Flexible film high-uniformity contact type alignment exposure device

A flexible film and exposure device technology, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of flexible film deformation, achieve the effects of reducing deformation, improving exposure resolution, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is combined with the attachment and the specific embodiments to further illustrate the present invention.

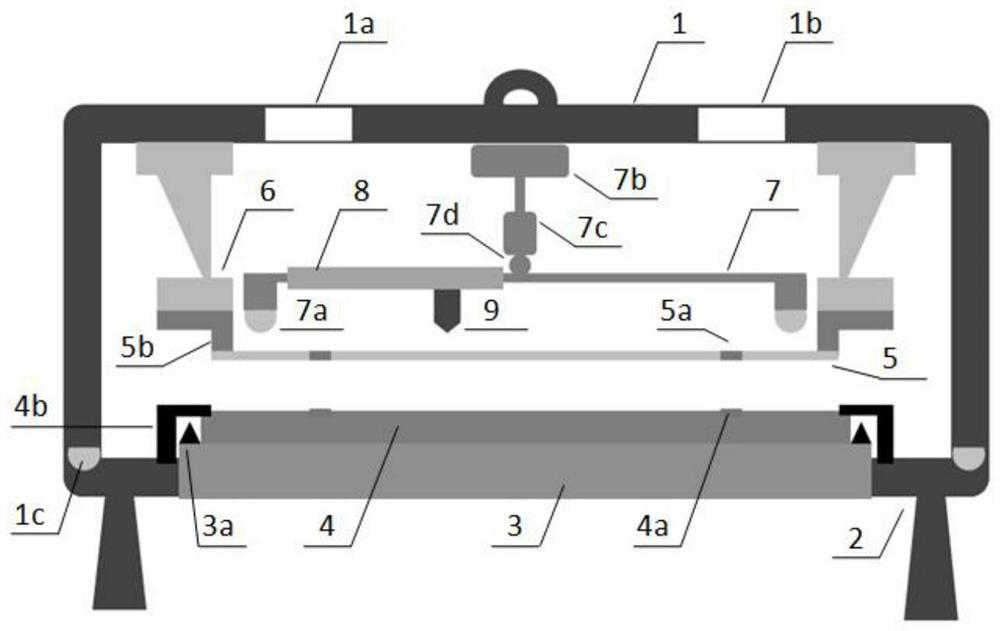

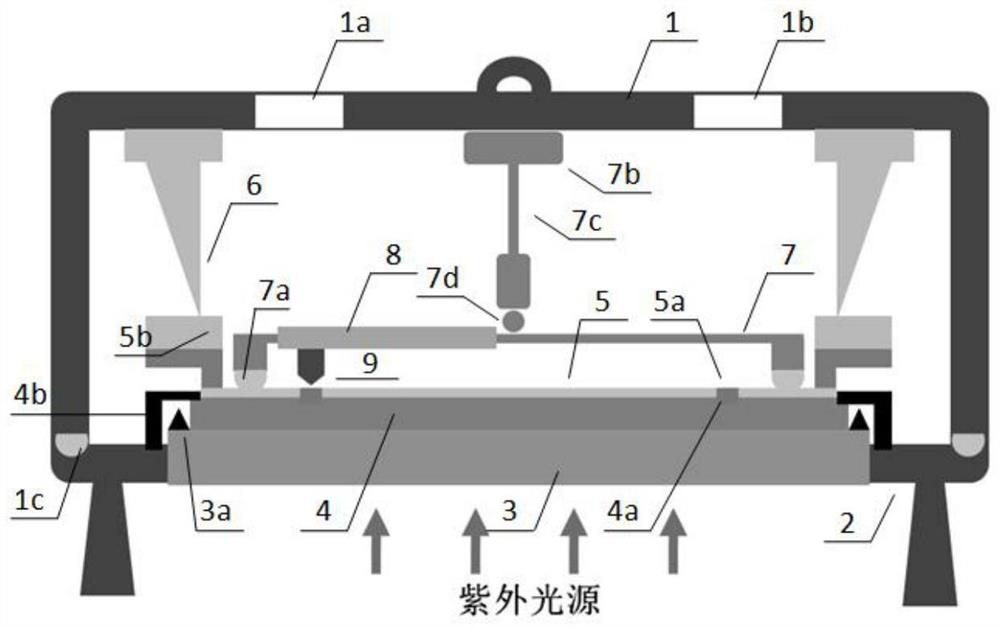

[0021] A flexible film high -uniform contact exposure device is a flexible film, which includes cavity skeleton 1, pumping air channel 1A, cable channel 1B, vacuum sealing parts 1C, vibration base 2. Optical window 3. Positioning sales 3A, 3A Light mask version 4. Covering the membrane positioning mark 4A, mask fixation 4B, flexible film 5, film positioning mark 5A, film bracket 5B, six free degree platform 6, pressure ring bracket 7, flexible pressure ring 7A, lifting mechanism 7B, rotating mechanism 7C, universal section 7D, microscopic displacement 8 and microscope 9. The connection relationship is the cavity skeleton 1 and the vibration base 2 connection to form a vacuum cavity. The six -freedom platform 6 and the 7B of the lifting mechanism are connected with the cavity skeleton 1. Optical window 3 is embedded in the vibration base 2 pairs of light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com