Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce thickness fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for rolling welding line under automatic control

InactiveCN102172634AReduce the rate of weld breakageImprove yieldRoll force/gap control deviceTension/compression control deviceAutomatic controlEngineering

The invention relates to the cold tandem rolling technology. The invention solves the problem that the thickness is seriously out of tolerance caused by the traditional manual control welding line thickening method and provides a method for rolling a welding line under automatic control. The technical scheme in the method can be summarized as follows: when the welding line passes through each rack, a gap between rollers and speeds of the rollers are changed by adopting an automatic control way, thus the welding line is thickened and the tensile force of strip steel is maintained to be constant. The method provided by the invention has the beneficial effects that the strip breakage rate of the welding line is reduced and the rate of finished products is improved, and the method is applicable to a cold tandem rolling machine set.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

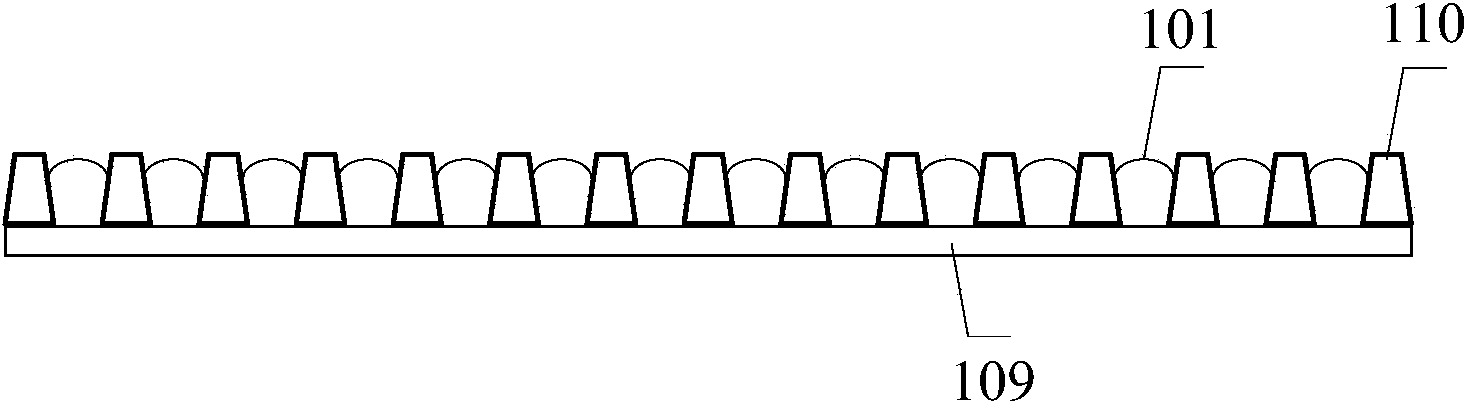

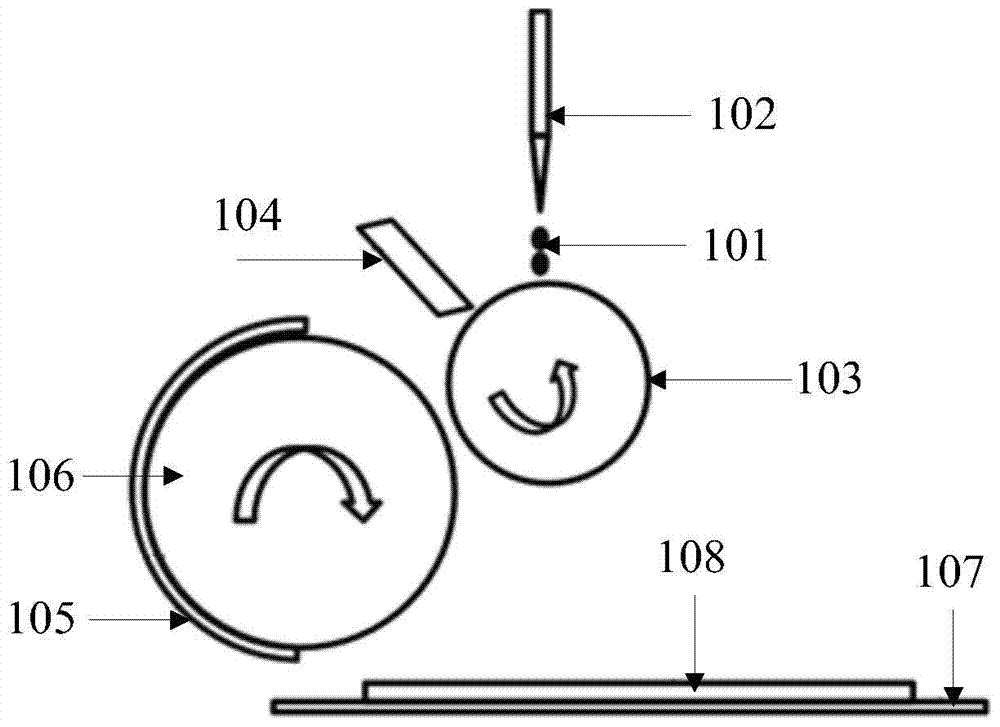

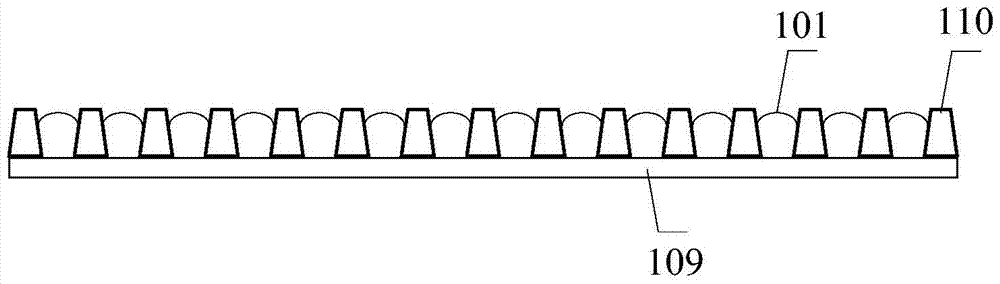

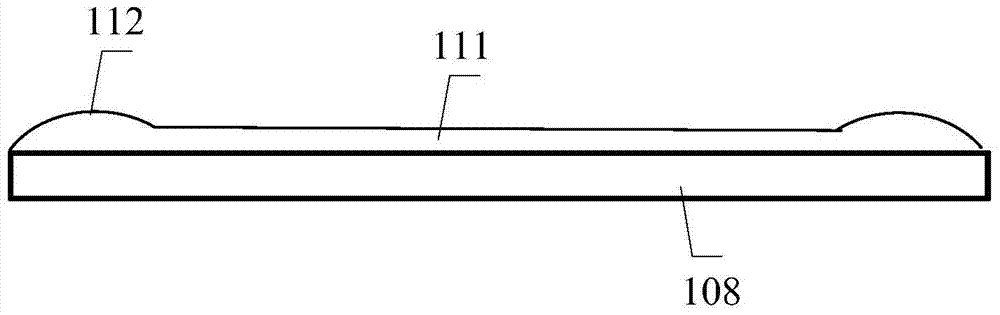

Transfer printing plate

ActiveCN104317110AReduce thickness fluctuationLower the altitudeNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a transfer printing plate. The problem that a printed orientation film is uneven in thickness through an existing transfer printing plate structure, so that following friction orientation is not even, and accordingly liquid crystal molecular orientation is abnormal is solved. The transfer printing plate comprises a base film and net point arrays formed by a plurality of net points placed on the base film. The base film is divided into an active zone and a non-active zone surrounding the active zone. The active zone corresponds to a liquid crystal display zone. The net point array in the active zone has a first net point angle. The net point array in the non-active zone has a second net point angle. The second net point angle is smaller than the first net point angle.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

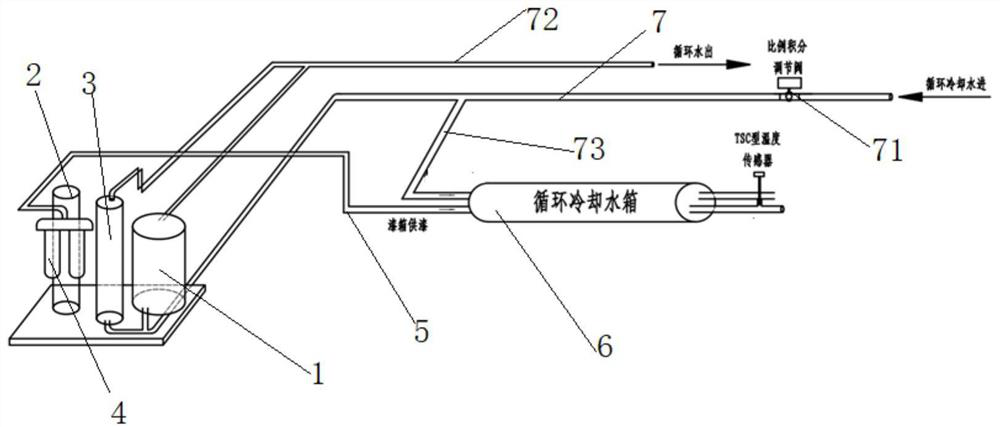

Control method of cooling liquid for cold rolling strip steel

InactiveCN100363122CReduce thickness fluctuationImprove thickness control accuracyTemperature control deviceCooling fluidStreamflow

The control method of cooling liquid for cold rolling strip steel includes: for the process computer to calculate the cooling liquid flow rate under the rated speed based on the friction and heat conductance in cold rolling; for the process computer to down send the cooling liquid flow rate during rolling; for the PLC to match based on the cooling liquid flow rate and the rolling speed and to apply the matched flow rate as the given value for controlling the valve; and for the PLC to calculate the control degree and opening of the valve, with the control degree being calculated based on the mathematical model. The present invention compensates the effect of pipeline, nozzle and other factors by means of the mathematical model to obtain the practical flow rate value and can raise the control precision of strip steel thickness.

Owner:ANGANG STEEL CO LTD

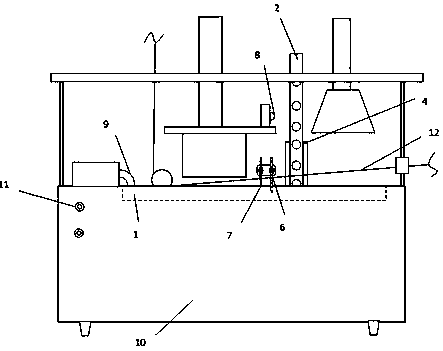

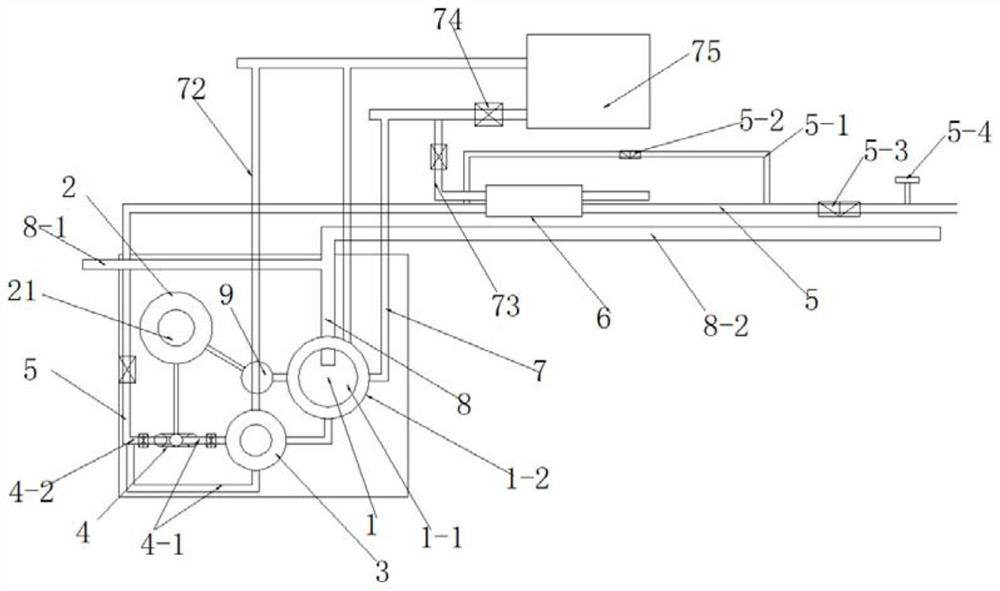

Automatic tin adding device of tin plating equipment and tin adding method

InactiveCN110000444AReduce shockReduce thickness fluctuationHot-dipping/immersion processesMetal working apparatusAutomatic controlTin plating

The invention discloses an automatic tin adding device of tin plating equipment and a tin adding method. According to the automatic tin adding device, a tin block is arranged in a tin box with the bottom provided with a hollow liquid outlet, a PLC automatic control module is utilized for controlling the action of the tin box, and when tin supplementing is needed, the bottom of the tin box is vertically immersed in tin liquid, heat of a tin pond is utilized for melting the tin block, meanwhile, the melted part is gradually supplemented through gravity of the tin block, and after the tin pond iscompletely supplemented, the whole tin box is automatically lifted, the whole tin supplementing action is soft and continuous, and the liquid level of the tin pond is stable. Through the above manner, impacts on the liquid level of the tin pond during tin block adding can be reduced, generation of ripples is reduced, product tin plating layer thickness fluctuation is obviously reduced, and the product precision is obviously improved; and the tin supplementing structure is exquisite and can be embedded in the tin plating equipment, the occupied space is small, and the integral size of the tinplating equipment is reduced.

Owner:江苏揽鑫新能源科技有限公司

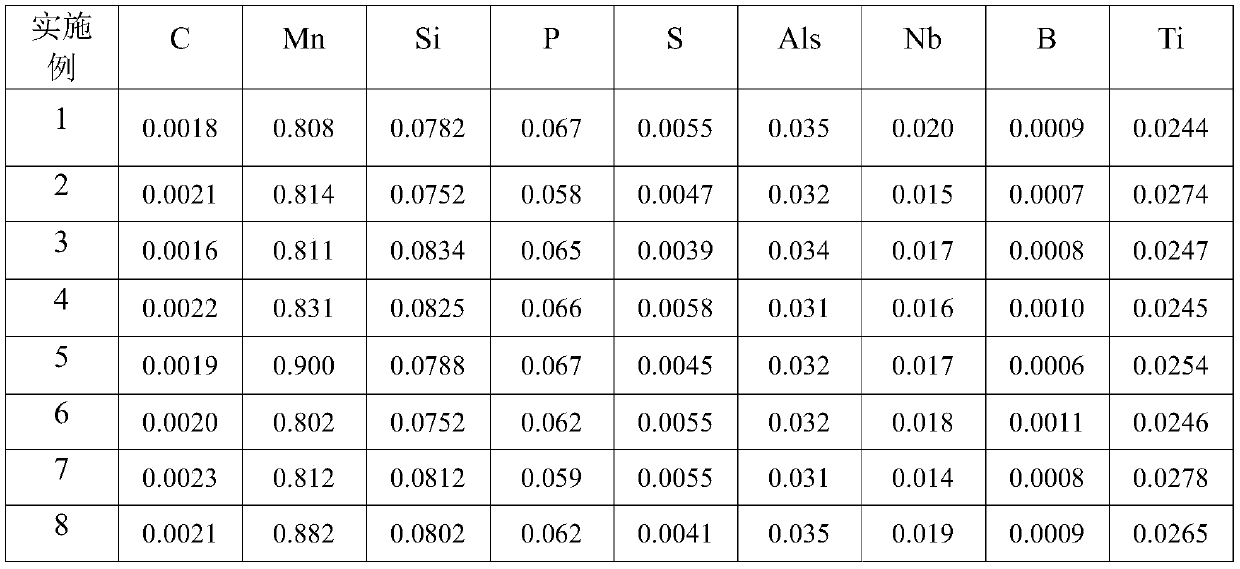

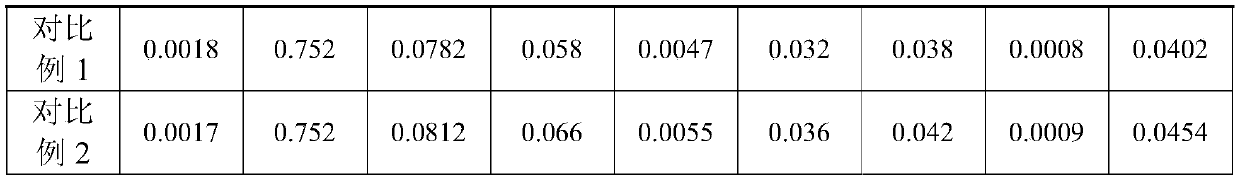

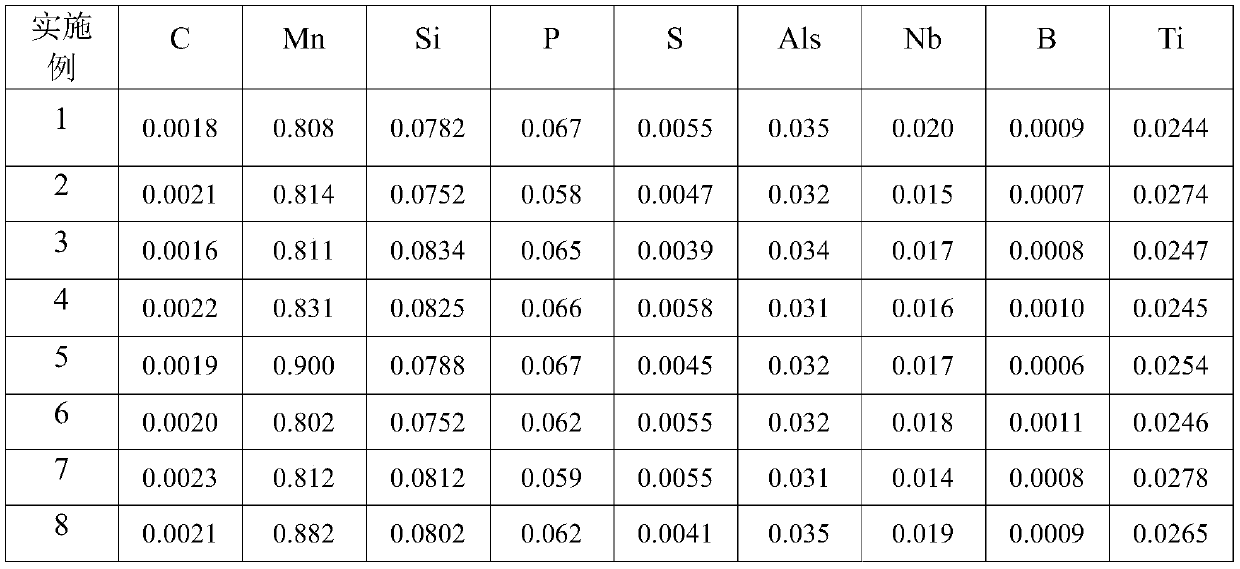

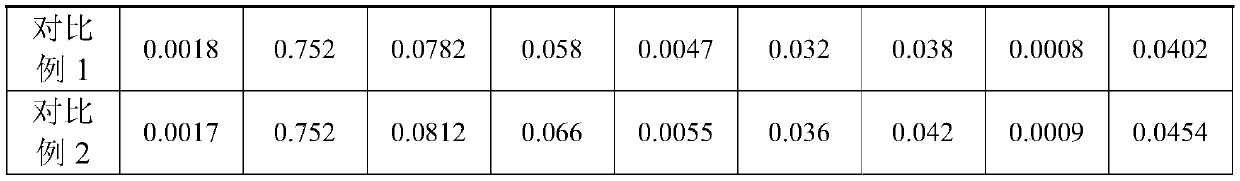

IF cold rolling steel with the tensile strength larger than or equal to 440 MPa and production method

ActiveCN109913754AStable rolling processStable rolling process is stable, reducing strip thickness fluctuationsMicrometerStrip steel

The invention discloses IF cold rolling steel with the tensile strength larger than or equal to 440 MPa. The steel comprises, by weight percent, 0.001 to 0.003% of C, 0.07 to 0.10% of Si, 0.70 to 0.90% of Mn, 0.020 to 0.045% of Als, 0.060 to 0.075% of P, not larger than 0.010% of S, 0.0005 to 0.0013% of B, not larger than 0.02% of Nb, and not larger than 0.03% of Ti. A production process comprisesthe steps of conventional smelting and casting to form a blank; rough rolling and finish rolling; segmented cooling to the coiling temperature; reeling a hot rolling plate; acid picking; cold rolling; and reeling a cold rolling plate. On the premise of ensuring the use mechanics of the steel plate, the mechanical property is small in fluctuation, the cold rolling rate is improved to not lower than 20%, the rolling speed can be stabilized to above 500 m / min, the thickness precision can be controlled to be within 15 micrometers, the strip steel rolling process is stable, the strip steel thickness is reduced, the fluctuation is stable, and the plate shape is greatly improved.

Owner:武汉钢铁有限公司

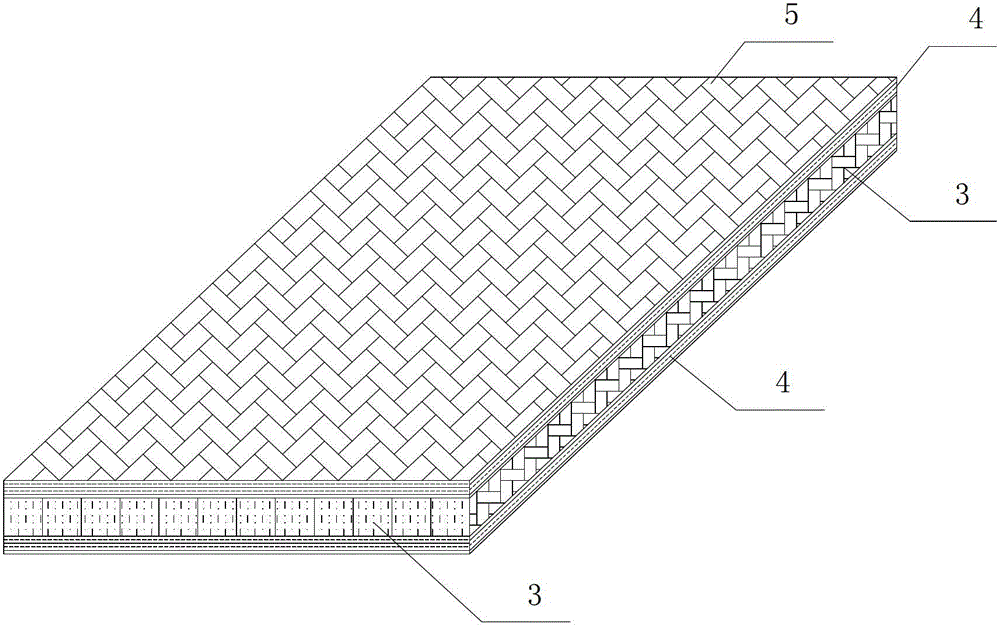

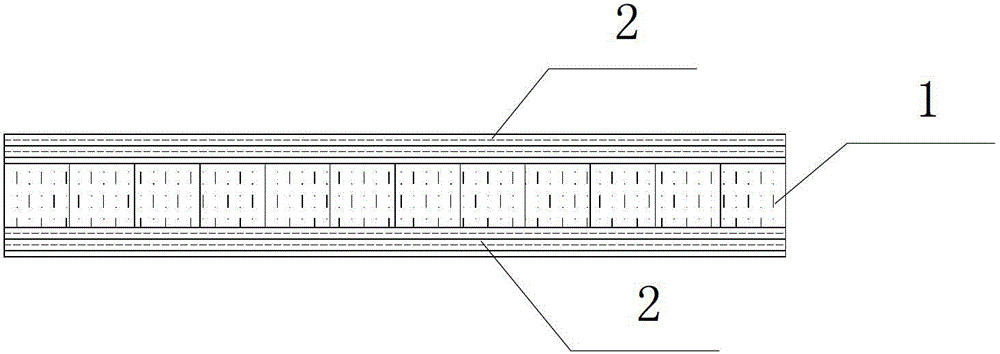

Bamboo plywood for structure

InactiveCN104015231AImprove gripThe problem of realizing double-sided nailingWood veneer joiningWood layered productsEngineeringLath

The invention discloses bamboo plywood for a structure. The bamboo plywood for the structure comprises a core board layer and hot-pressed layers arranged on the two sides of the core board layer. The core board layer is made of battens through lateral cold pressing and gluing and sanding thickness determining, wherein the battens are formed by cutting bamboo plywood GluBam which is used in a structure and has the thickness of 25 mm to 30 mm. The pressed forming surfaces of all the battens in the formed core board layer are perpendicular to pressed forming surfaces of the hot-pressed layers. According to the bamboo plywood for the structure, nails can be driven into two sides of the bamboo plywood, the thickness in each bamboo plywood layer is even, and the thickness tolerance between the plywood layers is small; in addition, the hot-pressing technology efficiency is high, and the mechanical property is high. The bamboo plywood for the structure can completely overcome the inherent defects of the existing plywood GluBam and is used for production and construction of the bamboo structure.

Owner:HUNAN UNIV

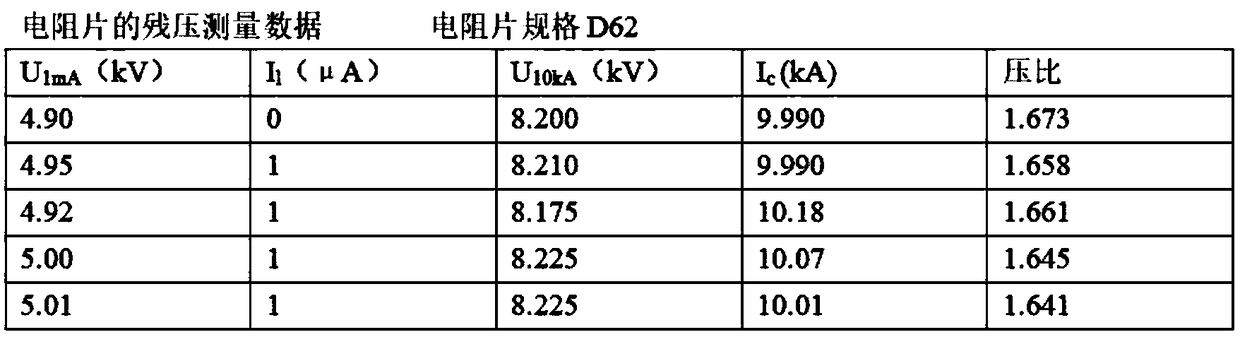

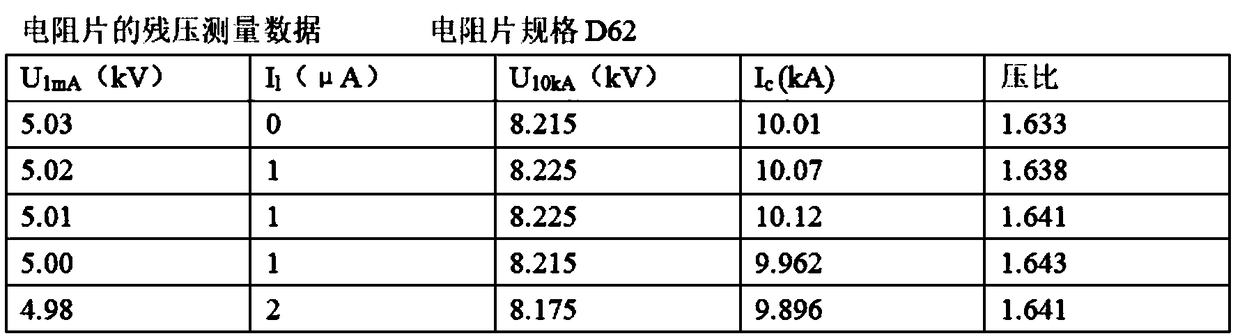

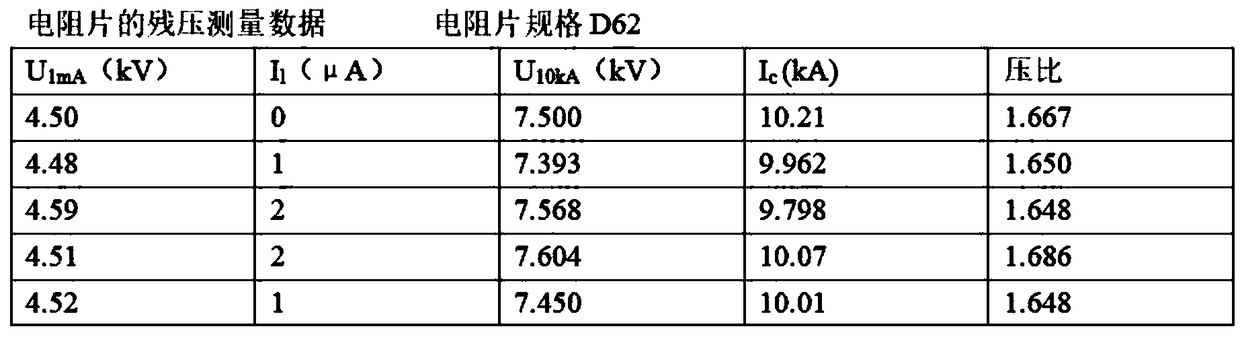

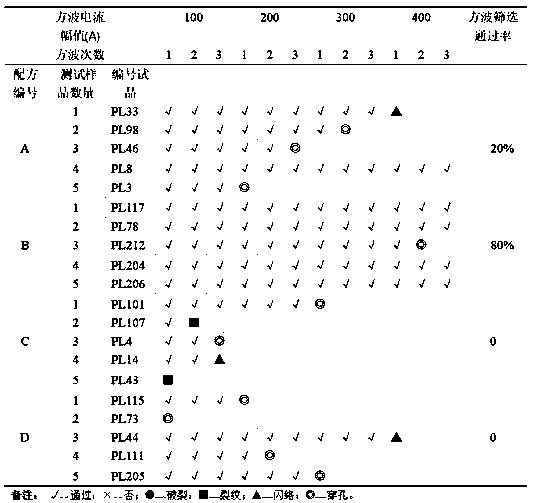

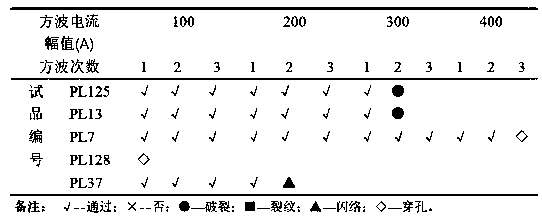

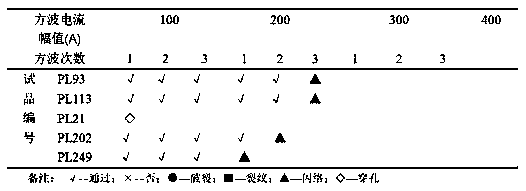

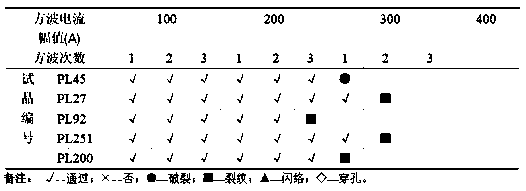

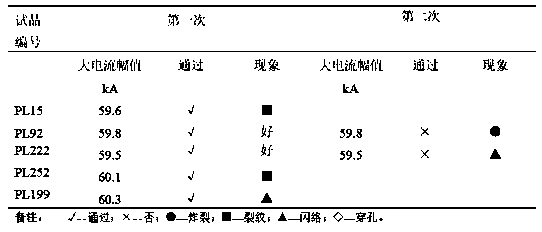

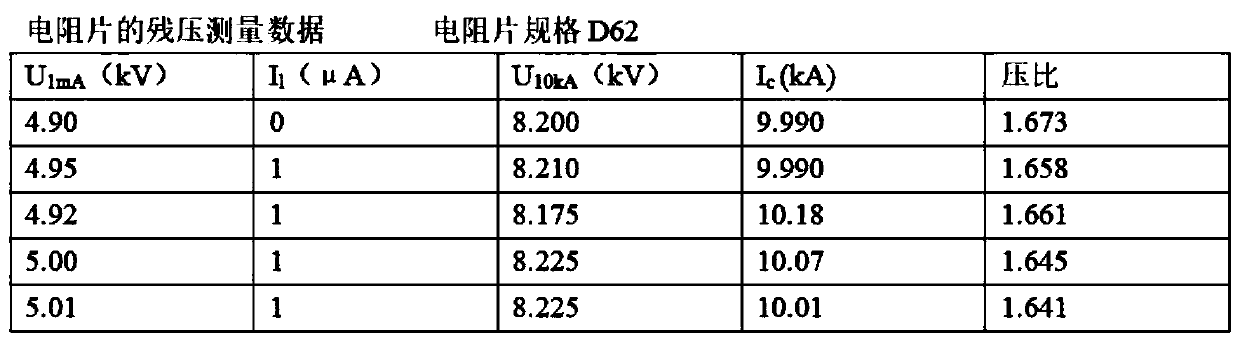

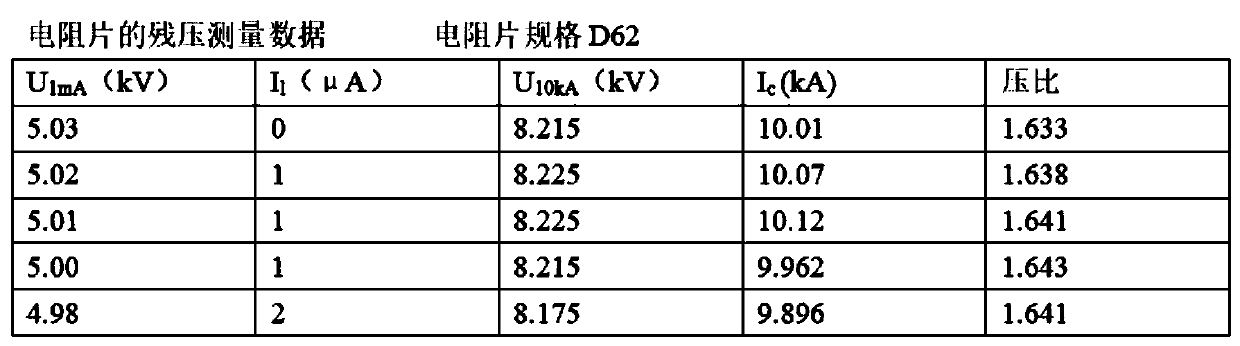

Liquid high-resistance layer for zinc oxide piezoresistor

ActiveCN108503392AReduce thickness fluctuationSolve side insulation problemsVaristor coresOvervoltage protection resistorsHigh resistanceSquare waveform

The invention provides a liquid high-resistance layer for a zinc oxide piezoresistor. A formula comprises Bi(NO3)3, Co(NO3)2, Mn(NO3)2 and CH3COOLi; a preparation method of the liquid high-resistancelayer comprises the following steps: mixing each raw material in the formula with a solvent; heating and dissolving. An application method of the liquid high-resistance layer coats a side face of a resistance piece with a formula solution. The liquid high-resistance layer of the zinc oxide piezoresistor has the beneficial effects that the formula of the high-resistance layer is adjusted and a technology is controlled, so that a body of the resistance piece is matched with the shrinkage rate of a glaze layer; the side face insulation problem of the resistance piece is solved; meanwhile, the square wave discharge capability of the resistance piece is improved. The original fluctuation of glaze layer thickness, caused by the fact that pre-firing shrinkage rates are different, is reduced; theresistance piece has no cracks and the technology is more stable.

Owner:TSINGHUA UNIV +1

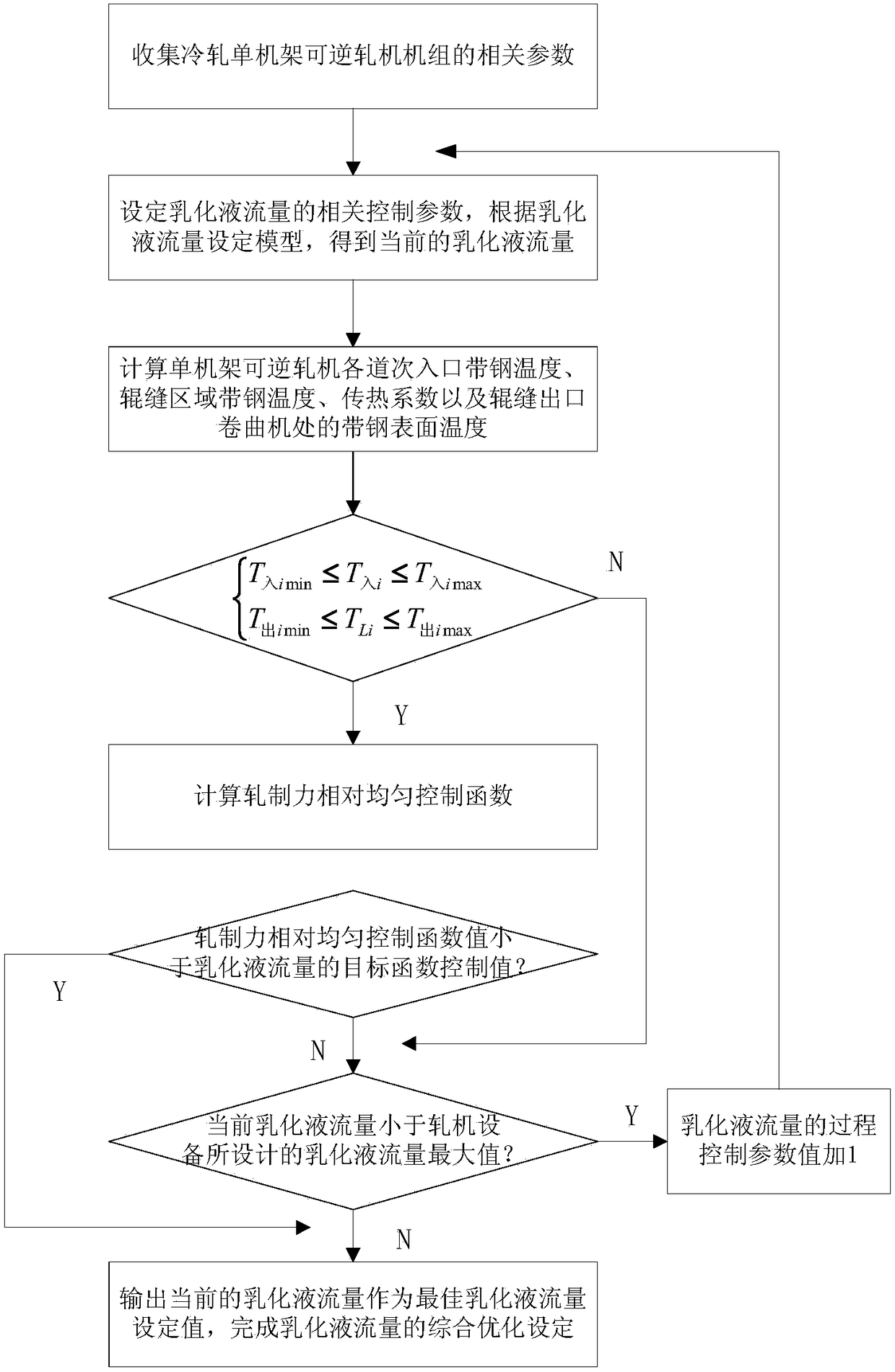

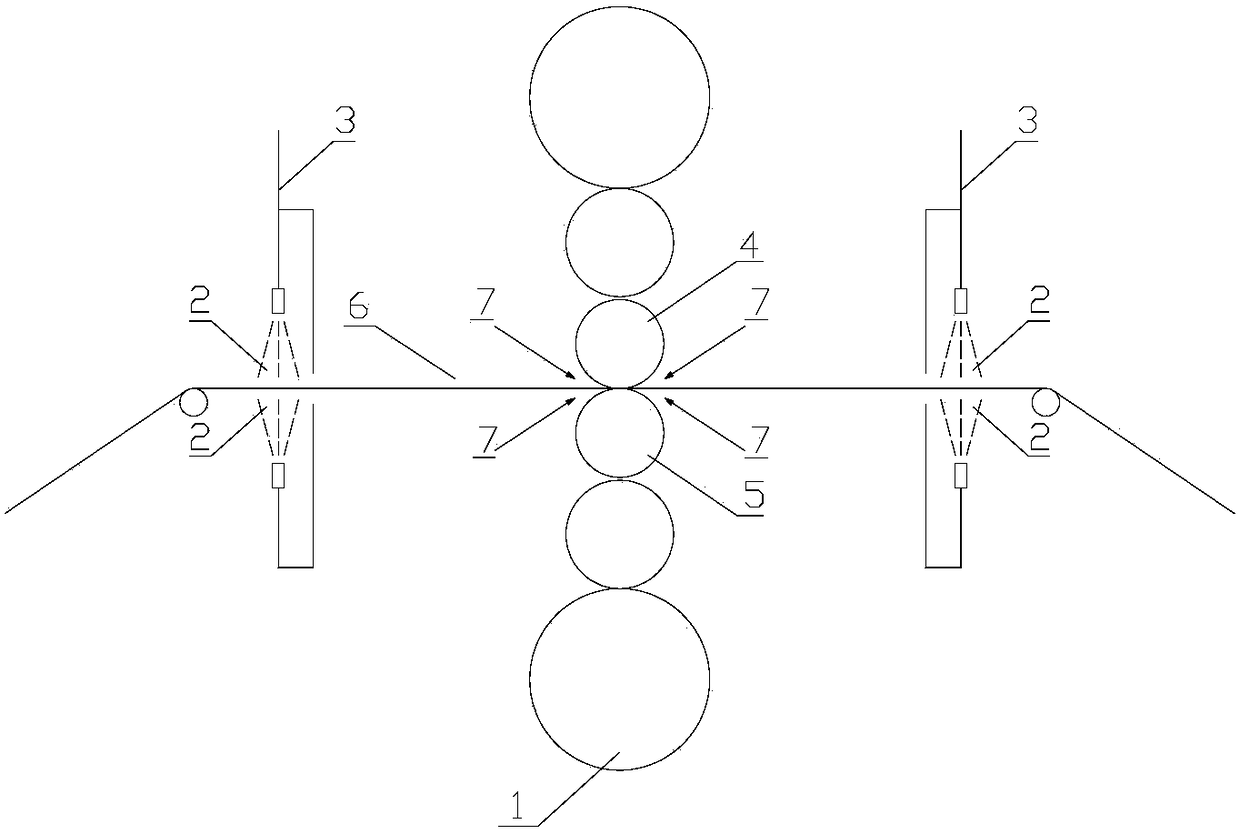

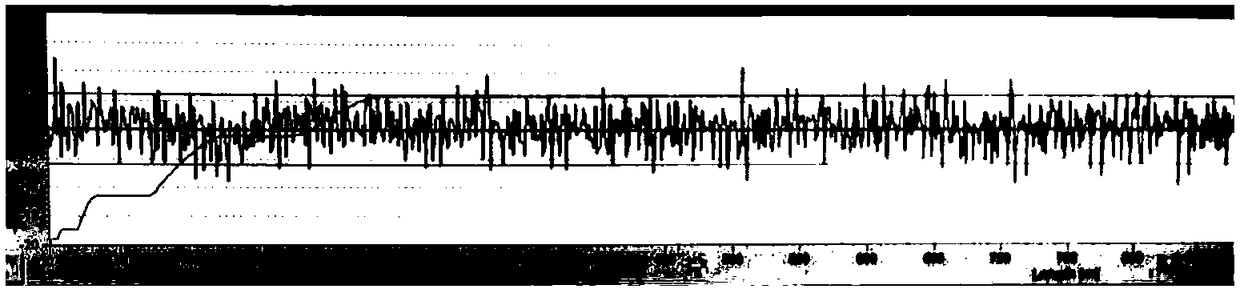

Technological lubrication system setting method for cold rolling single stand reversing mill

ActiveCN108237150AUniform rolling forceVariation of rolling force deviationWork treatment devicesRollsLubricationEngineering

The invention relates to a technological lubrication system setting method for a cold rolling single stand reversing mill. Through adjusting the flow of an emulsified liquid during a rolling process,the rolling pressure in the whole rolling process can be uniform, the whole rolling force deviation is smaller, the thickness fluctuation during the whole rolling process is reduced, and the problemsthat during an actual production process of an existing cold rolling single stand, the relatively fixed emulsified liquid flow is adopted, so that a big difference of the rolling force of each pass iscaused, and the thickness difference control fluctuation during the production process is larger are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

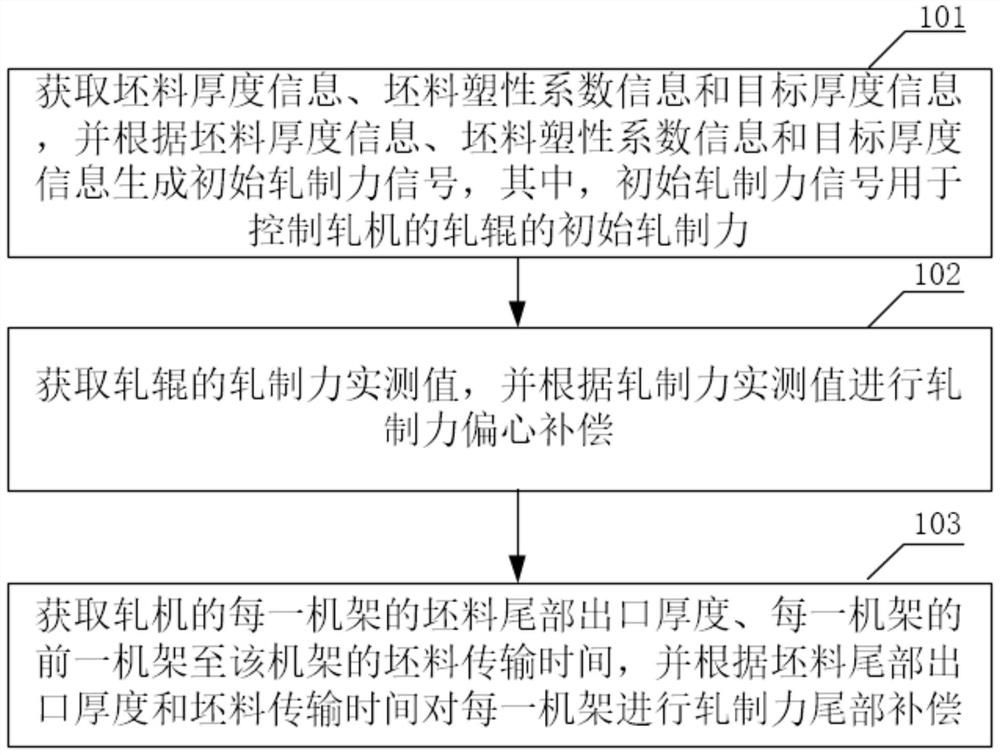

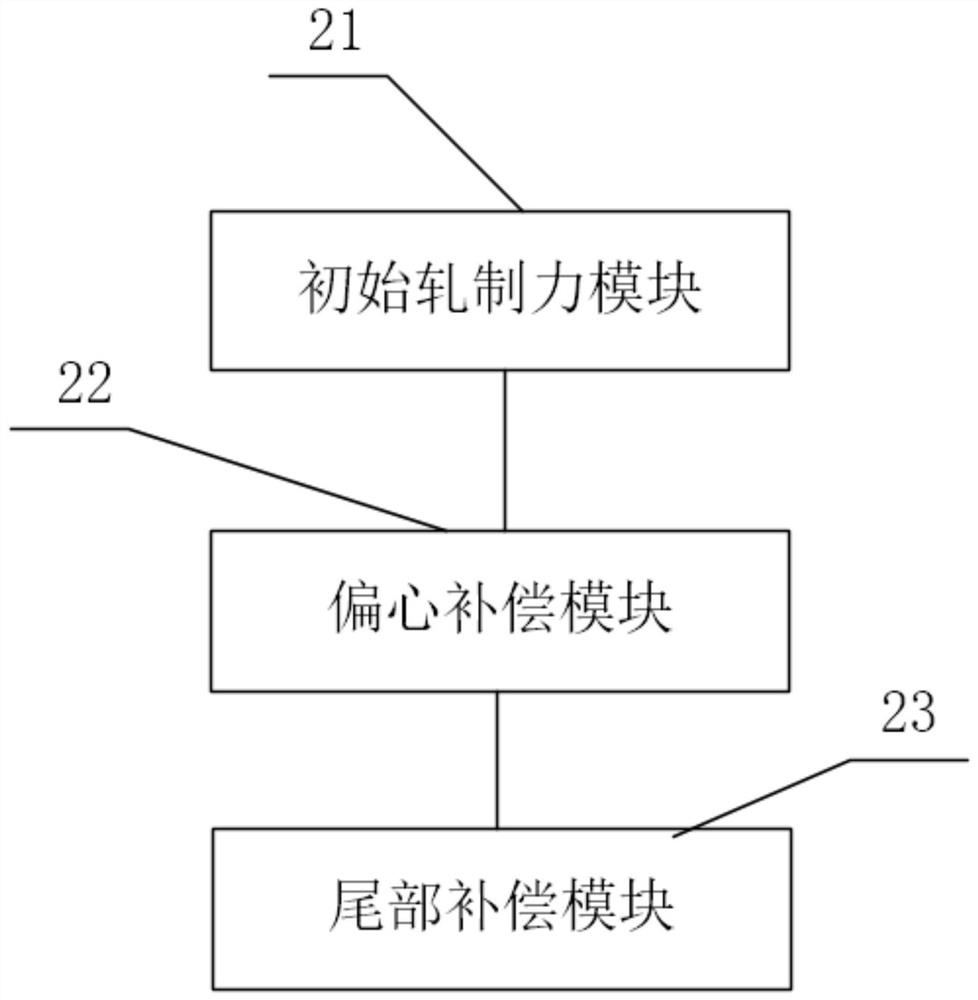

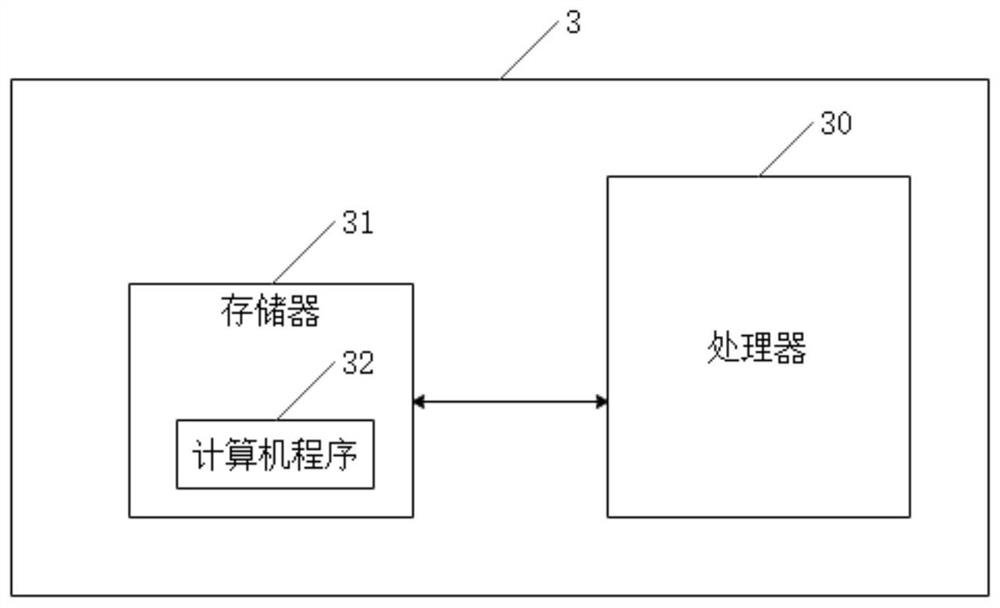

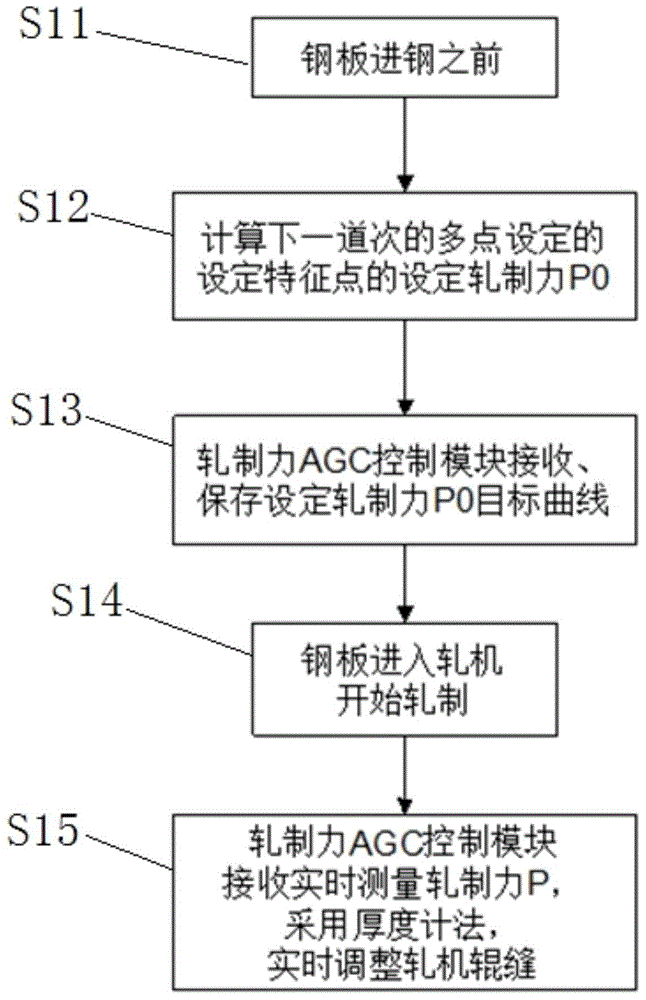

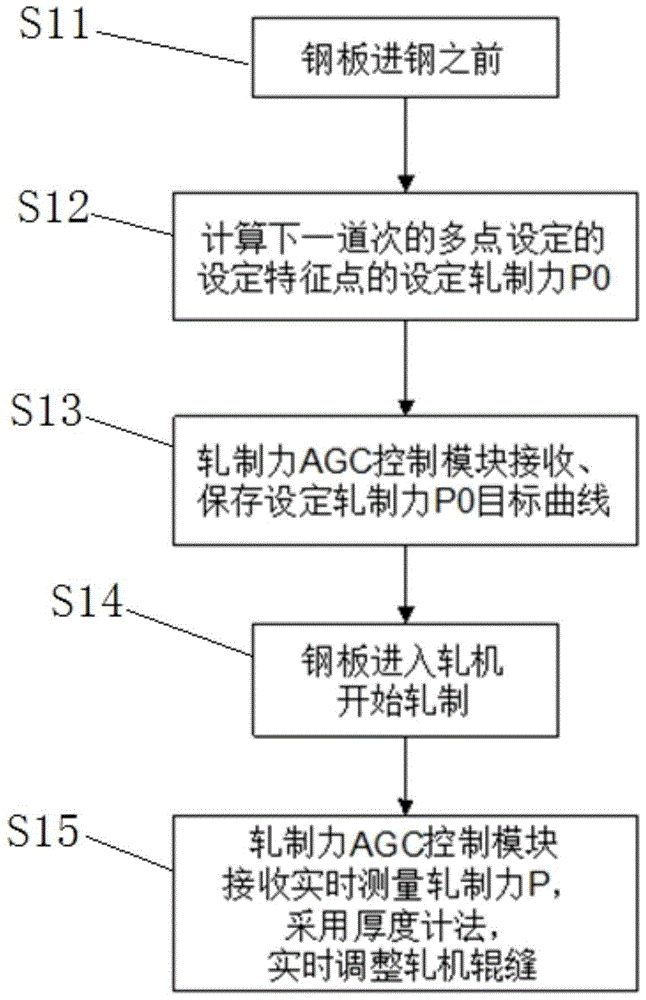

Thickness control method and device for hot-rolled strip steel and terminal equipment

InactiveCN112845613AAvoid the effects of eccentricityReduce thickness fluctuationRoll force/gap control deviceMetal rolling arrangementsTerminal equipmentEngineering

The invention provides a thickness control method for hot-rolled strip steel. The thickness control method comprises the following steps of acquiring blank thickness information, blank plasticity coefficient information and target thickness information, generating an initial rolling force signal according to the blank thickness information, the blank plasticity coefficient information and the target thickness information, obtaining a rolling force measured value of a roller, performing rolling force eccentric compensation according to the rolling force measured value, obtaining the blank tail outlet thickness of each rack of a rolling mill and the blank conveying time from a previous rack of each rack to the racks, and performing rolling force tail compensation on each rack according to the blank tail outlet thickness and the blank conveying time. According to the characteristics of raw materials and a rolling system in the rolling process, rolling signals are optimized, the rolling signals are prevented from being influenced by roller eccentricity through eccentricity compensation, the phenomena of tension loss and thickness jump are eliminated through tail compensation, and fluctuation of the thickness of a finished steel belt can be effectively reduced.

Owner:HEBEI IRON AND STEEL

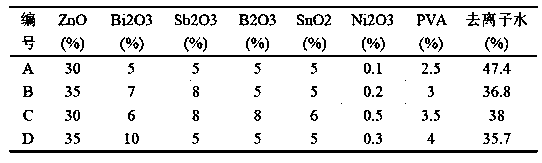

Preparation method of novel liquid side surface high-resistance layer for increasing 2ms square wave through flow of zinc oxide piezoresistor

InactiveCN109485406AReduce thickness fluctuationProcess stabilityResistive material coatingBall millOxide

The invention relates to a preparation method of a novel liquid side surface high-resistance layer for increasing the 2ms square wave through flow of a zinc oxide piezoresistor. The method comprises the steps of mixing the prepared raw materials, heating for dissolving to prepare a uniform solution, and directly coating the side surface of a foamed resistance piece with the solution. The method ischaracterized by comprising a raw material preparation step, a ball-mill mixing step, a spray drying step, a compression formation step, a sintering step, a coating step and a piece formation step, wherein the raw material preparation step, the ball-mill mixing step, the spray drying step, the compression formation step, the sintering step and the coating step are sequentially carried out. The preparation method has the beneficial effects that by selecting a formed upper high-resistance layer, the fluctuation, caused due to non-uniform pre-sintering shrinking rate of the thickness in the past, of a glaze layer is reduced, and the process is relatively stable.

Owner:TSINGHUA UNIV +1

Novel inorganic side high-resistance layer preparation process for increasing flow capacity of zinc oxide piezoresistor

InactiveCN109659107AReduce thickness fluctuationProcess stabilityVaristor coresResistive material coatingHigh resistanceShrinkage rate

A novel inorganic side high-resistance layer preparation process for increasing the flow capacity of a zinc oxide piezoresistor. The prepared raw materials are subjected to mixing and heating for dissolution to prepare a uniform solution, the solution is molded at a resistor disc to be directly coated on the side of the resistor disc. The method comprises a raw material preparation step, a ball milling mixing step, a spray drying step, a press molding step, a sintering step, a coating step and a sheet forming step. The raw material preparation step, the ball milling mixing step, the spray drying step, the press molding step, the sintering step and the coating step are performed in order. The high-resistance layer is added after molding to reduce the fluctuation of the thickness of the glaze layer caused by the inconsistent shrinkage rate, and the process is more stable.

Owner:TSINGHUA UNIV +1

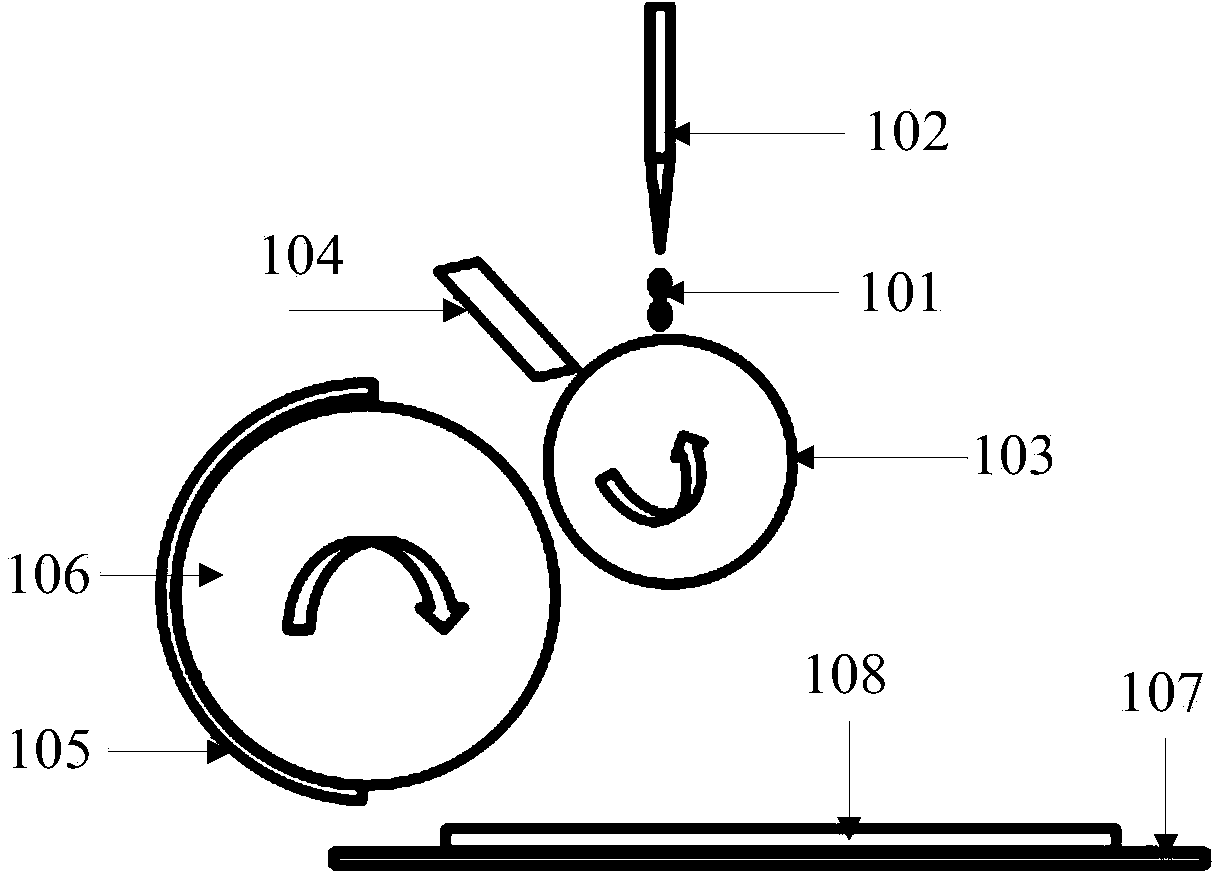

Roller press with pre-pressing function

PendingCN113368942AReduce air contentReduce thickness fluctuationGrain treatmentsHydraulic cylinderFine powder

The invention relates to a roller press with a pre-pressing function. The roller press with the pre-pressing function comprises a main body, a rack arranged at a charging hole of the main body and a plurality of charging devices arranged on the rack, wherein a pre-pressing mechanism is further arranged on the rack; and the pre-pressing mechanism comprises a hydraulic cylinder fixed to the bottom of the rack, a driving roller transversely and rotatably fixed to a telescopic end of the hydraulic cylinder, a main fixed roller rotatably fixed to the bottom of the rack and arranged at the right side of the driving roller in parallel, a driving roller driving assembly arranged at the rear side of the rack and capable of driving the driving roller to rotate, and a main fixed roller driving assembly arranged at the rear side of the rack and capable of driving the main fixed roller to rotate. According to the invention, violent vibration generated when the roller press grinds fine powder can be effectively avoided, then the operation stability of the roller press is remarkably improved so as to increase the operation rate, the phenomenon that key components such as foundation bolts and roller shafts are broken due to the violent vibration of the roller press is effectively prevented, and therefore serious production accidents are thoroughly avoided.

Owner:NANJING KISEN INT ENG

Preparation of novel side high-resistance layer special for high-pass ZnO varistor

InactiveCN109686520AReduce thickness fluctuationProcess stabilityResistive material coatingCompression moldingHigh resistance

The invention discloses a preparation method of a novel side high-resistance layer special for a high-pass ZnO varistor. Prepared raw materials are mixed, heated and dissolved to prepare a uniform solution, and the solution is directly applied to the side of a resistor disc after the resistor disc is formed. The preparation method is characterized by comprising the steps of raw material preparation, ball milling mixing, spray drying, compression molding, sintering, coating and disc forming, wherein the steps of raw material preparation, ball milling mixing, spray drying, compression molding, sintering, coating and disc forming are sequentially executed. The preparation method has the advantages that a high-resistance layer is arranged after formation, so that the fluctuation of glaze layerthickness caused by inconsistent pre-firing shrinkage rate is reduced, and the process is more stable.

Owner:TSINGHUA UNIV +1

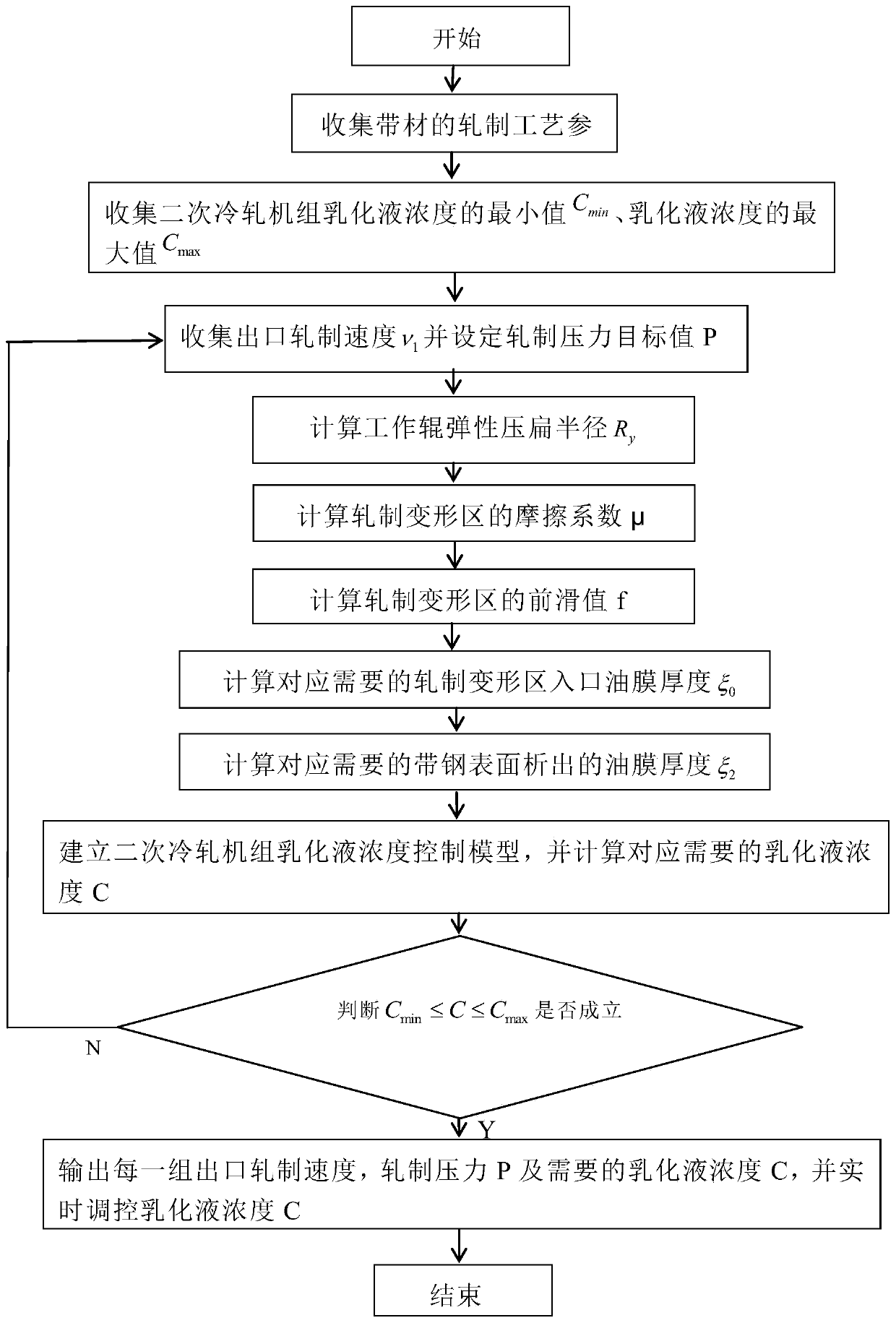

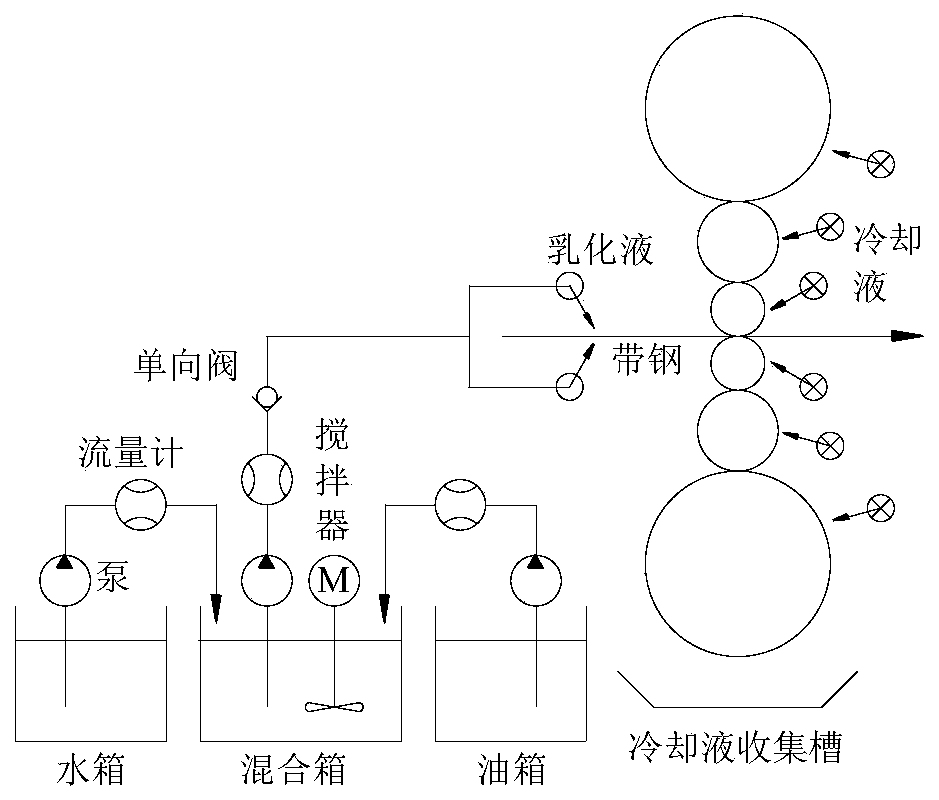

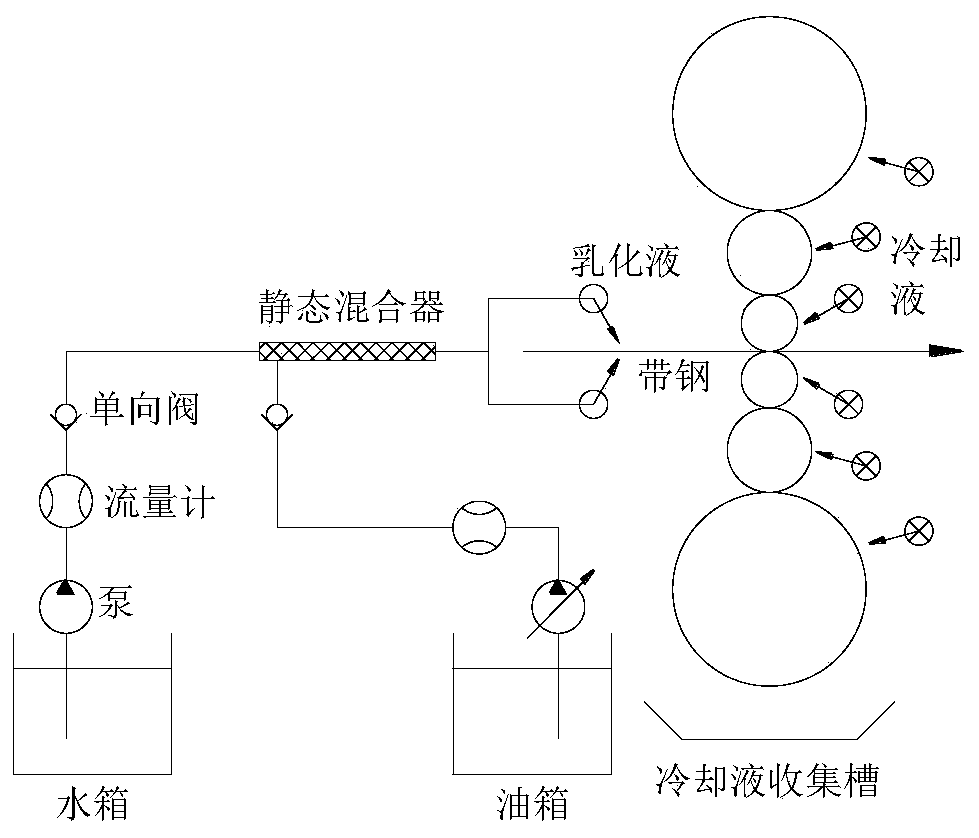

Online control method for concentration of emulsion of two-time cold rolling unit

ActiveCN110773571AGuaranteed lubrication effectReduce thickness fluctuationMass flow control deviceMetal rolling arrangementsFrictional coefficientEngineering

The invention provides an online control method for the concentration of an emulsion of a two-time cold rolling unit and belongs to the technical field of cold rolling. The aim is to overcome fluctuation of the lubrication performance, rolling pressure and strip steel thickness and the defects of strip steel plate thickness, plate shapes and surface quality in the speed increase and decrease process of the cold rolling unit. The method comprises the steps of S1, collecting a rolling technology parameter of a strip material; S2, collecting a minimum value Cmin and a maximum value Cmax of the concentration of the emulsion of the two-time cold rolling unit; S3, collecting an outlet rolling speed v1 and setting a rolling pressure target value P; S4, calculating an elastic flattening radius Ryof a work roller; S5, calculating a friction coefficient mu of a rolling deformation area; S6, calculating an advancing slip value f of the rolling deformation area; S7, calculating the thickness ksi0of an oil film of an inlet of the rolling deformation area; S8, calculating the thickness ksi2 of an oil film separated from the surface of strip steel; S9, establishing an online control model for the concentration of the emulsion of the two-time cold rolling unit, and calculating the corresponding concentration C of the emulsion; S10, judging whether or not Cmin<=C<=Cmax is established; S11, regulating the concentration C of the emulsion in real time. The concentration of the emulsion in the rolling speed increase and decrease process is online regulated in real time.

Owner:YANSHAN UNIV

Capacitance dynamic quantity sensor

InactiveCN1591907AReduce thickness fluctuationAvoid it happening againSpeed measurement using gyroscopic effectsAcceleration measurementCapacitanceMetallic electrode

Owner:SII SEMICONDUCTOR CORP

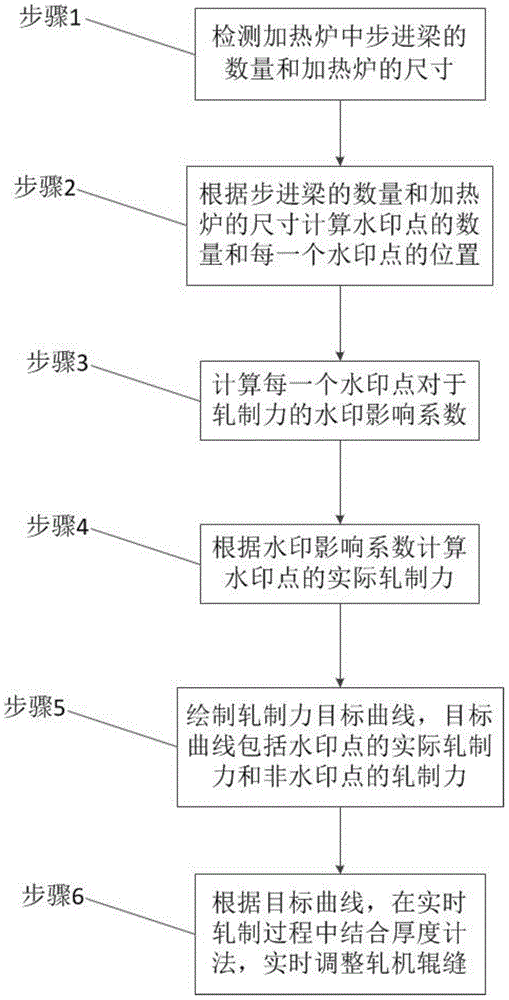

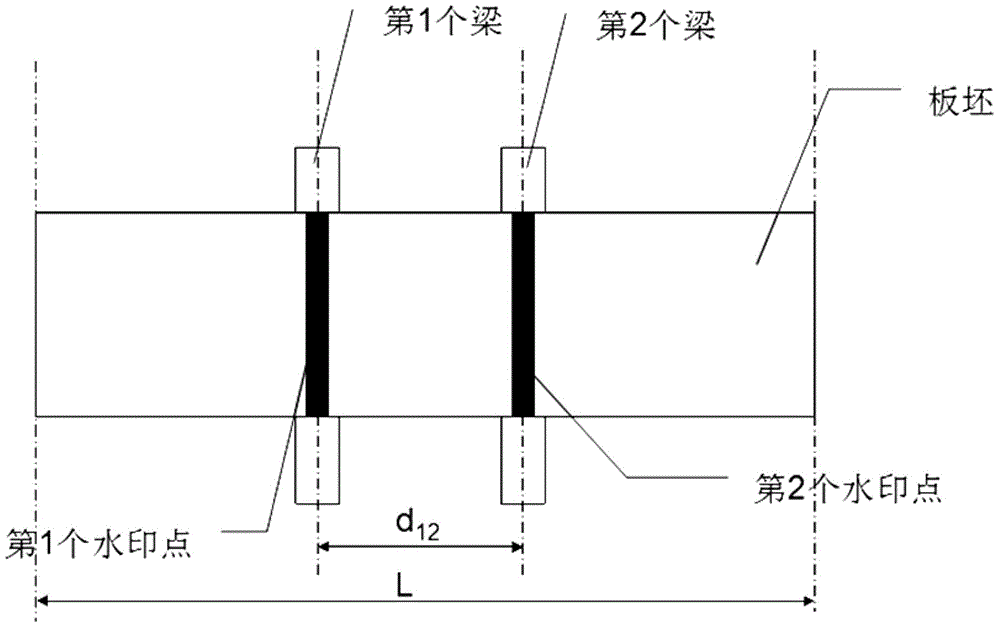

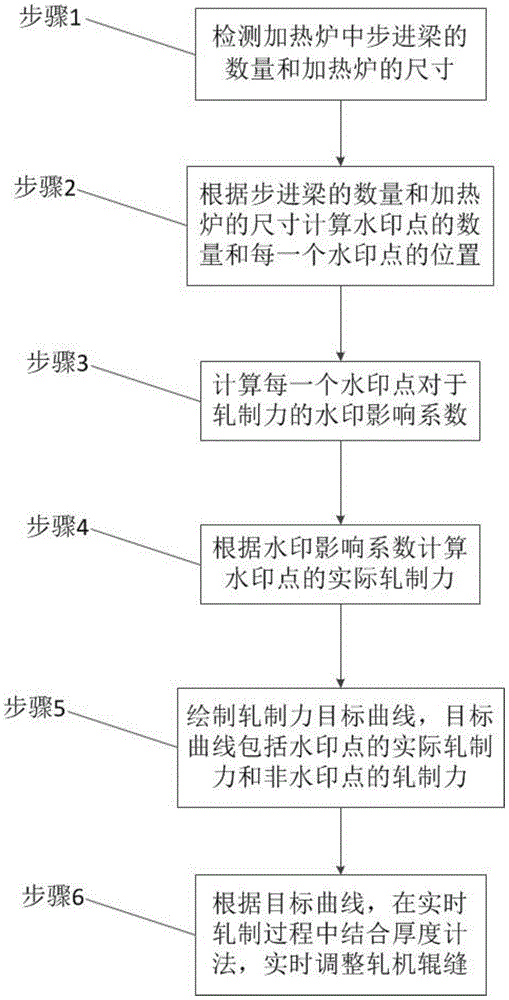

Rolling control method capable of lowering influence of watermarks of walking beams of heating furnace on thickness of finished products

ActiveCN105363796AReduce the effect of thicknessReduce outputRoll mill control devicesMetal rolling arrangementsThick plateEngineering

The invention discloses a rolling control method capable of lowering the influence of watermarks of walking beams of a heating furnace on the thickness of finished products. The method is characterized by including the following steps that 1, the number of the walking beams in the heating furnace and the size of the heating furnace are detected; 2, the number of watermark points and the position of each watermark point are calculated according to the number of the walking beams and the size of the heating furnace; 3, the watermark influence coefficient of each watermark point for rolling force is calculated; and 4, actual rolling force of the watermark points is calculated according to the watermark influence coefficients. By the adoption of the technical scheme, the influence of the watermarks of the walking beams of the heating furnace on the thickness of finished moderately-thick plates can be lowered, and especially, the thickness fluctuation caused by the watermarks can still be effectively relieved under the condition of short time in the heating furnace; and the hourly output of thick plates and the thickness and accuracy of the finished products can be guaranteed, and quality losses are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

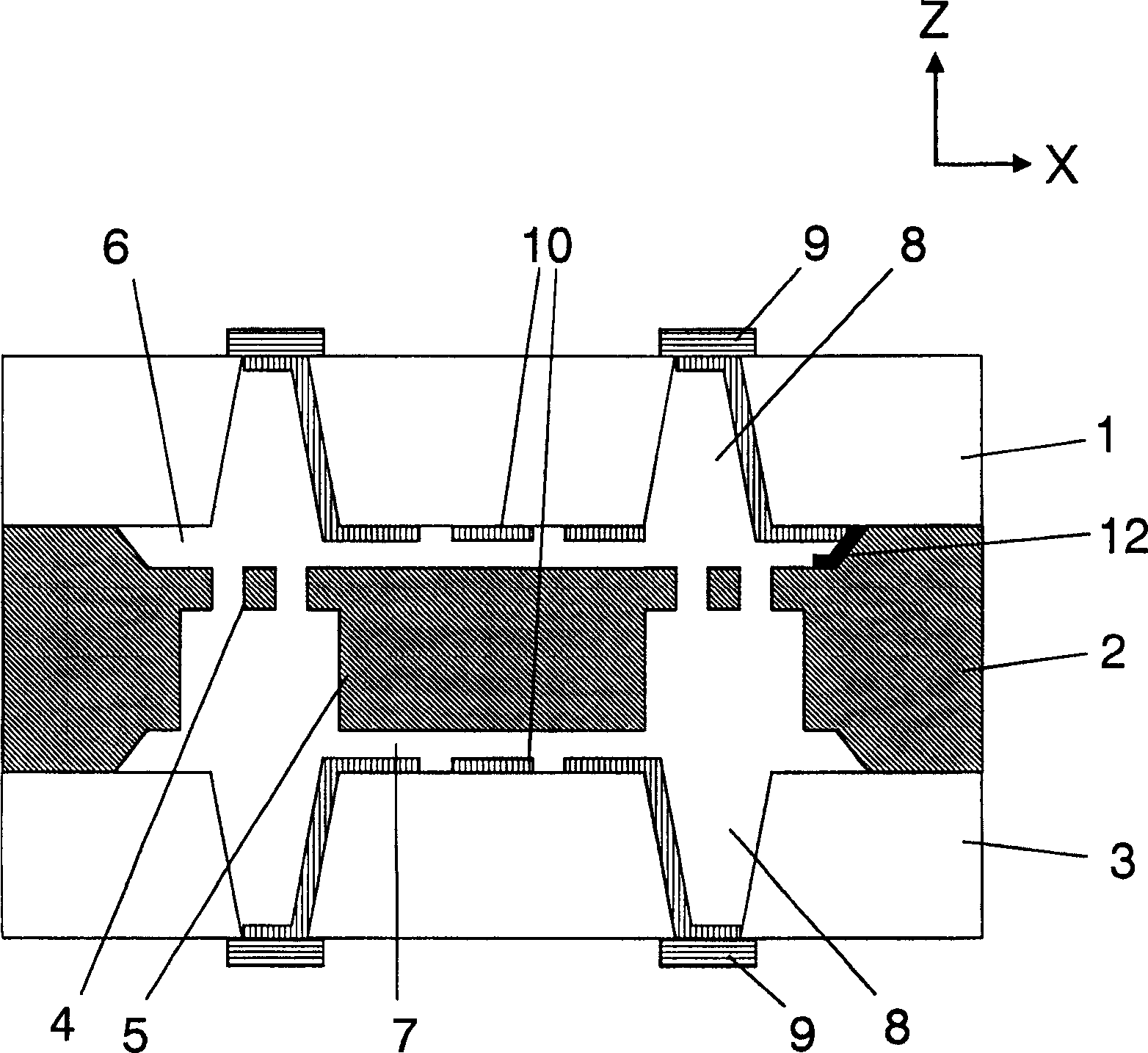

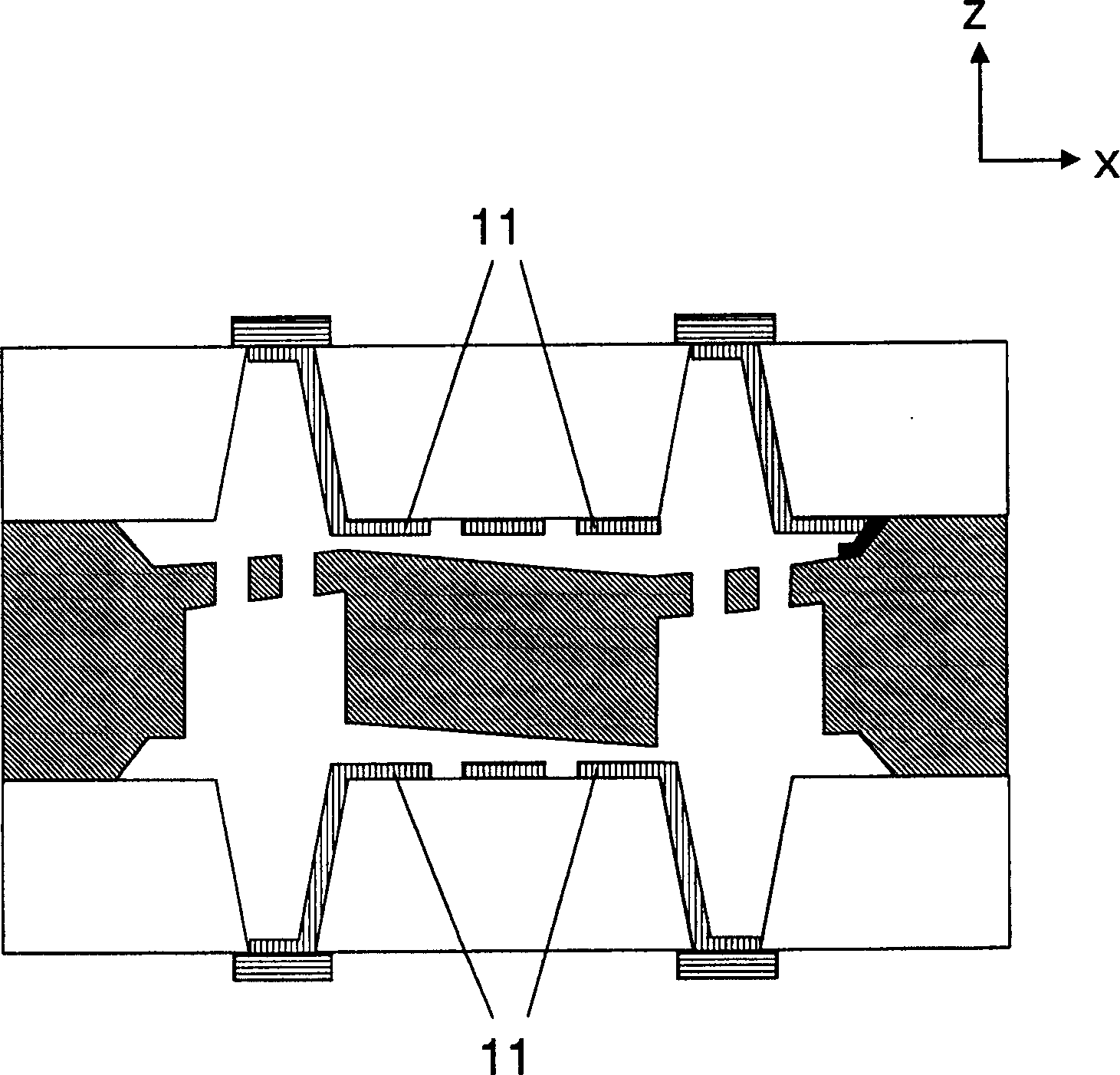

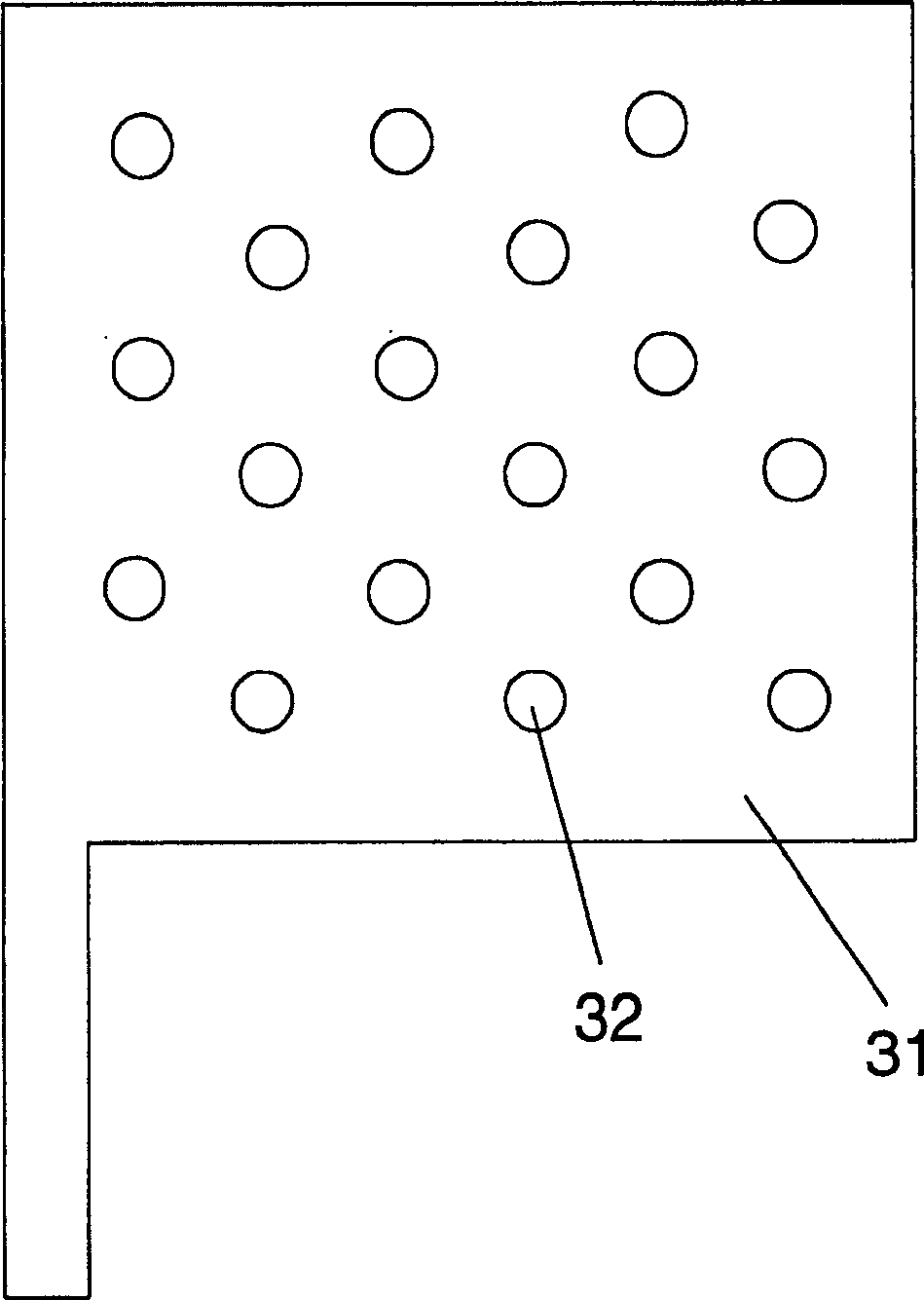

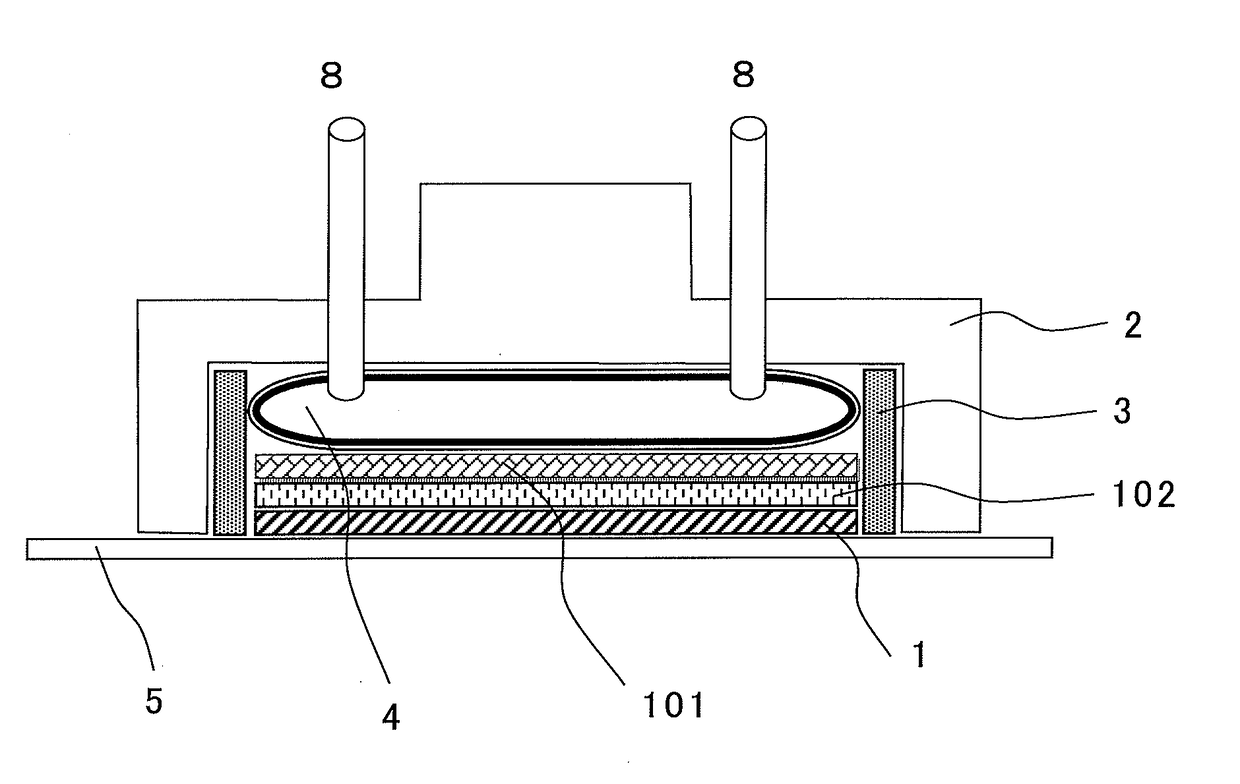

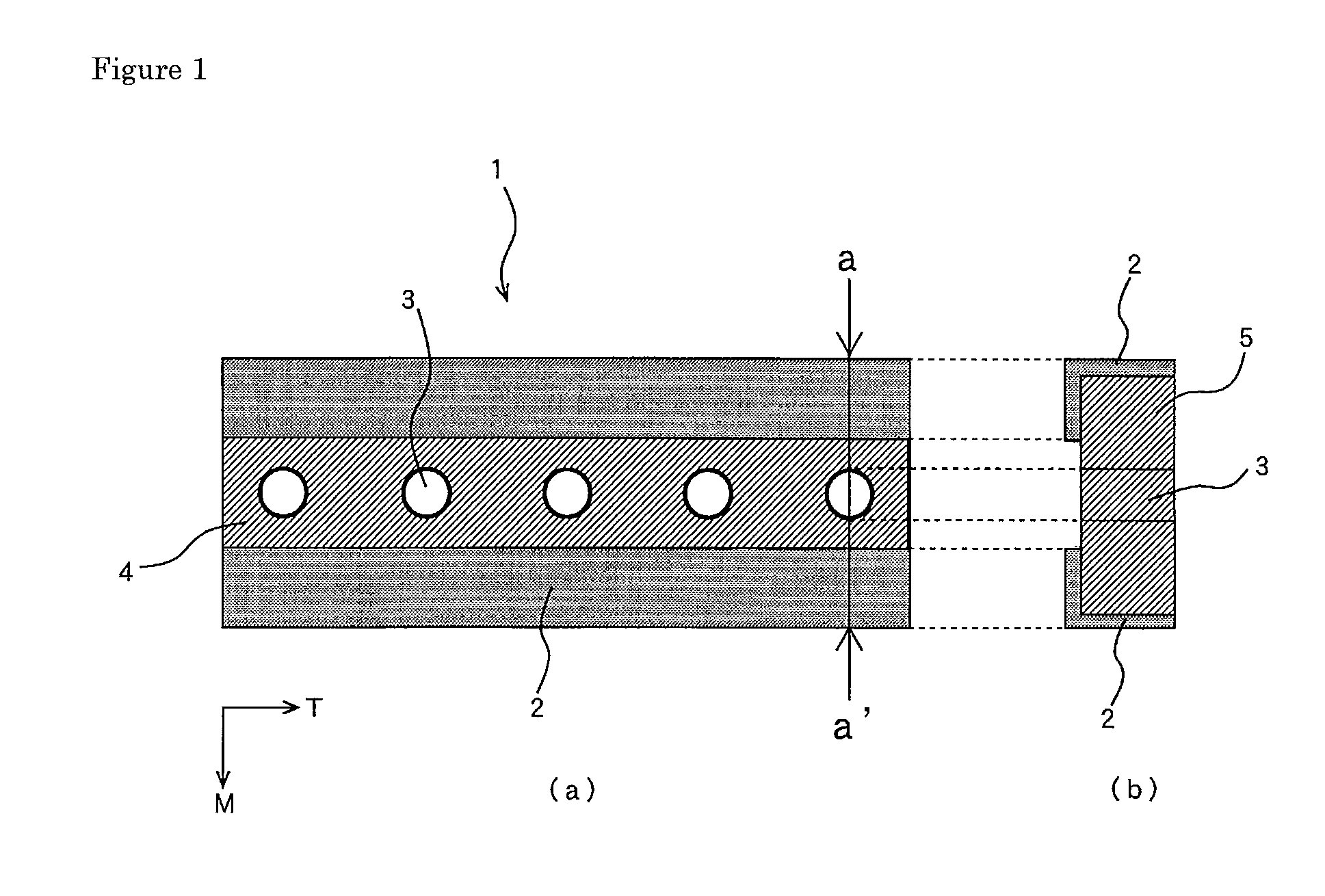

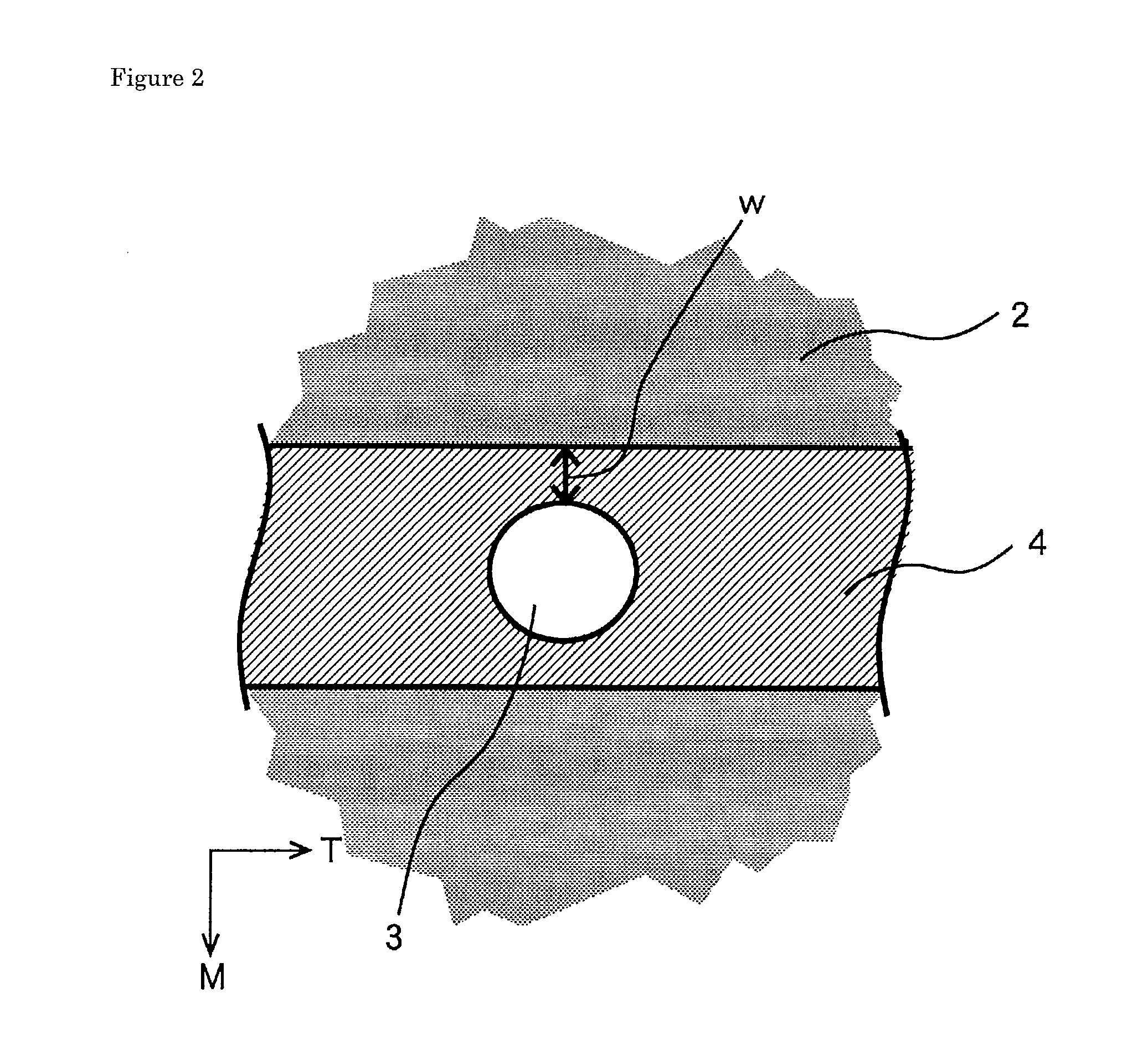

Polishing head, cmp apparatus including a polishing head, and manufacturing method of semiconductor integrated circuit device using a cmp apparatus

ActiveUS20180043496A1Reduce thickness fluctuationSemiconductor/solid-state device manufacturingLapping machinesIntegrated circuitEngineering

In a polishing head for a CMP apparatus, a stress distributing plate made of metal or ceramic is placed between a wafer on a polishing pad and an air bag configured to press down the wafer, and a shock absorbing sheet is provided between the stress distributing plate and the underlying wafer, to thereby make pressure applied from the air bag to the wafer uniform.

Owner:ABLIC INC

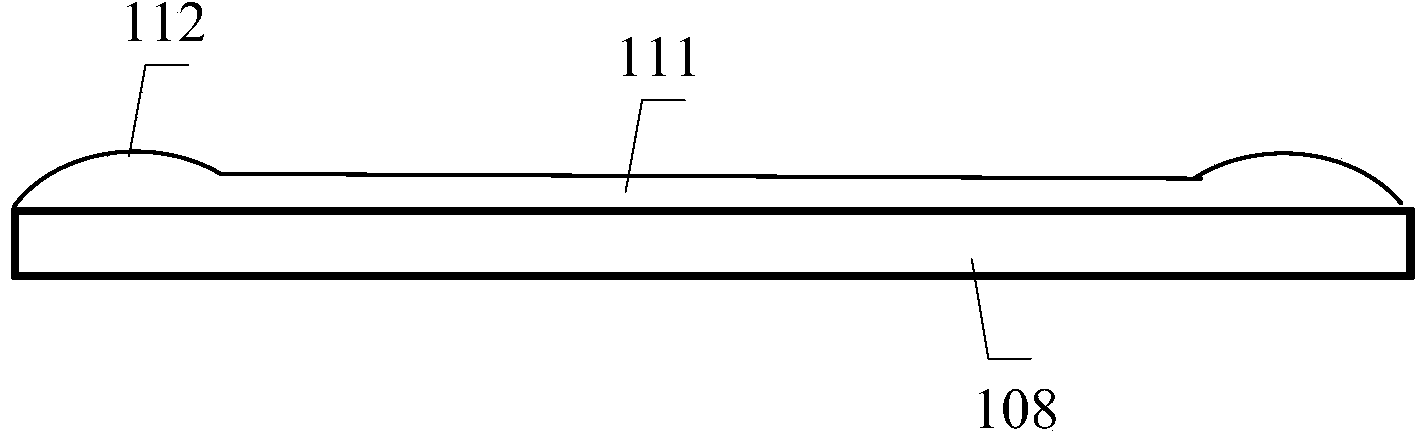

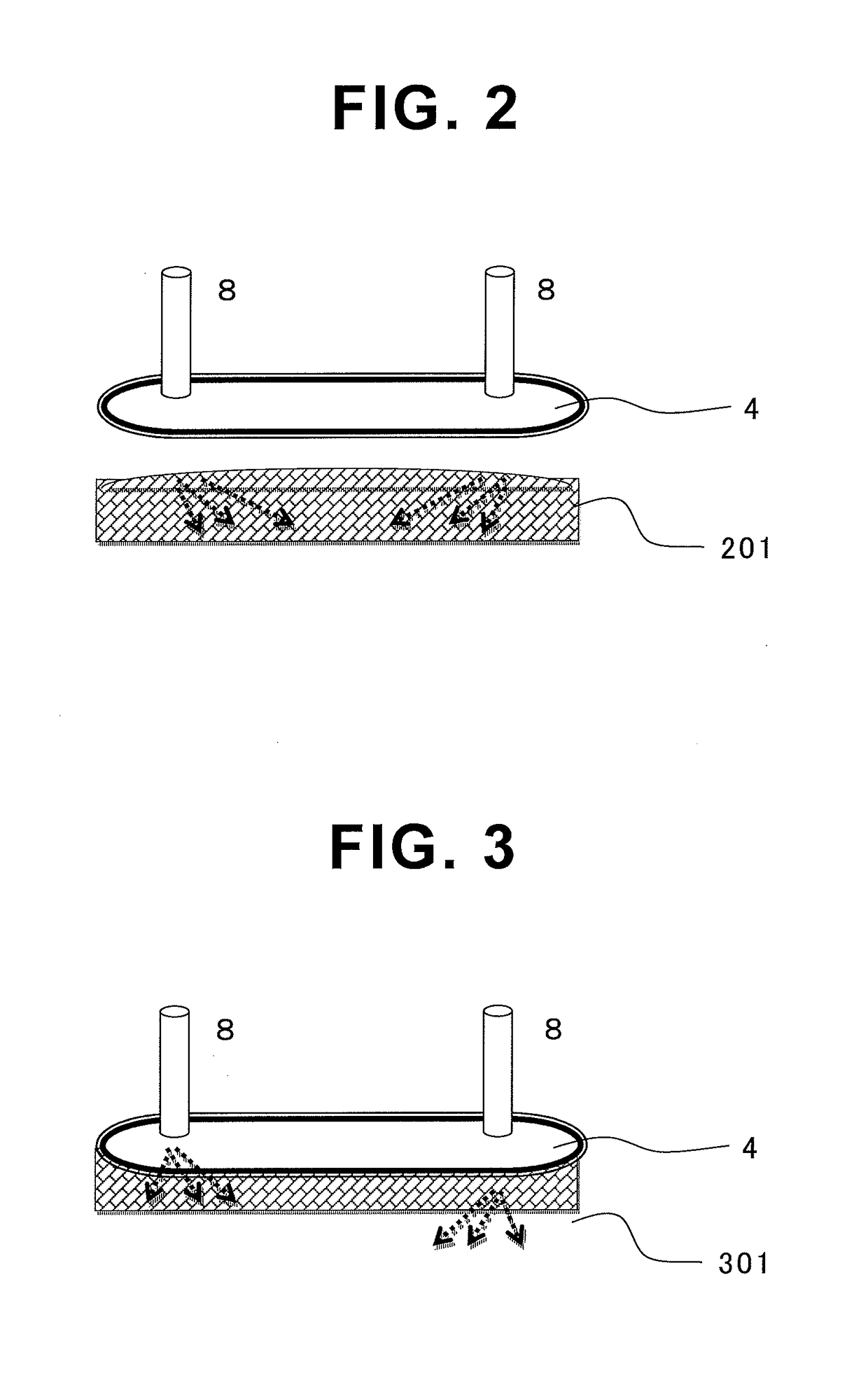

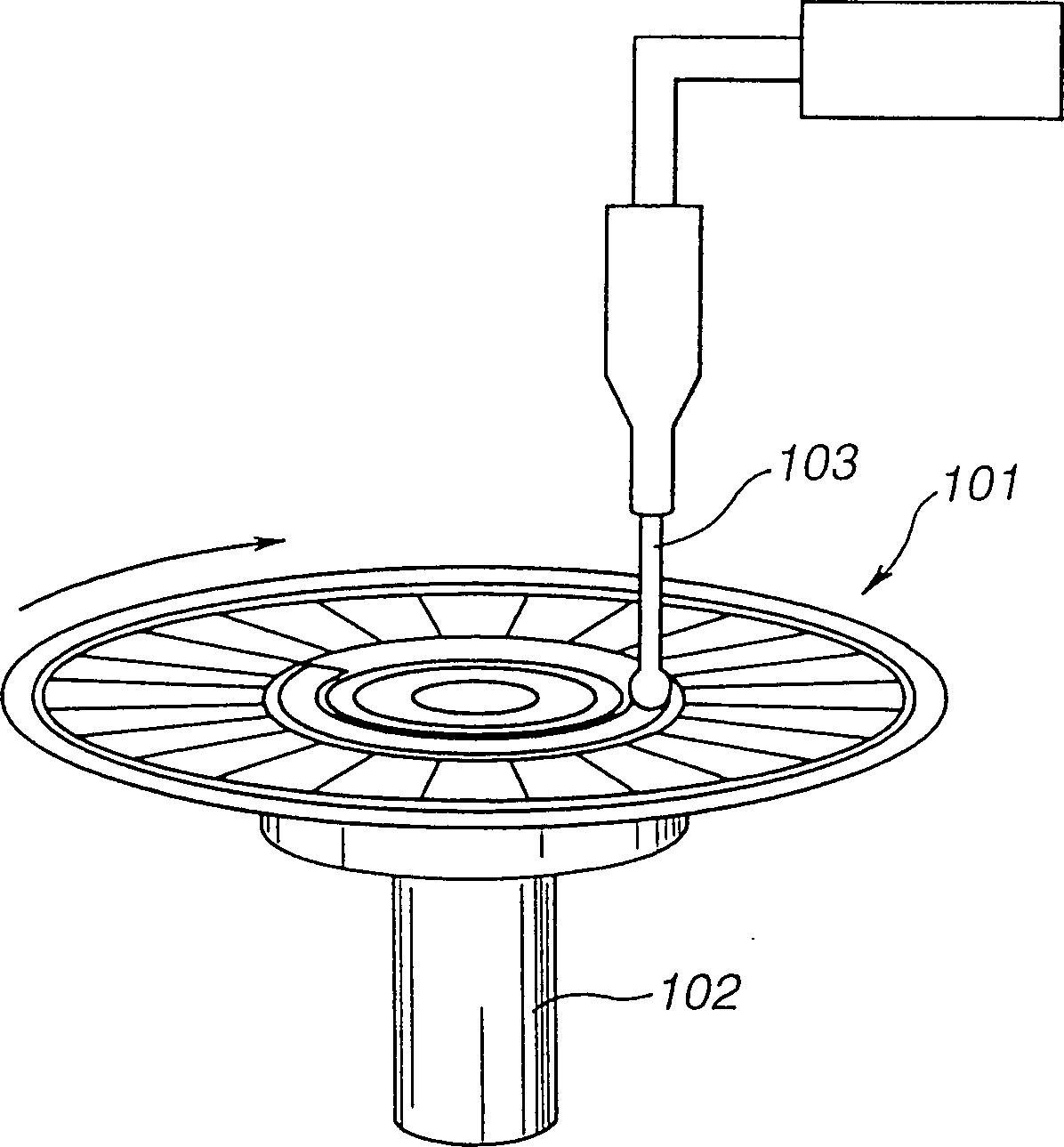

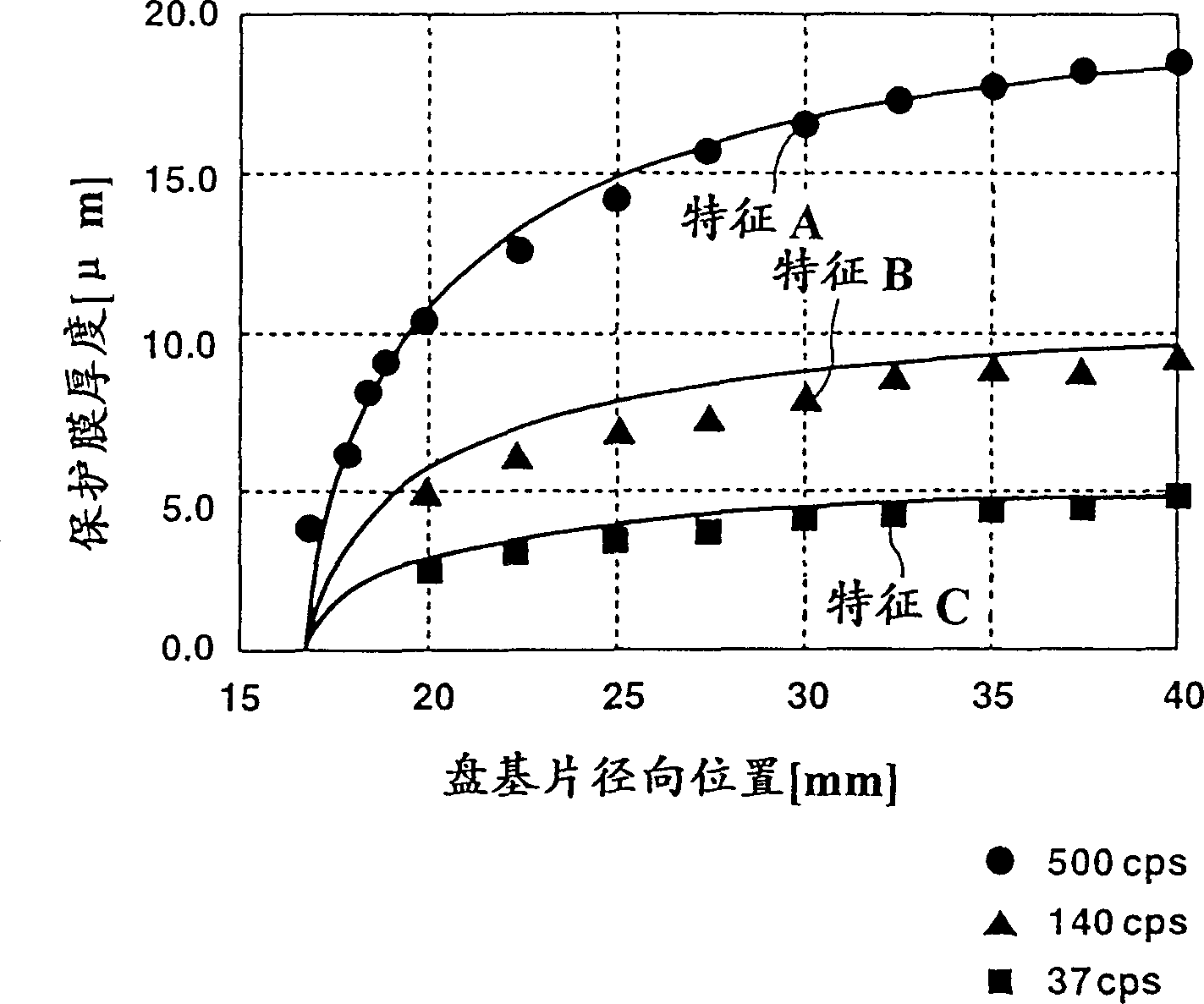

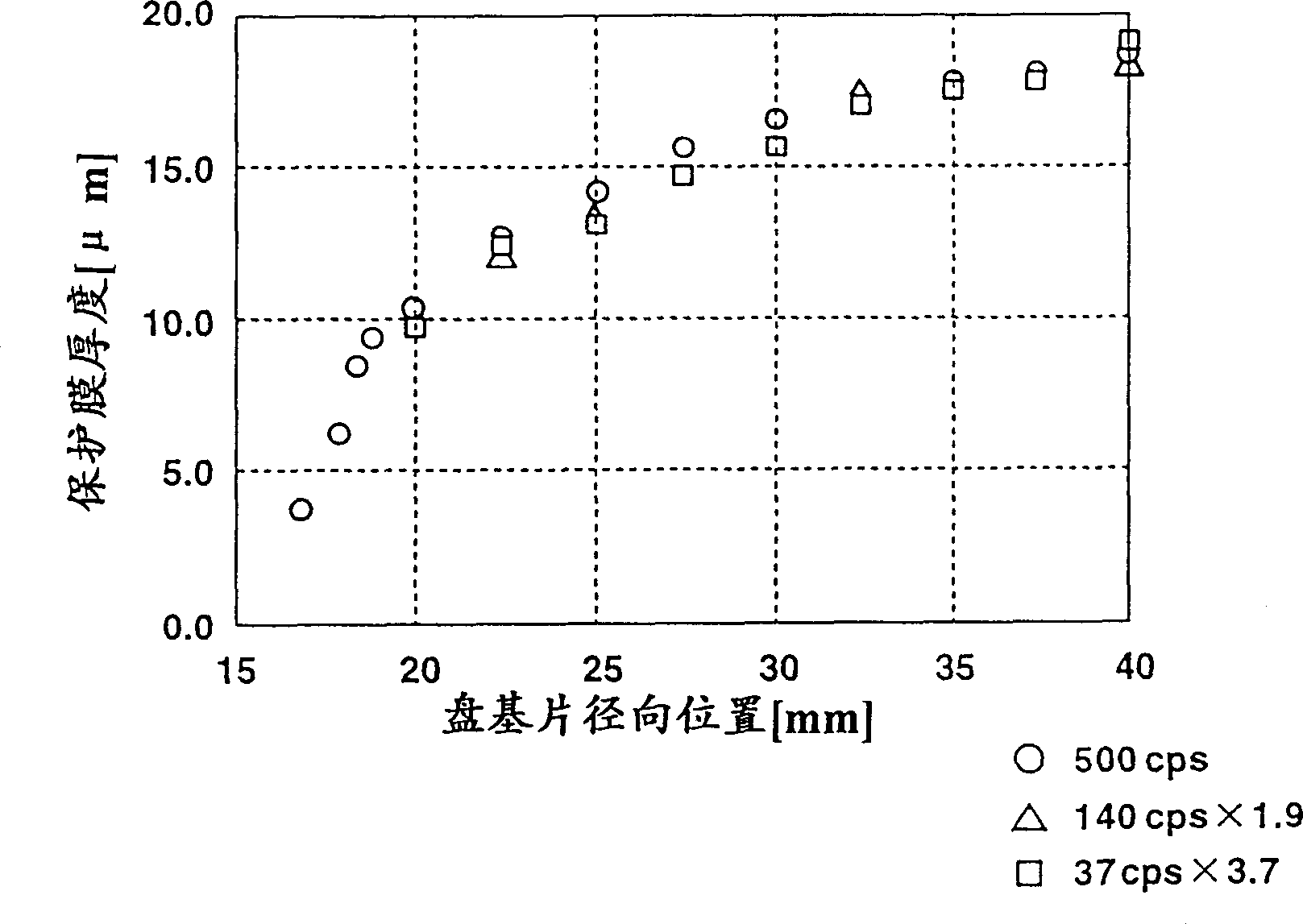

Method and appts. for mfg. disc-shaped recording medium

InactiveCN1132169CPrevent inflowReduce thickness fluctuationLiquid surface applicatorsRecord carriersEngineeringCentrifugal force

When applying a coating film by a spin coating method on a disc-shaped recording medium, the film thickness difference between the inner rim and the outer rim of the disc has to be suppressed. To this end, a coating liquid is supplied to a center portion of the disc-shaped recording medium and a rotary disc, as a center shaft of a rotary disc is inserted into a recess formed in a turntable on which the disc-shaped recording medium is set and the disc-shaped recording medium and a rotary disc are run in rotation. The coating liquid is spread under the centrifugal force caused by rotation for forming a coating film on the disc-shaped recording medium.

Owner:SONY CORP

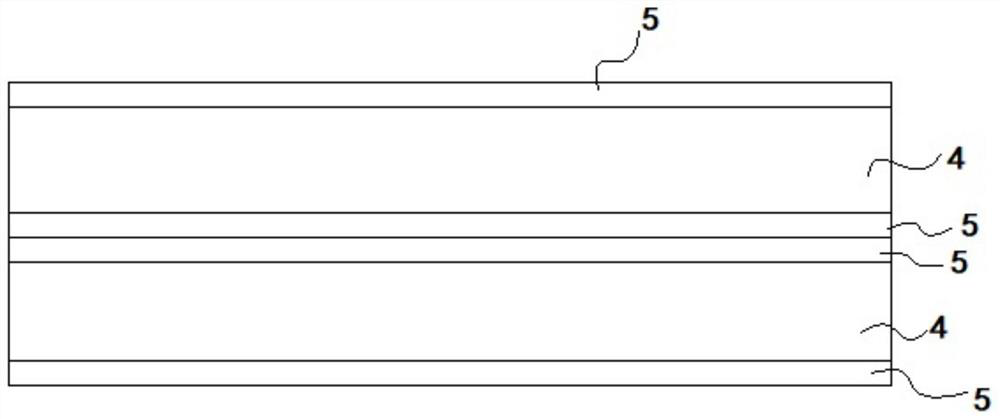

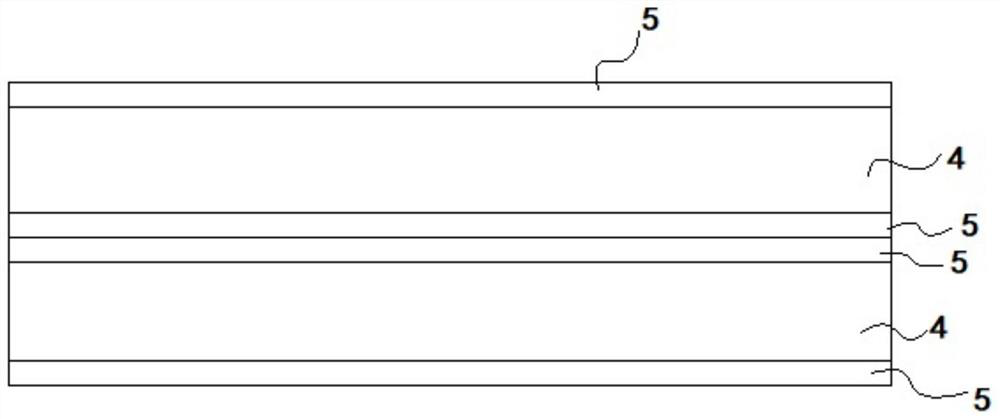

a transfer plate

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

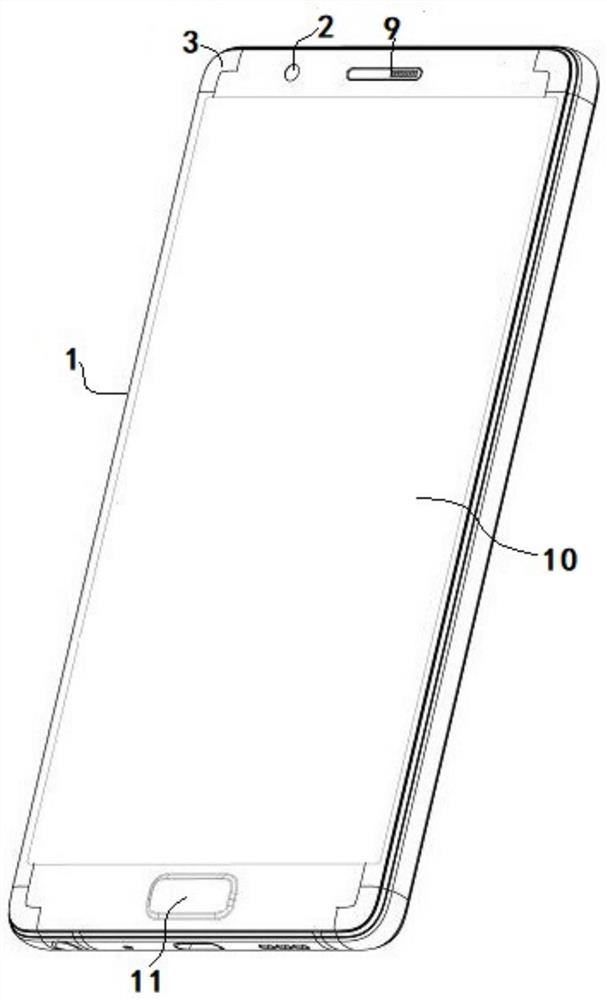

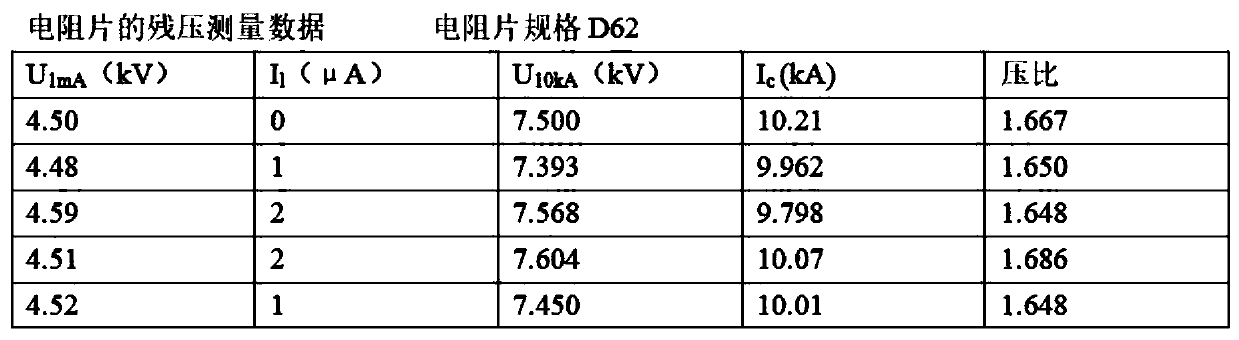

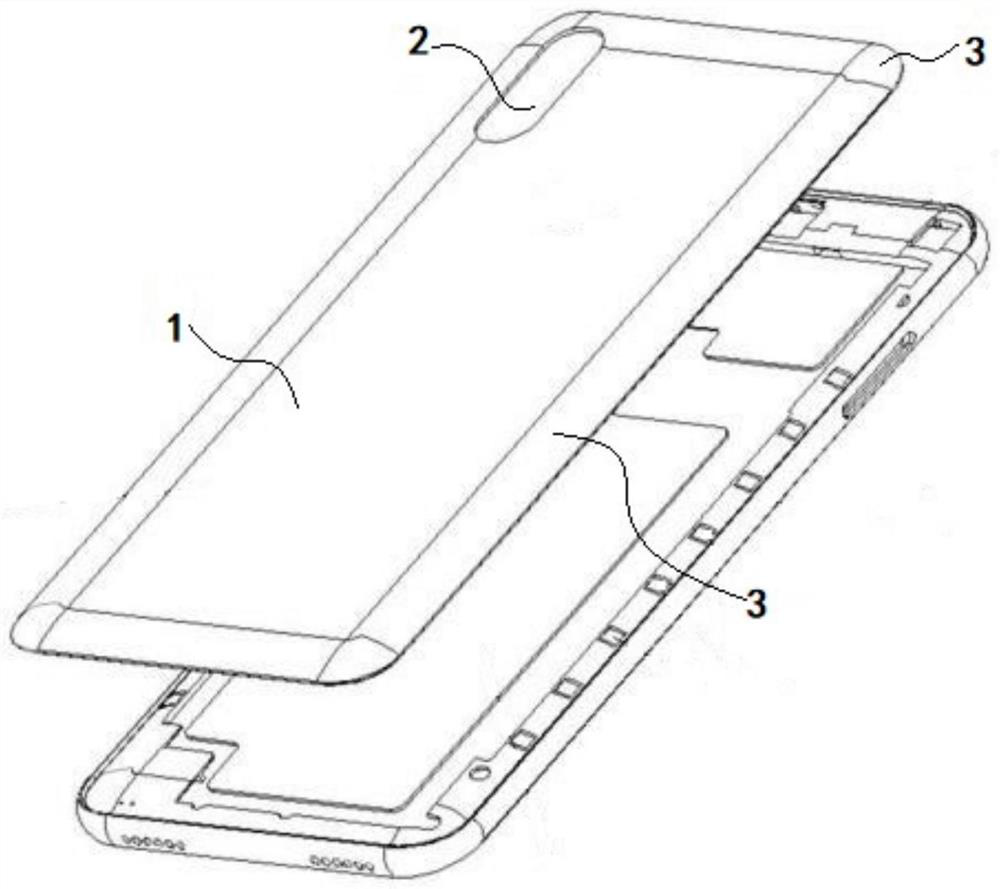

Glass mobile phone front cover thinning agent

The invention discloses a glass mobile phone front cover thinning agent, compared with the prior art, the produced glass mobile phone front cover (1) is provided with a hole site (2) for mounting a camera, a protective cover (6) for protecting the camera is arranged on the hole site (2), and the protective cover (6) and the hole site (2) are seamlessly and fixedly connected or integrally formed. The four corners and four edges of the glass mobile phone front cover (1) are provided with fixedly connected reinforcing ribs (3), the reinforcing ribs (3) and the glass mobile phone front cover (1) are seamlessly and fixedly connected or integrally formed, the glass mobile phone front cover (1) comprises two or more layers of plane glass (4), the plane glass (4) is provided with a protective layer (5), and the protective layer (5) is provided with a protective layer (6). The two or more layers of plane glass (4) are attached together through a bonding technology. A series of problems existing in a glass mobile phone front cover manufactured by a mobile phone shell front cover manufacturing process are solved.

Owner:BIEL OPTIC HUIZHOU

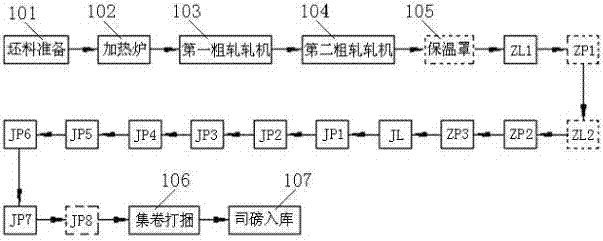

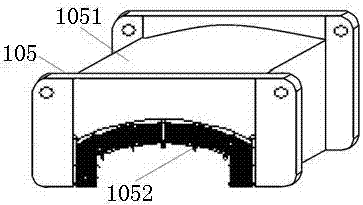

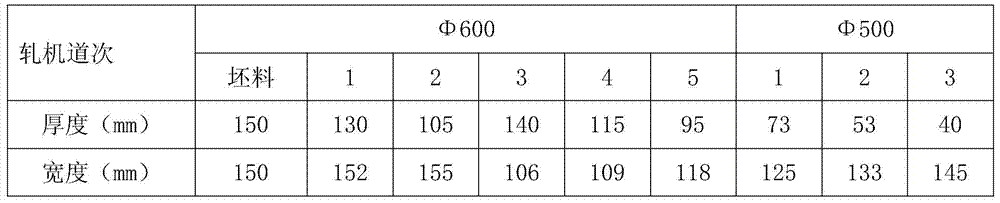

Ultra-thin hot-rolled narrow strip steel production line and its supporting technology

InactiveCN105057351BOptimize process systemReduce thicknessTemperature control deviceMetal rolling arrangementsProduction lineStrip steel

The invention discloses an ultra-thin hot-rolled narrow-strip steel production line and its supporting technology. A thermal insulation cover is installed on the steel-passing roller table from the second rough rolling mill to the first intermediate vertical rolling mill unit. The first intermediate rolling flat rolling mill and the second intermediate rolling vertical rolling mill are sequentially installed between the rolling mill unit and the second intermediate rolling flat rolling mill unit; The eighth finishing rolling flat rolling unit is installed between them. In the present invention, through the addition and modification of the main equipment and auxiliary facilities of the 3 / 4 continuous rolling mill production line, as well as the adjustment and optimization of the rolling line, billet, rolling temperature, rolling mill speed, roll matching system, etc., to achieve stable The purpose of producing ultra-thin hot-rolled narrow strip steel.

Owner:JIANGXI HONGDU STEELWORKS CO LTD

A kind of IF cold-rolled steel with tensile strength ≥ 440mpa and production method

The invention discloses IF cold rolling steel with the tensile strength larger than or equal to 440 MPa. The steel comprises, by weight percent, 0.001 to 0.003% of C, 0.07 to 0.10% of Si, 0.70 to 0.90% of Mn, 0.020 to 0.045% of Als, 0.060 to 0.075% of P, not larger than 0.010% of S, 0.0005 to 0.0013% of B, not larger than 0.02% of Nb, and not larger than 0.03% of Ti. A production process comprisesthe steps of conventional smelting and casting to form a blank; rough rolling and finish rolling; segmented cooling to the coiling temperature; reeling a hot rolling plate; acid picking; cold rolling; and reeling a cold rolling plate. On the premise of ensuring the use mechanics of the steel plate, the mechanical property is small in fluctuation, the cold rolling rate is improved to not lower than 20%, the rolling speed can be stabilized to above 500 m / min, the thickness precision can be controlled to be within 15 micrometers, the strip steel rolling process is stable, the strip steel thickness is reduced, the fluctuation is stable, and the plate shape is greatly improved.

Owner:武汉钢铁有限公司

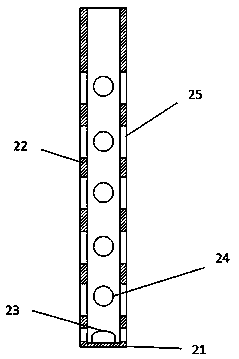

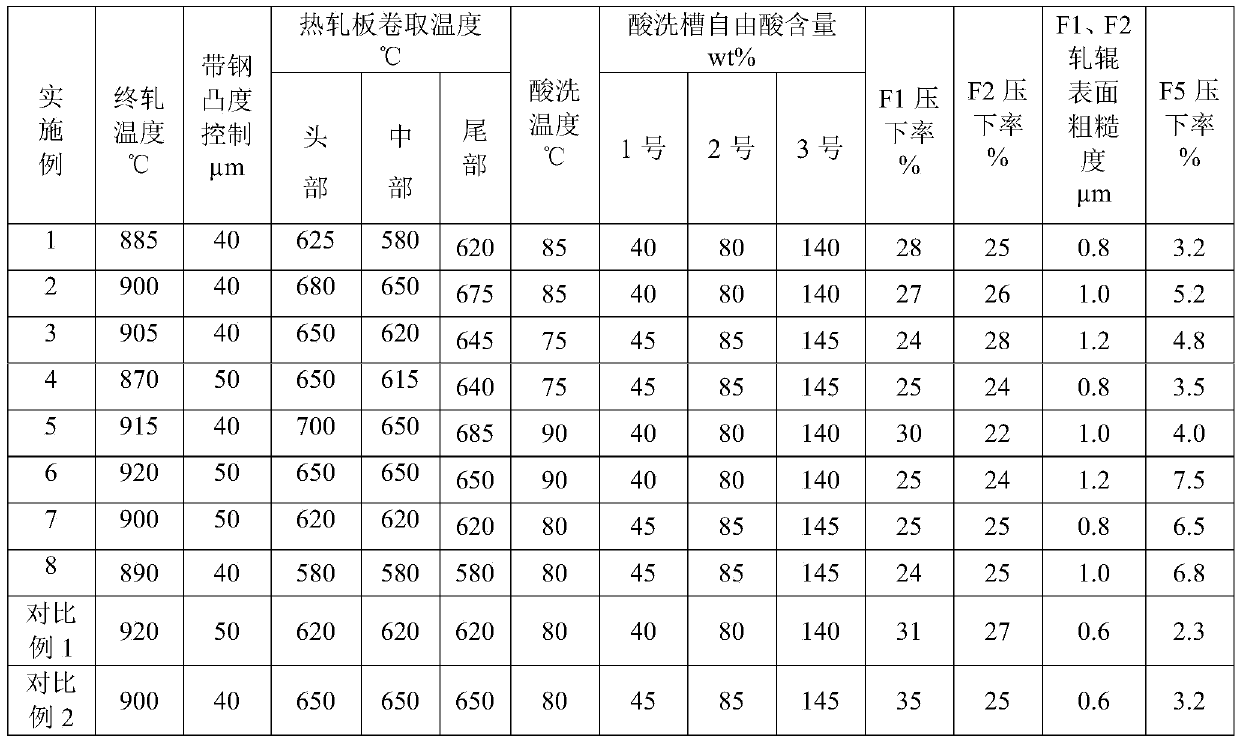

Production apparatus for electro-deposited metal foil, production method of thin plate insoluble metal electrode used in production apparatus for electro-deposited metal foil, and electro-deposited metal foil produced by using production apparatus for electro-deposited metal foil

ActiveUS8394245B2Reduce thickness fluctuationImprove thickness uniformityThin material handlingElectroforming processesElectrolysisMetal foil

An object of the present invention is to provide a production apparatus for electro-deposited metal foil or the like that can reduce thickness fluctuation of electro-deposited metal foil. To achieve the object, a production apparatus for electro-deposited metal foil or the like in which a cathode and an insoluble anode apart from each other, supplying an electrolytic solution through a gap between the cathode and the anode, making the cathode move along to the insoluble anode, electrodepositing a metal component on an electro-deposition surface of the moving cathode is applied. Wherein the insoluble anode is a thin plate insoluble metal electrode provided with a conductive electrode material coating layer on a surface of a substrate made of a corrosion-resistant material, and detachably mounted to an electrode base by using predetermined fixing means, and the conductive electrode material coating layer of the thin plate insoluble metal electrode is provided with a conductive electrode material stripped belt in a direction perpendicular to a moving direction of the cathode, and the fixing means is provided in the conductive electrode material stripped belt.

Owner:DE NORA PERMELEC LTD

Rolling control method that can reduce the influence of heating furnace walking beam watermark on the thickness of finished product

ActiveCN105363796BReduce the effect of thicknessReduce outputRoll mill control devicesMetal rolling arrangementsThick plateEngineering

The invention discloses a rolling control method capable of lowering the influence of watermarks of walking beams of a heating furnace on the thickness of finished products. The method is characterized by including the following steps that 1, the number of the walking beams in the heating furnace and the size of the heating furnace are detected; 2, the number of watermark points and the position of each watermark point are calculated according to the number of the walking beams and the size of the heating furnace; 3, the watermark influence coefficient of each watermark point for rolling force is calculated; and 4, actual rolling force of the watermark points is calculated according to the watermark influence coefficients. By the adoption of the technical scheme, the influence of the watermarks of the walking beams of the heating furnace on the thickness of finished moderately-thick plates can be lowered, and especially, the thickness fluctuation caused by the watermarks can still be effectively relieved under the condition of short time in the heating furnace; and the hourly output of thick plates and the thickness and accuracy of the finished products can be guaranteed, and quality losses are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

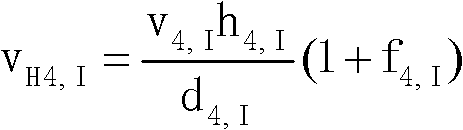

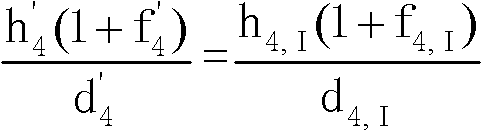

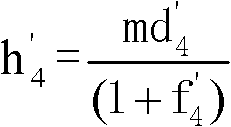

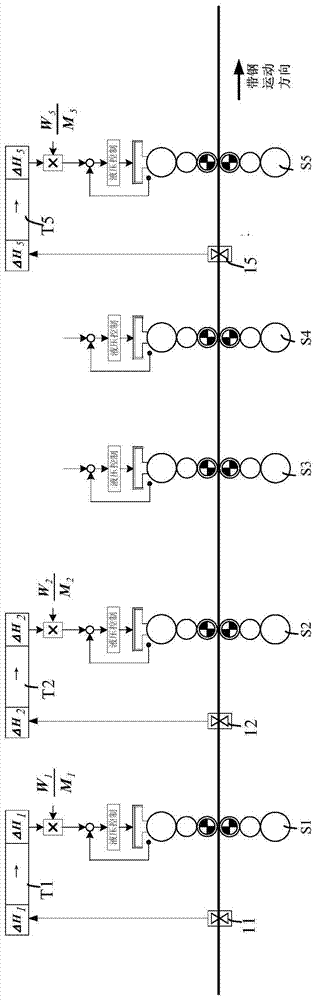

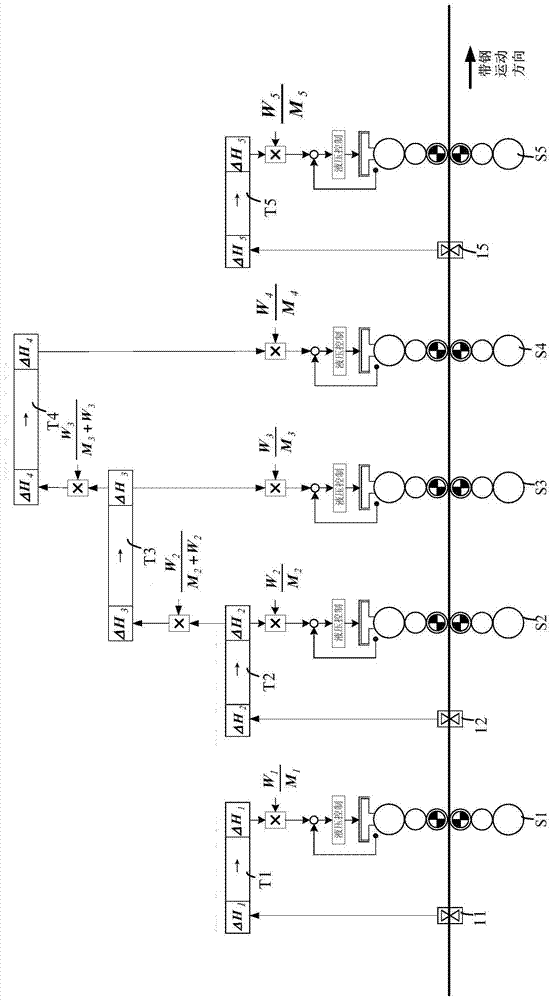

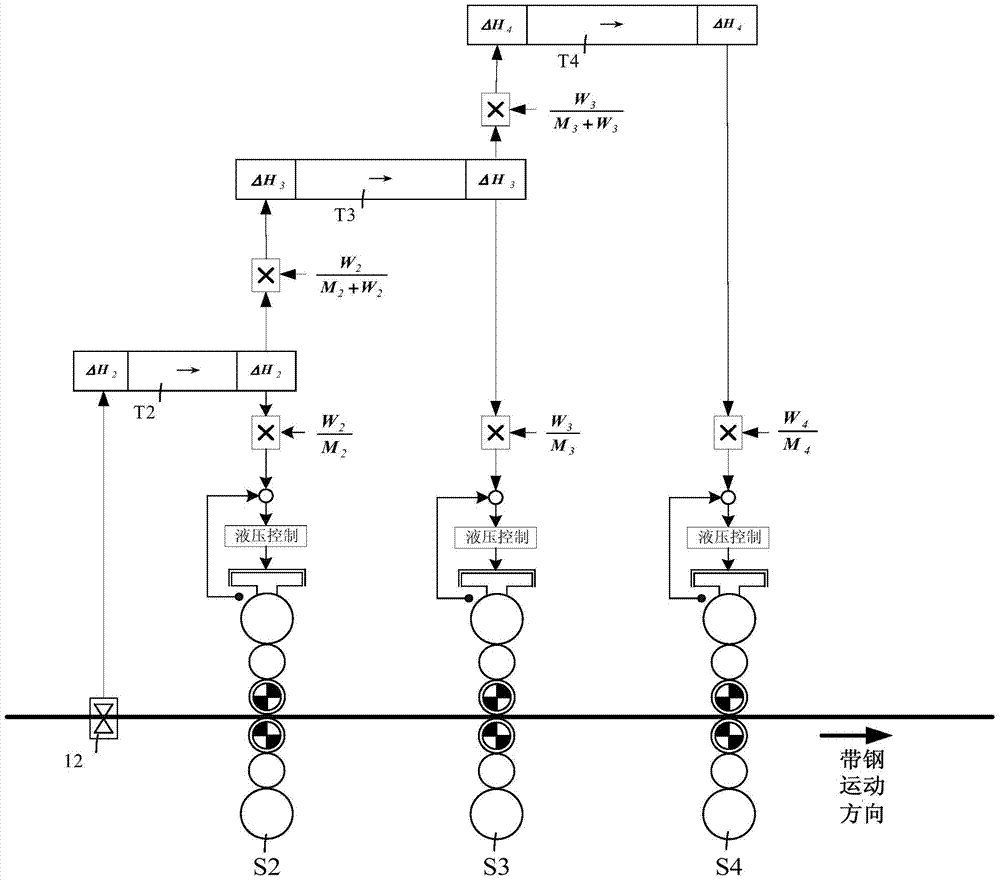

Feed-forward control method for thickness expansion of tandem cold rolling mill

ActiveCN106269898BReduce thickness fluctuationHigh precisionRare end control deviceMeasuring devicesEngineeringStrip steel

The invention discloses a cold continuous mill thickness extension feed-forward control method. The cold continuous mill thickness extension feed-forward control method comprises the steps that a first thickness gauge, a second thickness gauge and a fifth thickness gauge are installed in front of an inlet of a first rack, an inlet of a second rack and an inlet of a fifth rack correspondingly, the first thickness gauge, the second thickness gauge and the fifth thickness gauge are used for measuring the thickness deviations of incoming materials at the inlet of the first rack, the inlet of the second rack and the inlet of the fifth rack correspondingly, and the thickness deviations are used for feed-forward control of the first rack, the second rack and the fifth rack correspondingly; the thickness deviation of an inlet of a third rack is estimated according to the thickness deviation actually measured by the second thickness gauge, and the estimated thickness deviation of the inlet of the third rack is transmitted to the third rack so that thickness feed-forward control can be conducted; and the thickness deviation of an inlet of a fourth rack is estimated according to the estimated thickness deviation of the inlet of the third rack, and the estimated thickness deviation of the inlet of the fourth rack is transmitted to the fourth rack so that thickness feed-forward control can be conducted. By means of the cold continuous mill thickness extension feed-forward control method, the strip steel thickness control precision is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Glass mobile phone front cover thinning process

PendingCN114697422AReduce intensityShorten the timeGlass reforming apparatusTelephone set constructionsEngineeringProtection layer

The invention discloses a glass mobile phone front cover thinning process, which is characterized in that compared with the existing glass mobile phone front cover, the produced glass mobile phone front cover (1) is provided with a hole site (2) for mounting a camera, a protective cover (6) for protecting the camera is arranged on the hole site (2), and the protective cover (6) and the hole site (2) are seamlessly and fixedly connected or integrally formed. The four corners and four edges of the glass mobile phone front cover (1) are provided with fixedly connected reinforcing ribs (3), the reinforcing ribs (3) and the glass mobile phone front cover (1) are seamlessly and fixedly connected or integrally formed, the glass mobile phone front cover (1) comprises two or more layers of plane glass (4), the plane glass (4) is provided with a protective layer (5), and the protective layer (5) is provided with a protective layer (6). The two or more layers of plane glass (4) are attached together through a bonding technology. A series of problems existing in a glass mobile phone front cover manufactured by a mobile phone shell front cover thinning process are solved.

Owner:BIEL OPTIC HUIZHOU

A process for preparing a novel inorganic high-resistance layer used for a ZnO piezoresistor

InactiveCN109553410AReduce thickness fluctuationProcess stabilityResistive material coatingHigh resistanceMetallurgy

A process for preparing a novel inorganic high-resistance layer used for a ZnO piezoresistor is provided. The process includes subjecting prepared raw materials to mixing and heating for dissolution to prepare a uniform solution, and directly coating a side surface of a resistor sheet after the resistor sheet is molded. The process is characterized in that the process includes a raw material preparing step, a ball milling mixing step, a spray drying step, a compression moulding step, a sintering step, a coating step, and a sheet formation step; and the raw material preparing step, the ball milling mixing step, the spray drying step, the compression moulding step, the sintering step, and the coating step are performed in order. Beneficial effects of the process are that a high-resistance layer is formed after molding so that fluctuation in glaze layer thickness caused by nonuniform presintering shrinking percentages is reduced and the process is stabler.

Owner:TSINGHUA UNIV +1

Liquid high resistance layer for zinc oxide varistors

ActiveCN108503392BReduce thickness fluctuationSolve side insulation problemsVaristor coresOvervoltage protection resistorsElectrical resistance and conductanceShrinkage rate

The invention provides a liquid high-resistance layer for a zinc oxide piezoresistor. A formula comprises Bi(NO3)3, Co(NO3)2, Mn(NO3)2 and CH3COOLi; a preparation method of the liquid high-resistancelayer comprises the following steps: mixing each raw material in the formula with a solvent; heating and dissolving. An application method of the liquid high-resistance layer coats a side face of a resistance piece with a formula solution. The liquid high-resistance layer of the zinc oxide piezoresistor has the beneficial effects that the formula of the high-resistance layer is adjusted and a technology is controlled, so that a body of the resistance piece is matched with the shrinkage rate of a glaze layer; the side face insulation problem of the resistance piece is solved; meanwhile, the square wave discharge capability of the resistance piece is improved. The original fluctuation of glaze layer thickness, caused by the fact that pre-firing shrinkage rates are different, is reduced; theresistance piece has no cracks and the technology is more stable.

Owner:TSINGHUA UNIV +1

Glass mobile phone rear cover thinning process

PendingCN114697423AReduce intensityShorten the timeGlass reforming apparatusGlass severing apparatusBonding processStructural engineering

The invention discloses a glass mobile phone rear cover thinning process, which is characterized in that compared with the prior art, the produced glass mobile phone rear cover (1) is provided with a hole site (2) for mounting a camera, and the four corners and four sides of the glass mobile phone rear cover (1) are provided with fixedly connected reinforcing ribs (3); the reinforcing rib (3) and the glass mobile phone rear cover (1) are seamlessly and fixedly connected or integrally formed, the glass mobile phone rear cover (1) comprises two or more layers of plane glass (4), a protective layer (5) is arranged on the plane glass (4), and the two or more layers of plane glass (4) are attached together through a bonding process. A series of problems existing in a glass mobile phone rear cover manufactured by a mobile phone shell rear cover manufacturing process are solved.

Owner:BIEL OPTIC HUIZHOU

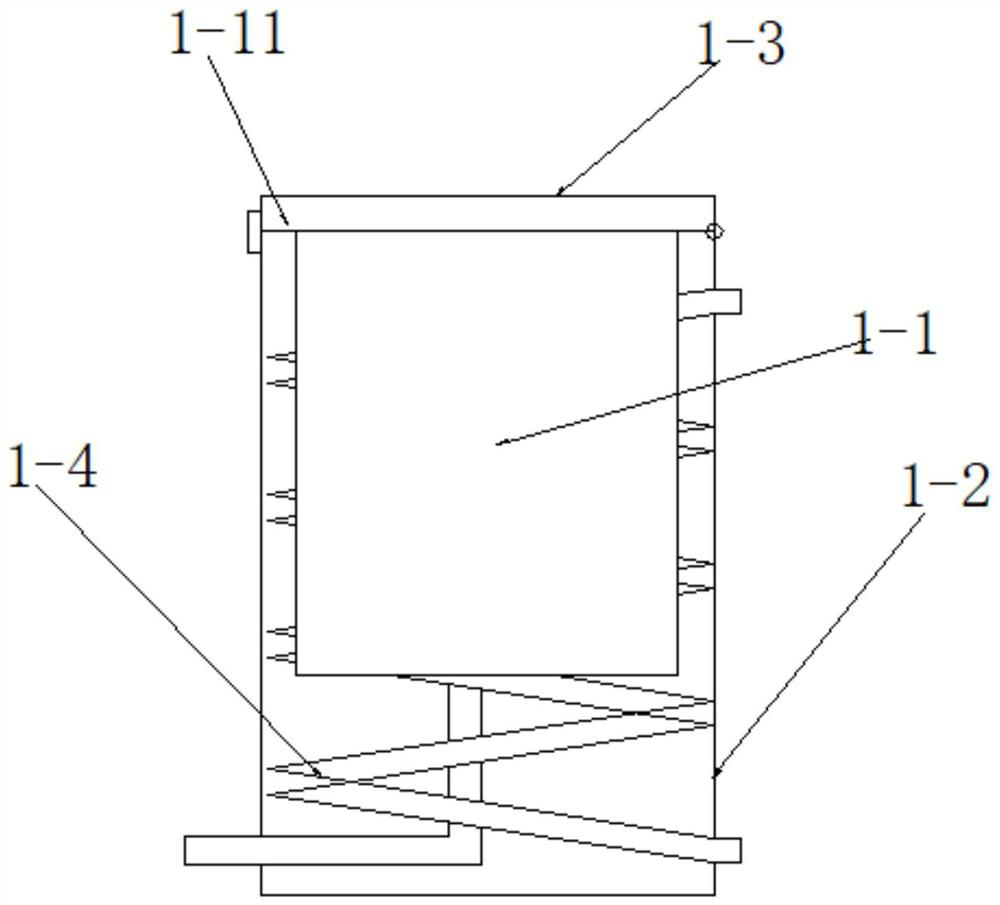

A paint liquid temperature control device

ActiveCN111026188BReduce thickness fluctuationAffect insulationTemperatue controlTemperature controlEngineering

The present invention relates to the field of enameled wire painting equipment, in particular to a paint liquid temperature control device, the temperature control device includes a paint liquid barrel for storing paint liquid, and the paint liquid barrel includes an inner barrel and an outer barrel; The inner barrel and the outer barrel are coaxially arranged; a water circulation temperature compensation device is provided between the inner barrel and the outer barrel; the paint liquid barrel is provided with a liquid inlet pipe for the paint liquid to enter; one end of the paint liquid inlet pipe extends to the inside of the inner barrel; the lower end of the inner barrel is connected with a drain pipe; the lower end of the outer barrel is provided with an outer barrel water inlet pipe; the upper end of the outer barrel is provided with an outer barrel water outlet pipe. The invention discloses a varnish liquid temperature control device. Through the setting of the temperature control device, the temperature of the insulating varnish can be kept within a set interval during the coating process of the enameled wire, so that the annual and leveling properties of the insulating varnish can be improved. It meets the design requirements, thereby reducing the fluctuation of the thickness of the enameled wire when coating the enameled wire, and reducing or avoiding the influence of the insulation performance of the enameled wire due to the difference in the thickness of the insulating varnish.

Owner:TONGLING JINGDA REA SPECIAL ENAMELED WIRE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com