Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Passing resistance is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

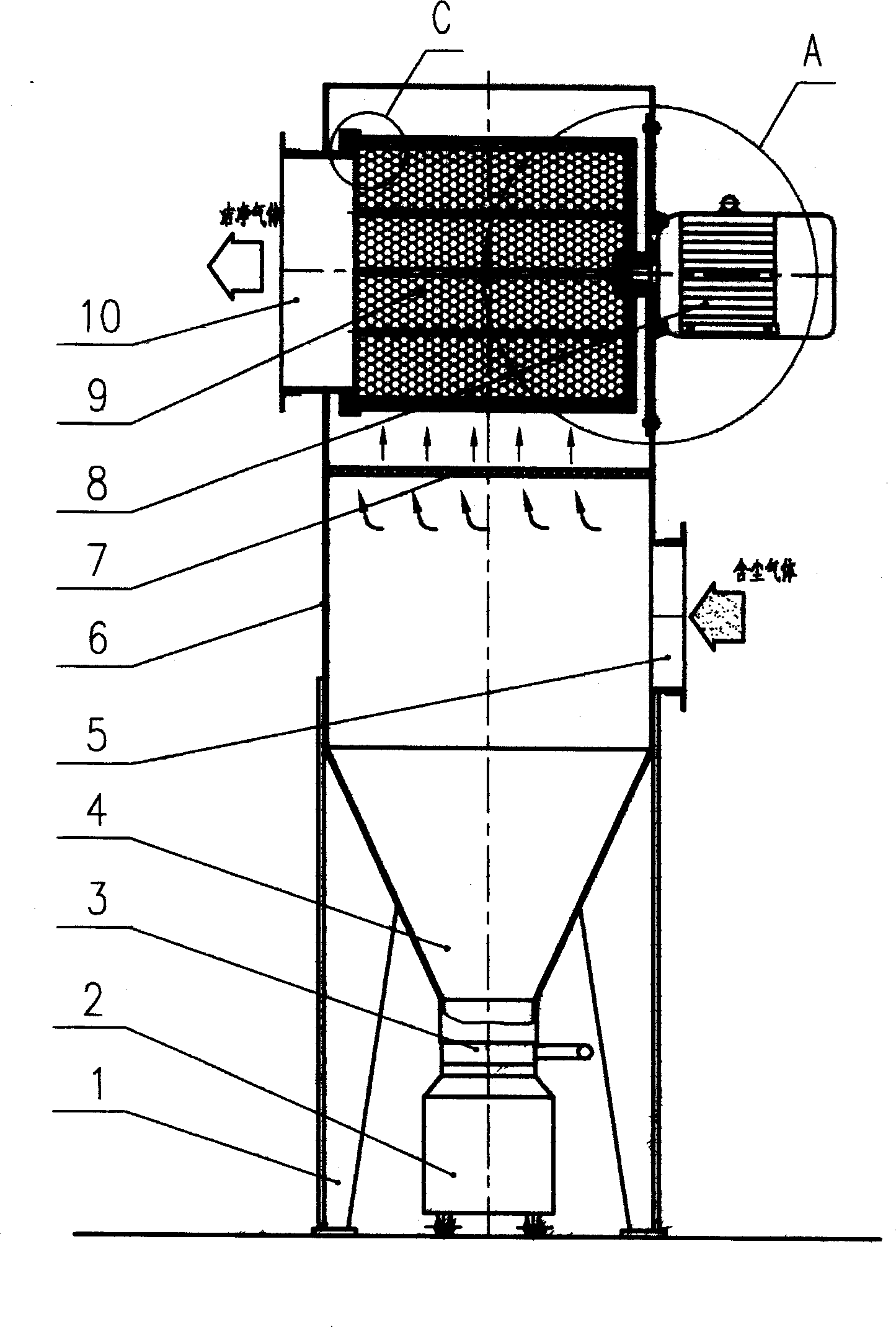

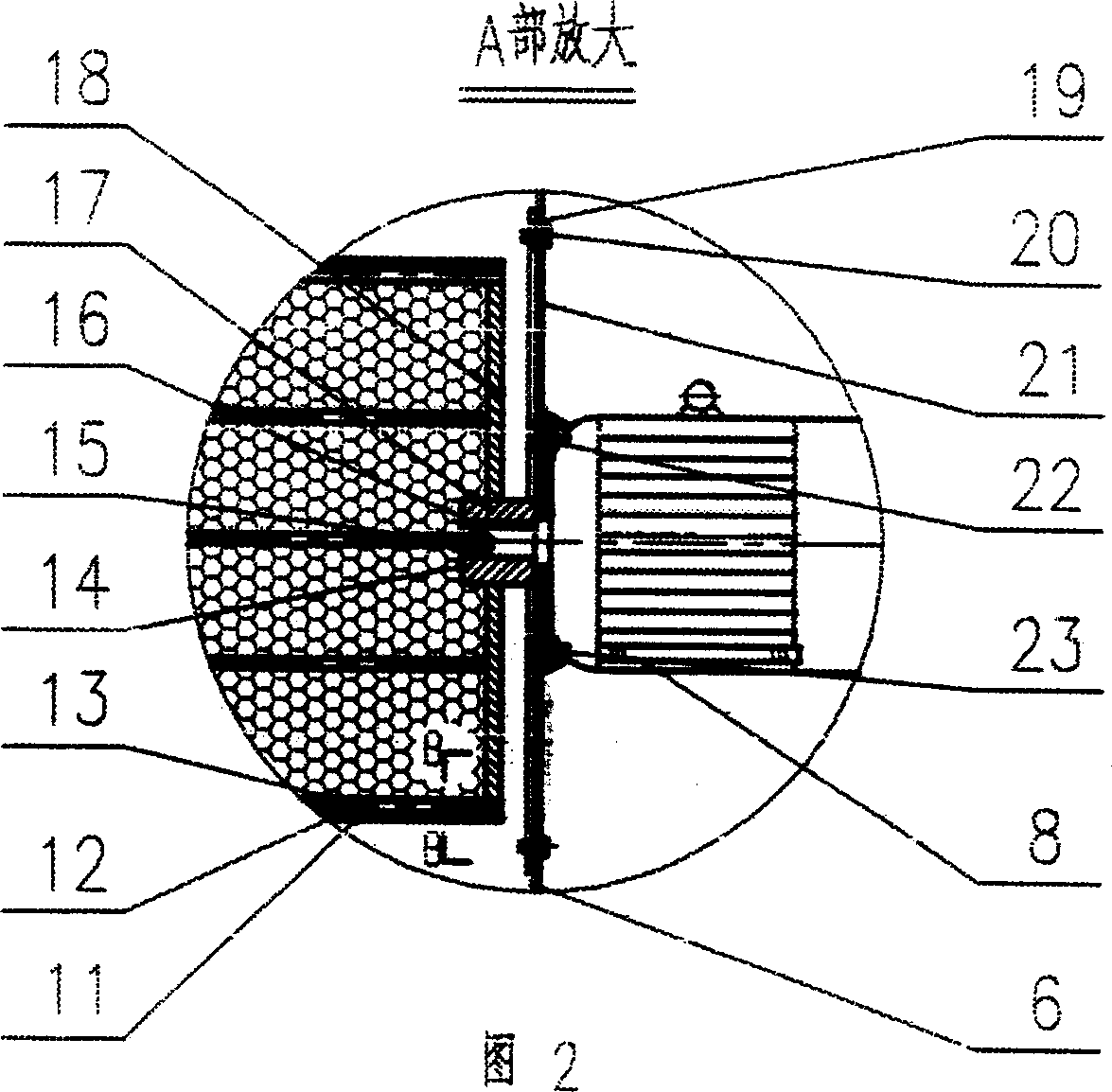

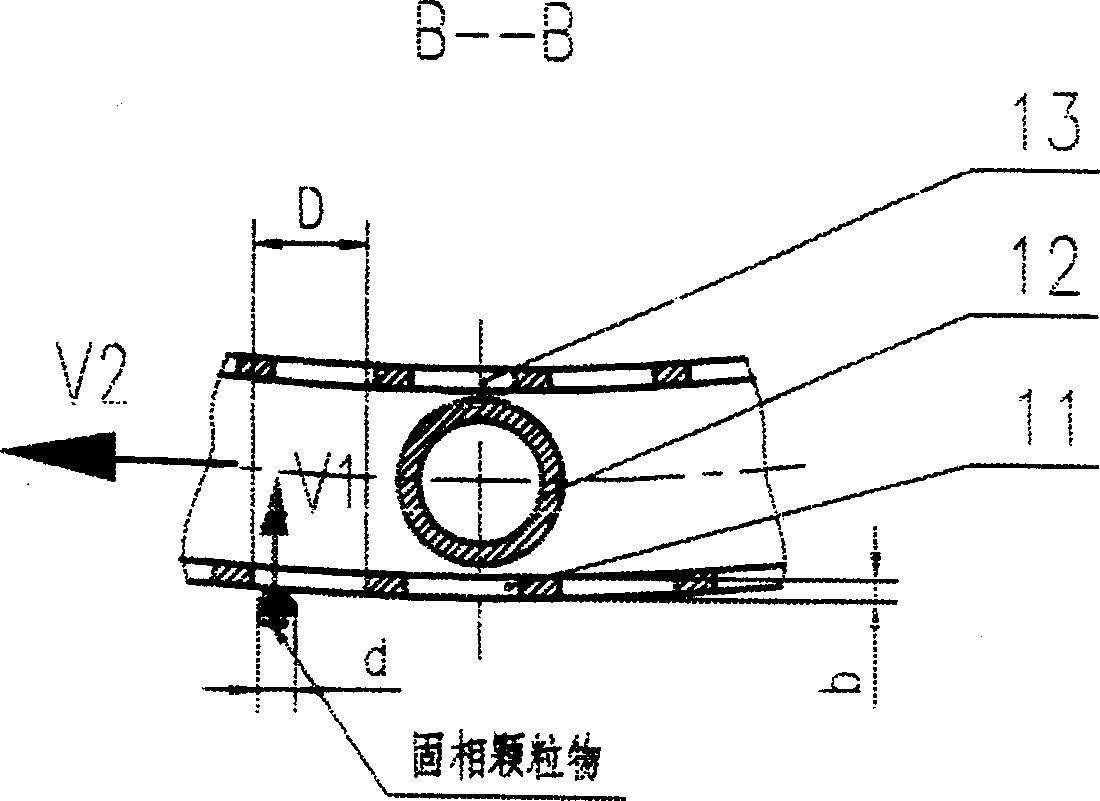

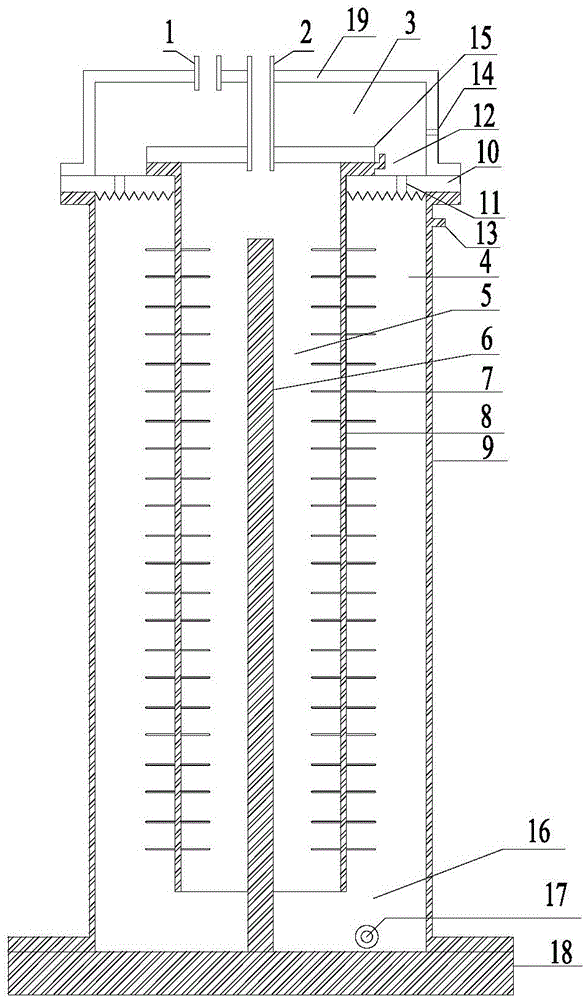

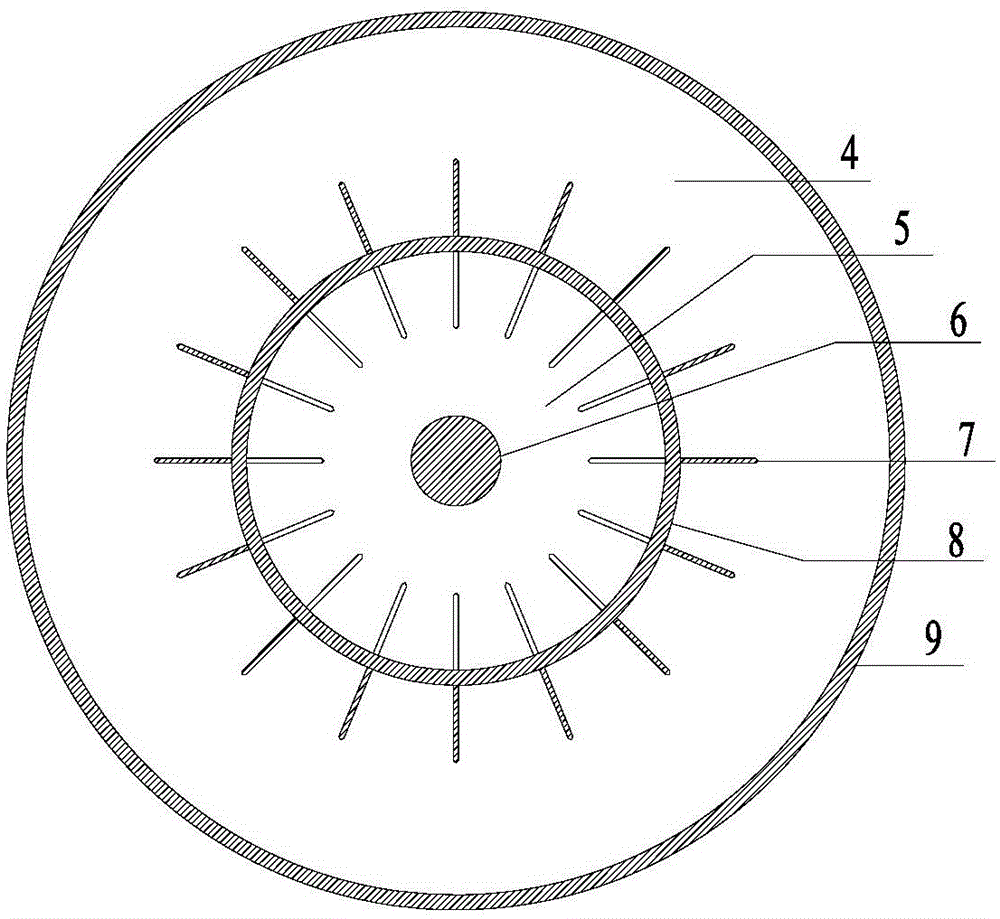

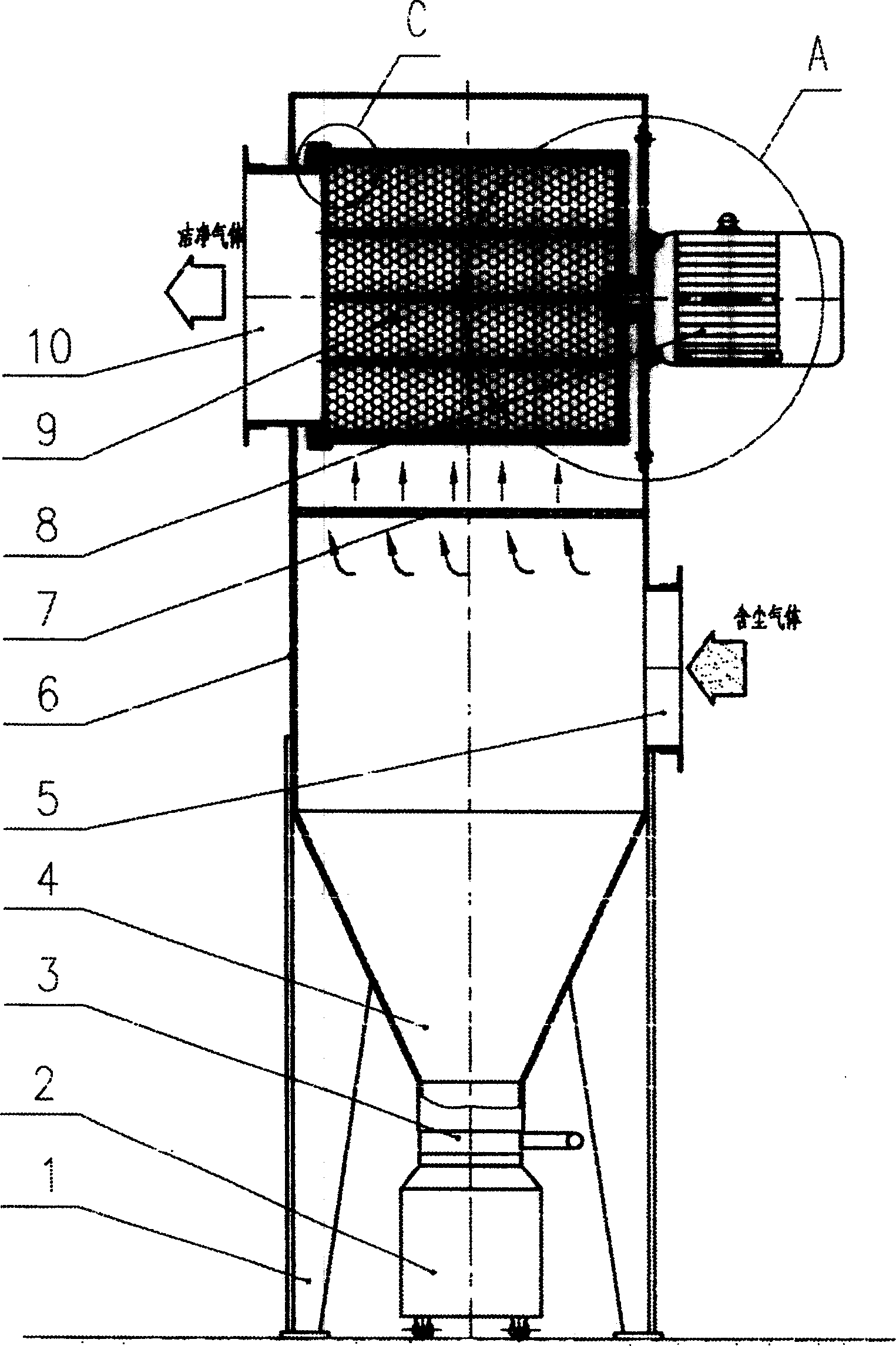

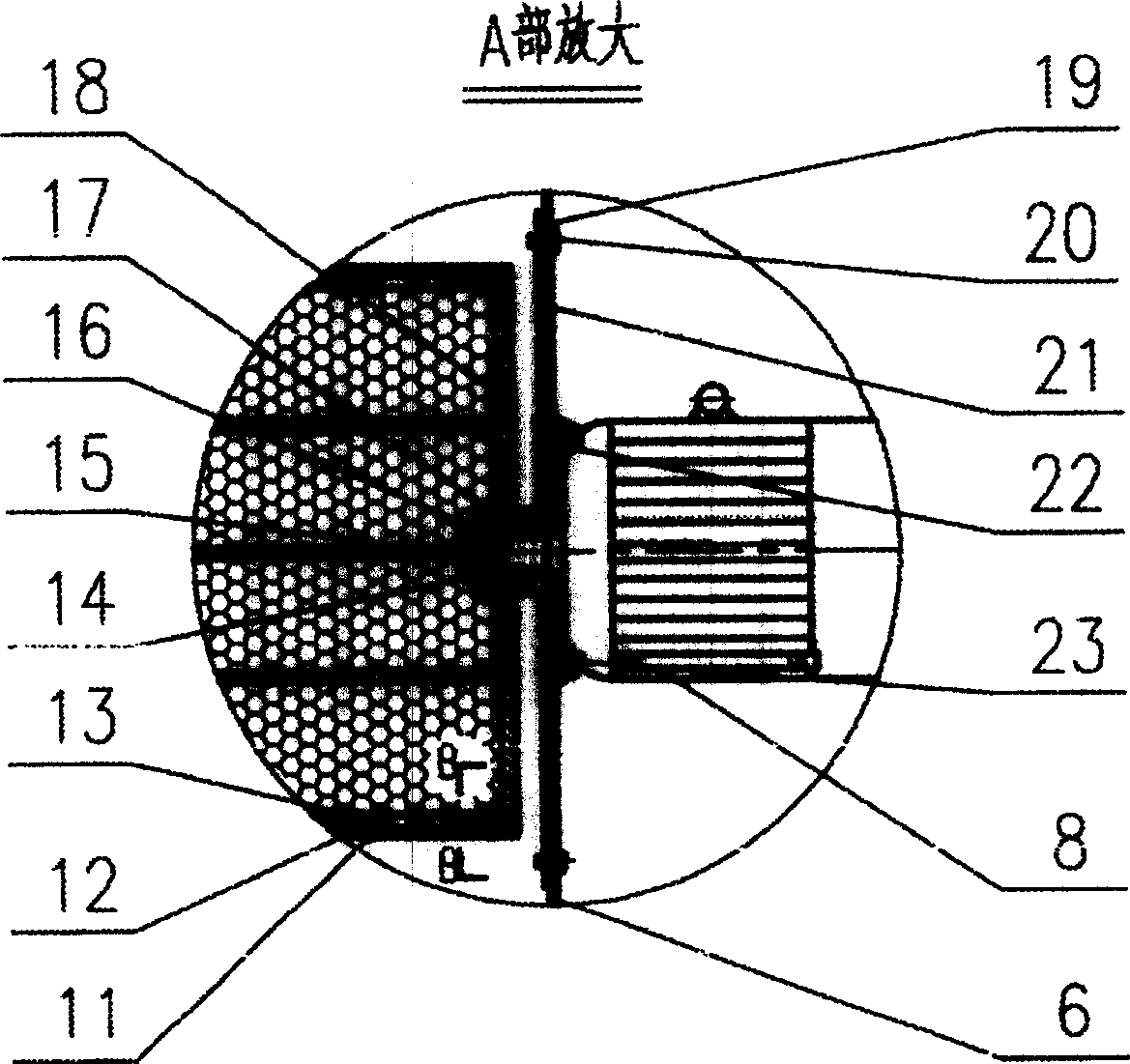

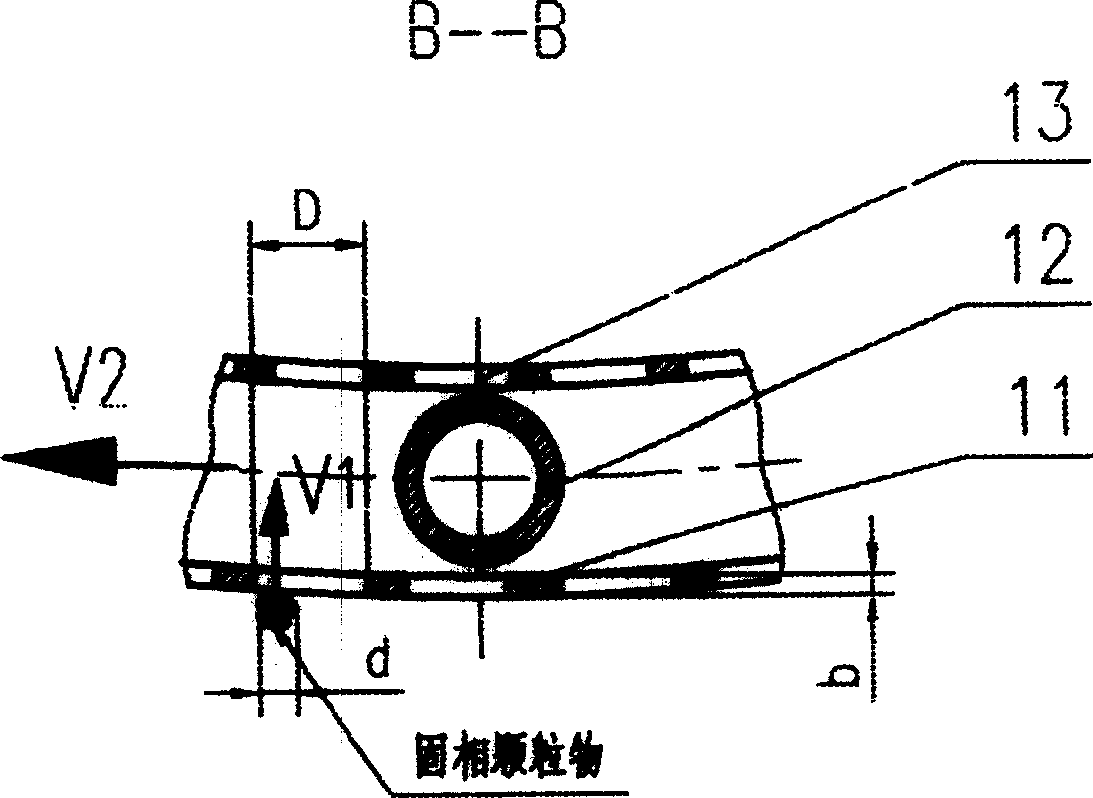

Filtration type gas separation and purification equipment with rapid moving filtering layer

InactiveCN1480239AEfficient separationEffective separation and purificationDispersed particle filtrationFiltrationProduct gas

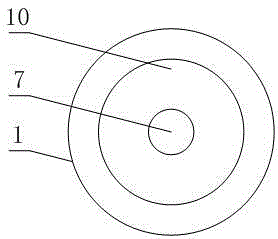

A filter-type gas separating-cleaning apparatus with quickly moving filter layer features that its filter cylinder rotating at high speed is composed of external filter net, supporting posts, internal filter net, shaft sleeve, shaft disk and supporting rings, and the gas containing solid particles and / or liquid drops is filtered by said filter cylinder. Its advantage is use of big-mesh filter material to remove fine solid particles and / or liquid drops, resulting in high filter speed, and easy cleaning.

Owner:暴辰生 +1

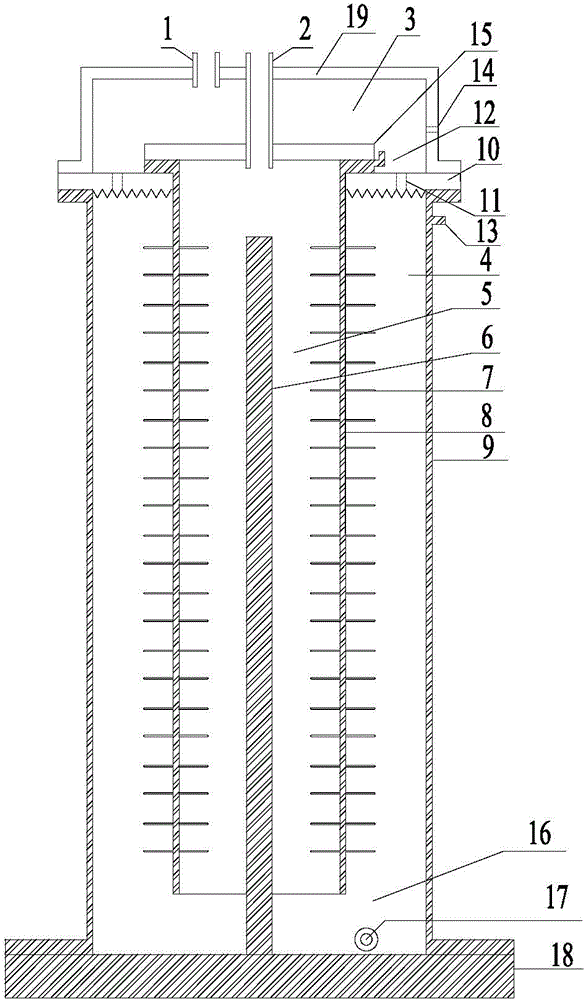

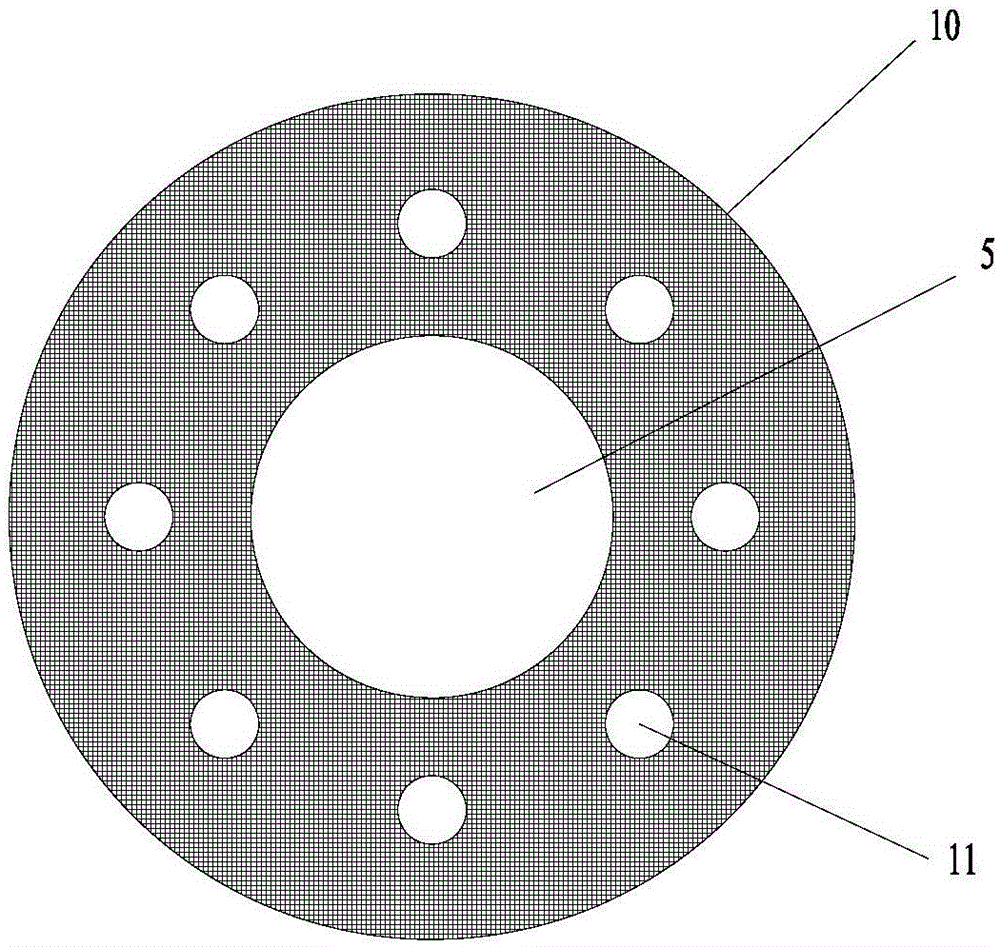

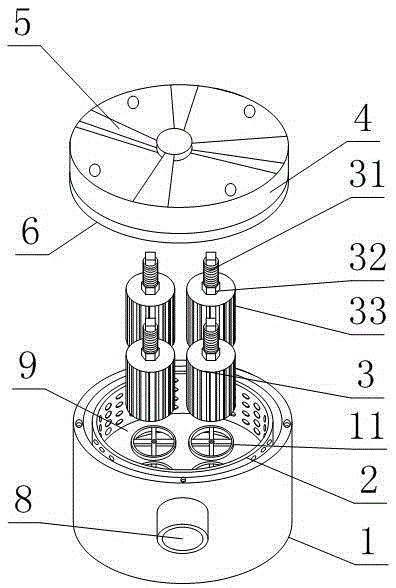

Superfine particulate matter purifying device

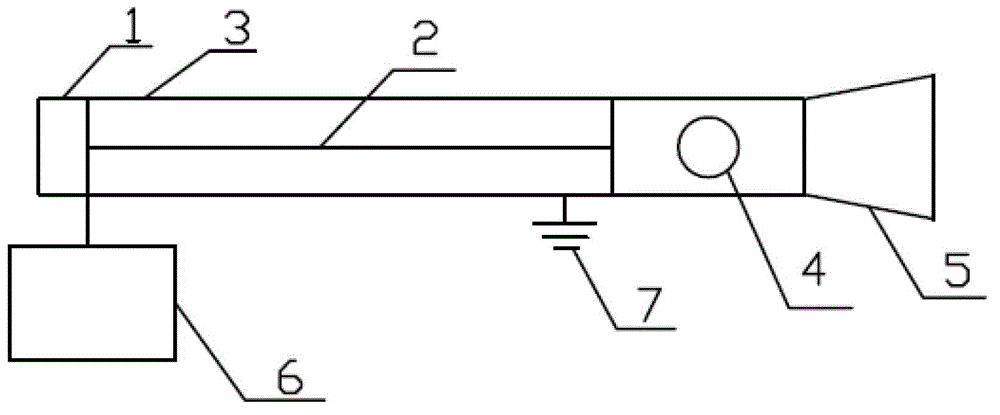

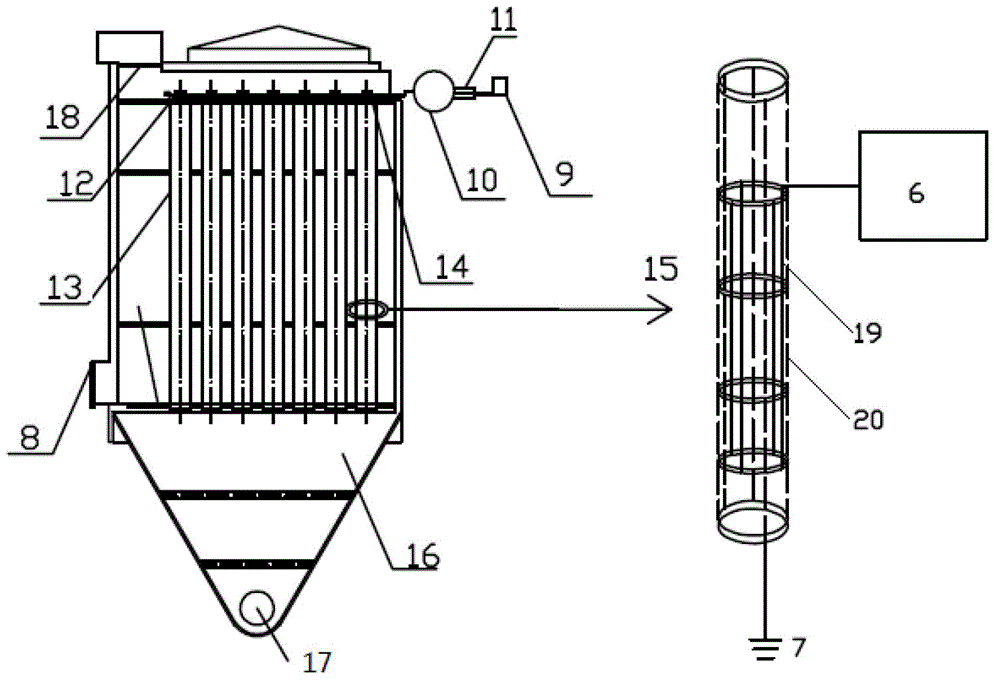

ActiveCN102772971AImprove charging effectIncrease the condensation effectCombination devicesAuxillary pretreatmentParticulatesElectrocoagulation

A superfine particulate matter purifying device comprises a gas discharge-electrocoagulation device and a static enhance bag type dedusting integrated device. The gas discharge-electrocoagulation device comprises an air flow inlet (1), a corona wire (2), a gas discharge tube (3), an air flow outlet divergent pipe (5), a direct current power supply (6) and a grounding electrode (7), and the static enhance bag type dedusting integrated device comprises an air inlet (8), a magnetic valve (9), an air pocket (10), a pulse valve (11), a jetting pipe (12), a filtering bag (13), a jetting hole (14), a dust skeleton (15), a dust hopper (16), a spiral dust discharge valve (17), wires (19) and ground wires (20). The air flow inlet is arranged at one end of the gas discharge tube, the other end of the gas discharge tube is connected with the air flow outlet divergent pipe, the dust skeleton is formed by distributing the wires and the ground wires in a vertical direction at intervals, and the superfine particulate matter purifying device is suitable for smoke dust removing and particularly superfine dust purifying devices for particulate matter (PM) below 2.5.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

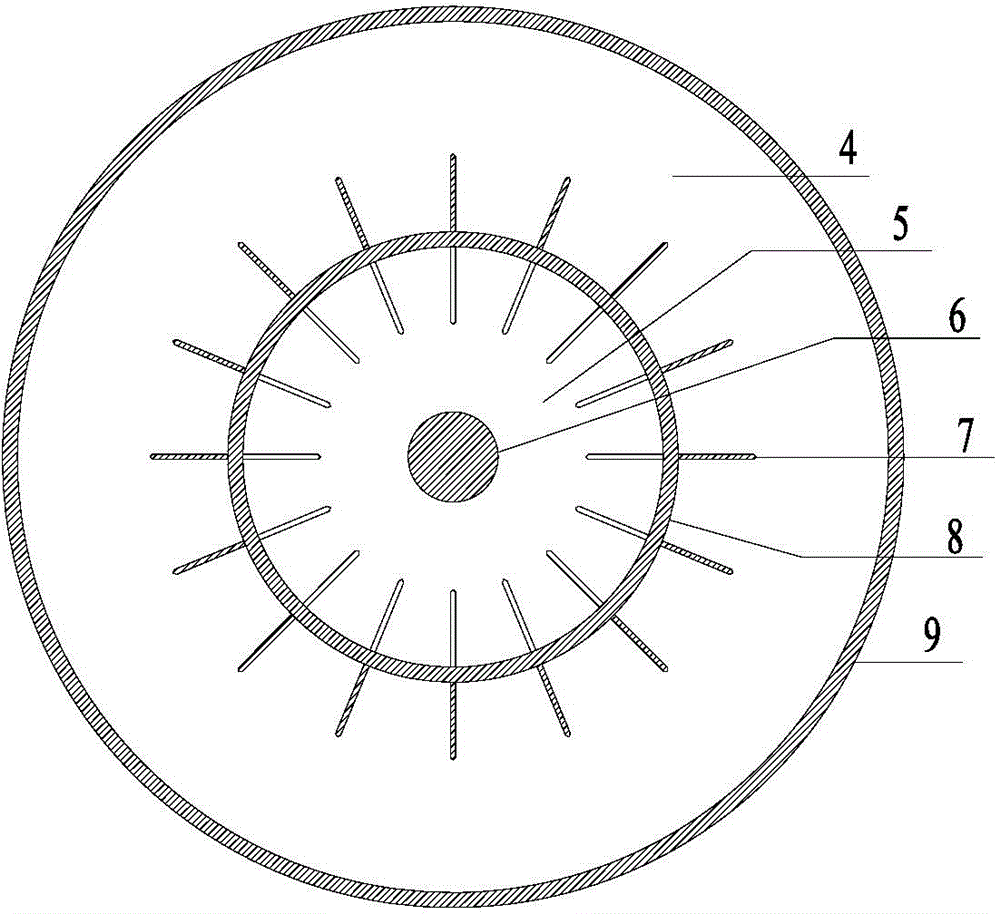

Double-layer sleeve type corona plasma generating device

ActiveCN104128077AInto the uniformAvoid direct impactDispersed particle separationProduct gasProcess engineering

The invention relates to a double-layer sleeve type corona plasma generating device comprising a gas buffering chamber, an outer-layer processing chamber and an inner-layer processing chamber. A gas inlet is provided on the outer side of the gas buffering chamber. An insulation baffle is provided on the inner side of the buffering chamber. Airway through holes are provided on the baffle. Gas to be processed sequentially enters the outer-layer processing chamber and the inner-layer processing chamber through the airway through holes. When the gas is completely processed, the gas is discharged from a gas outlet connected to an end of the inner-layer processing chamber. According to the invention, with the buffering chamber, the gas to be processed can be uniformly and stably delivered in the processing chambers. The chambers adopt a coaxial multi-pin-plate structure, such that electric field unevenness coefficient is high, discharge voltage is low, and thus operation energy consumption is reduced. Also, voltage adjustable range is wide, and application scope is wide. With the inner-outer double layer structure, low temperature plasma dedusting and waste gas degradation are separated, such that the influence of dust in waste gas to waste gas molecule degradation is avoided, and energy utilization rate is improved. Also, reactor structure is compact. The device provided by the invention is suitable for the fields such as waste gas treatment, sterilization and disinfection, ozone synthesis, and the like.

Owner:XI AN JIAOTONG UNIV

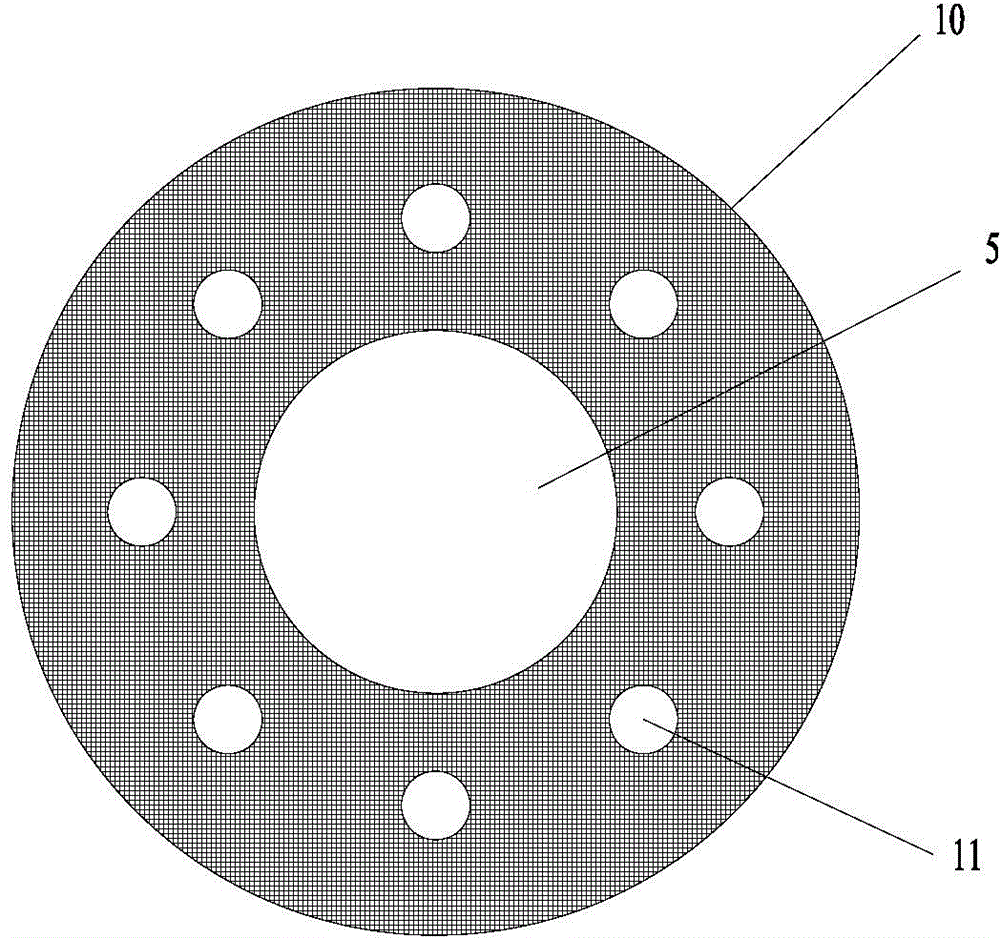

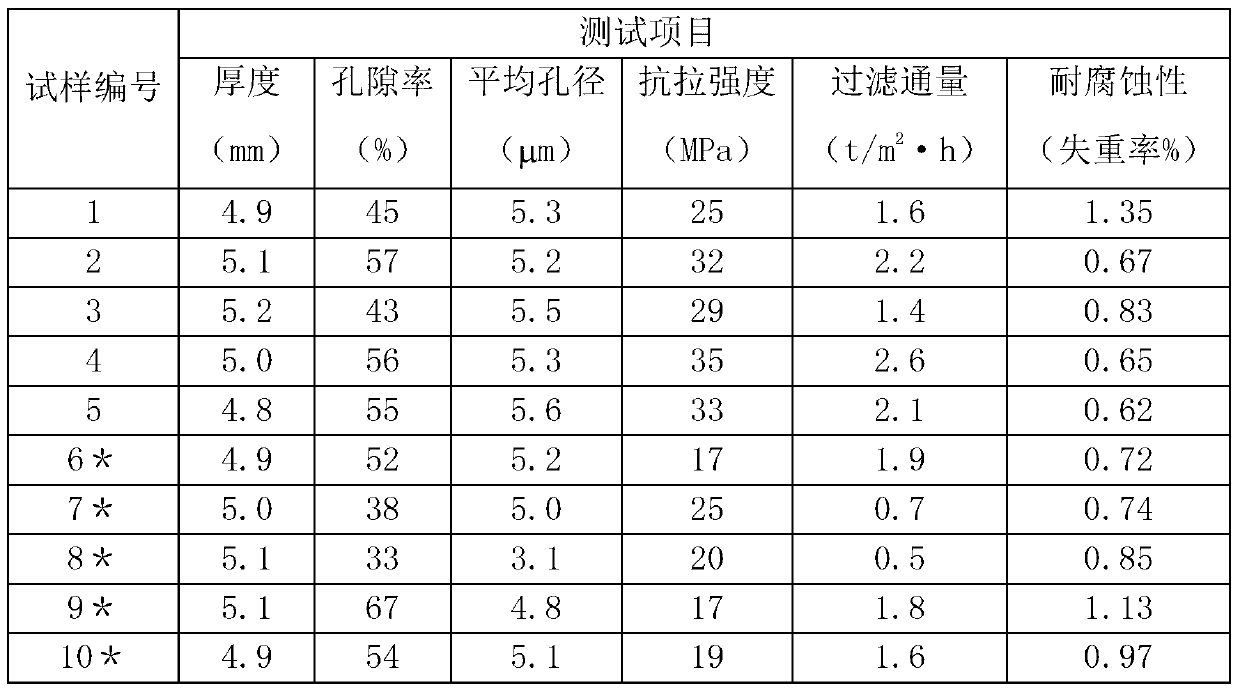

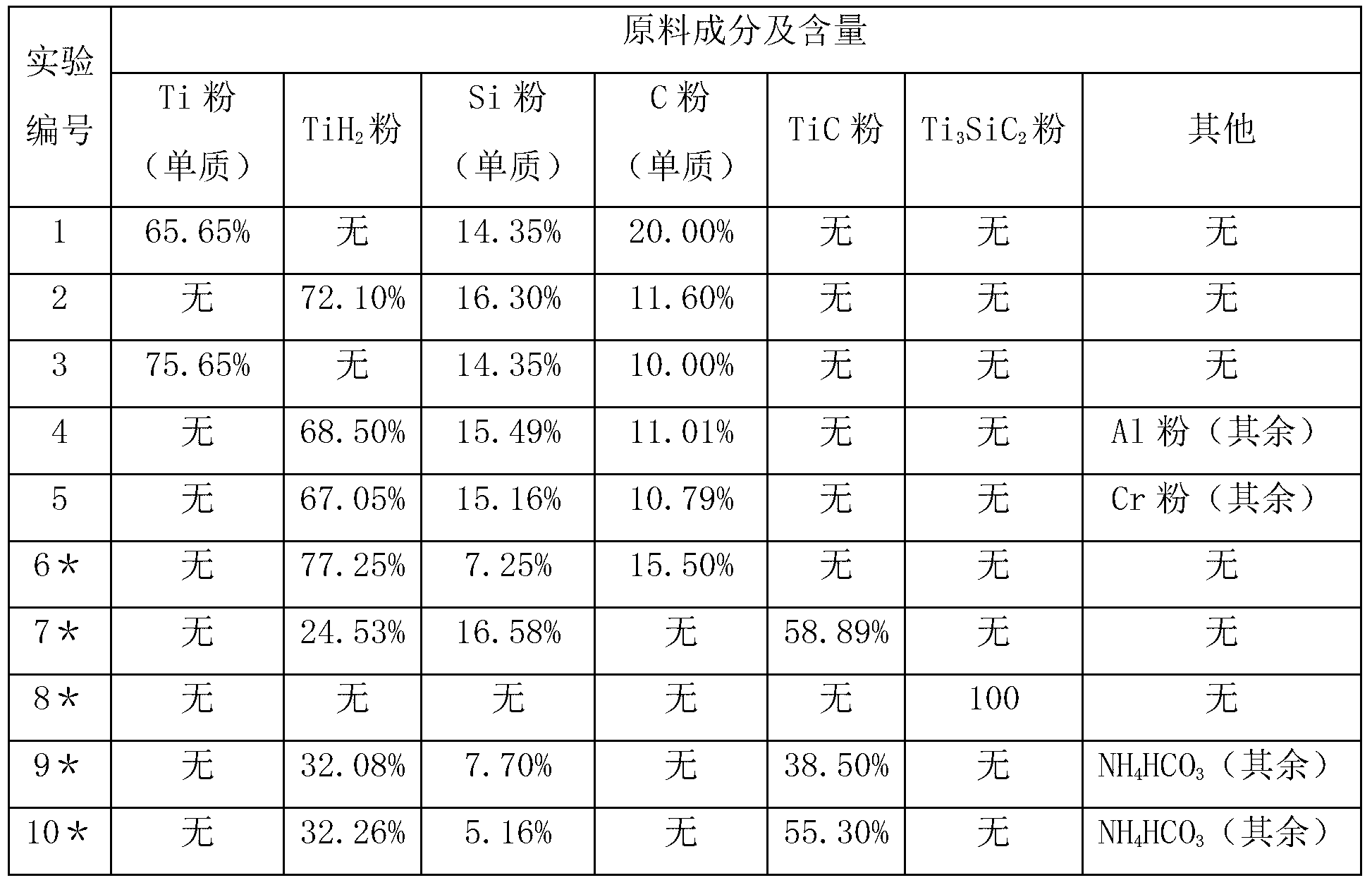

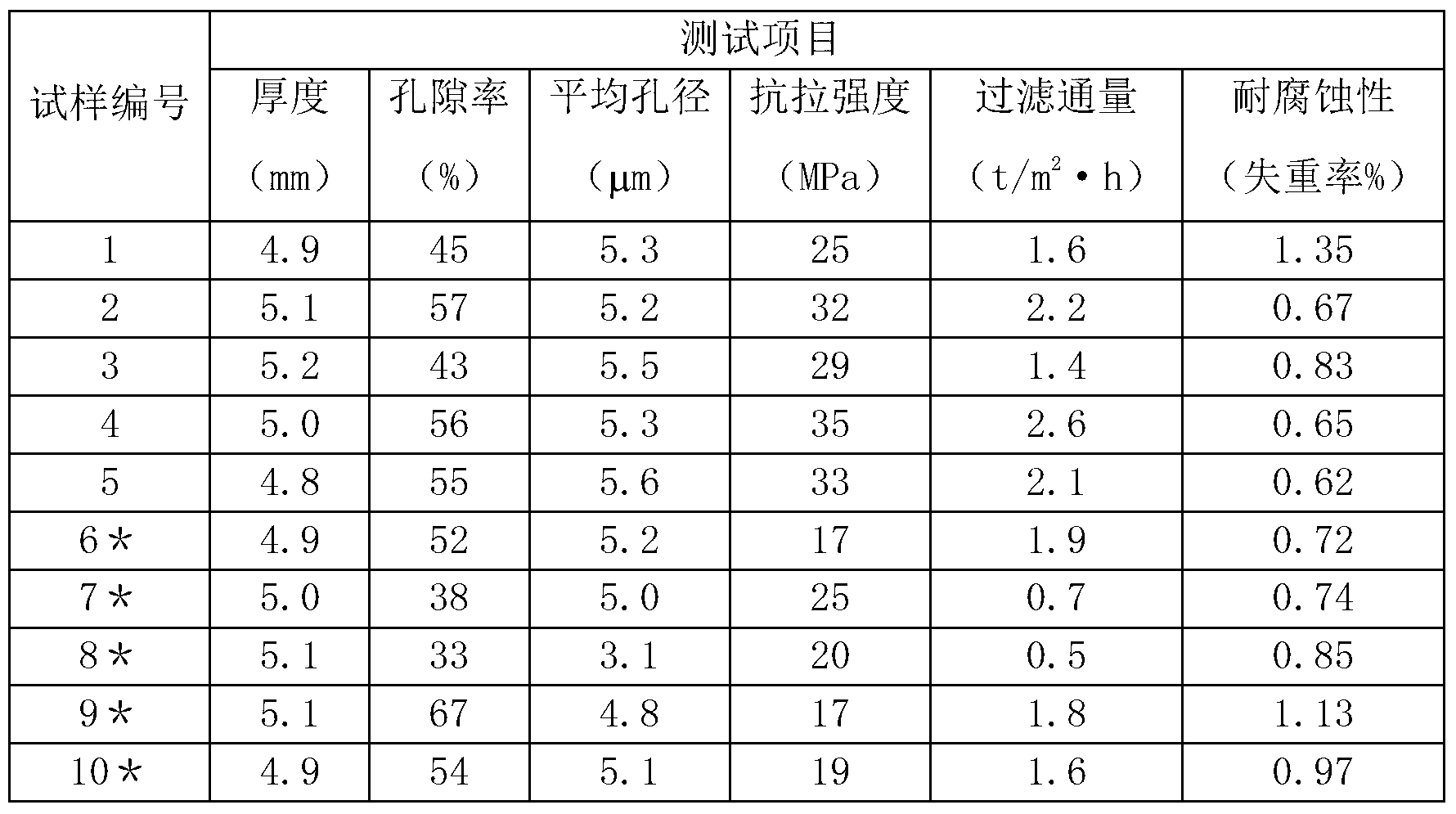

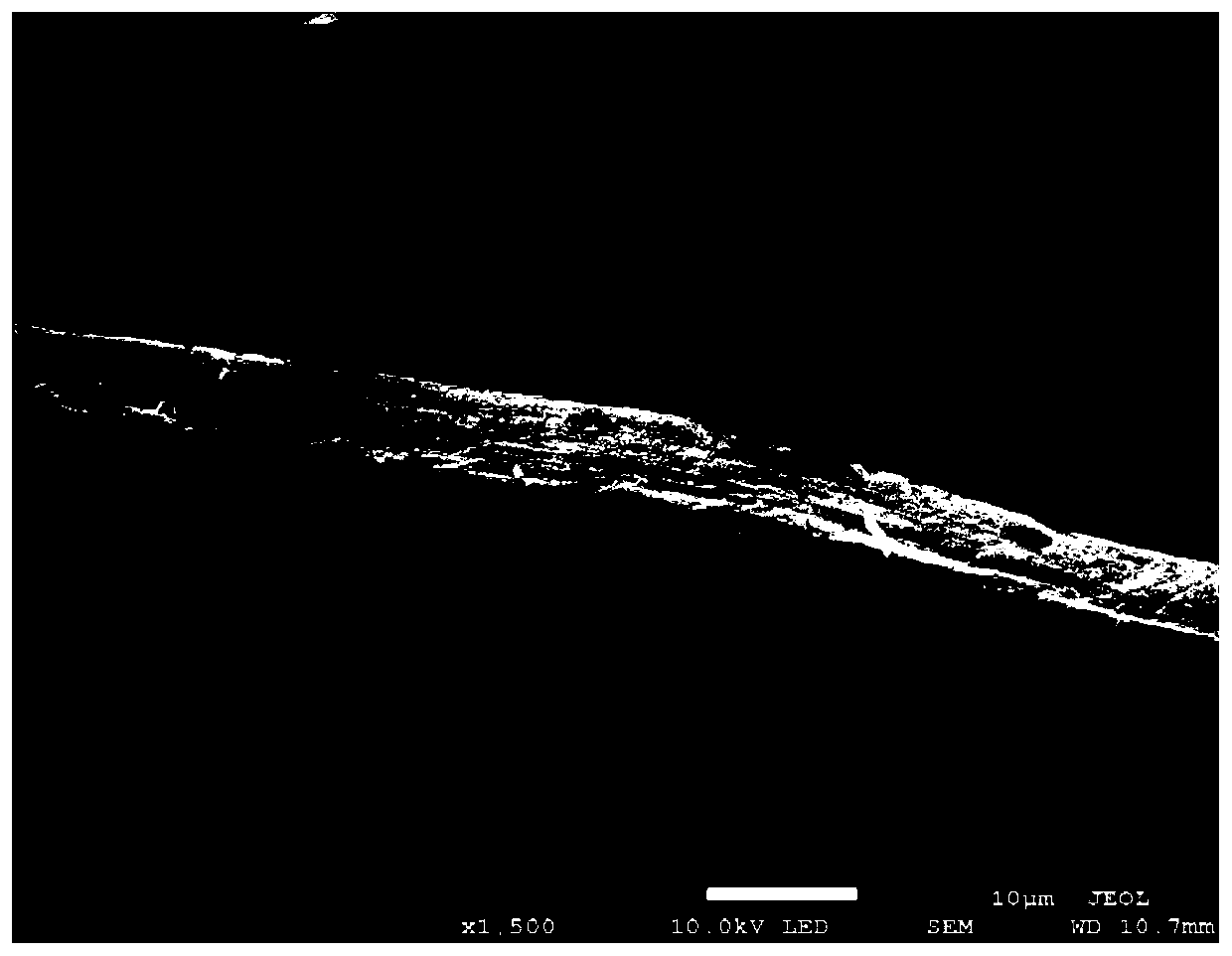

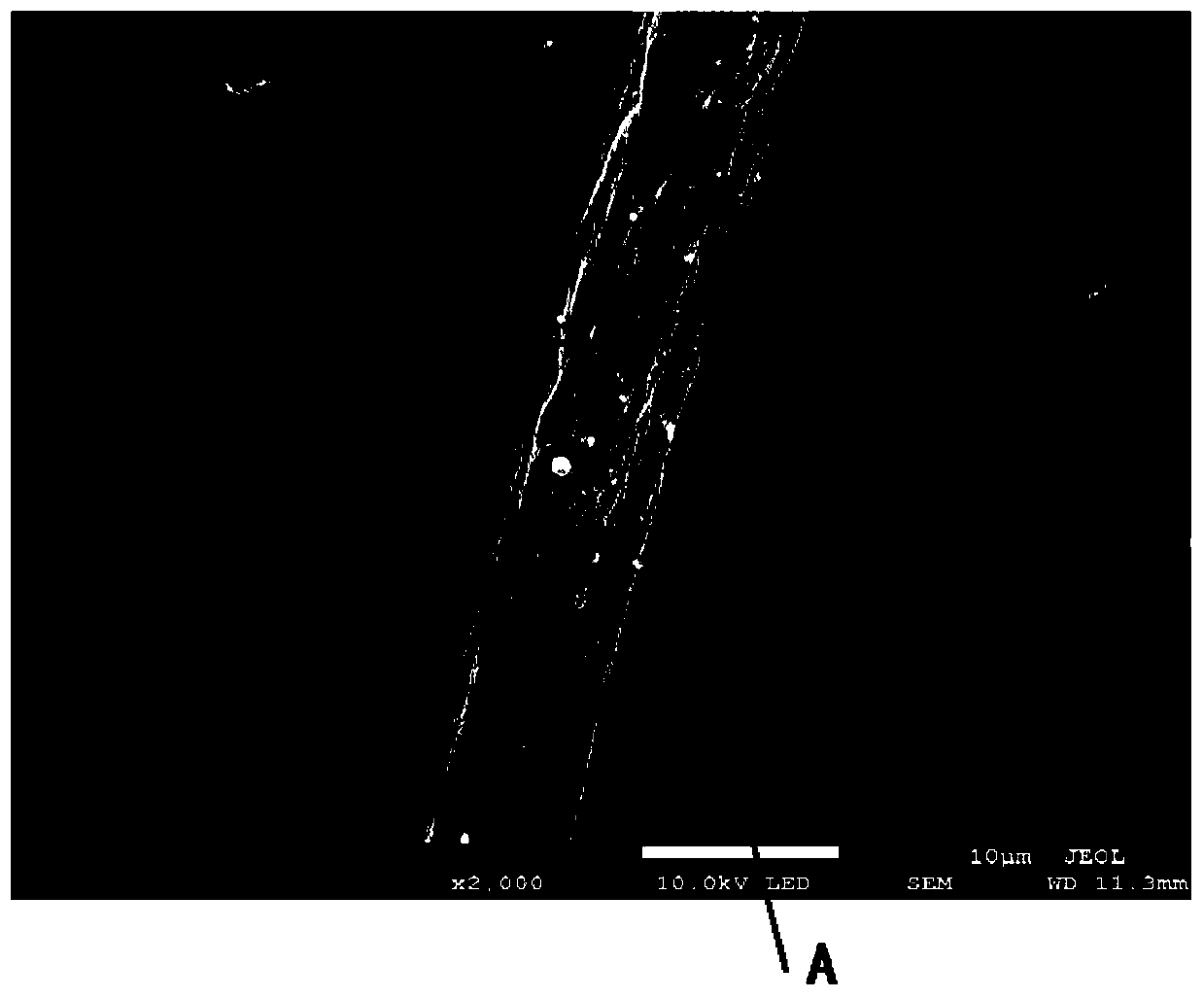

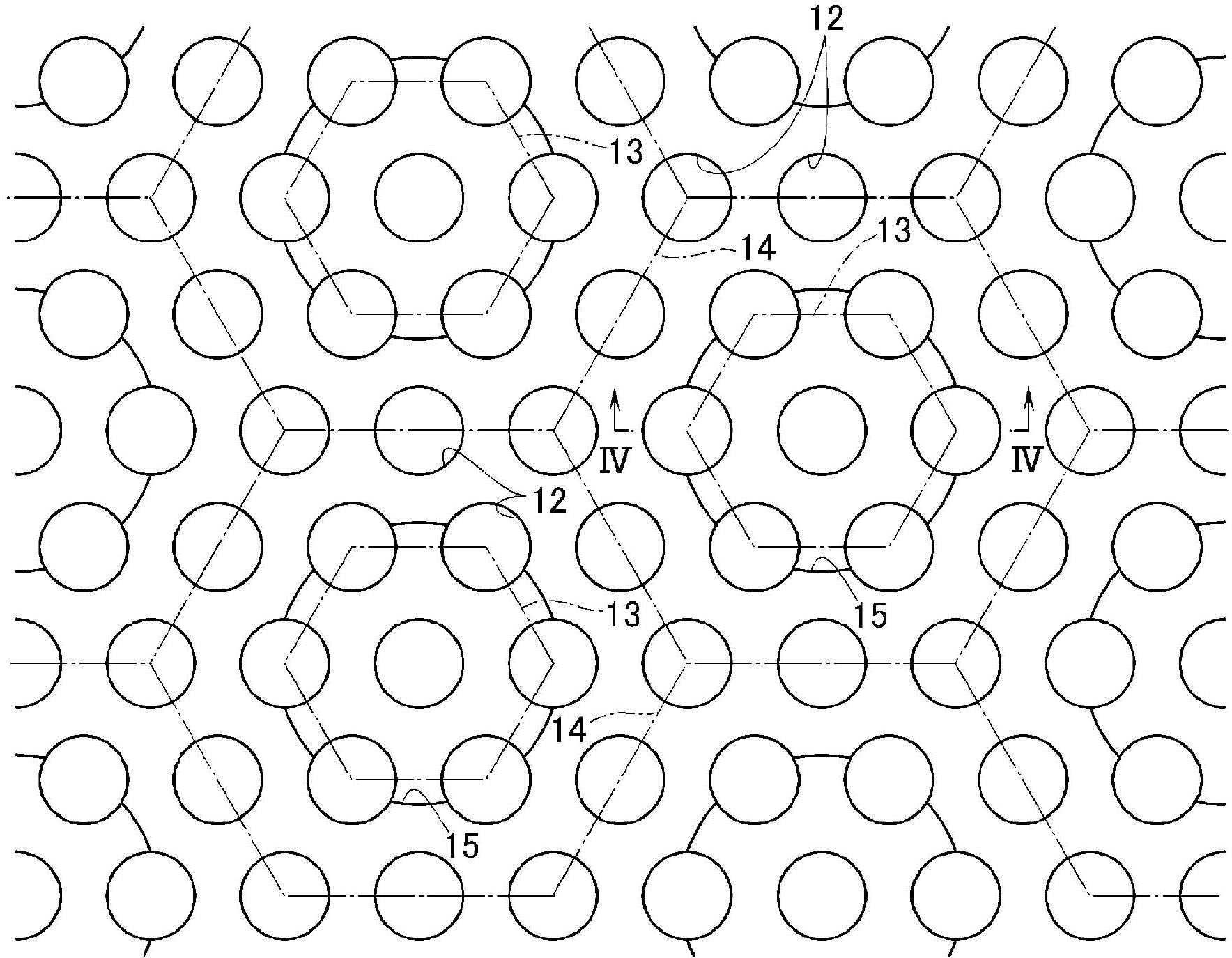

Sintered porous material and filter element using same

ActiveCN103341291AImprove corrosion resistanceSmall tortuosity factorMembrane filtersFiltration separationPorosityFiltration

The invention discloses a sintered porous material with high corrosion resistance and a filter element using the same. The sintered porous material disclosed by the invention has the following characteristics: a) the sintered porous material is mainly composed of Ti, Si and C which account for more than 90 wt% of the sintered porous material, wherein the Ti accounts for 60-75 wt% of the Ti, Si and C, and the Si accounts for 10-20 wt% of the Ti, Si and C; b) the C in the sintered porous material mainly exists in the form of a Ti3SiC2 three-element MAX-phase compound, and is approximately uniformly distributed in the porous material; and c) the test proves that the pure water filtration flux of the sintered porous material, of which the porosity is 30-60%, the average pore size is 0.5-50 mu m, the tensile strength is greater than or equal to 23 MPa and the thickness is less than or equal to 5 mm, is greater than or equal to 1t / m<2>.h under the filtration pressure difference of 0.05 MPa, and the weight loss rate of the sintered porous material is less than 1.5% after being soaked in a 5 wt% hydrochloric acid solution at room temperature for 48 hours. The sintered porous material disclosed by the invention has very excellent corrosion resistance.

Owner:成都易态膜分离技术有限公司

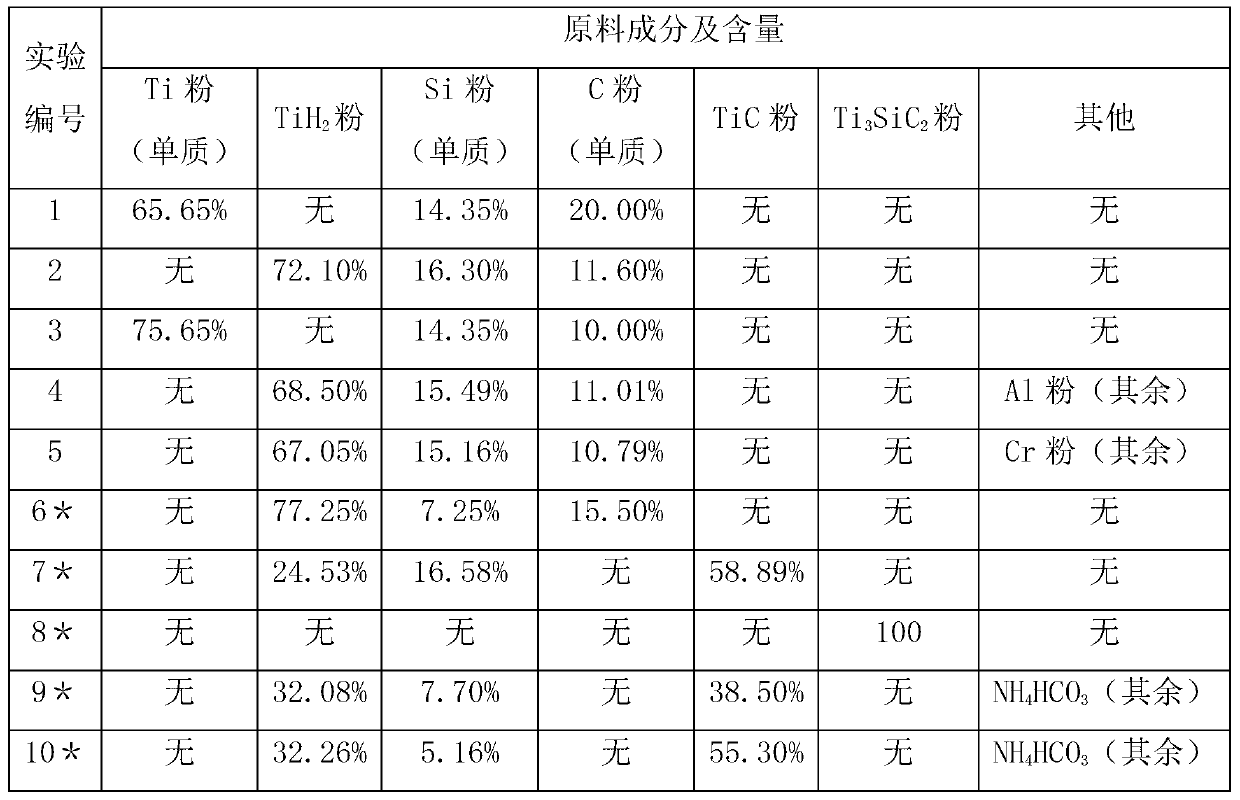

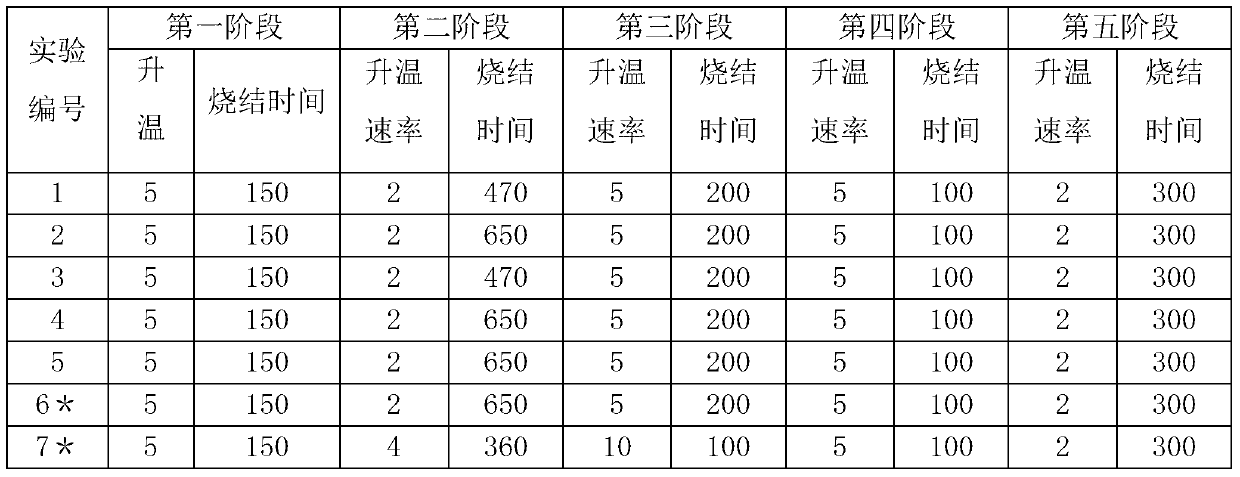

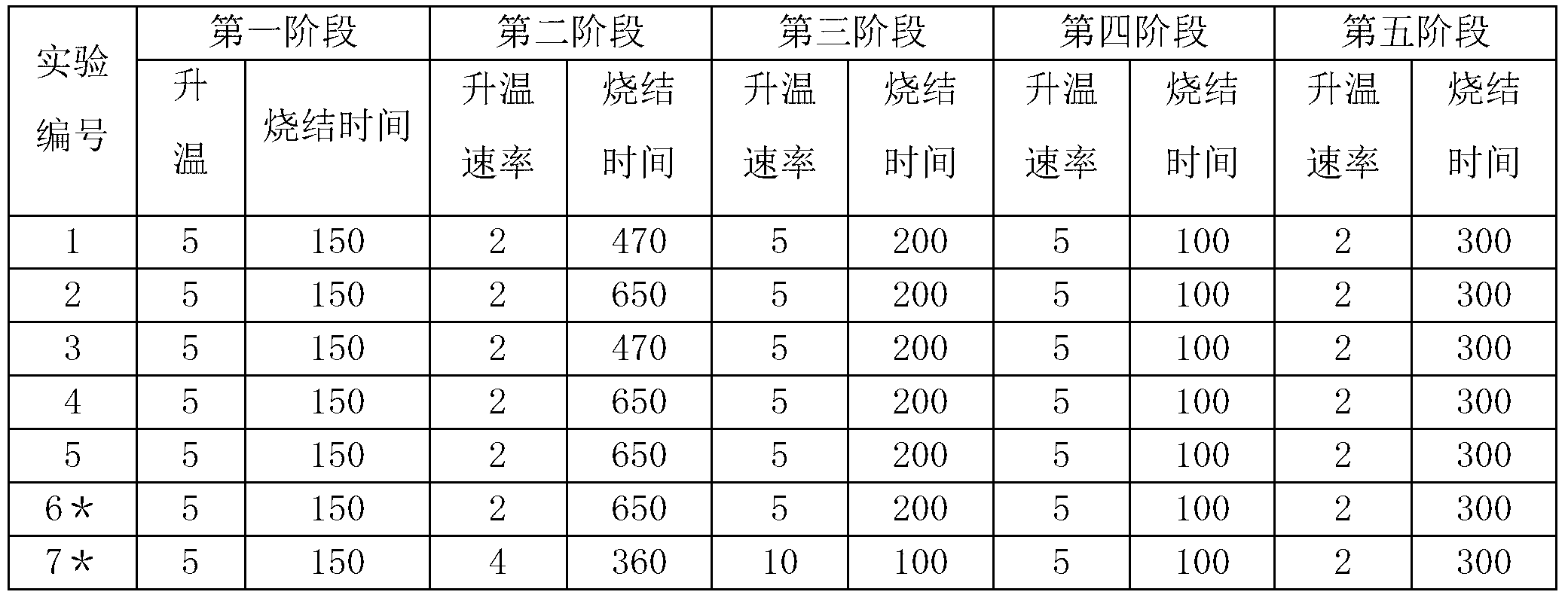

Preparation method of sintered porous material

ActiveCN103320638AImprove corrosion resistanceSmall tortuosity factorCeramicwareRoom temperatureMaterials science

The invention discloses a preparation method of a sintered porous material with strong corrosion resistance. The preparation method comprises the steps of: sequentially granulating, drying, forming and sintering mixed powder of at least one of Ti powder and TiH2 power, as well as Si powder and C powder so as to prepare the sintered porous material. The content of Ti in the sintered porous material prepared from the raw materials is 60-75 percent of the total weight of the Ti, Si and C, and the content of Si is 10-20 percent of the total weight of the Ti, the Si and C; the sintering schedule comprises five stages, namely firstly gradually raising the sintering temperature from room temperature to 450 DEG C, wherein the temperature raising rate is controlled to be 1-25 DEG C / min, and the total sintering time of the first stage is 30-600min; secondly, gradually raising the sintering temperature from 450 DEG C to 900 DEG C, wherein the temperature raising rate is controlled to be 1-20 DEG C / min, the total sintering time of the second stage is 180-1000min; thirdly, gradually raising the sintering temperature from 900 DEG C to 1000 DEG C, wherein the temperature raising rate is controlled to be 1-20 DEG C / min, and the total sintering time of the third stage is 30-1000min.

Owner:CHENGDU INTERMENT TECH

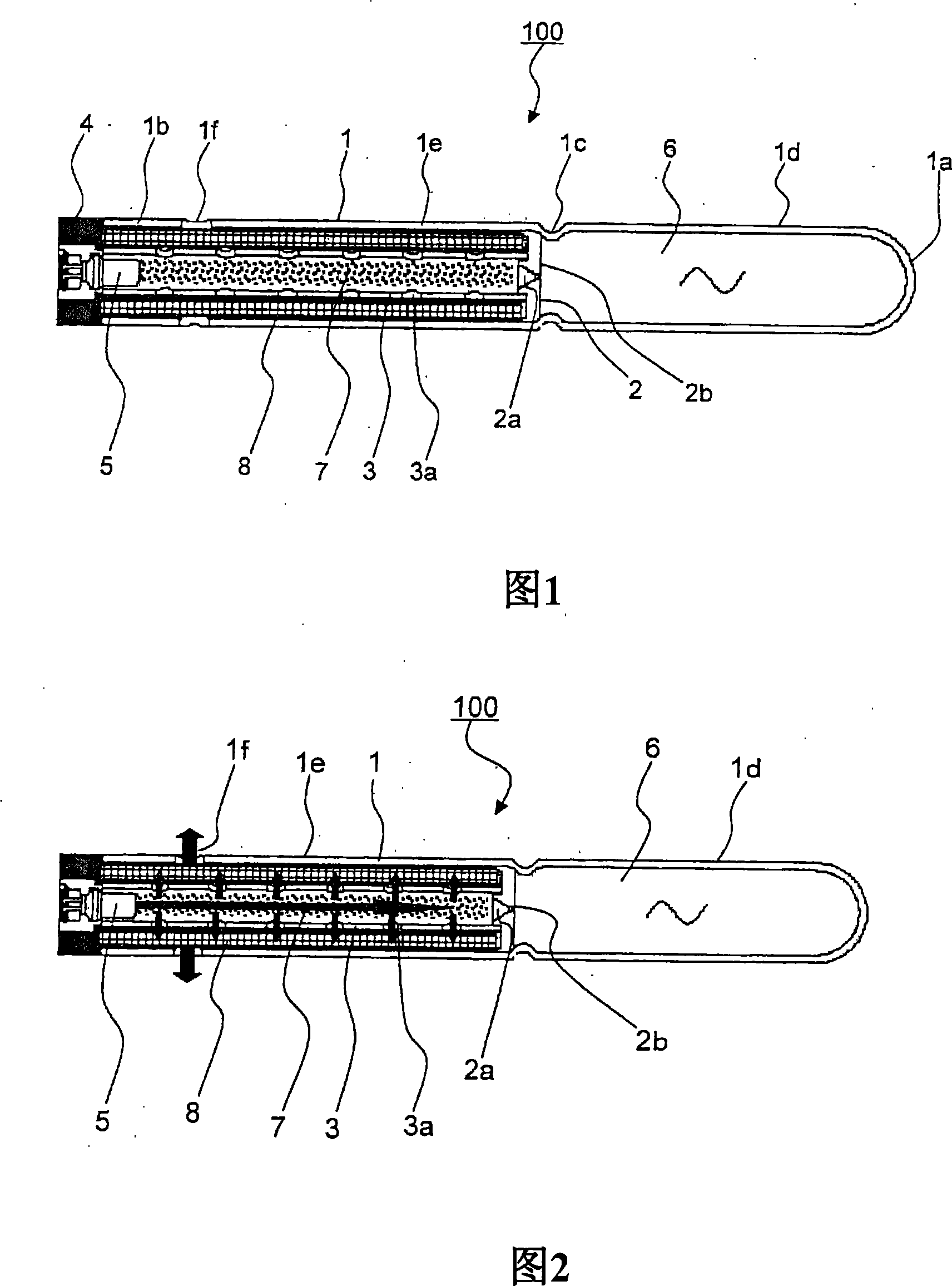

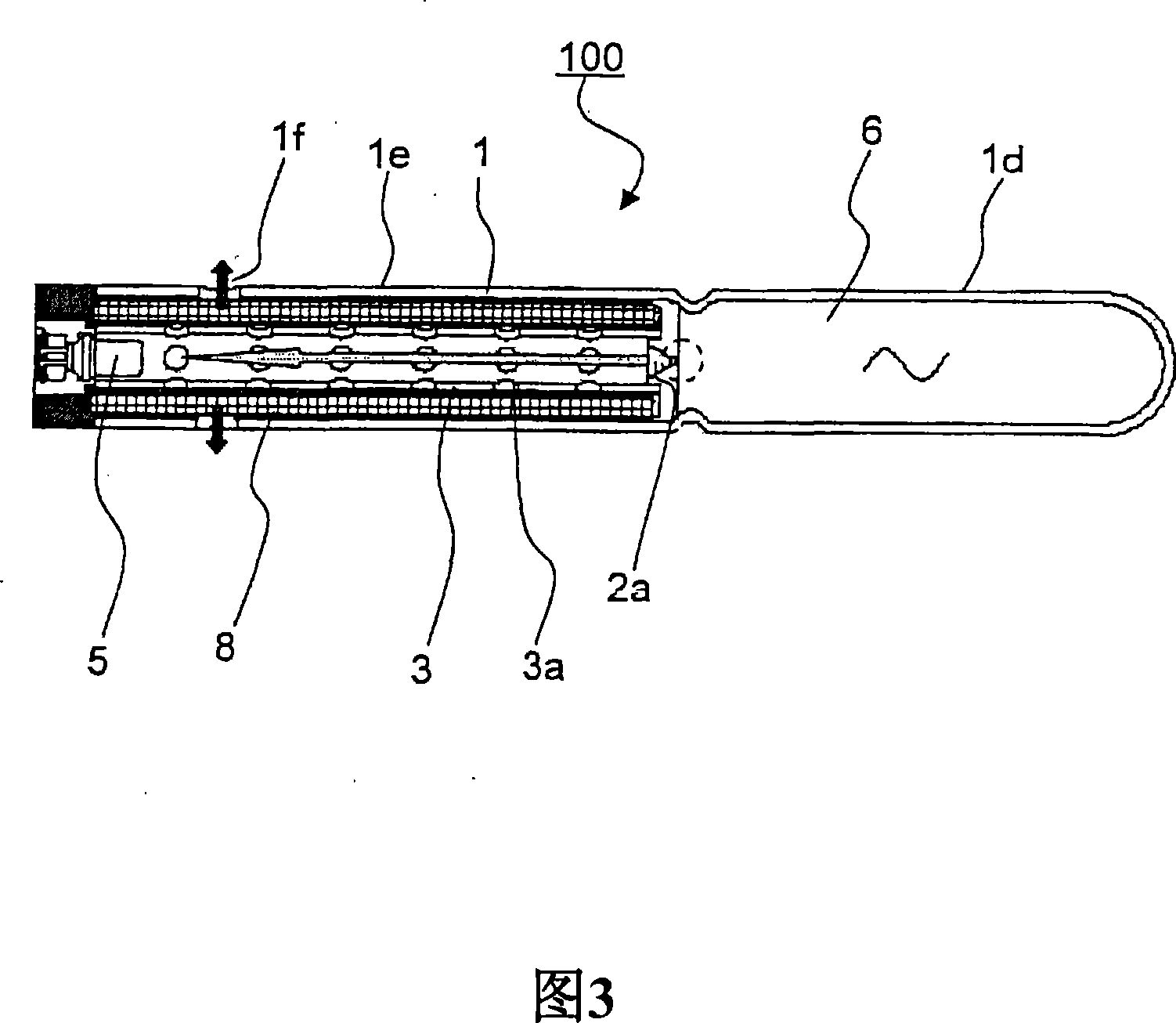

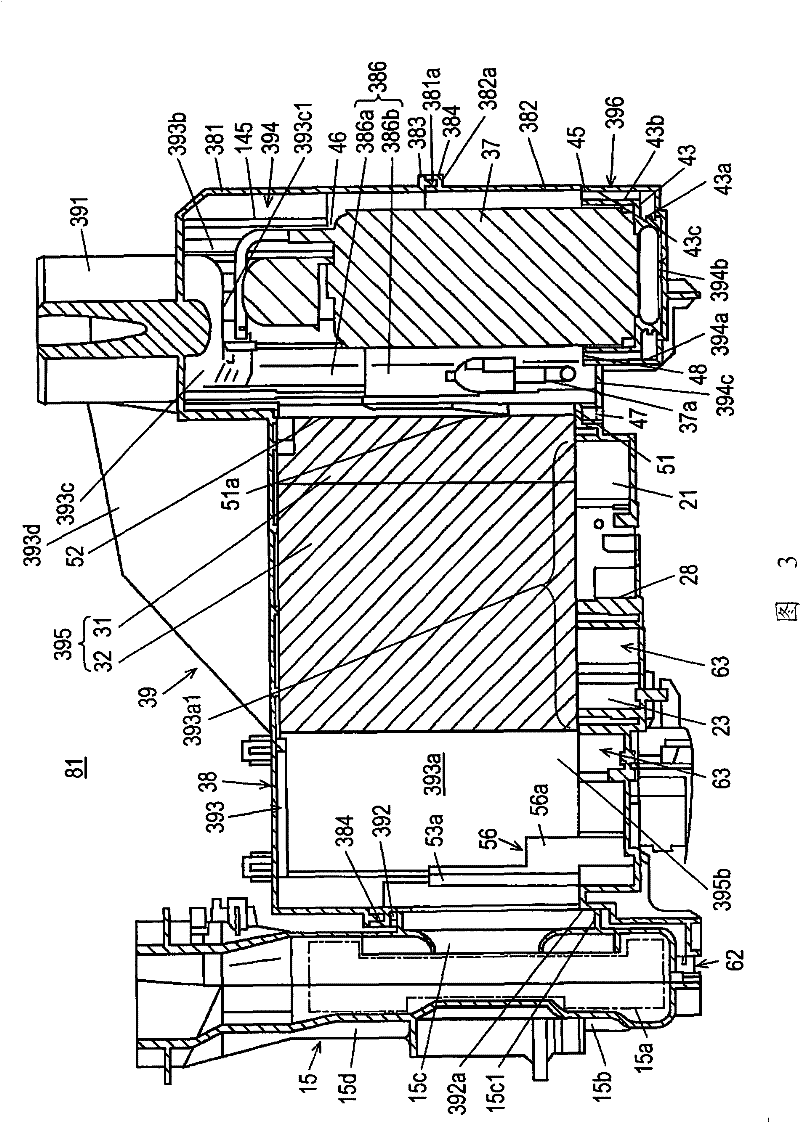

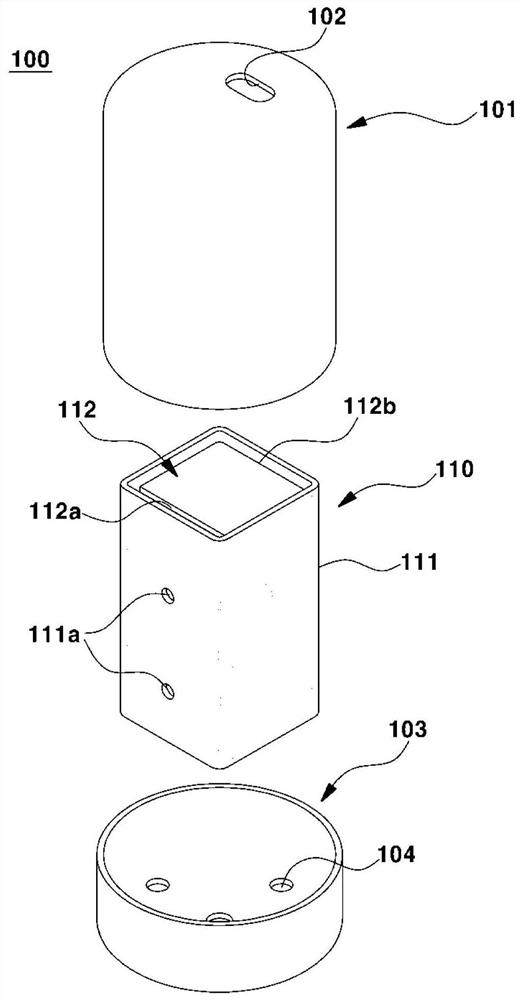

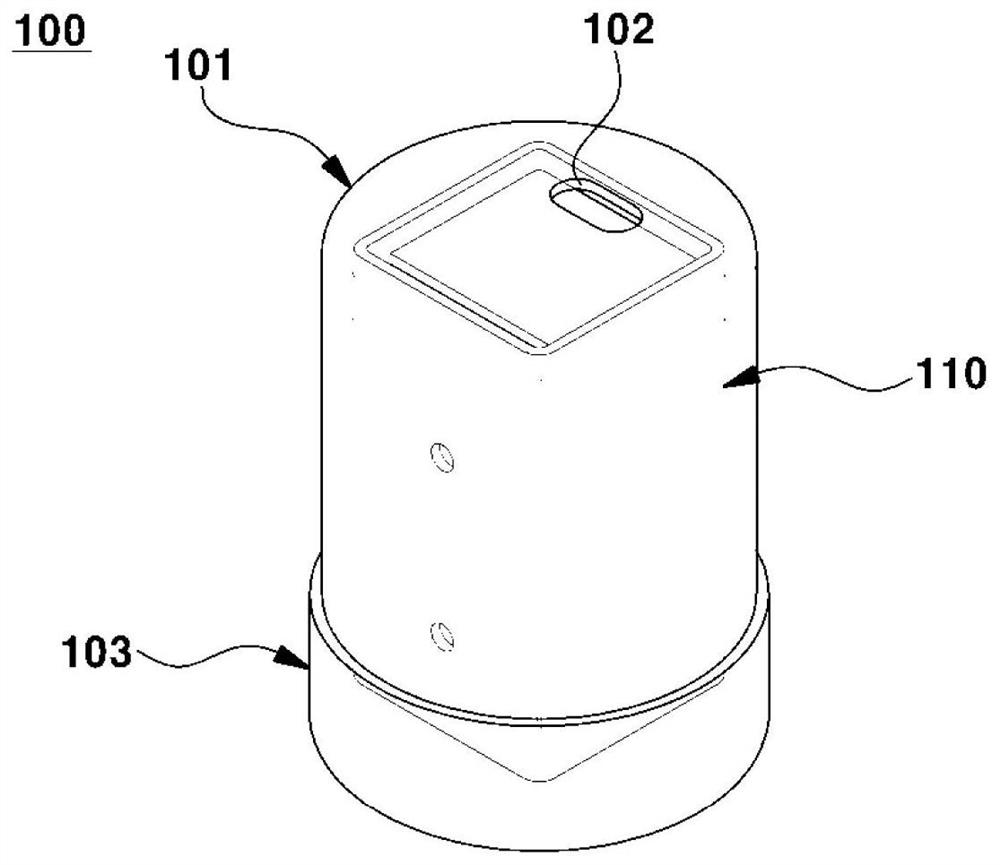

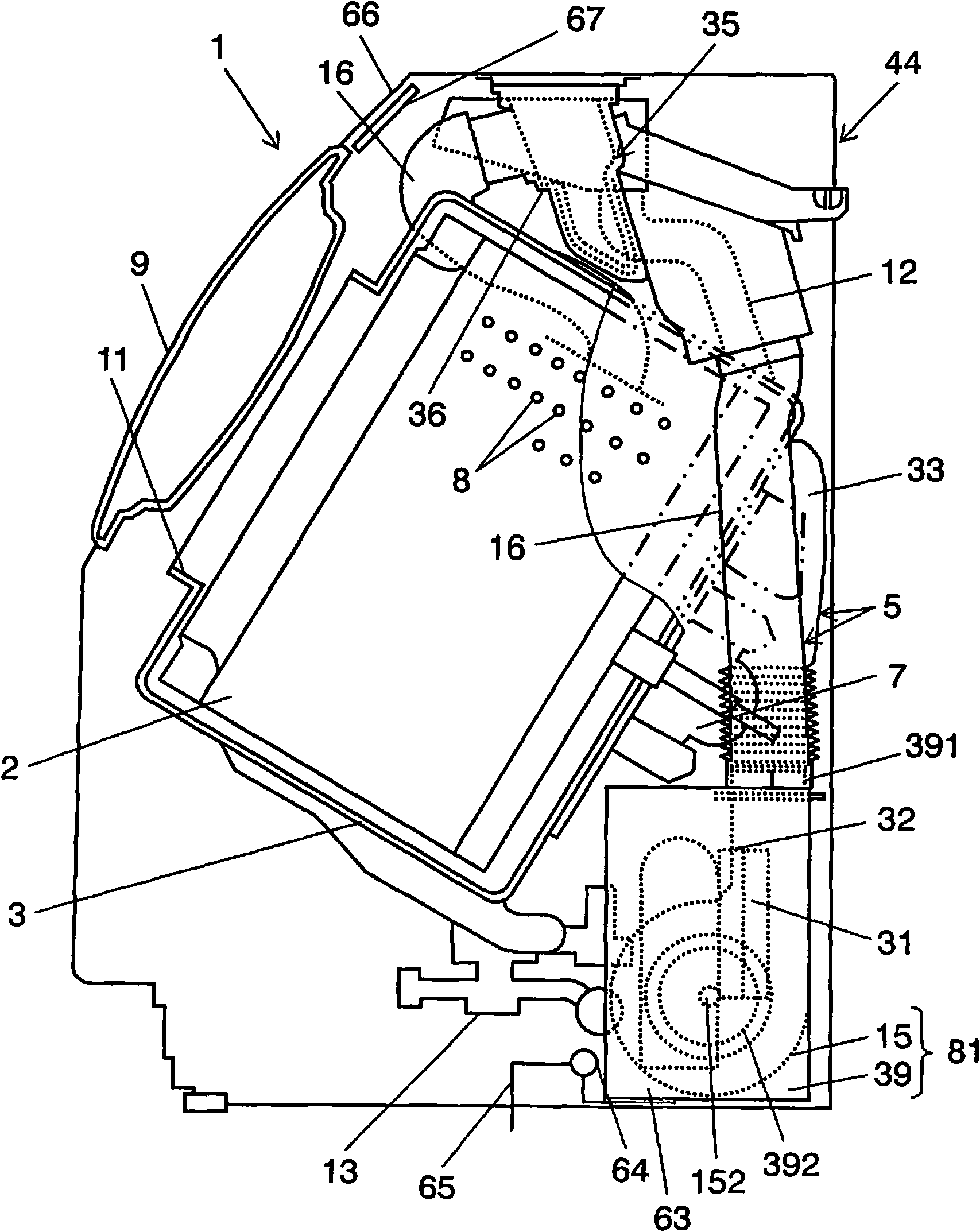

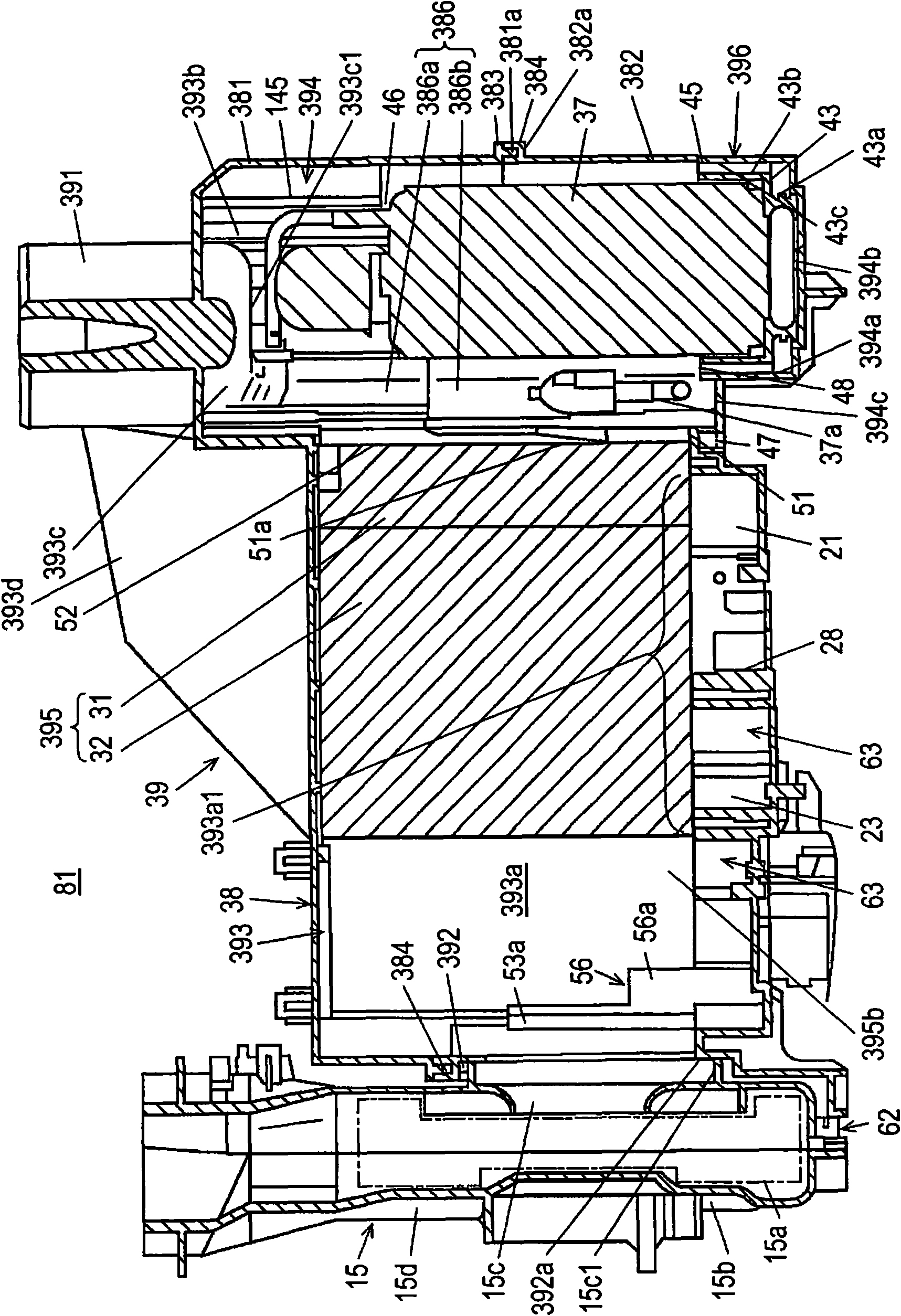

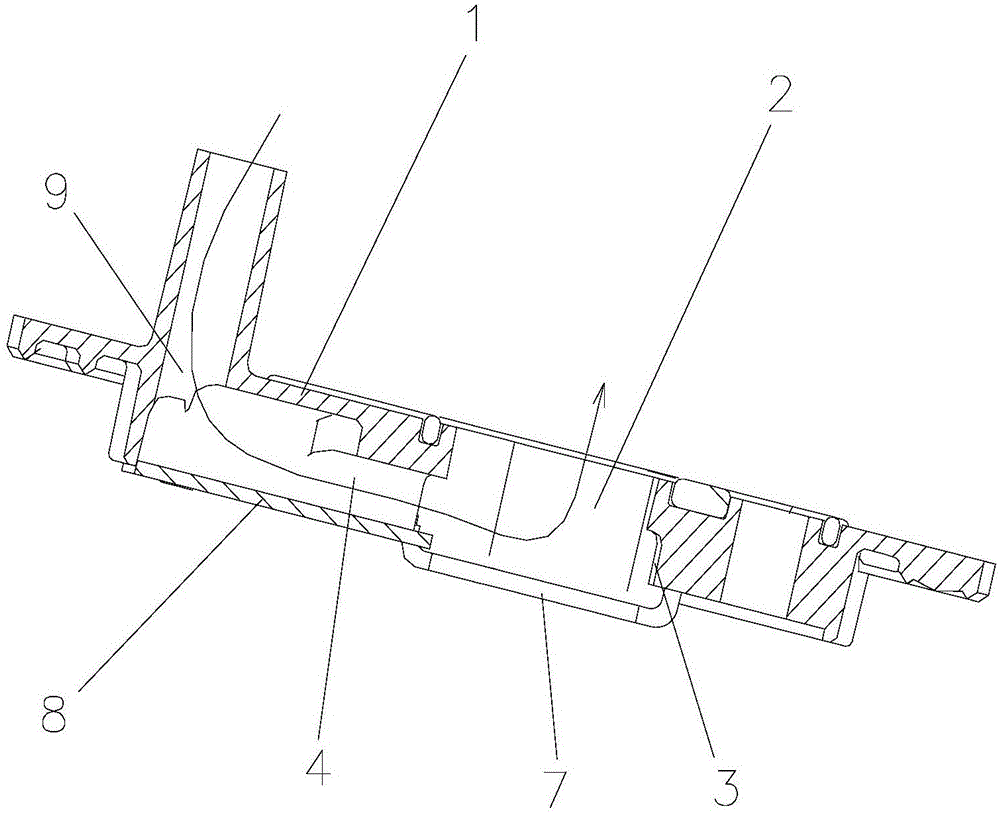

Inflator

InactiveCN101138974AMaintenance timeSquirt out quicklyPedestrian/occupant safety arrangementGas generation devicesEngineeringHeat of combustion

The inflator satisfies both of the strength of a first impact of the airbag and a keeping operation for a duration of expansion of the airbag. The inflator 100 supplies gas into an airbag mounted on a motor vehicle and deploys the same. A first chamber 1e where a gas-blowing outlet 1f is provided and a gas-generating agent 7 generating the gas while being ignited by means of an initiator 5 is encapsulated. A filter 8 is arranged between the gas-blowing outlet 1f of the first chamber 1e and the gas-generating agent 7, absorbs heat of combustion of the gas-generating agent 7, and captures a residue thereof. A second chamber 1d is partitioned from the first chamber 1 e with a flow amount control member 2 where the compressed gas 6 is encapsulated. A blocking member 2b of a control hole 2a of the flow amount control member 2 is provided which opens the control hole 2a by being ruptured or removed by expanding pressure of the gas-generating agent 7 .

Owner:TAKATA CORPORATION

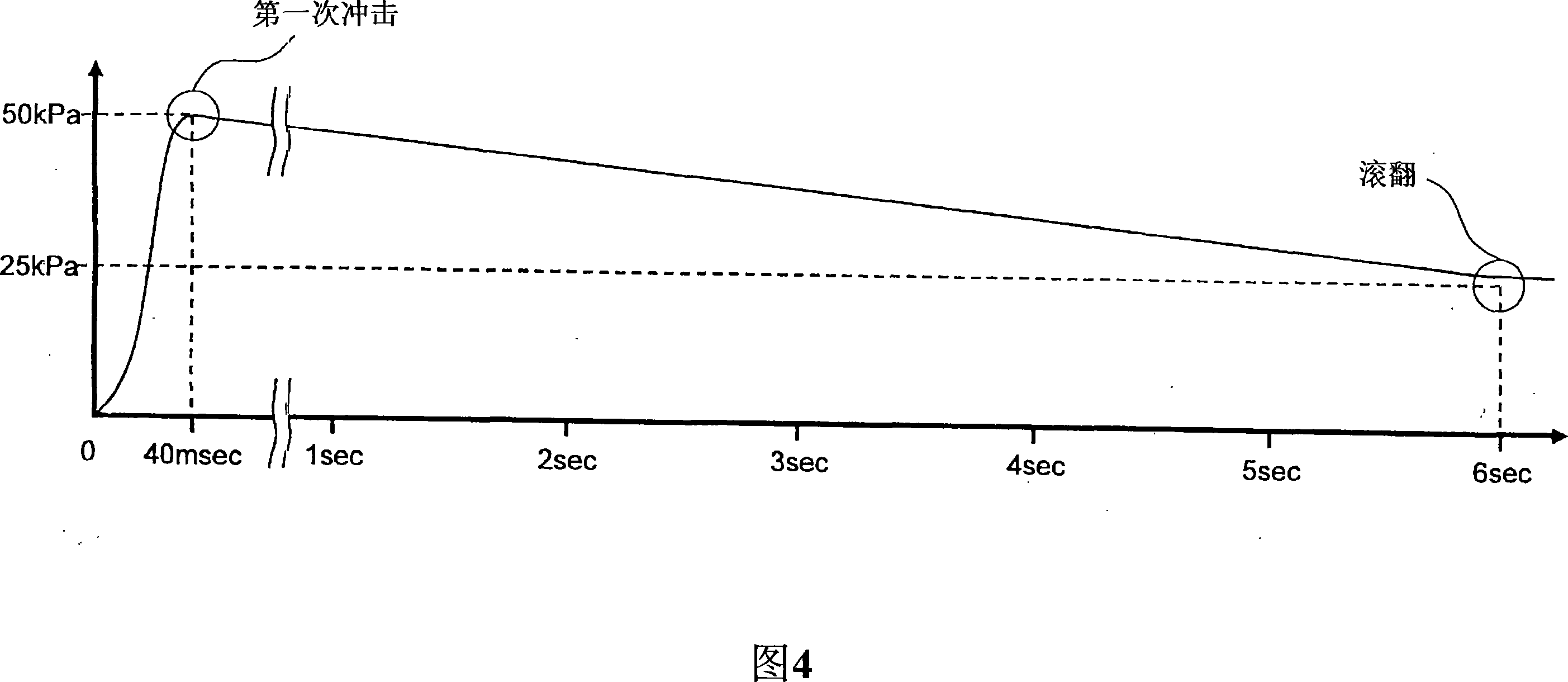

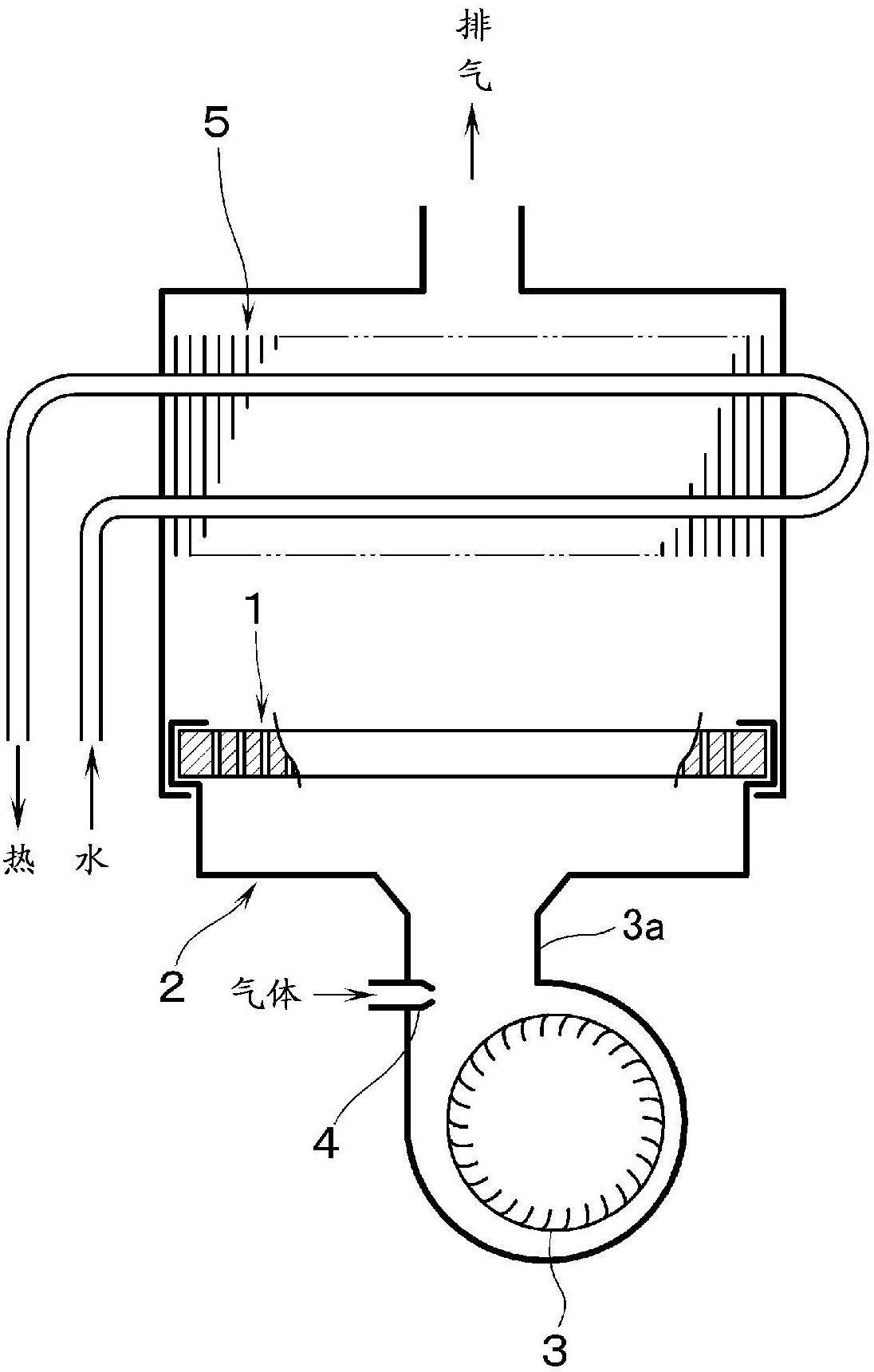

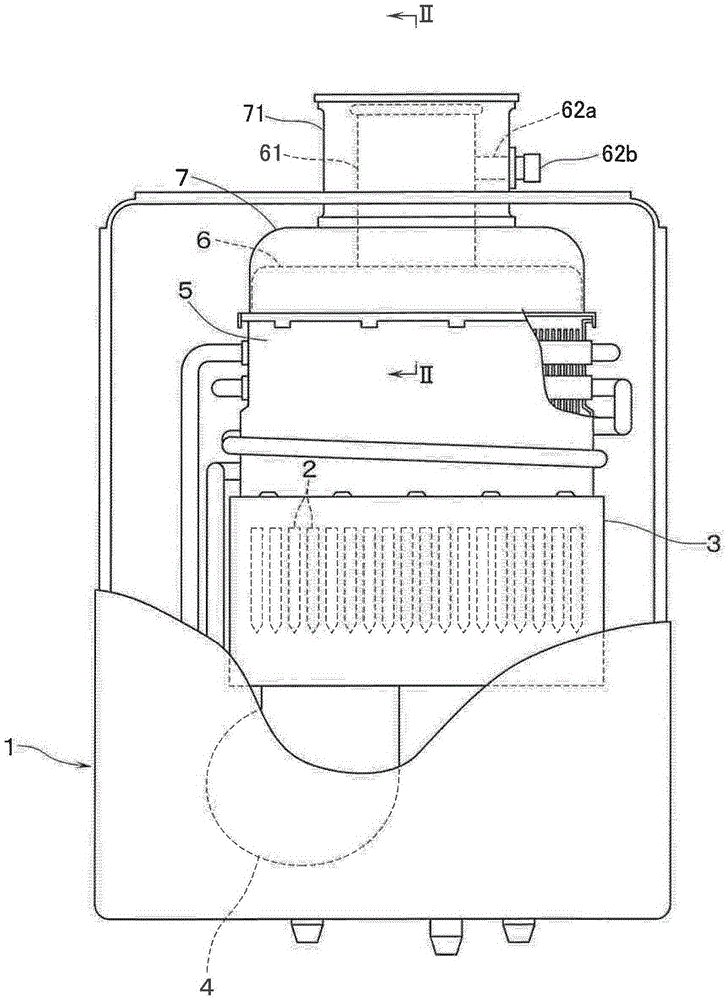

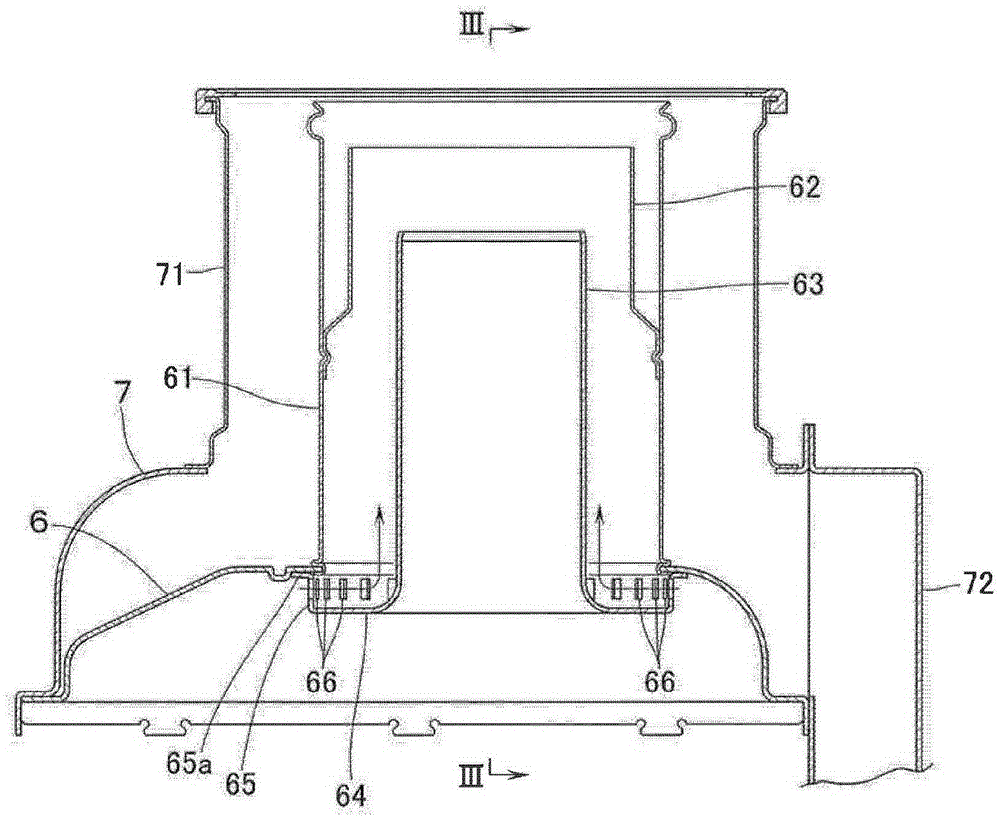

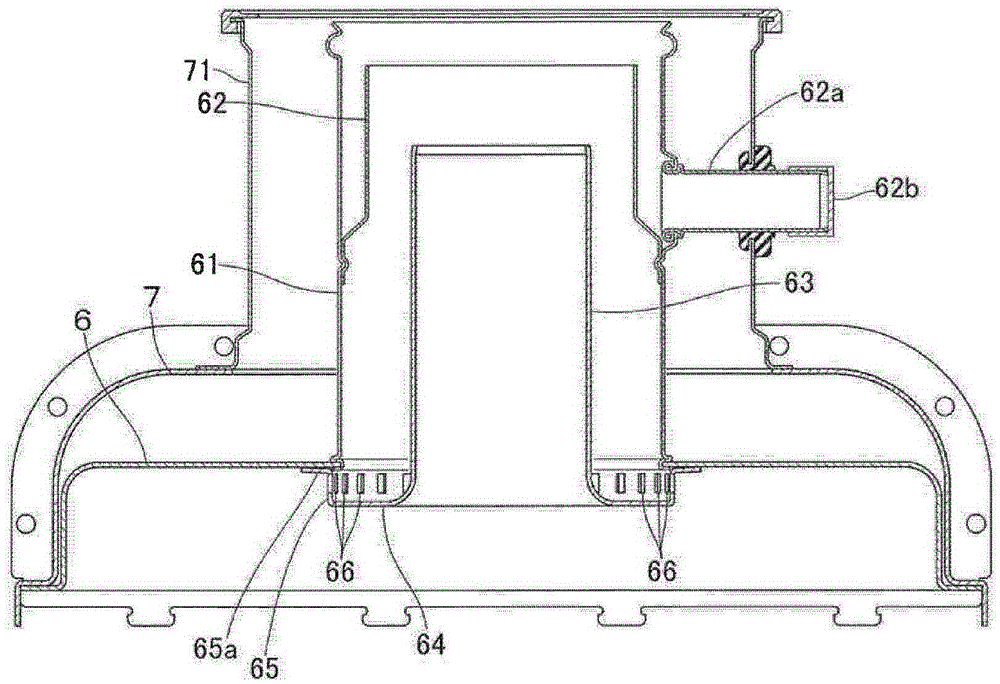

Combustion device

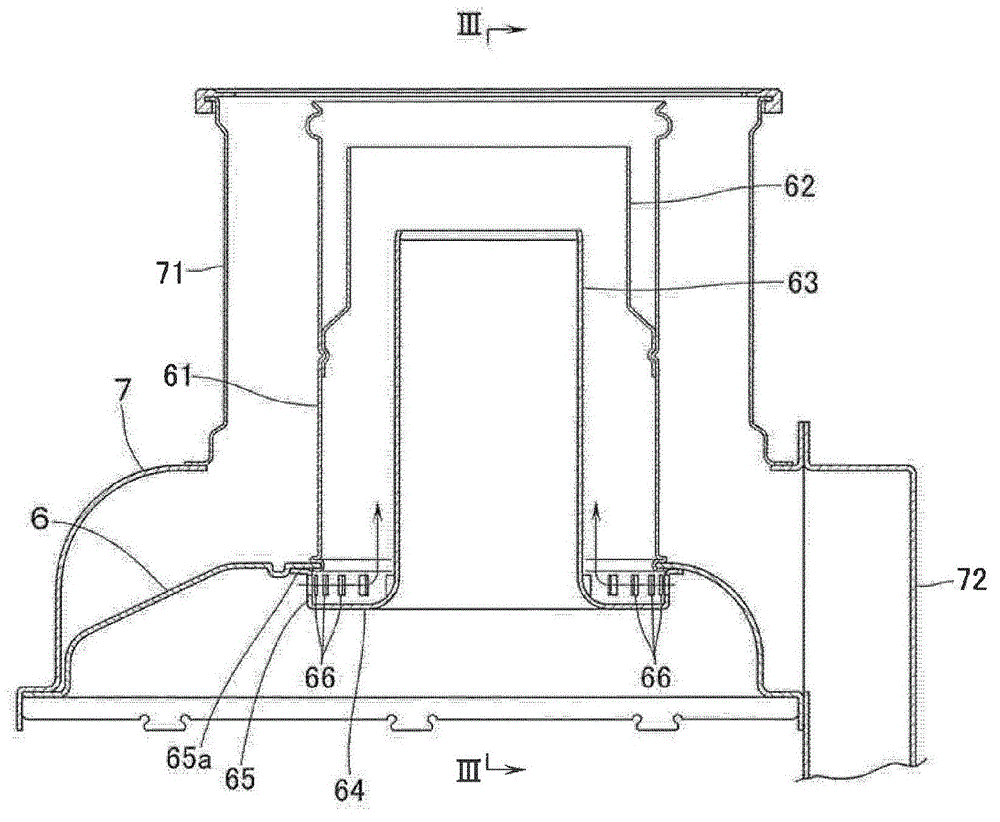

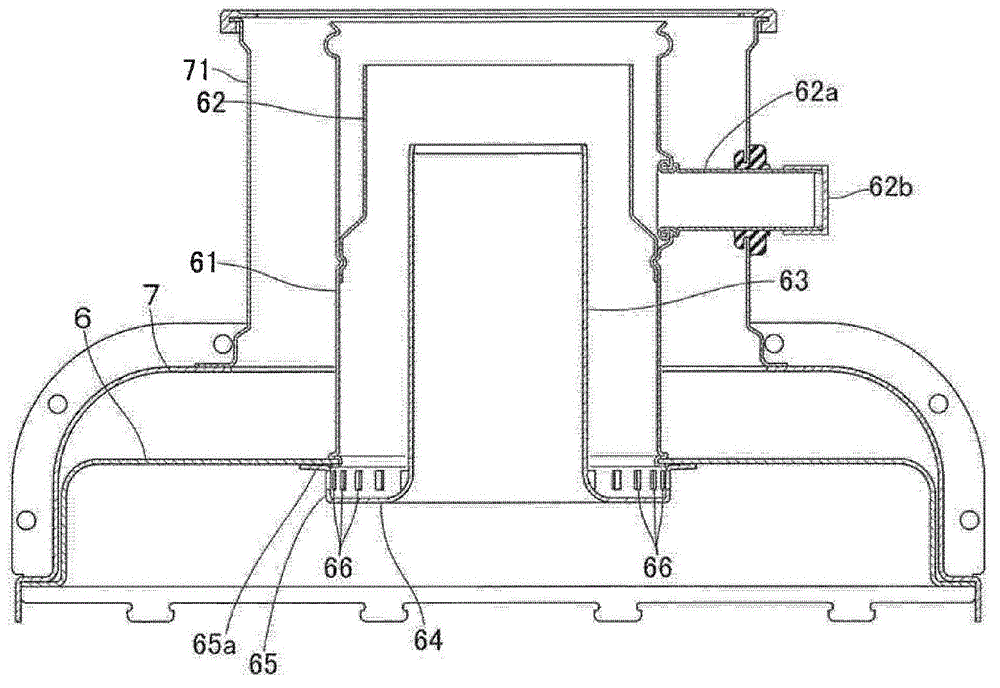

ActiveCN103148492AReduce resonance noisePassing resistance is smallBafflesChimneysCombustorHelmholtz resonator

The invention provides a combustion device comprising a combustion frame provided with a combustor therein, a fan supplying air for combustion into the combustion frame, a heat exchanger disposed above the combustion frame and an exhaust hood arranged above the heat exchanger. Combustion exhaust is discharged via a barrel-shaped exhaust port extending from the upper wall portion of the exhaust hood to the top. The combustion device comprises an exhaust restricting barrel (63) which is inserted to the exhaust port from the bottom. The combustion device has the advantages that the fan noise can be reduced and Helmholtz resonance noise can also be reduced. A barrel part (632) erecting towards the top is formed on the periphery of an annular flange part (631) extending from the lower end of the exhaust restricting barrel (63) to the radial outside. The upper end of the barrel part (632) is fixed to an opening edge of the exhaust port in the upper wall portion of the exhaust hood. A plurality of ventilation holes (633) allowing the combustion exhaust to pass through are arranged in the barrel part circumferentially in a spaced manner.

Owner:RINNAI CORP

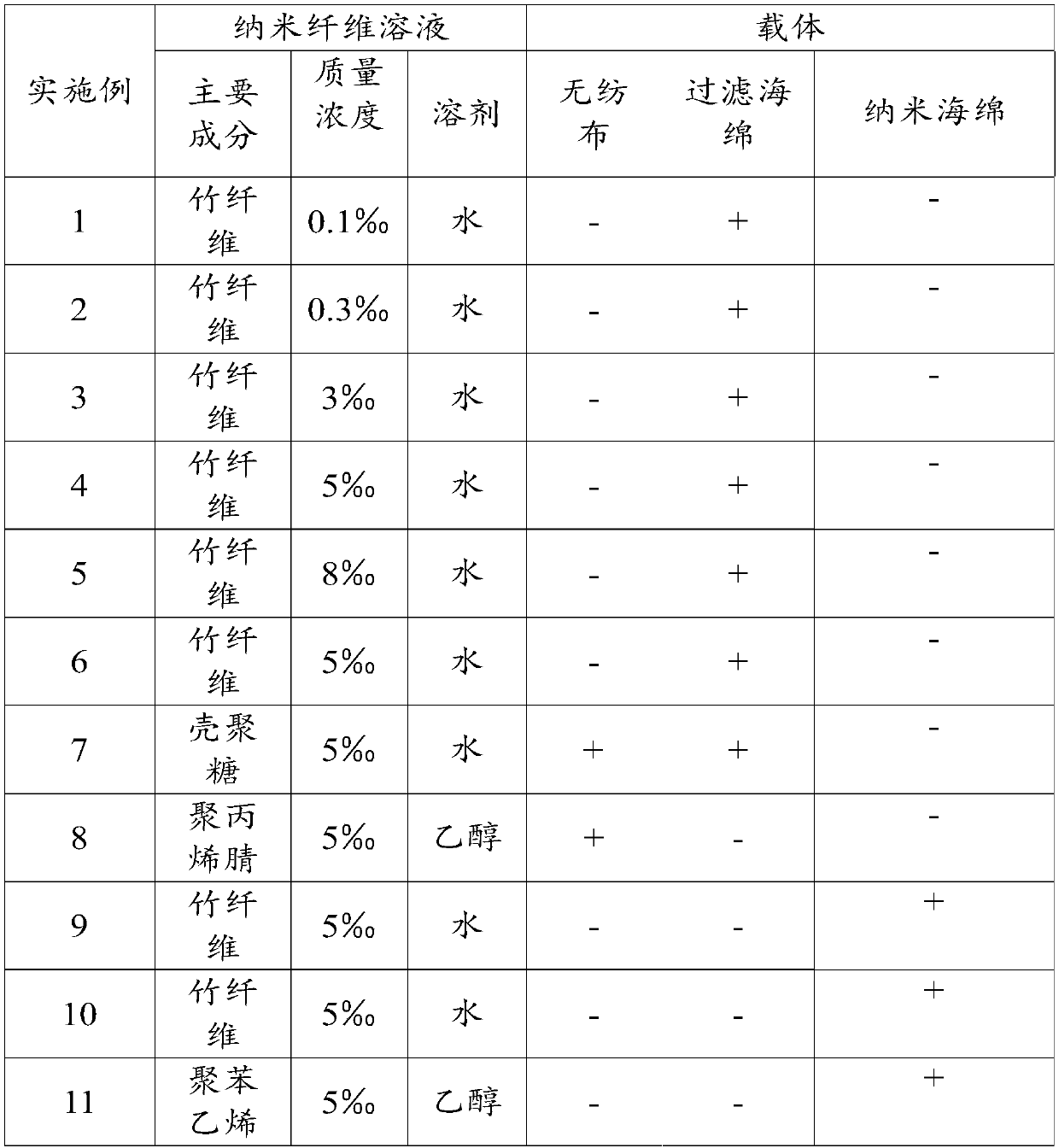

Chitosan-manganese dioxide composite adsorption material and preparation method thereof

InactiveCN110787774AProcess that saves on separate loadsReduce energy costsGas treatmentOther chemical processesFiberAlcohol

The invention discloses a preparation method of a chitosan-manganese dioxide composite adsorption material. The method comprises: 1) a step of preparing a redox reaction base solution: fully dissolving potassium permanganate powder in distilled water, adding oleic acid into the solution, and stirring to form an O / W emulsion; 2) a step of soaking: soaking chitosan degradation fibers as a base material in the redox reaction base solution, and standing for 24 hours at room temperature; 3) a step of cleaning: washing the soaked chitosan degradation fibers with absolute ethyl alcohol to remove unreacted oleic acid, and then washing the fibers with distilled water to remove residual ethyl alcohol; and 4) a step of drying the cleaned chitosan degradation fibers at 70 DEG C for 6 hours. The invention also discloses the chitosan-manganese dioxide composite adsorption material. According to the preparation method and the chitosan-manganese dioxide composite adsorption material, preparation of the chitosan composite material at room temperature is achieved so that a chitosan purification base material can be effectively compounded with other materials without the need of a binder.

Owner:TIANJIN UNIV

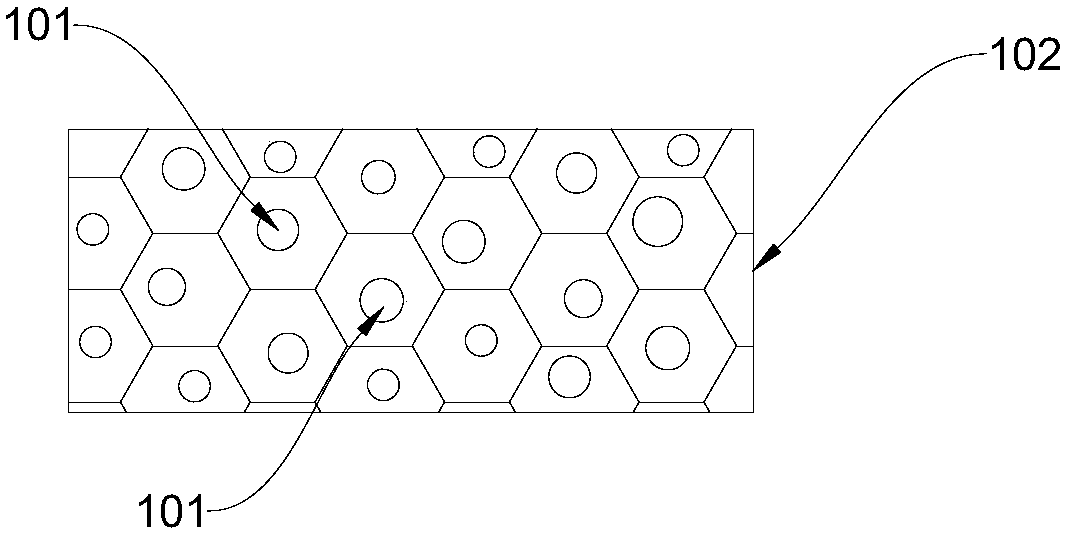

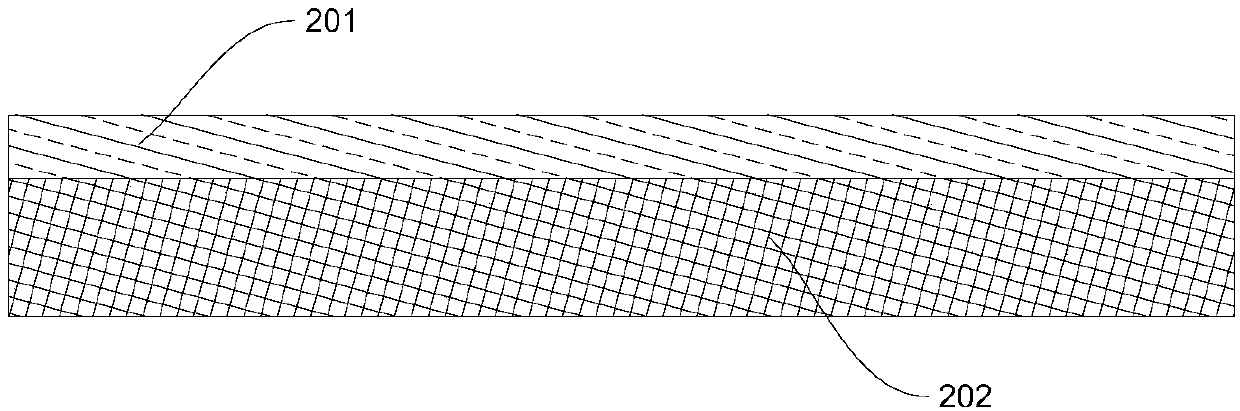

A filter layer and mask

ActiveCN106858823BImprove comfortEasy breathingGas treatmentDispersed particle filtrationPorosityRespirator

Owner:嘉兴宇鸣科技有限公司

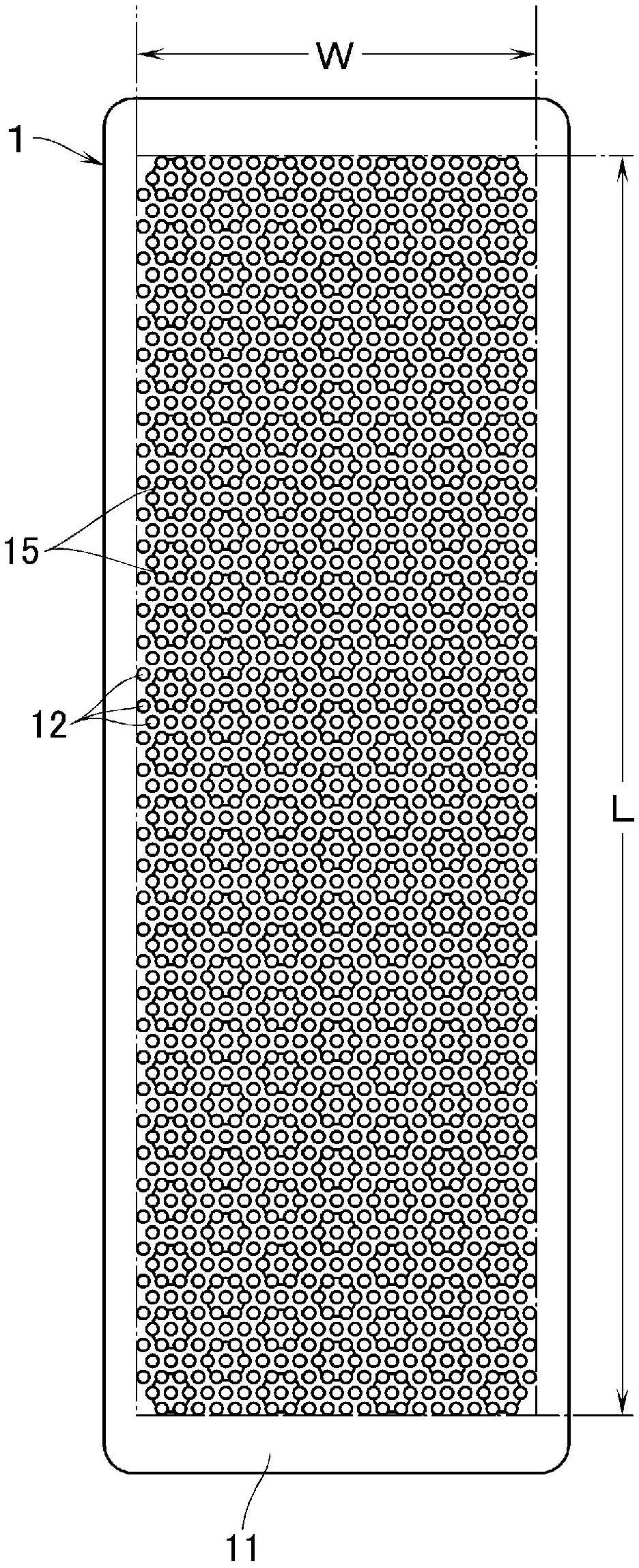

Combustion plate

InactiveCN102597623ACompact configurationIncrease opening ratioBurner noise abatementGaseous fuel burnerCombustionResonance

Provided is a combustion plate wherein combustion resonance or instability during high-load combustion can be overcome, and a high opening percentage for flame holes can be ensured. Flame holes (12) having the same diameter are evenly arranged over the entirety of the combustion area of a plate main body so that three adjacent flame holes are positioned so as to define an equilateral triangle. Flame hole groups, each of which is comprised of six flame holes (12) positioned so as to define a regular hexagon (13) and one flame hole (12) positioned at the center of the regular hexagon, are adjacent to each other across large regular hexagons (14), each of which surrounds a regular hexagon (13). Each of the flame hole groups is defined as a unit flame hole group, and bottomed holes (15), each of which is coaxial with the flame hole (12) positioned at the center of each unit flame hole group, are formed in the surface of the plate main body. Furthermore, if a predetermined diagonal direction or a predetermined opposing direction of the opposite sides of each regular hexagon (13) is defined as a column direction, at least one of twelve flame holes is closed, said twelve flame holes positioned on each large regular hexagon (14) surrounding each unit flame hole group that belongs to a selected column which is selected from among the columns of the unit flame hole groups arranged in the column direction and is spaced from apart from other selected columns by a predetermined distance in a direction perpendicular to the column direction.

Owner:RINNAI CORP

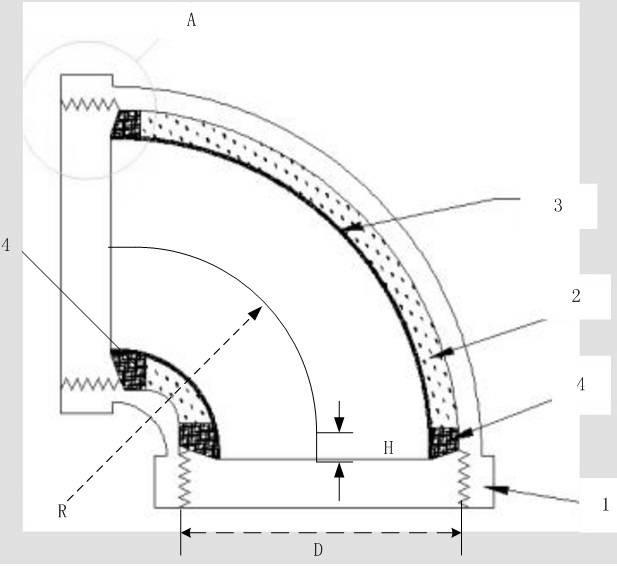

Stainless steel elbow with threaded opening lining

PendingCN112524379APassing resistance is smallExcellent pressure and corrosion resistanceCoatingsSiphonsButt jointPipe fitting

The invention provides a stainless steel elbow with a threaded opening lining, and belongs to the technical field of drinking water pipeline connecting piece manufacturing. The stainless steel elbow with the threaded opening lining comprise an outer sleeve and a lining layer, wherein the outer sleeve is of a circular pipe elbow structure; the lining layer is arranged in the outer sleeve in a sleeved mode, and a filling layer is arranged between the lining layer and the outer sleeve; the lining layer is a stainless steel elbow; the inner walls of the two ends of the outer sleeve are each provided with a threaded connector. an elastic sealing ring is further arranged at the threaded connector; the section of the sealing ring is in a right trapezoid shape; the two parallel edges of the righttrapezoid make contact with the outer wall of the lining layer and the inner wall of the outer sleeve respectively; and the bevel edge of the right trapezoid faces the threaded connector. The sealingring embedded in the edge of the outer sleeve and the edge of the lining layer is in butt joint with the end of the pipeline, the inclined butt joint face of the sealing ring provides an elastic installation space, and therefore the tolerance range generated in the installation and production process of pipe threads and pipe fittings is made up, the excellent pressure-bearing and corrosion-resisting performance is kept, the inner wall is smooth, and the passing resistance of fluid is reduced.

Owner:山西素腾管业有限公司

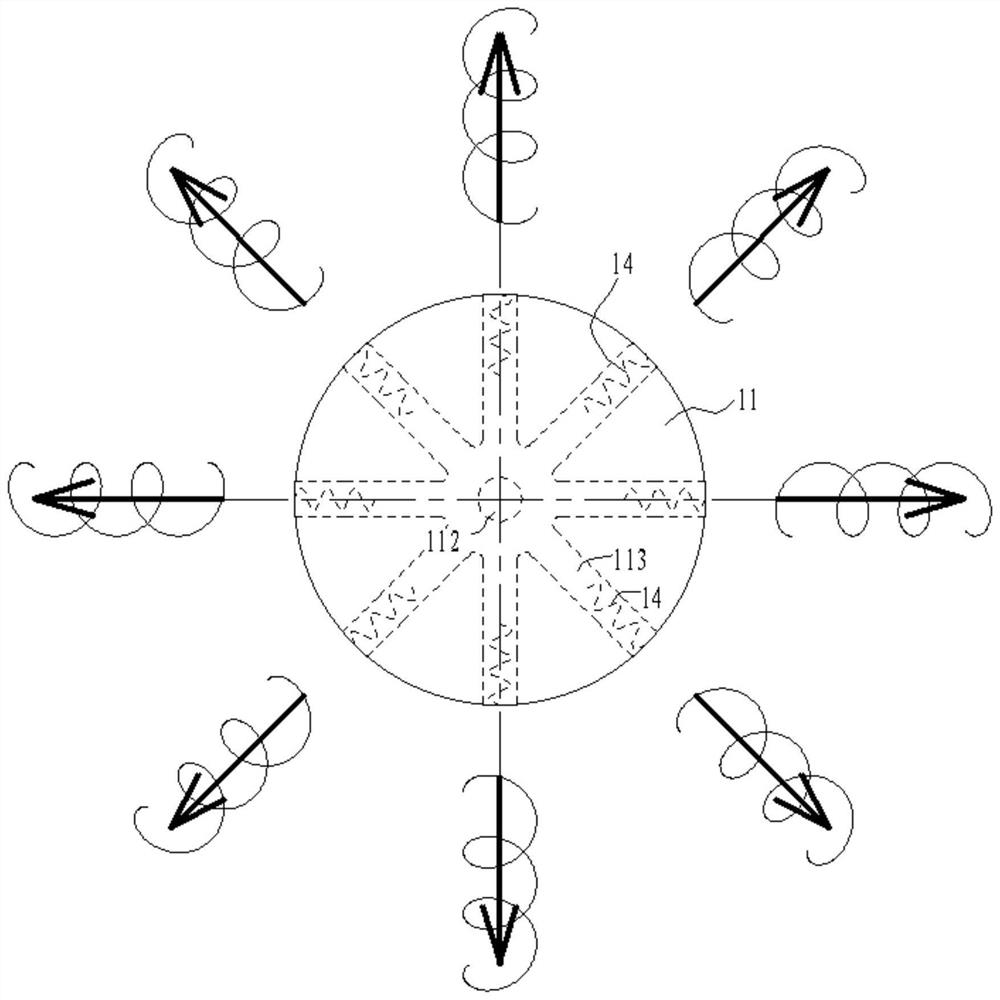

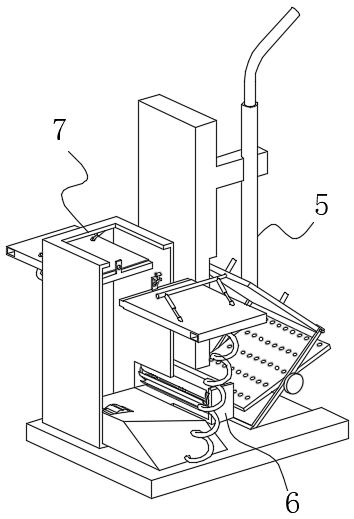

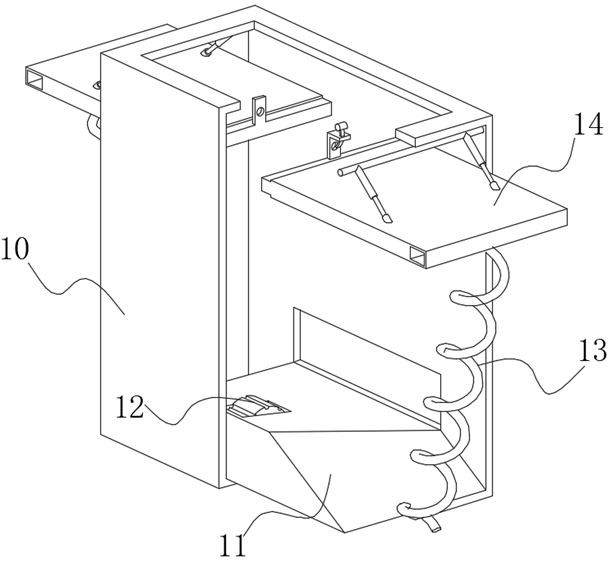

Omnibearing insect pest prevention trapping device for forestry

ActiveCN112715503APassing resistance is smallReduce living conditionsInsect catchers and killersEnvironmental engineeringInsect pest

The invention discloses an omnibearing insect pest prevention trapping device for forestry. The omnibearing insect pest prevention trapping device for forestry comprises a luring device, a trapper and a collector, wherein the collector is placed on the ground, the trapper is arranged on the collector, the luring device is arranged on the trapper, the luring device lures surrounding pests to fly to the luring device in a form of smell emission and to be trapped by the trapper, and the trapper regularly sends the pests into the collector for storage; the luring device comprises a shell, an air inlet net and flow guide fans, wherein an air inlet duct extending inwards is arranged on the lower surface or the side face of the lower portion of the shell and bent to enter the trapper, a vertical confluence air duct is arranged on the lower portion of the shell, the lower end of the confluence air duct is connected with the trapper, and the upper end of the confluence air duct is divided into a plurality of branch air outlet ducts in a branch mode, and the branch air outlet ducts horizontally discharge air outwards ; the flow guide fans are arranged in the confluence air ducts, the air inlet net is arranged at the initial position of the air inlet ducts, and the outer surface of the shell and the air inlet net are coated with pest trapping agents.

Owner:蒙阴县林业局

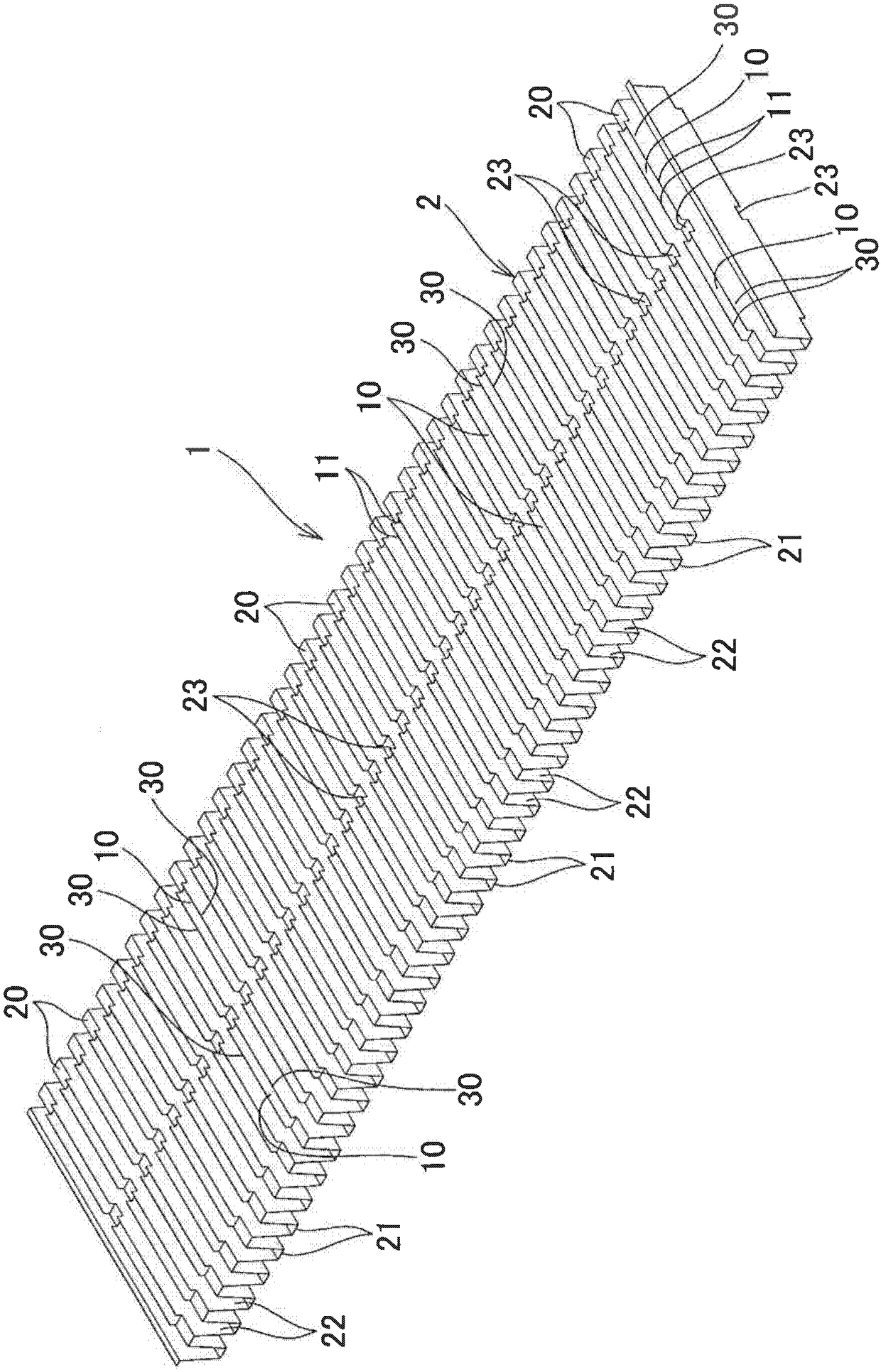

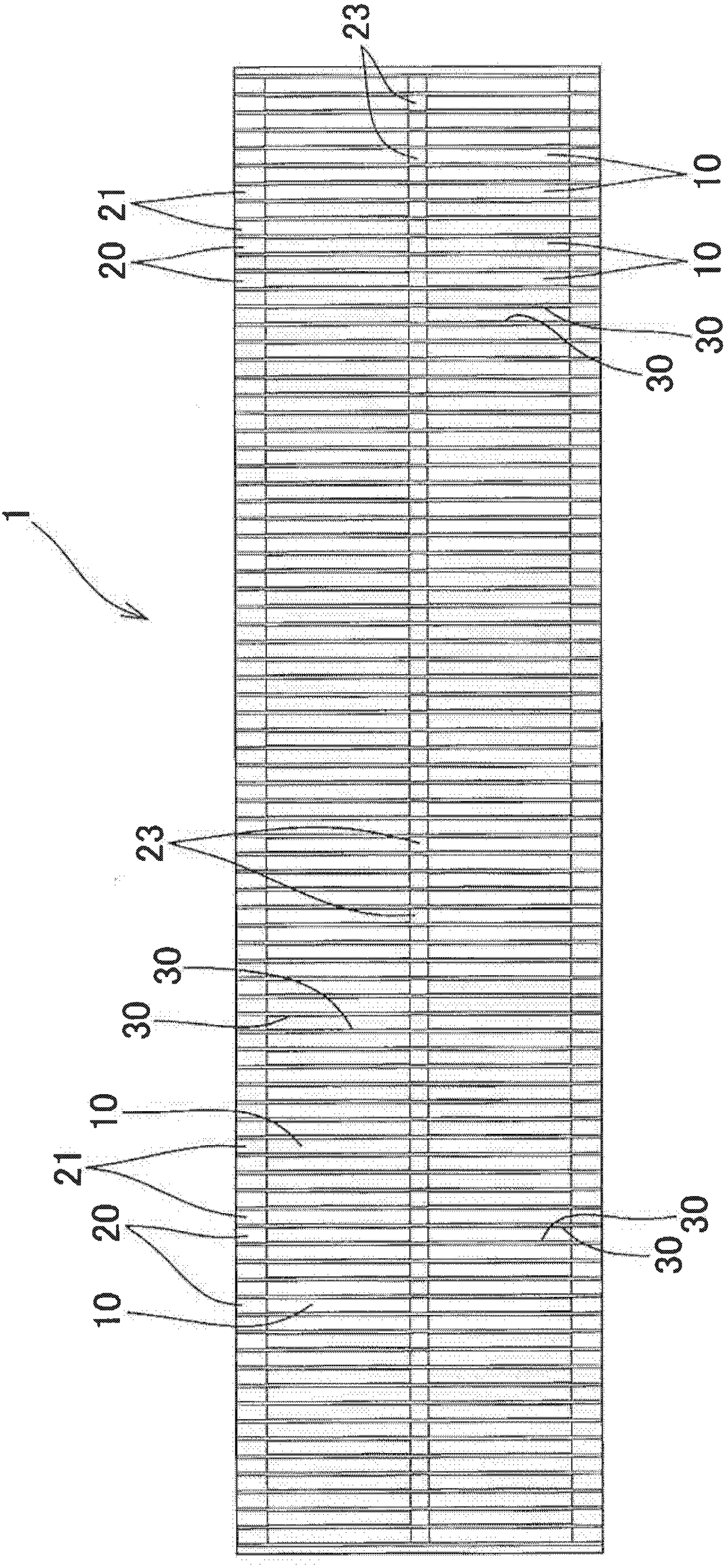

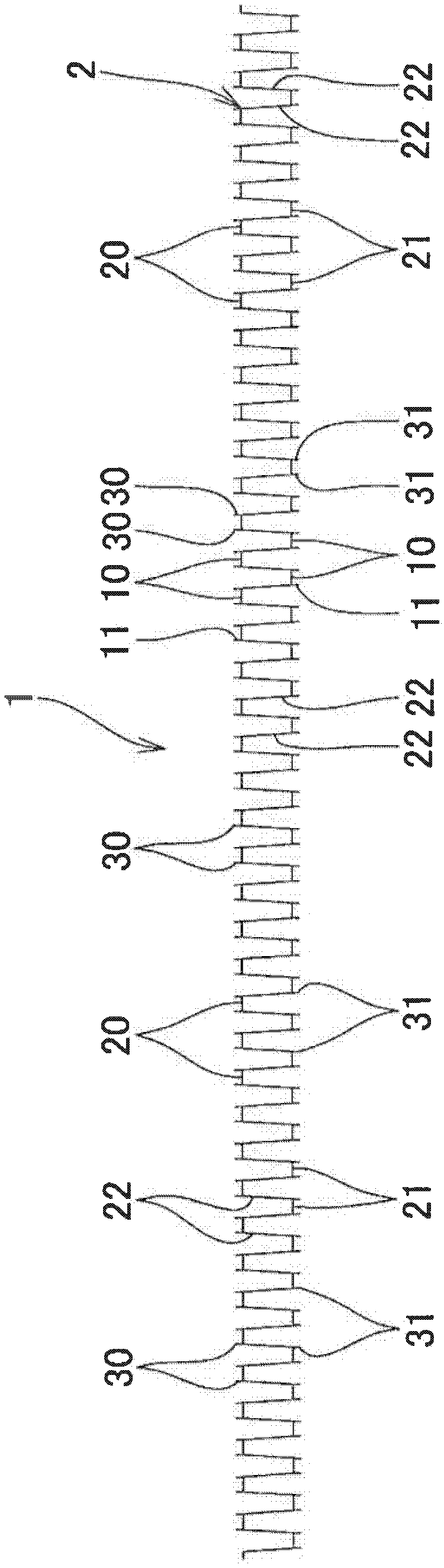

Metal filter

ActiveCN108211789AEfficient catalyst reactionGood adsorptionGas treatmentDomestic stoves or rangesEngineeringElectrical and Electronics engineering

The invention provides a metal filter. Either or both of a peak and a trough of a metal plate body (2) of peaks (20) and troughs (21) in multiple lines is or are formed in an alternating manner. The metal filter is provided with a communicating groove (10) enabling fluids to extend along a line direction. Additionally, an opening edge part (11) of the communicating groove is equipped with verticalpieces (30, 31) laterally vertical to convex surfaces of a peak (20) and a trough (21). For instance, the vertical pieces (30, 31) are respectively arranged on both sides of a pair of opening edge parts which extend along a line direction by being opposite to each other. The vertical pieces are long pieces which roughly extend at all opening edge parts. Accordingly, contact areas between fluids such as air and the like, and a catalyst layer and an absorption layer are ensured at low cost. Furthermore, passing resistance of fluids is inhibited so that passing efficiency is increased. As a result, excellent purification effect can be efficiently obtained.

Owner:JAPAN

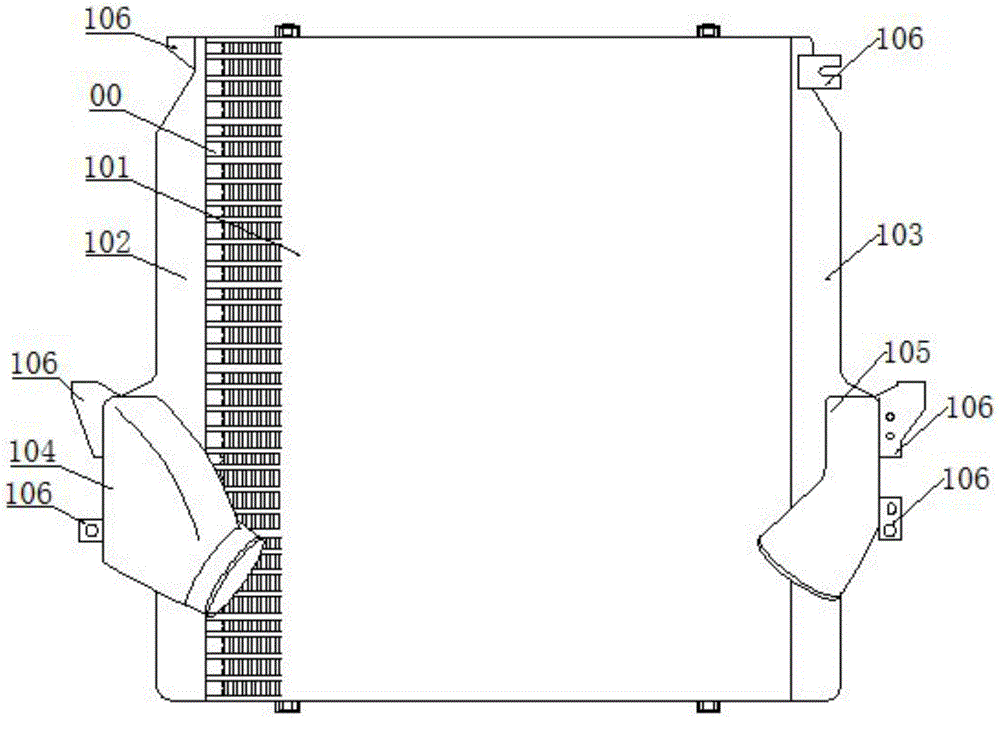

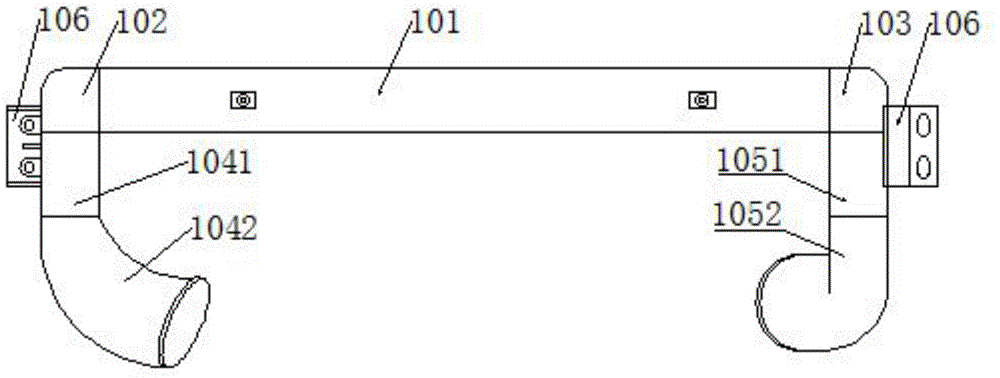

Intercooler applied to large heavy truck

InactiveCN104912650AImprove cooling efficiencyGuaranteed normal operationInternal combustion piston enginesEngineeringIntercooler

The invention discloses an intercooler applied to a large heavy truck and belongs to the field of structure design of intercoolers. The intercooler applied to the large heavy truck comprises a cooling body internally provided with a cooling core. A left end socket is encapsulated on the left end face of the cooling body, a right end socket is encapsulated on the right end face of the cooling body, an air inlet pipe is arranged on the front plate face of the left end socket, and an air outlet pipe is arranged on the front plate face of the right end socket. The air inlet pipe and the left end socket are of an integrated structure, and the air outlet pipe and the right end socket are of an integrated structure. By means of the structure, the intercooler applied to the large heavy truck solves the problem that the air pass resistance in an intercooler in the prior art is large, and consequently the operation of an engine is influenced; the air passing resistance is reduced, the smoothness of air is ensured, and thus the good operation of the engine is ensured; meanwhile, the cooling efficiency of the intercooler applied to the large heavy truck is improved, and the normal running of the large heavy truck is further ensured.

Owner:WUXI JIUSHENG HEAT EXCHANGER

A double-layer sleeve type corona plasma generator

ActiveCN104128077BInto the uniformAvoid direct impactDispersed particle separationPlasma generatorProduct gas

The invention relates to a double-layer sleeve type corona plasma generating device comprising a gas buffering chamber, an outer-layer processing chamber and an inner-layer processing chamber. A gas inlet is provided on the outer side of the gas buffering chamber. An insulation baffle is provided on the inner side of the buffering chamber. Airway through holes are provided on the baffle. Gas to be processed sequentially enters the outer-layer processing chamber and the inner-layer processing chamber through the airway through holes. When the gas is completely processed, the gas is discharged from a gas outlet connected to an end of the inner-layer processing chamber. According to the invention, with the buffering chamber, the gas to be processed can be uniformly and stably delivered in the processing chambers. The chambers adopt a coaxial multi-pin-plate structure, such that electric field unevenness coefficient is high, discharge voltage is low, and thus operation energy consumption is reduced. Also, voltage adjustable range is wide, and application scope is wide. With the inner-outer double layer structure, low temperature plasma dedusting and waste gas degradation are separated, such that the influence of dust in waste gas to waste gas molecule degradation is avoided, and energy utilization rate is improved. Also, reactor structure is compact. The device provided by the invention is suitable for the fields such as waste gas treatment, sterilization and disinfection, ozone synthesis, and the like.

Owner:XI AN JIAOTONG UNIV

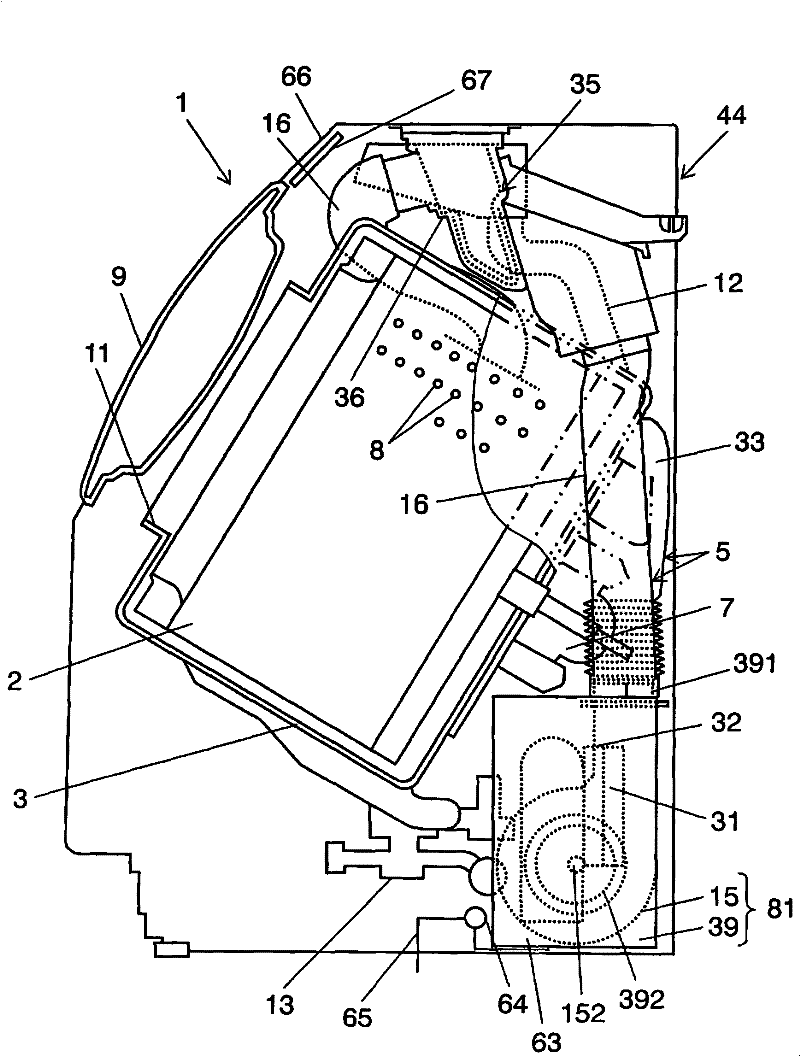

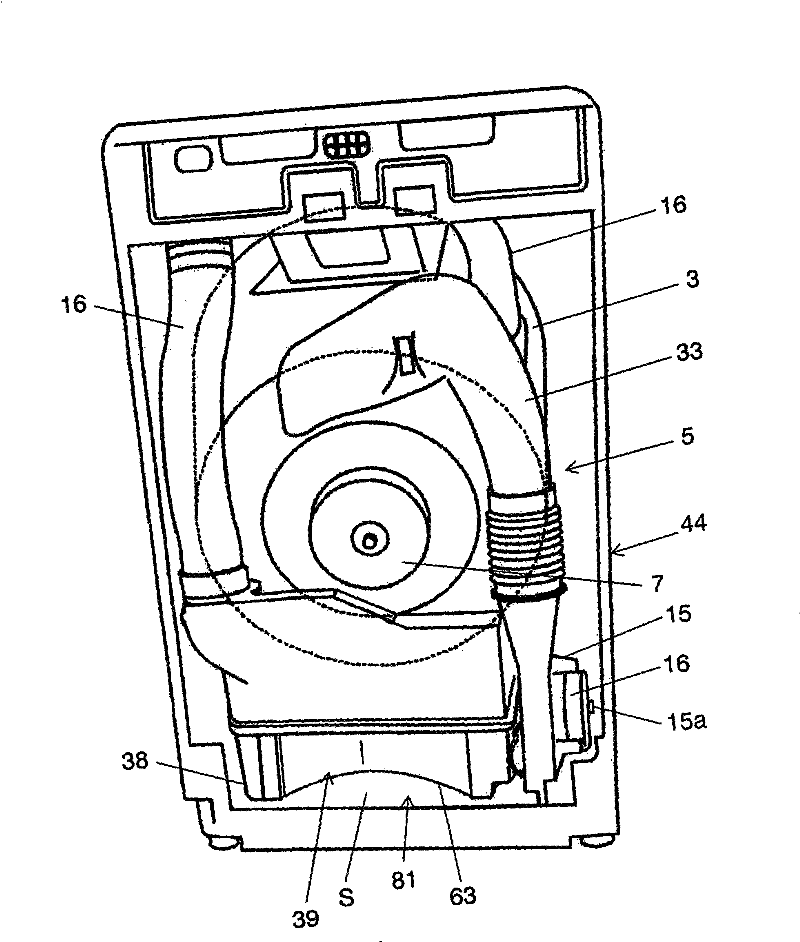

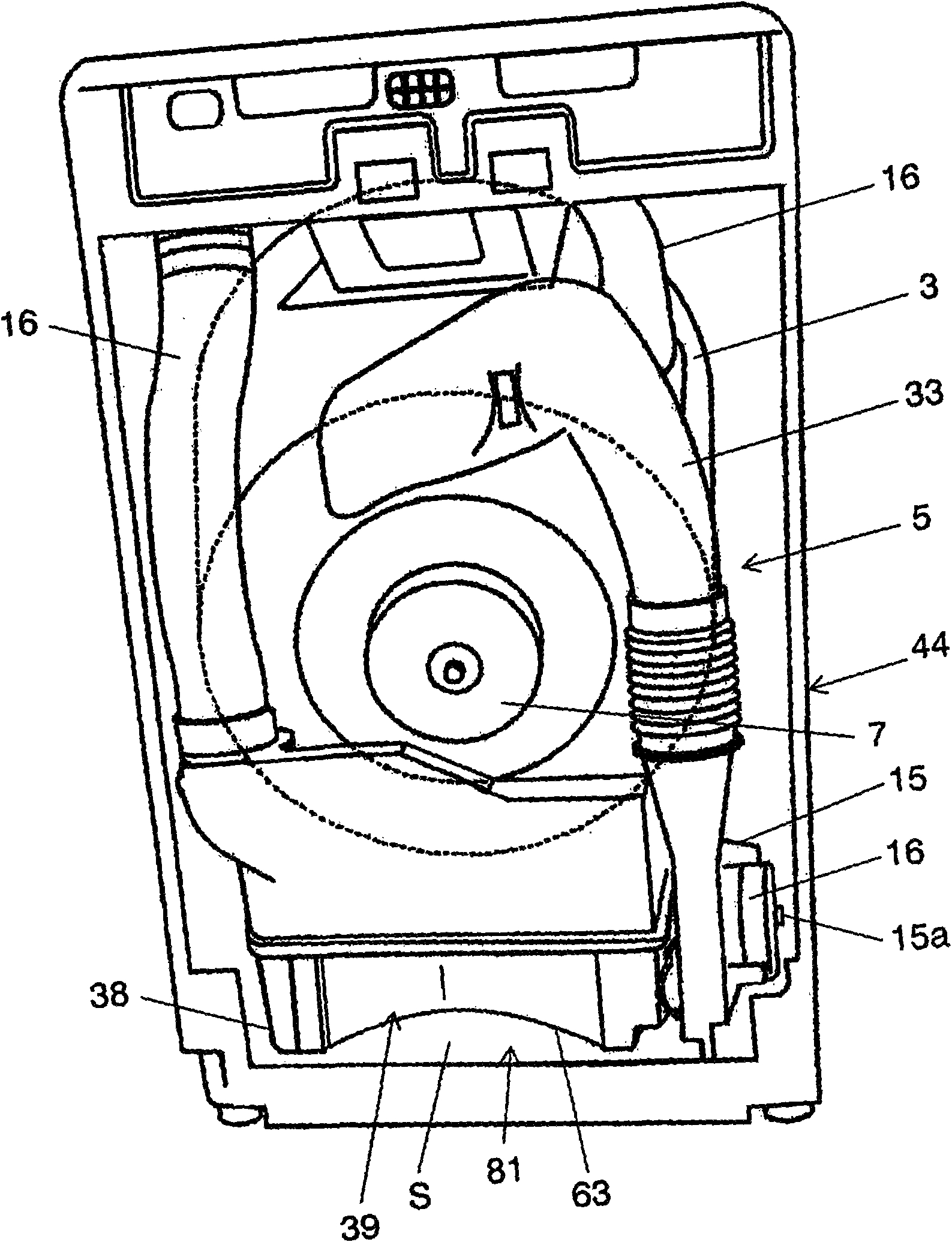

Air conditioning unit

ActiveCN101671941BSave spaceSuppression of upsizingLighting and heating apparatusTextiles and paperEngineeringHeat sink

There is provided an air conditioning unit in which an evaporator and a condenser located in the middle of an air passage from a suction inlet port to a suction outlet port for dehumidifying and heating a circulating air, and a compressor for circulating a cooling medium therethrough are build inside a unit casehaving the suction inlet port and the suction outlet port, wherein the evaporator and the condenser compose a heat exchanger in which each other's fins are aligned in parallel, and the heat exchanger is installed inside the air passage of the unit case in which a suction outlet port surface formed by the suction outlet port is opposed to an opening surface of the evaporator or the condenser so as to form an angle smaller than a right angle.

Owner:PANASONIC CORP

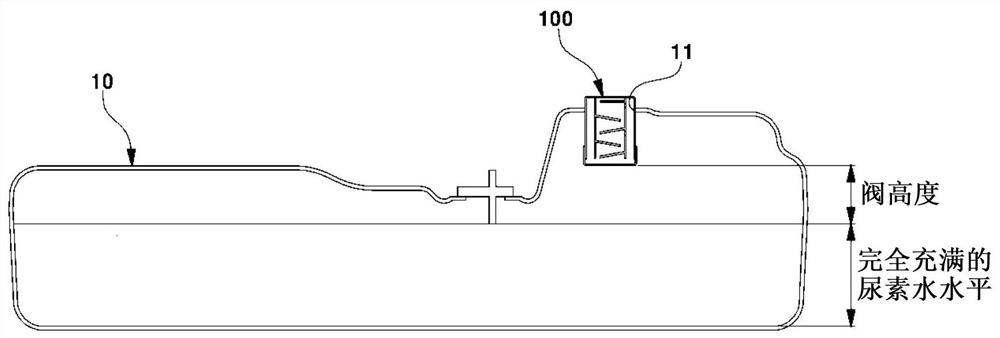

Vent valve for closed tank

PendingCN111981173AEnsure desired breathabilityReduce manufacturing costInternal combustion piston enginesClosuresGas passingMechanical engineering

Owner:HYUNDAI MOTOR CO LTD +1

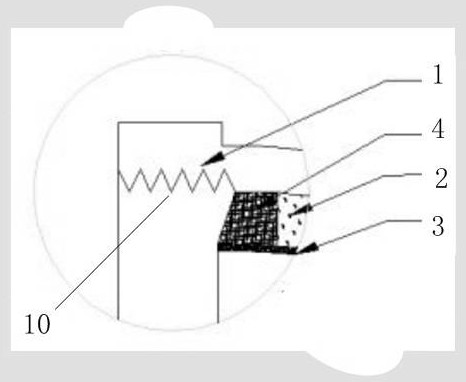

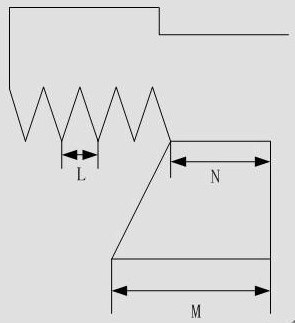

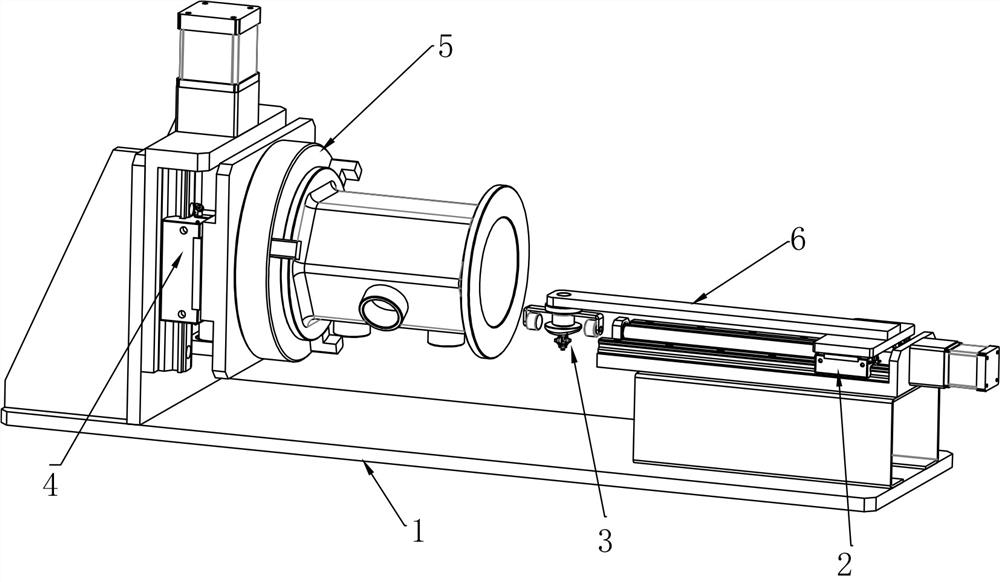

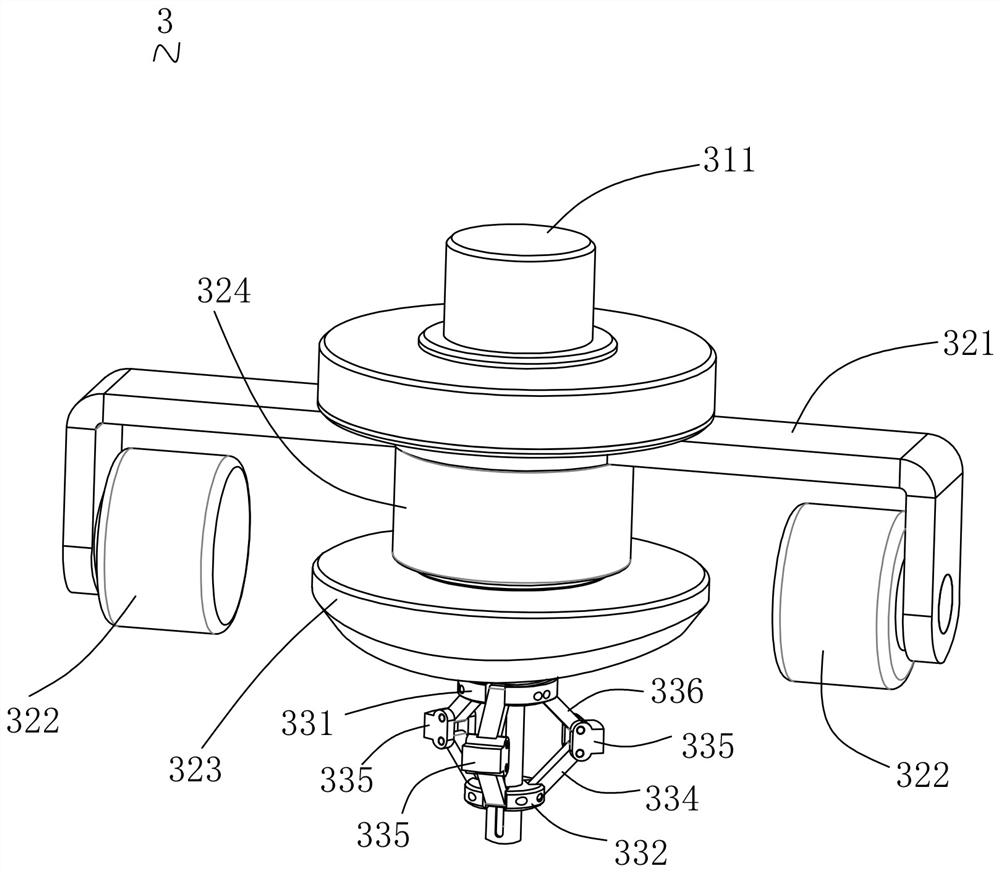

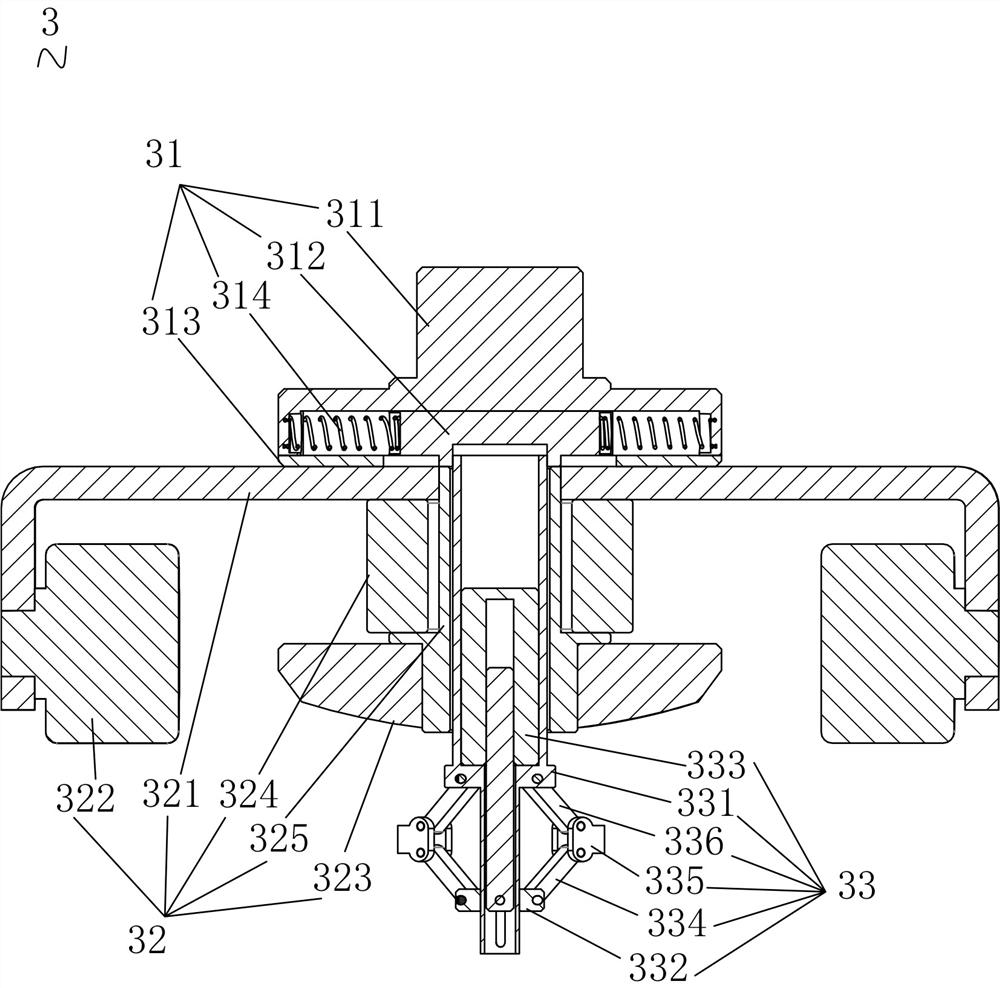

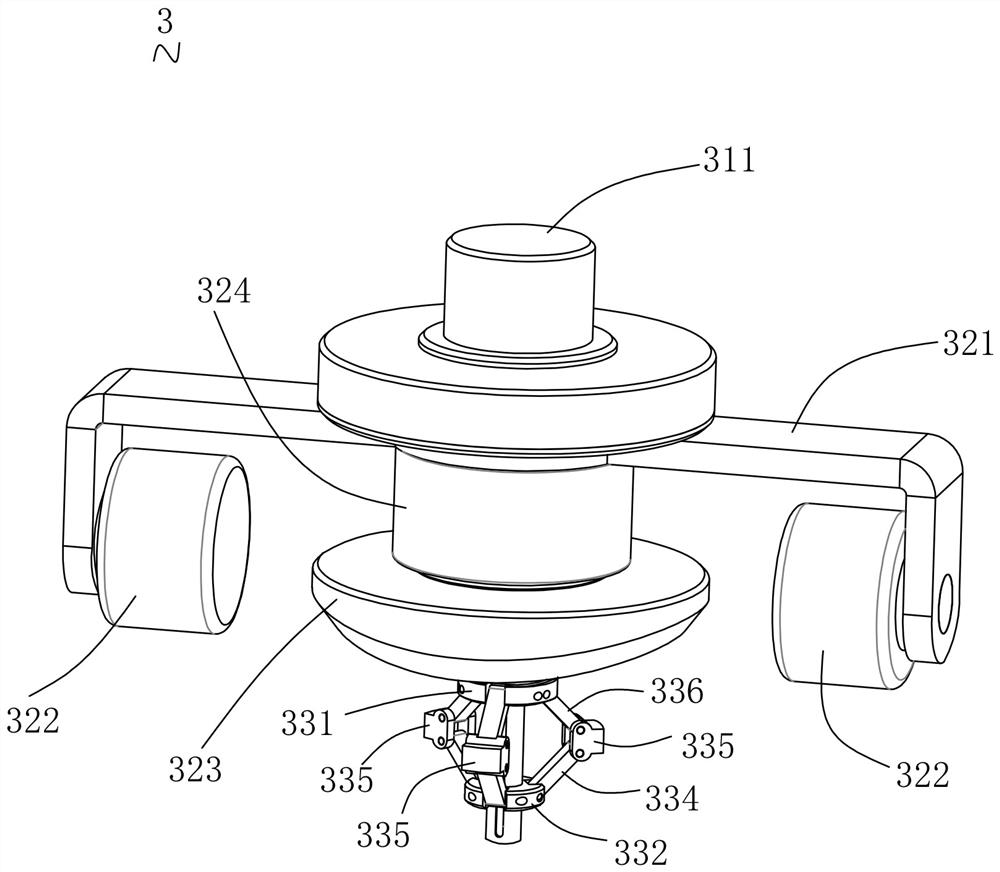

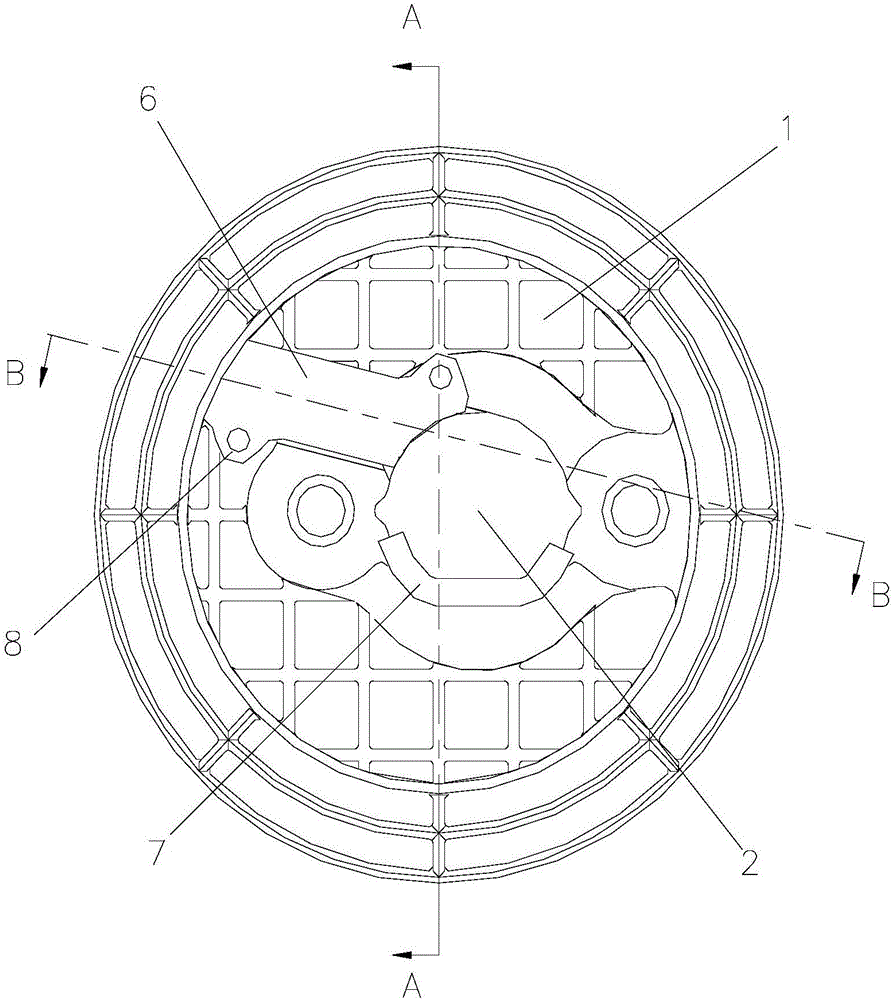

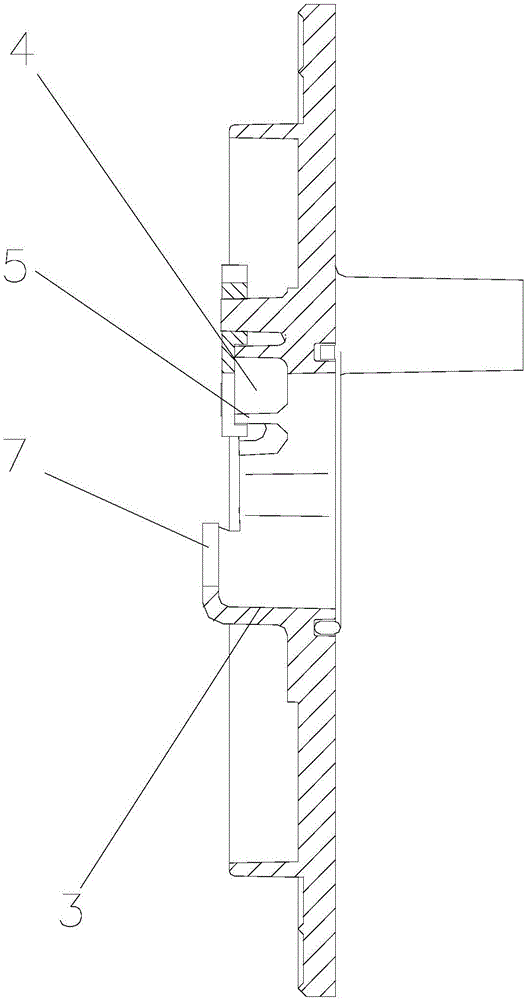

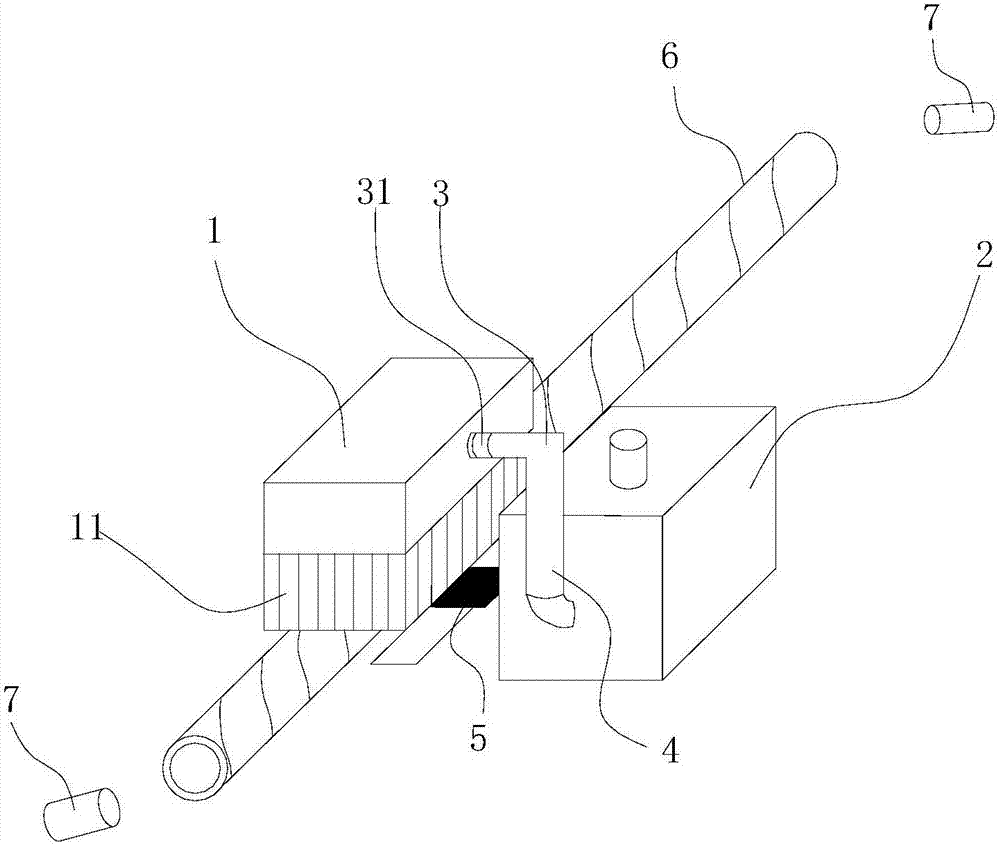

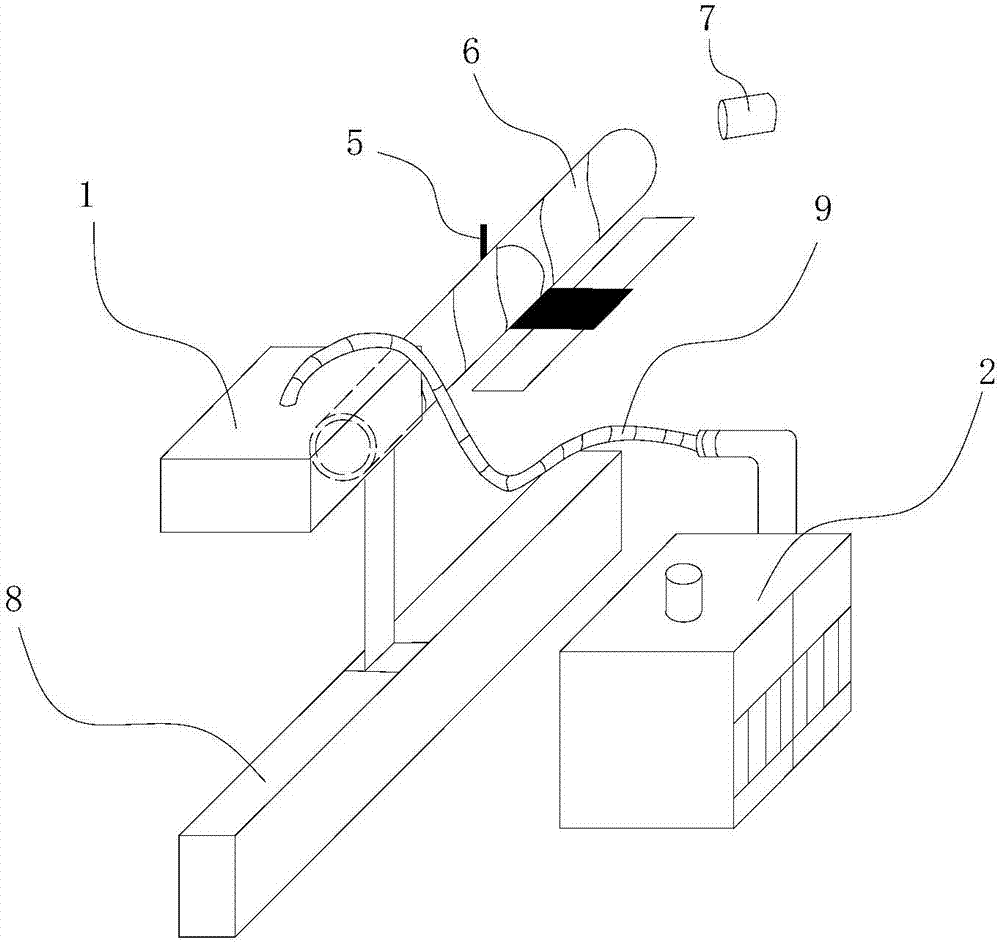

High-precision electric arc type self-adaptive grinding shaping device

InactiveCN112388485APassing resistance is smallReduce labor intensityGrinding carriagesGrinding machinesGrindingElectric arc

The invention discloses a high-precision electric arc type self-adaptive grinding shaping device. The device comprises a rack, a horizontal displacement mechanism, a self-adaptive grinding shaping mechanism, a vertical displacement mechanism and a rotary clamping mechanism; the horizontal displacement mechanism is installed at one end of the rack, the self-adaptive grinding shaping mechanism is connected with the output end of the horizontal displacement mechanism through a cantilever, the vertical displacement mechanism is installed at the other end of the rack, and the rotary clamping mechanism is fixed to the output end of the vertical displacement mechanism; and the self-adaptive grinding shaping mechanism comprises an elastic deflection compensation component, a self-orientation electrode component and a self-centering tensioning component, the elastic deflection compensation component is fixed on the cantilever, the self-centering tensioning component is connected with the deflection output end of the elastic deflection compensation component, and the self-orientation electrode component is movably connected to the self-centering tensioning component in a sleeving mode, and can rotate relative to the self-centering tensioning component. According to the device, the high-precision grinding shaping operation on an valve orifice intersection line is achieved, the mechanicaloperation is achieved, the labor intensity is reduced, the efficiency is high, and a valve is not prone to being scratched.

Owner:JINGMEN YIMEI IND DESIGN CO LTD

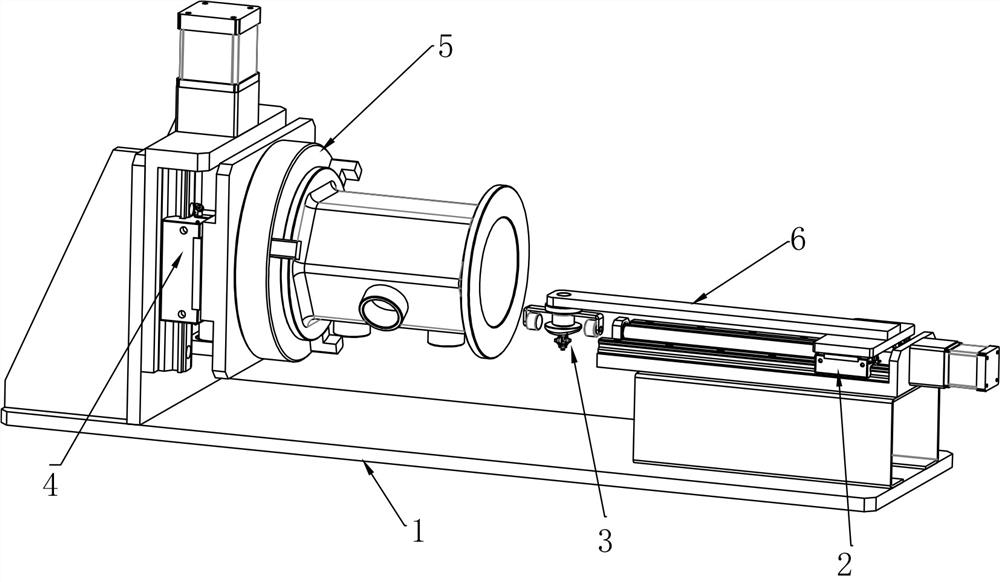

High-precision electric arc type self-adaptive grinding and shaping robot complete machine

InactiveCN112318329ANot easy to scratchPassing resistance is smallGrinding carriagesGrinding drivesEngineeringMachine

The invention discloses a high-precision electric arc type self-adaptive grinding and shaping robot complete machine. The high-precision electric arc type self-adaptive grinding and shaping robot complete machine comprises a machine tool, an electric arc type grinding robot unit, a material moving and transferring unit and a conveying unit, wherein the electric arc type grinding robot unit and theconveying unit are arranged on the machine tool at intervals, and the material moving and transferring unit is arranged on the machine tool and is located between the electric arc type grinding robotunit and the conveying unit; and the electric arc type grinding robot unit comprises a machine frame, a horizontal displacement mechanism, a self-adaptive grinding and shaping mechanism, a vertical displacement mechanism and a rotary clamping mechanism. According to the high-precision electric arc type self-adaptive grinding and shaping robot complete machine, high-precision grinding and shapingoperation at the intersection line of valve orifices is realized, mechanical operation is realized, the labor intensity is reduced, the efficiency is high, and a valve is not prone to being scratched.

Owner:JINGMEN YIMEI IND DESIGN CO LTD

burner

ActiveCN103148492BReduce resonance noisePassing resistance is smallBafflesChimneysCombustorHelmholtz resonator

The invention provides a combustion device comprising a combustion frame provided with a combustor therein, a fan supplying air for combustion into the combustion frame, a heat exchanger disposed above the combustion frame and an exhaust hood arranged above the heat exchanger. Combustion exhaust is discharged via a barrel-shaped exhaust port extending from the upper wall portion of the exhaust hood to the top. The combustion device comprises an exhaust restricting barrel (63) which is inserted to the exhaust port from the bottom. The combustion device has the advantages that the fan noise can be reduced and Helmholtz resonance noise can also be reduced. A barrel part (632) erecting towards the top is formed on the periphery of an annular flange part (631) extending from the lower end of the exhaust restricting barrel (63) to the radial outside. The upper end of the barrel part (632) is fixed to an opening edge of the exhaust port in the upper wall portion of the exhaust hood. A plurality of ventilation holes (633) allowing the combustion exhaust to pass through are arranged in the barrel part circumferentially in a spaced manner.

Owner:RINNAI CORP

Air conditioning unit

ActiveCN101671941ASave spaceSuppression of upsizingLighting and heating apparatusTextiles and paperEngineeringHeat sink

There is provided an air conditioning unit in which an evaporator and a condenser located in the middle of an air passage from a suction inlet port to a suction outlet port for dehumidifying and heating a circulating air, and a compressor for circulating a cooling medium therethrough are build inside a unit casehaving the suction inlet port and the suction outlet port, wherein the evaporator and the condenser compose a heat exchanger in which each other's fins are aligned in parallel, and the heat exchanger is installed inside the air passage of the unit case in which a suction outlet port surface formed by the suction outlet port is opposed to an opening surface of the evaporator or the condenser so as to form an angle smaller than a right angle.

Owner:PANASONIC CORP

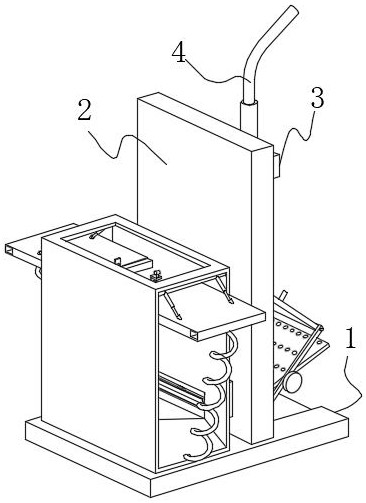

A food packaging printing device with clear printing

ActiveCN113459659BEasy to observe statusWon't loosen and collapseRotary pressesOther printing apparatusCardboardTextile printer

The invention belongs to the field of cardboard printing, and specifically relates to a food packaging and printing device with clear printing, including a base plate; a partition is fixedly connected to the upper surface of the bottom plate, and a fixing block is fixedly connected to the outer surface of the right side of the partition . The food packaging printing device with clear printing is equipped with a collar. Due to different batches and different types of cardboards, the thickness of the cardboard varies greatly. Eccentric movement, the movable rod tilts, the vertical height of the splint at the bottom increases, the gap between the support plate and the splint increases, and the passage resistance of the thick cardboard is reduced. When the cardboard is thin, the feeding mechanism is affected by the centrifugal force while rotating , so that the rotation diameter and space of the splint are increased, and the gap between the support plate and the splint is reduced. As long as the thickness of the cardboard is within the working range of the feeding mechanism, it is applicable, which solves the problem of traditional feeding equipment with fixed structure, poor passability and flexibility. The problem.

Owner:JIANGSU YUANZHONG MOTOR

Moisture-proof type filtering core supporting plate, air filter and engine of air filter

InactiveCN106801652AGuaranteed fermentation effectKeep dryCombustion-air/fuel-air treatmentMachines/enginesAir filterFilter effect

The invention discloses a moisture-proof type filtering core supporting plate, an air filter and an engine of the air filter. The moisture-proof type filtering core supporting plate comprises a supporting plate body provided with an air outlet hole and a waste gas inlet hole. The waste gas inlet hole guides waste gas into the air outlet hole through a guide channel. The supporting plate body is further provided with a flow guiding part used for limiting the waste gas flowing out from the guide channel to be at the air outlet hole. By arranging the flow guiding part, the situation that a filtering core is wetted due to the fact that the waste gas is directly condensed on the surfaces of relatively cold parts in the air filter after flowing out from the guide channel is avoided; the filtering core of the air filter is kept dry beneficially; the passing resistance of the filtering core is small; and meanwhile, the filtering effect of the air filter and the good performance of the engine are ensured.

Owner:LONCIN MOTOR

Gas purifier

PendingCN108525433ASimple structureReduce manufacturing costRotary stirring mixersMixing methodsFine particulateChemistry

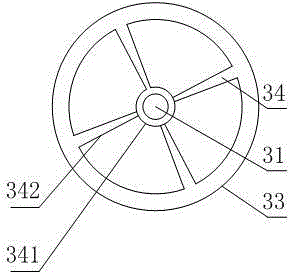

The invention belongs to the field of purification of gases and particularly relates to a gas purifier for purifying fine particulate matters. The gas purifying module mainly comprises a purifying main body, a purifying solution and a motor, the purifying main body is provided with a gas inlet and a gas outlet, the gas purifier is characterized by further comprising a bearing system and a flow stirrer for stirring and mixing the gas and purifying solution, the purifying main body comprises a purifying main body I and a purifying main body II, the purifying main body I and the purifying main body II form a purifying cavity, the purifying solution is arranged in the purifying cavity, the bearing system is connected with the flow stirrer to fix the flow stirrer on the purifying main body, andthe flow stirrer is driven by the motor to stir and mix the gas needing to be purified with the purifying solution in the purifying cavity. The cost and the later-period use cost of the gas purifierare very low, the fine particulate matters are relatively thoroughly filtered at the same time, the accumulated total quantity of the filtered fine particulate matters is huge, and the remarkable economic, social and environmental benefits are produced.

Owner:高雪真

Filtration type gas separation and purification equipment with rapid moving filtering layer

InactiveCN1218768CEfficient separationStop passingDispersed particle filtrationFiltrationProduct gas

A filter-type gas separating-cleaning apparatus with quickly moving filter layer features that its filter cylinder rotating at high speed is composed of external filter net, supporting posts, internal filter net, shaft sleeve, shaft disk and supporting rings, and the gas containing solid particles and / or liquid drops is filtered by said filter cylinder. Its advantage is use of big-mesh filter material to remove fine solid particles and / or liquid drops, resulting in high filter speed, and easy cleaning.

Owner:暴辰生 +1

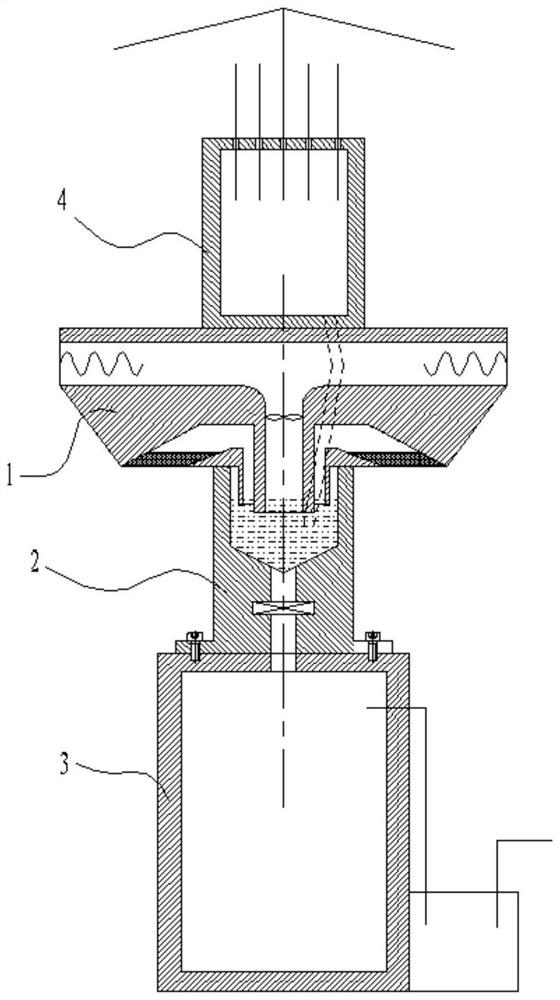

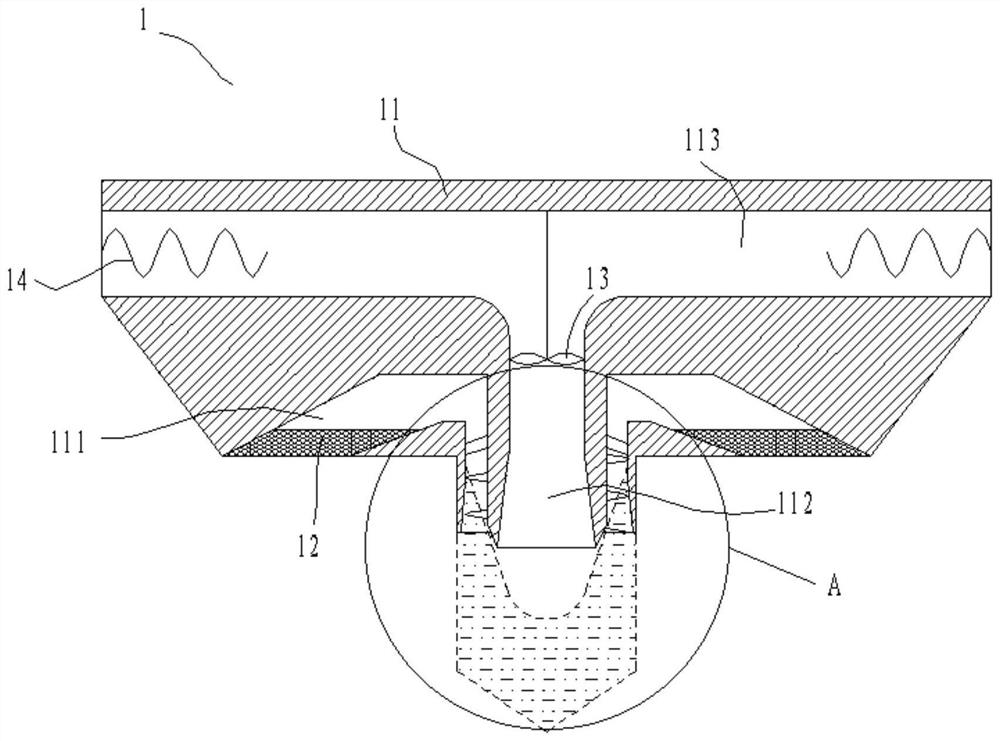

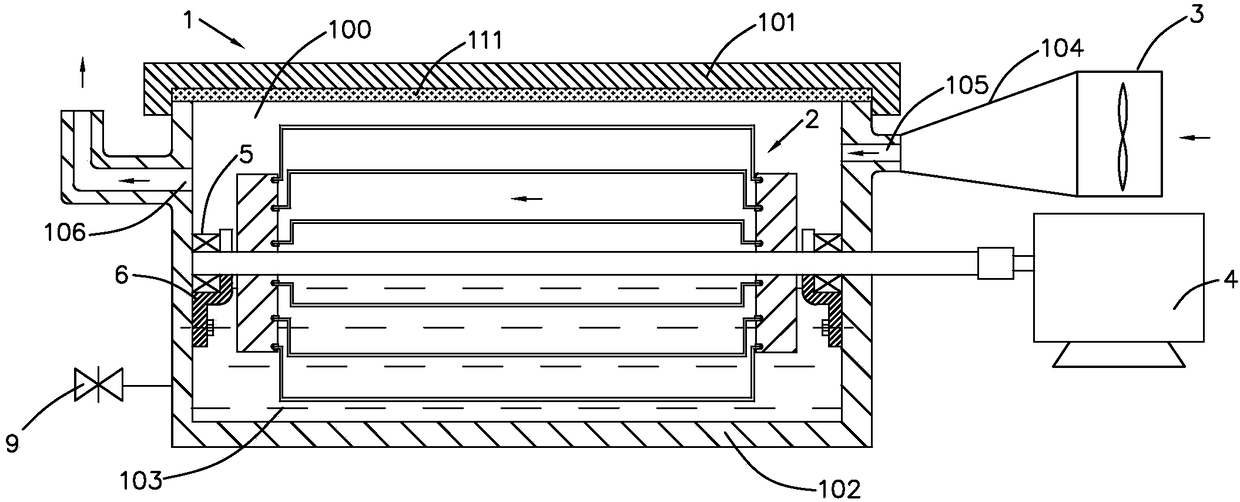

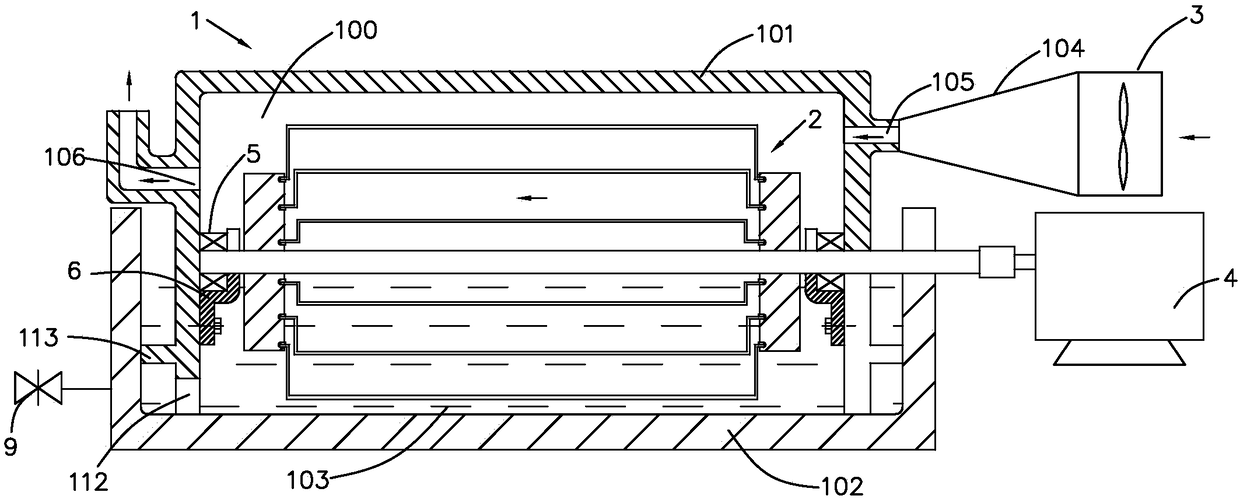

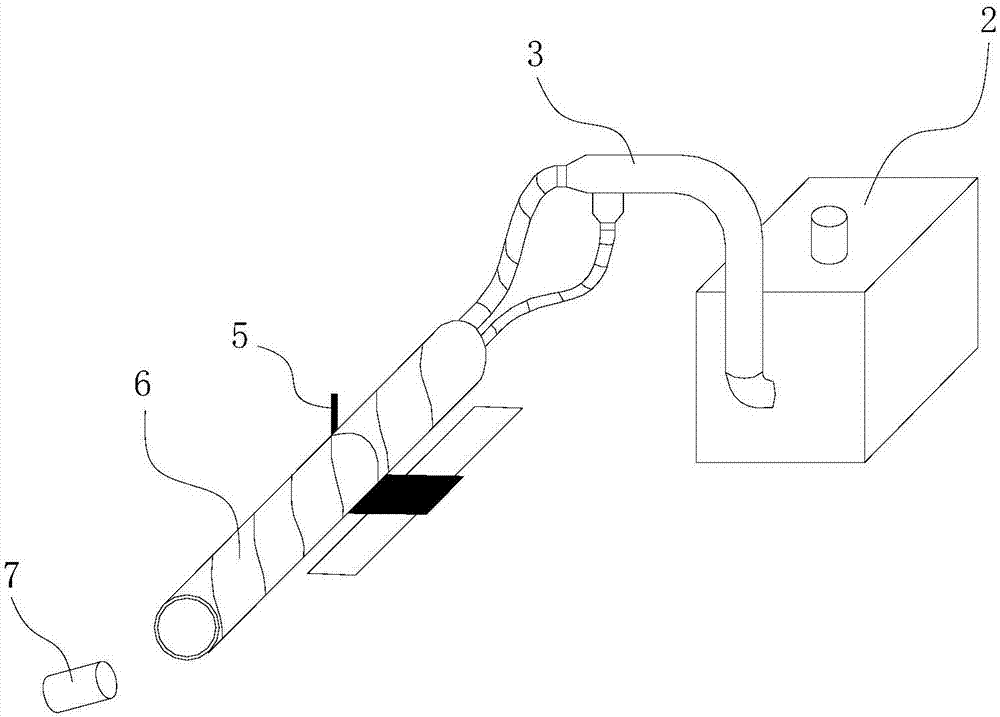

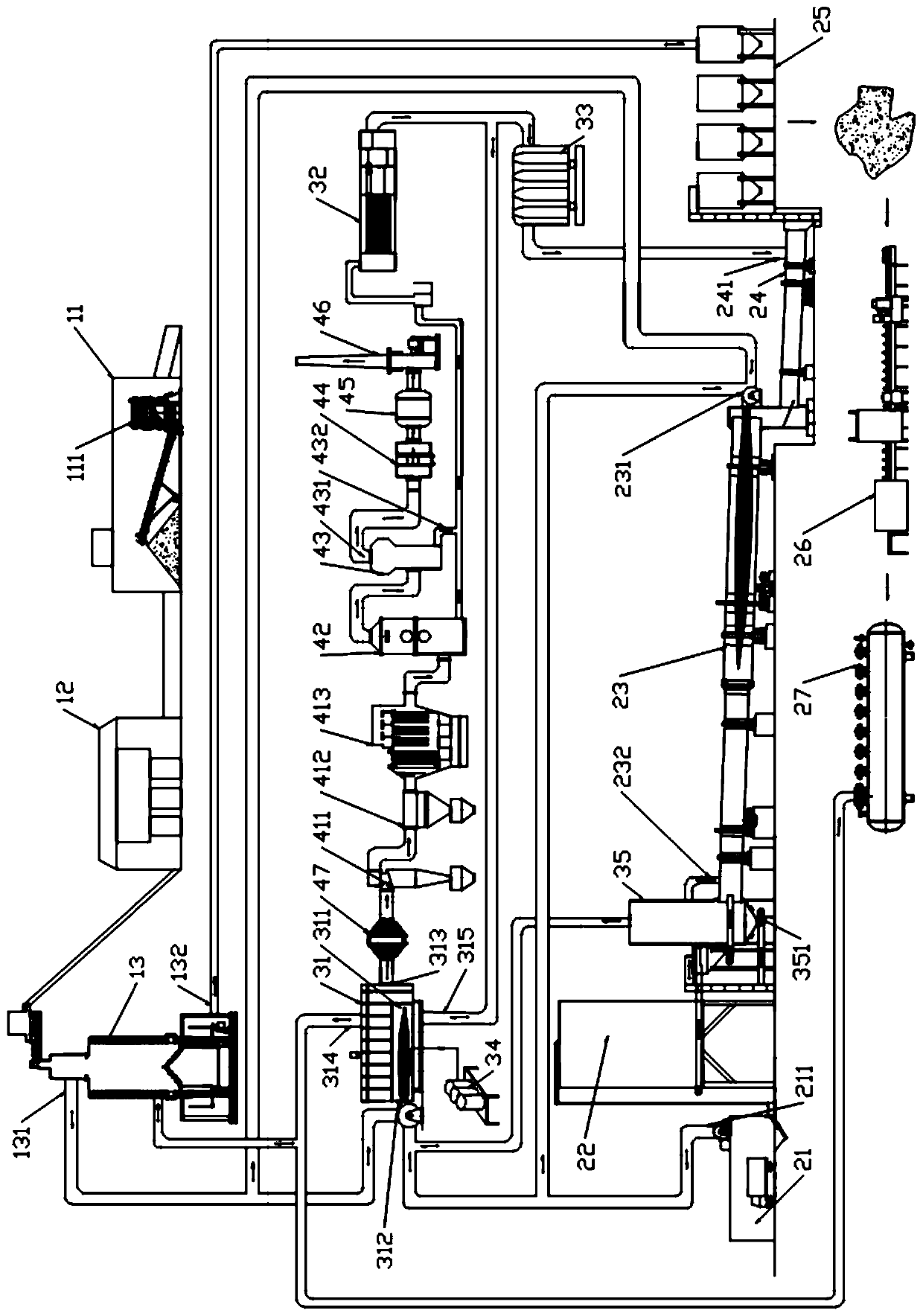

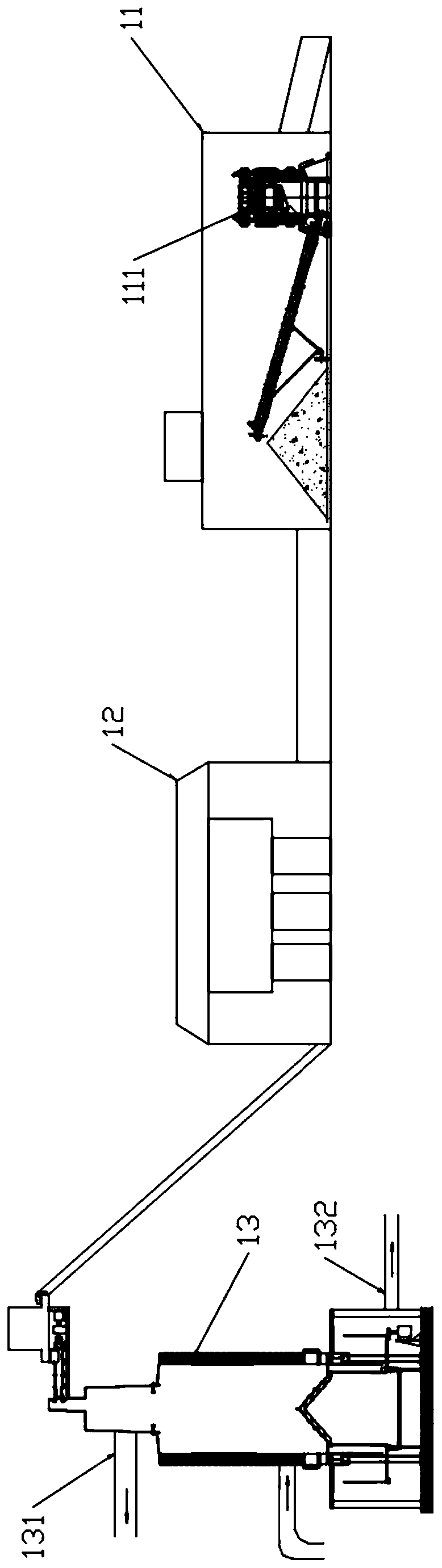

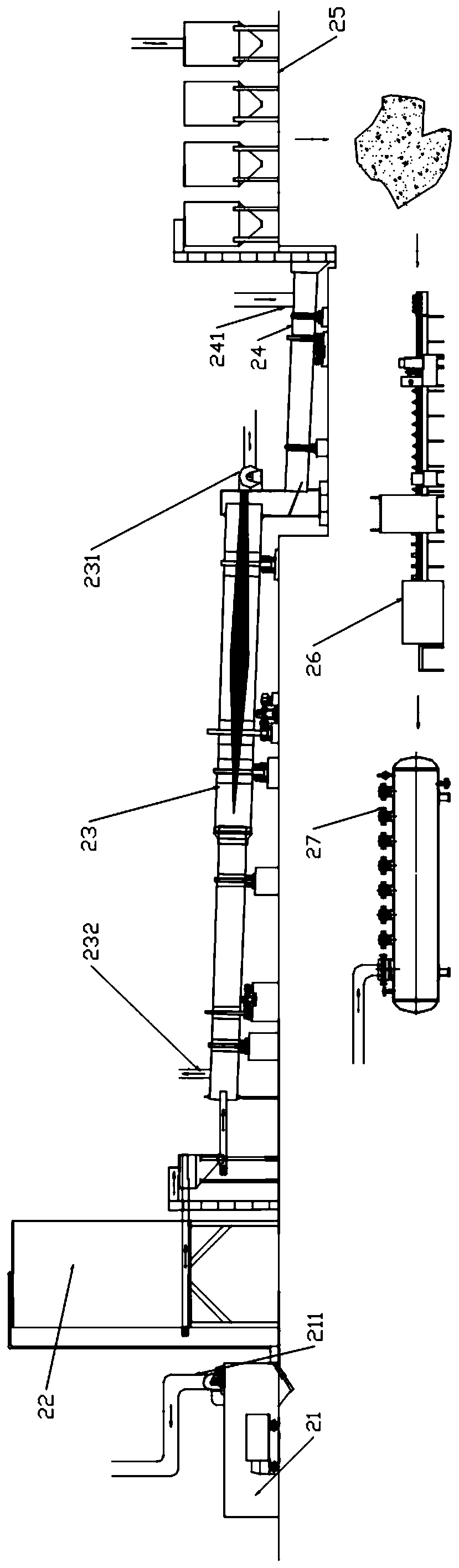

Plasma cutting fume processing system and method for spiral welded steel pipe

ActiveCN105414141BAvoid spreadingPassing resistance is smallCombination devicesDispersed particle filtrationEngineeringSteel tube

The invention discloses a spiral-welded steel pipe ion cutting smoke treatment system capable of improving the dust removing efficiency and preventing the dust dispersion and being provided with good popularity. The smoke treatment system comprises a dust sucking cover and a dust removing host machine; the spiral-welded steel pipe ion cutting smoke treatment system further comprises a rigid dust removing pipe; two dust sucking ports are at least formed in the lower surface of the dust sucking cover; the dust sucking ports are uniformly distributed in the length direction of the dust sucking cover; fireproof soft curtains are arranged around the lower surface of the dust sucking cover; the dust removing host machine is provided with an exhaust port and a dust sucking main pipe; the dust sucking ports of the dust sucking cover are communicated with the dust sucking main pipe through dust removing pipes; the dust sucking ports and the dust removing pipes are corresponding one to one; and valves are arranged on the dust removing pipes. The invention further discloses a method for treating smoke by using the smoke treatment device. The device and the method, provided by the invention, can improve the smoke sucking efficiency, are excellent in popularity, and can prolong the service life of a filter barrel.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

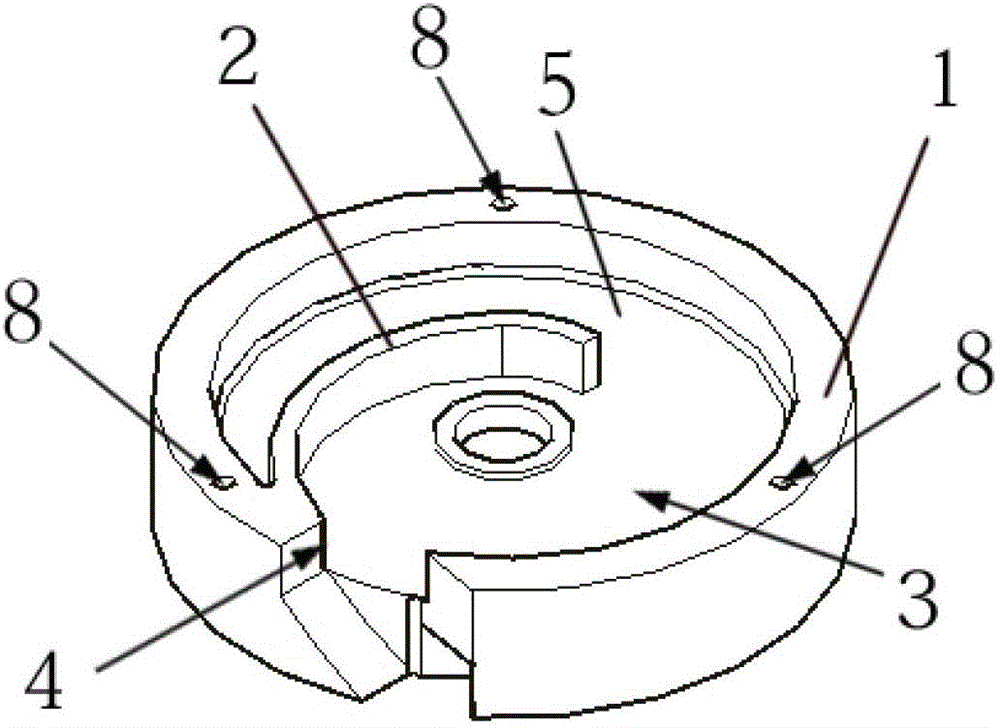

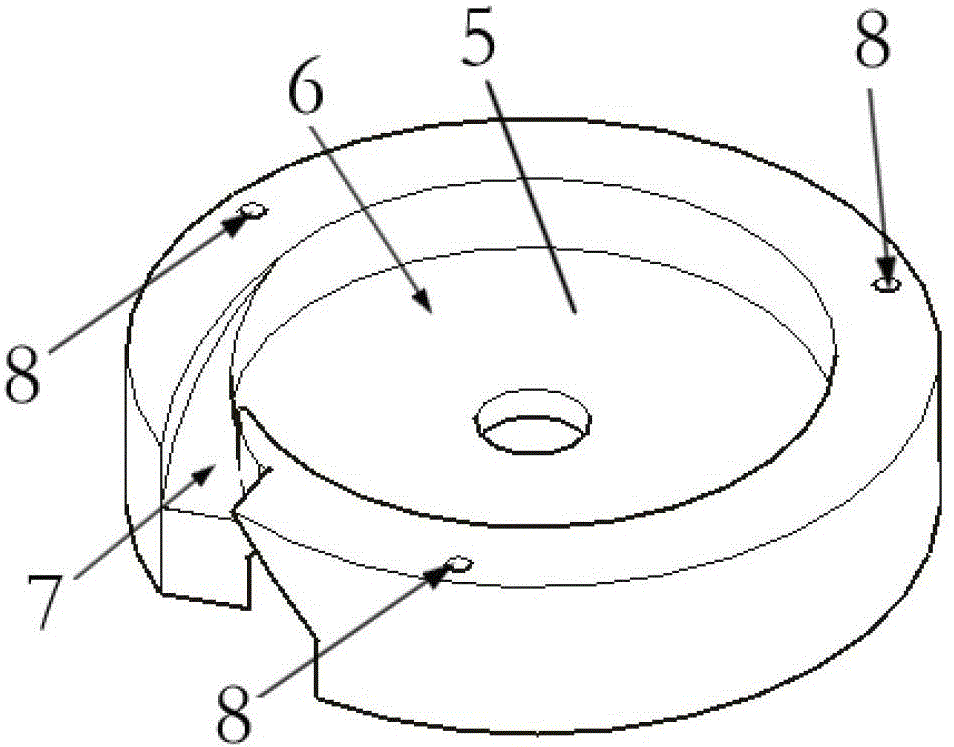

A volute guide vane

The invention discloses a volute type guide vane. The volute type guide vane mainly comprises a guide valve casing, a middle plate, a water baffle plate, a volute chamber and a water outlet chamber. The guide vane is of a tubular structure, the middle plate is arranged in the guide vane casing to divide the same into the water outlet chamber and the volute chamber, the middle plate is provided with a hole in the middle, the water outlet chamber is provided with a water inlet on the guide vane casing, the volute chamber is provided with a water outlet on the guide vane, the water baffle plate is arranged in the water outlet chamber and extends from the water inlet to the center of the water outlet chamber, and the inner wall of the volute chamber is an arc-shaped surface or a spiral curved surface. By the volute type guide vane, efficiency of a clean water pump and a sewage pump is improved, the sewage and waste pump can be of a multi-stage pump structure on the premise of guaranteeing solid particle passing capability, and lift of the sewage and waste pump is improved greatly so as to realize substantial breakthrough.

Owner:遵义海立水泵制造有限责任公司

Comprehensive treatment method and treatment system for domestic garbage and sludge

The comprehensive treatment method and treatment system of the domestic garbage and sludge by waste treatment of the present invention can greatly improve the utilization rate of the combustible gas by directly transporting the combustible gas generated by the pyrolysis furnace to the drying and calcining furnace for use as combustion-supporting gas At the same time, the drying calciner no longer needs to use natural gas as fuel, which greatly reduces the cost of sludge recovery; by transporting the remaining combustible gas to the steam boiler for combustion, and transporting the generated steam to the autoclave for use, The autoclave does not need to provide additional external steam, so the cost of sludge recovery can be greatly reduced. The invention realizes the organic combination of the garbage pyrolysis process and the sludge recovery process, and utilizes the waste gas and waste residues produced by the two processes to achieve the purpose of treating waste with waste, which not only meets the requirements of environmental protection, but also improves production efficiency, and has the advantages of Very high promotional value.

Owner:GUANGZHOU CHUNMEI ENVIRONMENT POLUTION CONTROL SPECIAL EQUIP TECH CO LTD

A compressor silencer

ActiveCN104153968BLarge lateral areaImprove sound absorptionPositive displacement pump componentsPositive-displacement liquid enginesEngineering

The invention discloses a compressor silencing mechanism which comprises a lower shell. An upper cover is fixedly connected with the head end of the lower shell, the upper cover and the lower shell define a silencing cavity, a resistive silencing portion is arranged in the silencing cavity, and an air outlet and an air inlet are further formed in the upper cover or the lower shell. The compressor silencing mechanism further comprises a cylindrical inner barrel, multiple through holes are formed in the side wall of the inner barrel, the resistive silencing portion comprises multiple silencing barrels which are open at the lower ends, multiple strip-shaped ridges parallel to the axial direction of the silencing barrels are arranged on the side faces of the silencing barrels, and resistive sound absorption materials are fixedly connected with the left side and the right side of each strip-shaped ridge respectively. The resistive sound absorption material between every two adjacent strip-shaped ridges form a lip protruding to the inside of the silencing barrels, and the bottom of the lower shell is further provided with silencing barrel connectors which are the same as the silencing barrels in number. The compressor silencing mechanism is good in silencing effect, and can conveniently avoid the phenomenon that the resistive silencing portion is easily damaged due to large partial loads.

Owner:安徽顺风机械设备有限公司

Superfine particulate matter purifying device

ActiveCN102772971BImprove charging effectIncrease the condensation effectCombination devicesAuxillary pretreatmentParticulatesElectrocoagulation

A superfine particulate matter purifying device comprises a gas discharge-electrocoagulation device and a static enhance bag type dedusting integrated device. The gas discharge-electrocoagulation device comprises an air flow inlet (1), a corona wire (2), a gas discharge tube (3), an air flow outlet divergent pipe (5), a direct current power supply (6) and a grounding electrode (7), and the static enhance bag type dedusting integrated device comprises an air inlet (8), a magnetic valve (9), an air pocket (10), a pulse valve (11), a jetting pipe (12), a filtering bag (13), a jetting hole (14), a dust skeleton (15), a dust hopper (16), a spiral dust discharge valve (17), wires (19) and ground wires (20). The air flow inlet is arranged at one end of the gas discharge tube, the other end of the gas discharge tube is connected with the air flow outlet divergent pipe, the dust skeleton is formed by distributing the wires and the ground wires in a vertical direction at intervals, and the superfine particulate matter purifying device is suitable for smoke dust removing and particularly superfine dust purifying devices for particulate matter (PM) below 2.5.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com