Glass mobile phone rear cover thinning process

A mobile phone back cover and glass technology, applied in glass tempering, glass molding, glass manufacturing equipment, etc., can solve problems such as defects, strength reduction, rigidity and strength reduction, etc., achieve low polishing efficiency, improve efficiency, and shorten time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

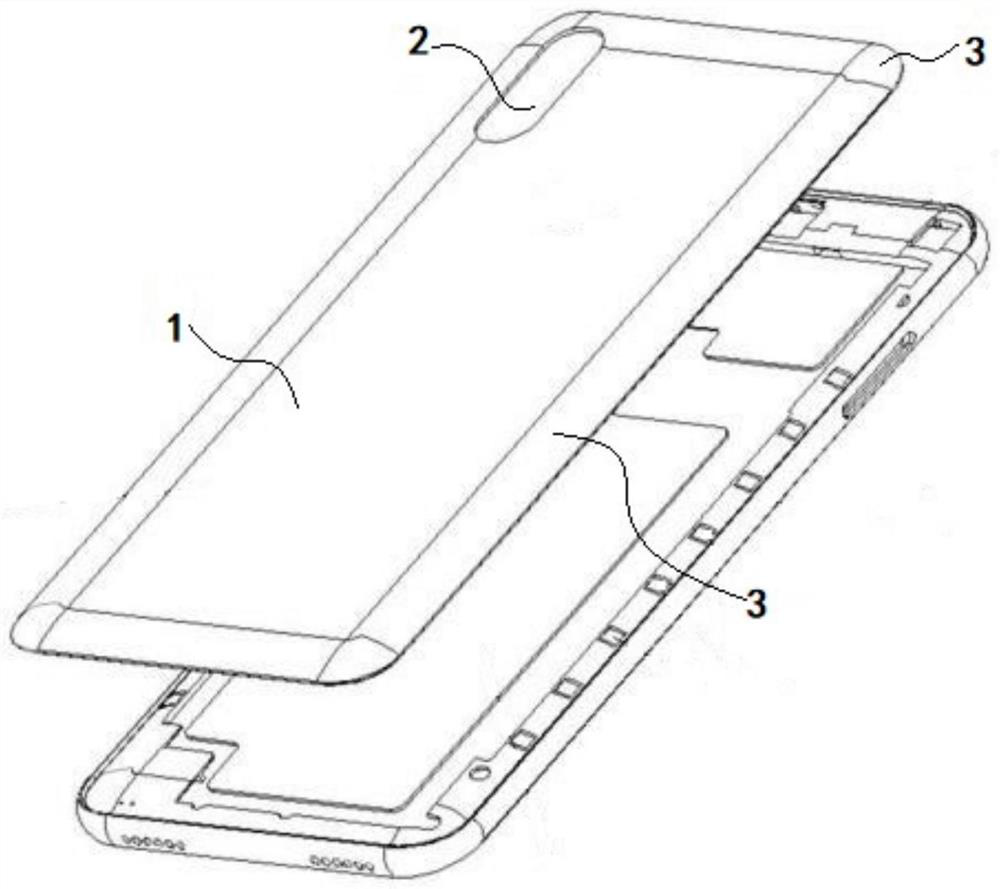

[0026] As shown in the figure, the back cover of the glass mobile phone is an integrally formed glass mobile phone back cover 1 , the glass mobile phone back cover 1 is provided with a hole 2 for installing a camera, and the four corners and four sides of the glass mobile phone back cover 1 are provided with fixed connections The reinforcing rib 3 and the glass mobile phone back cover 1 are seamlessly connected or integrally formed, the reinforcing ribs 3 provided on the four corners of the glass mobile phone back cover 1 are rectangular, and the reinforcing ribs 3 provided on the four sides of the glass mobile phone back cover 1 The whole is a "well" shape. The reinforcing rib 3 is made of transparent plastic or glass. In this embodiment, the reinforcing ribs 3 and the glass mobile phone back cover 1 are seamlessly and fixedly connected, and in this embodiment, the reinforcing ribs 3 at the four corners of the glass mobile phone back cover 1 are rectangular, and the reinforci...

specific Embodiment approach 2

[0029] The main difference between the second embodiment and the first embodiment is:

[0030] (1) In this embodiment, the reinforcing rib 3 and the back cover 1 of the glass mobile phone are integrally formed.

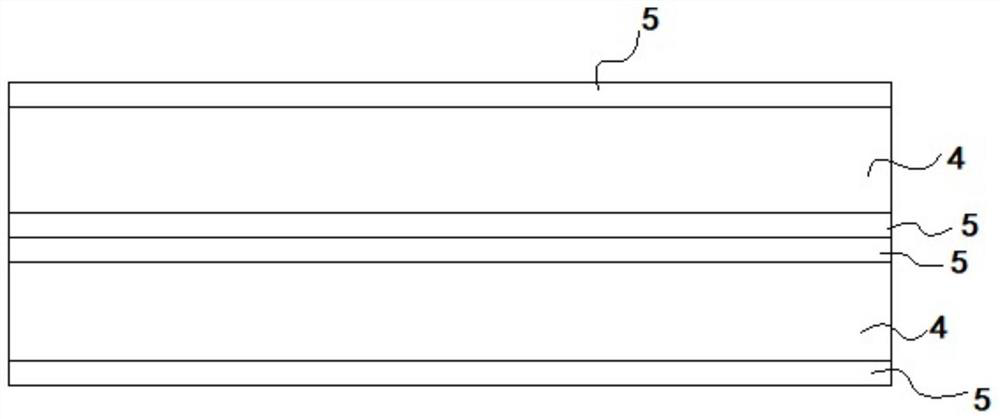

[0031] (2) The back cover 1 of the glass mobile phone includes two or more layers of flat glass 4, and a protective layer 5 is provided on the flat glass 4. The protective layer 5 is a screen-printed protective layer formed by a silk-screen process, or the protective layer 5 is formed by a film-sticking process. Formed film protective layer. Two or more layers of flat glass 4 are bonded together through a bonding process. In this embodiment, three layers of flat glass 4 are used for the film protective layer formed by the film bonding process, and the three layers of flat glass are synthesized together by a high temperature bonding process to form an integrated glass mobile phone back cover 1 .

[0032] (3) The flatness of the back cover 1 of the glass mobile phone ...

specific Embodiment approach 3

[0033] The main difference between the third embodiment and the first embodiment is:

[0034] (1) In this embodiment, the reinforcing rib 3 and the back cover 1 of the glass mobile phone are integrally formed.

[0035] (2) The back cover 1 of the glass mobile phone includes two or more layers of flat glass 4, and a protective layer 5 is provided on the flat glass 4. The protective layer 5 is a screen-printed protective layer formed by a silk-screen process, or the protective layer 5 is formed by a film-sticking process. Formed film protective layer. Two or more layers of flat glass 4 are bonded together through a bonding process. In this embodiment, four layers of flat glass 4 are used for the film protective layer formed by the film bonding process, and the four layers of flat glass are synthesized together through a high temperature bonding process to form an integrated glass mobile phone back cover 1 .

[0036] (3) The flatness of the back cover 1 of the glass mobile phon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com