A Coal Gas Treatment Method for Eliminating Black Smoke from Blast Furnace Top

A technology for coal gas and blast furnace, which is applied in the field of gas treatment to eliminate black smoke from the top of the furnace during the rewinding process of the blast furnace, and can solve the problems of black smoke from the top of the furnace, unpredictable effects, and difficulty in guiding gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

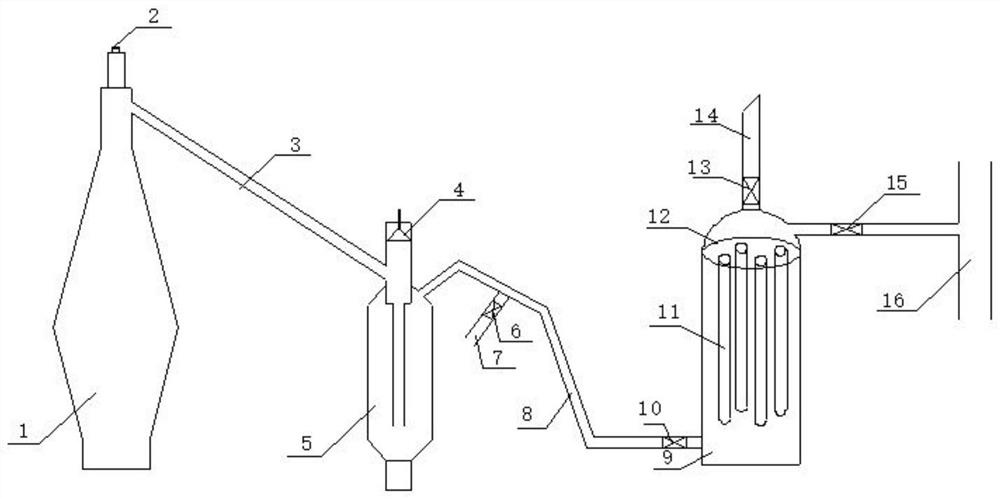

[0022] Below, combine figure 1 The present invention is described in further detail. Only one set of bagged box equipment is shown, 1. Blast furnace body, 2. Blast furnace top relief valve, 3. Blast furnace gas downpipe, 4. Gravity dust collector shutoff valve, 5. Gravity dust collector, 6. Nitrogen valve, 7. Nitrogen purge pipe, 8. Raw gas main pipe, 9. Bag box, 10. Imported butterfly valve for bag dust removal, 11. Dust bag, 12. Bag orifice plate, 13. Bag box release valve, 14. Bag box Diffuse pipe, 15 outlet butterfly valve for cloth bag dust removal, 16, clean gas main pipe.

[0023] In order to avoid black smoke from the top of the furnace during shutdown and recovery, this method changes the gas treatment operation procedure. Specifically, for the wind break process, the steps include:

[0024] (1) Reduce the wind of the blast furnace until the wind pressure is below 30Kpa, turn on the steam on the top of the furnace, and then perform the gas cutting operation;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com