Connecting structure of transformer wire outgoing device

A connection structure and transformer technology, which is applied in the field of transformer manufacturing, can solve the problems affecting the overall shielding effect of the outlet device, screw discharge, easy separation, etc., and achieve the effect of solving corrugated cardboard movement, solving easy discharge, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

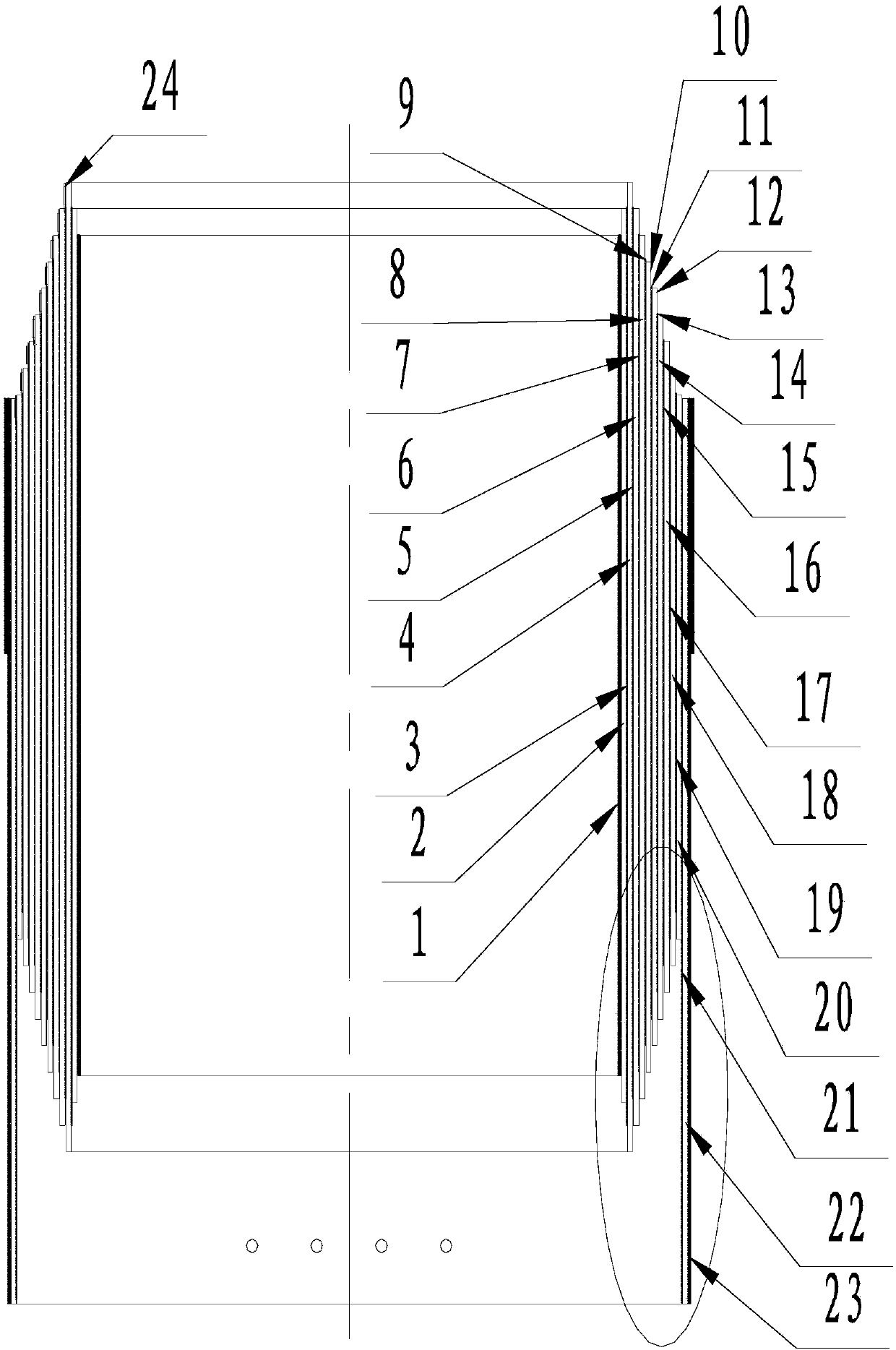

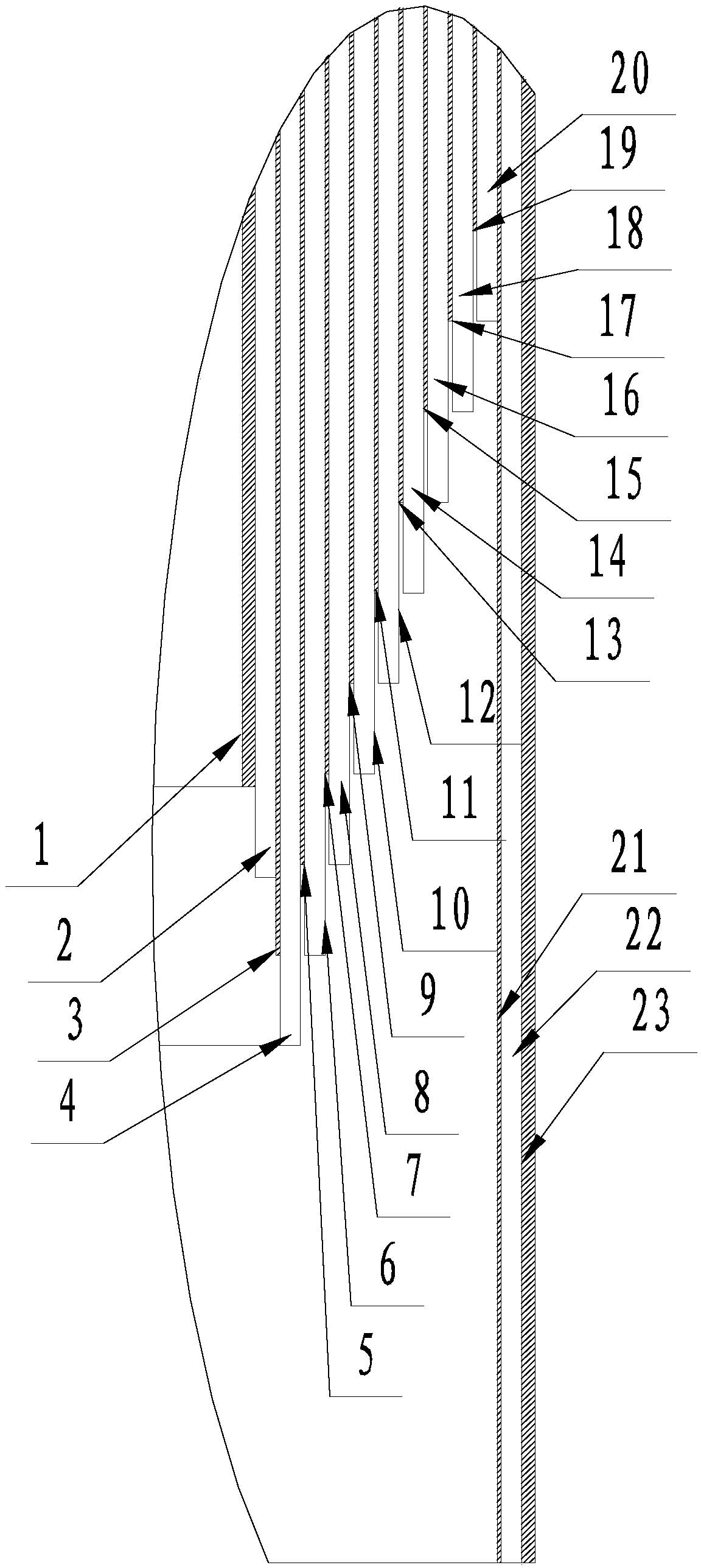

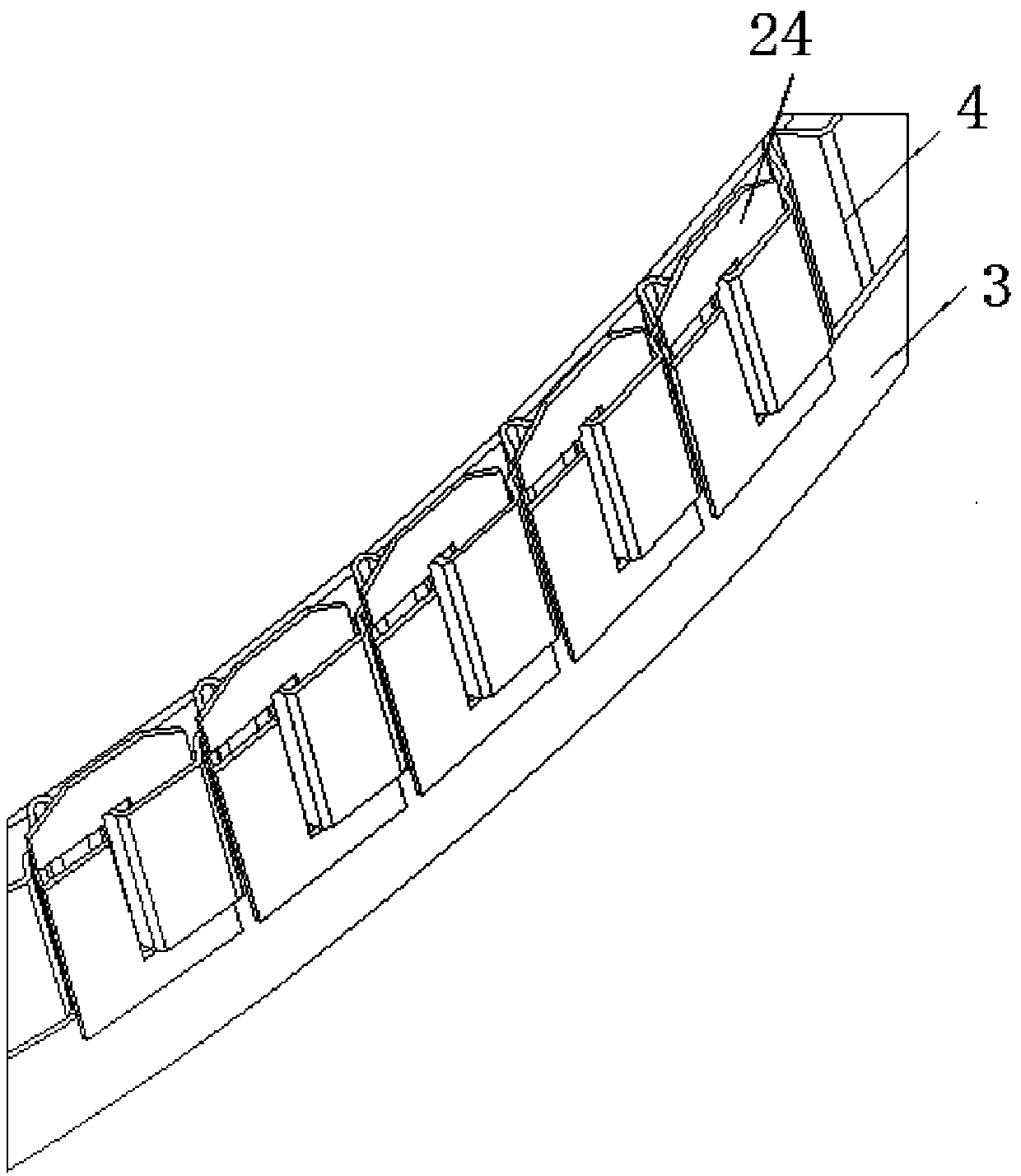

[0021] Such as figure 1 As shown, a connection structure of a transformer outlet device in the present invention adopts a structure in which multi-layer cardboard tubes are used to divide the oil gap, and corrugated cardboard tubes are inserted between the cardboard tubes; there is a distance difference between the ends of each layer of cardboard tubes and adjacent corrugated cardboard tubes , assemble cards 24 at the upper and lower ends of each level of corrugated cardboard tube.

[0022] Each layer of cardboard tube and from the inside to the outside, the height of the upper end gradually decreases from two layers to other layers; each layer of corrugated cardboard tubes from the inside to the outside, the upper end height gradually decreases from two layers to other layers, and each layer of corrugated cardboard The height of the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com