Conveyor gateway large-angle rotary stoping method of unequal length fully-mechanized mining working surfaces

A technology of fully mechanized mining face and transportation along the trough, which is used in ground mining, earthwork drilling, underground mining, etc., can solve the problems of unbendable coal transportation routes, large rotation angle of transportation along the trough, etc., to solve the problem of scraper conveyor. swaying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiment of the method of transporting along the groove and rotating the unequal-length fully mechanized mining face provided by the present invention is as follows:

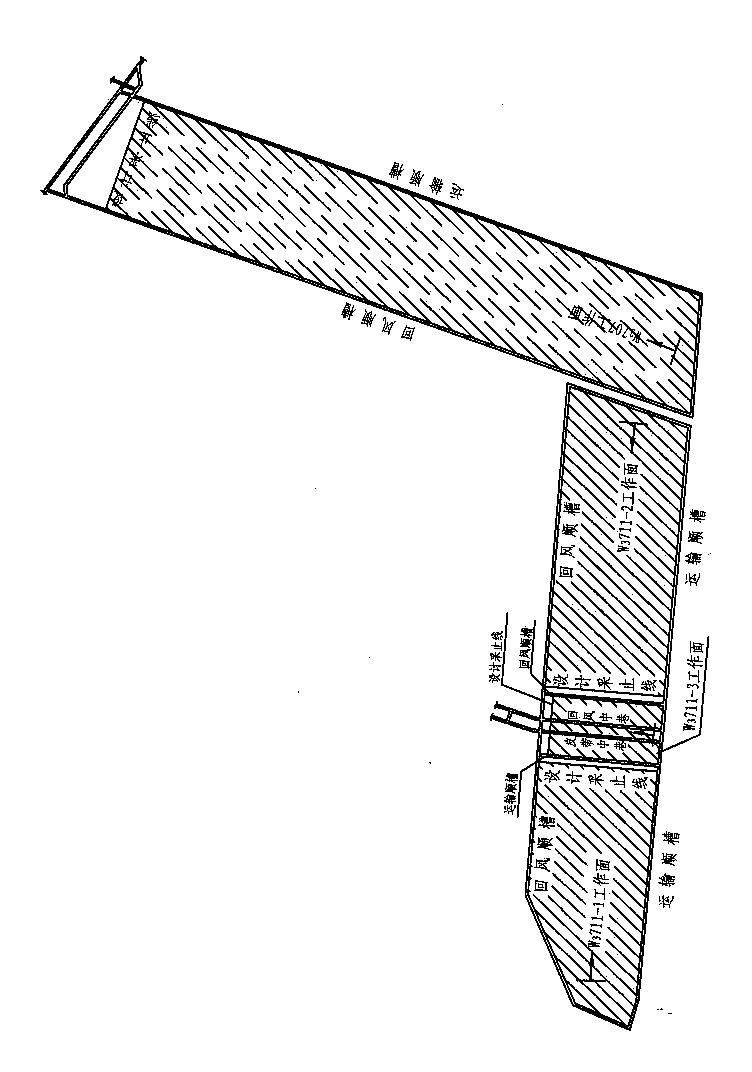

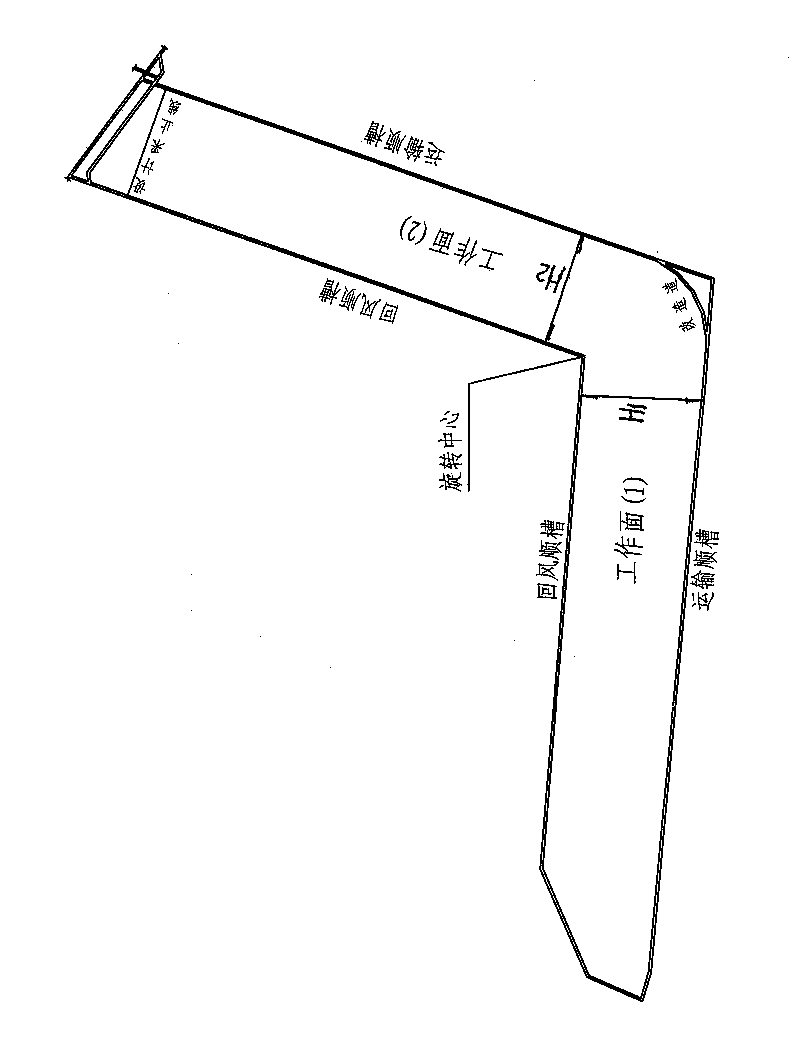

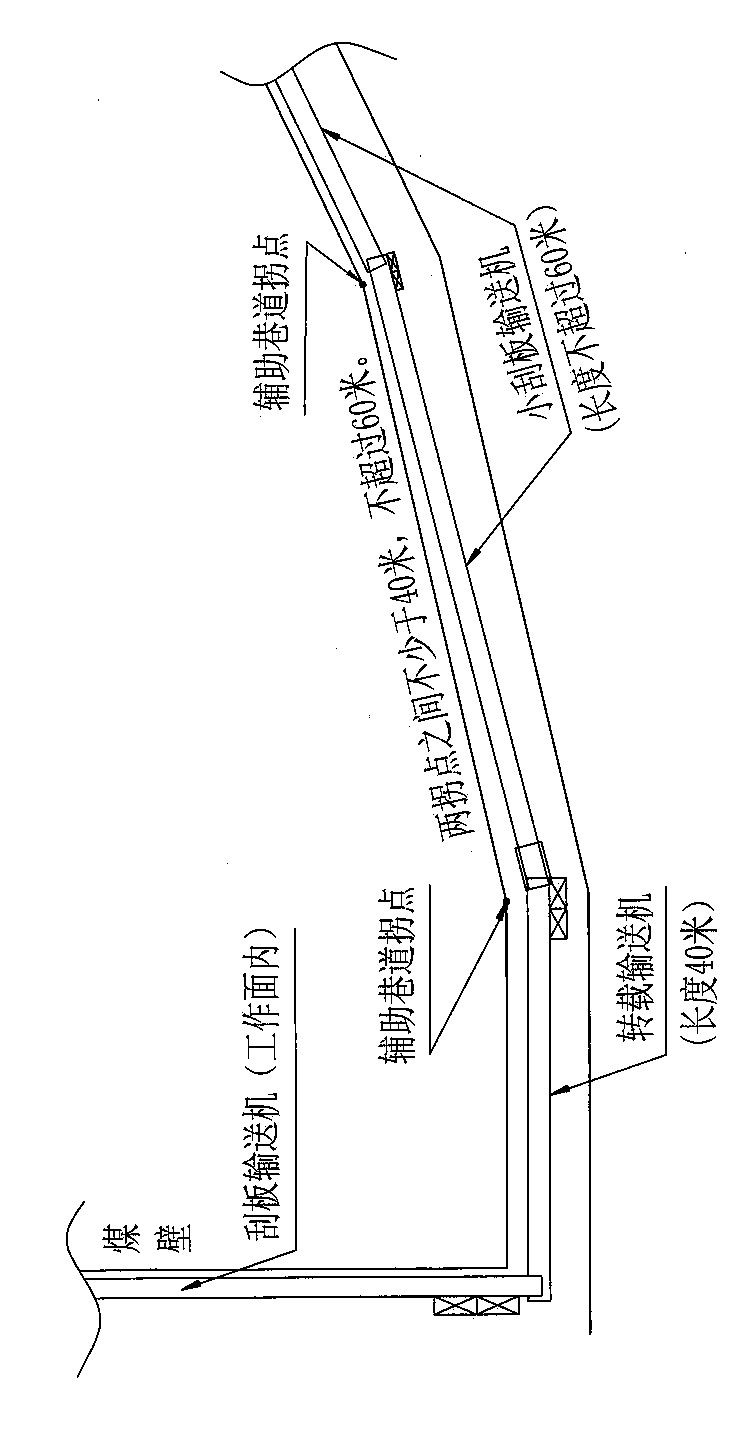

[0015] See figure 2 , 3 , the arc-shaped auxiliary roadway is set at the corner of the L-shaped joint working face where the working face 1 and the working face 2 form an angle β of 70°-90°, and the length of the entire arc-shaped auxiliary roadway is 248m ( image 3 The two tangent points f point to point g in the middle), according to the problem that there are many equipments and cannot advance along the arc roadway, in order to meet the requirements of the L-shaped joint working face of rotary mining at 75°-90°, it is necessary to ensure the safety of the transportation equipment Smooth operation, the arc-shaped auxiliary roadway is transformed into 4 straight roadways, with a total length of 186m ( Figure 4 from point a to point e in ), plus 6 transport lanes (to the tangent point) connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com