burner

A combustion device and burner technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of unobtainable, difficult to reduce fan noise, and inability to fully reduce the passage resistance of combustion exhaust, so as to reduce fan noise, Effect of Resonance Noise Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

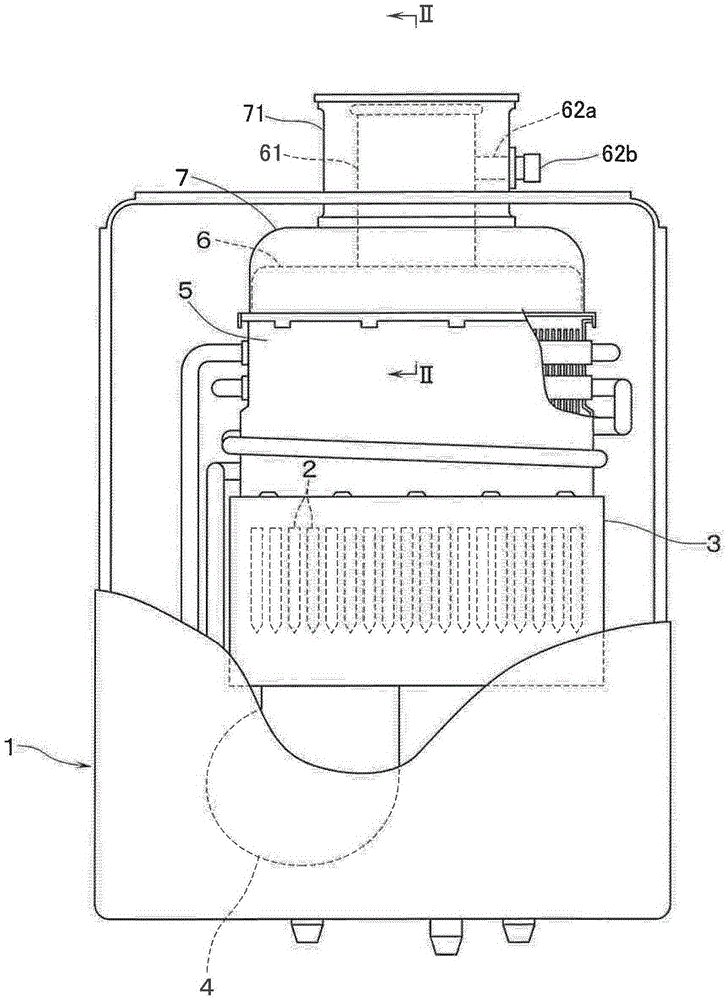

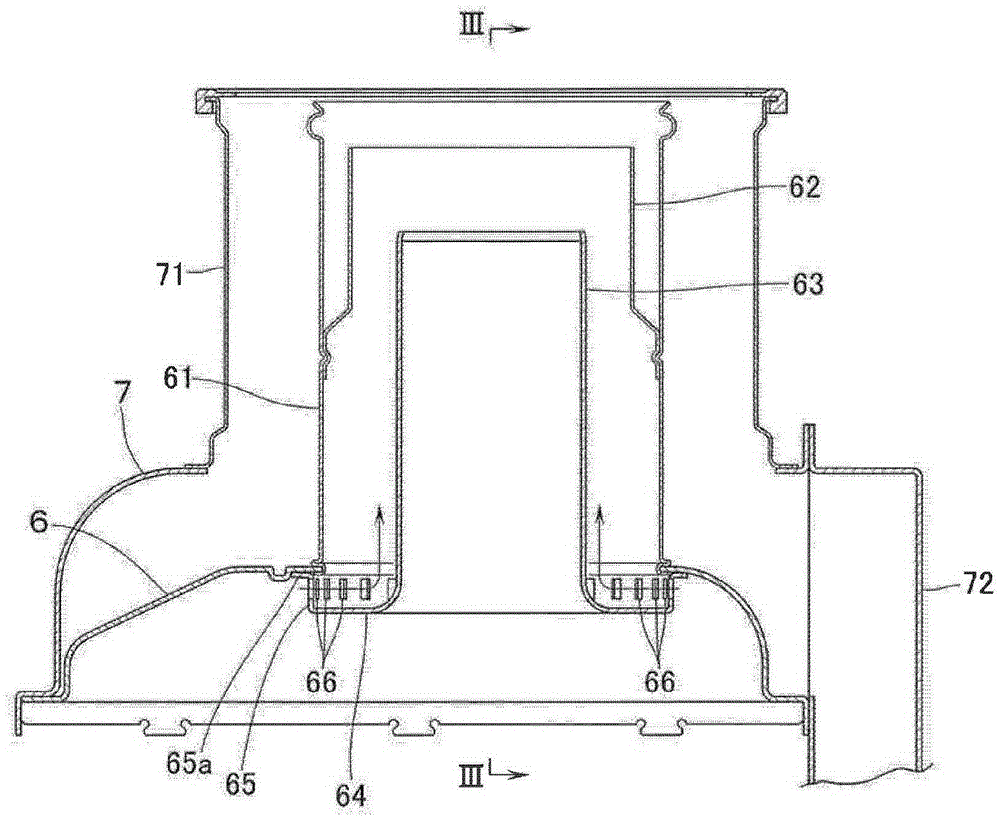

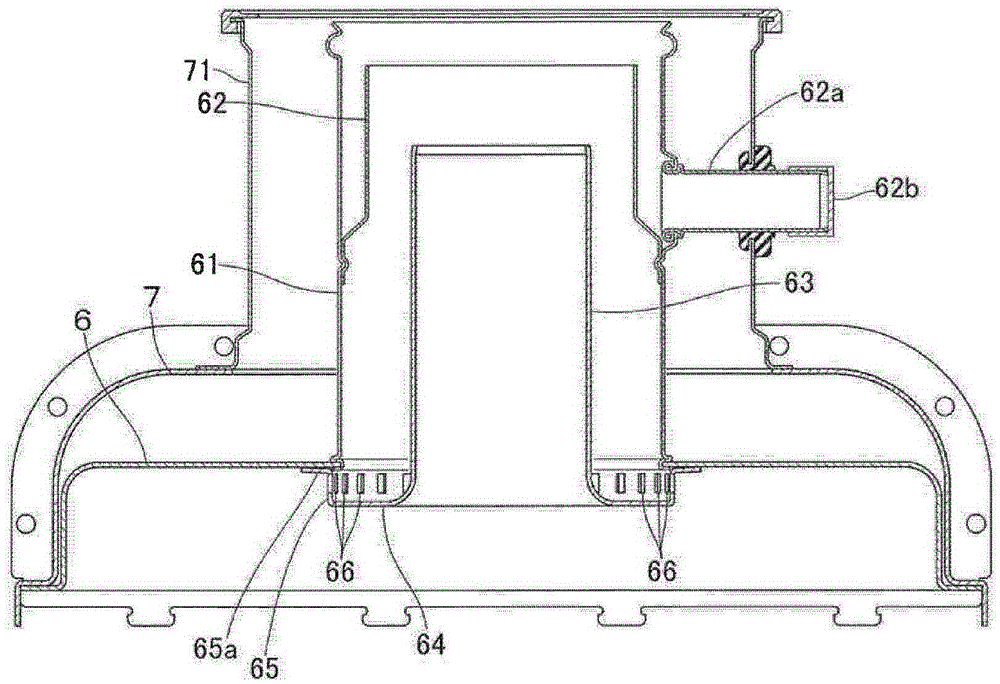

[0019] figure 1 A combustion device composed of a heat source device for water supply installed indoors is shown. This combustion device includes an exterior case 1 . Disposed in the outer casing 1 are: a combustion frame 3 with a plurality of rich-lean combustion type burners 2 built in; a fan 4 below the combustion frame 3; a heat exchanger 5 for water supply above the combustion frame 3; a heat exchanger 5 above the exhaust hood 6; and the exhaust hood 6 covered air supply hood 7. And, utilize the fan 4 via the air supply hood 7 and the air supply pipe 72 connected with the air supply hood 7 (refer to figure 2 ) sucks outside air from an air supply tube extending outside (not shown), and supplies the outside air as combustion air into the combustion frame 3 . Combustion exhaust gas from the burner 2 flows from the combustion frame 3 to the heat exchanger 5 and heats the outside air. Then, the combustion exhaust gas passing through the heat exchanger 5 flows into the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com