Filtration type gas separation and purification equipment with rapid moving filtering layer

A technology of high-speed movement and gas separation, which is applied in the fields of ventilation and environmental protection. It can solve problems such as poor mechanical properties, high temperature resistance and corrosion resistance, reduced service life of the filter layer, and difficulty in directly handling gas, etc., so as to achieve stable working conditions and reduce Manufacturing cost and usage cost, effect of power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

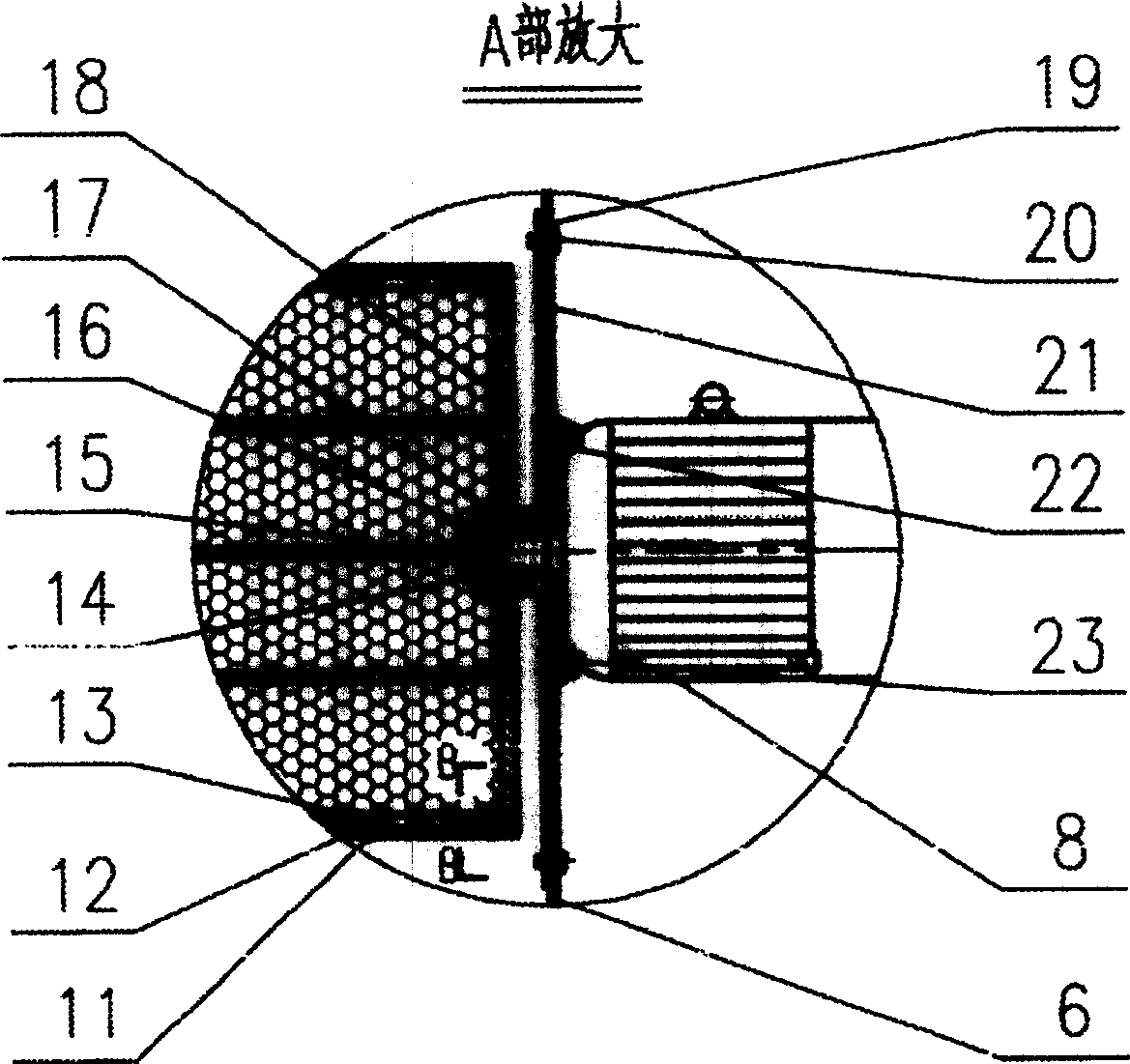

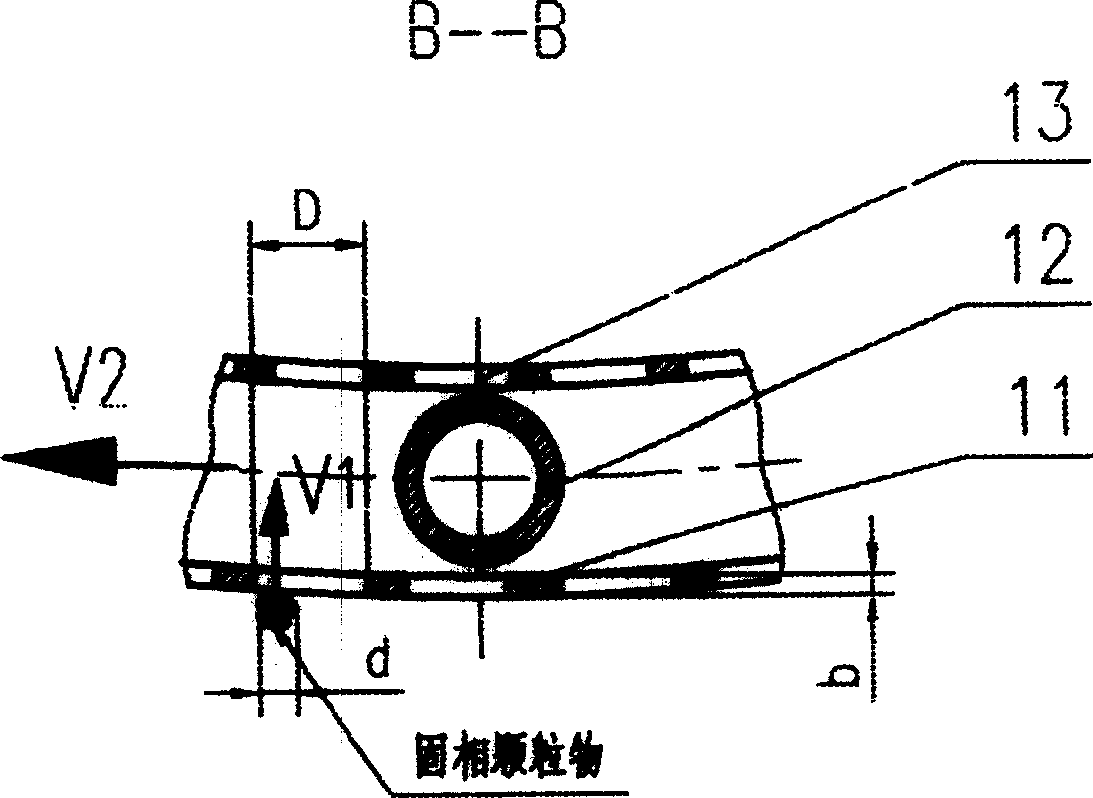

[0029] In the XGD4F axial flow fan (the flow rate is 3080-6180m 3 / h, the total pressure is 505-250Pa, the power of the axial flow fan motor 30 is 0.75kW, and the fan speed is 1450r / min), on the basis of the axial flow fan with a filter cartridge 9 added to the coaxial and coaxial power source, It can replace the current fresh air unit consisting of filter cloth primary filter, high efficiency filter and axial flow fan, such as Figure 5 shown. Axial flow fan housing 29 is welded with 2mm ordinary steel plate, the basic shape is cylindrical, the diameter is 448mm, and the length is 340mm; Filter screen 13, outer layer filter screen 11 constitute, and wherein blind plate 26 diameters are 300mm, and thickness is 3mm, and outer ring 28 external diameters are 440mm, and internal diameter is 400mm, and the axial fan impeller 27 of welding in it, blind plate 26 and The outer rings 28 are connected by pillars 12 and constitute the framework of the filter cartridge 9. The inside and...

specific Embodiment approach 3

[0030] The hybrid heat exchanger used for heat exchange between cold and hot fluid is water and air, and the heat exchange gas volume per unit time is 10800m 3 / h, the heat exchange capacity per unit time is 8m 3 / h, the thermal parameters of air before heat exchange are: dry bulb temperature = 28°C, wet bulb temperature = 22.5°C, and the thermal parameters of water before heat exchange are 14°C. Such as Figure 6 shown. The main body of the equipment is welded with 3mm ordinary steel plate. The basic dimensions of the equipment are: length 1050mm, width 550mm, height 1100mm. The heat exchanger shell 33 is welded with 3mm ordinary cold-rolled steel plate. The body 33 has a built-in 450×550mm plastic wire mixed flow net 35 with a thickness of 180mm. The mixed flow net 35 is fixed by a fence 34, and 16 centrifugal nozzles 36 are arranged on the right side of the mixed flow net 35, and the centrifugal nozzles 36 are installed on the liquid distribution pipe 37. , and supply th...

specific Embodiment approach 4

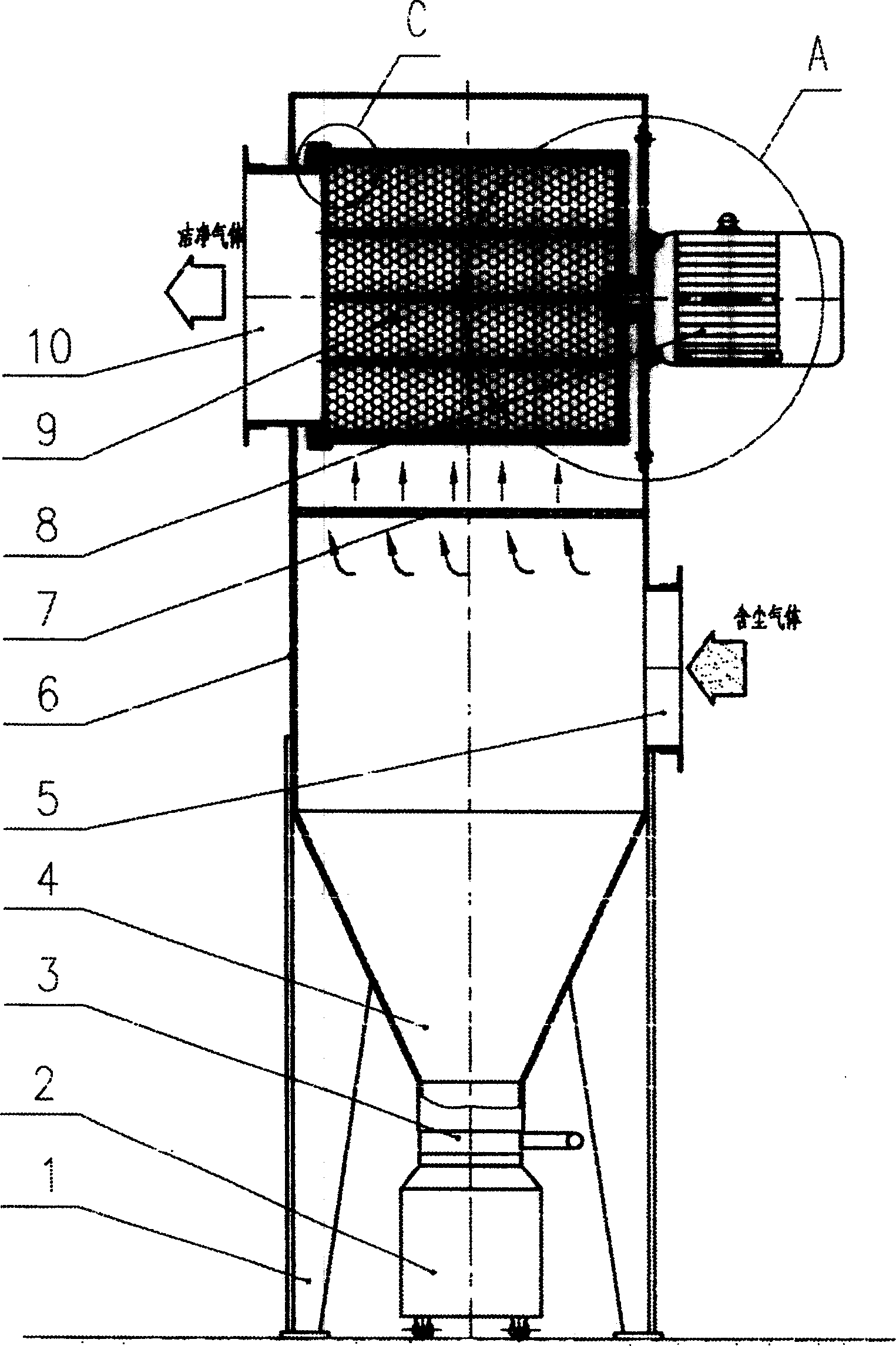

[0031] with a power of 7.5kW and a flow rate of 7m 3 / min, the filter in the centralized dust collection unit matched with the Roots vacuum pump with a vacuum degree of 35000Pa can replace the current bag filter in the unit, such as Figure 7 As shown; the equipment body is welded with 6mm ordinary steel plate, the basic shape of the equipment is cylindrical, the external dimension is Φ850mm, and the height is 2550mm. The ash hopper 4 is arranged between the filter housing 44 and the ground from bottom to top, and a vertical filter cylinder 9 is arranged on the top of the filter housing 44. It is 0.75kW, driven by a motor 8 with a speed of 16r / s; the outer filter 11 is made of diamond-shaped stainless steel steel mesh with a diameter of 2mm×4mm and a thickness of 1mm, and its inner filter 13 is made of a diameter of 1mm×1.5 It is made of diamond-shaped stainless steel expanded mesh with a thickness of 1mm. The elbow pipe 41 is welded on the inner wall of the filter housing 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com