Small down-draft type smokeless firewood kiln

A technology of inverted flame and wood burning, which is applied in the field of traditional Chinese ceramic wood burning kilns, can solve the problems of uneven kiln temperature, low production efficiency, short service life, etc. The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] In view of the problems existing in the above traditional kiln, the present invention provides a complete and effective solution.

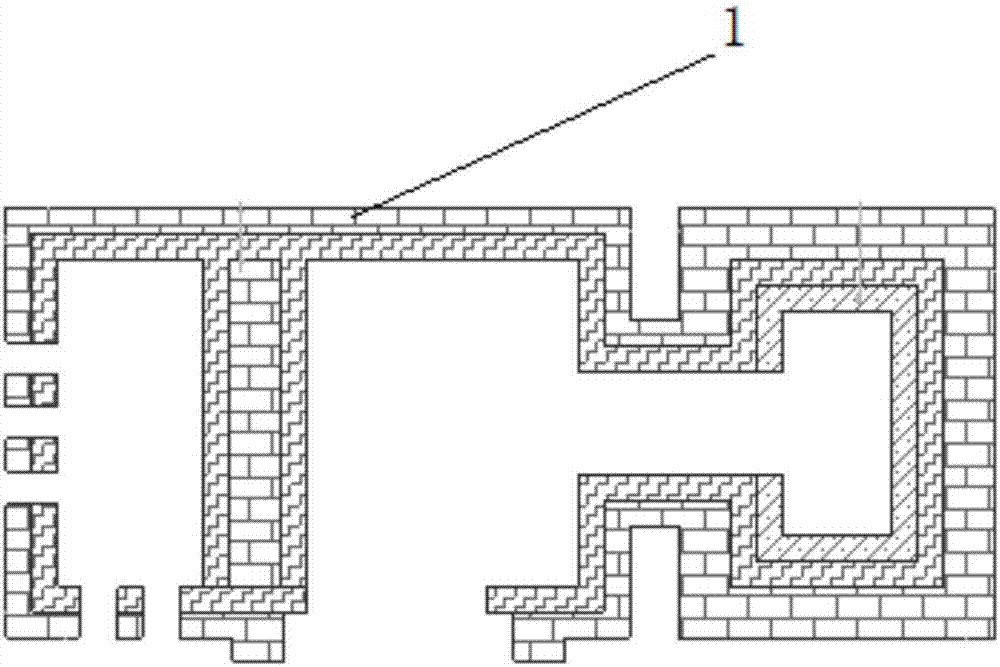

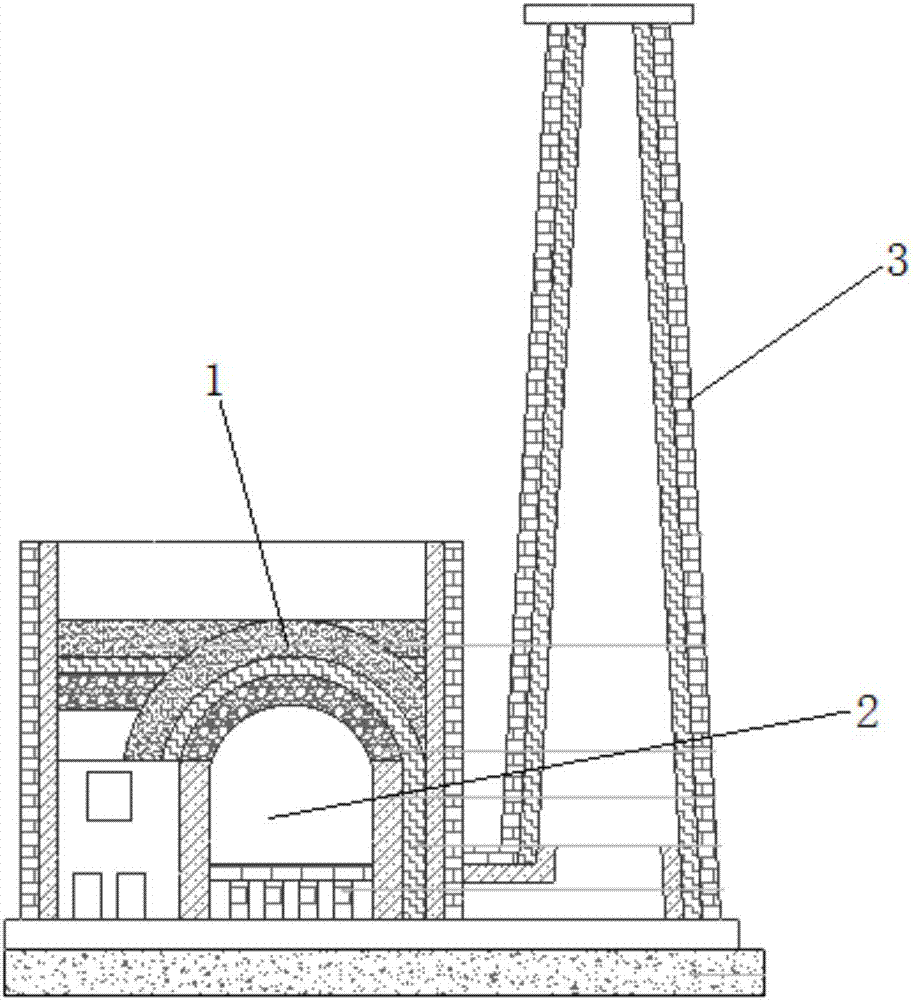

[0024] Downdraft kiln is a kiln body construction and firing technology that appeared in modern times. It is developed on the basis of traditional Chinese kiln technology. It makes the flame flow direction from top to bottom, so as to reach the temperature inside the kiln body 1 more even purpose. This kiln is a small firewood kiln with a volume of 1 cubic meter. It is small in size and easy to operate. It is suitable for the firing needs of modern artists, studios and workshops.

[0025] The traditional downdraft kiln is mostly circular because of its large kiln body 1 . This time, the small downdraft kiln is set as a square vaulted kiln. Combining the principle that most of the kiln furniture such as modern kiln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com