Glass mobile phone front cover thinning process

A mobile phone and glass technology, applied in the field of glass mobile phone front cover thinning technology, can solve the problems of reduced strength, easy to break, rigidity and strength reduction, etc., and achieve the effects of improving efficiency, low polishing efficiency, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

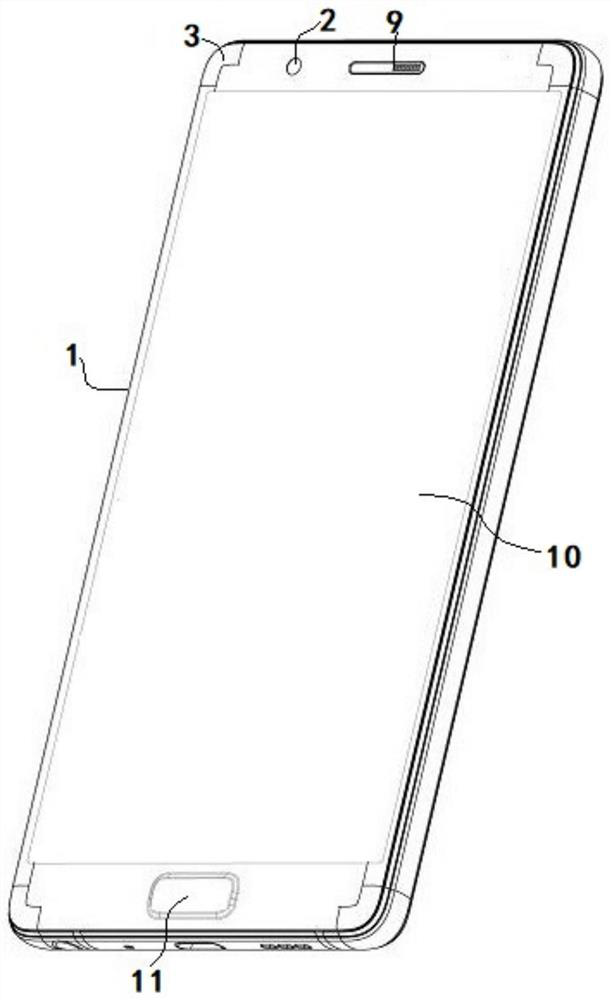

[0030] As shown in the figure, the glass mobile phone front cover is integrally formed with a glass mobile phone front cover 1, a hole 2 for installing a camera is provided on the glass mobile phone front cover 1, and a protective cover for protecting the camera is provided on the top of the hole 2 6. The protective cover 6 and the hole 2 are seamlessly connected or integrally formed. There is a volume receiver hole 9 at the front end of the glass mobile phone front cover 1, and a display area for installing the display screen is arranged in the middle of the glass mobile phone front cover 1. Position 10, a mechanical or touch-sensitive key position 11 is provided at the rear end of the glass mobile phone front cover 1, and the protective cover 6 is provided with an upright edge 7 or a sloped edge 8 arranged perpendicular to the glass mobile phone front cover 6. The protective cover 6 is made of transparent plastic or glass; in this embodiment, the protective cover and the hole...

specific Embodiment approach 2

[0034] The main difference between the second embodiment and the first embodiment is:

[0035] (1) In this embodiment, the reinforcing rib 3 and the front cover 1 of the glass mobile phone are integrally formed.

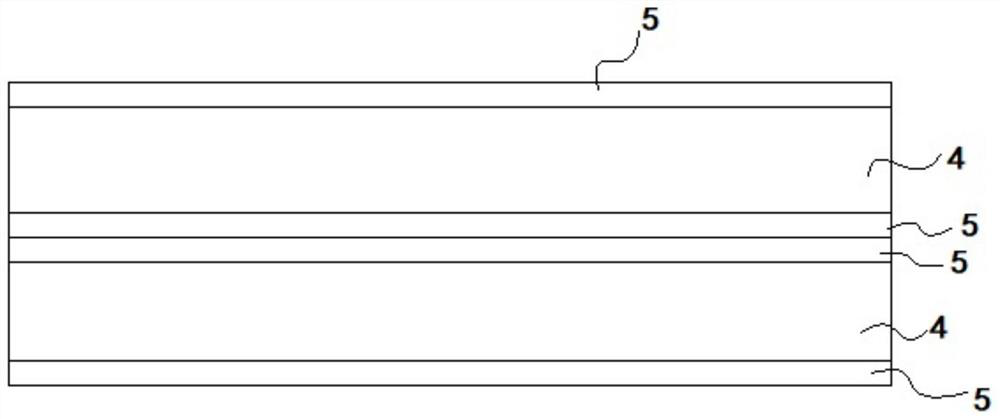

[0036] (2) The front cover 1 of the glass mobile phone includes two or more layers of flat glass 4, and a protective layer 5 is provided on the flat glass 4. The protective layer 5 is a screen printing protective layer formed by a screen printing process, or the protective layer 5 is formed by a film sticking process. Formed film protective layer. Two or more layers of flat glass 4 are bonded together through a bonding process. In this embodiment, three layers of flat glass 4 are used for the film protective layer formed by the film bonding process, and the three layers of flat glass are synthesized together by a high temperature bonding process to form an integrated glass mobile phone front cover 1 .

[0037] (3) The flatness of the front cover 1 of the glass mobi...

specific Embodiment approach 3

[0039] The main difference between the third embodiment and the first embodiment is:

[0040] (1) In this embodiment, the reinforcing rib 3 and the front cover 1 of the glass mobile phone are integrally formed.

[0041] (2) The front cover 1 of the glass mobile phone includes two or more layers of flat glass 4, and a protective layer 5 is provided on the flat glass 4. The protective layer 5 is a screen printing protective layer formed by a screen printing process, or the protective layer 5 is formed by a film sticking process. Formed film protective layer. Two or more layers of flat glass 4 are bonded together through a bonding process. In this embodiment, four layers of flat glass 4 are used for the film protective layer formed by a film bonding process, and the four layers of flat glass are synthesized together by a high temperature bonding process to form an integrated glass mobile phone front cover 1 .

[0042] (3) The flatness of the front cover 1 of the glass mobile ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com