Metal filter

A metal filter and peak technology, which is applied in the field of metal filters, can solve the problems of large smoke exhaust passage resistance and high production cost, and achieve the effects of improved passage efficiency, excellent cleaning, and high-efficiency adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Next, embodiments of the present invention will be described in detail with reference to the drawings.

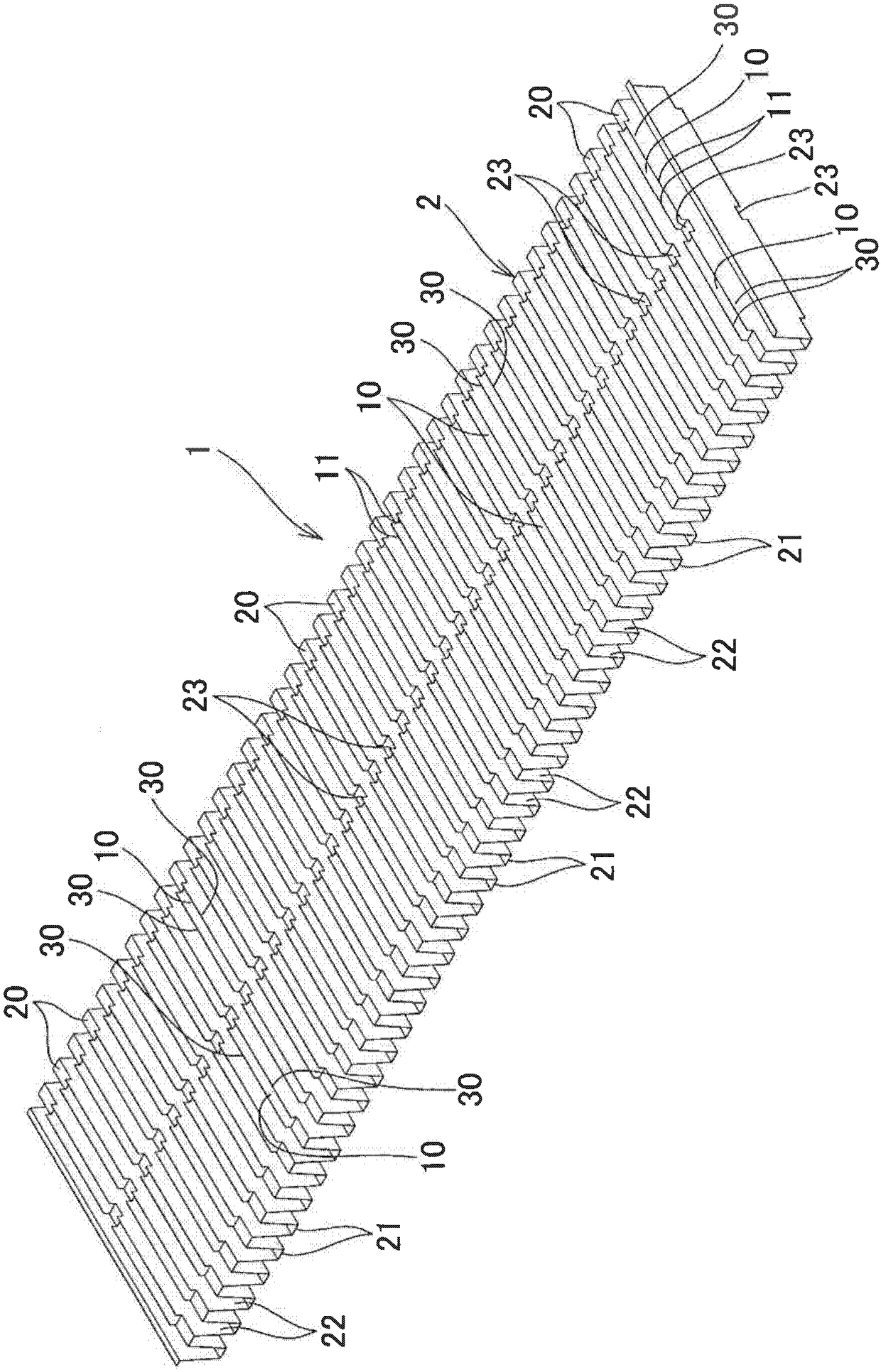

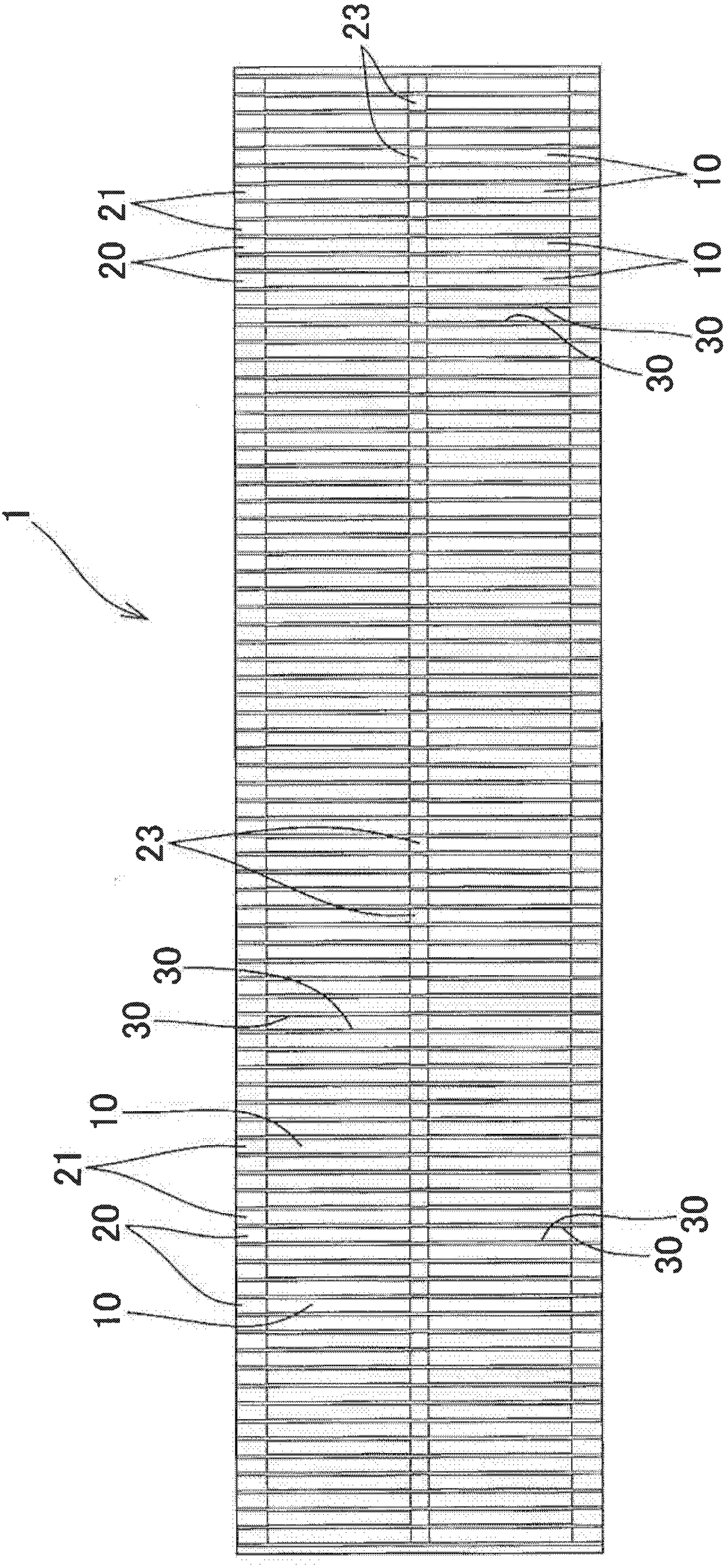

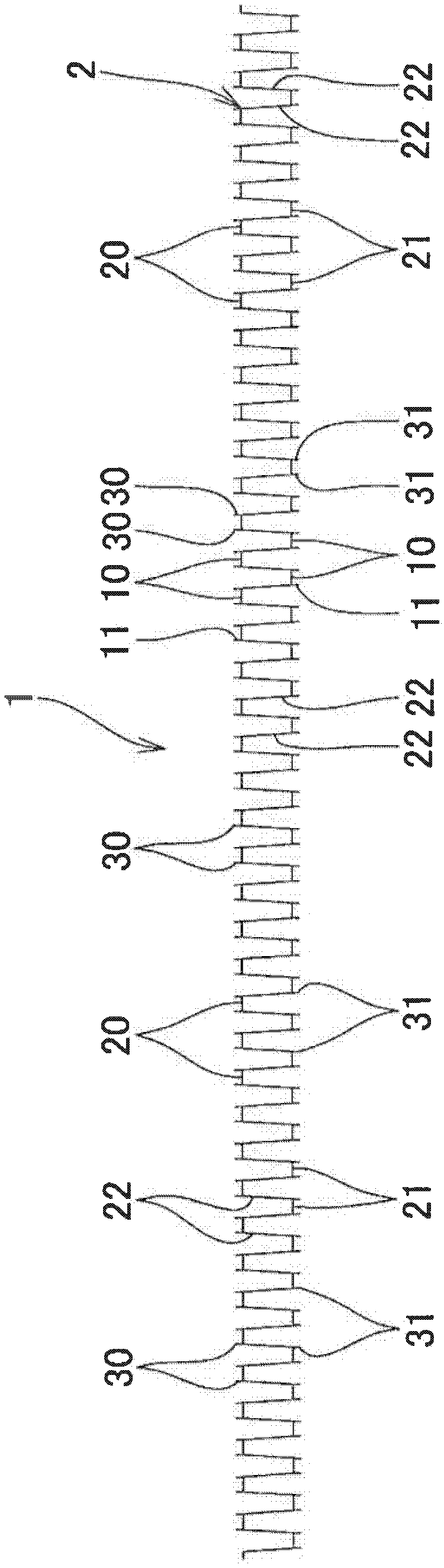

[0081] Such as Figure 1 to Figure 5 As shown, the metal filter 1 of the present invention is provided on one or both of the above-mentioned peaks 20 and valleys 21 of the metal plate main body 2 having a plurality of columns of peaks 20 and valleys 21 alternately formed for Through grooves 10 extending in the row direction through which fluid passes, and opening edge portions 11 of the through grooves 10 are provided with rising pieces 30 and 31 rising toward the convex side of the peaks 20 or valleys 21 .

[0082] Although not shown in the figure, the metal filter 1 can be formed as a cleaning filter having catalyst layers such as photocatalysts, activated carbon, aromatics, manganese dioxide, etc., and adsorption layers on the surface, or without forming such catalyst layers, And it is preferable to directly use the metal material as a grease filter in the kitche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com