Capacitance dynamic quantity sensor

一种电容型、传感器的技术,应用在传感器领域,能够解决电极厚度波动、固定电极变厚等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

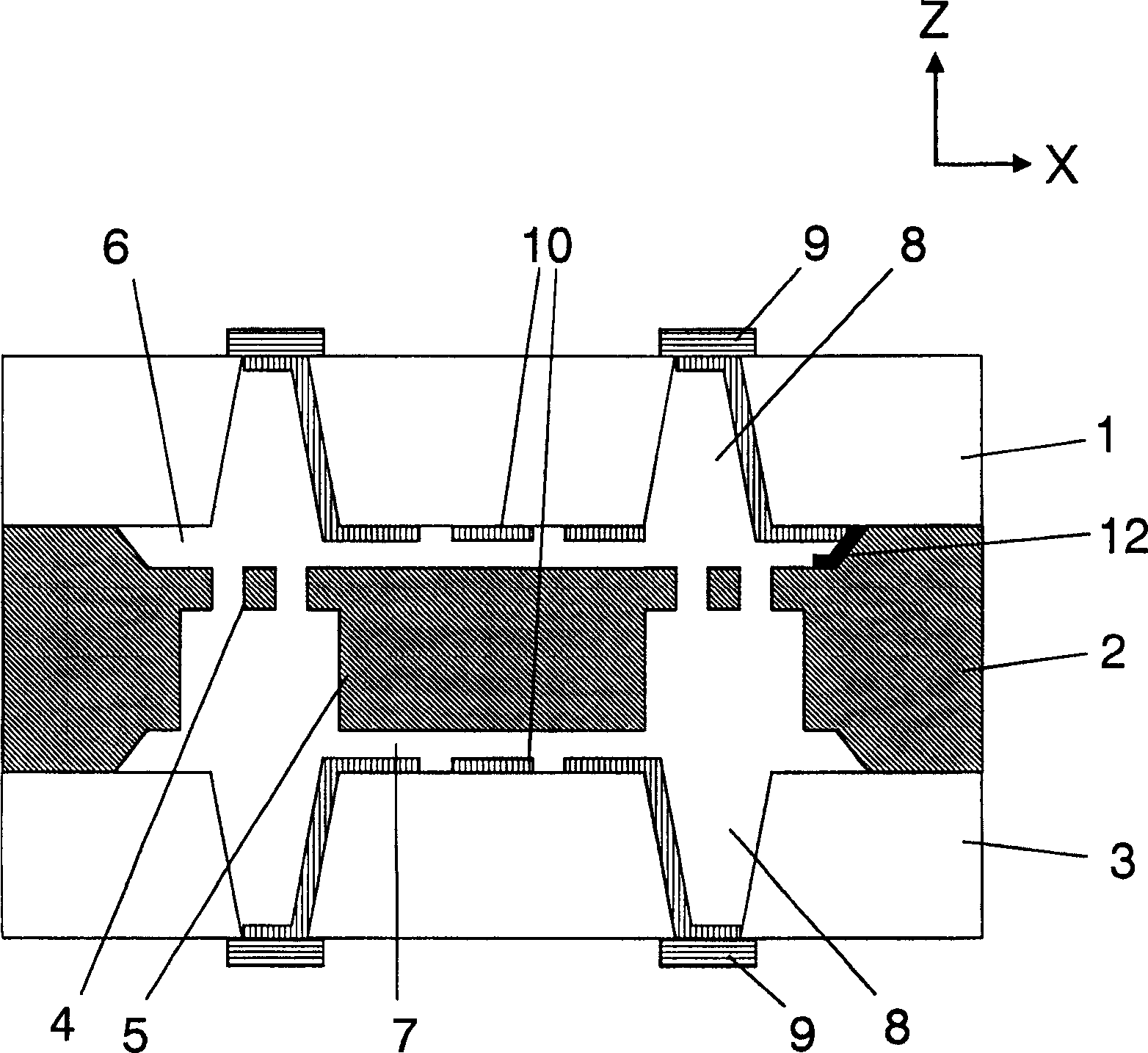

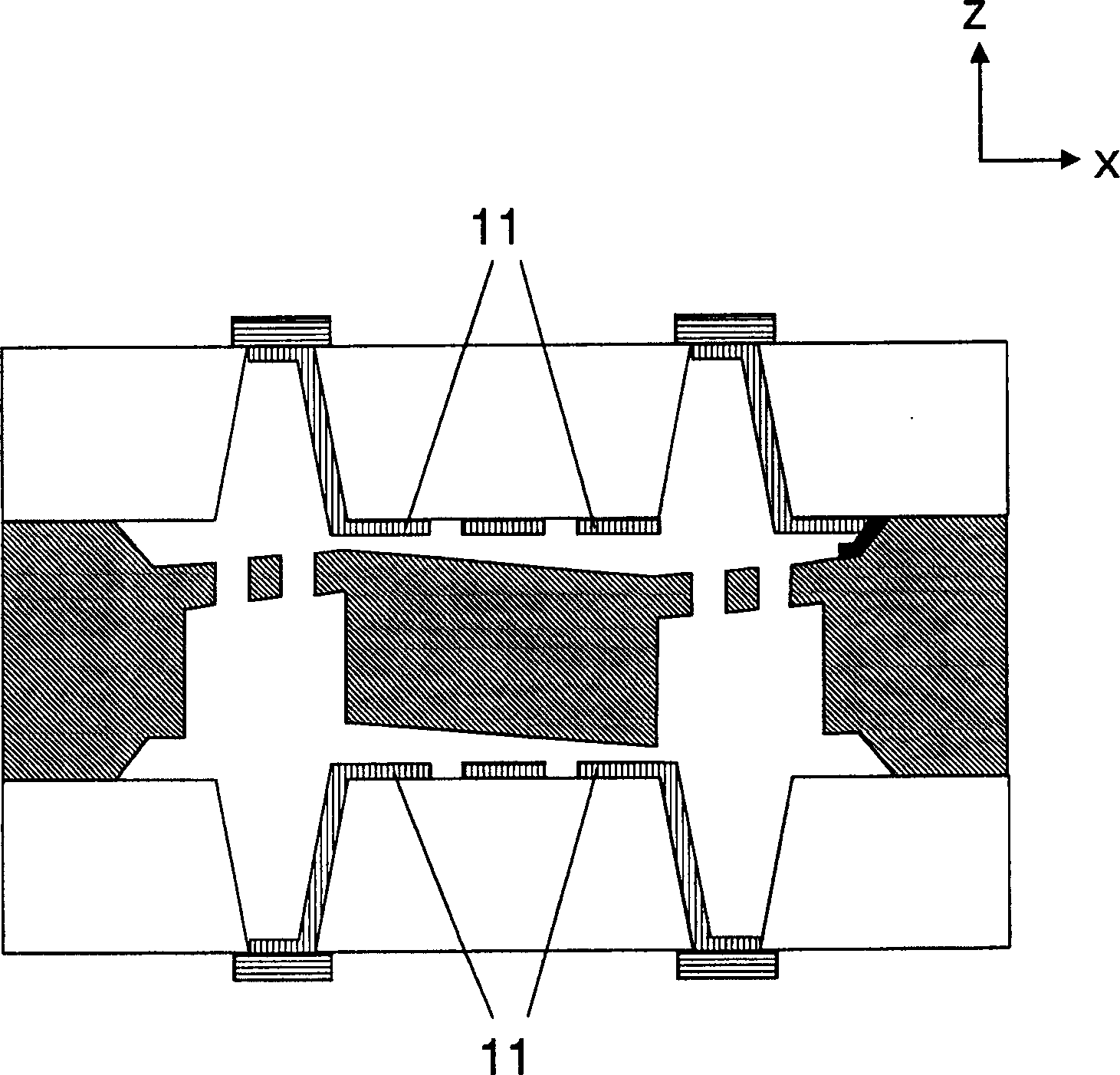

[0018] Preferred embodiments of the present invention will be described in detail below by taking a typical angular velocity sensor as an example of a capacitive dynamic quantity sensor of the present invention with reference to the accompanying drawings.

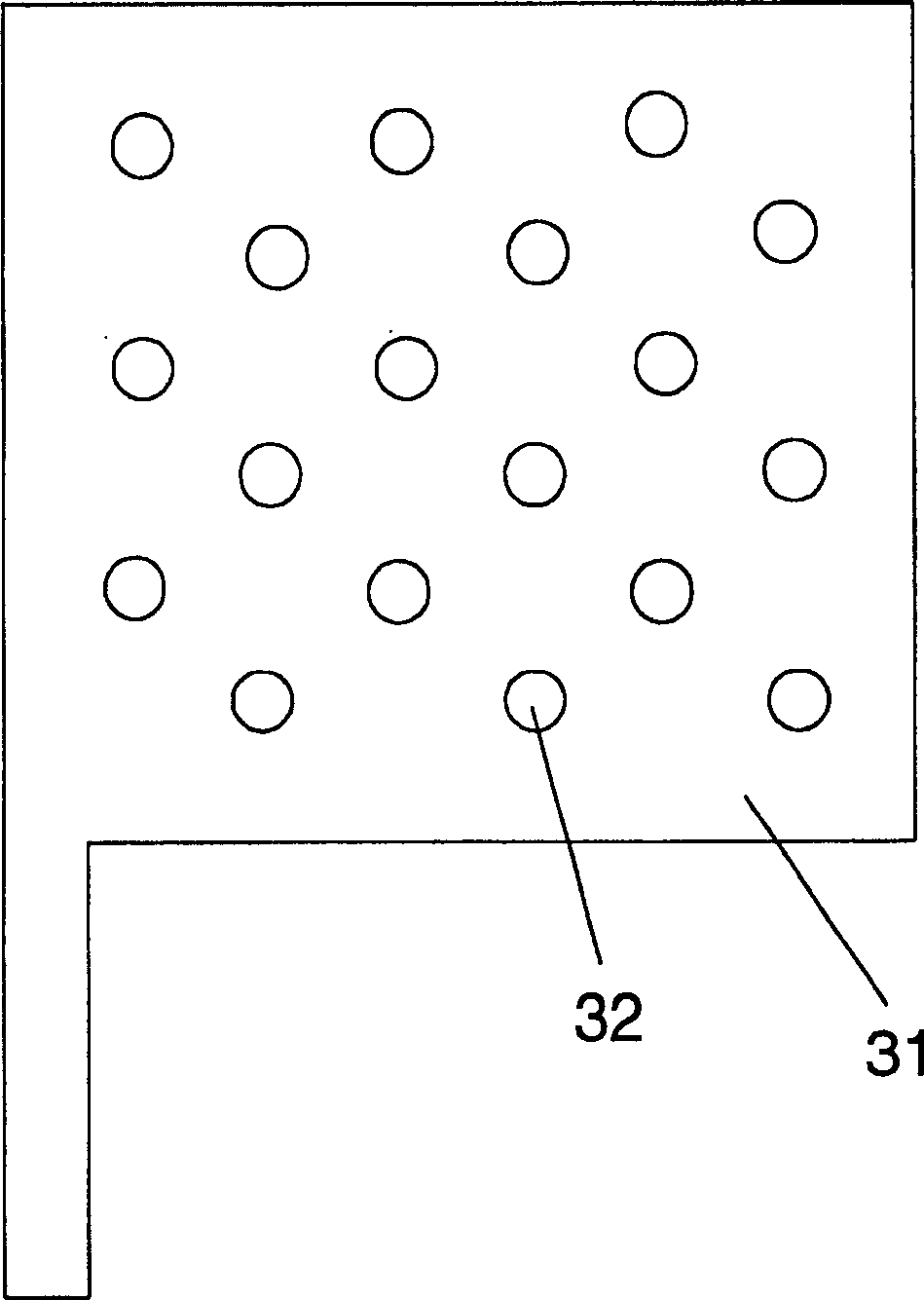

[0019] first, figure 1 A schematic cross-sectional view of a capacitive dynamic quantity sensor according to an embodiment of the present invention is shown. refer to figure 1 , this capacitive dynamic quantity sensor has a three-layer structure including an upper glass substrate 1 , a silicon substrate 2 and a lower glass substrate 3 . These three substrates 1, 2 and 3 are bonded to each other to form a three-layer structure. A vibrating element with a beam 4 and a weight 5 is formed in the silicon substrate 2 by an etching process. The vibration element can vibrate or twist due to a force applied from the outside. The shape of each beam 4 is designed to be related to its thickness, length and width, and the shape of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com