Feed-forward control method for thickness expansion of tandem cold rolling mill

A feedforward control, tandem cold rolling mill technology, applied in rolling mill control devices, metal rolling, tail end control, etc., can solve the problems of huge investment costs, no installation of thickness gauges, heavy equipment maintenance burden, etc., to improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

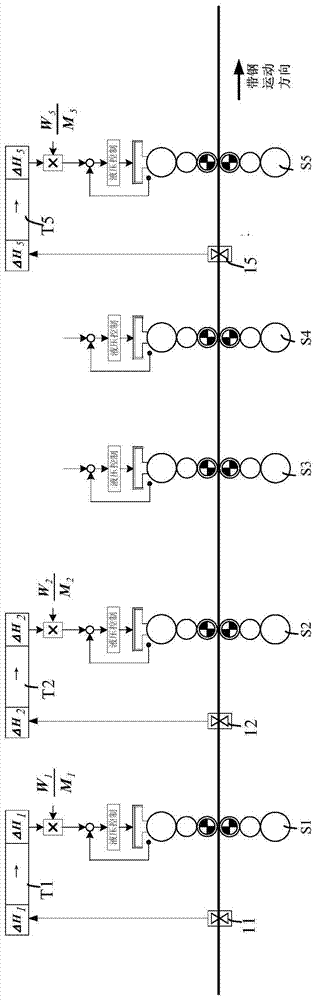

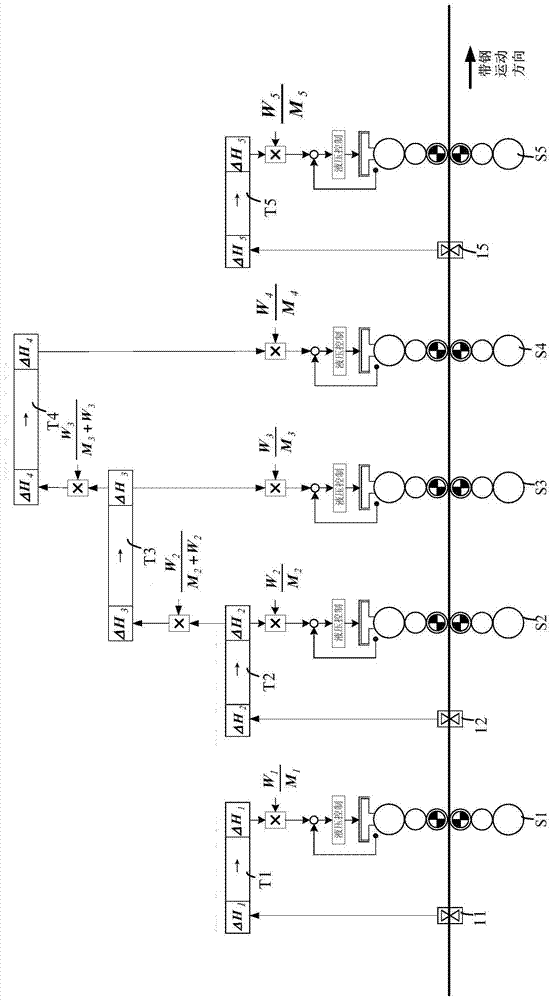

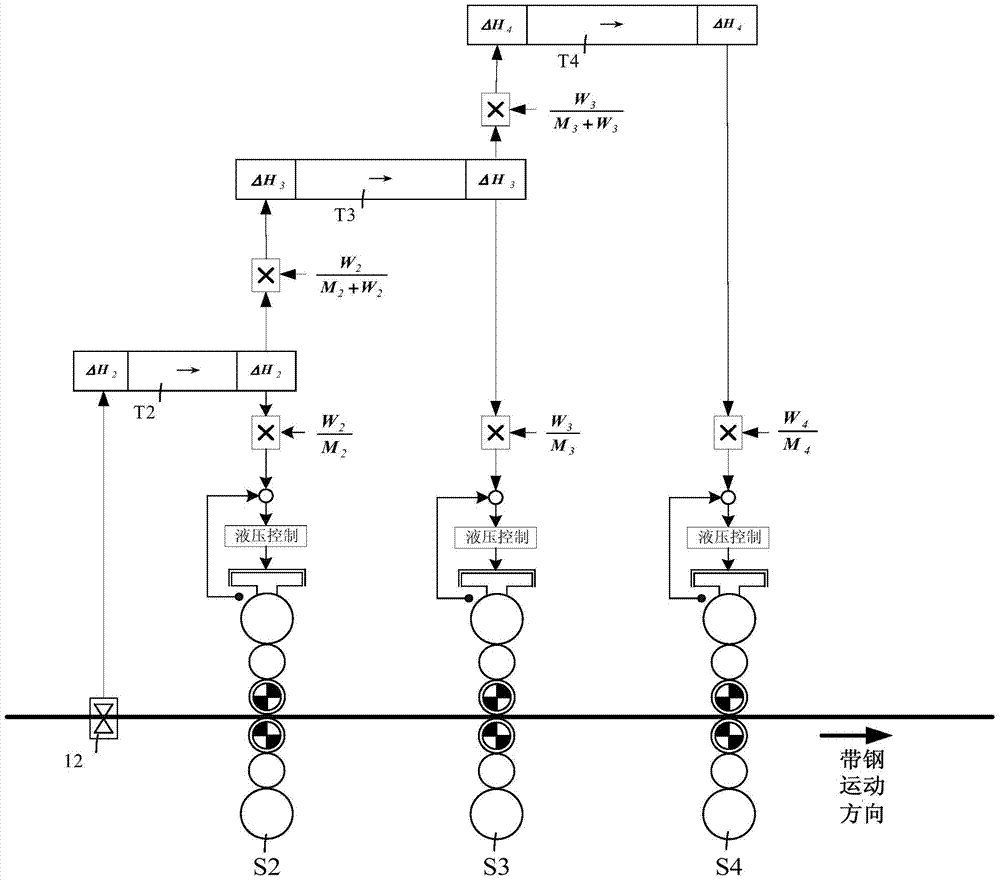

[0032] Such as figure 2 and 3 As shown, the tandem cold rolling mill thickness extension feed-forward control method of the present invention includes the first stand S1, the second stand S2, the third stand S3, the fourth stand S4 and the fifth stand S5 , the first thickness gauge 11, the second thickness gauge 12 and the fifth thickness gauge 15 are respectively installed before the entrances of the first frame S1, the second frame S2 and the fifth frame S5, the first thickness gauge The gauge 11 , the second thickness gauge 12 and the fifth thickness gauge 15 respectively detect the thickness deviation of the entrance strip of the first rack S1 , the second rack S2 and the fifth rack S5 . In the first frame S1, the second frame S2 and the fifth frame S5, the thickness deviation of the incoming material directly measured by the first thickness gauge 11, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com