Rolling control method capable of lowering influence of watermarks of walking beams of heating furnace on thickness of finished products

A technology of finished product thickness and control method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., to achieve the effect of ensuring the thickness accuracy of finished products, reducing thickness fluctuation and ensuring output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

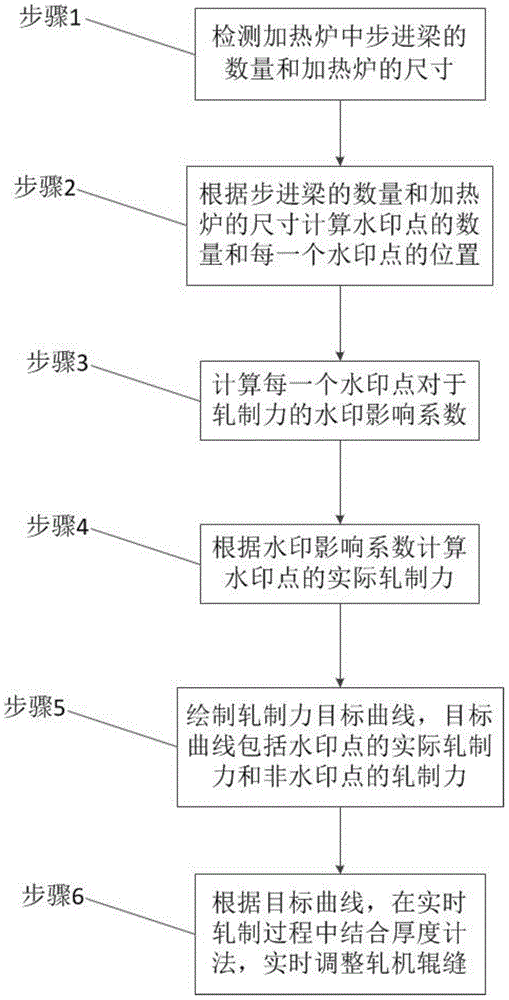

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

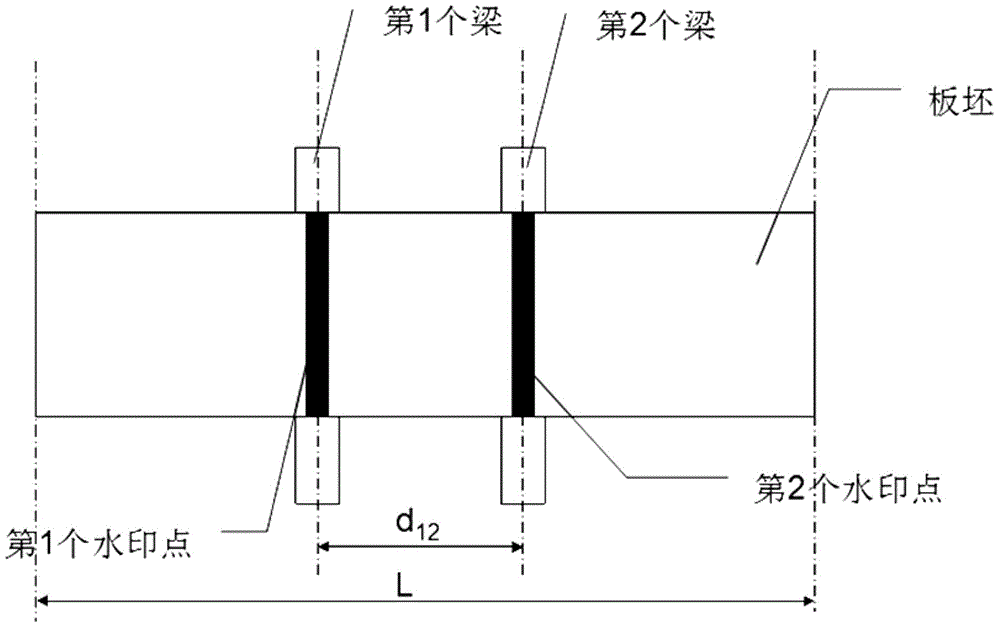

[0049] In the automatic system of multi-point setting and rolling force AGC based on model process control, the present invention establishes a watermark influence estimation model based on information such as the furnace time, size, and steel type of the slab heating furnace, and pre-calculates the watermark The relative position of the point and the estimated value of the influence on the rolling force give the AGC a more reasonable pre-set rolling force target and initial roll gap, thereby reducing the adjustment amount of the AGC system, thereby achieving the purpose of reducing the thickness fluctuation affected by the watermark.

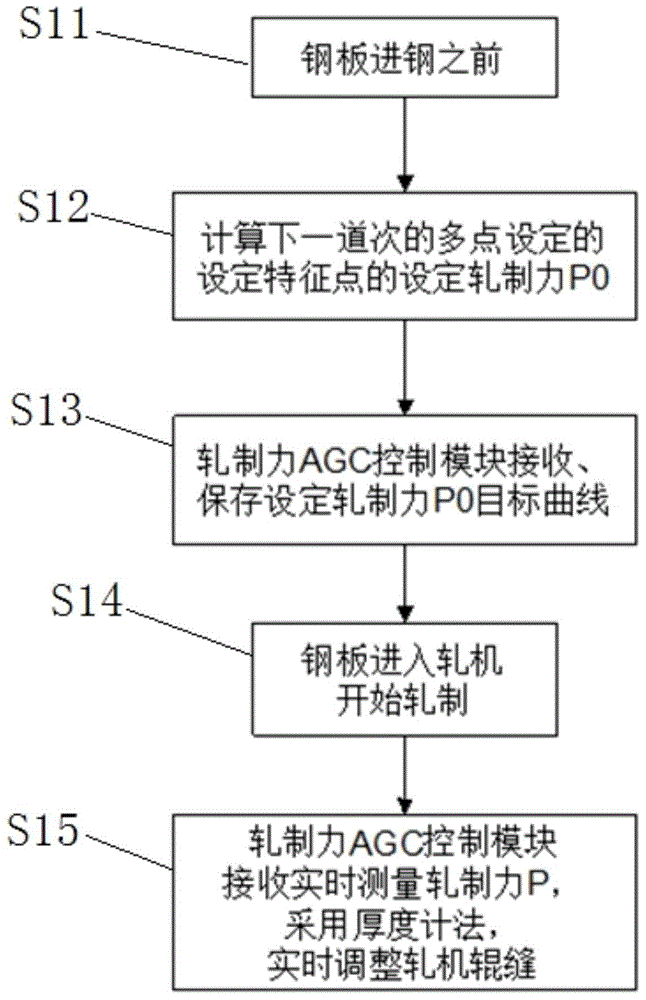

[0050] Therefore, the present invention provides an automatic rolling thickness control method for a medium and heavy plate mill that reduces the influence of the watermark of the walking beam o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com