Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Solve the movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

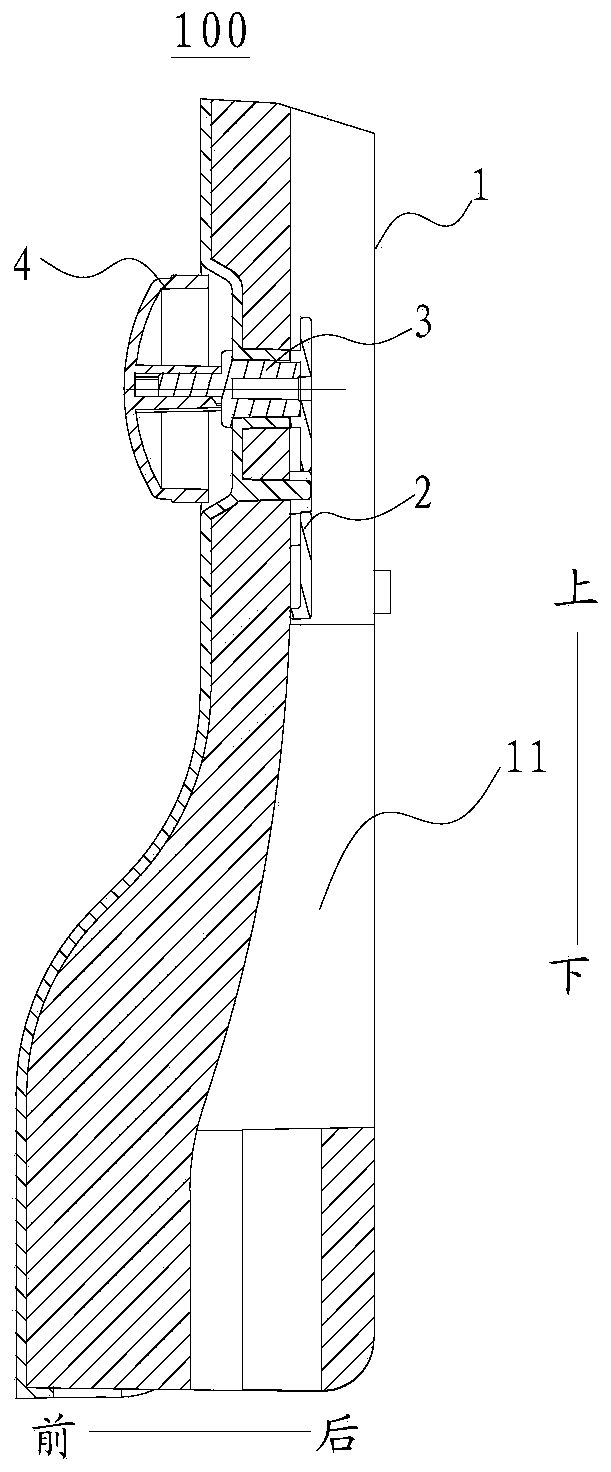

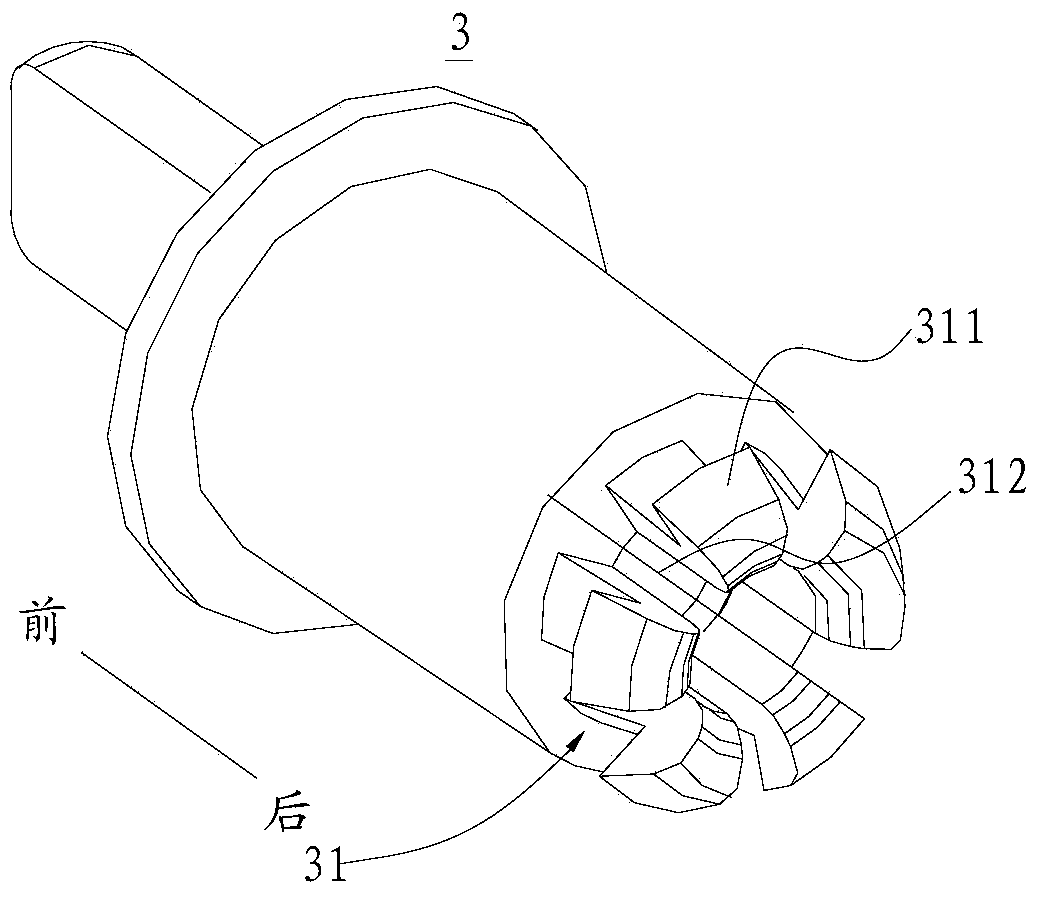

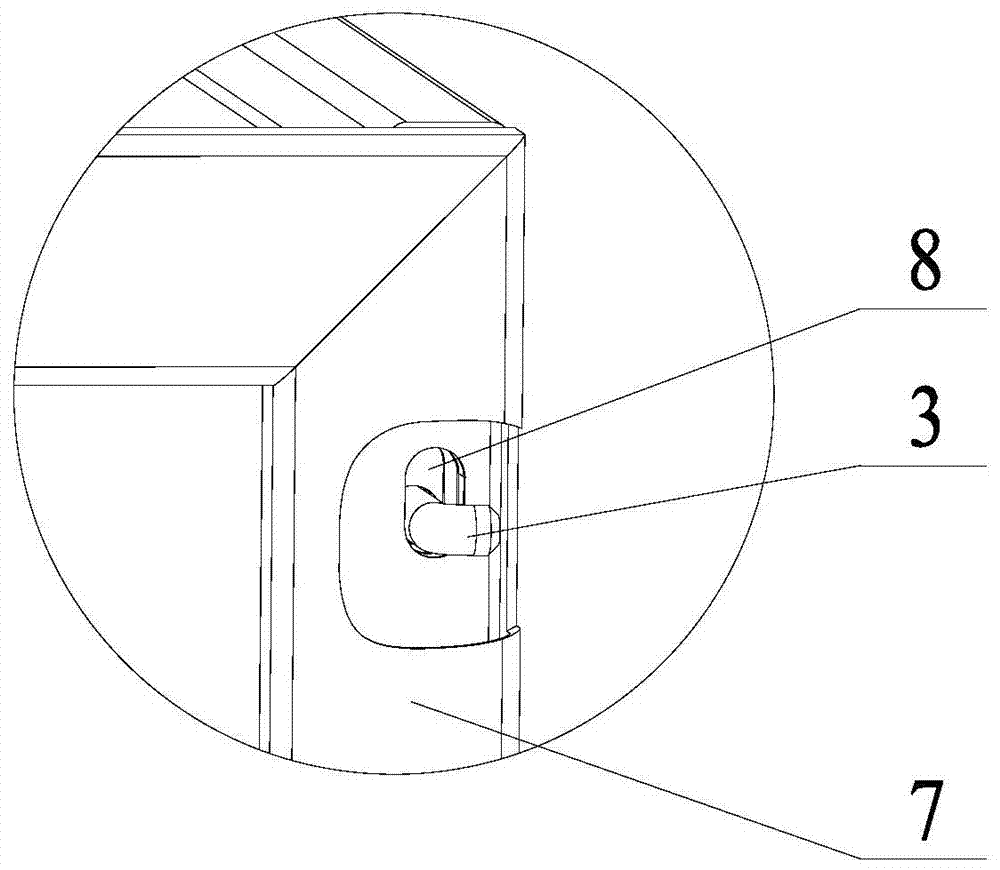

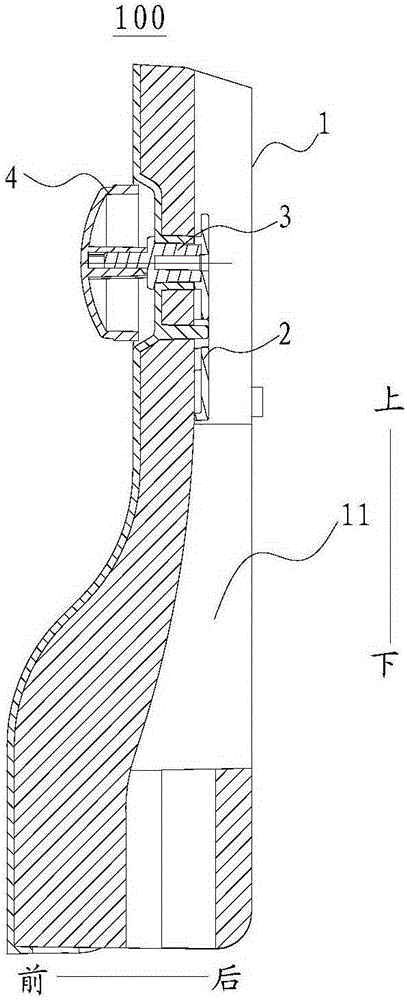

Air duct assembly for refrigerator and refrigerator with same

ActiveCN103411369ASolve the damper movementSimplify the installation processLighting and heating apparatusCooling fluid circulationRefrigerator carAir door

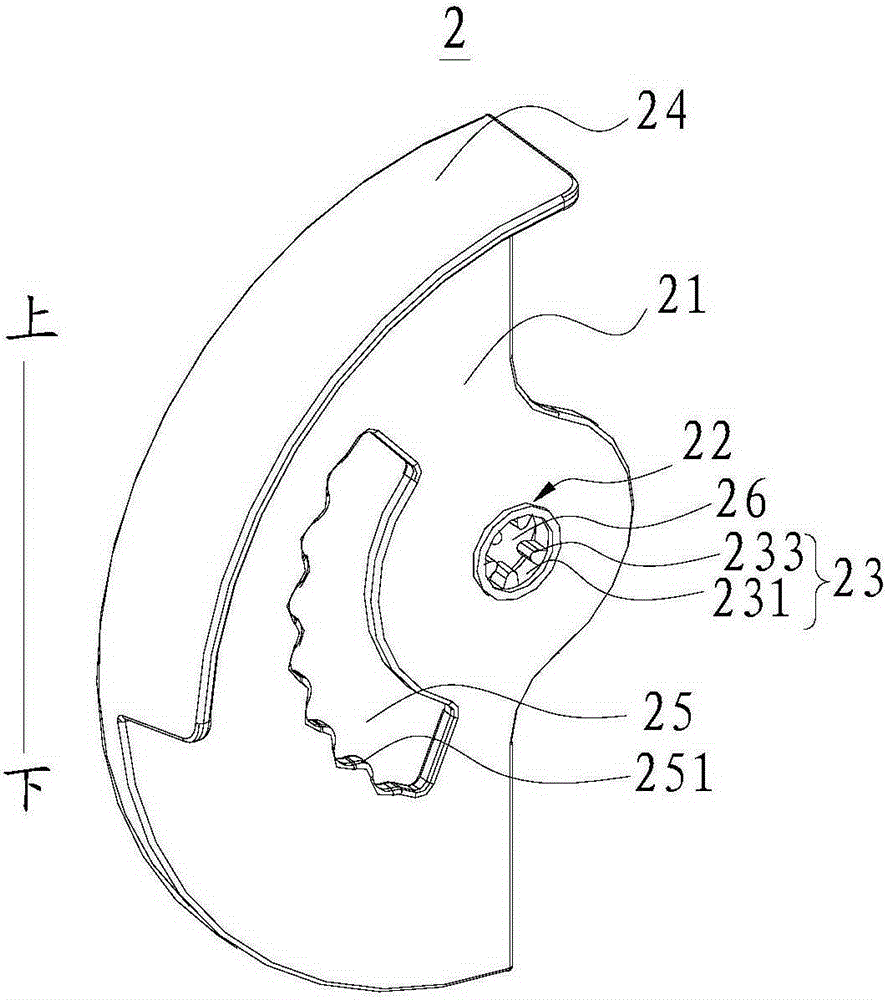

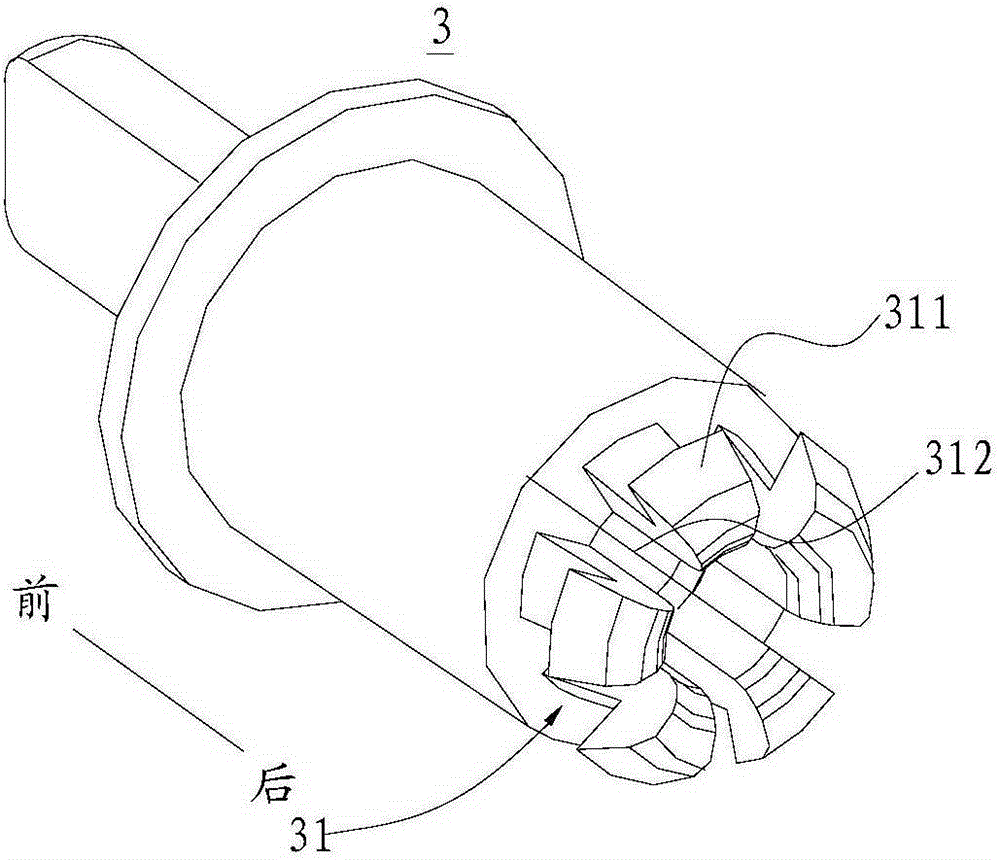

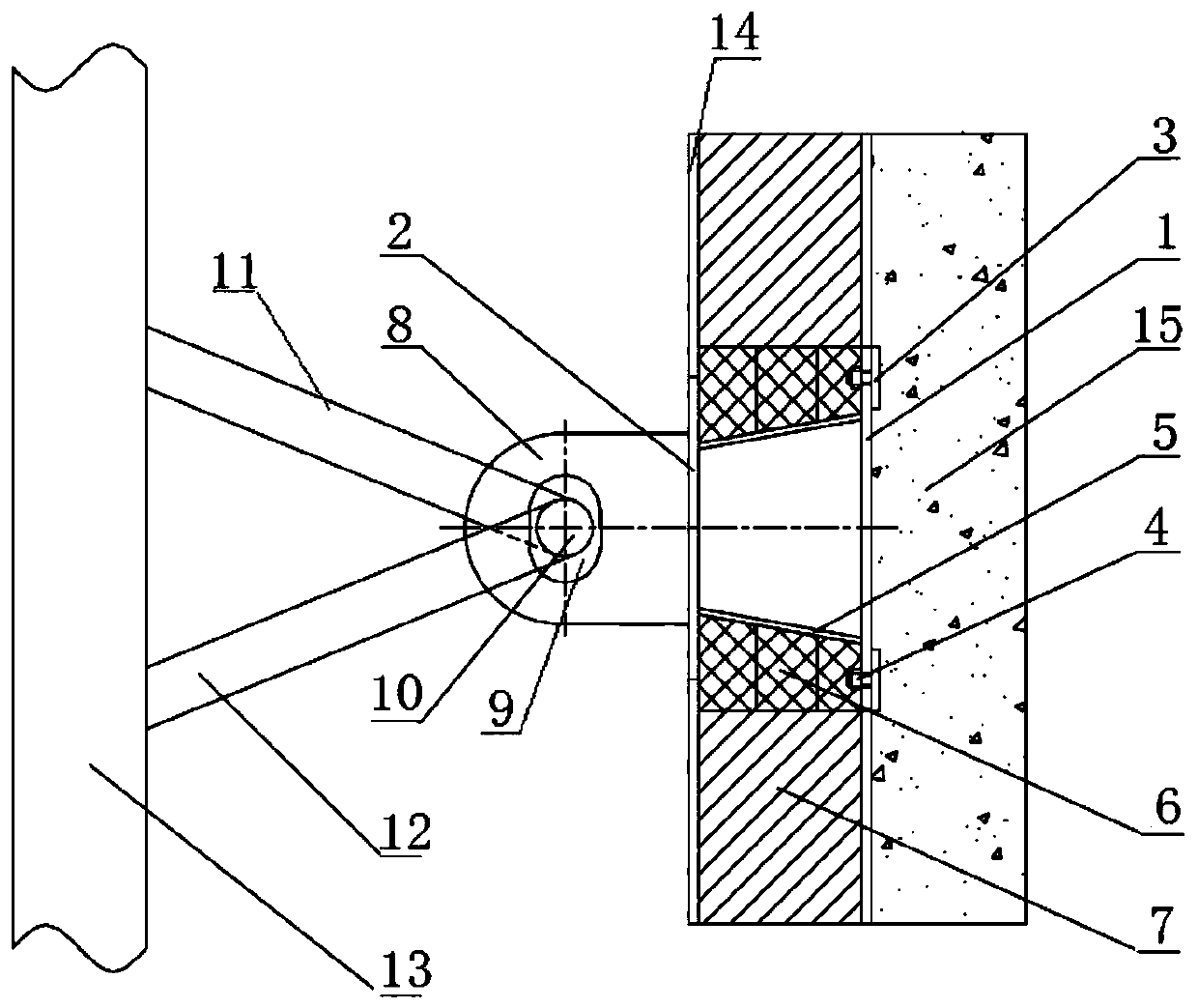

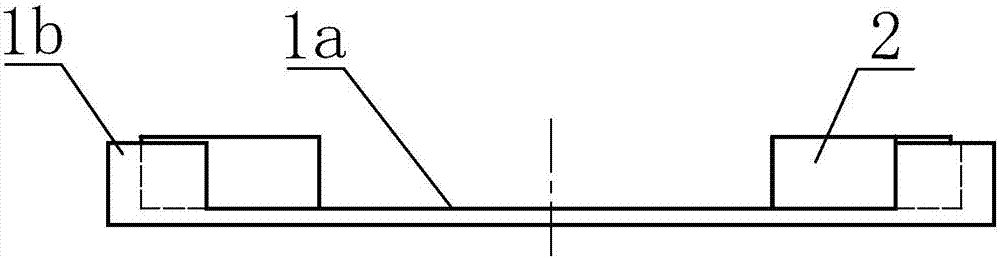

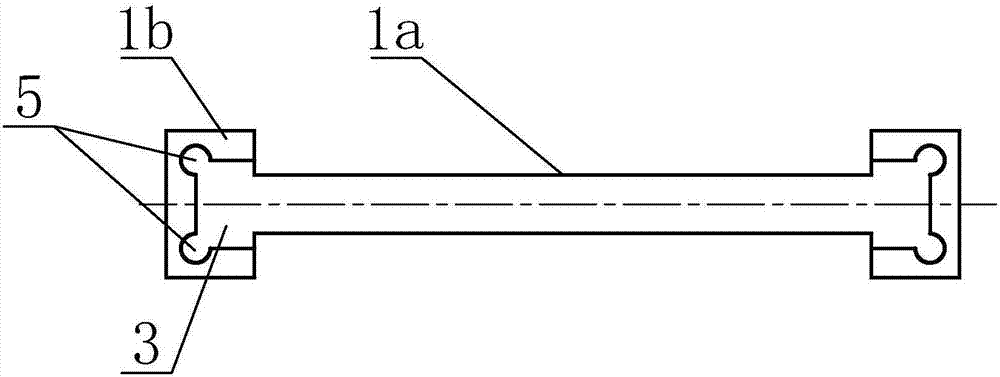

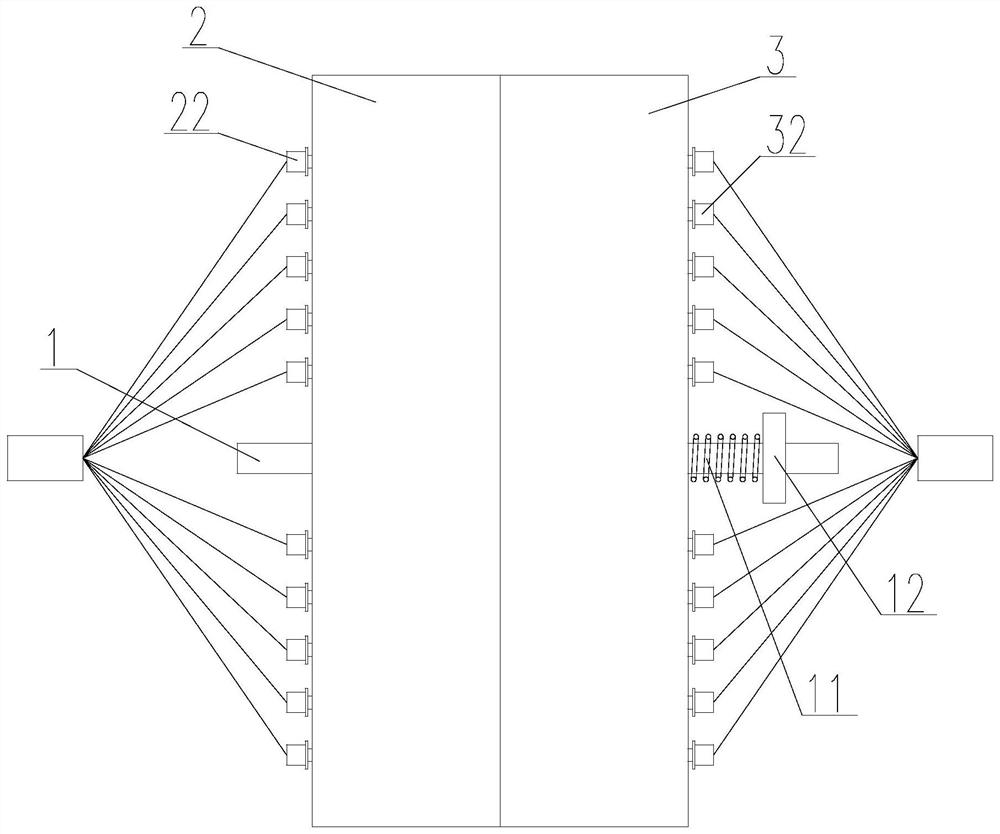

The invention discloses an air duct assembly for a refrigerator and a refrigerator with the same. The air duct assembly is suitable for being arranged inside a chamber of the refrigerator and comprises an air duct piece, an air door and a rotating shaft, wherein an air duct groove which is recessed forwards is formed on the air duct piece, and the air duct groove and the rear wall of the chamber of the refrigerator limit air outlet duct; the air door is rotatably arranged inside an air duct to adjust the ventilation rate inside the air duct, and a first limit part is formed on the air door; the rear end of the rotating shaft is connected with the air door after penetrating the air duct piece to drive the air door to rotate, and a second limit part is formed at the rear end of the rotating shaft and is matched with the second limit part. According to the air duct assembly for the refrigerator of the embodiment of the invention, the problem of air door displacement can be effectively solved through the tight matching of the first limit part on the air door and the second limit part on the rotating shaft, the installation process is simple and the accuracy of the adjustment of the ventilation rate inside the air duct through the air door is high.

Owner:HEFEI HUALING CO LTD

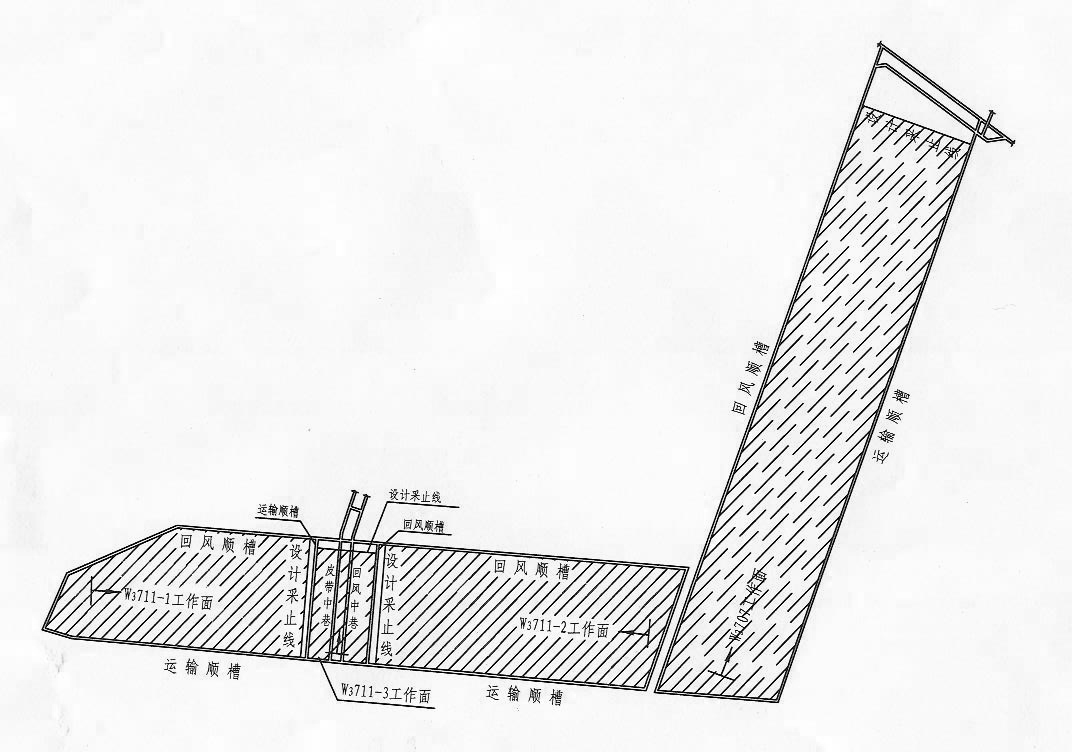

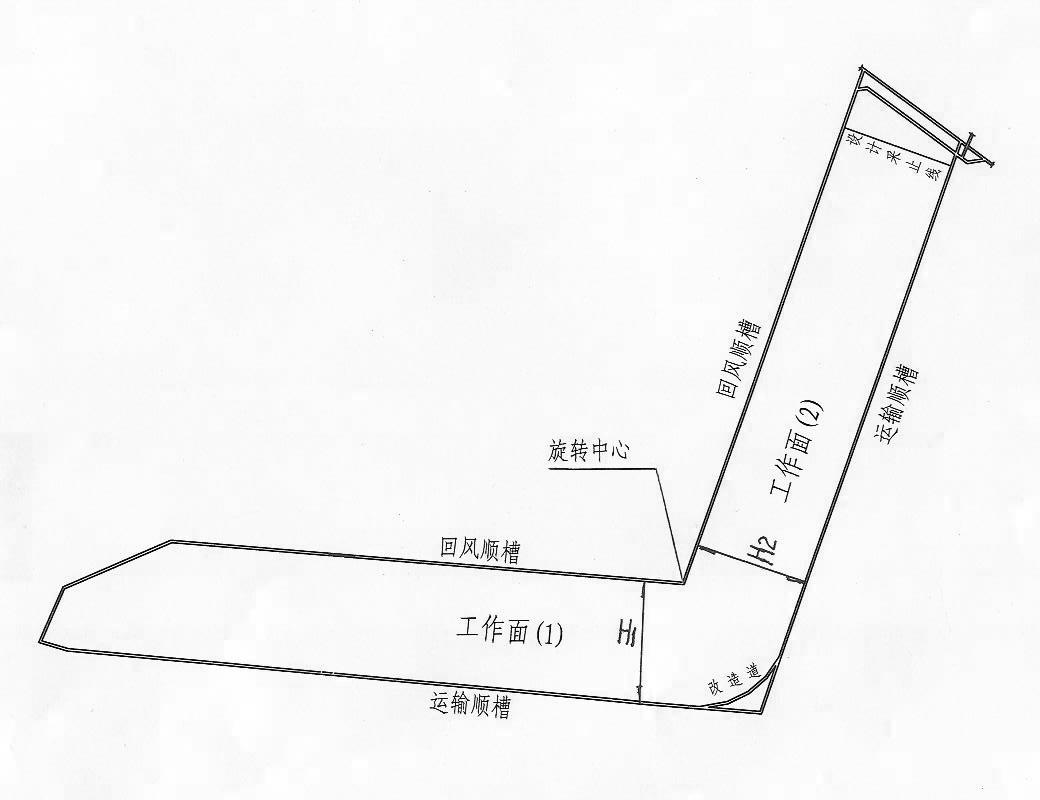

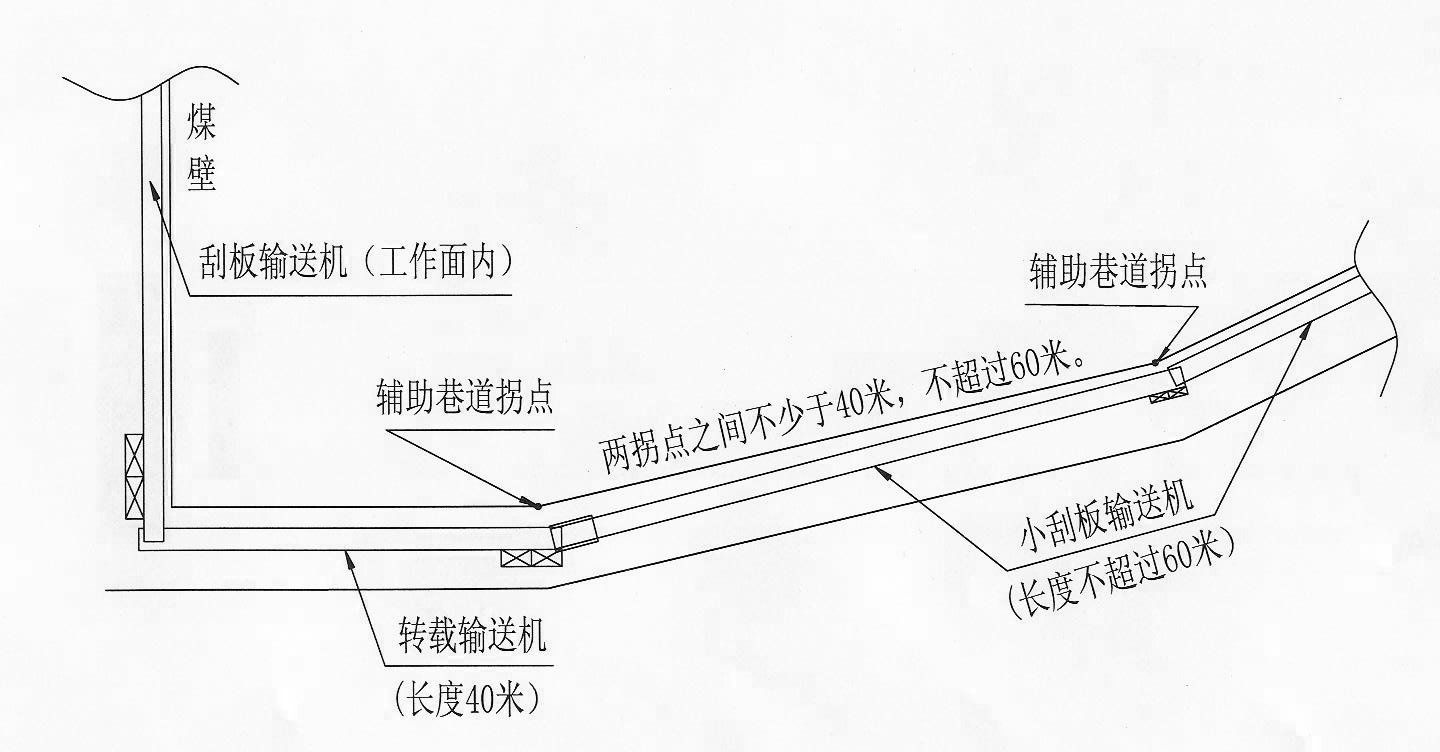

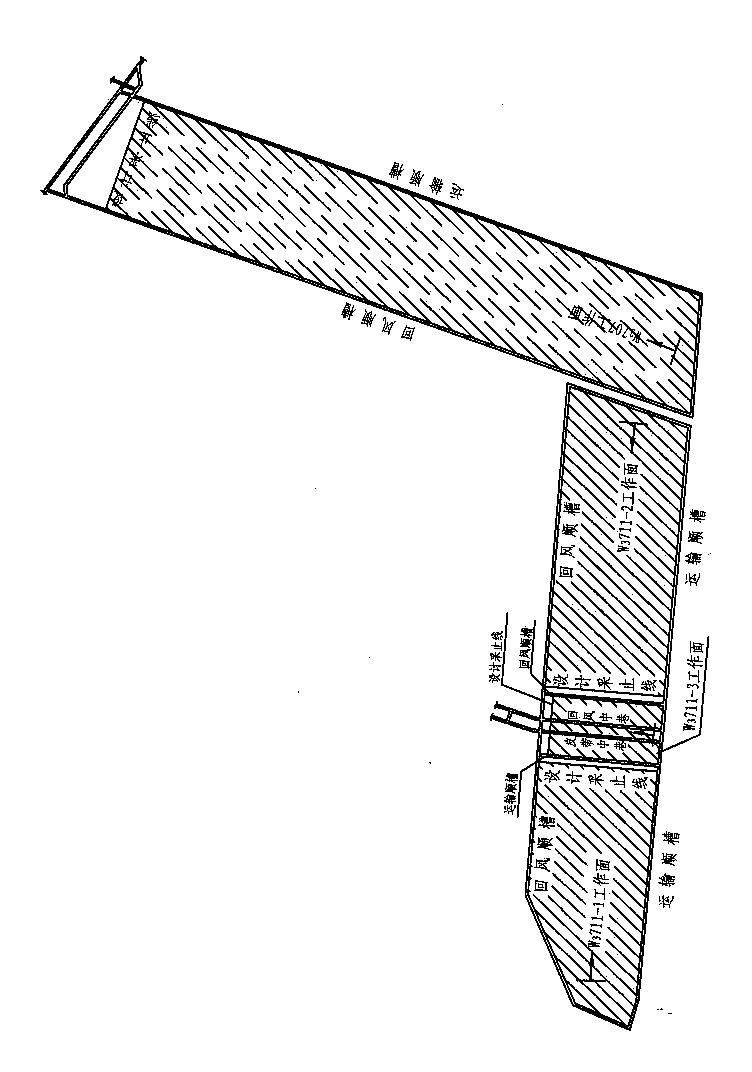

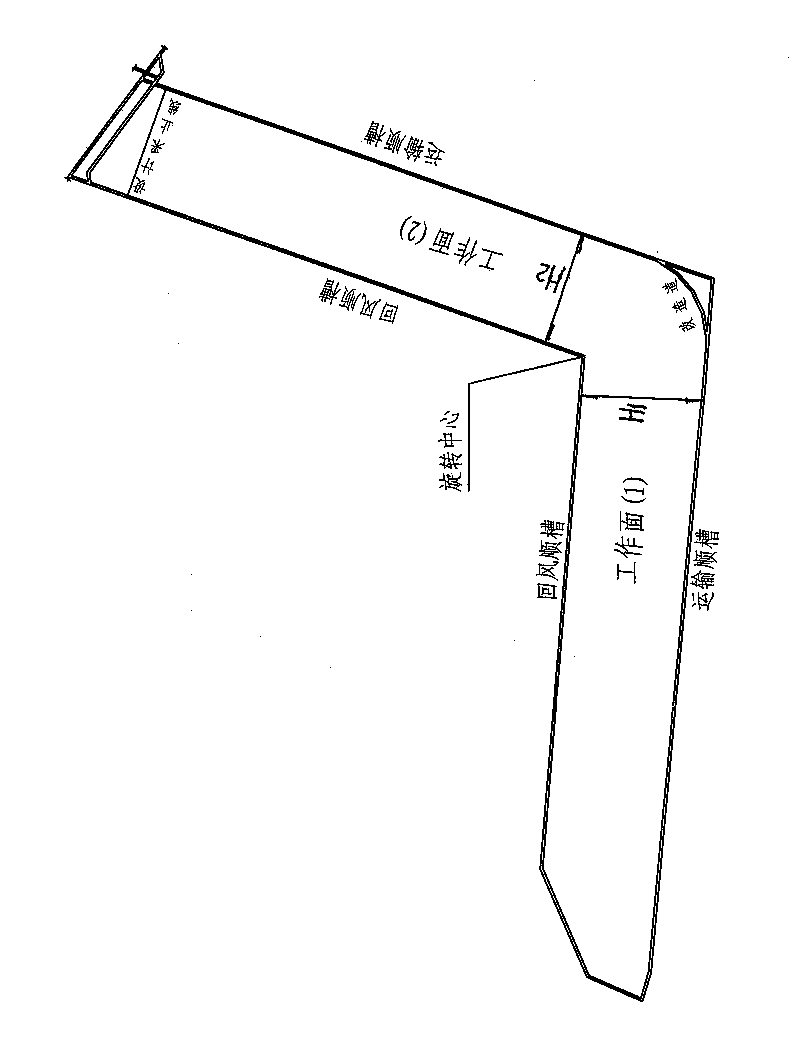

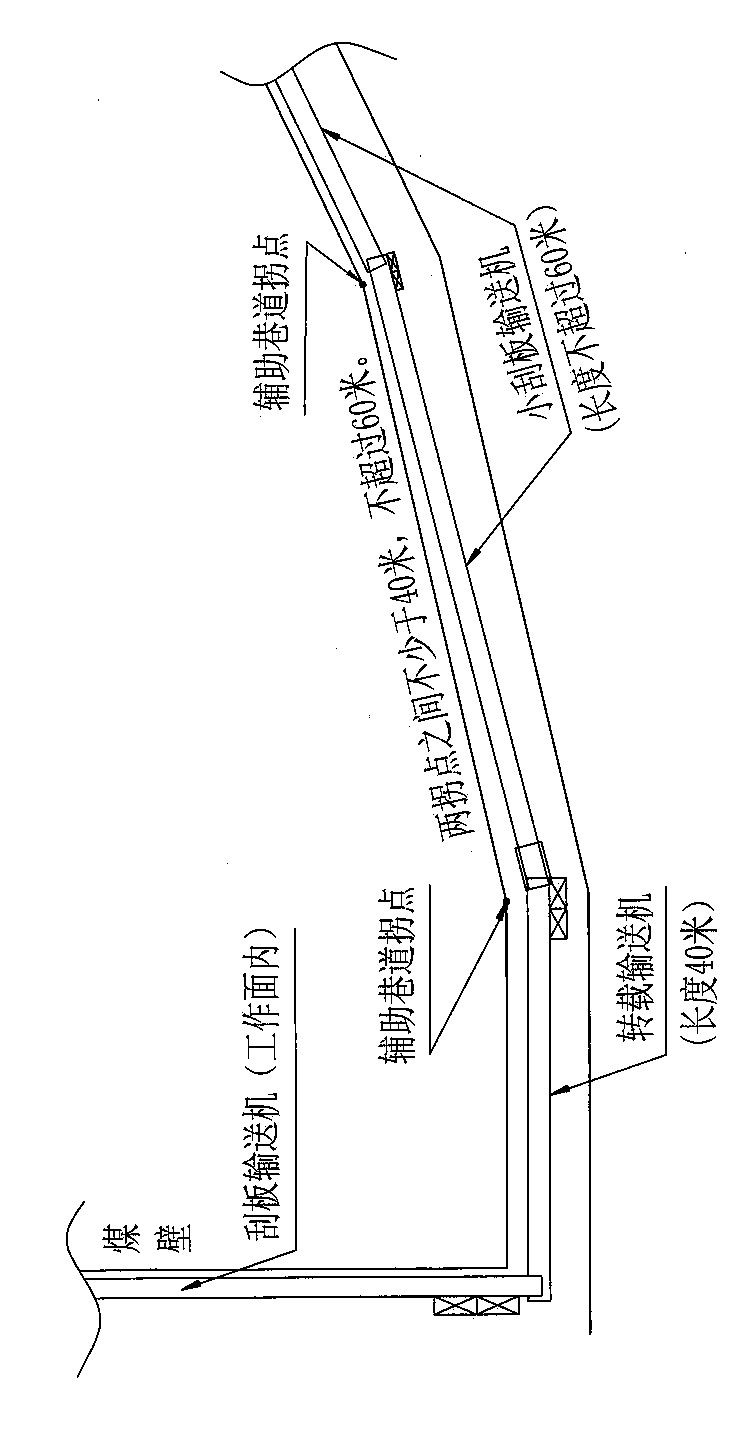

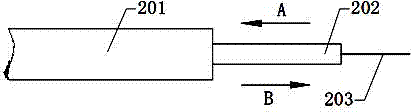

Conveyor gateway large-angle rotary stoping method of unequal length fully-mechanized mining working surfaces

InactiveCN102536242AEasy maintenanceSolve the movementUnderground miningSurface miningHydraulic cylinderCentre of rotation

The invention discloses a conveyor gateway large-angle rotary stoping method of unequal length fully-mechanized mining working surfaces, and is characterized in that the turning part of the L-shaped working surface is provided with an arc auxiliary roadway formed by a plurality of linear roadways, wherein the rotation angle between adjacent linear roadways is 13-17 degrees; the length of each linear roadway not only exceeds the length of a transfer conveyor, but also does not exceed the maximal conveying length of a small scraper conveyor; the rotation center is subjected to secondary confirmation through rotation slope regulation, the hydraulic support is increased during the regulation process of the rotation center; the state of the scraper conveyor is regulated through the auxiliary hydraulic cylinder; and a timely top contact frame moving mode is adopted at the rotation center region of the operating surface, and maintaining is strengthened by an auxiliary supporting mode in the range of the section. According to the invention, the arc roadways are formed by a plurality linear roadways, the rotary stoping arc subsection is subjected to slope regulating and stoping, and the difficulties that the rotation angle of the conveyer gateway is over large and the coal conveying path can not be bent are solved. The rotation center is pushed appropriately, a top plate at the rotation center region is maintained greatly, and the problems that the support pushing quantity at the rotation center is less and is required to be supported repeatedly, and the top plate is difficult to maintain are solved.

Owner:铁法煤业(集团)有限责任公司晓南矿

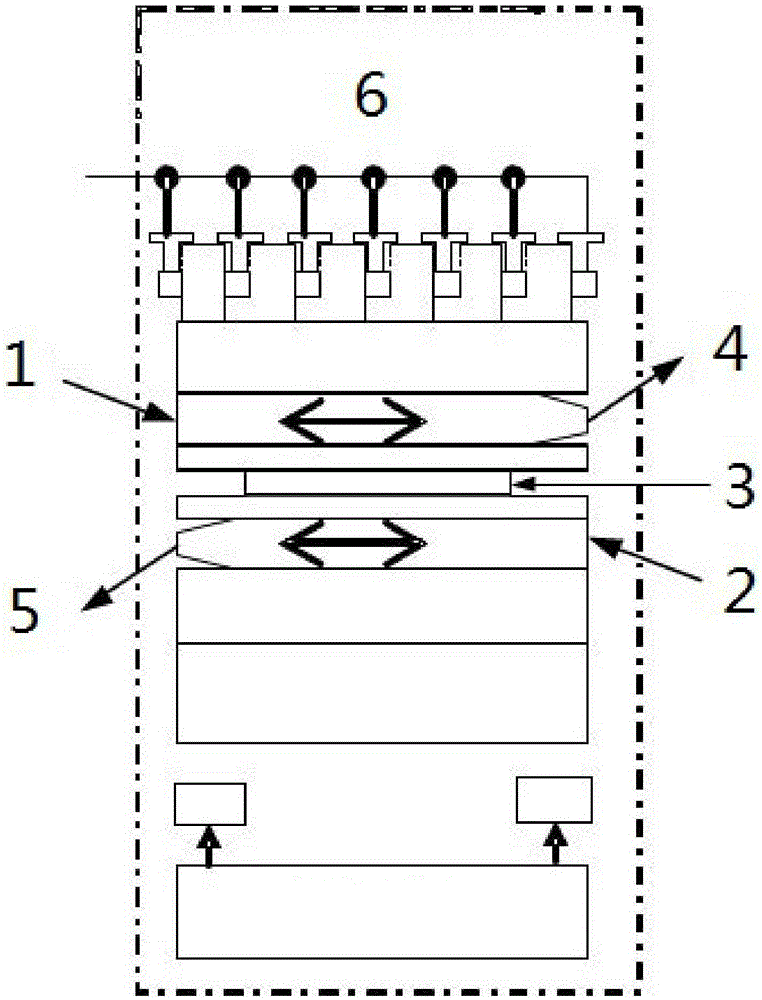

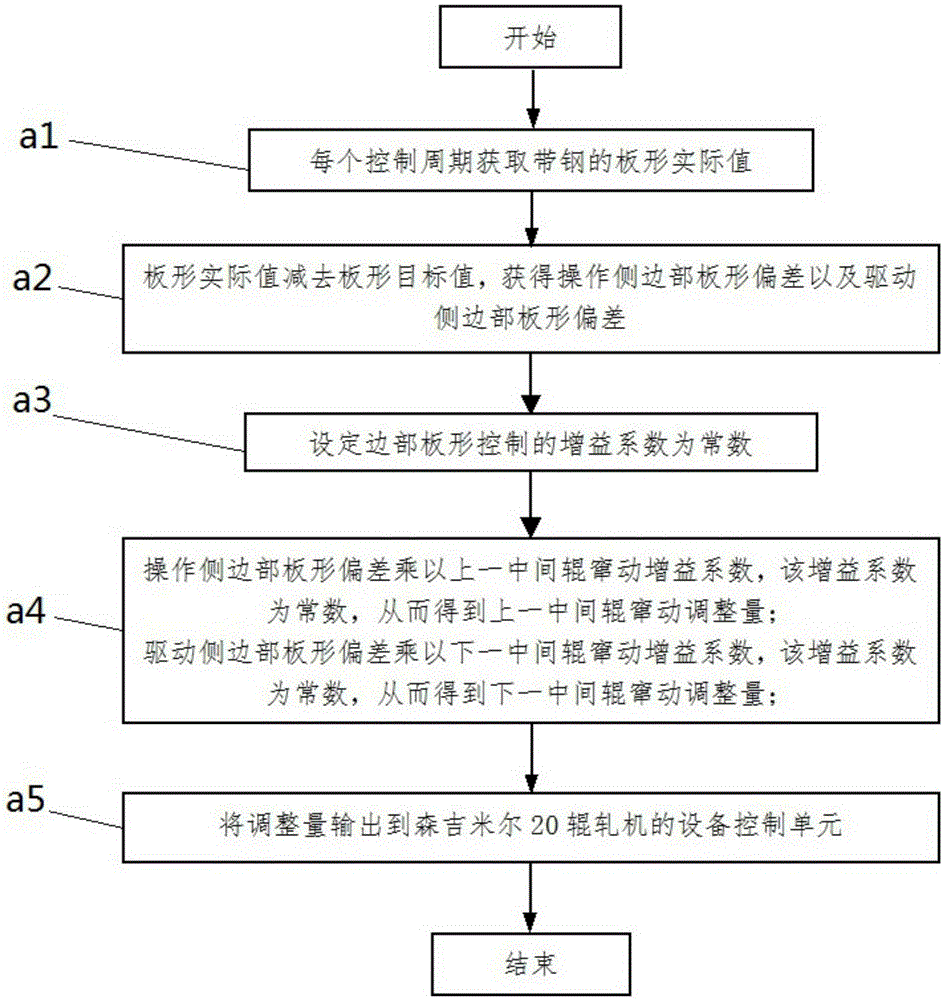

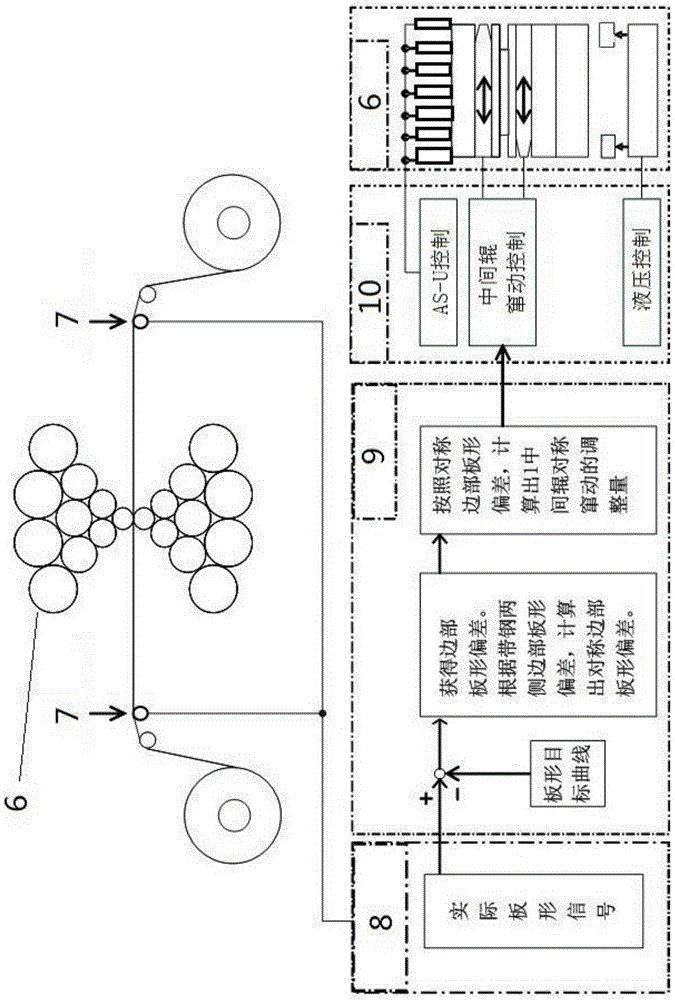

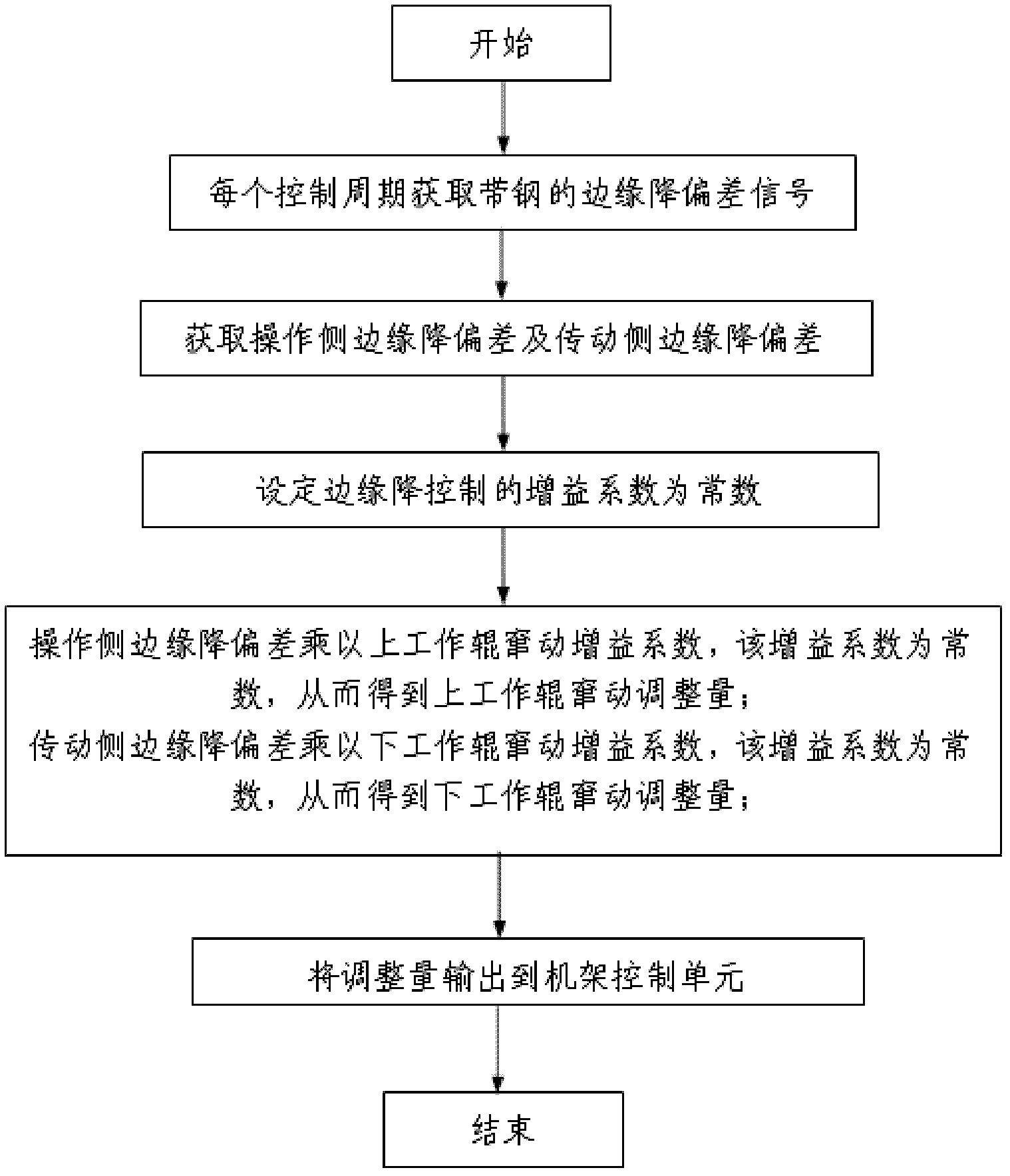

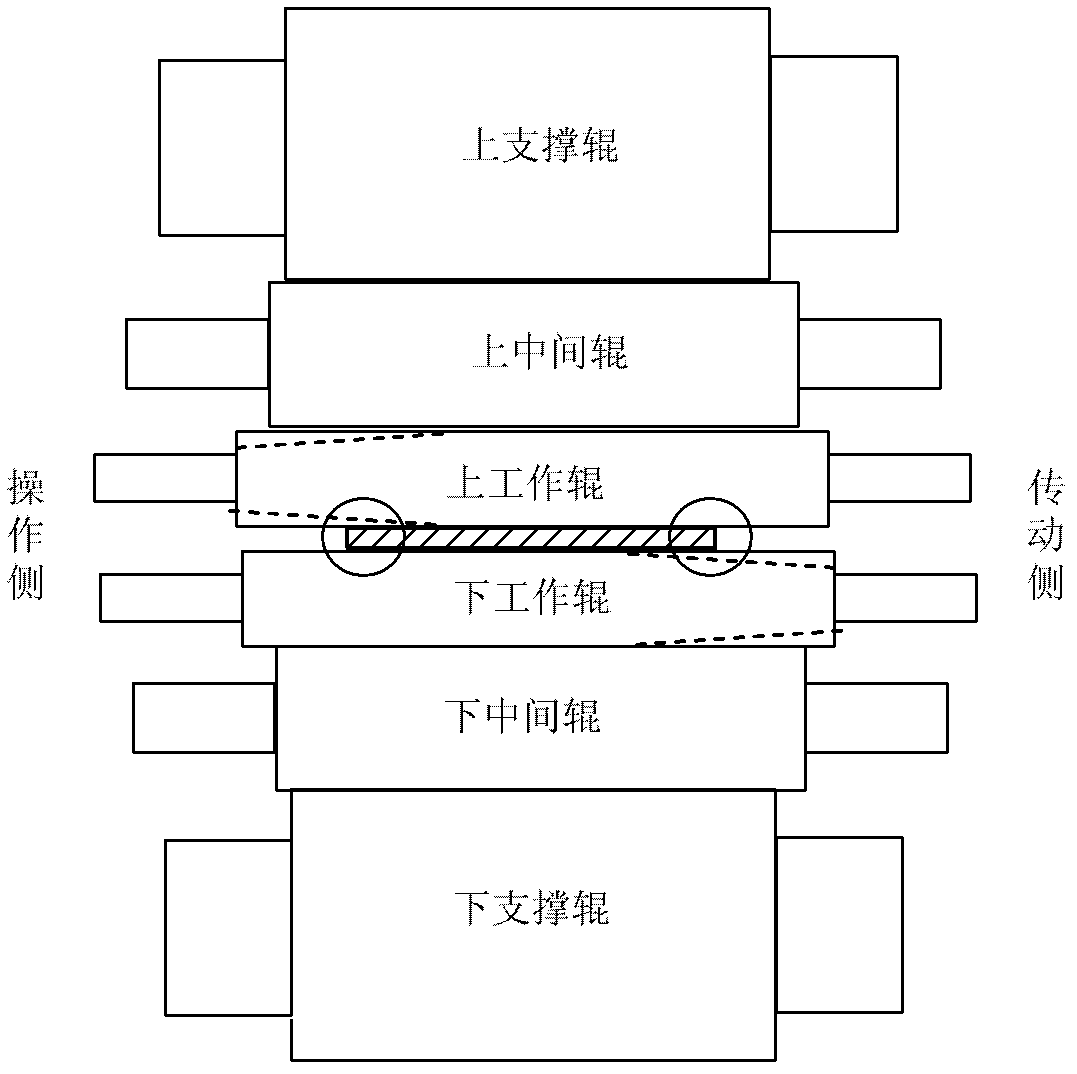

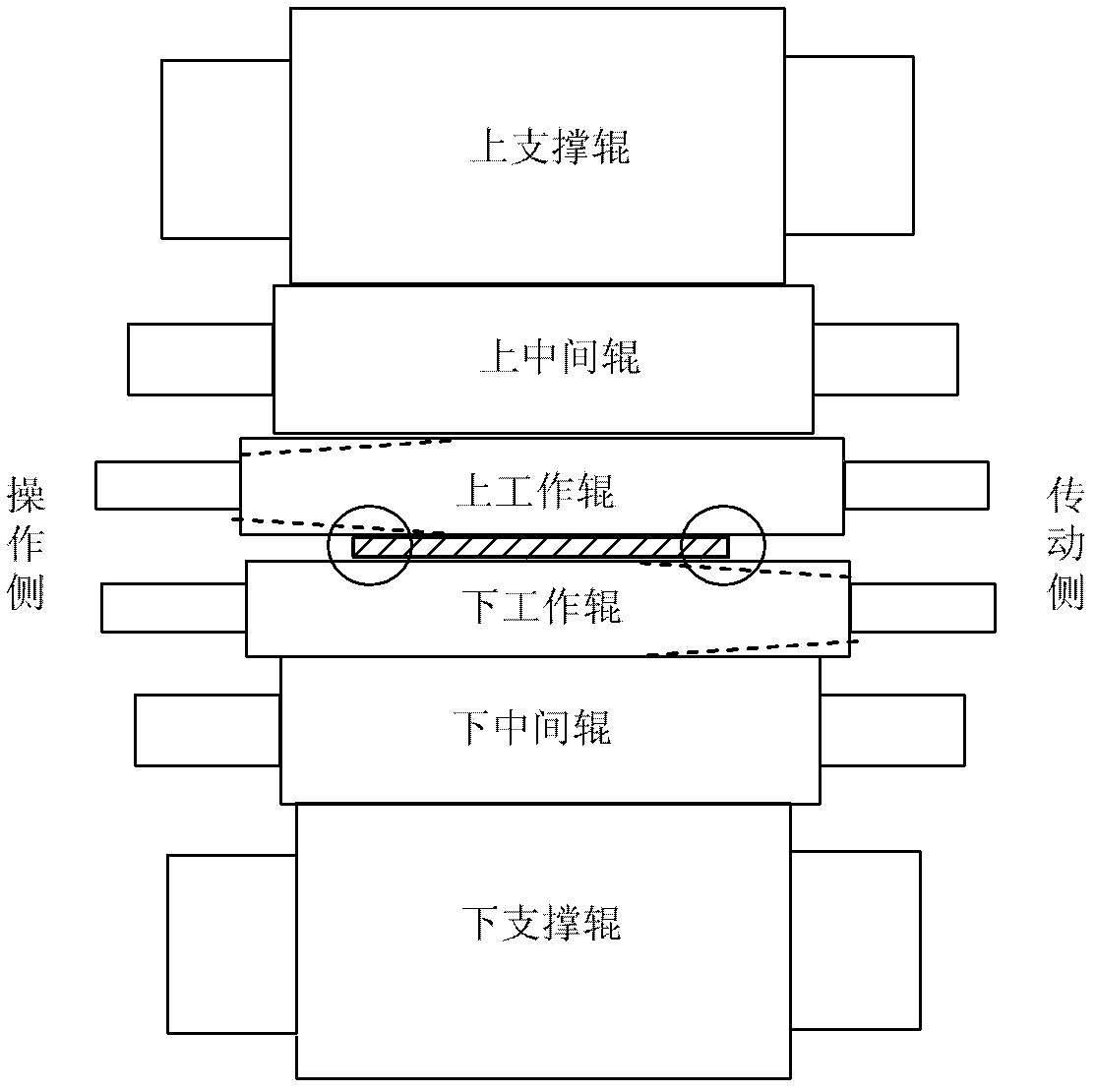

Sendzimir 20 rolling mill edge plate shape controlling method and device

ActiveCN106607460AGuaranteed control effectSolve the movementProfile control deviceShape deviationGain coefficient

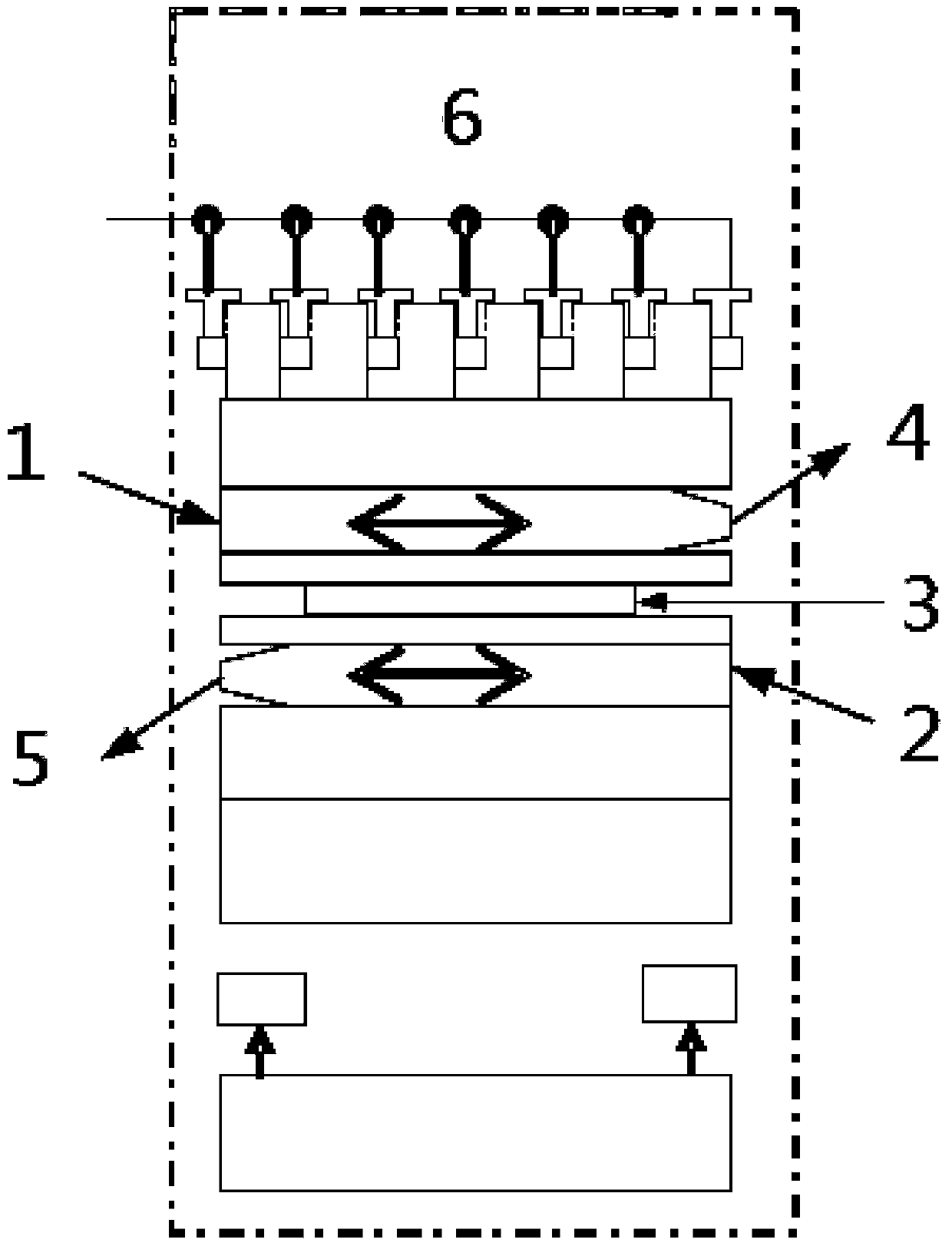

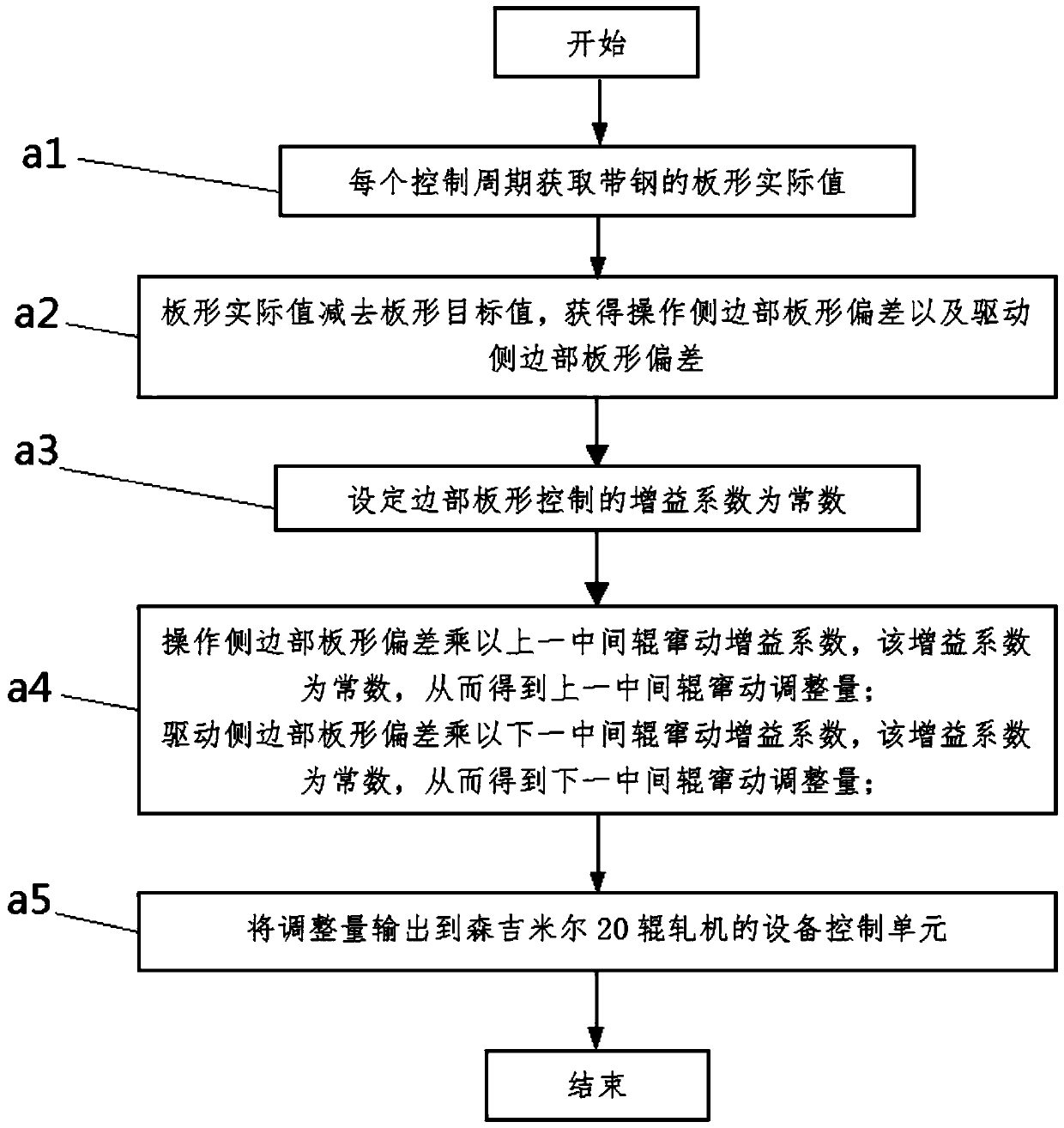

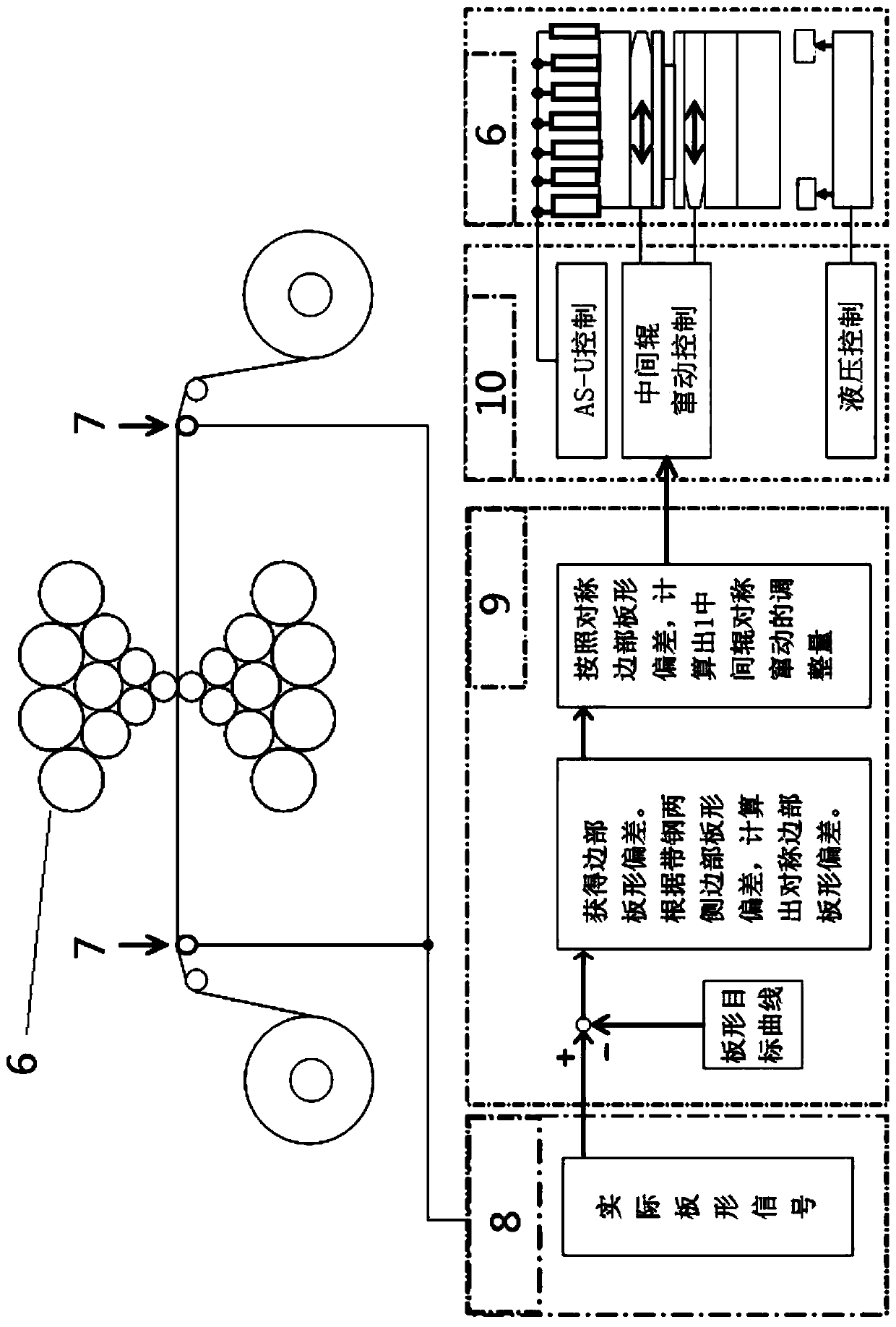

The invention discloses a sendzimir 20 rolling mill edge plate shape controlling method and device. The method comprises the following steps that (1) strip steel plate shape actual values in all control periods are obtained; (2) operation side edge plate shape deviations and driving side edge plate shape deviations are obtained by subtracting target plate shape values from the plate shape actual values; (3) symmetrical side plate shape deviations are calculated according to strip steel two-side edge plate shape deviations; (4) side plate shape control gain coefficients are calculated; (5) symmetrical side plate shape deviations multiply by the side plate shape control gain coefficients to obtain a middle roller symmetrical moving adjustment amount; and (6) the adjustment amount is output to a mill. By means of the sendzimir 20 rolling mill edge plate shape controlling method and device, the stability in the rolling process is guaranteed, the side plate shape control effect is guaranteed, and the problem of moving of non-symmetrical middle rollers is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Stabilizing pin for formed metal plate

The invention belongs to the technical field of punching and manufacturing of metal plates and particularly relates to a stabilizing pin for a formed metal plate. The stabilizing pin is characterized by comprising a carrier, a conical head threaded rod and a locating pin, a threaded hole and a locating pin mounting hole are formed in the axial direction of the carrier, the locating pin mounting hole is formed in an eccentric mode, a step table is arranged in the locating pin mounting hole, the locating pin enters the locating pin mounting hole from the bottom of the carrier and is fixed through a screw plug, a cavity is formed in the back of the locating pin, a spring is arranged in the cavity, the bottom of the spring abuts against the screw plug, the side face of the carrier is provided with a steel ball mounting hole, the steel ball mounting hole is communicated with the threaded hole, and the front face of the conical head threaded hole is screwed into the threaded hole and tightly presses a steel ball arranged in the steel ball mounting hole. The stabilizing pin for the formed metal plate is simple in structure, convenient to install, capable of effectively solving the problem that a part formed through stretching jumps on a blank holder, and capable of improving the debugging efficiency of a die and ensuring the punching stability of the die.

Owner:天津星原汽车零部件有限公司

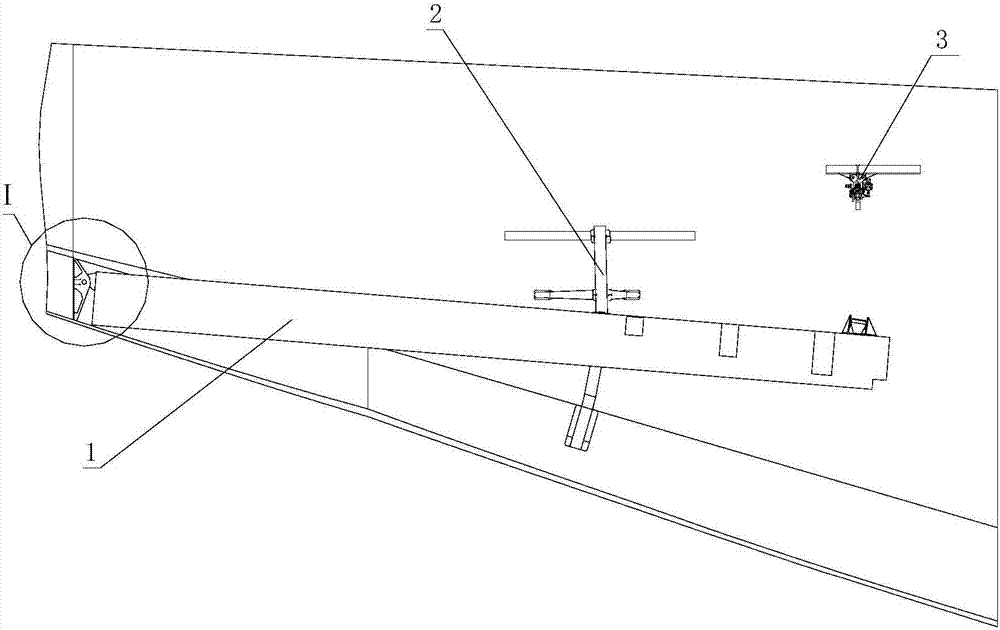

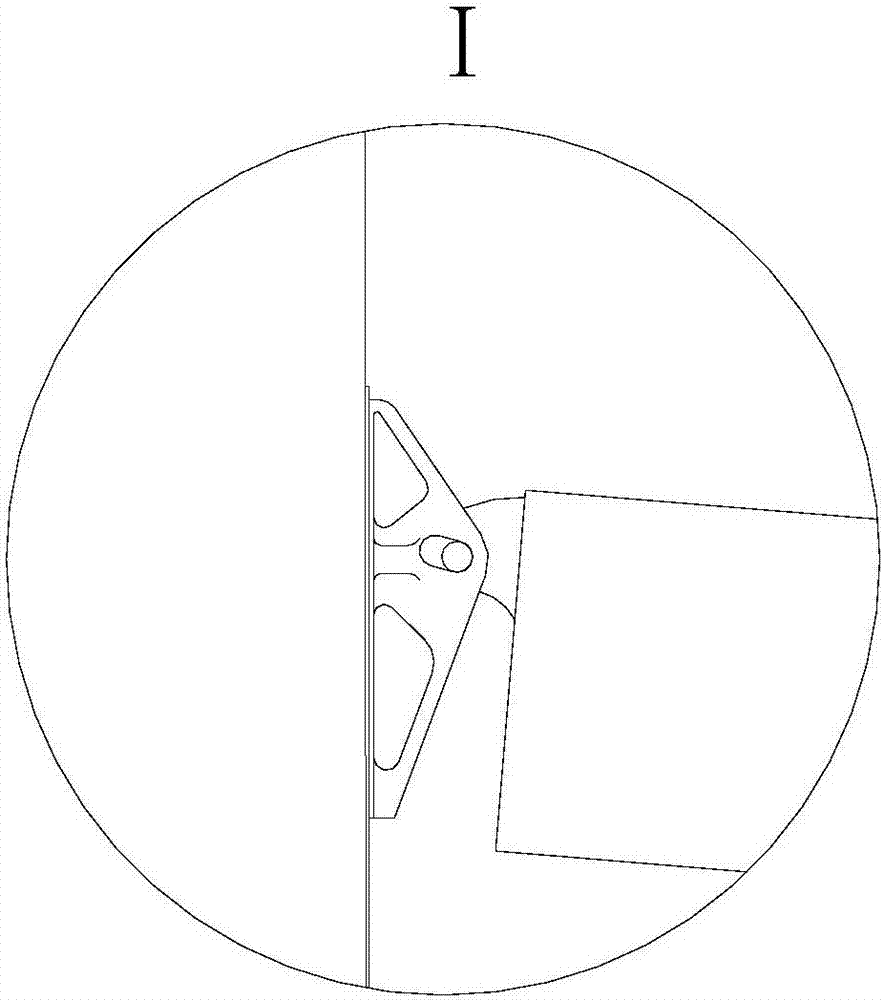

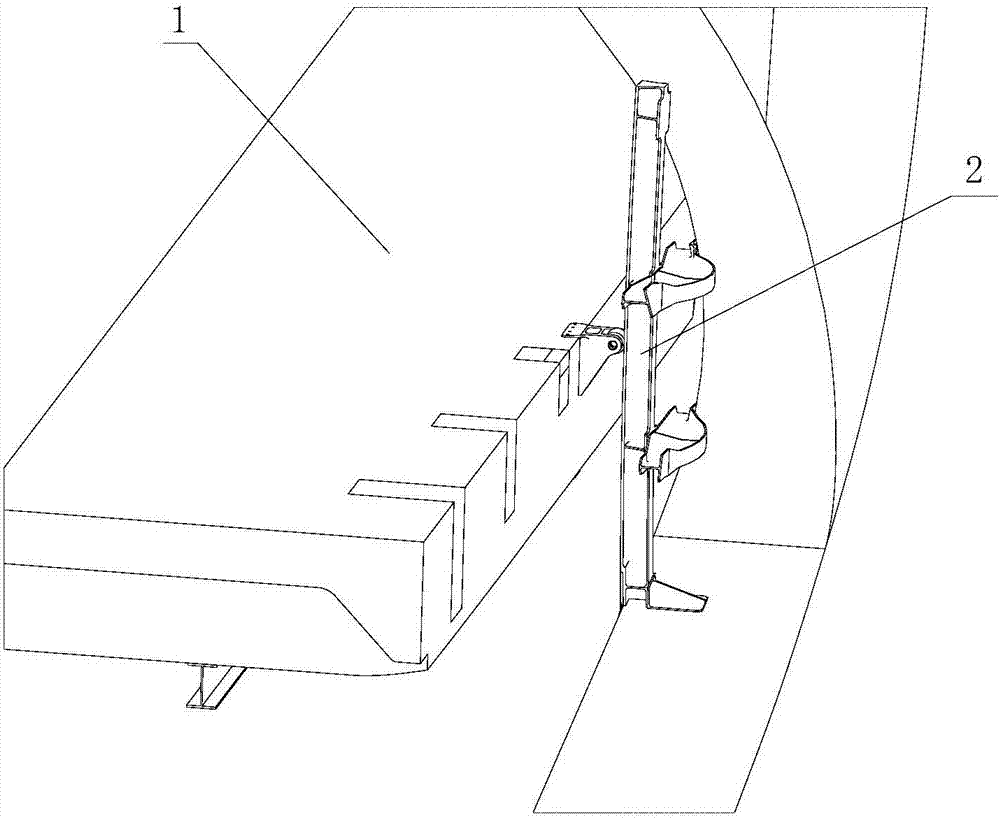

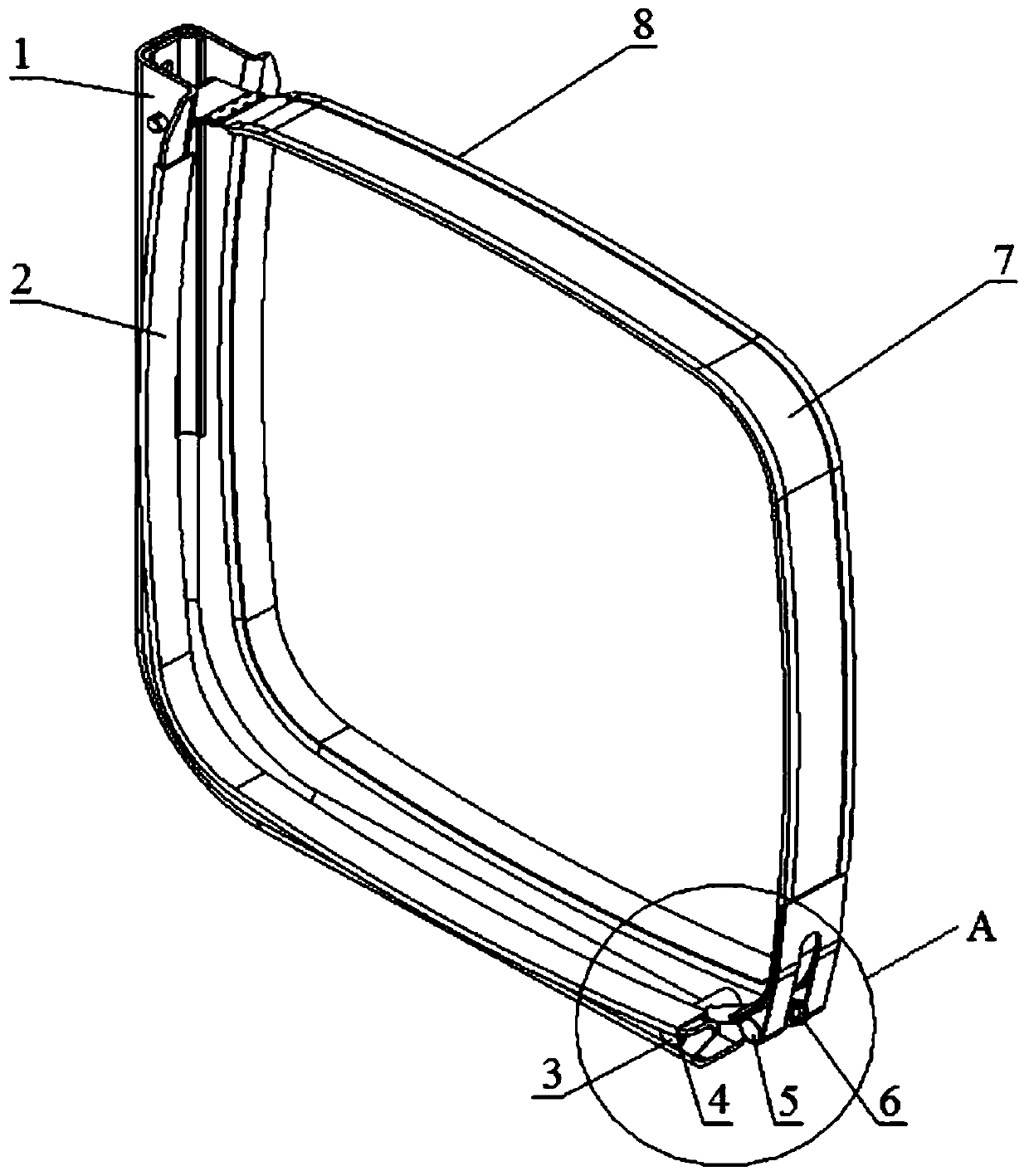

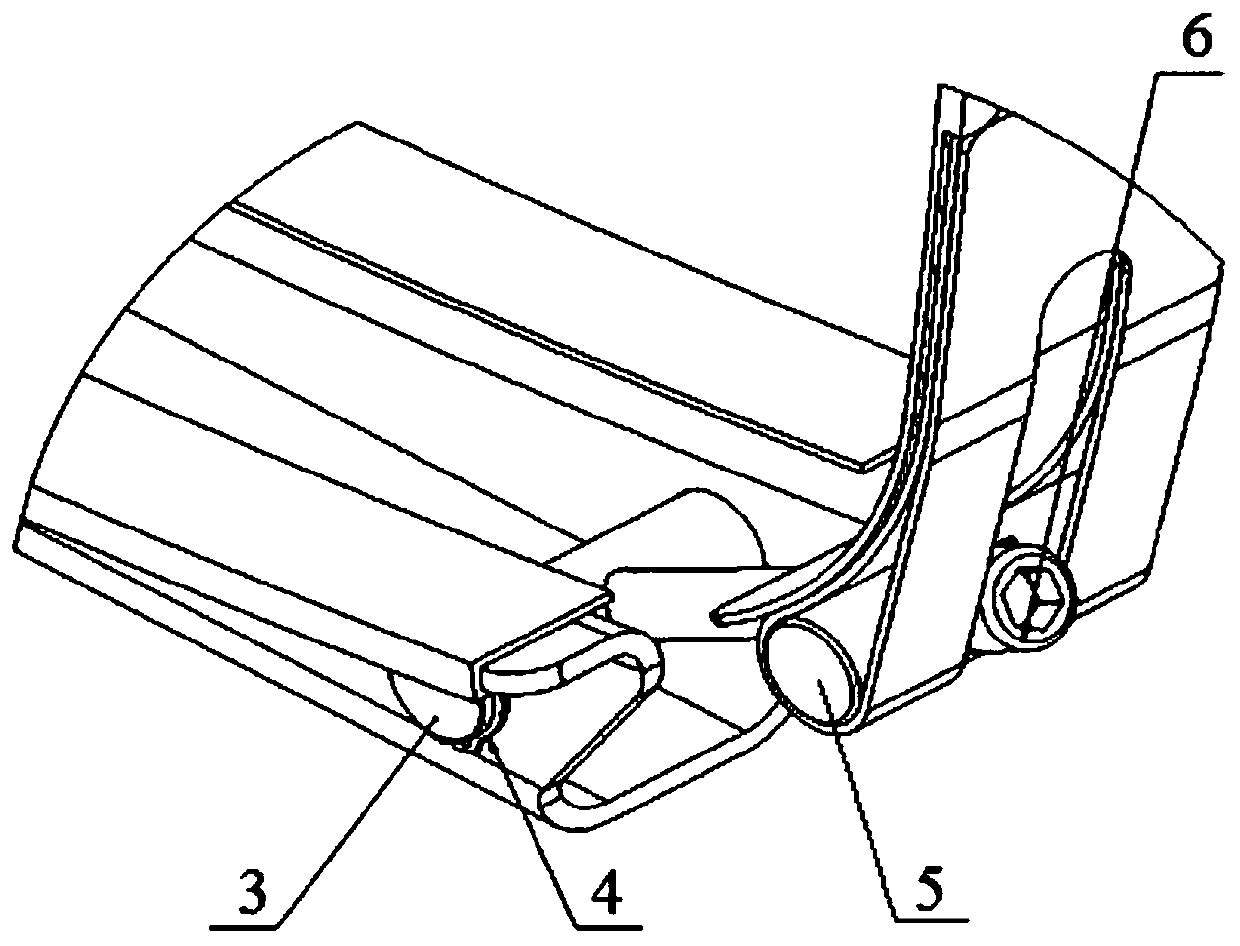

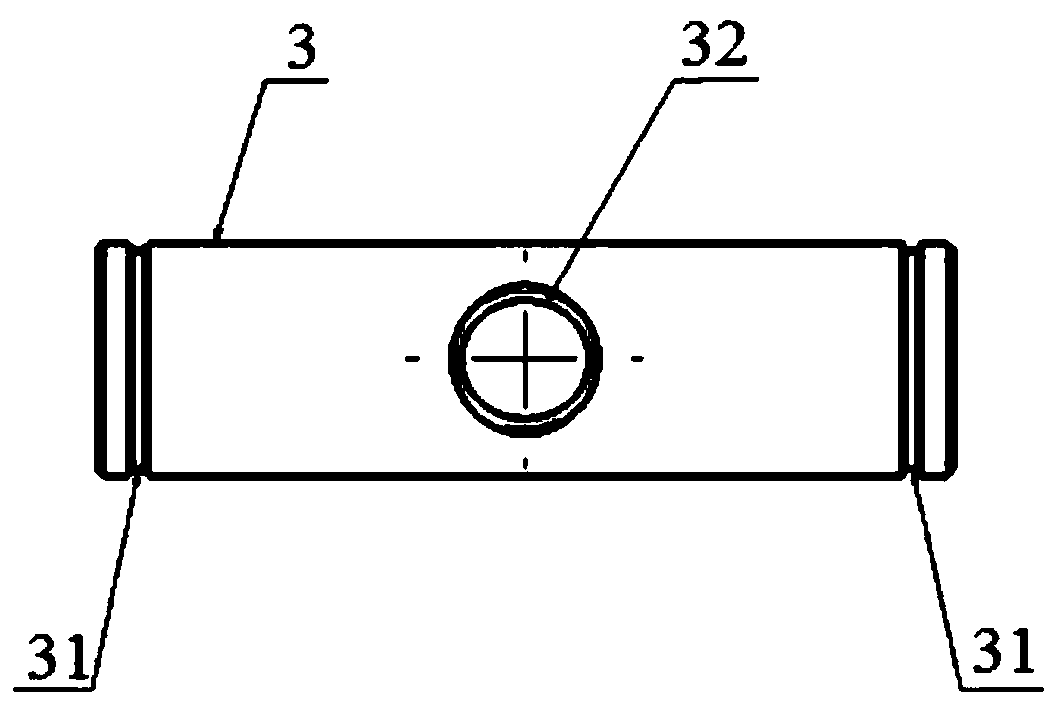

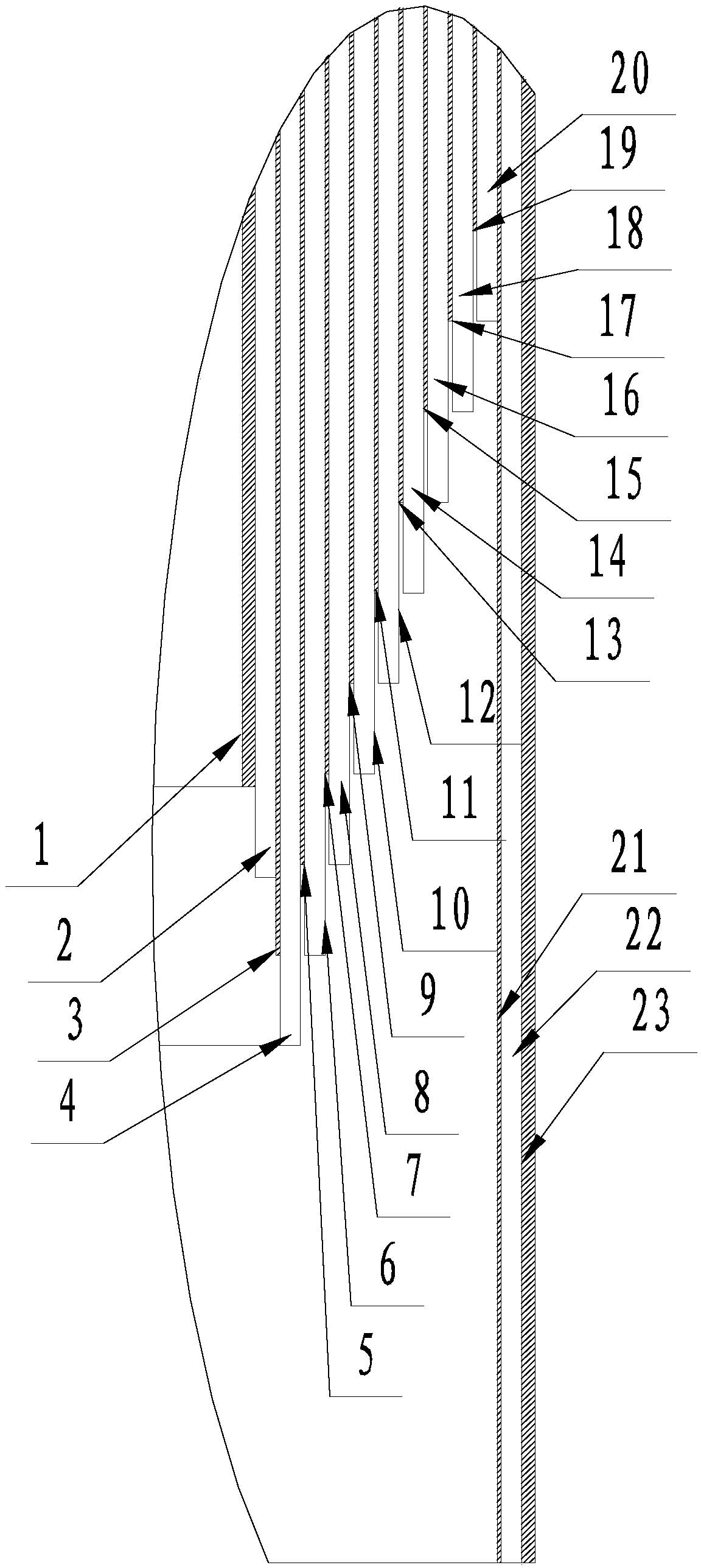

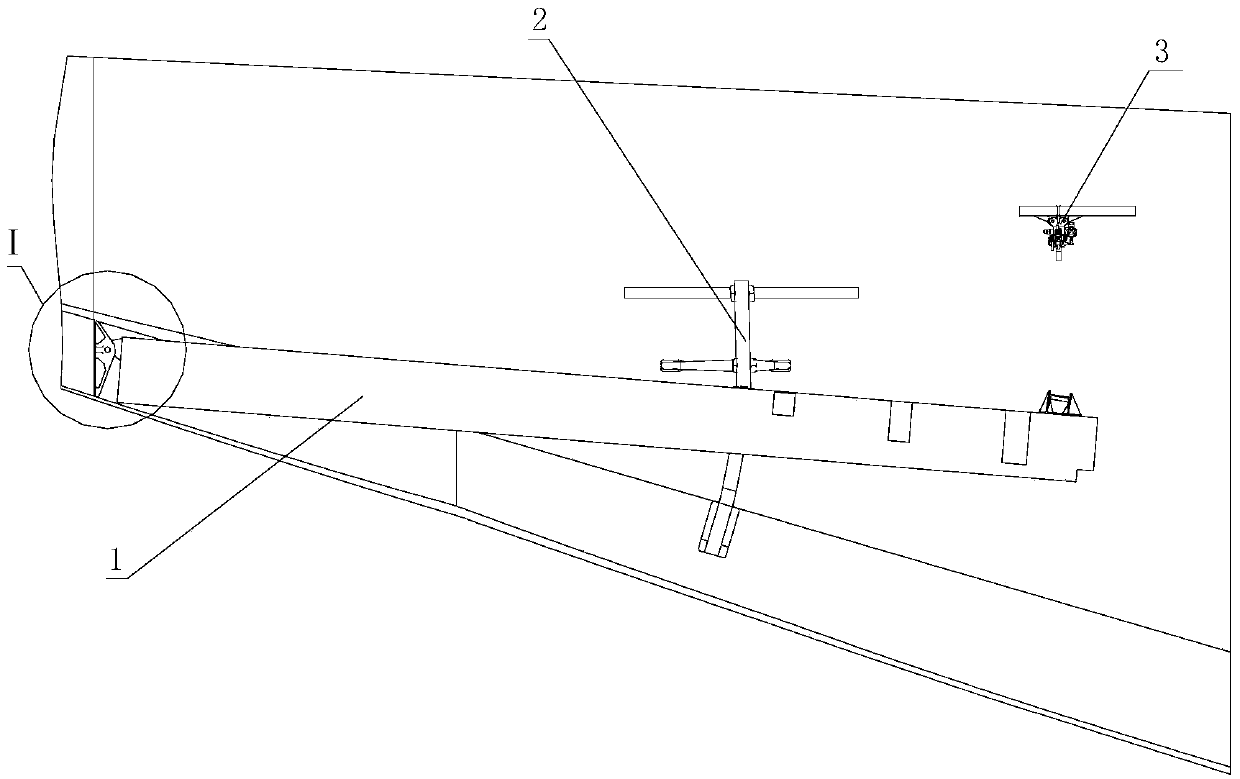

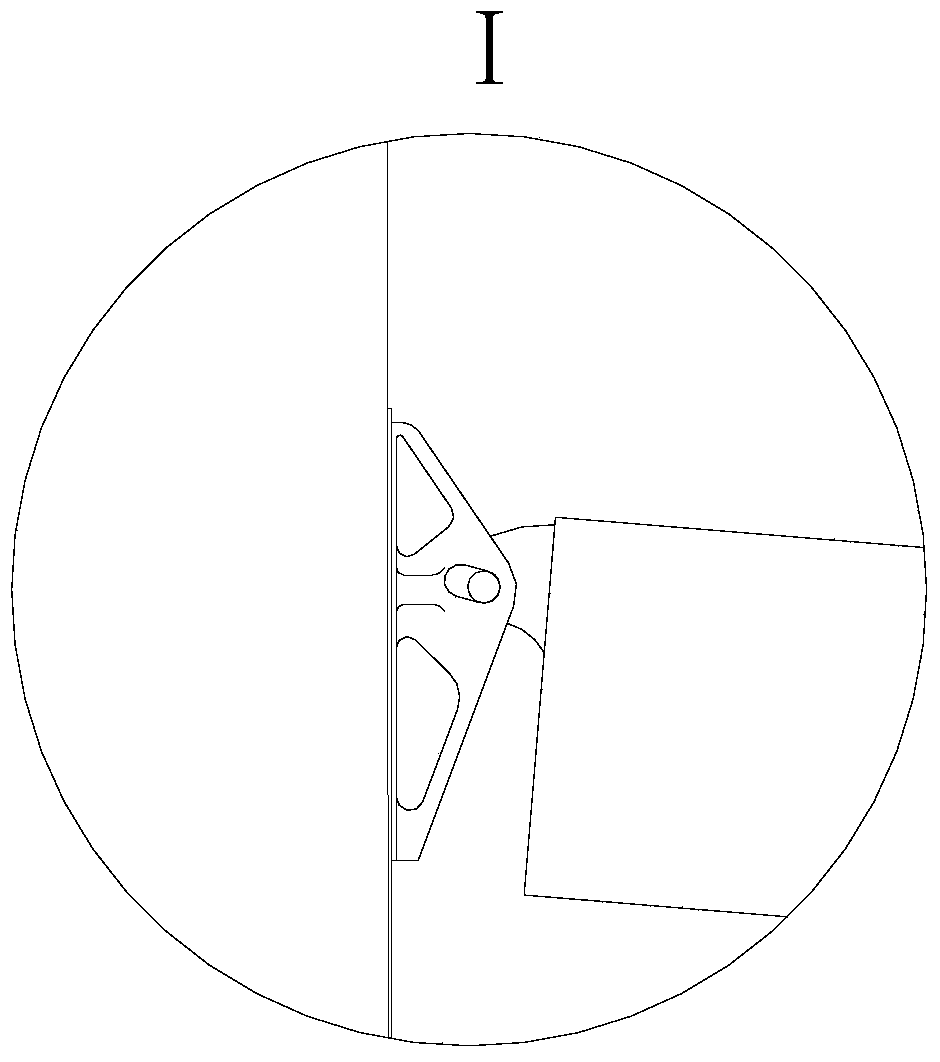

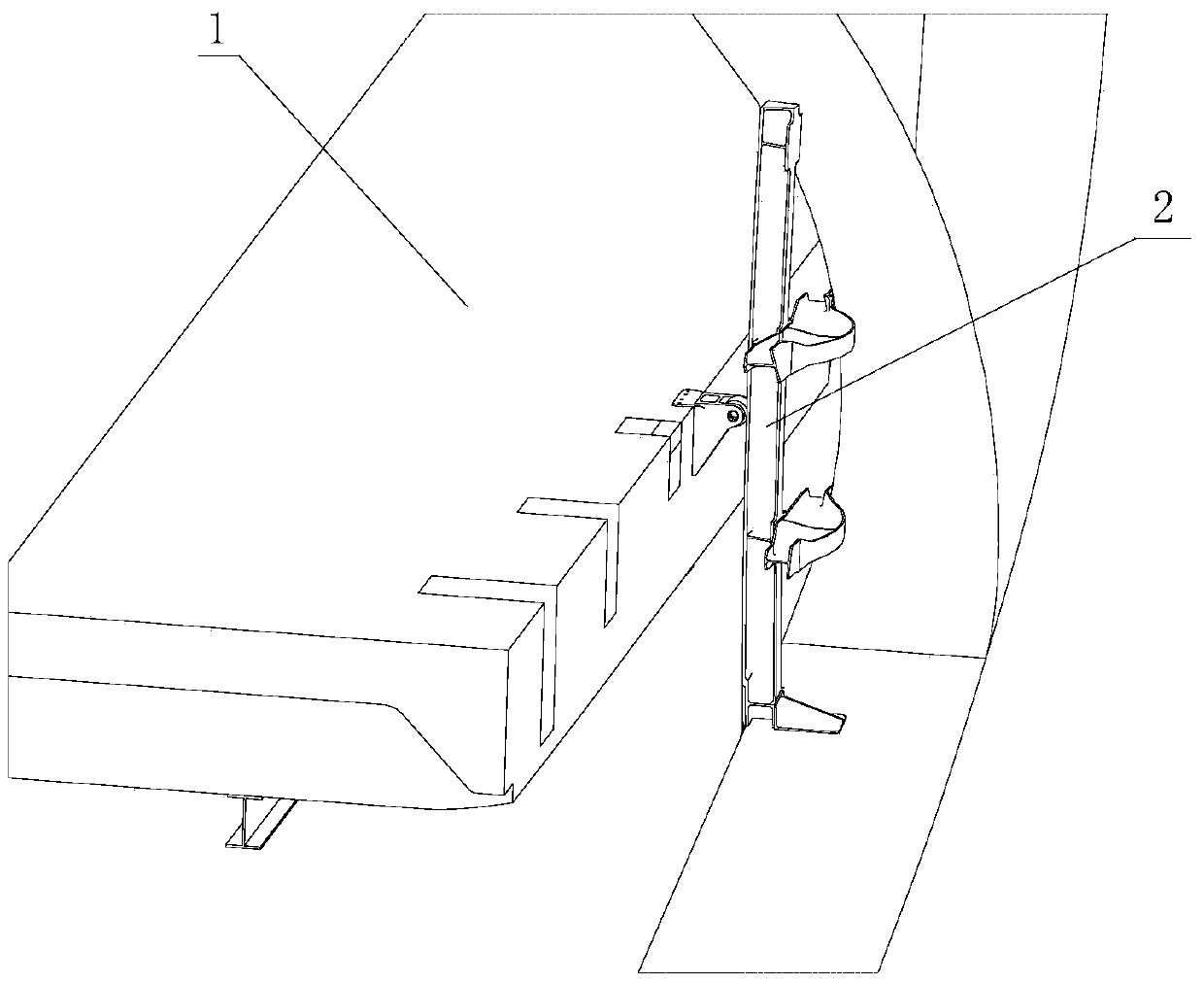

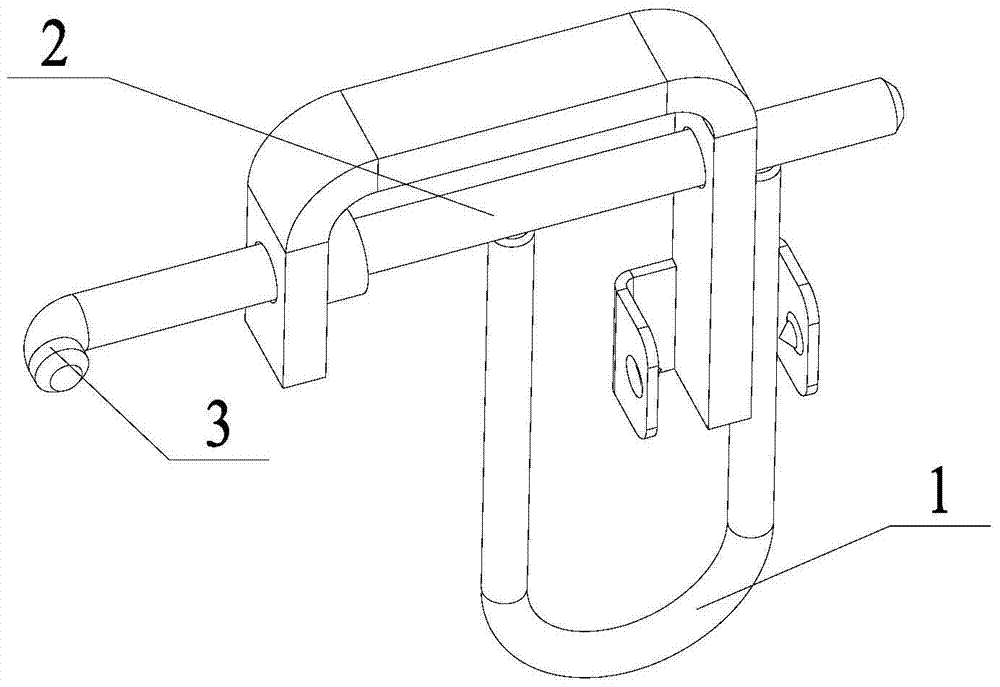

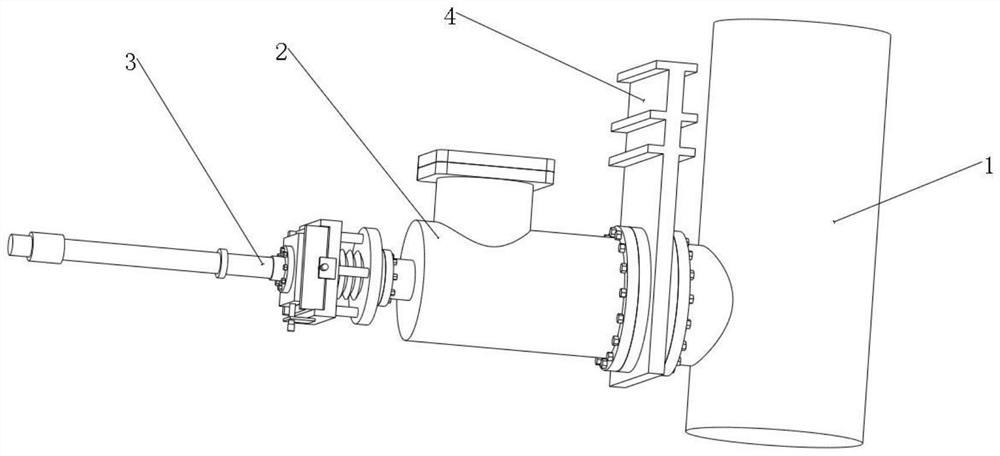

Aircraft freight cabin door positioning and guiding structure

ActiveCN107264772AReliable positioningReliable Implementation OrientationAircraft accessoriesBuilding braking devicesAirplaneDesign technology

The invention belongs to the technical field of aircraft structure design and particularly relates to an aircraft freight cabin door positioning and guiding structure. The structure comprises a cabin door (1), a sliding rail assembly (2) and an uplatch (3). The cabin door (1) is hinged to an aircraft body, the sliding rail assembly (2) is mounted on the aircraft body and the cabin door (1), and the uplatch (3) is mounted on the aircraft body and the cabin door (1). According to the structure, stable and reliable positioning and guiding of the aircraft freight cabin door are achieved.

Owner:SHAANXI AIRCRAFT CORPORATION

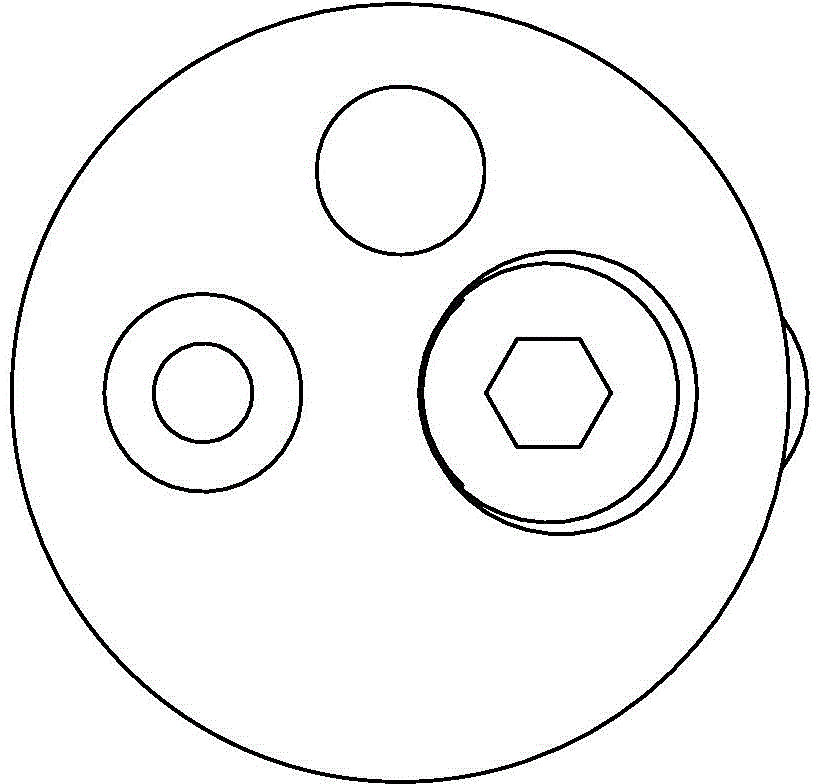

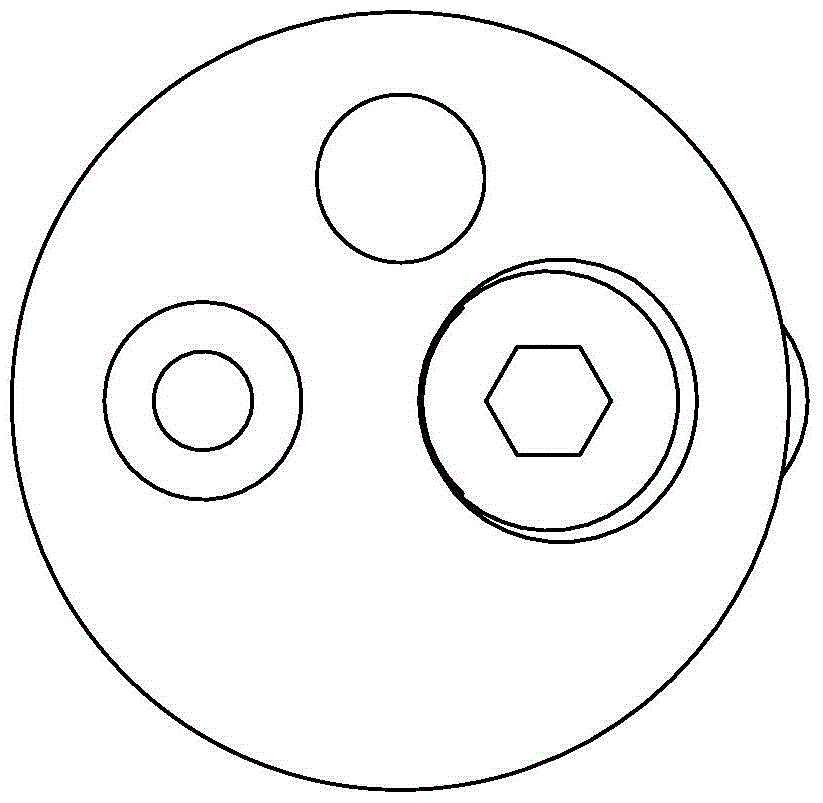

Oil tank strap locking mechanism and heavy type fuel oil truck provide with same

PendingCN110370920ASolve installation stability issuesEasy to installFuel supplyLocking mechanismFuel tank

The invention discloses an oil tank strap locking mechanism. The oil tank strap locking mechanism comprises an oil tank bracket, an oil tank strap, a pin shaft nut, a pin shaft and a hexagon socket screw, wherein the inner side of the oil tank bracket is provided with an oil tank bracket cushion belt, the inner side of the oil tank strap is provided with an oil tank strap cushion belt, one end ofthe oil tank strap is hinged to the oil tank bracket, the other end of the oil tank strap is provided with the pin shaft, the other end of the oil tank bracket is provided with the pin shaft nut, anda screw rod of the hexagon socket screw penetrates through the pin shaft to be connected with the pin shaft nut. The invention provides the oil tank strap locking mechanism according to the use working condition of a heavy type truck, the problem of the installation stability of an oil tank is solved, the use reliability of the oil tank is increased, and the problem of oil tank shifting is effectively solved. According to the oil tank strap locking mechanism, favorable conditions are provided for improving the passing property of a vehicle, the oil tank is installed more conveniently, and thefoundation is provided for improving the use reliability of a supply system of the heavy type truck.

Owner:XUZHOU XUGONG AUTOMOBILE MFG CO LTD

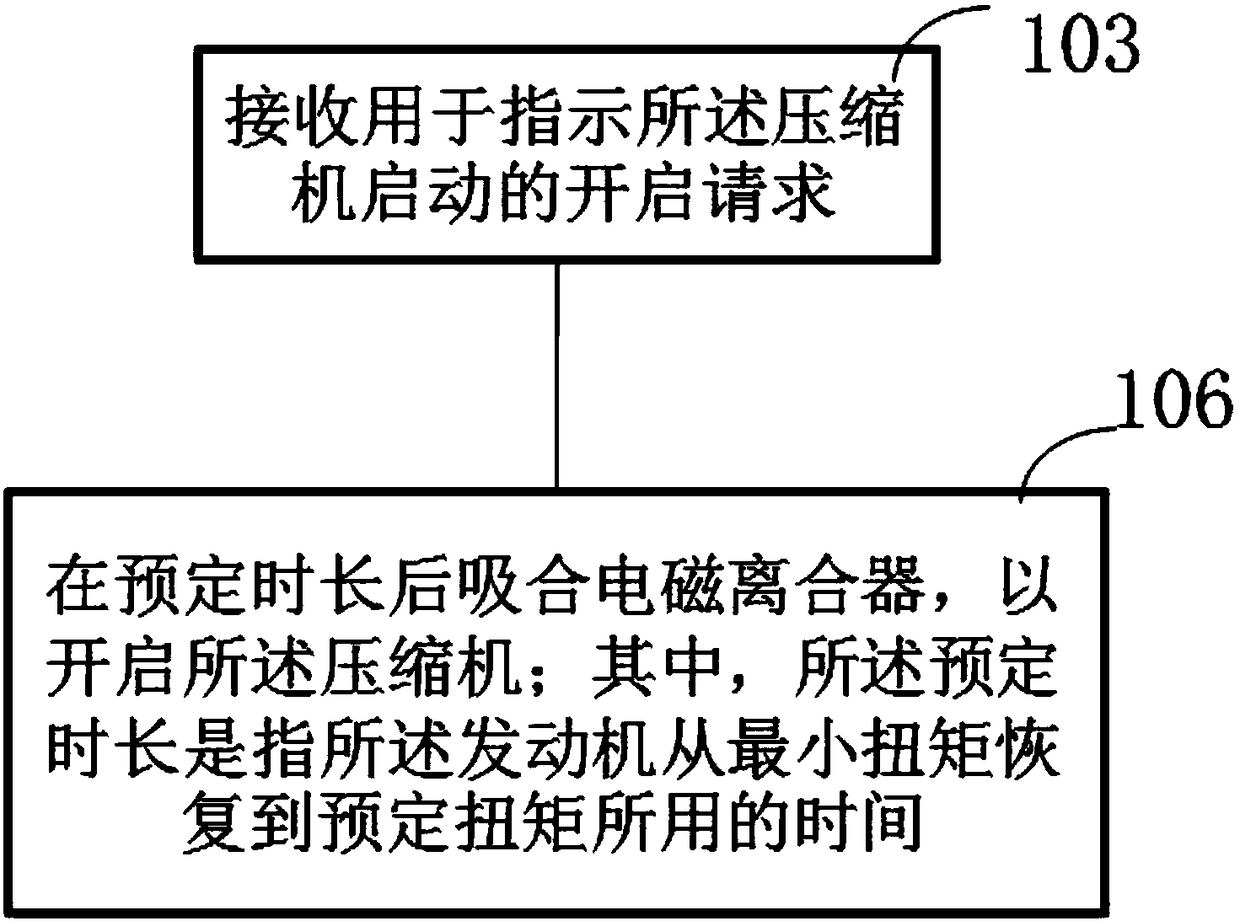

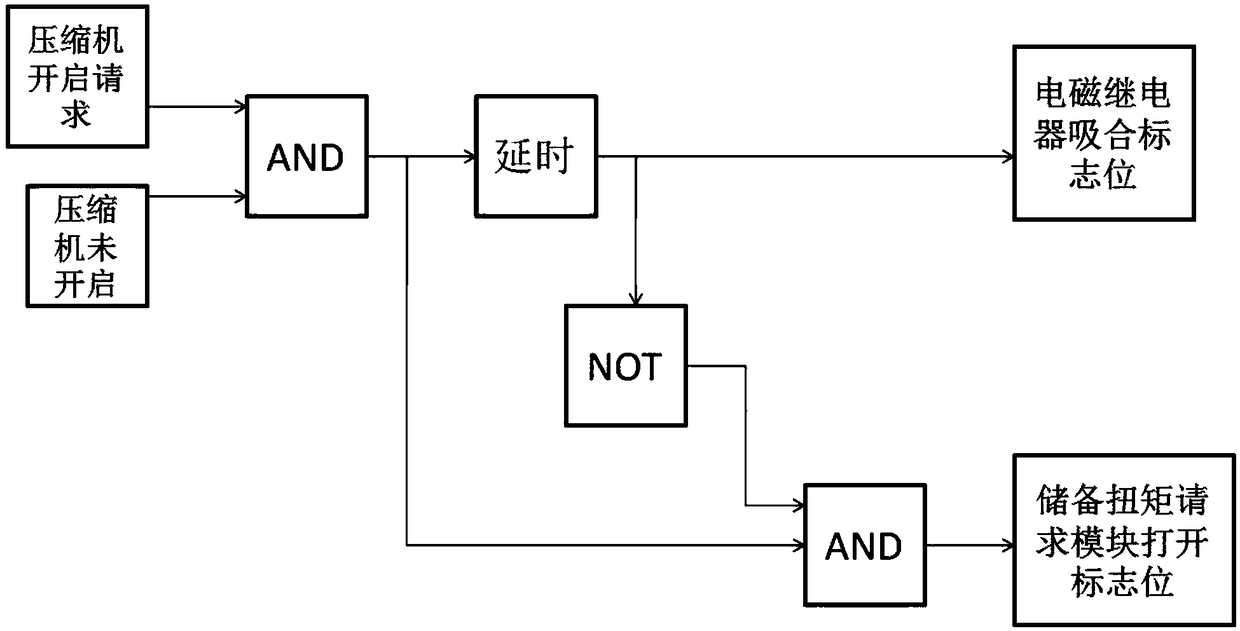

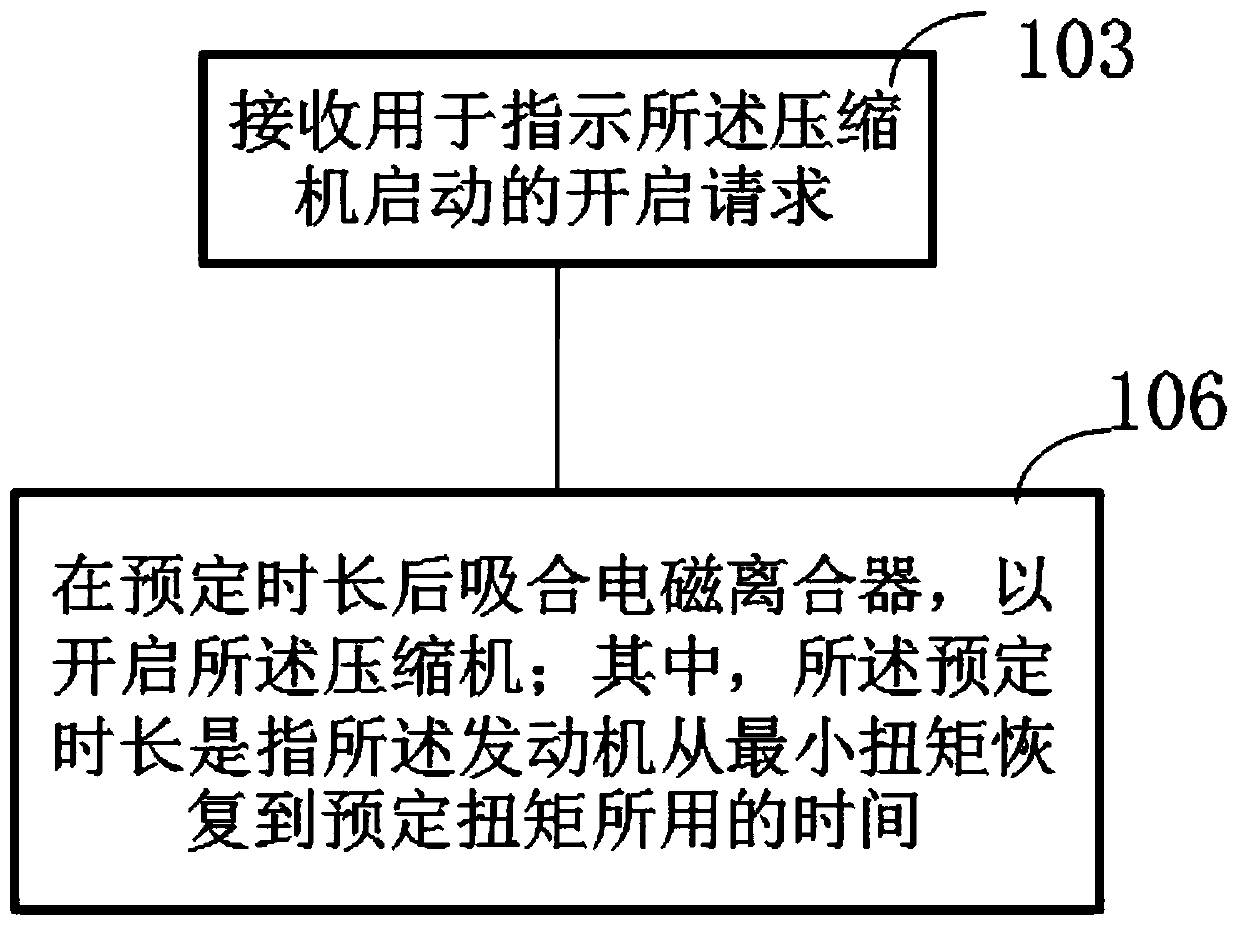

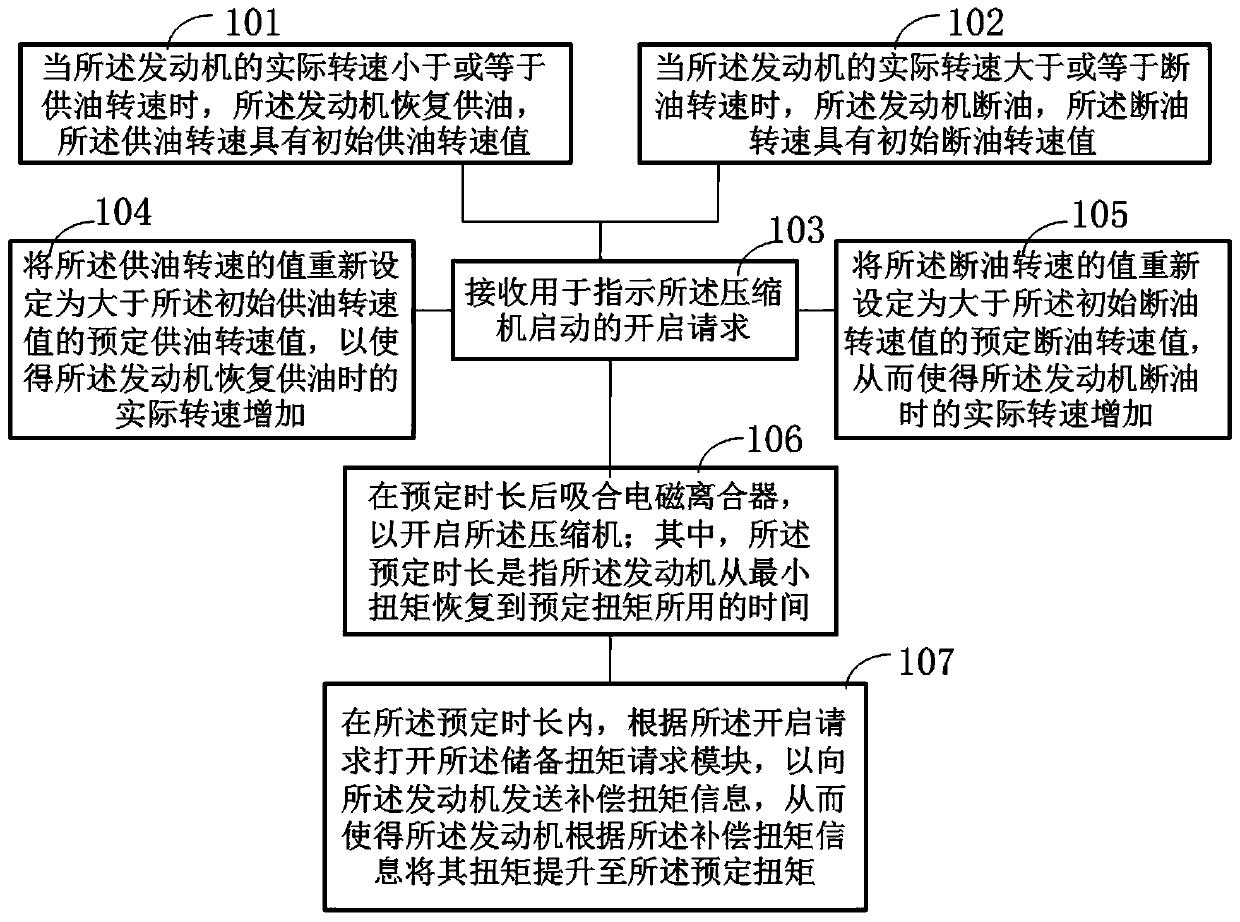

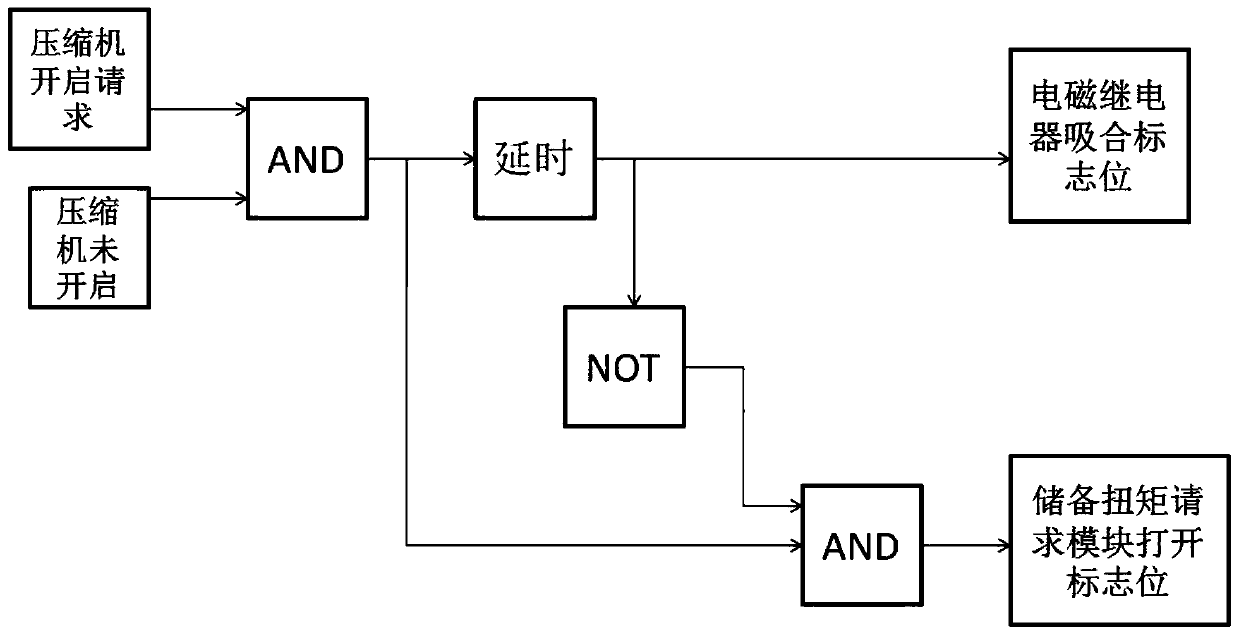

Control method for balancing influence of compressor on engine torque of vehicle

ActiveCN108087131ASolve the movementAvoid stackingFuel-injection pumpsMachines/enginesElectromagnetic clutchEngineering

The invention provides a control method for balancing an influence of a compressor on engine torque of a vehicle. An engine is located in a fuel cut gliding state, the compressor is in a shut-down state, and the control method comprises the steps that a starting-up request used for indicating the compressor to be started up is received; and an electromagnetic clutch is actuated after a preset duration so as to start up the compressor, wherein the preset duration refers to the time consumed by the compressor to restore from the minimum torque to the preset torque. The control method is used forsolving the problem of vehicle movement caused by superposition of the engine torque when the vehicle glides in a fuel cut state and the compressor actuates to make the engine restore fuel supply. Particularly after design of a vehicle suspension structure and rigidity matching are completed, when the vehicle is still in an abnormal state, the control method is the best way of solution.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

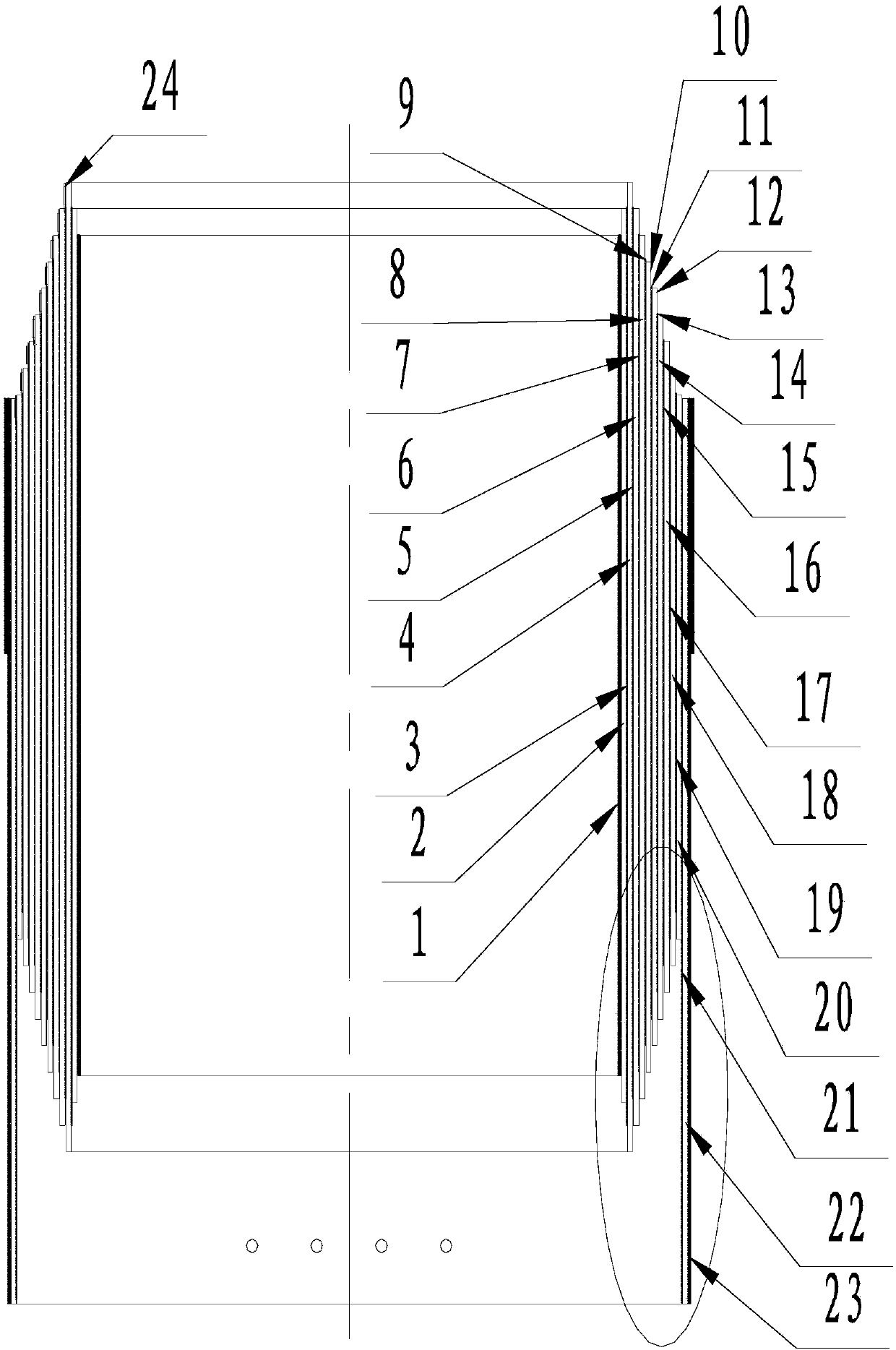

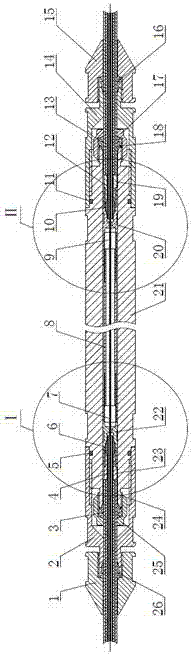

Connecting structure of transformer wire outgoing device

ActiveCN111210979ASolve the problem of easy dischargeImprove reliabilityTransformers/inductances coils/windings/connectionsTransformerPaperboard

The invention discloses a connecting structure of a transformer wire outgoing device. According to the structure, a plurality of layers of paperboard cylinders divide oil gaps. Corrugated paperboard cylinders are inserted among the paperboard cylinders; a distance difference exists between the end parts of each layer of paperboard cylinder and adjacent corrugated paperboard cylinders; clamping sheets are assembled at the upper end and the lower end of each stage of corrugated paperboard cylinder; for the paperboard cylinders distributed from inside to outside, the height of the upper ends of the paperboard cylinders is gradually increased and gradually decreased in a transitional manner from two layers of paperboard cylinders to the other layers of paperboard cylinders; for the corrugatedpaperboard cylinders from inside to outside, the height of the upper ends of the corrugated paperboard cylinders is gradually increased, and gradually decreased in a transitional manner from two layers of corrugated paperboard cylinders to the other layers of corrugated paperboard cylinders; the height of the upper end of each layer of corrugated paperboard cylinder is higher than that of the corresponding layer of paperboard cylinder; as for the paperboard cylinders from inside to outside, the length of the lower ends of the paperboard cylinders is gradually increased, and then is gradually decreased in a transitional manner from the two innermost layers of paperboard cylinders to the other layers of the paperboard cylinders, and the length of the lower ends of the two outermost layers ofthe paperboard cylinders are increased; and as for the corrugated paperboard cylinders from inside to outside, the length of the lower ends of the corrugated paperboard cylinders is gradually increased, and then is gradually decreased in a transitional manner from the innermost two layers of corrugated paperboard cylinders, and the outermost layer of corrugated paperboard cylinder is lengthened.According to the connecting structure of the invention, the clamping sheets are adopted for limiting connection, so that the problem that an insulating screw is prone to discharging, and the problem acushion block falls off or the problem that a corrugated board moves are solved, and the reliability of the wire outgoing device is improved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD +1

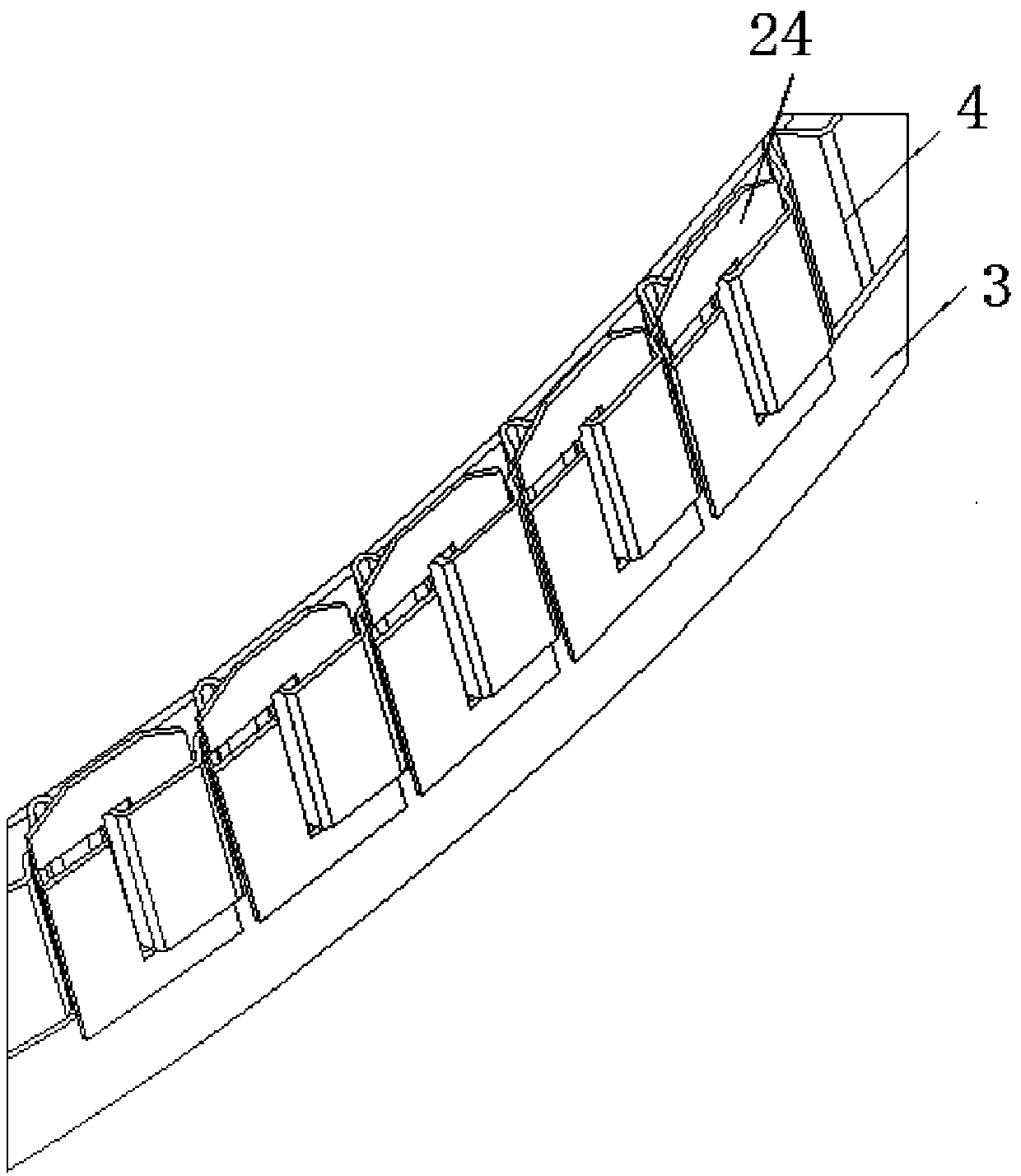

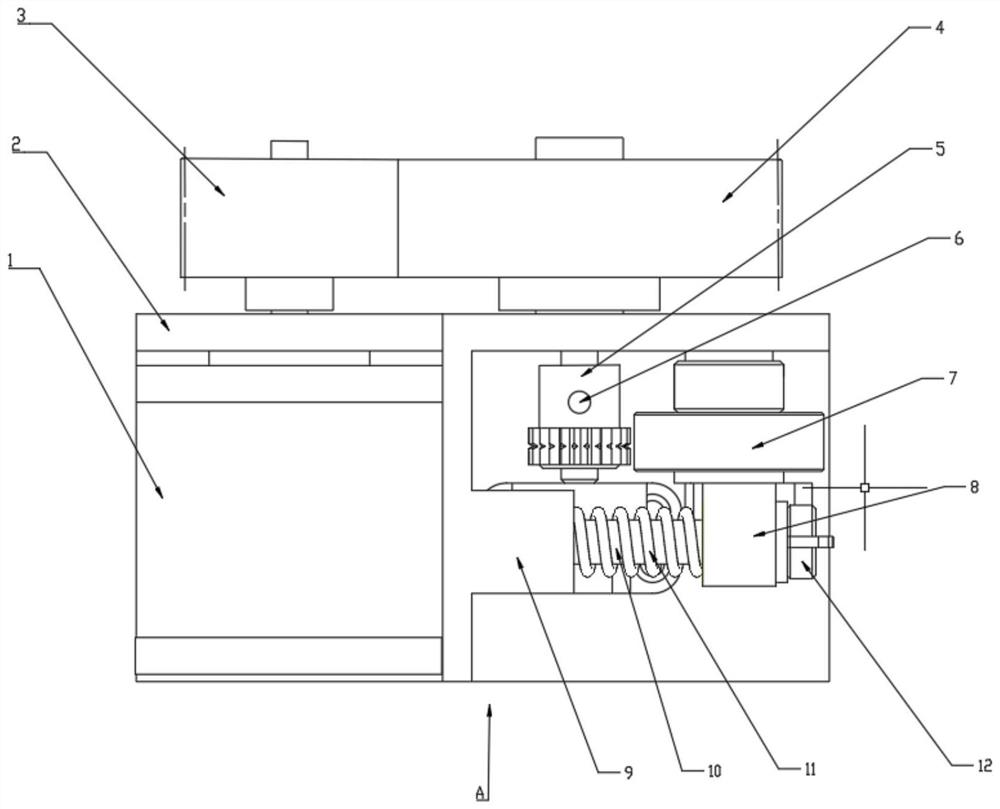

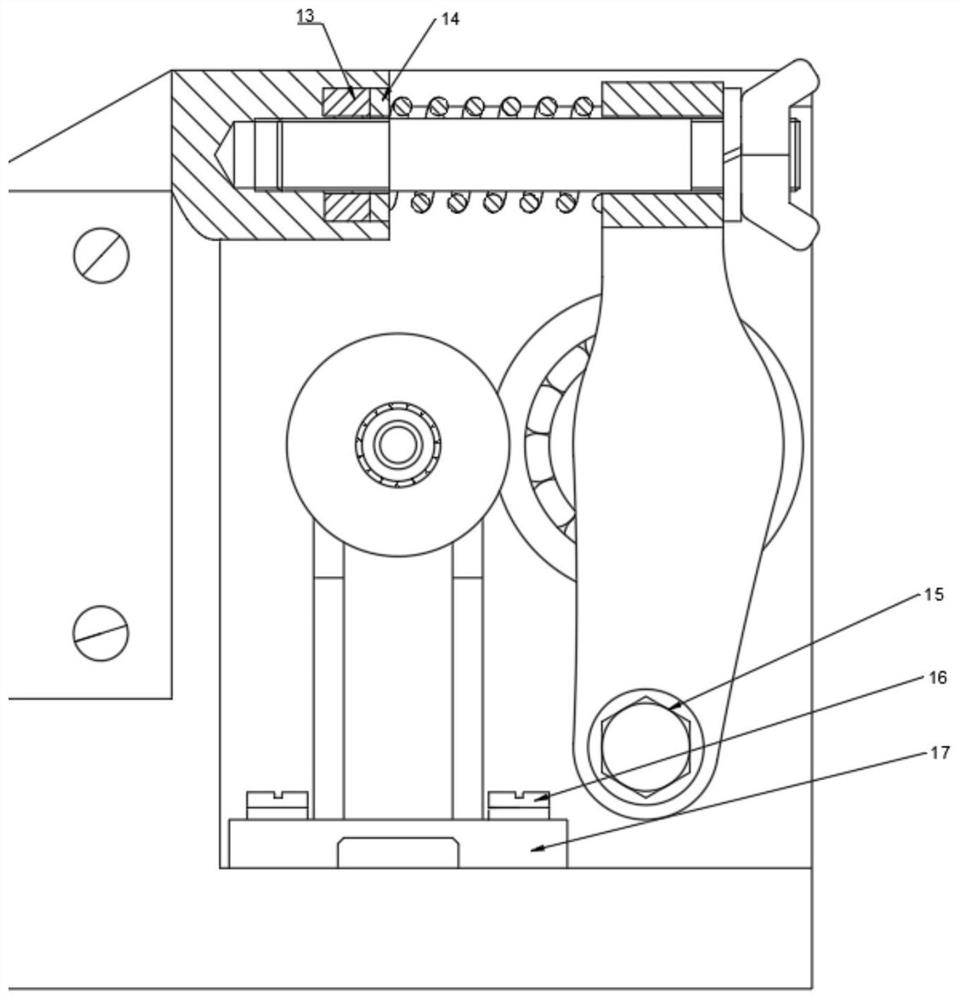

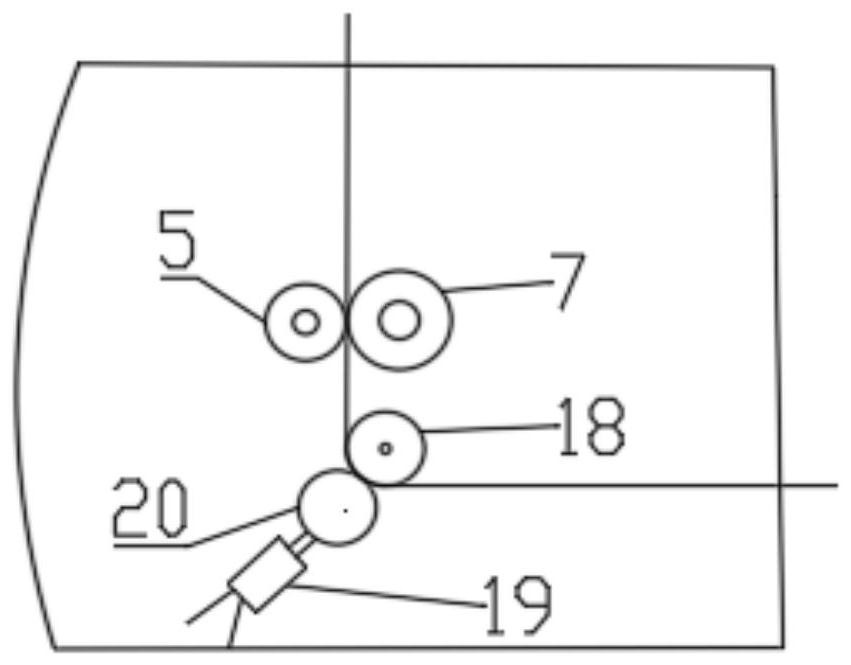

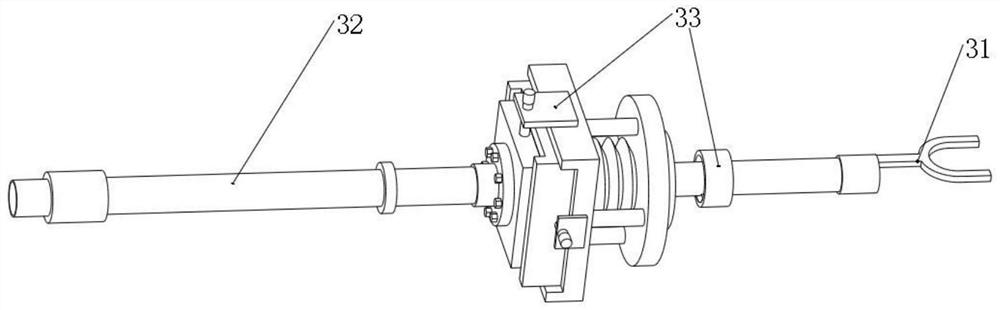

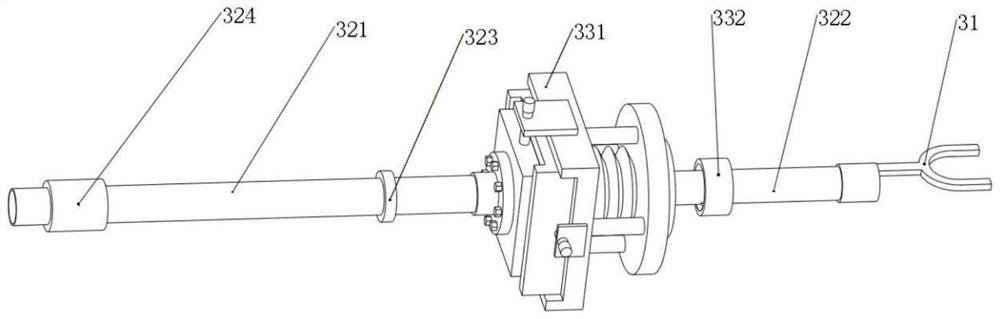

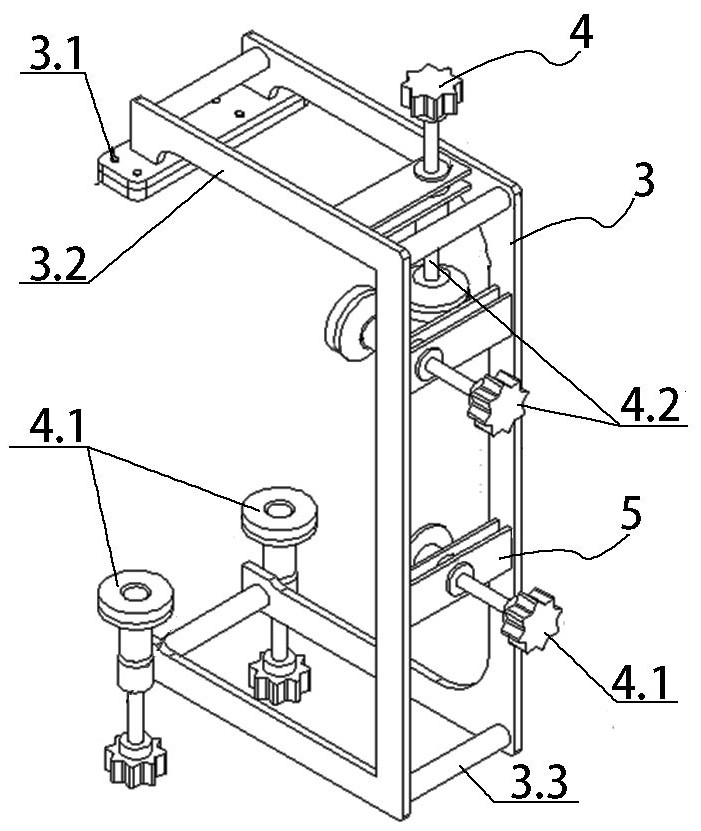

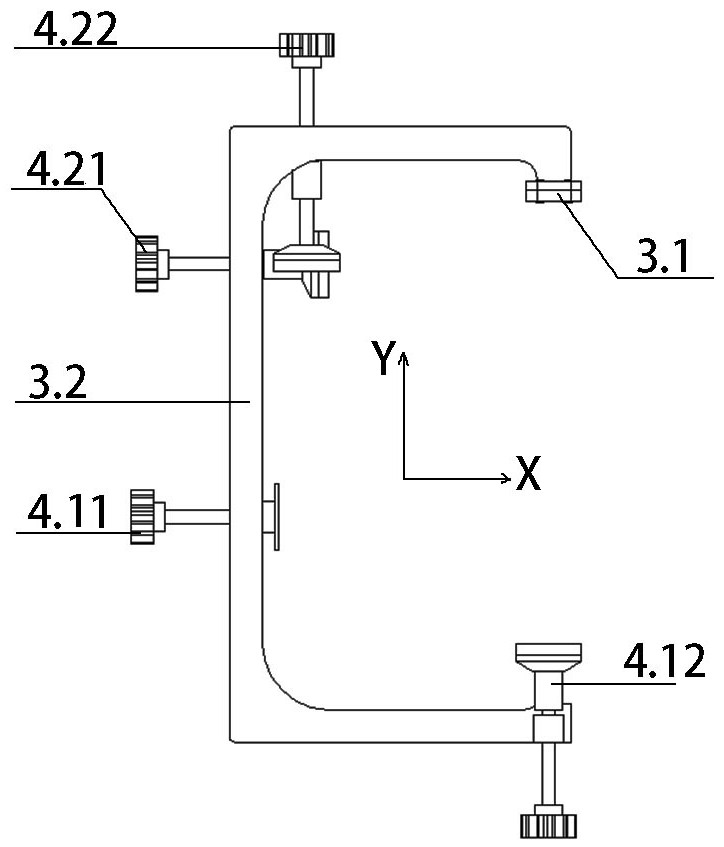

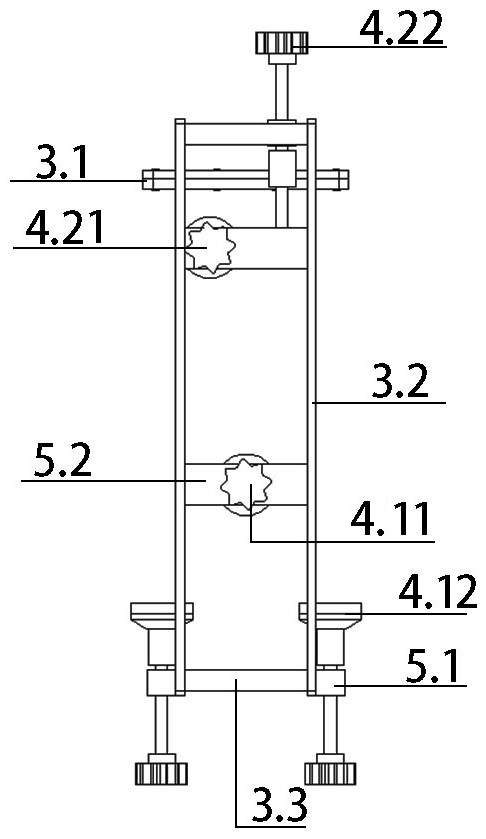

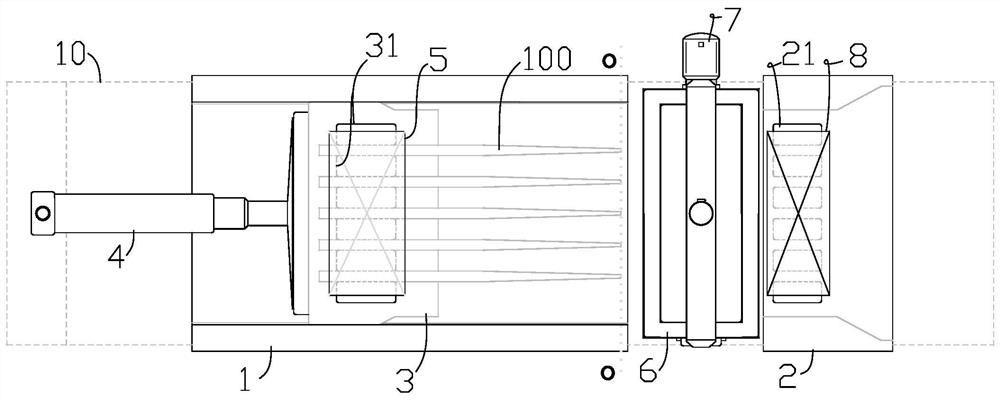

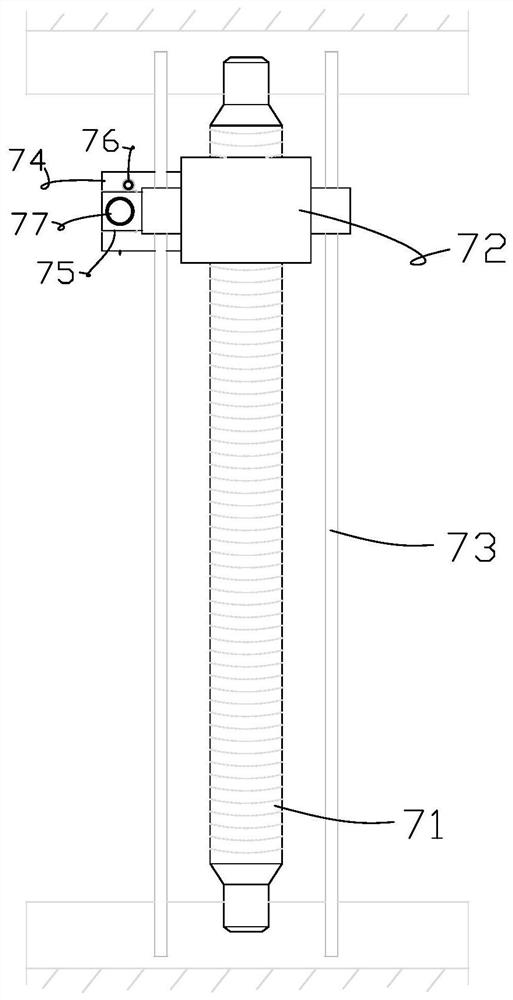

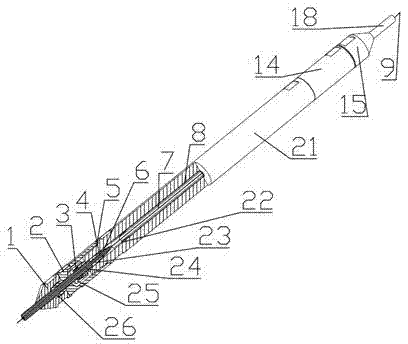

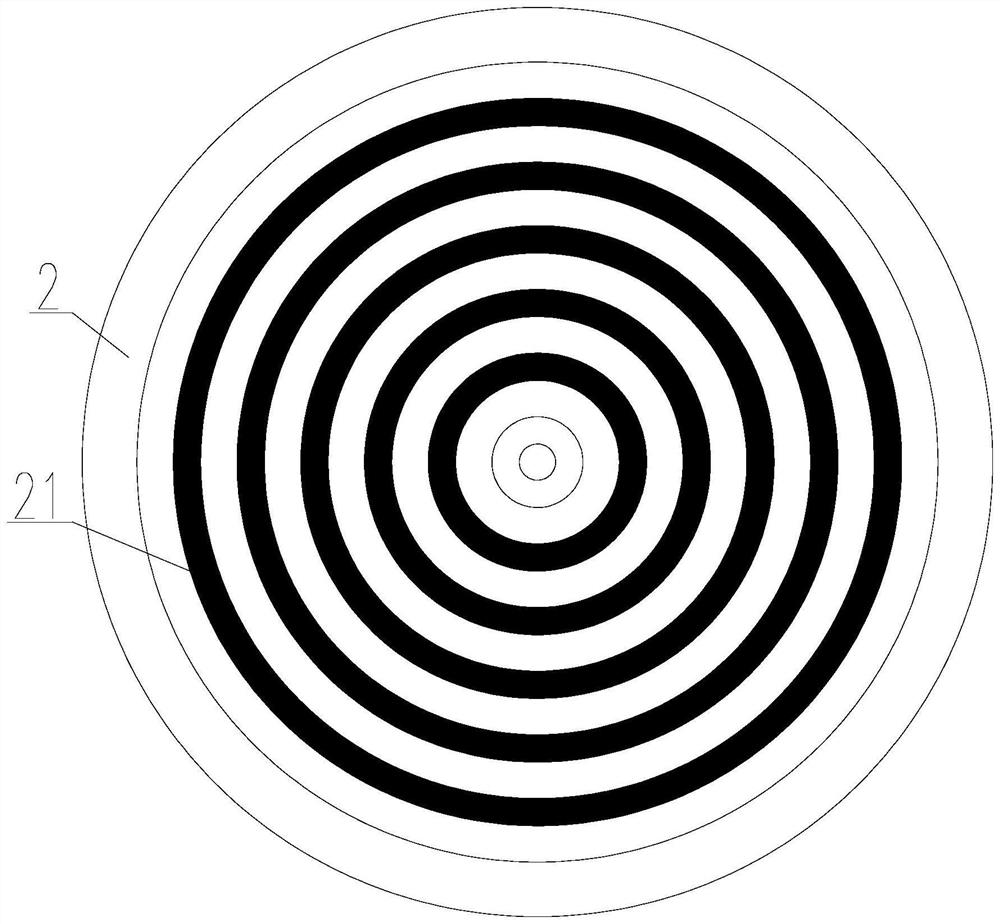

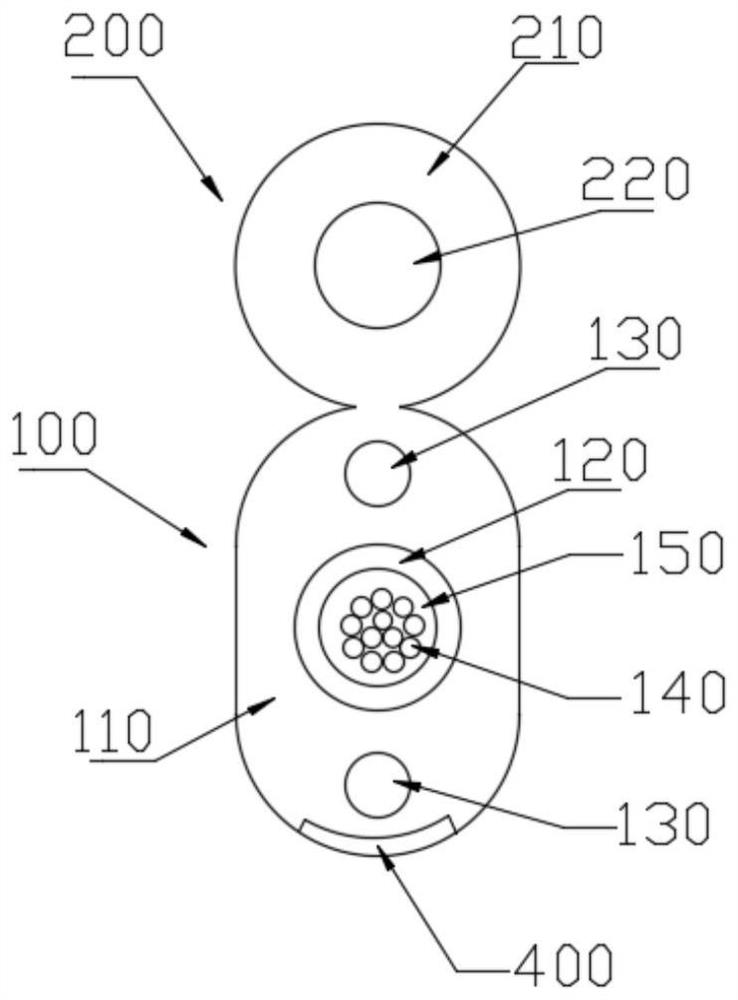

Wire feeding mechanism provided with adjustable pressing force and used for 3D printer

PendingCN112829298AChange directionSolve the movementAdditive manufacturing apparatus3D object support structuresElectric machineryEngineering

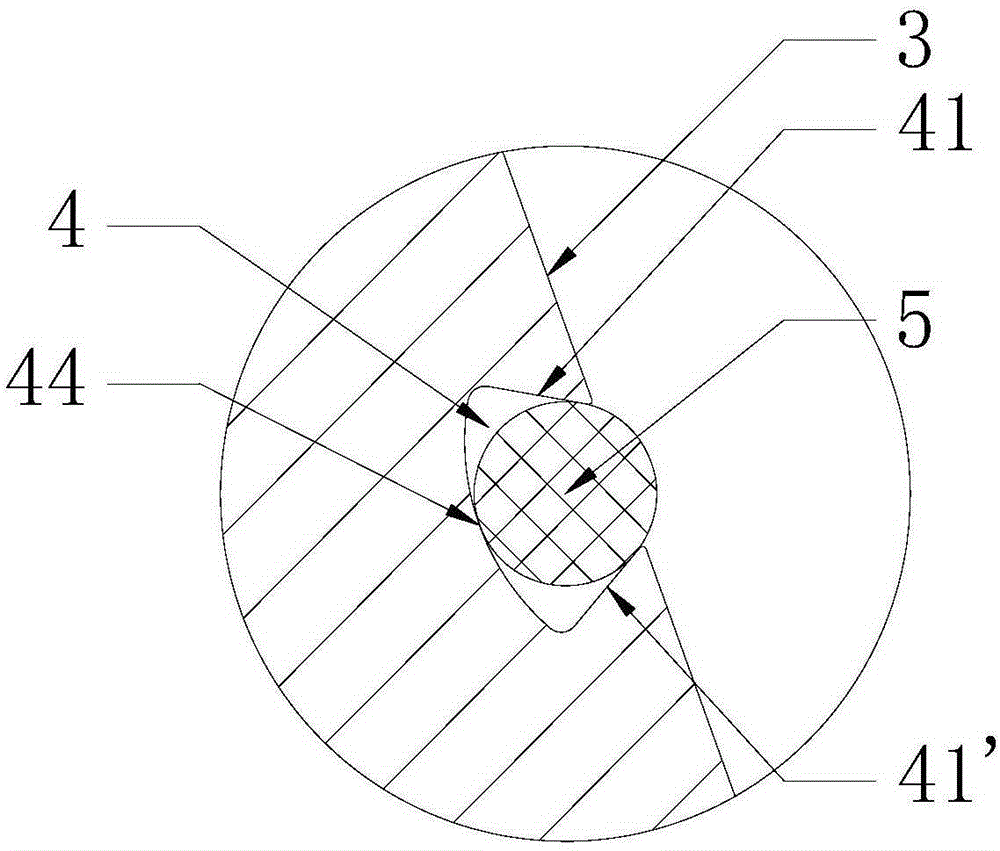

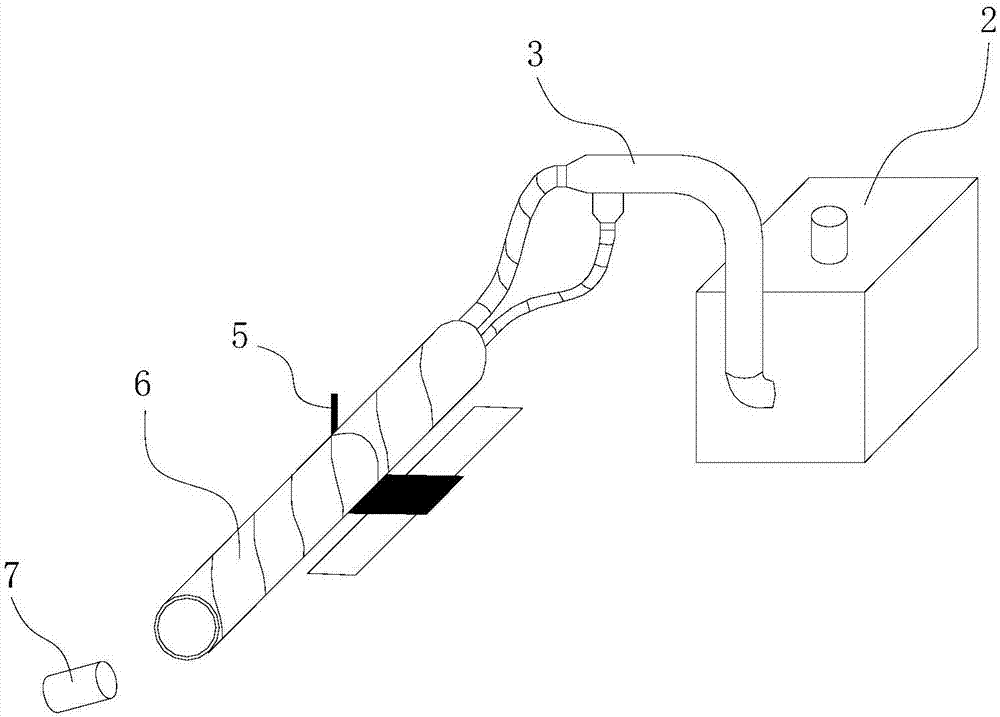

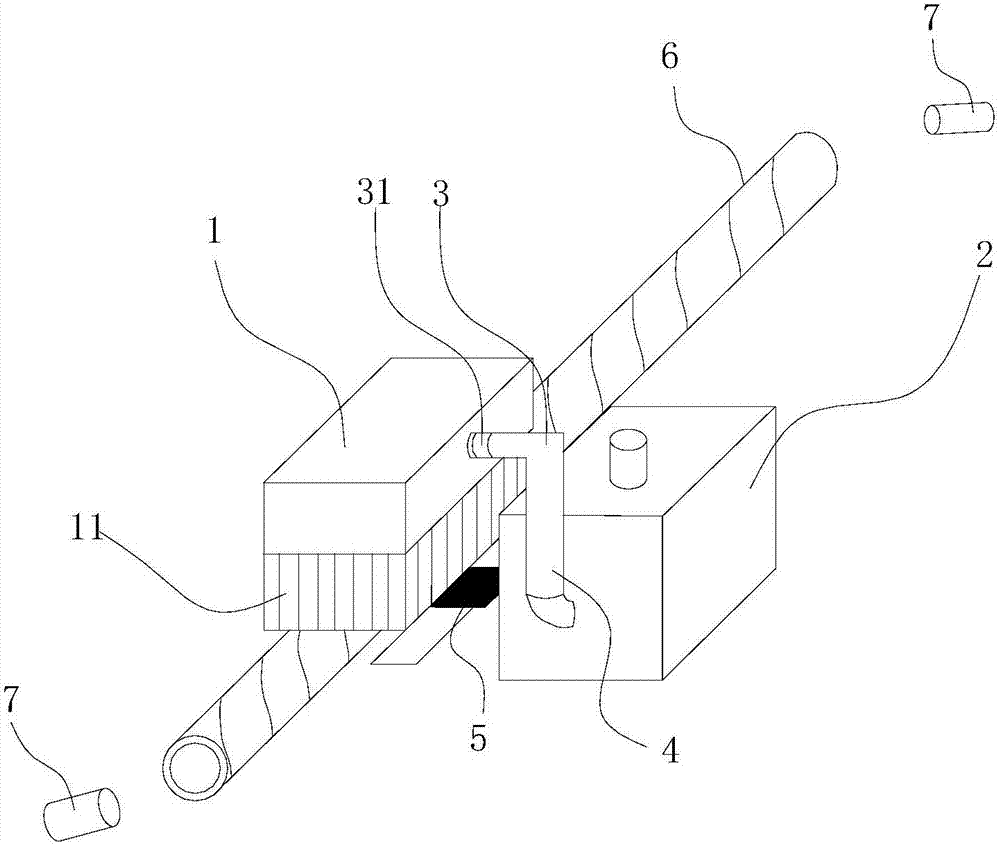

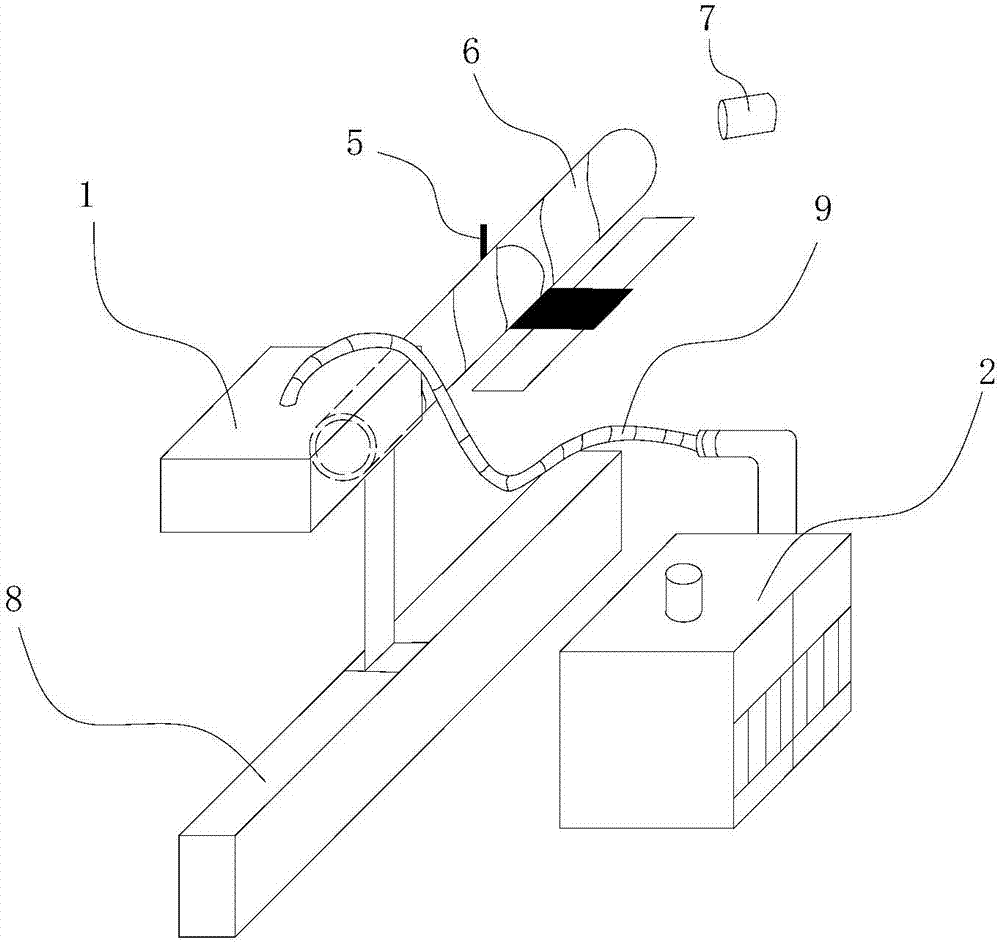

The invention designs a wire feeding mechanism provided with adjustable pressing force and used for a 3D printer. The wire feeding mechanism comprises a rack (2), wherein a motor (1) is arranged at the left side of the rack; a pinion (3) is mounted on the output shaft of the motor; a meshing transmission belt drives a big gear (4) to rotate, a wire feeding drive wheel (5) is mounted on a big gear shaft; the wire feeding drive wheel is fixed to a big gear shaft through a fastening screw (6); the right side of the wire feeding drive wheel is equipped with a wire feeding driven wheel (7) which is pressed on a pressing frame (8); the lower portion of the pressing frame is hinged to the lower end of the right side of the rack through a bolt (15); a stand column (9) is arranged on a baffle plate on the middle of the rack; a mounting hole is formed in the stand column; the left side of a screw (10) is mounted in the mounting hole; the right side of the screw is connected to the upper end of the pressing frame through a screw-up nut (12); and a pressing spring (11) is arranged between the upper end of the pressing frame and the stand column. The wire feeding mechanism has the beneficial effects that the structure is compact, drive force is adjustable, pressing force is conveniently adjusted, and requirements of wires with different diameters can be adapted.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

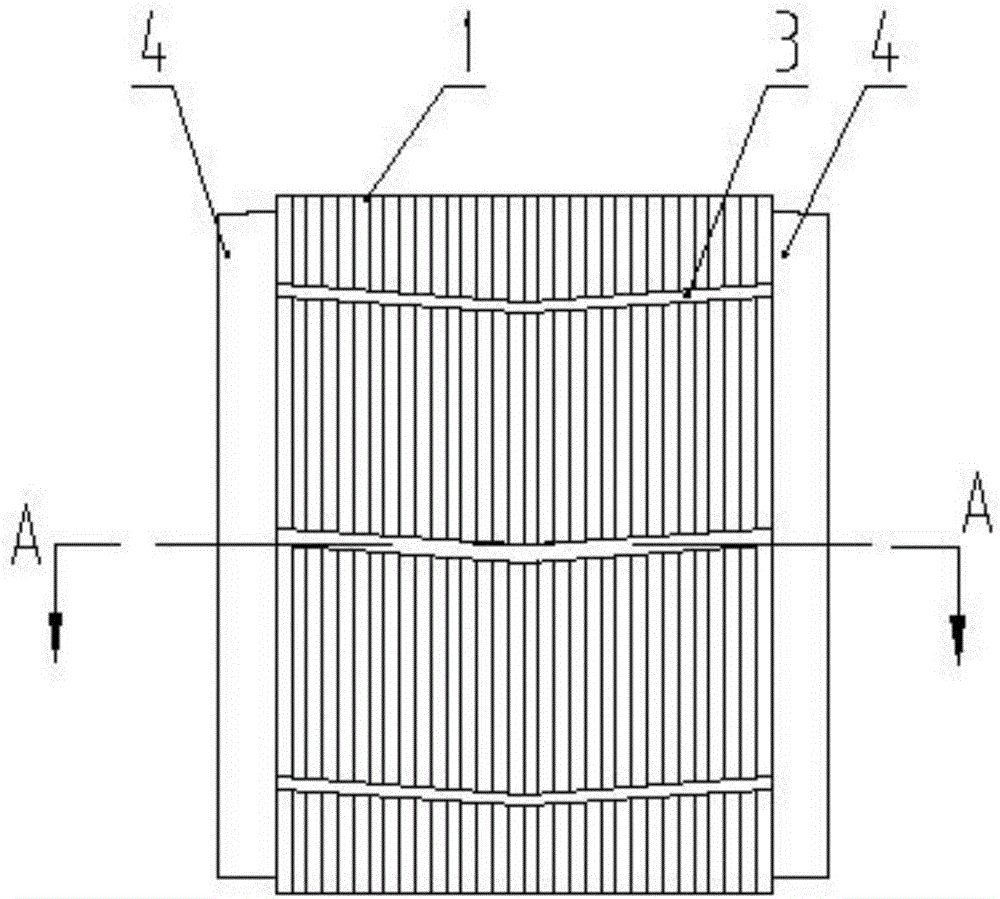

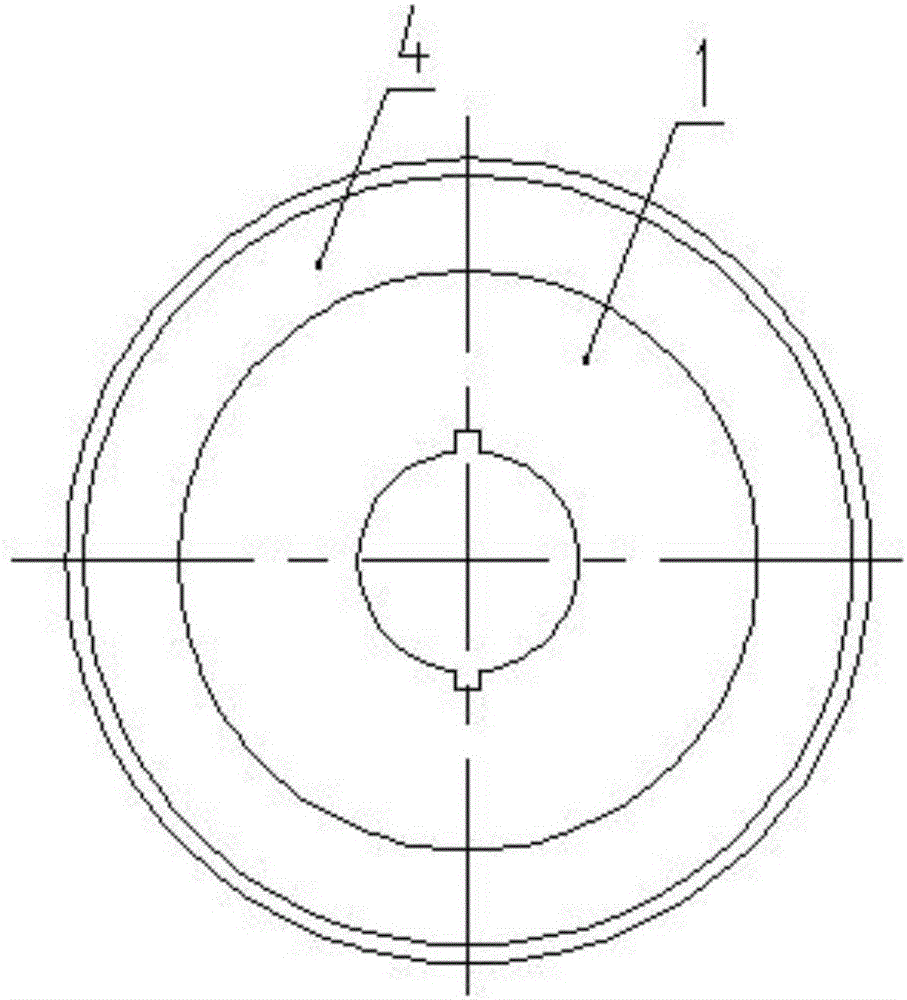

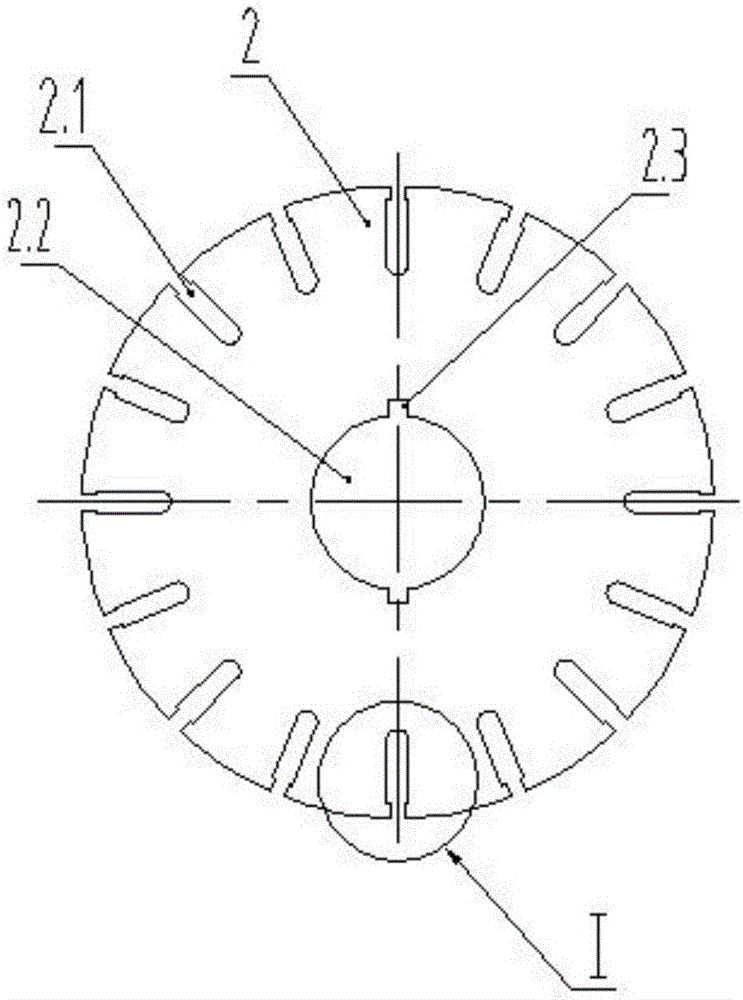

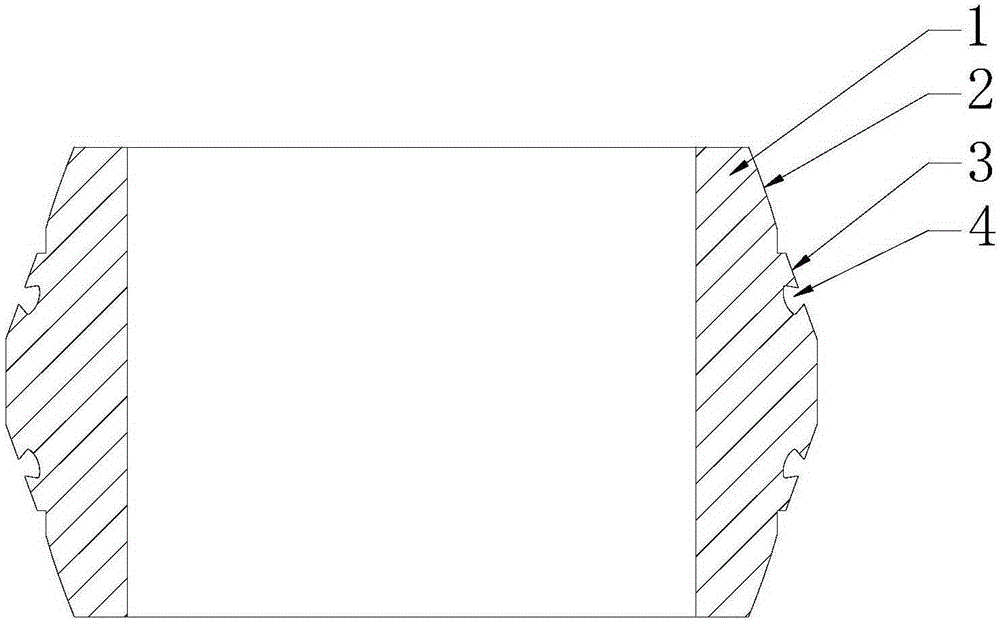

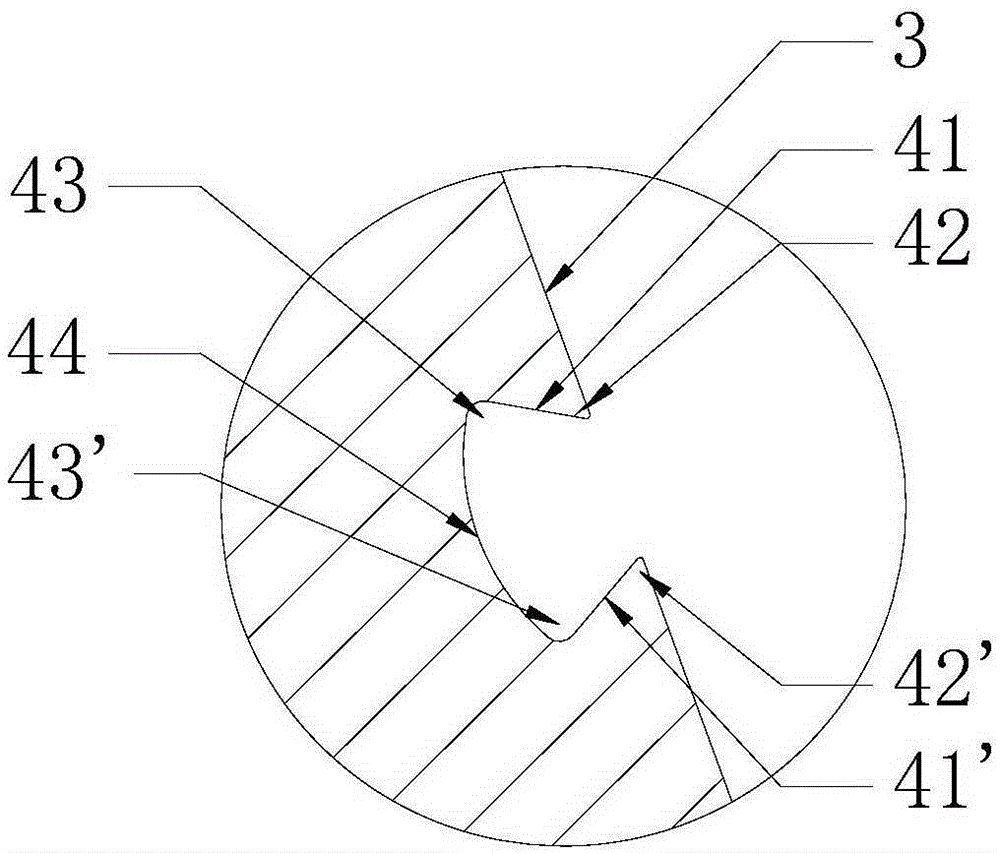

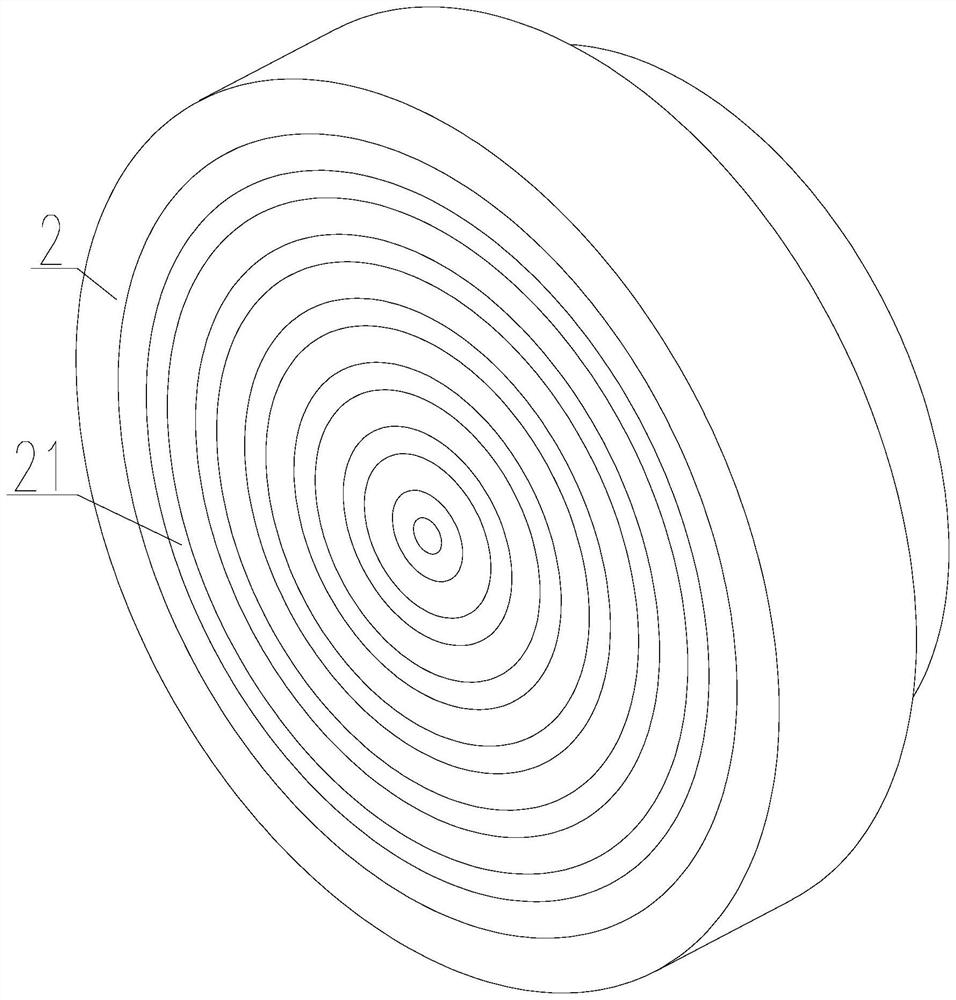

Cast copper rotor of motor

InactiveCN106787299ASolve the movementImprove reliabilityMagnetic circuit rotating partsNeck structureDie casting

The invention discloses a cast copper rotor of a motor. The cast copper rotor comprises a rotor core, wherein the rotor core is laminated by a plurality of rotor sheets with the same size and shape; shaft holes are formed in the middles of the rotor sheets; a plurality of conducting bar holes are uniformly distributed around the rotor sheets; the conducting bar holes in the rotor sheets are laminated and then connected to form conducting bar grooves in the rotor core; key grooves are formed in inner walls of the shaft holes of the rotor sheets; copper conducting bars are arranged in the conducting bar grooves; copper end rings are arranged at the two ends of the rotor core, and fixedly connected with the two ends of the copper conducting bars; the conducting bar grooves are herringbone grooves; and the herringbone copper conducting bars are embedded into the conducting bar grooves. The cast copper rotor is further characterized in that the key grooves symmetrical to central axes of the shaft holes of the rotor sheets are formed in the inner walls of the shaft holes of the rotor sheets; the copper conducting bars are die-casted in the conducting bar grooves; the copper end rings at the two ends of the rotor core are die-casted and connected with the copper conducting bars; and openings of the conducting bar holes around the rotor sheets are in necking structures. The cast copper rotor can avoid displacement of copper bars in the conducting bar grooves, and is good in reliability.

Owner:丁玉林

Outer sealing groove structure of O-shaped ring of non-standard sealing face

An outer sealing groove structure of an O-shaped ring of a non-standard sealing face comprises a composite sealing ring installed on a pipeline flange, and a spherical sealing face arranged on the composite sealing ring. A sealing bevel is arranged on the spherical sealing face and is internally provided with a non-standard sealing groove. An O-shaped sealing ring is arranged in the non-standard sealing groove. The inner cavity of the non-standard sealing groove is in the shape of an inner dovetail groove structure installed in cooperation with the O-shaped sealing ring. By means of the outer sealing groove structure, it can be guaranteed that the O-shaped sealing ring and a sealing cone are sealed, the displacement problem of the O-shaped ring is solved during the installing and replacing process of the sealing ring, and sealing reliability is improved; and besides, deviation and sliding of the O-shaped ring are greatly reduced, the failure problem caused by interval meshing damage and extrusion of the O-shaped ring is solved, the service life of the O-shaped ring is greatly prolonged, and reliability of composite sealing is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Edge Shape Control Method of Sendzimir 20-high Rolling Mill

ActiveCN106607460BGuaranteed control effectSolve the movementProfile control deviceShape deviationStrip mill

The invention discloses a sendzimir 20 rolling mill edge plate shape controlling method and device. The method comprises the following steps that (1) strip steel plate shape actual values in all control periods are obtained; (2) operation side edge plate shape deviations and driving side edge plate shape deviations are obtained by subtracting target plate shape values from the plate shape actual values; (3) symmetrical side plate shape deviations are calculated according to strip steel two-side edge plate shape deviations; (4) side plate shape control gain coefficients are calculated; (5) symmetrical side plate shape deviations multiply by the side plate shape control gain coefficients to obtain a middle roller symmetrical moving adjustment amount; and (6) the adjustment amount is output to a mill. By means of the sendzimir 20 rolling mill edge plate shape controlling method and device, the stability in the rolling process is guaranteed, the side plate shape control effect is guaranteed, and the problem of moving of non-symmetrical middle rollers is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Positioning and guiding structure of aircraft cargo cabin door

ActiveCN107264772BReduce installation difficultyReduce the difficulty of coordinationAircraft accessoriesBuilding locksAirplaneDesign technology

The invention belongs to the technical field of aircraft structure design and particularly relates to an aircraft freight cabin door positioning and guiding structure. The structure comprises a cabin door (1), a sliding rail assembly (2) and an uplatch (3). The cabin door (1) is hinged to an aircraft body, the sliding rail assembly (2) is mounted on the aircraft body and the cabin door (1), and the uplatch (3) is mounted on the aircraft body and the cabin door (1). According to the structure, stable and reliable positioning and guiding of the aircraft freight cabin door are achieved.

Owner:SHAANXI AIRCRAFT CORPORATION

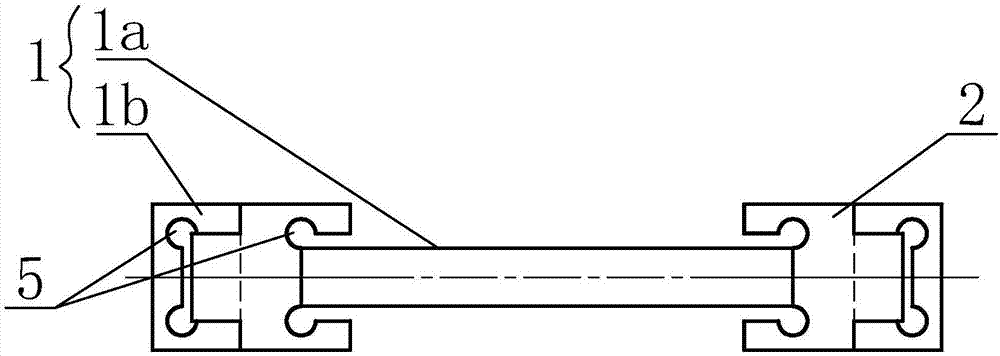

pallet box

ActiveCN104627474BSolve the movementAvoid interferenceRigid containersLocking devicesEngineeringPallet

The invention discloses a tray box. A tray box lock is installed on the tray box. The tray box lock comprises a lock support, a lock rod, a handle and a hook head, wherein the lock support is provided with a containing space opened towards one side of the lock support, the lock rod is movably connected with the lock support, a part of the lock rod is contained in the containing space, the two ends of the lock rod are located outside the containing space, the handle is at least fixedly connected with the portion, inside the containing space, of the lock rod, the hook head is arranged to protrude from one end of the lock rod to the direction opposite to the opening direction of the containing space and is inclined upwards relative to the horizontal plane, and a handle containing space for containing the handle is formed between the tray box lock and an upper edge beam. According to the tray box, the handle can smoothly rotate relative to a half folding door and does not collide with the lower box wall anymore; meanwhile, after the half folding door and the adjacent box walls are locked by the tray box lock, no gap exists above the hook head, and the problem that the box wall where the half folding door is located moves upwards is effectively solved.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +2

Double-cavity system and equipment for chemical vapor deposition diamond

PendingCN114277355AAchieve growthAccurate locationChemical vapor deposition coatingWater vaporEngineering

The invention relates to a double-cavity system and equipment for chemical vapor deposition diamond, which comprises a first cavity, a second cavity, a vacuum gate valve and a material transportation mechanism, the vacuum gate valve is fixedly connected with one end of the second cavity and the first cavity, and the material transportation mechanism is connected with the other end of the second cavity. And the material conveying mechanism can telescopically move in the first cavity and the second cavity. According to the double-cavity system for the chemical vapor deposition diamond, the technical defect that in the prior art, when a cabin door of the reaction cavity is opened and closed for multiple times to conduct lattice defect removal operation, water vapor and other impurity gases in air are promoted to be introduced into the reaction cavity can be overcome, and growth of the high-quality diamond is achieved.

Owner:深圳优普莱等离子体技术有限公司

Conveyor gateway large-angle rotary stoping method of unequal length fully-mechanized mining working surfaces

InactiveCN102536242BEasy maintenanceSolve the movementUnderground miningSurface miningHydraulic cylinderCentre of rotation

The invention discloses a conveyor gateway large-angle rotary stoping method of unequal length fully-mechanized mining working surfaces, and is characterized in that the turning part of the L-shaped working surface is provided with an arc auxiliary roadway formed by a plurality of linear roadways, wherein the rotation angle between adjacent linear roadways is 13-17 degrees; the length of each linear roadway not only exceeds the length of a transfer conveyor, but also does not exceed the maximal conveying length of a small scraper conveyor; the rotation center is subjected to secondary confirmation through rotation slope regulation, the hydraulic support is increased during the regulation process of the rotation center; the state of the scraper conveyor is regulated through the auxiliary hydraulic cylinder; and a timely top contact frame moving mode is adopted at the rotation center region of the operating surface, and maintaining is strengthened by an auxiliary supporting mode in the range of the section. According to the invention, the arc roadways are formed by a plurality linear roadways, the rotary stoping arc subsection is subjected to slope regulating and stoping, and the difficulties that the rotation angle of the conveyer gateway is over large and the coal conveying path can not be bent are solved. The rotation center is pushed appropriately, a top plate at the rotation center region is maintained greatly, and the problems that the support pushing quantity at the rotation center is less and is required to be supported repeatedly, and the top plate is difficult to maintain are solved.

Owner:铁法煤业(集团)有限责任公司晓南矿

Air duct assembly for refrigerator and refrigerator with the air duct assembly

ActiveCN103411369BSolve the movementPrecise adjustment of ventilation volumeLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

The invention discloses an air duct assembly for a refrigerator and a refrigerator with the air duct assembly. The air duct assembly is suitable for being arranged in a compartment of the refrigerator. The air duct assembly includes: an air duct piece, and the air duct piece is formed There is a forward concave air duct groove, and the air duct groove and the rear wall of the refrigerator compartment define an air duct; the air door is rotatably arranged in the air duct to adjust the ventilation volume in the air duct, wherein the air door is formed with a first A limiting part; and a rotating shaft, the rear end of the rotating shaft is connected to the damper after passing through the air duct to drive the damper to rotate, wherein a second limiting part is formed on the rear end of the rotating shaft, and the second limiting part is connected to the damper. The first limit part is matched. According to the air duct assembly used in the refrigerator according to the embodiment of the present invention, through the close cooperation between the first limit part on the air door and the second limit part on the rotating shaft, the problem of the air door moving can be effectively solved, and the installation process is simple , and the damper adjusts the ventilation volume in the air duct with high accuracy.

Owner:HEFEI HUALING CO LTD

Stabilizing pins after sheet metal forming

ActiveCN104128441BThe solution cannot be adjustedSolve the movementShaping toolsMetal sheetEngineering

The invention belongs to the technical field of sheet metal stamping manufacturing, and particularly relates to a stabilizer pin after sheet metal forming, which is characterized in that it includes a carrier, a tapered threaded rod and a positioning pin, and the axial direction of the carrier is provided with a threaded hole and a positioning pin. Pin mounting holes, the positioning pin mounting holes are set eccentrically, and a stepped platform is provided in the positioning pin mounting holes, and the positioning pins enter the positioning pin mounting holes from the bottom of the carrier and are fixed by screw plugs , the back of the positioning pin is provided with a cavity, the spring is placed in the cavity, the bottom of the spring is against the plug; the side of the carrier is provided with a steel ball mounting hole, and the steel ball mounting hole is in contact with the screw plug. The threaded hole communicates with each other, and the front side of the tapered threaded rod is screwed into the threaded hole to compress the steel ball placed in the steel ball mounting hole. This structure is simple and easy to install, which effectively solves the problem of parts moving on the blank holder after stretch forming, thereby improving the efficiency of mold debugging and ensuring the stamping stability of the mold.

Owner:天津星原汽车零部件有限公司

Method for automatically controlling strip steel edge drop of cold tandem mill

ActiveCN102641898BSolve the movementHigh yieldRoll mill control devicesMetal rolling arrangementsAutomatic controlProgrammable logic controller

The invention relates to a method for automatically controlling a strip steel edge drop of a cold tandem mill, comprising the following steps of: obtaining a deviation value of the strip steel edge drop; obtaining edge drop deviations on an operating side and a transmission side, respectively; calculating the adjustment amount of symmetric drifting of a first frame work roll; calculating the adjustment amount of symmetric drifting of a second frame work roll; calculating the adjustment amount of symmetric drifting of a third frame work roll; correcting a set value in a PLC (Programmable Logic Controller) frame control device according to the adjustment amount delta TS1 of symmetric drifting of the first frame work roll, the adjustment amount delta TS2of symmetric drifting of the second frame work roll and the adjustment amount delta TS3 of symmetric drifting of the third frame work roll, thereby finally completing control on the actual edge drop of the strip steel. In the control method, the operating mode of symmetric drifting is adopted for the first frame to the third frame, so that the stability of the rolling process is ensured and the control effect of the edge drop is also ensured simultaneously.

Owner:BAOSHAN IRON & STEEL CO LTD

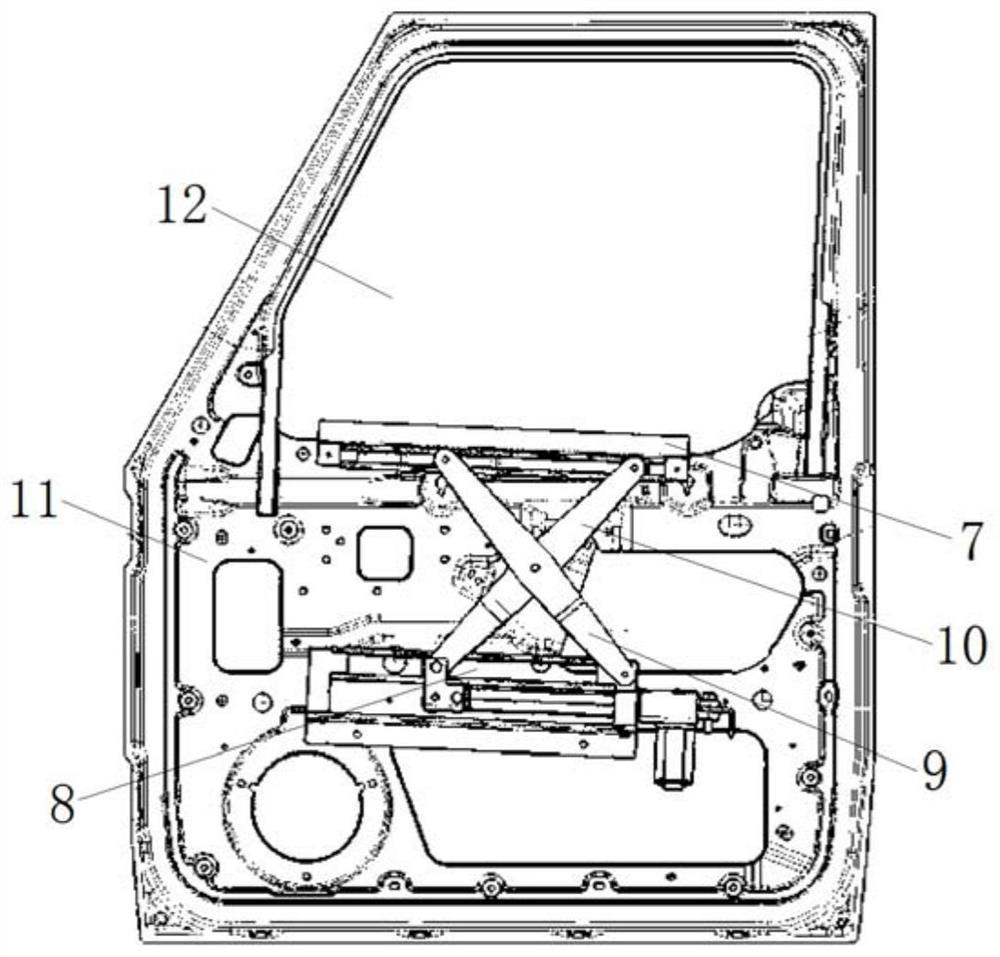

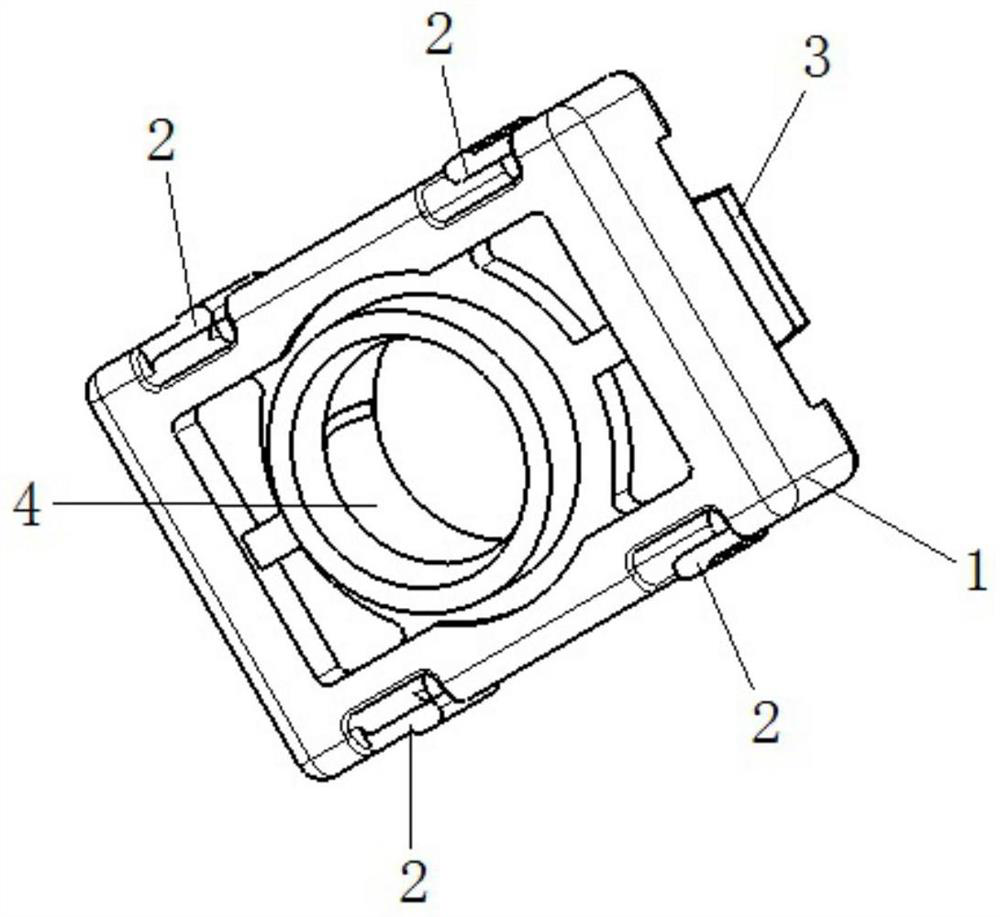

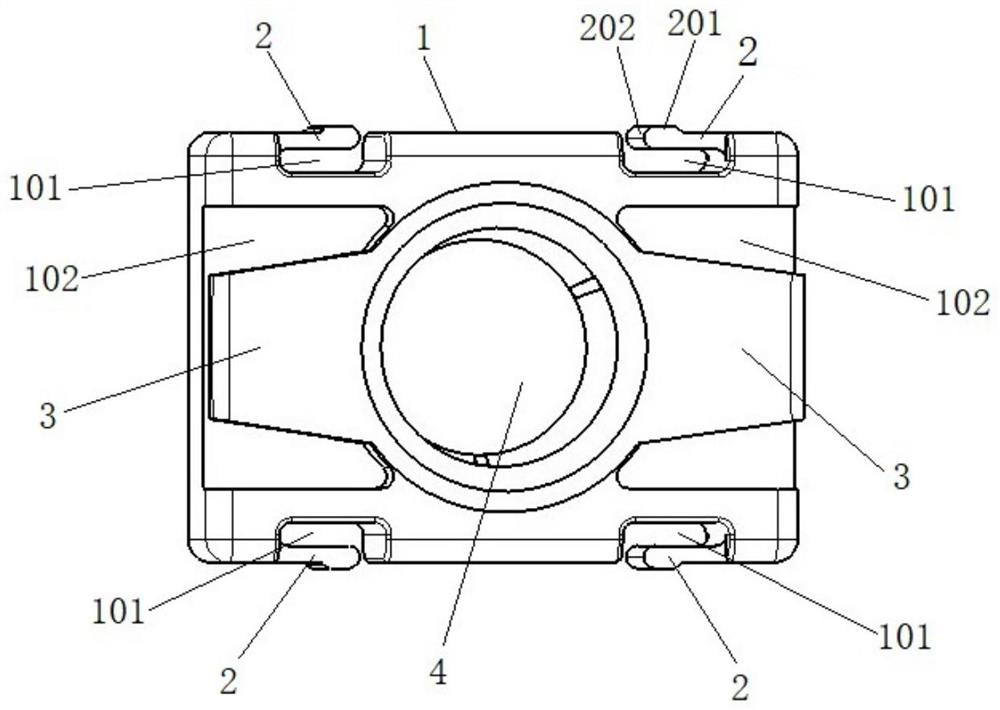

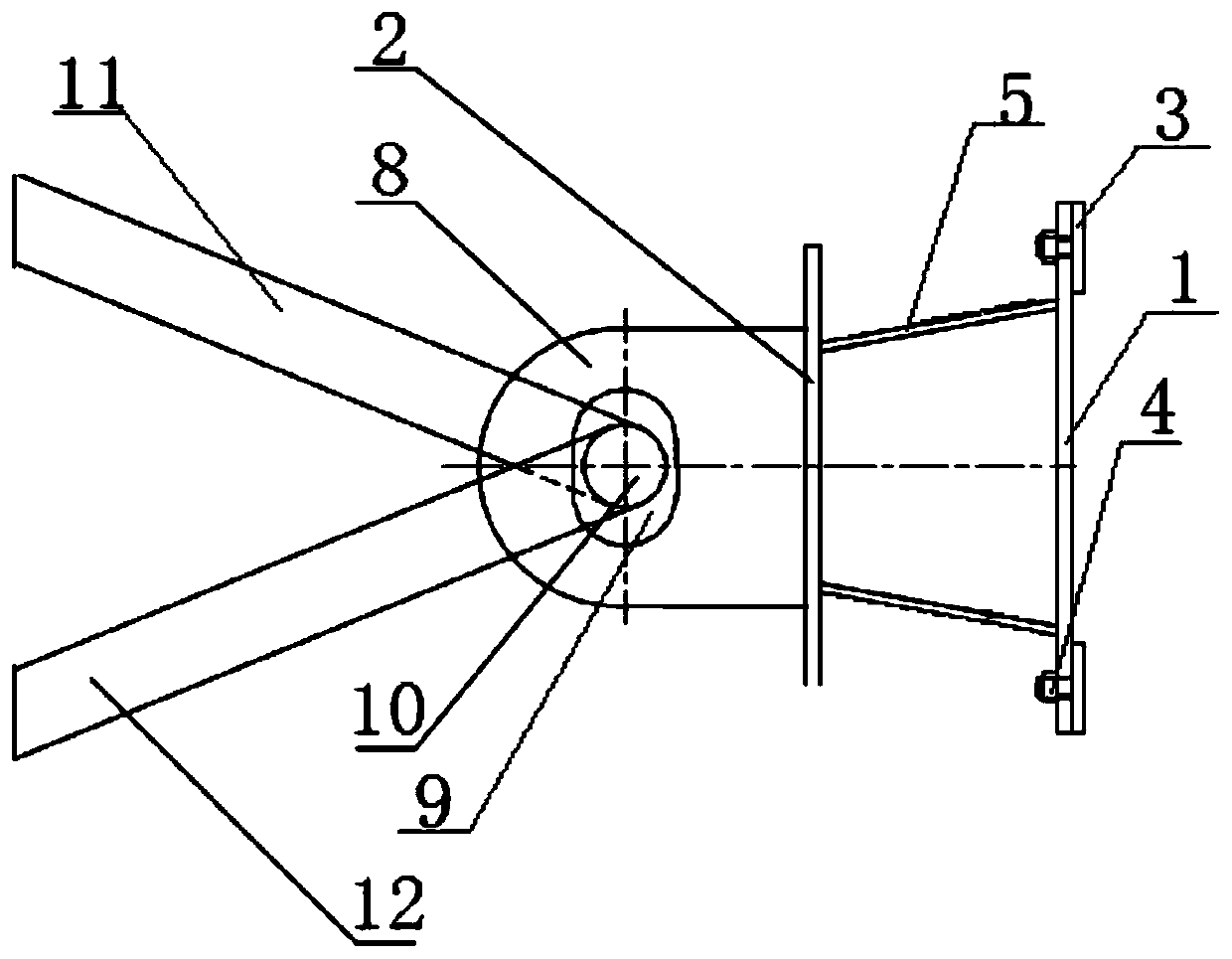

Lifter sliding block for double-fork-arm lifter and vehicle

InactiveCN112459649ASolve the movementAvoid noisePower-operated mechanismWing suspension devicesEngineeringStructural engineering

Owner:CHERY AUTOMOBILE CO LTD

Flexible supporting device for pump pipe of film type LNG land storage tank

InactiveCN111043518AImprove stabilityGuaranteed tightnessVessel mounting detailsVessel manufacturingPipeScrew thread

The invention discloses a flexible supporting device for a pump pipe of a film type LNG land storage tank. The device comprises a bottom plate, a top plate, embedded parts, fastening bolts, a supporting part, a connecting plate, a connecting column and a supporting pipe, each embedded part is of a plate-shaped structure with threaded holes, the two embedded parts are pre-embedded in one side, close to the inner tank, of the outer tank, one end of the supporting part is welded on the bottom plate, the other end is welded on the top plate, mounting holes matched with the threaded holes are formed in the bottom plate, the bottom plate is fixed to the outer tank through the fastening bolts, the connecting plate is welded to the top plate, a kidney-shaped hole is vertically formed in the connecting plate, the connecting column is arranged in the kidney-shaped hole, one end of the supporting pipe is fixedly connected to the connecting column, and the other end of the supporting pipe is fixedly connected to a pump pipe. Pump tower limiting is optimized into pump pipe distributed limiting, the manufacturing difficulty and the manufacturing cost are greatly reduced, the weight is greatly reduced, and transportation and installation are convenient.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

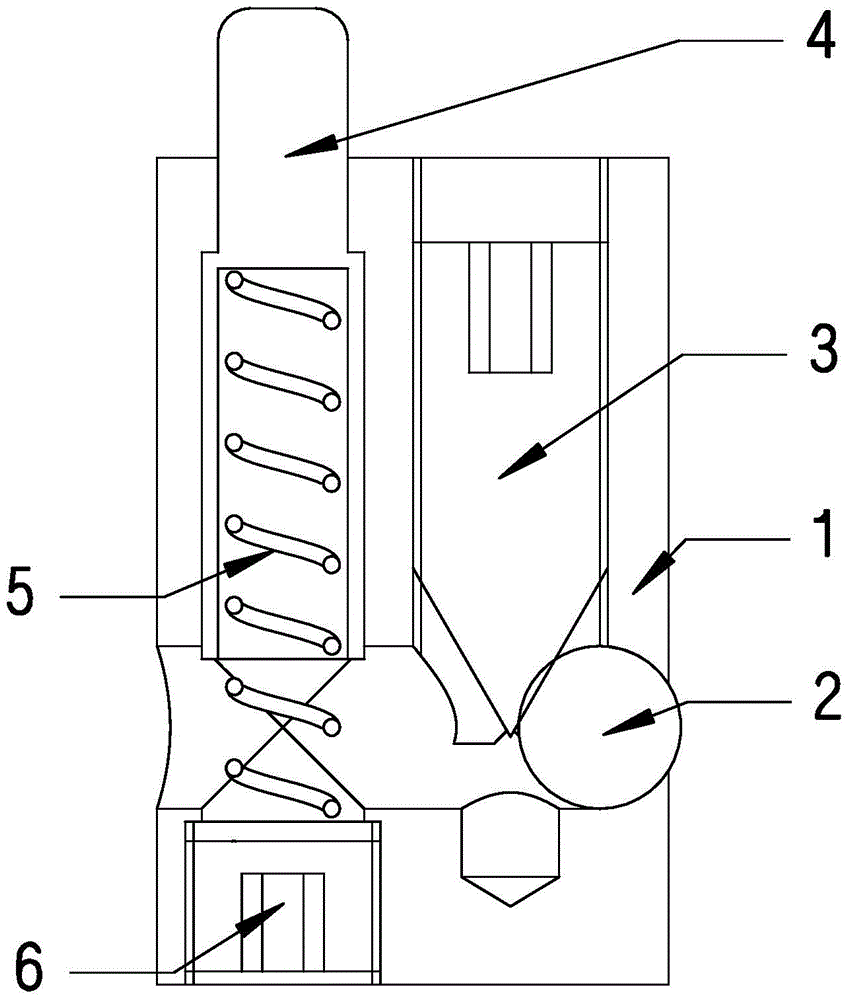

Plasma cutting fume processing system and method for spiral welded steel pipe

ActiveCN105414141BAvoid spreadingPassing resistance is smallCombination devicesDispersed particle filtrationEngineeringSteel tube

The invention discloses a spiral-welded steel pipe ion cutting smoke treatment system capable of improving the dust removing efficiency and preventing the dust dispersion and being provided with good popularity. The smoke treatment system comprises a dust sucking cover and a dust removing host machine; the spiral-welded steel pipe ion cutting smoke treatment system further comprises a rigid dust removing pipe; two dust sucking ports are at least formed in the lower surface of the dust sucking cover; the dust sucking ports are uniformly distributed in the length direction of the dust sucking cover; fireproof soft curtains are arranged around the lower surface of the dust sucking cover; the dust removing host machine is provided with an exhaust port and a dust sucking main pipe; the dust sucking ports of the dust sucking cover are communicated with the dust sucking main pipe through dust removing pipes; the dust sucking ports and the dust removing pipes are corresponding one to one; and valves are arranged on the dust removing pipes. The invention further discloses a method for treating smoke by using the smoke treatment device. The device and the method, provided by the invention, can improve the smoke sucking efficiency, are excellent in popularity, and can prolong the service life of a filter barrel.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A door frame installation auxiliary device and using method thereof

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES +1

Control Method for Balancing Compressor Effects on Vehicle Engine Torque

ActiveCN108087131BSolve the movementAvoid stackingFuel-injection pumpsMachines/enginesElectromagnetic clutchSuspension (vehicle)

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Automatic tube breaking device for microscopic tube

ActiveCN112811807AEnsure consistencyImprove consistencyGlass severing apparatusGlass productionEngineeringWorkbench

The invention relates to an automatic tube breaking device for a microscopic tube. The automatic tube breaking device comprises a pair of workbenches, a pushing mechanism, a cutter, a sliding table arranged on one workbench, a pressing block mechanism a arranged over the sliding table and a pressing block mechanism b arranged over the other workbench. The upper end face of the sliding table is provided with a plurality of protruding blocks A which are arranged at intervals, and the other workbench is provided with a plurality of protruding blocks a which are arranged at intervals. The microscopic tube can be clamped between the two adjacent protruding blocks A. The pressing block mechanism a is pressed on the microscopic tube. The pushing mechanism can push the sliding table to move towards the other workbench, and the block pressing mechanism a can move synchronously with the sliding table during the period. The tip end of the microscopic tube can gradually pass through the space between the adjacent bumps a. The middle part of the microscopic tube can be clamped between the two bumps a so that the pressing block mechanism b can be pressed on the microscopic tube. By improving the clamping structure in the microscopic tube cutting process, the problem that the microscopic tube moves in the tube breaking process is solved, and it is guaranteed that the lengths of the cut microscopic tubes are good in consistency.

Owner:山东美毅生物技术有限公司

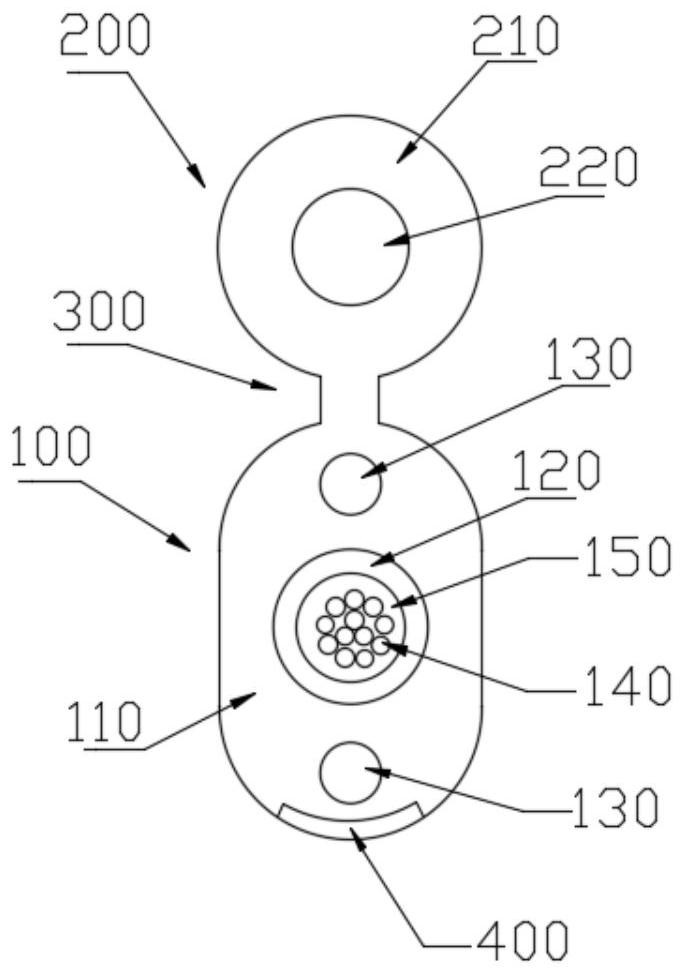

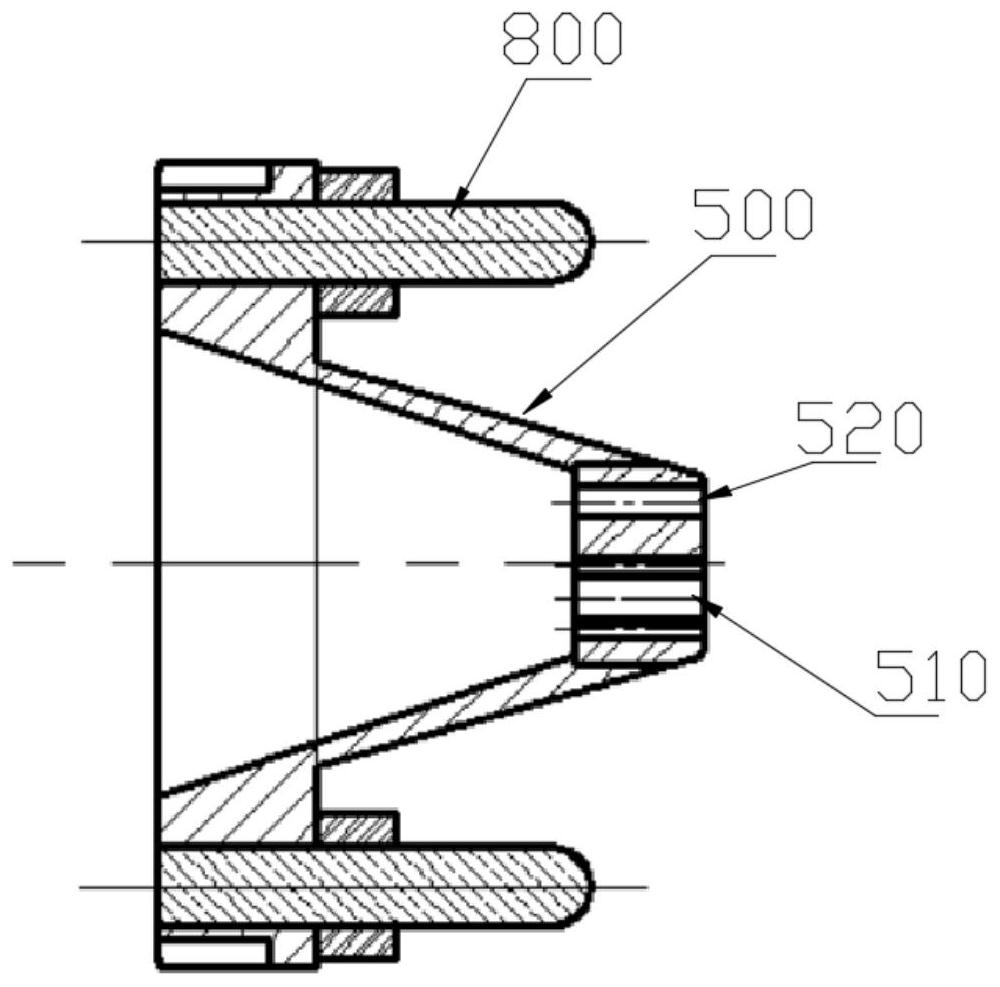

Special optical cable connection device for oil field

ActiveCN103676054BAvoid loss or even breakageGuaranteed continuityCoupling light guidesFibre mechanical structuresEngineeringMechanical engineering

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Clamp used for milling special-shaped samples of galvanized sheets

ActiveCN107052875ASolve the movementMeet the precision requirements of tensile testPositioning apparatusMetal-working holdersEngineeringStructural engineering

Owner:鞍钢蒂森克虏伯(重庆)汽车钢有限公司

Ball type data rotation transmitter

PendingCN114678748ATransmission is accurateAvoid entanglementFlexible/turnable line connectorsCircular discButt joint

The invention relates to the technical field of connectors, in particular to a ball type data rotating transmitter which comprises a rotating shaft, a rotating part and a static part, and the rotating part and the static part are arranged on the rotating shaft in a sleeving mode. A plurality of ring pieces are installed on the head end face of the rotating piece in the radial direction, the ring pieces are annular, each ring piece is provided with a plurality of movable connectors, and the movable connectors are located on the tail end face of the rotating piece. A plurality of annular grooves are formed in the tail end face of the static piece in the radial direction, each annular piece corresponds to one groove, the annular pieces are rotationally installed in the corresponding grooves, a plurality of static connectors are installed on the head end face of the static piece, and the static connectors are connected with the static piece through coaxial double-disc rail discs of the rotating piece and the static piece. The problem of moving and static butt joint is solved, data of a rotating part in a mechanical system can be accurately transmitted without being limited by the number of turns of a rotating angle, and a data line of a rotating part is prevented from being wound in the rotating process.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

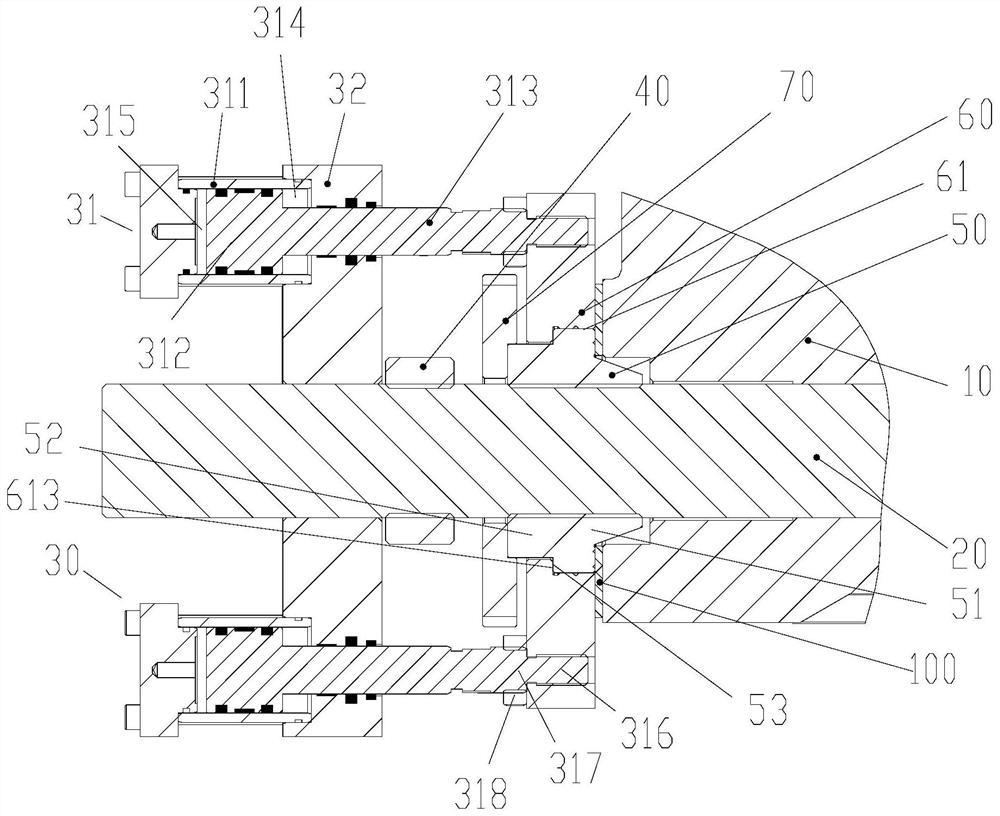

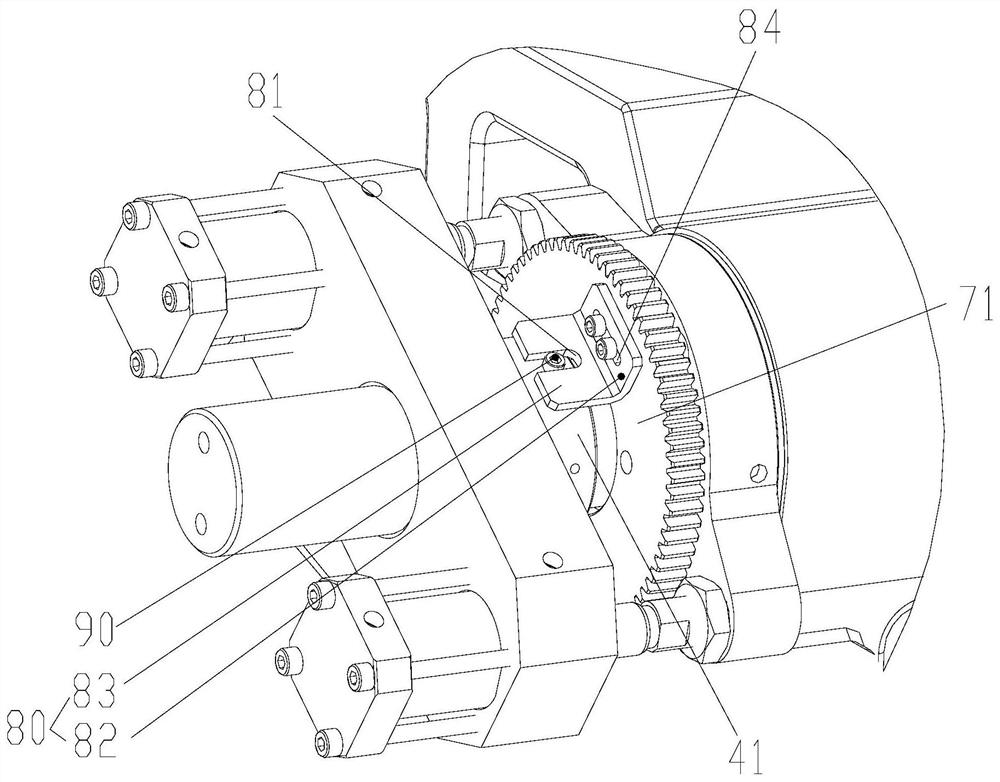

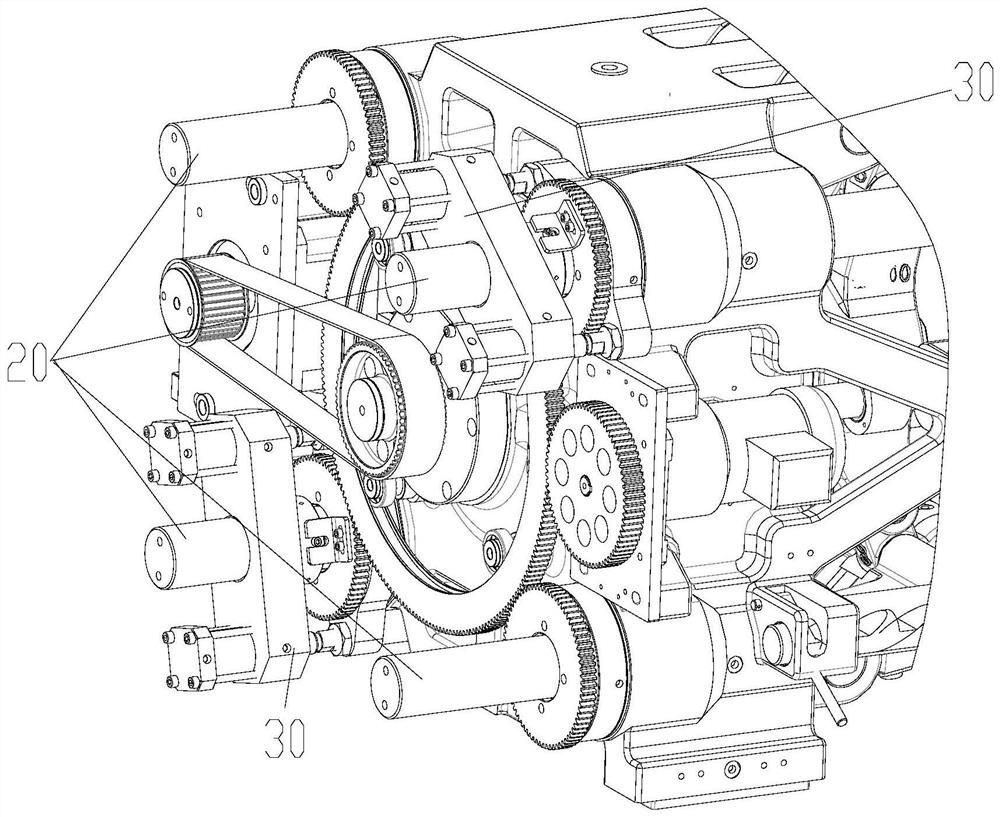

Mold adjusting mechanism and injection molding machine having the same

The invention provides a mold adjusting mechanism and an injection molding machine having the same. The mold adjustment mechanism includes an adjustment plate, a mold adjustment nut and a guide post. The adjustment plate is sleeved on the guide post and is movably arranged along the guide post. The mold adjustment nut is threadedly connected to the guide post. The mold adjustment mechanism also includes: a pressing component, Including a pressing part, the pressing part includes a connecting piece and a pressing main body, the connecting piece is connected with the adjusting plate, the pressing main body is connected with the guide post and is movably arranged along the guide post, the pressing body is connected with the connecting piece and the two are opposite to each other It is movably arranged; the pressing piece is connected with the guide post and is arranged between the pressing body and the adjusting plate; the adjusting nut is arranged between the pressing piece and the adjusting plate, and the pressing body and the connecting piece are subject to the relative movement When the force is applied, the adjusting plate is pressed on the adjusting nut, and the pressing body moves toward the pressing member and is pressed on the pressing member. The mold adjusting mechanism of the present invention solves the problem that the adjusting plate of the mold adjusting mechanism in the prior art is easy to move.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Lead-in optical cable and manufacturing mold, manufacturing method and air tightness testing method thereof

PendingCN113721334ASolve the problem of large attenuationSolve the movementFibre mechanical structuresYarnAir tightness

The invention provides a lead-in optical cable and a manufacturing mold, a manufacturing method and an air tightness testing method thereof, which relate to the technical field of optical cable manufacturing. The lead-in optical cable comprises an optical cable part, the optical cable part comprises an optical cable outer protection layer, a sleeve and at least one first reinforcing element, and the sleeve and the first reinforcing element are located in the optical cable outer protection layer and jointly form a tight wrapping structure; at least one optical fiber is arranged in a tube cavity of the sleeve, and the tube cavity is filled with a sleeve filler in a sealing manner; the lifting part is connected with the optical cable part; and the lifting belt is connected between the optical cable part and the lifting part. According to the technical scheme, the lead-in optical cable is characterized in that when the sleeve and the reinforcing element are wrapped by the outer protective layer, a layer of glass yarn or aramid yarn is not covered outside the sleeve any more, but the sleeve and the reinforcing element are tightly wrapped inside the outer protective layer to form an integral tightly-wrapped structure, so that strain generated in construction is reduced, therefore, the lead-in optical cable does not loosen any more, and the problems that the lead-in optical cable is poor in air tightness and not easy to block water, and the sleeve is easy to retract to cause large optical fiber attenuation are solved.

Owner:SHENZHEN SDGI OPTICAL NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com