Photomask and its manufacture method and pattern definition method

A manufacturing method and a technology of a photomask, which are applied to originals for photomechanical processing, optics, and microlithography exposure equipment, etc., can solve the problem of bending and deformation of the photomask 130, the inability to improve the exposure resolution, and affecting the correctness of the exposure pattern sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

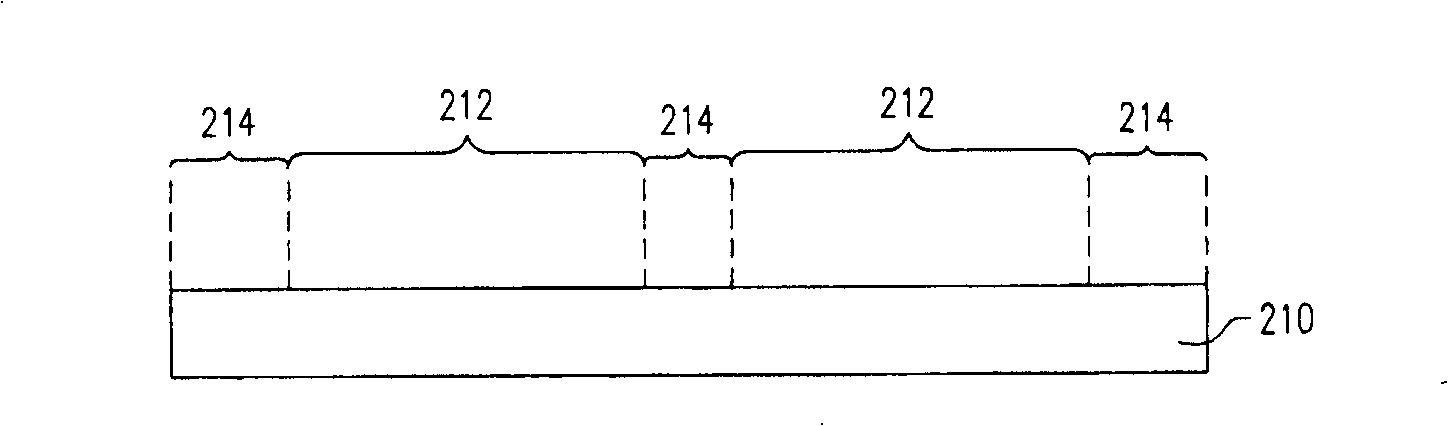

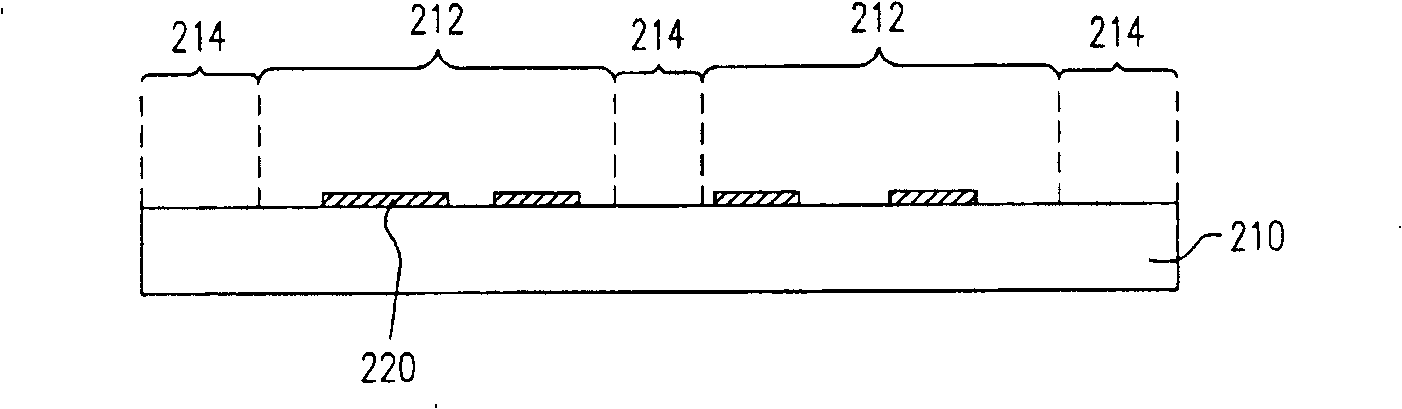

[0031] Figure 2A-2C A flow chart of photomask fabrication according to a preferred embodiment of the present invention is shown in sequence. First please refer to Figure 2A , providing a photomask substrate 210 , a surface of the photomask substrate 210 is divided into a pattern area 212 and a non-pattern area 214 . In one embodiment, the material of the photomask substrate 210 is, for example, quartz glass.

[0032] Then please refer to Figure 2B , forming a shielding pattern 220 in the pattern area 212 . In one embodiment, the method for forming the shielding pattern 220 includes photolithography, and the shielding pattern 220 is made of an opaque material, such as metal.

[0033] Please refer to later Figure 2C , a plurality of protrusions 230 are formed in the non-pattern area 214 of the photomask substrate 210 , wherein the height of the protrusions 230 relative to the surface of the photomask substrate 210 is greater than the thickness of the masking pattern 220...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com