Stainless steel elbow with threaded opening lining

A technology of stainless steel and elbows, applied in the direction of elbows, pipes/pipe joints/fittings, coatings, etc., can solve problems such as corrosion and easy leakage at the end of the pipe, achieve excellent pressure-bearing corrosion resistance, smooth inner wall, reduce through the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

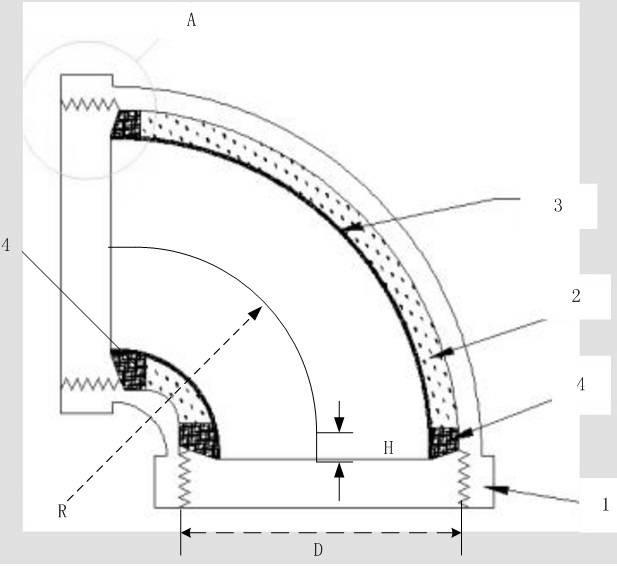

[0027] The stainless steel elbow lined with the wire opening in the embodiment of the present invention refers in particular to a 90-degree elbow.

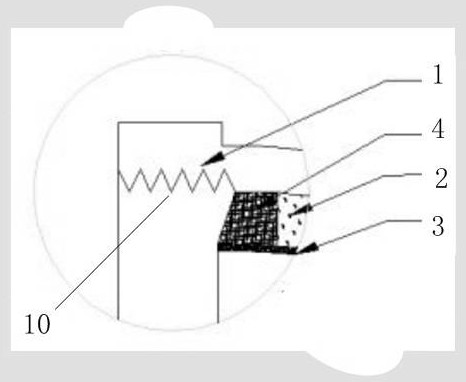

[0028] figure 1 It is a schematic cross-sectional view of a stainless steel elbow lined with a thread opening in an embodiment of the present invention; the stainless steel elbow lined with a thread opening in an embodiment of the present invention includes: an outer jacket 1 and an inner lining layer 3; the outer jacket 1 is a round pipe elbow structure; The inner lining layer 3 sets are arranged in the outer jacket, and there is a filling layer 2 between the inner lining layer 3 and the outer jacket 1; the inner lining layer 3 is a stainless steel elbow; the inner lining layer is processed separately The integrated stainless steel thin-walled elbow is sleeved in the jacket 1 and fixed by adhesion of the filling layer.

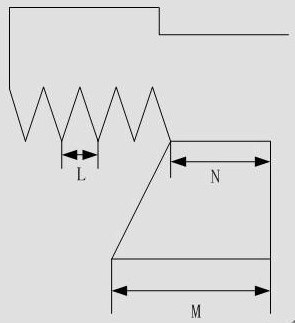

[0029] The inner walls of the two ends of the outer jacket 1 are respectively provided with threaded joints 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com