Exposure platform of exposure machine

An exposure machine and platform technology, which is applied in the field of exposure platform, can solve the problems of deformation of light-transmitting plate, reduction of exposure resolution, and inability of photomask to fit tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

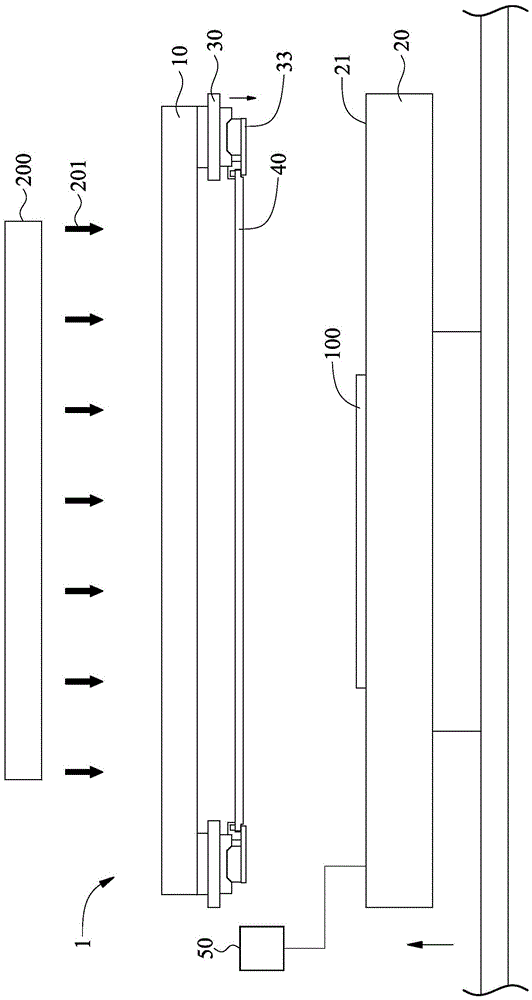

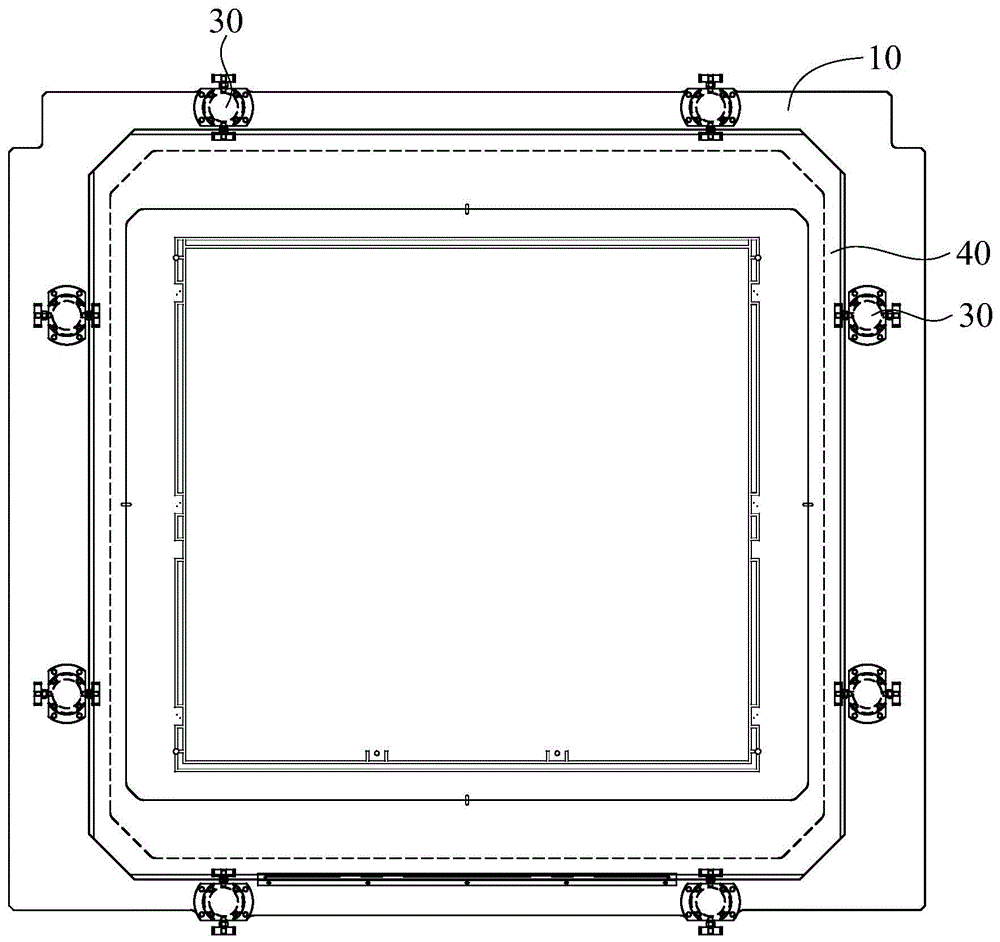

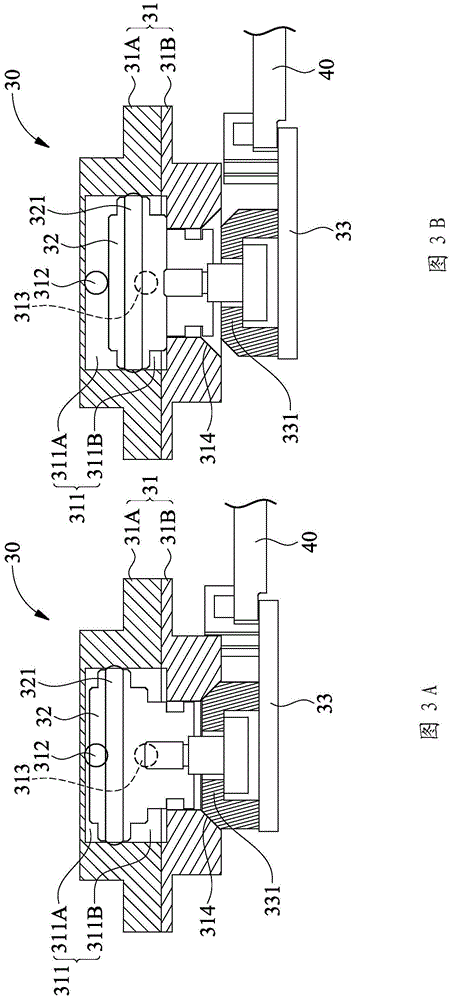

[0043] The exposure platform 1 of the embodiment of the present invention is applied in an exposure machine for manufacturing circuit boards. The exposure machine has an internal space and an exposure light source 200 is disposed therein. Please refer to figure 1 The exposure platform 1 of the embodiment of the present invention is used to carry a substrate 100 and is positioned under the exposure light source 200. The exposure platform 1 includes an exposure frame 10, a stage 20, a plurality of lifting units 30 and a light-transmitting plate 40 ;Cooperate figure 2 As shown, the exposure frame 10 is a rectangular frame; the stage 20 can approach or move away from the exposure frame 10, and the upper surface 21 of the stage 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com