Pure smokeless, coal saving type heat transfer oil stove with external combustion and inner rotational flow

A technology of heat conduction oil furnace and internal swirling flow, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc. It can solve the problems of black smoke from coal burning, waste of coal resources, etc., to protect the environment and facilitate centralized processing , the effect of saving coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

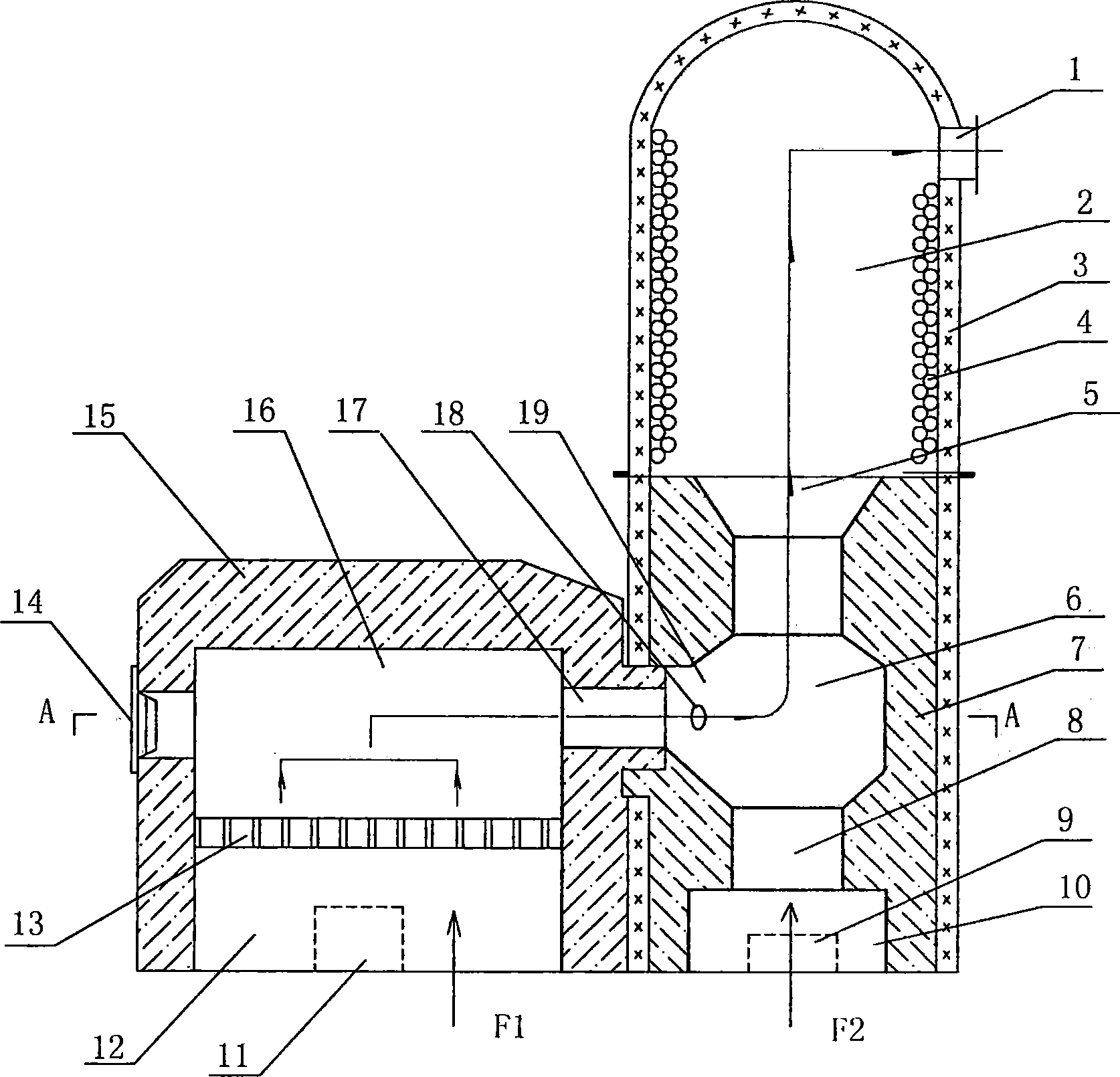

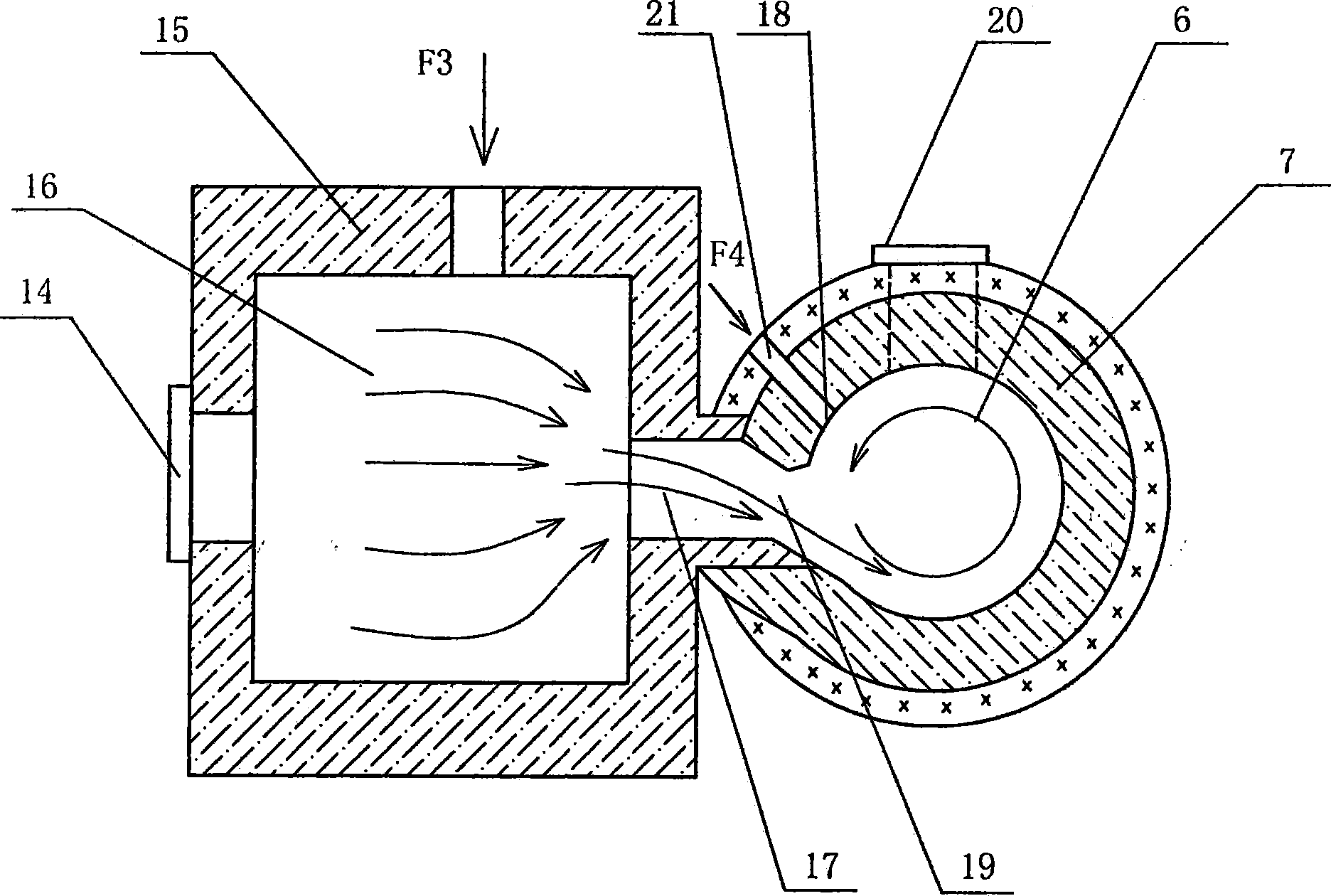

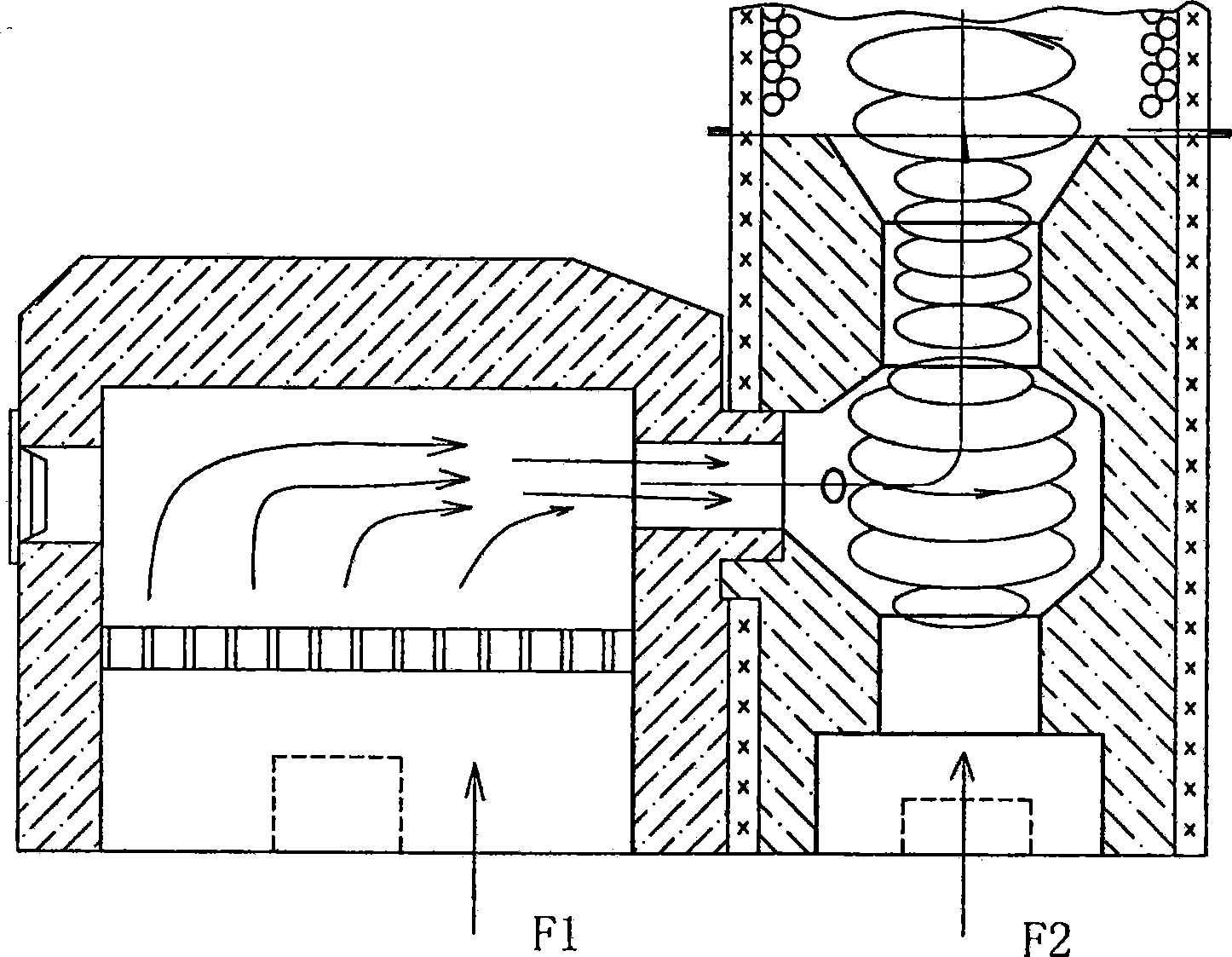

[0024] like figure 1 , figure 2 As shown, in the pure smokeless coal-saving type external combustion internal swirling heat transfer oil furnace of the present invention, the upper part of the furnace body 3 is a heating zone 2, and the furnace body of the heating zone 2 is equipped with a heat conduction oil pipe 4, and the heating zone 2 The top is connected to the induced draft fan through the induced draft fan connection nozzle 1, and the bottom of the furnace body 3 is a coal burning area, which is equipped with a coal burning device. Flow combustion device 7, coal-fired combustion device 15 has coal-fired furnace 16, fire grate 13 and coal filling port 14, and the rear portion of coal-fired furnace 16 has flue gas outlet 17; The swirling furnace 6 has a high-temperature gas outlet 5 on the top of the swirling furnace 6, an air inlet 8 below,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com