Photomask, manufacturing method thereof, and exposure method

A manufacturing method and photomask technology, applied in the field of photomask and its manufacturing and exposure, can solve the problems of exposure resolution reduction, exposure failure, etc., and achieve the goals of improving exposure resolution, reducing key dimensions, and optimal exposure resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

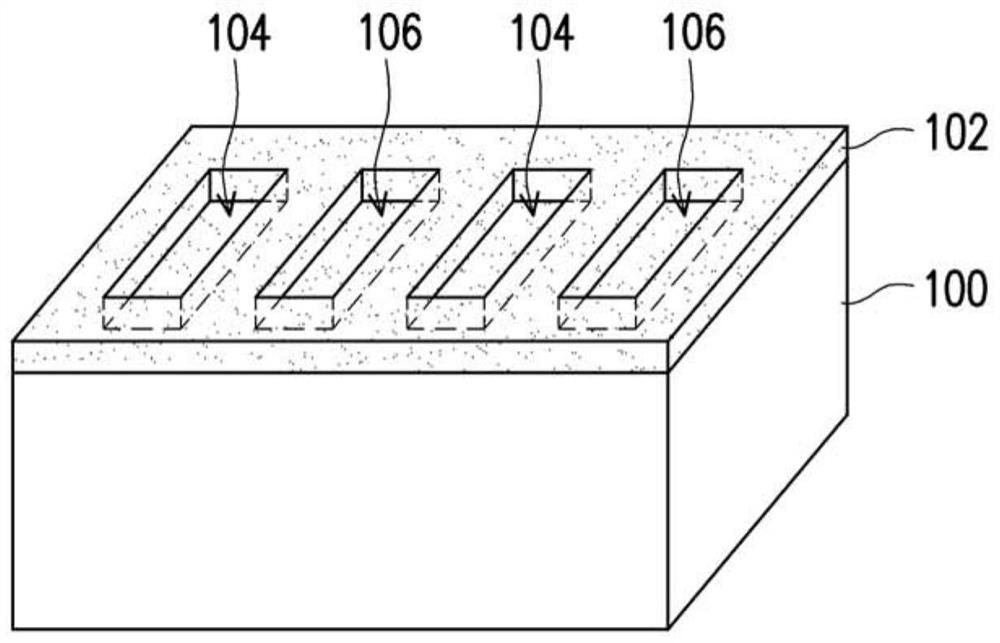

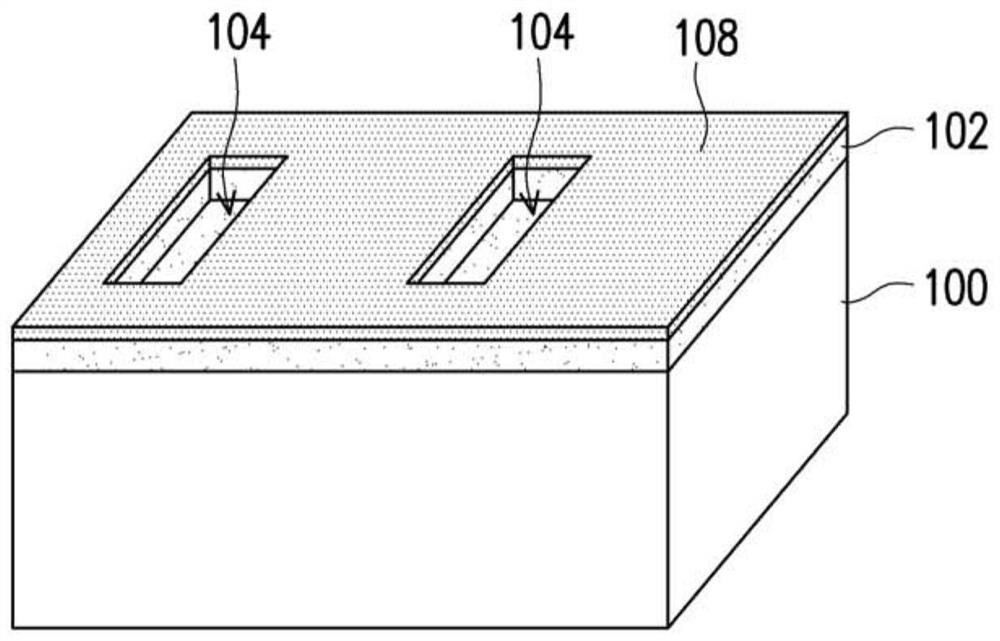

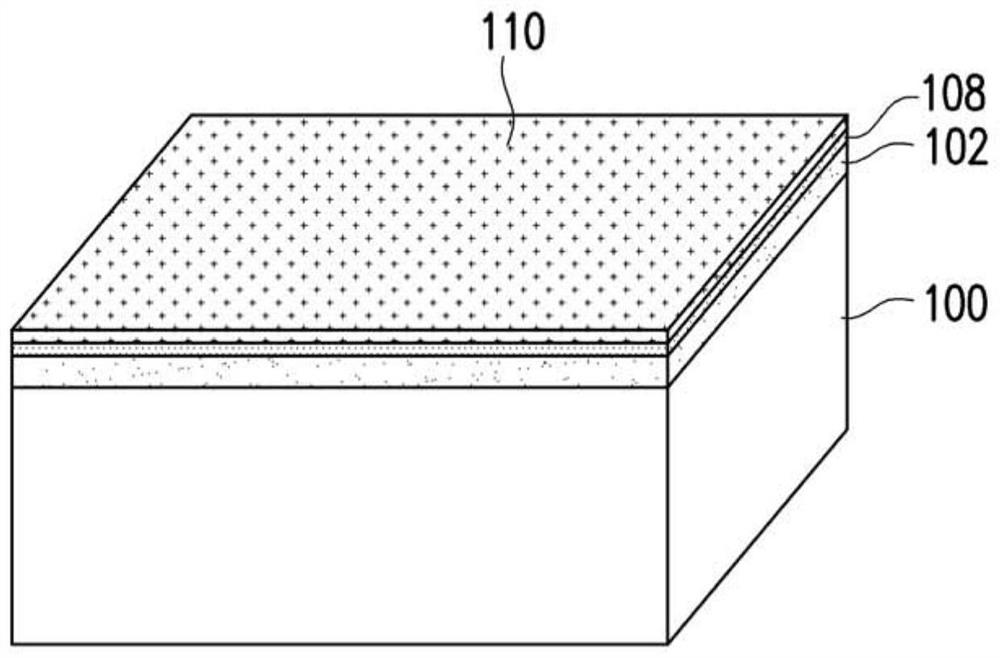

[0042] Figure 1A to Figure 1G It is a three-dimensional schematic diagram of a manufacturing process of a photomask according to an embodiment of the present invention. figure 2 for Figure 1C Schematic cross-section of the filter layer in . image 3 for Figure 1F Schematic cross-section of the filter layer in .

[0043] Please refer to Figure 1A , forming a light blocking layer 102 on the transparent substrate 100 . The light blocking layer 102 has at least one opening 104 and at least one opening 106 arranged alternately. The material of the transparent substrate 100 is, for example, quartz. The material of the light blocking layer 102 is, for example, Cr, MoSi or a combination thereof. The method for forming the light-shielding layer 102 is, for example, physical vapor deposition. The forming method of the opening 104 and the opening 106 is, for example, performing a patterning process on the light-shielding layer 102 . The opening 104 and the opening 106 can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com