Inflator

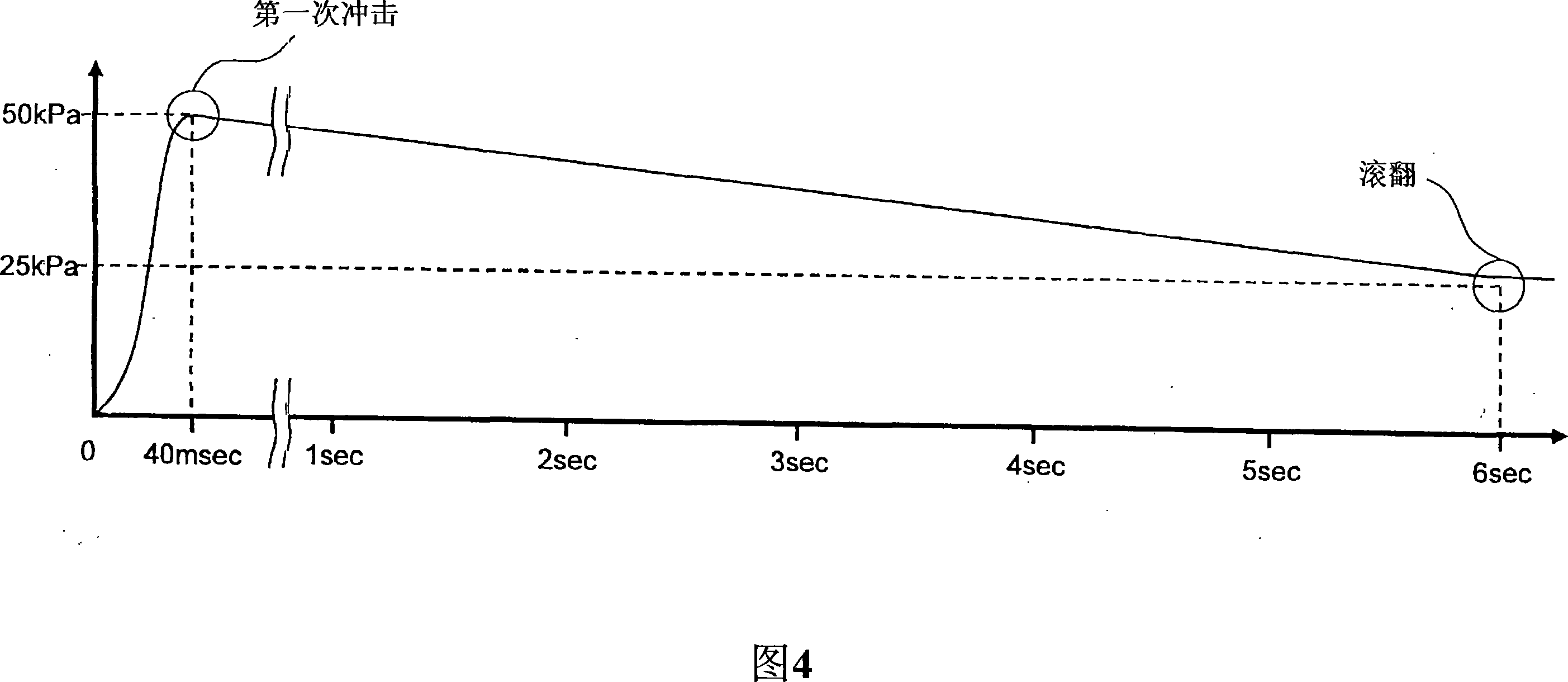

An inflator and gas technology, applied in the direction of gas generating devices, vehicle safety arrangements, pedestrian/passenger safety arrangements, etc., can solve the problems of longer release time, weakening, and difficulty in maintaining the first impact and inflation time of the airbag at the same time, Achieve the effect of compact cylindrical frame and enhance the first impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

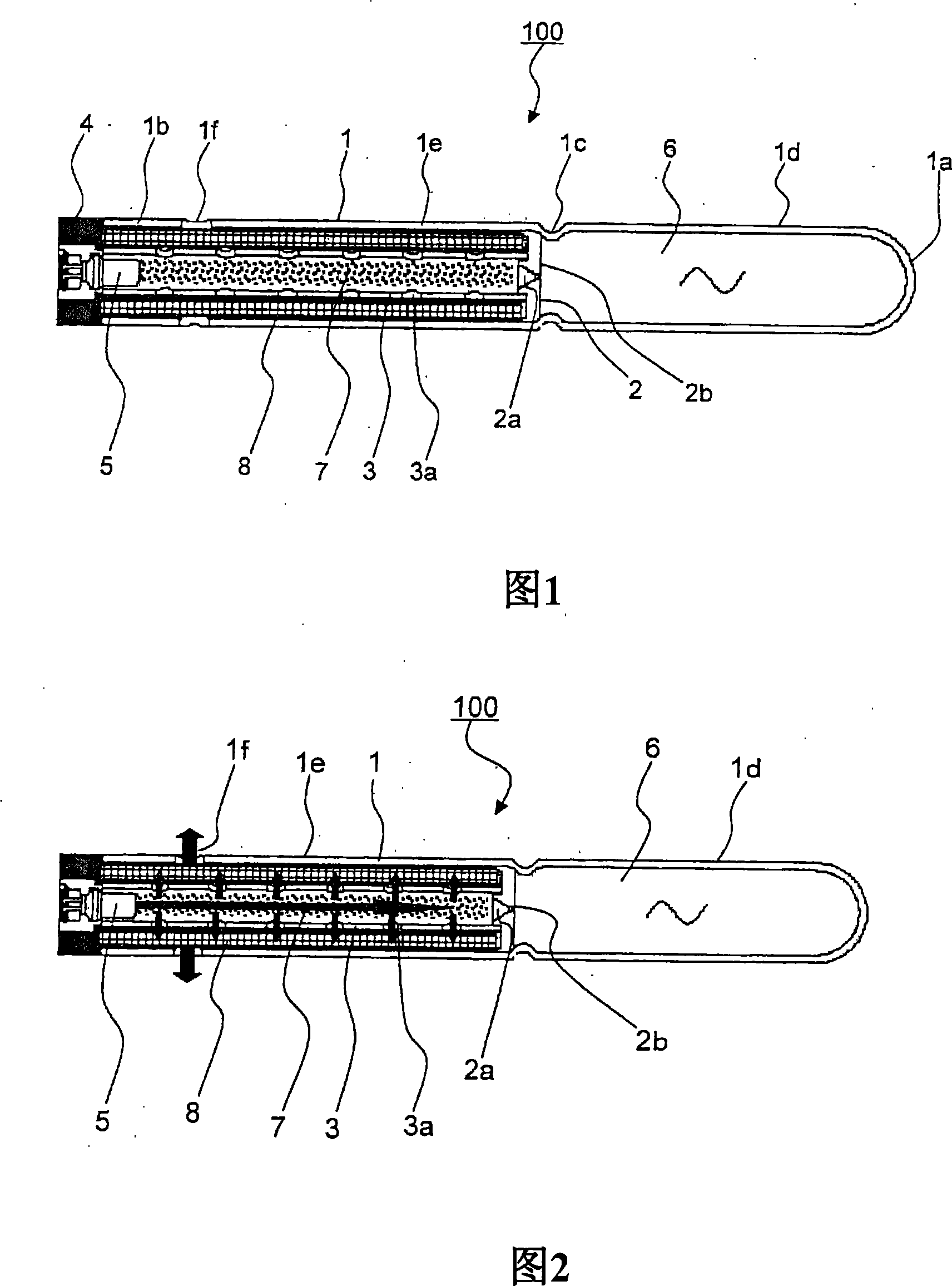

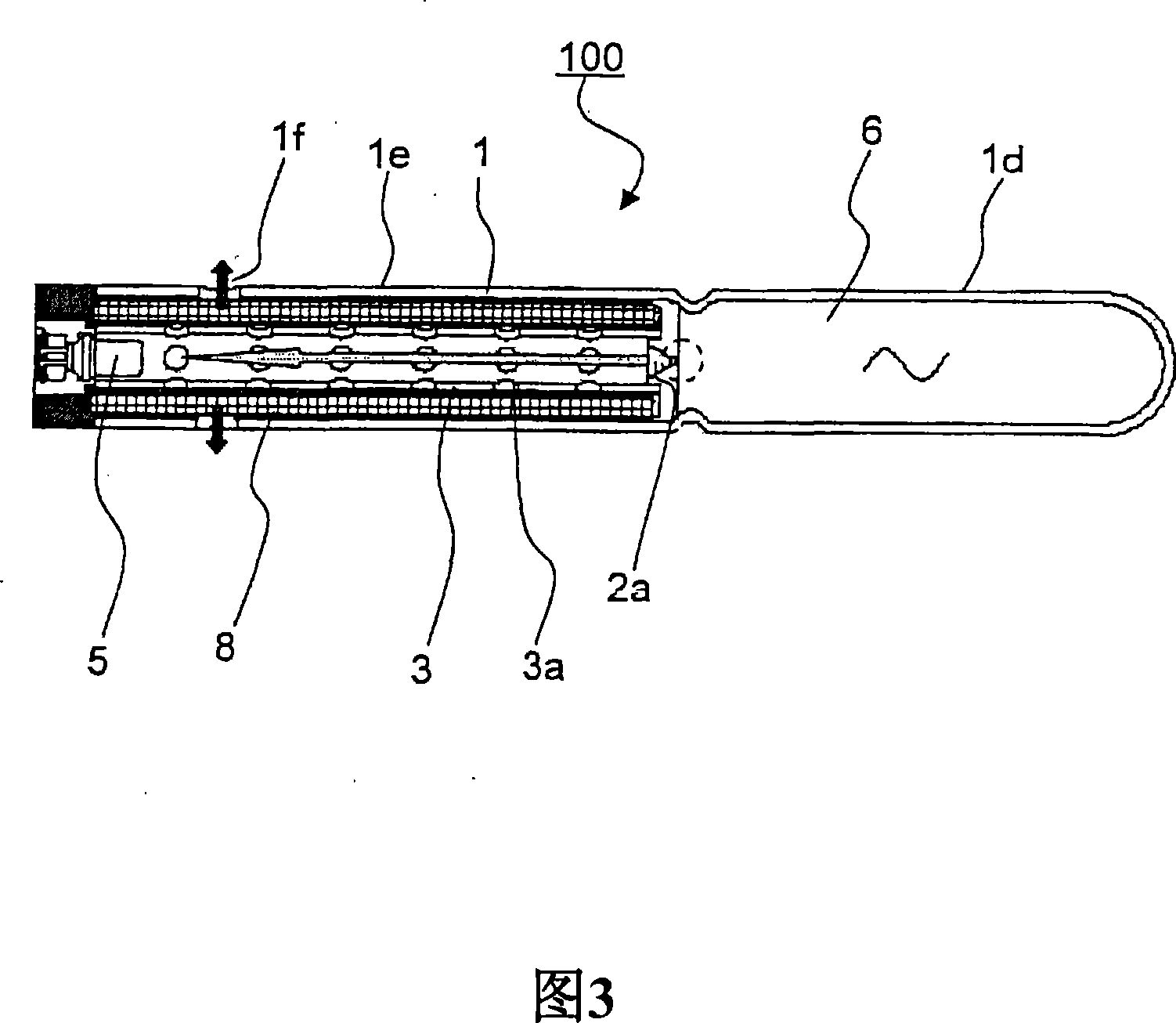

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a cross-sectional view showing an embodiment of the inflator of the present invention.

[0022] As shown in FIG. 1 , the inflator 100 of the present embodiment is suitable for an inflator used in, for example, a curtain air bag (not shown) that can be deployed on the side of a vehicle compartment. The frame is a cylindrical frame 1 similar to a test tube, with a hemispherical bottom 1a at one end, an opening 1b at the other end, and a narrow portion 1c in the middle.

[0023] An orifice plate 2 serving as a flow adjustment member inserted from the side of the opening 1 b is airtightly fixed to the narrow portion 1 c of the cylindrical frame 1 . At the center of the orifice plate 2, an orifice 2a is formed as an adjustment hole for generating airflow resistance. The orifice 2a has a diameter of about 1 mm, and is closed by a thin metal plate 2b having a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com