Display substrate, manufacturing method thereof, and display device

A manufacturing method and a technology for displaying a substrate, which are applied in photoplate-making process exposure devices, identification devices, pattern-surface photo-plate-making processes, etc., which can solve the problems of reduced exposure resolution and uniformity, different thicknesses of photoresist, and signal lines. Problems such as narrowing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

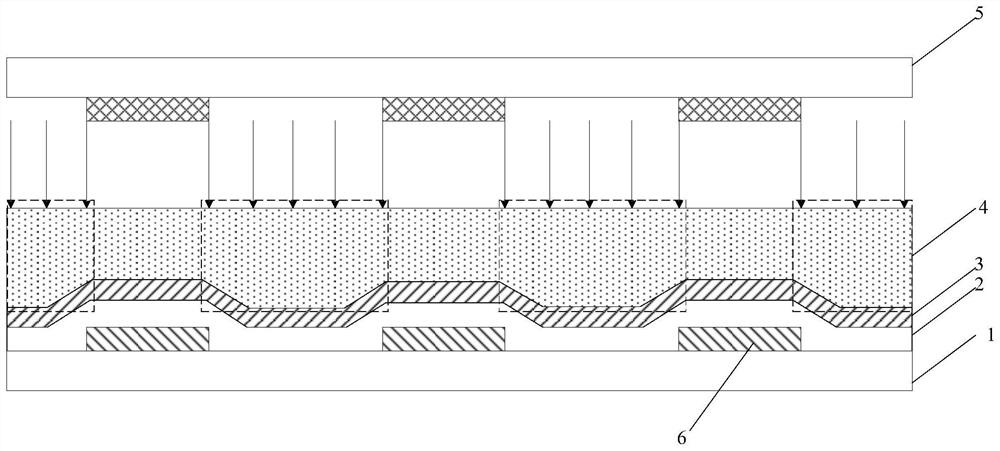

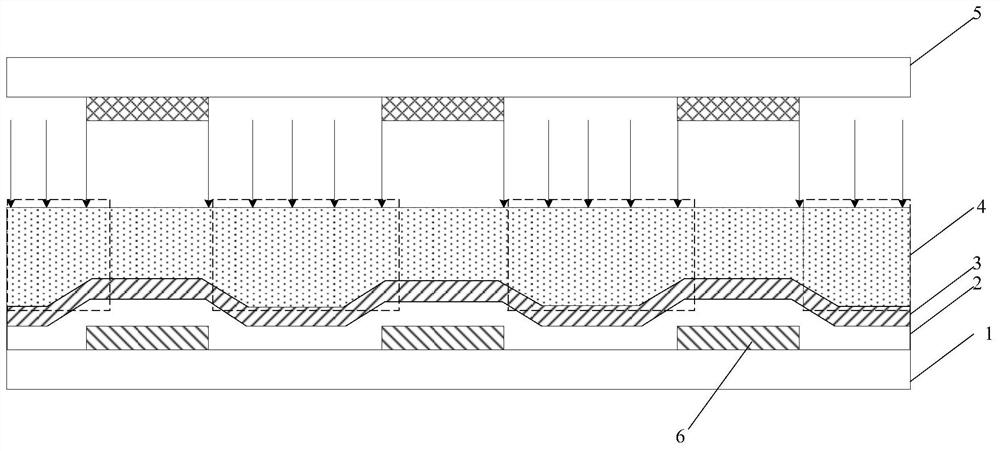

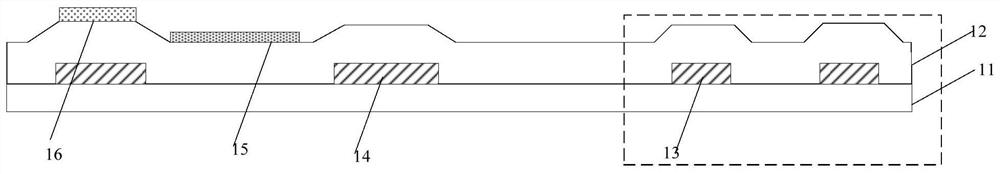

[0051] The existing wiring design uses two layers of metal to overlap to create a fan-out area to reduce the layout space of the signal line. However, when making the upper layer of metal, the thickness of the resist during exposure is different due to the existence of alignment offset. figure 1 is a schematic diagram without alignment shift, figure 2 is a schematic diagram of alignment offset, wherein, 1 is the base substrate, 2 is the insulating layer, 3 is the second metal layer, 4 is the photoresist, 5 is the mask plate, and 6 is the pattern of the first metal layer, because Exposure resolution and uniformity are greatly reduced, the line width of the signal line made of the upper layer metal will become smaller, and the risk of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com