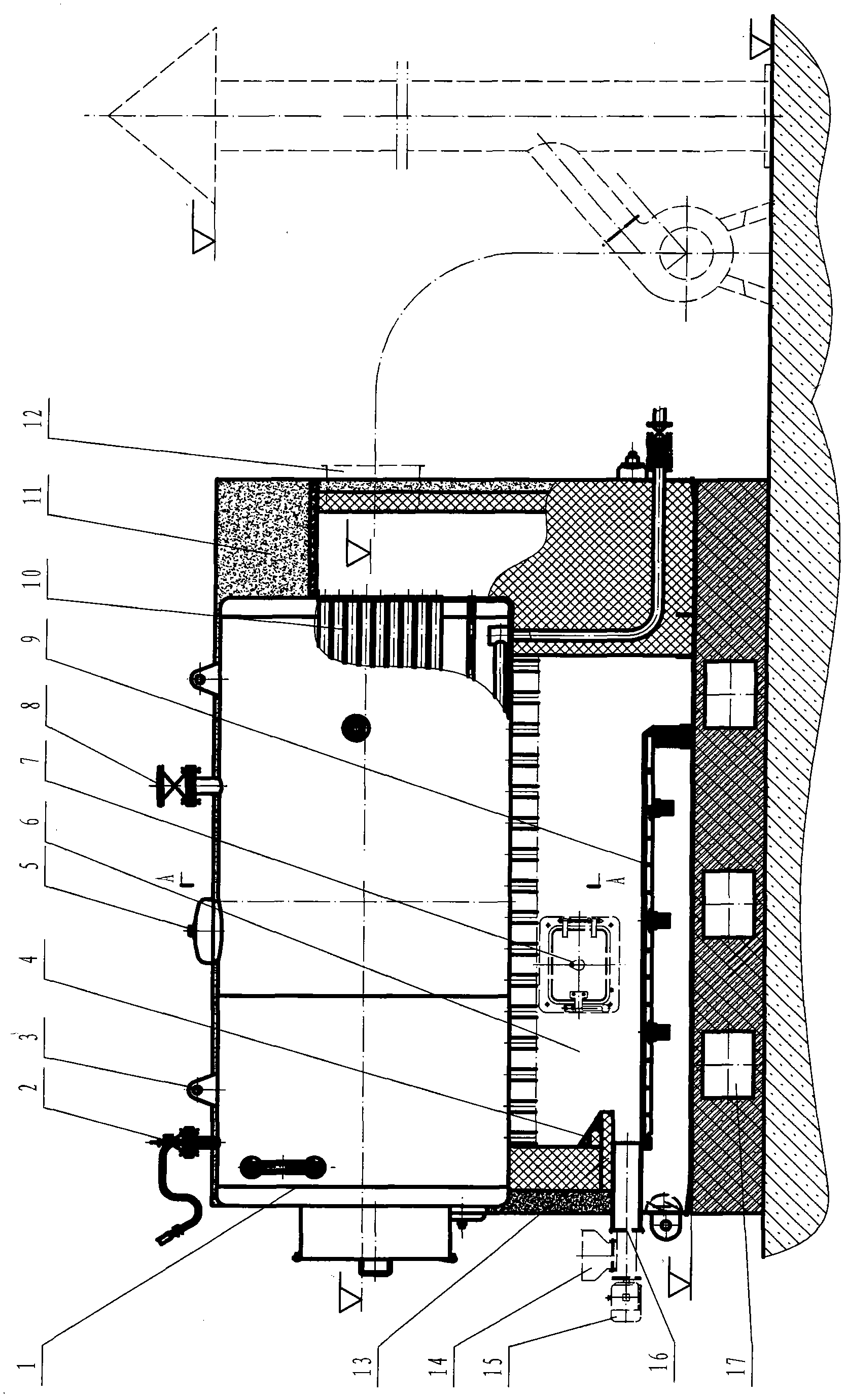

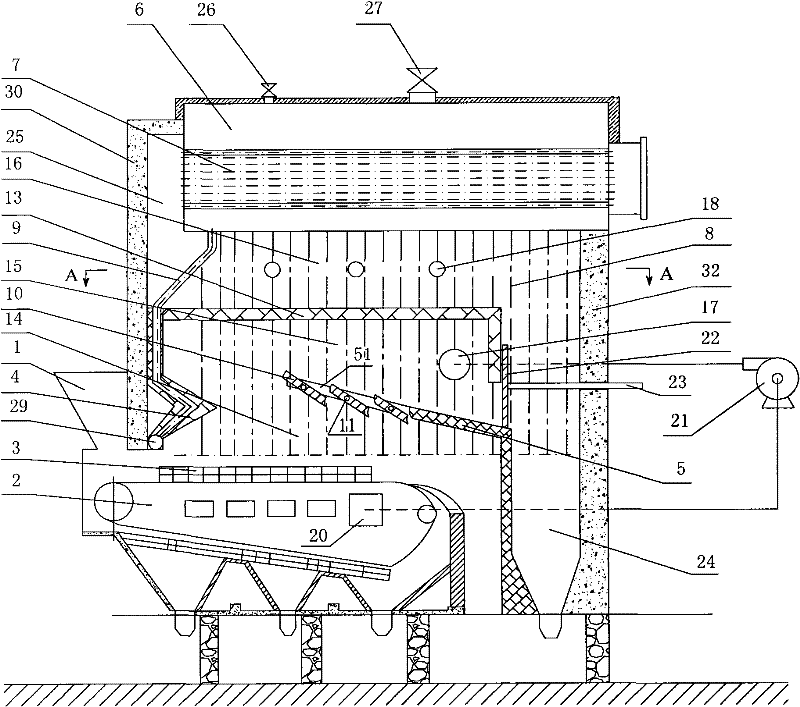

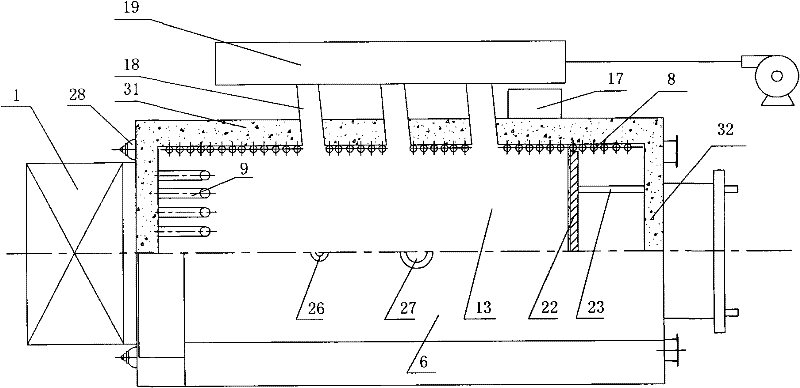

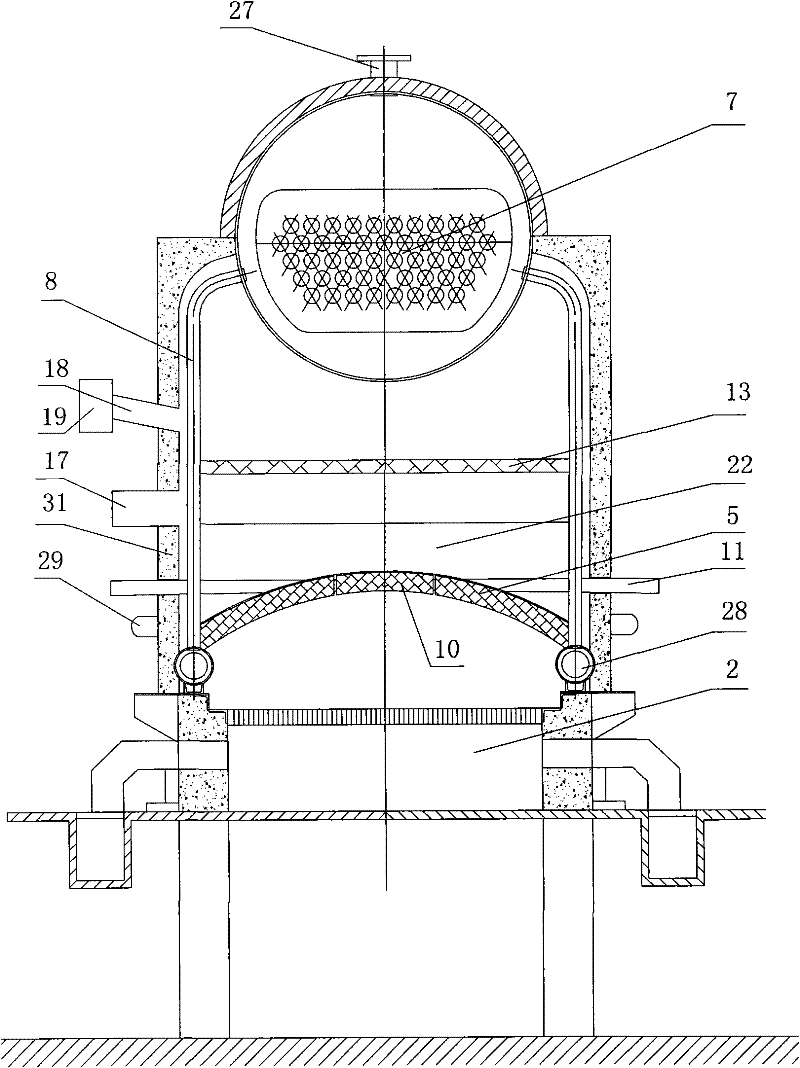

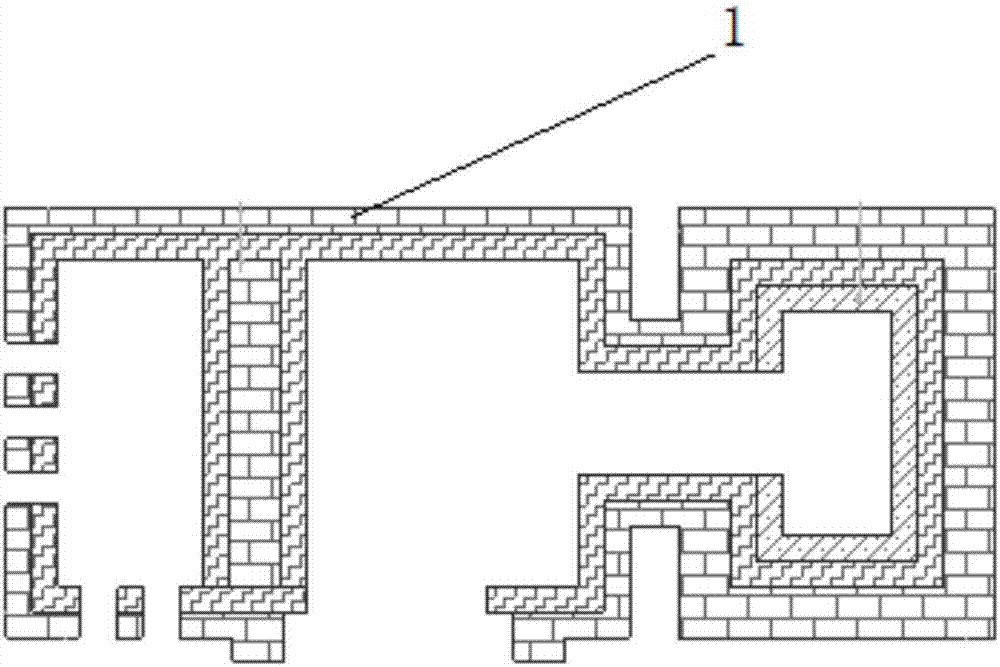

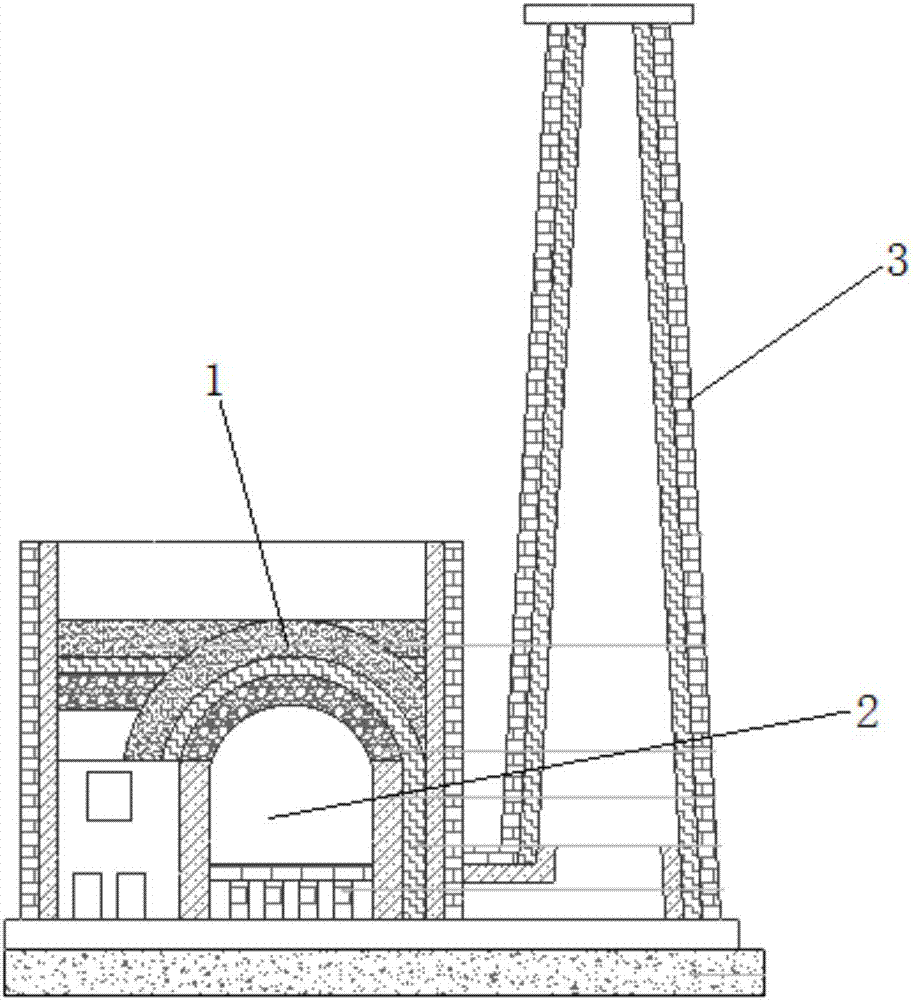

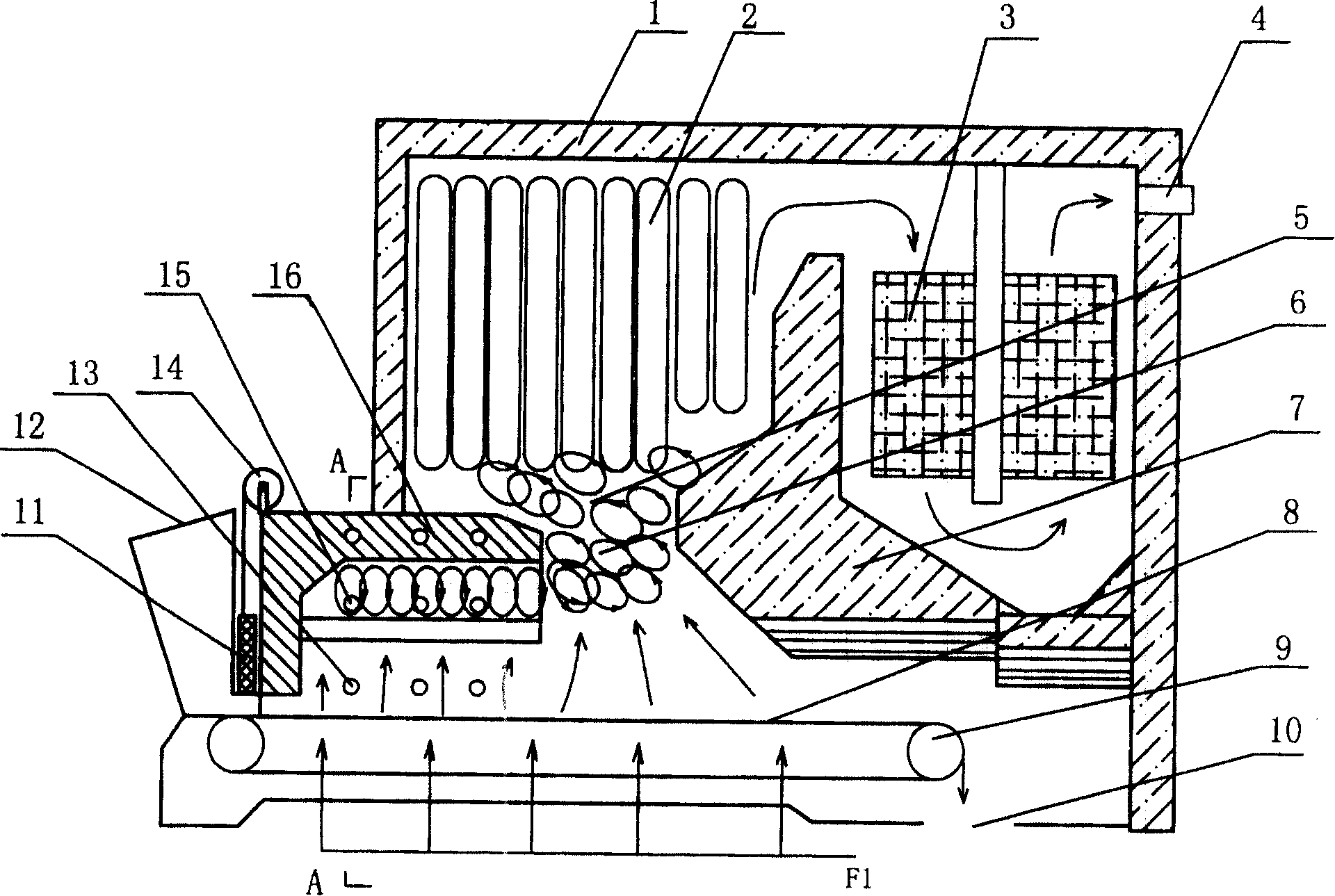

Industrial boiler for burning bio-briquettes

ActiveCN101818891BEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention discloses an industrial boiler for burning bio-briquettes. A front arch and a rear arch of which the front part is in an interdigitated shape are arranged in a body of the boiler; upper edges of two adjacent interdigitated parts of the rear arch are provided with corresponding grooves; a check block is arranged between two adjacent interdigitated parts; and two sides of the check block are fixedly connected with rotating shafts which are respectively arranged in the corresponding grooves. Furthermore, a figure-7 partition laminate is arranged above the rear arch; a movable division door is arranged between the rear end of the partition laminate and the rear arch; a circulating air pipe is connected with an air inlet of a draught fan outside the body through an air pipe; the air outlet of the draught fan is connected with a last-stage air bin of a chain grate; and a secondary air pipe at the air inlet on the side wall of a third combustion chamber is deflected toward the lower rear part, and is communicated with a main secondary air pipe outside the body. The industrial boiler has the advantages that: the bio-briquettes are efficiently and stably combusted; the boileris started at a high speed and has high heat efficiency; black smoke is not generated when the boiler is started; and the integral delivery of the boiler can also be realized.

Owner:ZHEJIANG JINGUO BOILER

Small down-draft type smokeless firewood kiln

InactiveCN107192265AUniform temperatureSuitable for firing needsFurnace componentsFurnace typesFirewoodSuction force

The invention discloses a small down-draft type smokeless firewood kiln. A kiln body is arranged to be in a square dome form. The kiln bottom is square. Flame suction holes become smaller sequentially from a hearth to a chimney. The chimney is 6-meter long. A flashboard is arranged on the chimney. The atmosphere in the kiln body is adjusted by controlling the flashboard of the chimney. The small down-draft type smokeless firewood kiln provided by the invention has the characteristics that (1) flames flow from top to bottom, and the temperature in the kiln body is uniform; (2) the size is small, operation is easy and convenient, and sintering requirements of modern artists, studios and workshops can be met; and (3) the kiln bottom is square, the flame suction holes become smaller sequentially from the hearth to the chimney, by utilizing the theory that the closer to the chimney, the higher the suction force is, the defect that kiln positions away from the chimney are prone to generating dead flame angles is overcome, the temperature in the kiln body is more uniform, and the sintering success probability is increased.

Owner:陶朴科技(上海)有限公司

A Coal Gas Treatment Method for Eliminating Black Smoke from Blast Furnace Top

ActiveCN112251552BSolve the problem of black smokeEliminate black smoke phenomenonBlast furnace detailsDust arrestersThermodynamicsDust control

The invention discloses a gas treatment method for eliminating black smoke from the top of a blast furnace. In the method, without adding any equipment, by changing the operation procedure of the gas treatment, the existing dry dust removal gas purification system is used to solve the problem of blast furnace shutdown. The problem of black smoke from the furnace top during the wind and rewind process. Specifically, in the process of shutting down and revitalizing the blast furnace, when the furnace is still under positive pressure, the gas is not opened on the top of the furnace, but the gas is introduced into the bag dust removal box, and the dust removal function of the bag is used to remove the dust from the gas. Afterwards, the clean gas is discharged from the release pipe of the bag filter, thereby completely eliminating the phenomenon of black smoke from the top of the furnace during shutdown and rewinding.

Owner:NANJING IRON & STEEL CO LTD

A Method for Preventing Faults When Construction Machinery Starts

ActiveCN109611224BReduce loadSolve the problem of black smokeEngine controllersPositive-displacement liquid enginesProportional controlMaster controller

The invention discloses a method for preventing faults when construction machinery is started. The start-up process is divided into two stages: in the first stage, the main controller controls the absorbed power of the hydraulic main pump to increase at a rate of k1 through an electric proportional control valve to 3-10% of its target power; in the second stage, the main controller controls the absorbed power of the hydraulic main pump to rise to its target power at a rate of k2 through the electric proportional control valve; the first stage is the first 0.6-10% of the start-up process 1s, the rate k2 is 2 to 6 times of the rate k1. The invention controls the absorbed power of the hydraulic main pump to match the power of the diesel engine during the starting process, reducing the initial load of the diesel engine, enabling the diesel engine to start normally, and avoiding black smoke when the diesel engine starts with load. Problem: The present invention does not need to modify the start-up control system of construction machinery, which saves the cost of modification.

Owner:CHTC JOVE HEAVY IND

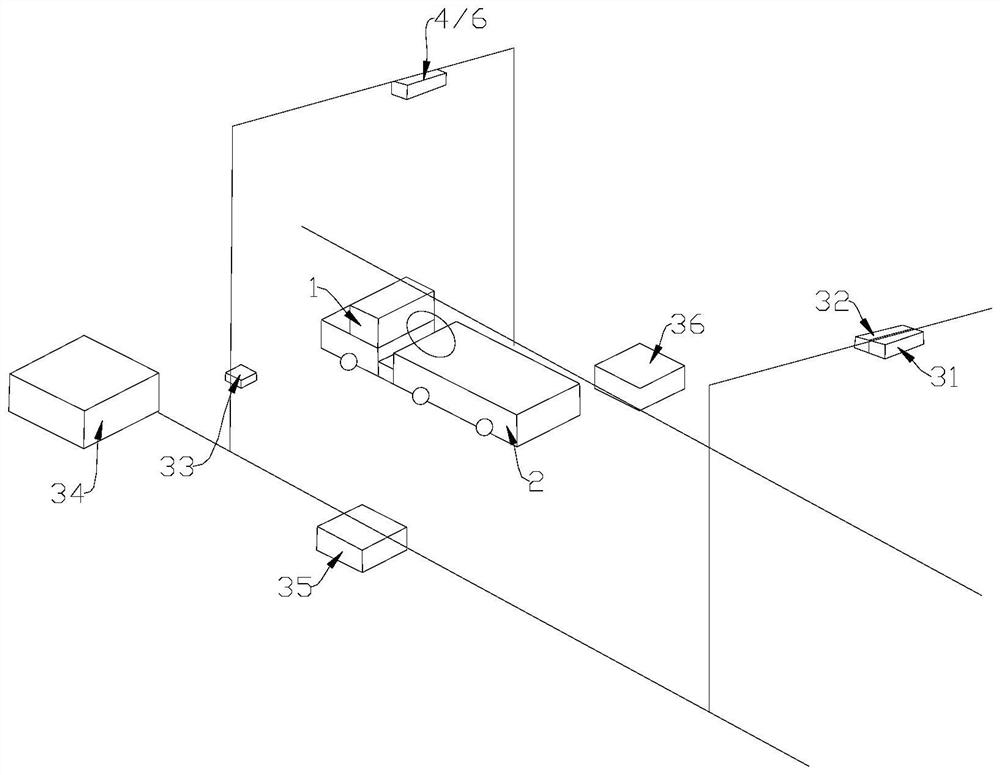

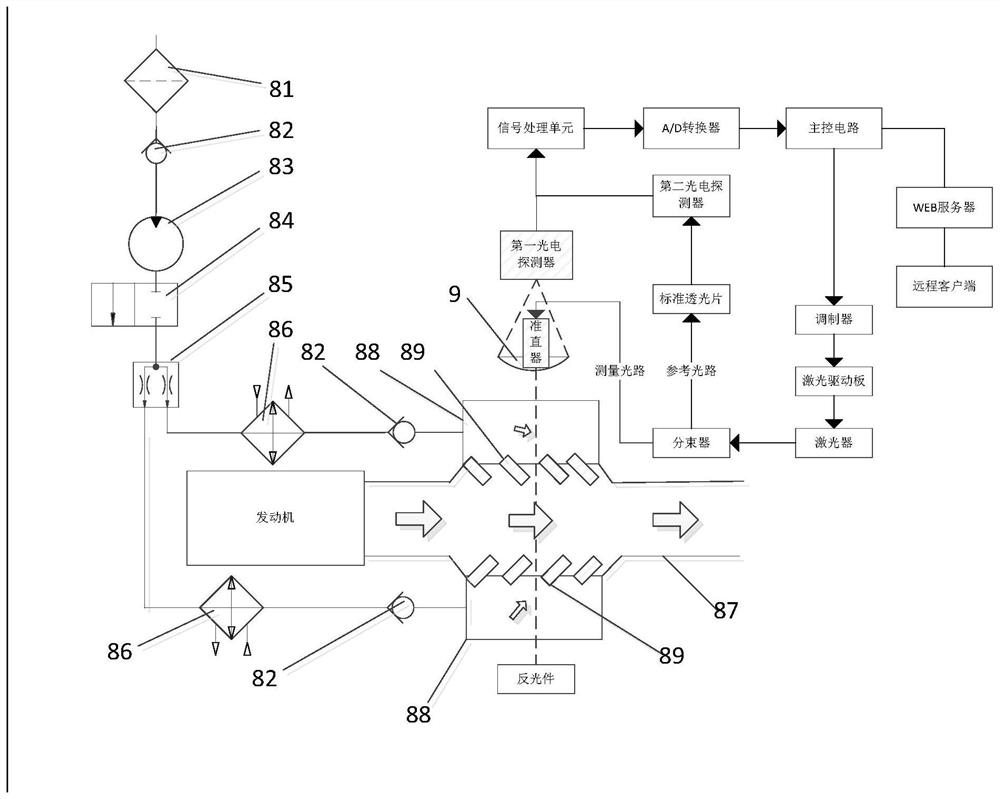

Black smoke vehicle snapshot system of large truck with separated truck head and carriage

InactiveCN111899523AReduce false recognition rateImprove detection accuracyDetection of traffic movementMaterial analysisTruckReal-time computing

The invention relates to a black smoke vehicle snapshot system of a large truck with a separated truck head and carriage. The black smoke vehicle snapshot system comprises a video data acquisition assembly; the video information acquisition assembly comprises a same-direction snapshot unit and an opposite-direction snapshot unit which are installed above a road, a side-direction snapshot unit installed on the side edge of the road, and a service processor which is in communication connection with the same-direction snapshot unit, the opposite-direction snapshot unit and the side-direction snapshot unit. The same-direction snapshot unit performs video acquisition on the tail part and the side surface of the vehicle, and the opposite-direction snapshot unit performs video acquisition on thefront part and the side surface of the vehicle; the side-direction snapshot unit performs video acquisition on a single side surface of the vehicle and a gap between a vehicle head and a carriage; andthe service processor processes the acquired video so as to compare the acquired video with a pre-stored database to obtain discharged smoke data. The black smoke vehicle snapshot system is low in false identification rate and high in detection precision; the system is high in environmental adaptability, is not interfered by environmental conditions, achieves the all-weather recognition and detection of the black smoke vehicle, and solves a problem that black smoke emitted from a long carriage cannot be recognized.

Owner:深圳大雷汽车检测股份有限公司

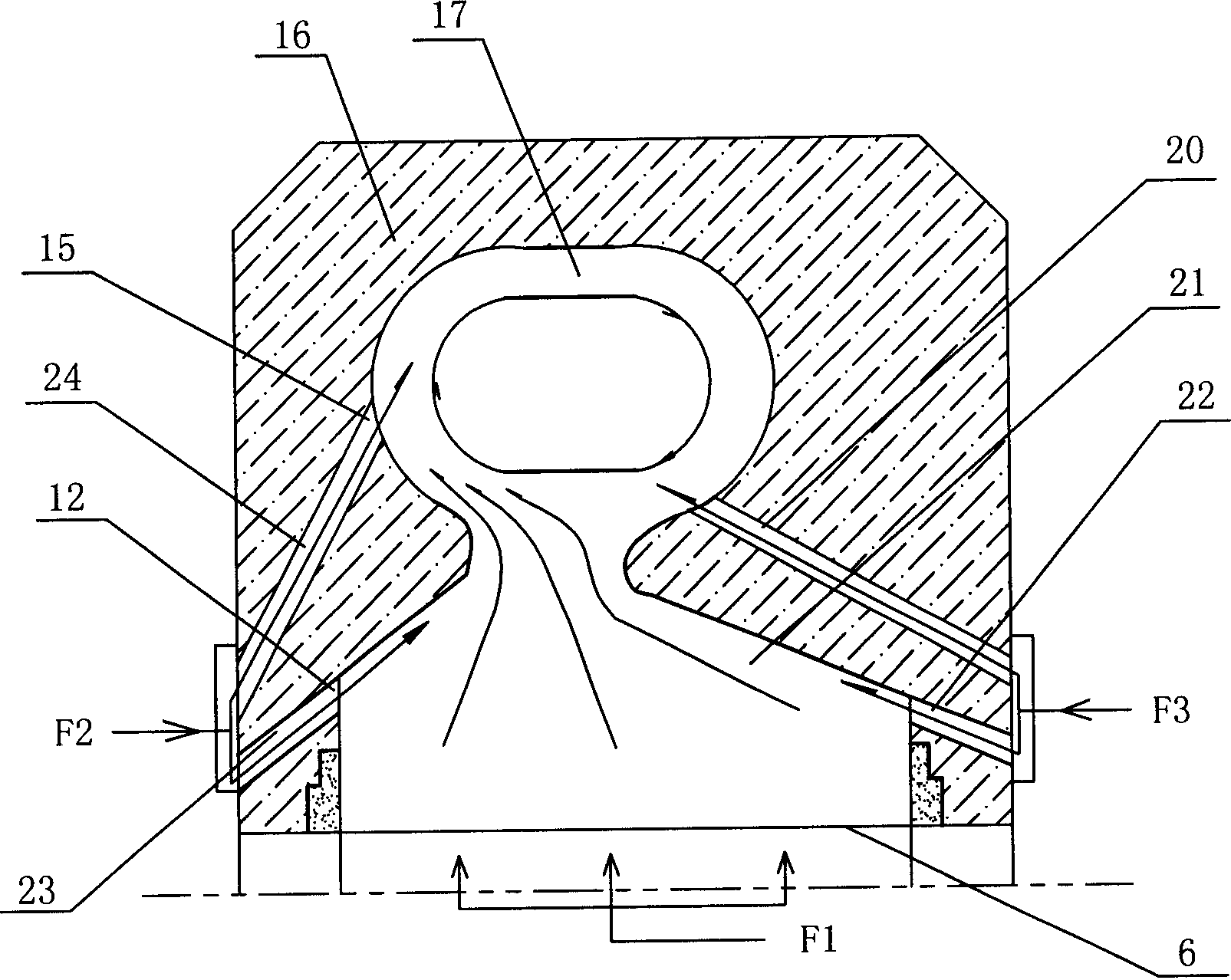

Coal firing equipment with single rotational flow

InactiveCN100394105CSimple structureLow costPulverulent fuel combustion burnersCasings/liningsCombustionEngineering

The present invention relates to a single-cyclone coal-burning equipment. It includes combustion furnace cavity, fire grate, coal-adding device and high-temperature gas outlet. It is characterized by that the top portion of its furnace cavity cross-section is made into the arched form capable of forming cyclone combustion, the side wall of said furnace cavity is equipped with a combustion-supporting air inlet communicated with the furnace cavity, said combustion-supporting air inlet is tangential to said arched form of top portion of furnace cavity, the rear portion of said furnace cavity, is connected with high-temperature gas outlet. Said invention is simple in structure, and can completely solve the problem of discharging black smoke by burning coal, and can save fuel coal.

Owner:王树洲

Smokeless, coal saving type heat transfer oil stove with large mechanical fire grate

InactiveCN100394103CNo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving large-size mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that said furnace body has heating zone and hot gas supply zone, the interior of furnace body of heating zone is equipped with heat-absorbing tube bank, the bottom portion of heating zone is equipped with a hot gas inlet, and the top portion of said heating zone is equipped with a draught fan; the hot gas supply zone possesses a coal-burning device, said coal-burning device has a combustion furnace cavity, meachinical fire grate, coal-adding device and high-temperature gas outlet. Said invention also provides the concrete structure of said furnace cavity. Said invention is simple in structure and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

a boiler

ActiveCN105927956BAvoid pipe burstIncrease profitSteam generation using pressureIndirect carbon-dioxide mitigationWater storageCombustion chamber

Owner:平原通元商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com