Liquid high-resistance layer for zinc oxide piezoresistor

A varistor and high-resistance layer technology, which is applied in the field of zinc oxide varistor production, can solve the problems of poor uniformity of the glaze layer, limitation of the flow capacity of the resistor sheet, complex manufacturing process of the high-resistance layer, etc., and reduce the thickness of the glaze layer Fluctuation, solve the problem of side insulation, improve the effect of square wave flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

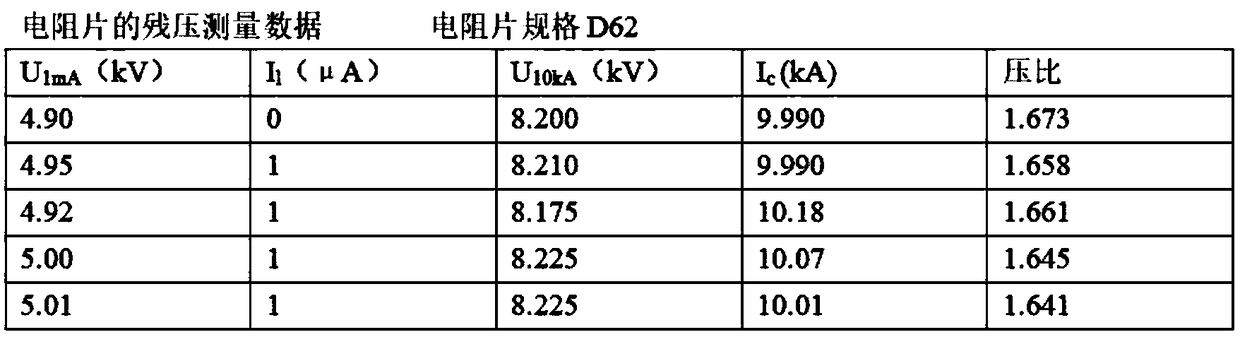

[0032] Select the million volt formula D62 specification resistor, and match the high resistance layer in the following way: bismuth nitrate 1%, cobalt nitrate 0.5%, manganese nitrate 1%, lithium acetate 0.05%, deionized water 97.45%. After the various raw materials are prepared, they are turned into a solution, and evenly coated on the side of the resistor, each resistor is 2g, and then the resistor is subjected to normal subsequent manufacturing processes such as debinding, firing, grinding, and aluminum spraying, and then tested.

[0033] figure 1 It is the liquid high-resistance layer used for zinc oxide varistor according to the present invention. After configuring and coating according to the mass fraction described in Example 1, the residual pressure measurement data table of D62 resistance sheet, as figure 1 As shown, the square wave capacity test is carried out on the resistance sheet, 600A 18 times, the resistance sheet is intact, and then 800A 18 times, the resistan...

Embodiment 2

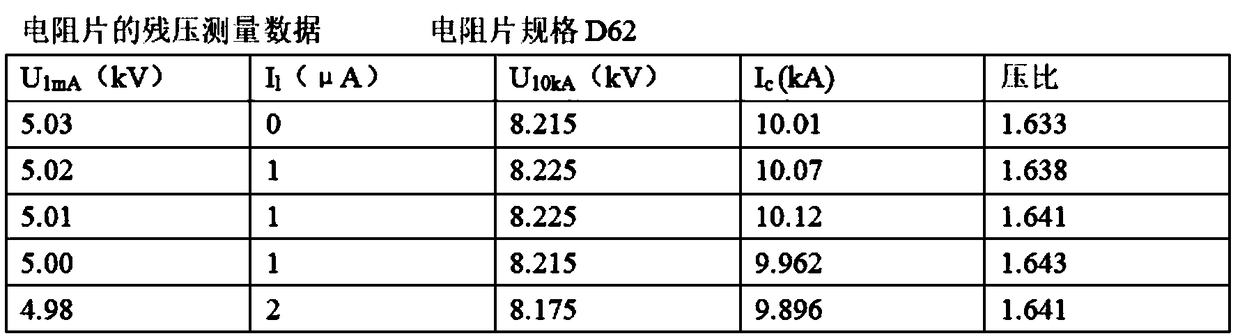

[0035] The high resistance layer is prepared in the following manner: 3% bismuth nitrate, 0.5% cobalt nitrate, 1% manganese nitrate, 95.50% alcohol. After the various raw materials are prepared, they are turned into a solution, and the million volt formula D62 specification resistor is selected, and the solution is evenly coated on the side of the resistor, 2g for each resistor, and then the resistor is degummed, fired, and ground normally. , aluminum spraying and other follow-up production processes, and then conduct tests,

[0036] figure 2 It is the liquid high-resistance layer used for zinc oxide varistor according to the present invention. After configuring and coating according to the mass fraction described in Example 1, the residual pressure measurement data table of D62 resistance sheet, as figure 2 As shown, the square wave capacity experiment is carried out on the resistance sheet, and the 600A resistance sheet breaks down along the side.

Embodiment 3

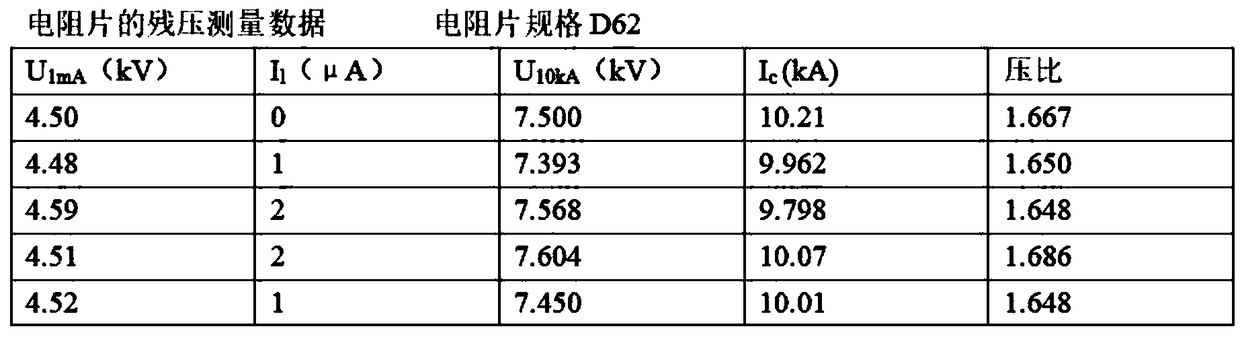

[0038] The high-resistance layer is formulated in the following manner: 1% bismuth nitrate, 1% cobalt nitrate, 0.5% manganese nitrate, and 97.5% deionized water. After the various raw materials are prepared, they are turned into a solution, and the million volt formula D62 specification resistor is selected, and the solution is evenly coated on the side of the resistor, 2g for each resistor, and then the resistor is degummed, fired, and ground normally. , aluminum spraying and other follow-up production processes, and then conduct tests,

[0039] image 3 It is the liquid high-resistance layer used for zinc oxide varistor according to the present invention. After configuring and coating according to the mass fraction described in Example 1, the residual pressure measurement data table of D62 resistance sheet, as image 3 As shown, the square wave capacity test is carried out on the resistance sheet, 600A 18 times, the resistance sheet is intact, increase the experimental capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com