Sendzimir 20 rolling mill edge plate shape controlling method and device

A technology of shape control and rolling mill, applied in the direction of contour control, etc., can solve the problems of large difference in the movement of the middle roll, strip deviation, broken strip, etc., to ensure the stability and edge shape control effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

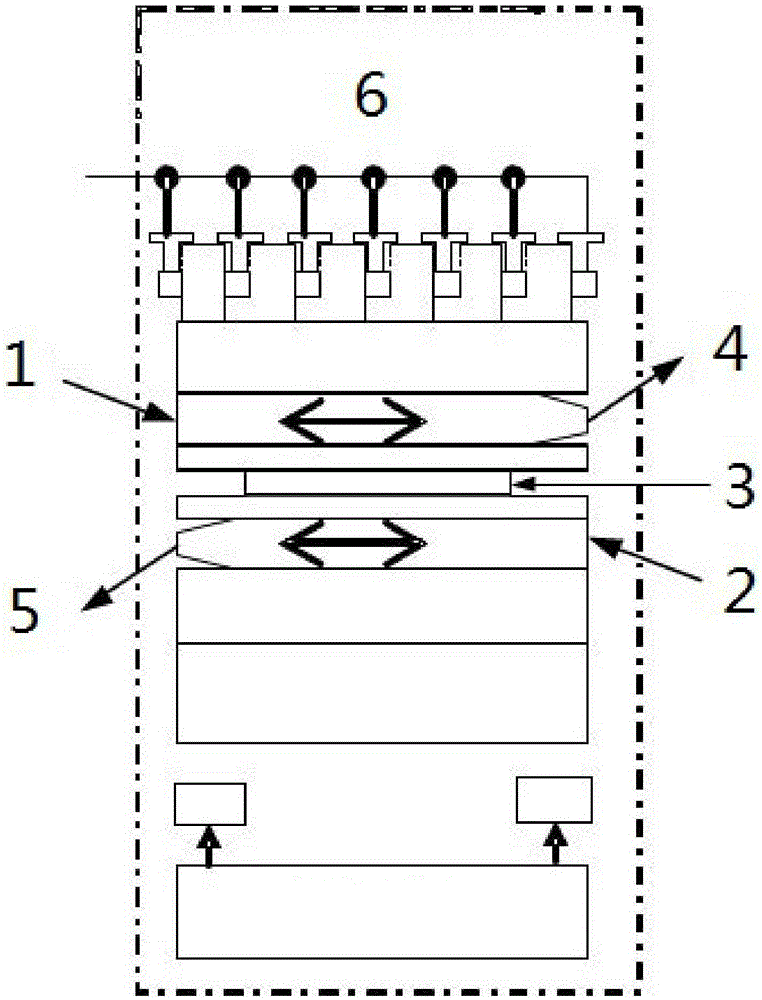

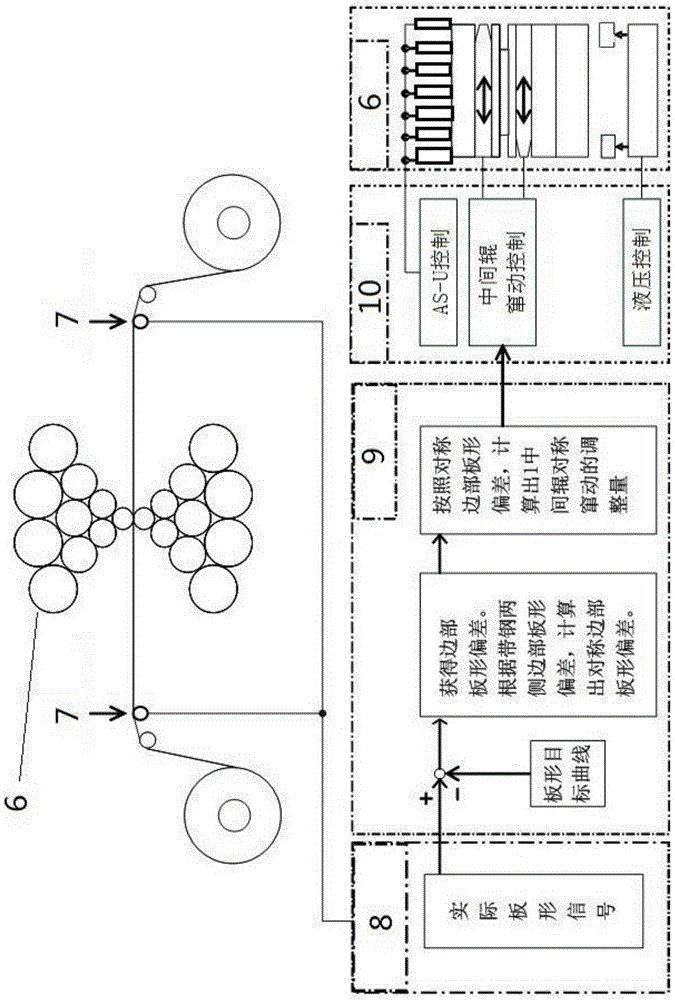

[0060] The edge shape control technology was applied to a Sendzimir 20-high mill. Such as image 3 As shown, the horizontal distance between the Sendzimir rolling mill and the shape measuring roll is 2.3m, the diameter of the shape measuring roll is 0.4m, and the maximum speed of the strip is 800m / min.

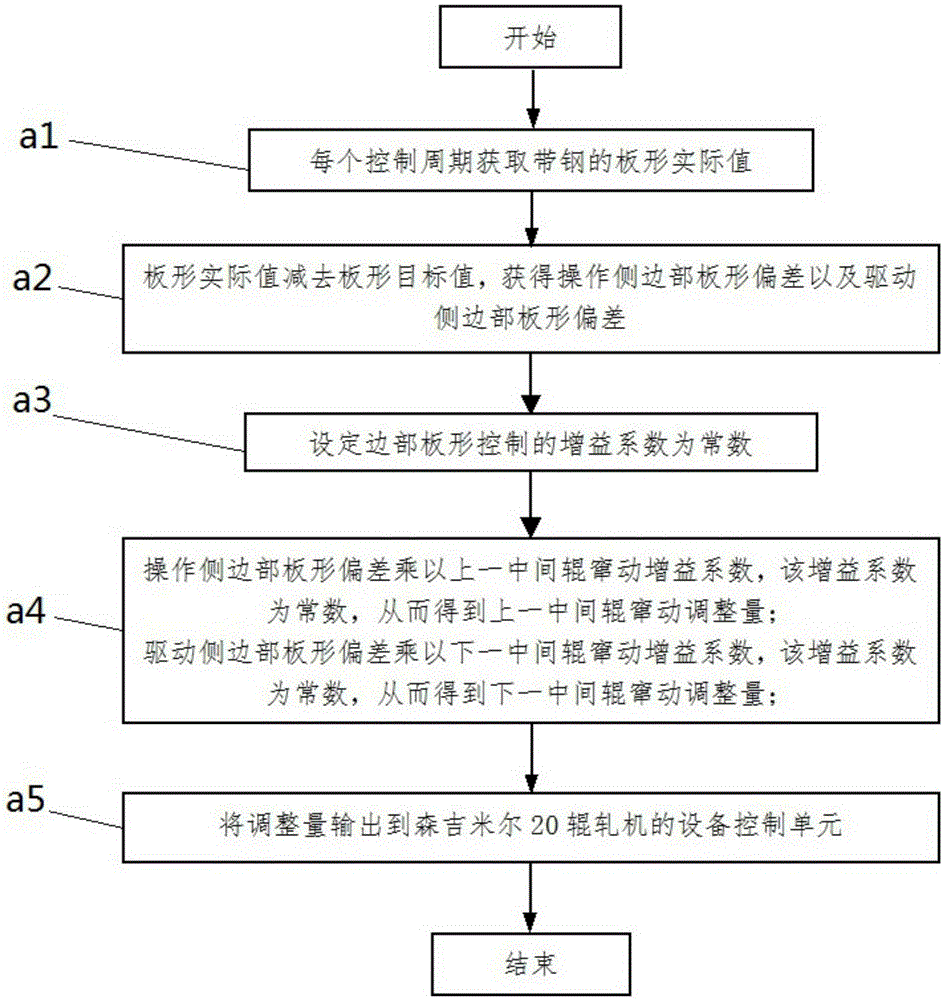

[0061] Before the edge flatness control is put into operation, first test the edge flatness control ability of the symmetric-middle roll movement, and obtain the control coefficient of the symmetric-middle roll movement:

[0062] k T = 5.0

[0063] The target flatness, the edge flatness deviation weighting coefficient and the control coefficient k of the symmetrical intermediate roll movement T Stored in the shape control CPU.

[0064] Based on the above, the edge flatness control program performs the following calculations according to the control cycle (T=0.2s).

[0065] Receive the actual flatness signal from the flatness measurement computer, and perform the moving average processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com