Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Reduce magnetic flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

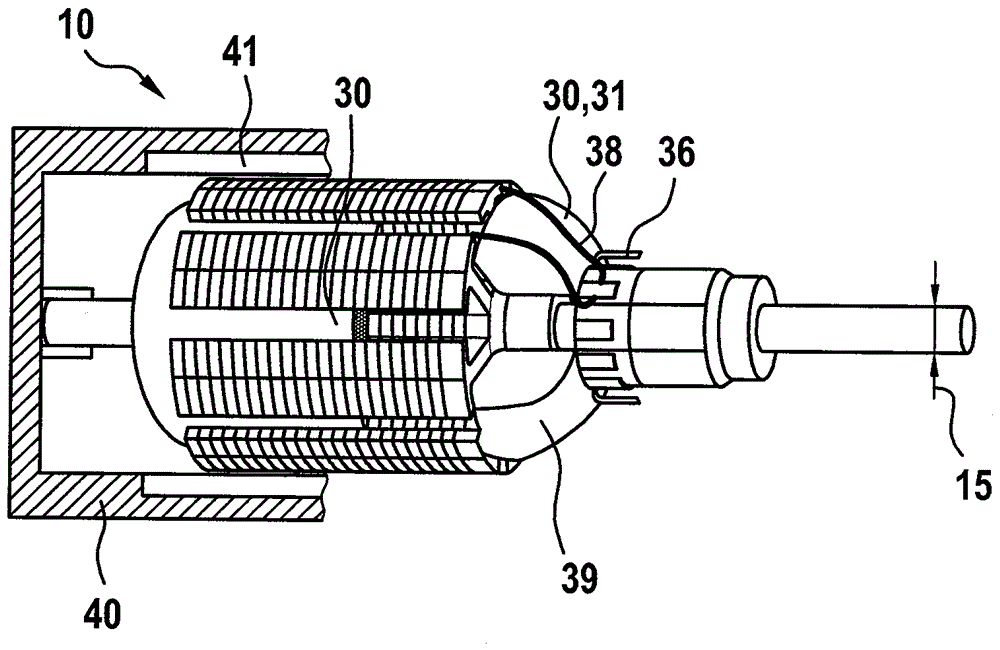

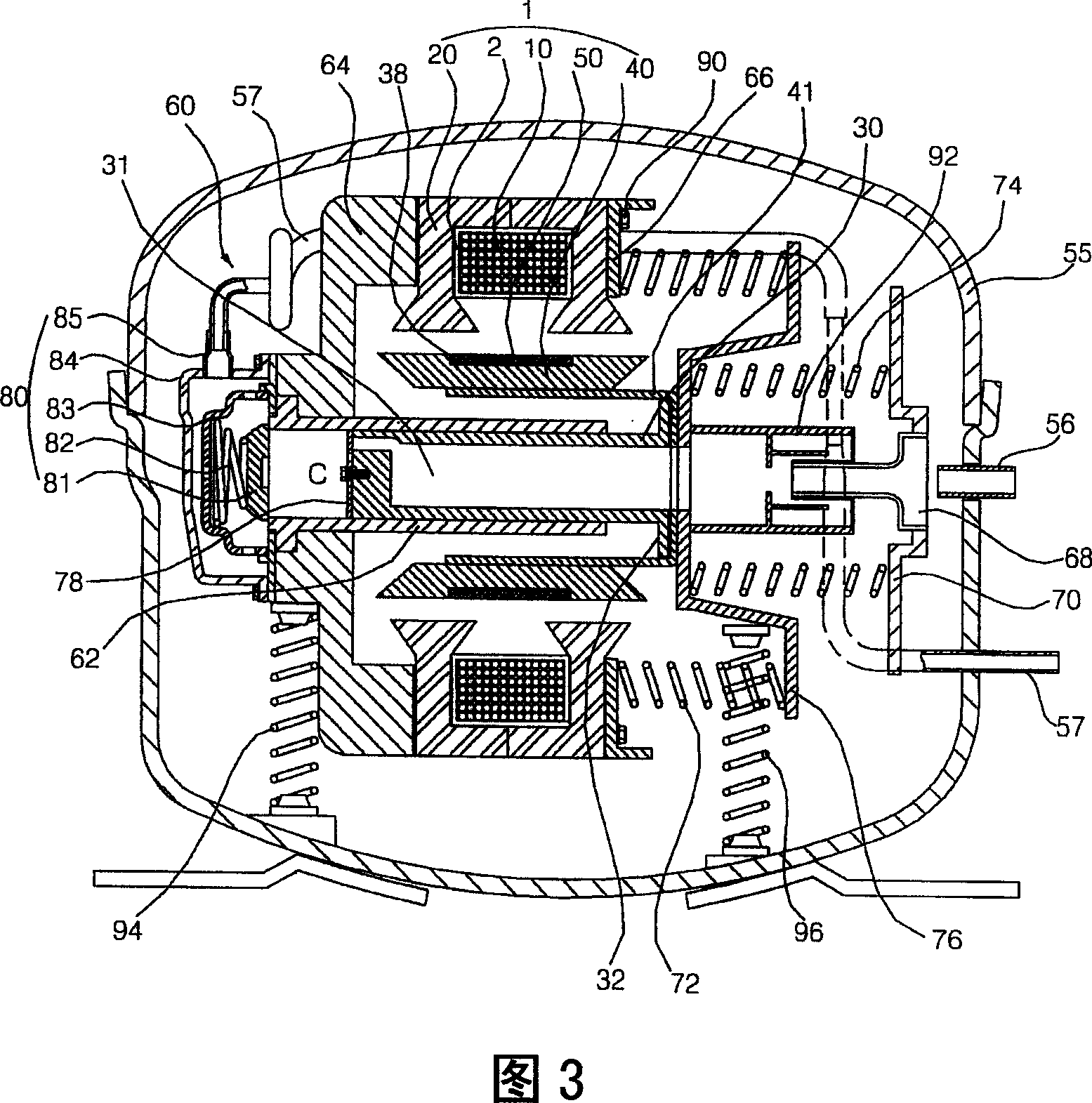

Electric power steering device

InactiveCN1736014AShorten the lengthHigh sensitivityElectrical steeringMechanical energy handlingElectric power steeringBrushless motors

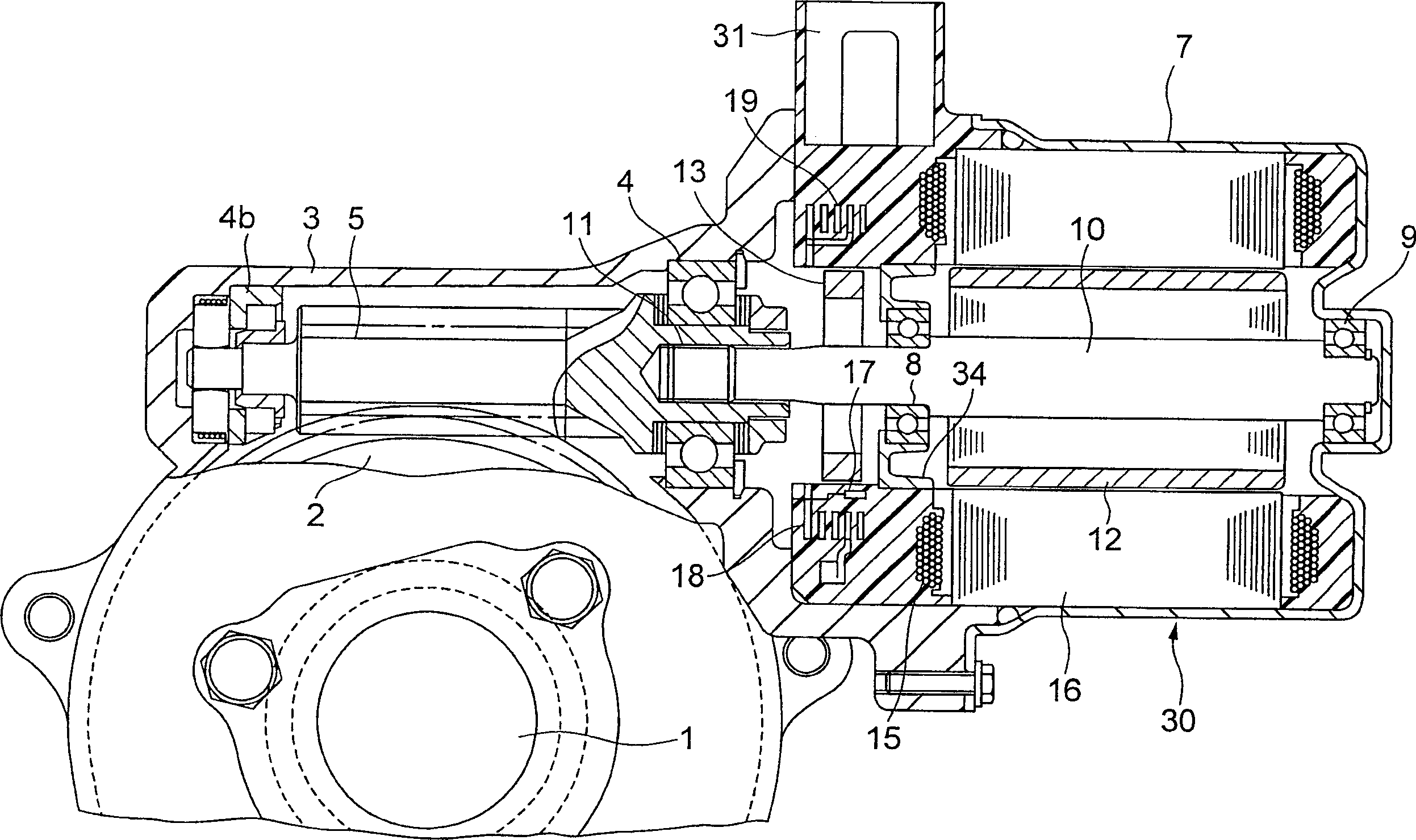

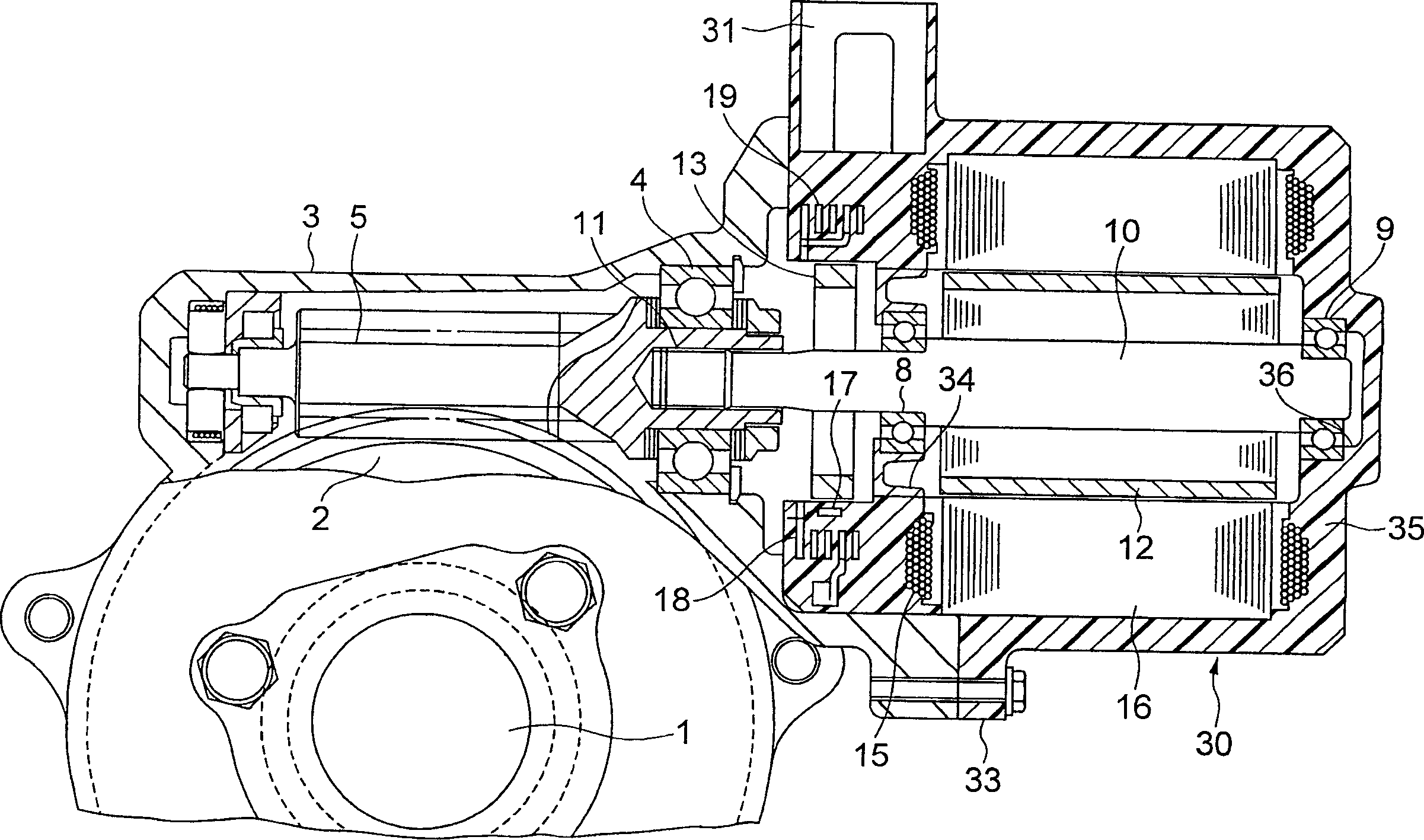

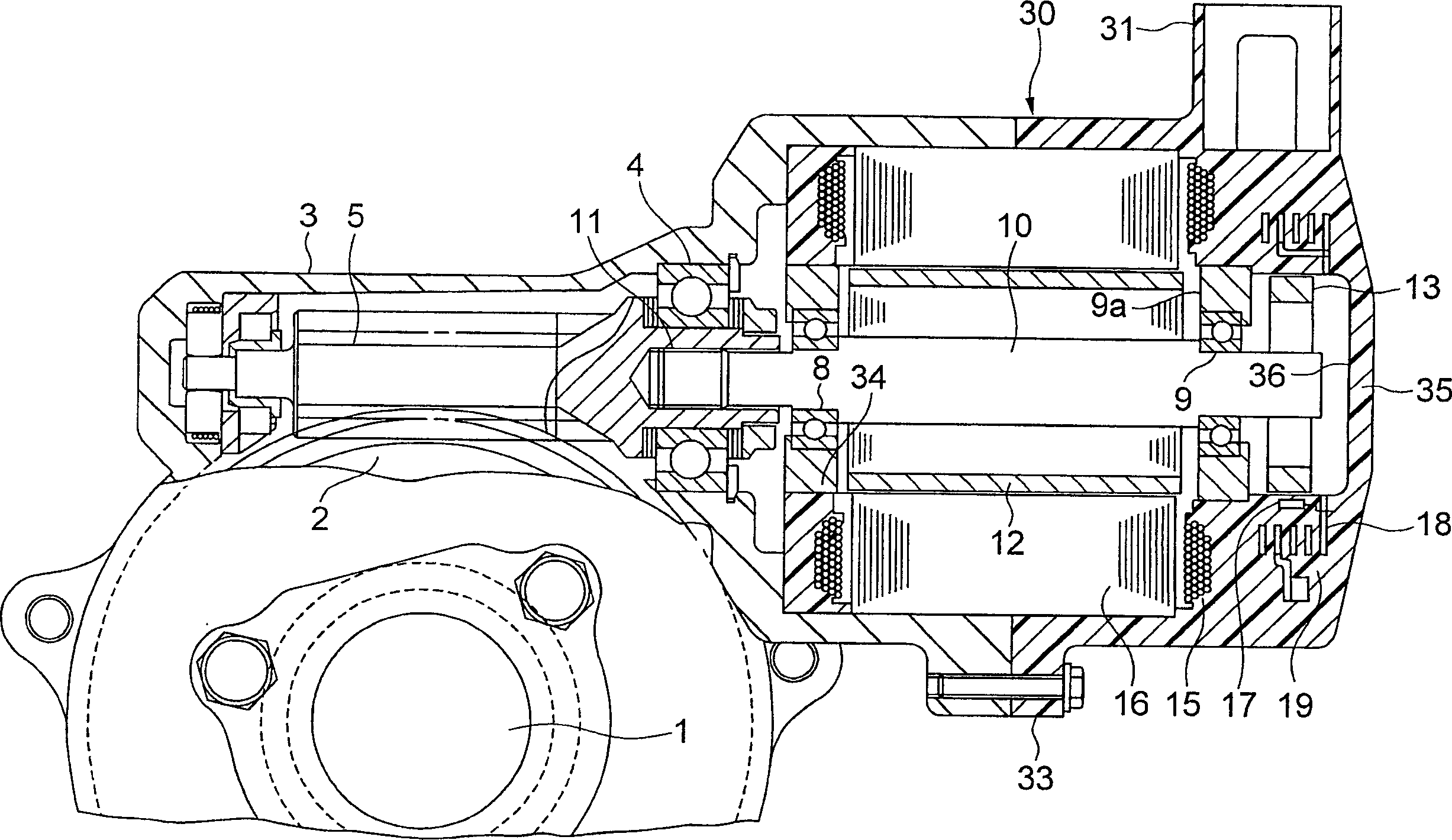

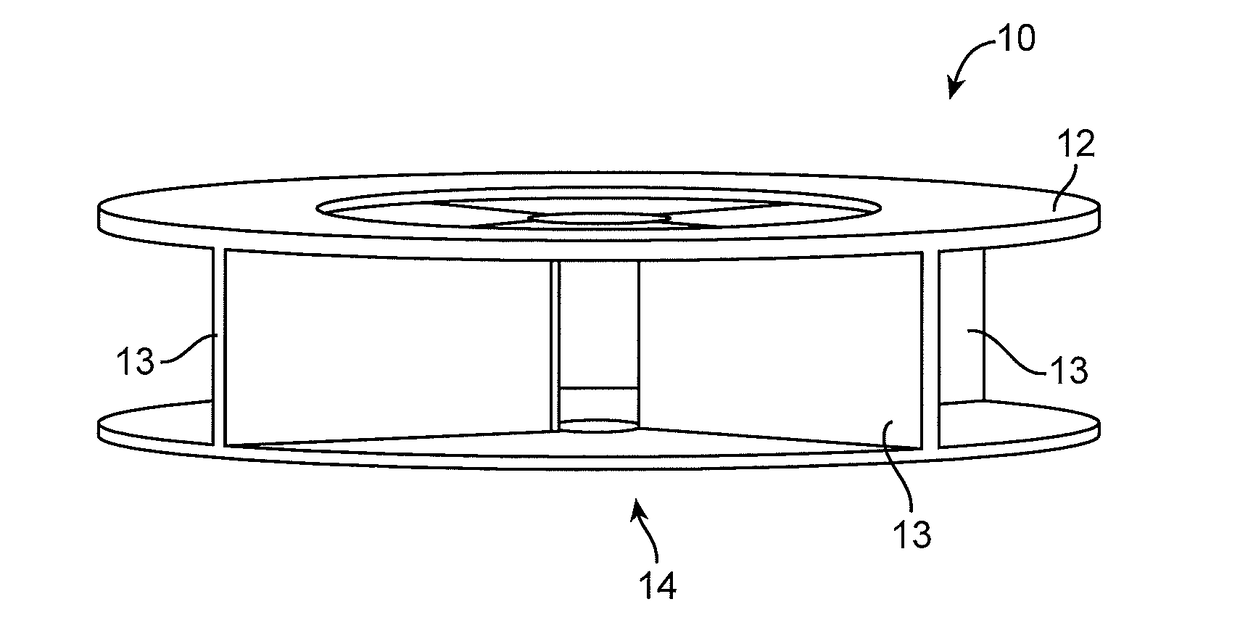

In an electric power steering apparatus that generates an auxiliary steering torque by a brushless motor in response to a steering torque applied on a steering wheel and transmits it to an output shaft of a steering mechanism while reducing it by means of a reduction gear, the apparatus comprises a rotor ( 10 ) to which a cylindrical permanent magnet for rotational driving ( 12 ) and a member to be detected ( 13 ) for detection of a rotational angle of the rotor are attached and a cylindrical stator ( 30 ) opposed to the rotor in which a laminated core ( 16 ) on which a coil is wound, detection means ( 17 ) for detecting the rotational angle of the rotor by the member to be detected and a terminal ( 19 ) for providing connection to the coil are integrally formed by resin molding. At least one bearing ( 8, 9 ) for rotatably supporting the rotor is disposed radially inside the stator and between the permanent magnet for rotational driving and the member to be detected.

Owner:NSK LTD +1

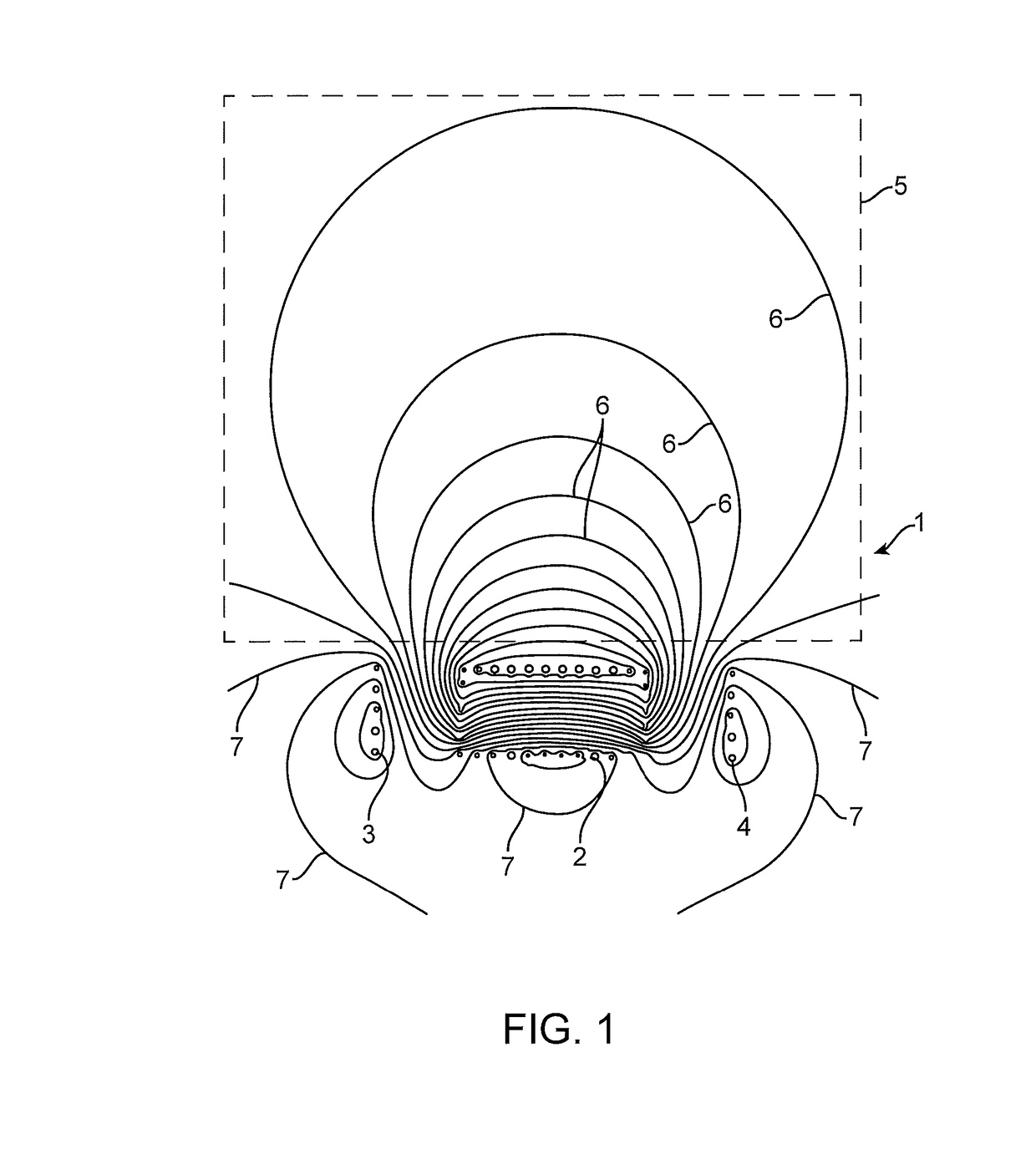

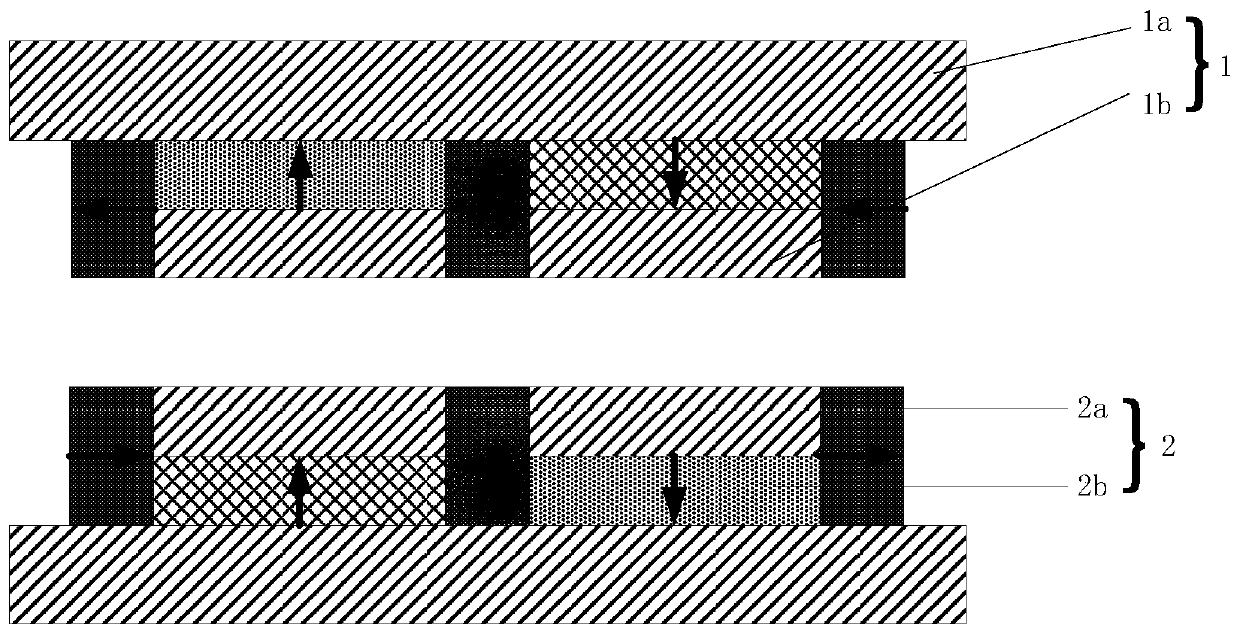

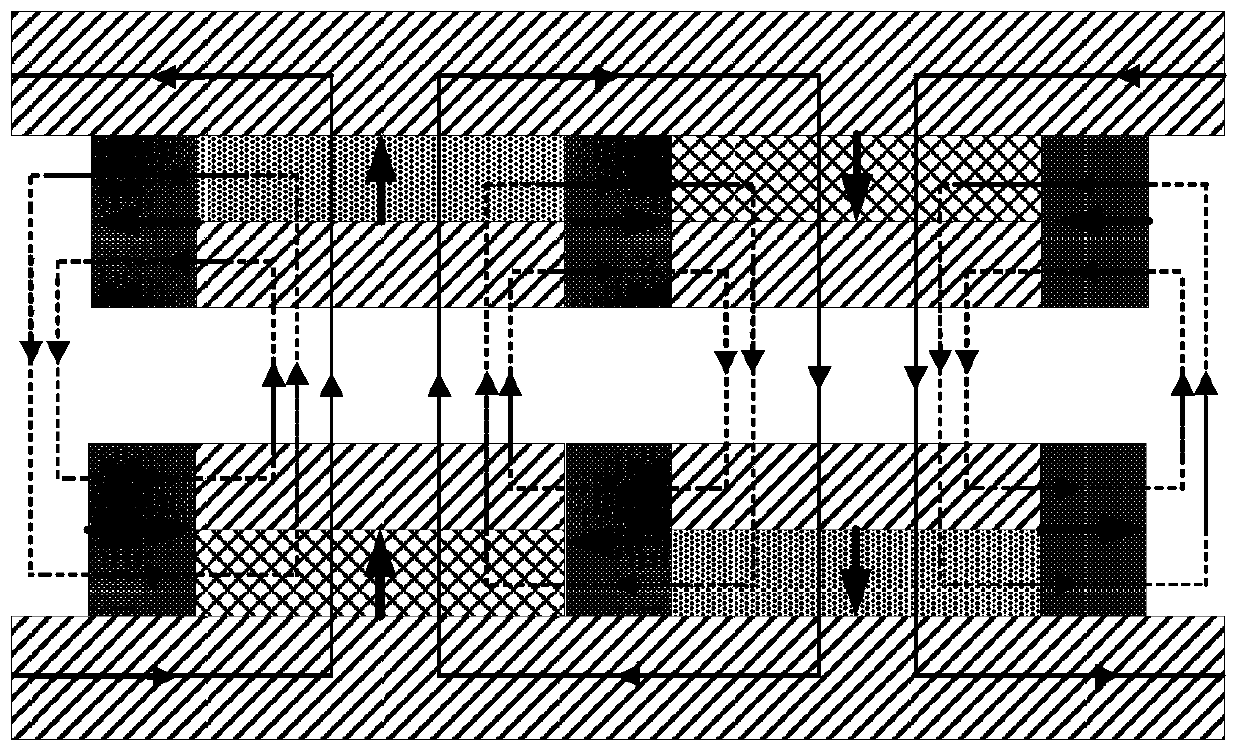

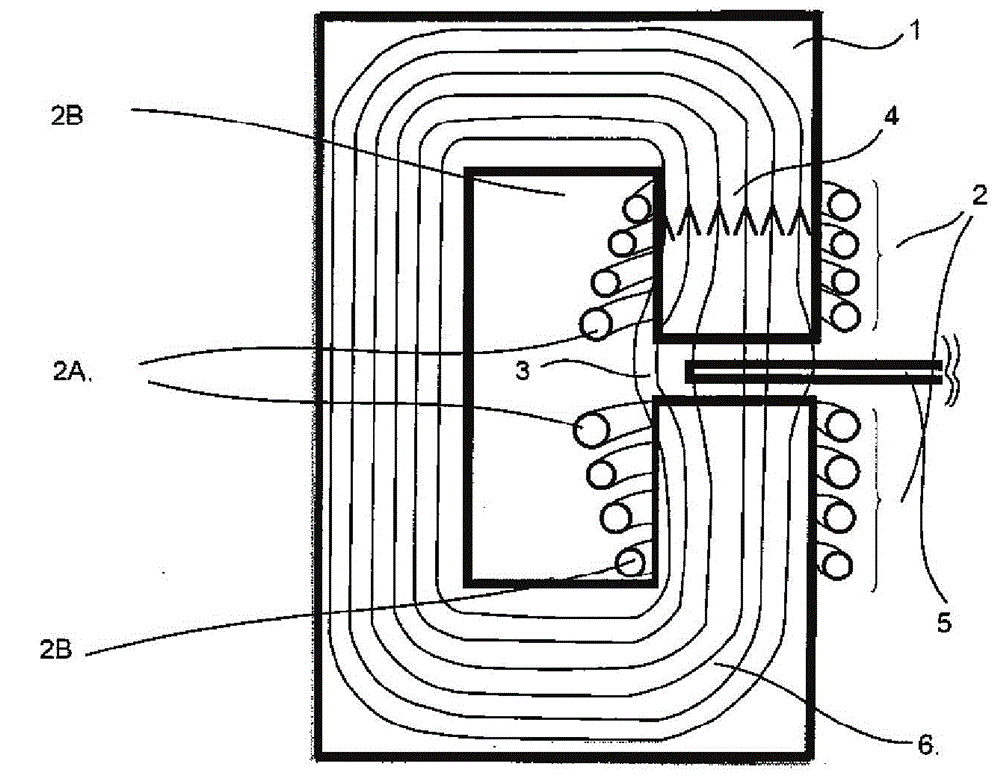

Magnetic flux coupling structures with controlled flux cancellation

ActiveUS20170222490A1Overcome disadvantagesReduce leakage fluxBatteries circuit arrangementsCharging stationsCouplingMagnetic flux

Inductive power transfer flux coupling apparatus includes a first coil arranged in a first layer and configured to generate or receive a magnetic coupling flux in a flux coupling region, and a second coil. At least part of the second coil being arranged in a second layer and is configured to generate a magnetic flux that reflects flux from the first coil,

Owner:AUCKLAND UNISERVICES LTD

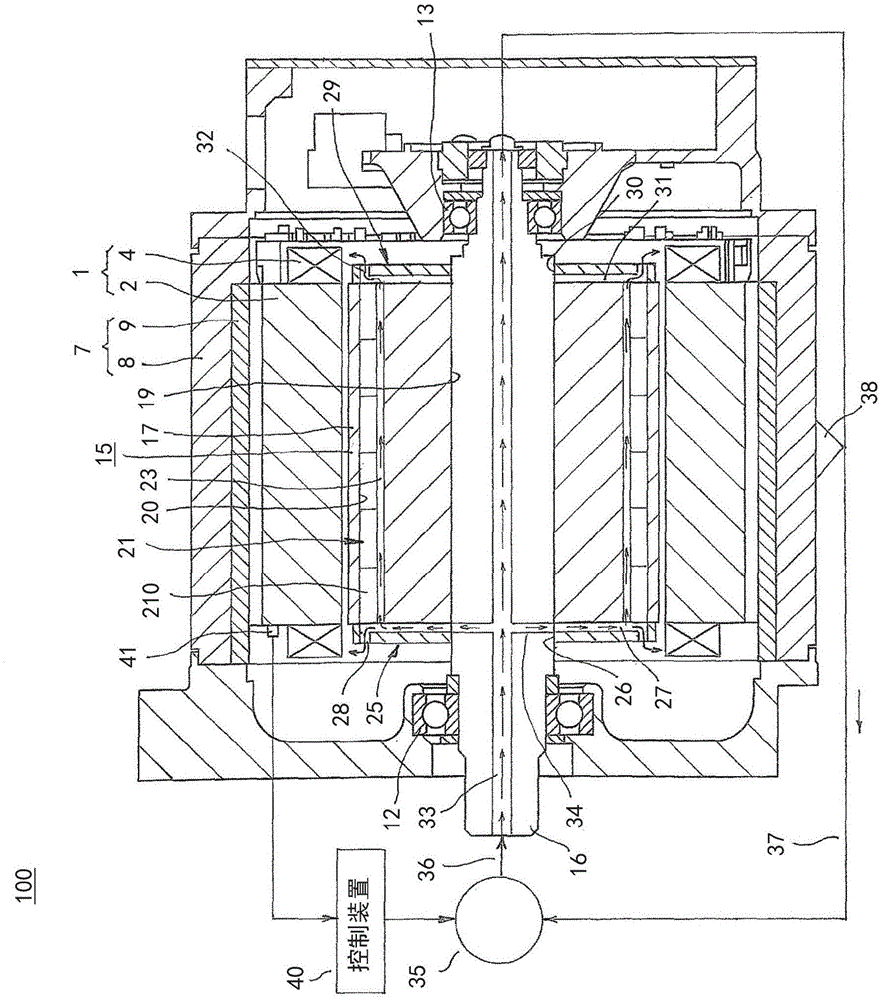

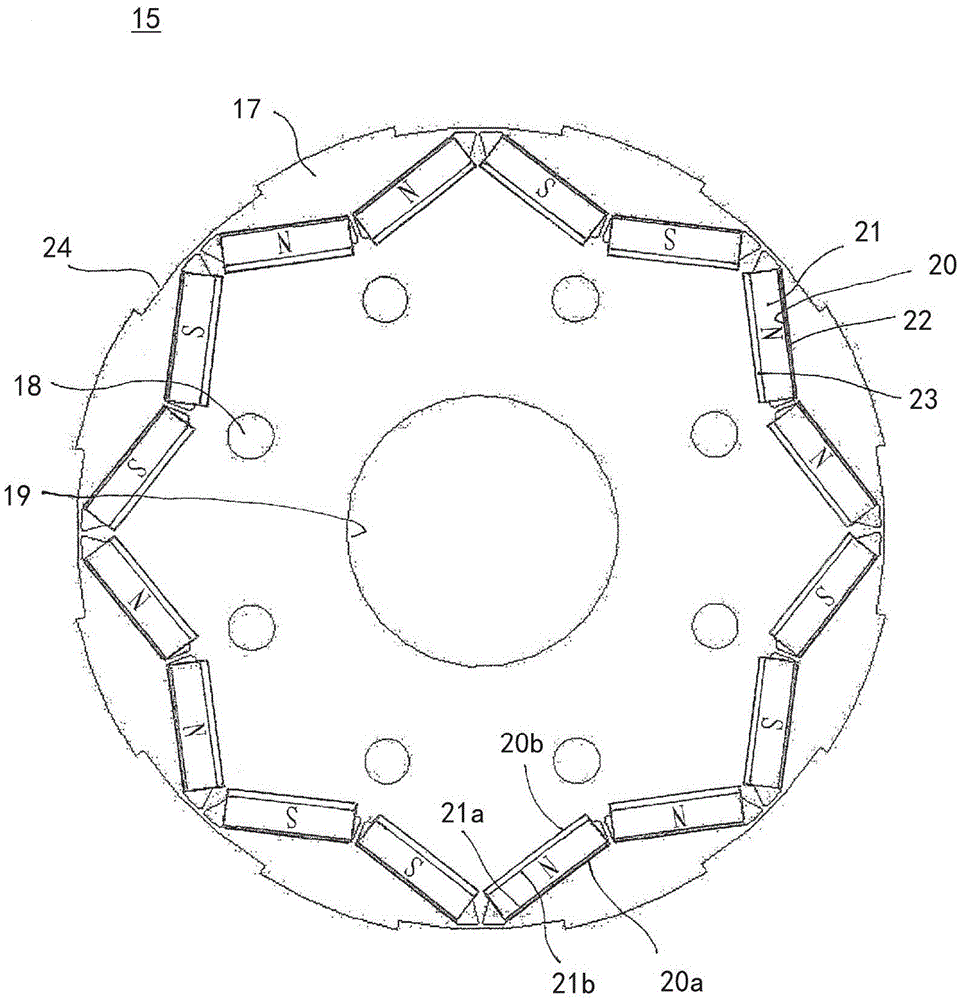

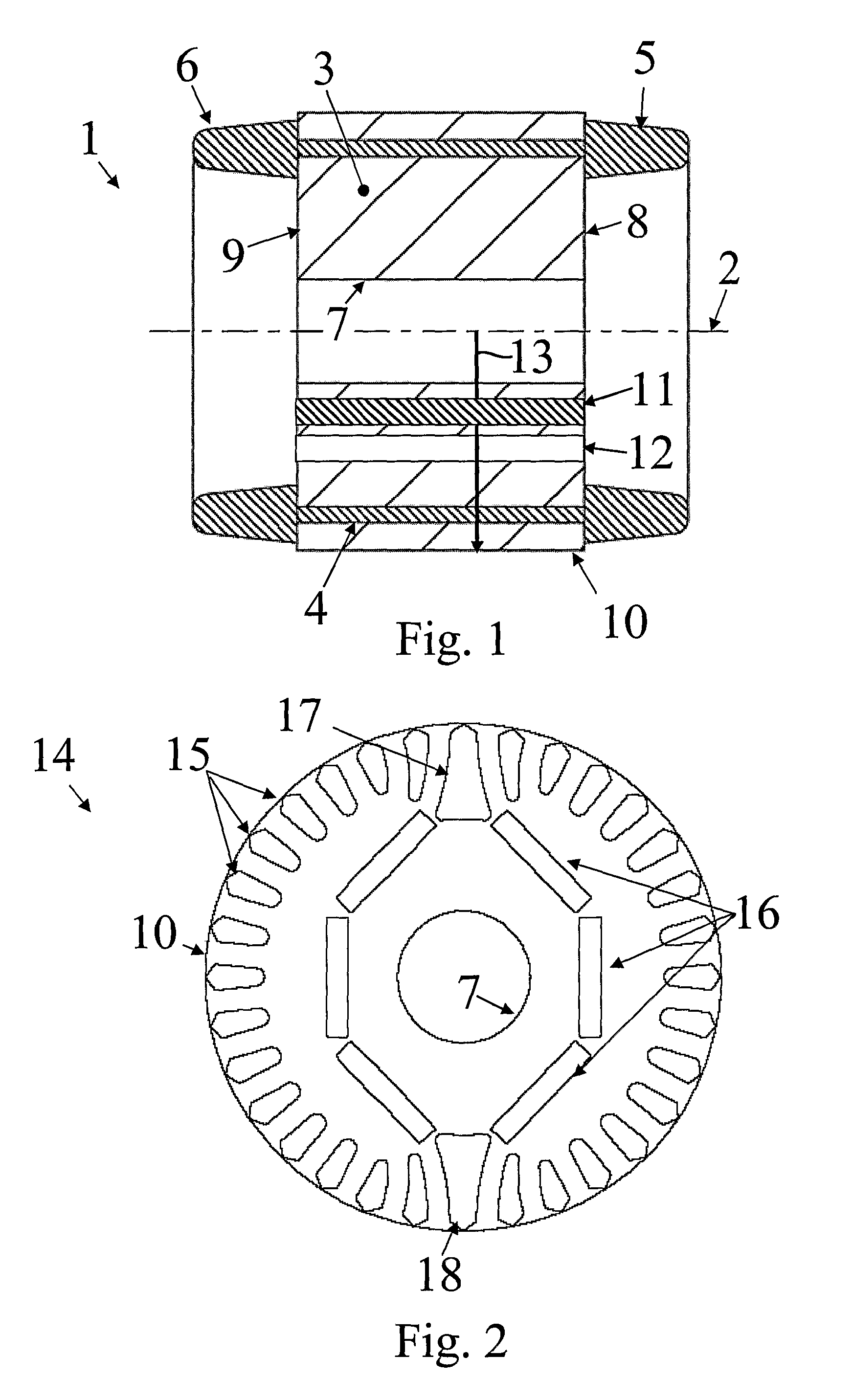

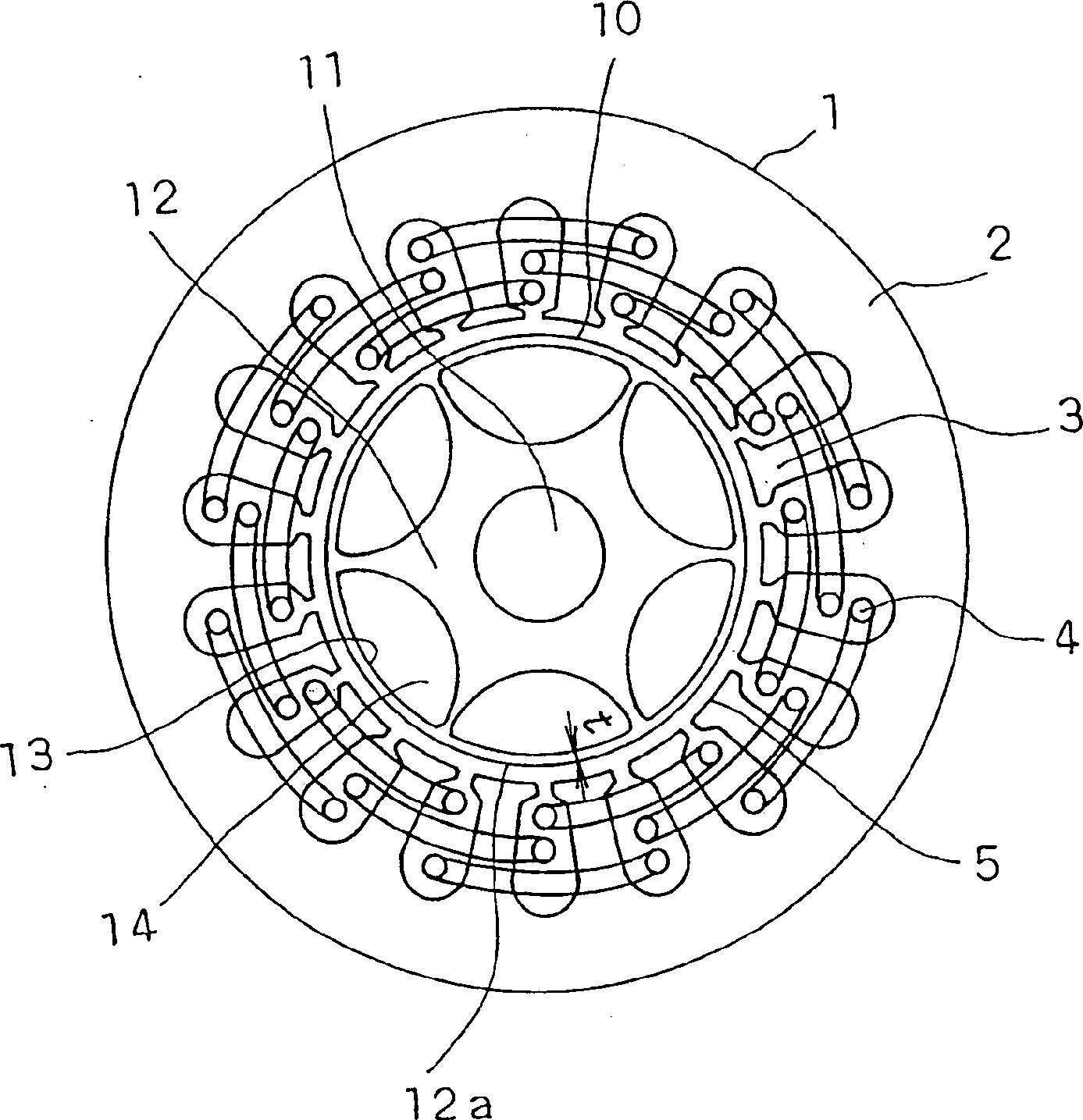

Permanent magnet embedded type rotating electric machine

ActiveCN105453387ALess quantityReduce the cross-sectional areaMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic flux

The purpose of this invention is to obtain a permanent magnet embedded type rotating electric machine in which the amount of magnetic flux of a permanent magnet can be prevented from reducing and the permanent magnet can be effectively cooled. In the permanent magnet embedded type rotating electric machine, a rotor (15) has: a rotor iron core (17) constructed by laminating and integrating magnetic steel sheets and firmly fixed to a shaft; a plurality of magnet housing openings (20) each formed so as to penetrate in an axial direction on the outer circumferential side of the rotor iron core (17) and disposed in a circumferential direction; and permanent magnets (21) housed in the respective magnet housing openings (20). An adhesive agent (22) is disposed only between the outside wall surface (20a) of the inner wall surfaces of each of the magnet housing openings (20), which is positioned outward in the radial direction, and the outside surface (21a) of the surfaces of each of the permanent magnets (21), which is positioned outward in the radial direction. The permanent magnets (21) are each disposed one-sided to the outside wall surface (20a) of each of the magnet housing openings (20) and fixed. A cooling flow path (23) through which a refrigerant flows is constituted by the inside surface (21b) of the surfaces of each of the permanent magnets (21), which is positioned inward in the radial direction, and the inside wall surface (20b) of the inner wall surfaces of each of the magnet housing openings (20), which is positioned inward in the radial direction.

Owner:MITSUBISHI ELECTRIC CORP

Production method of transparent microcrystal glass

A process for preparing transparent microcrystalline glass features that the P2O5 and BaO are used as part of its raw material to generate a lot of nano-crystals and its crystallizing temp is controlled to less than 950 deg.C, resulting in nano-class crystals.

Owner:JINGNIU GLASS CERAMICS GROUP

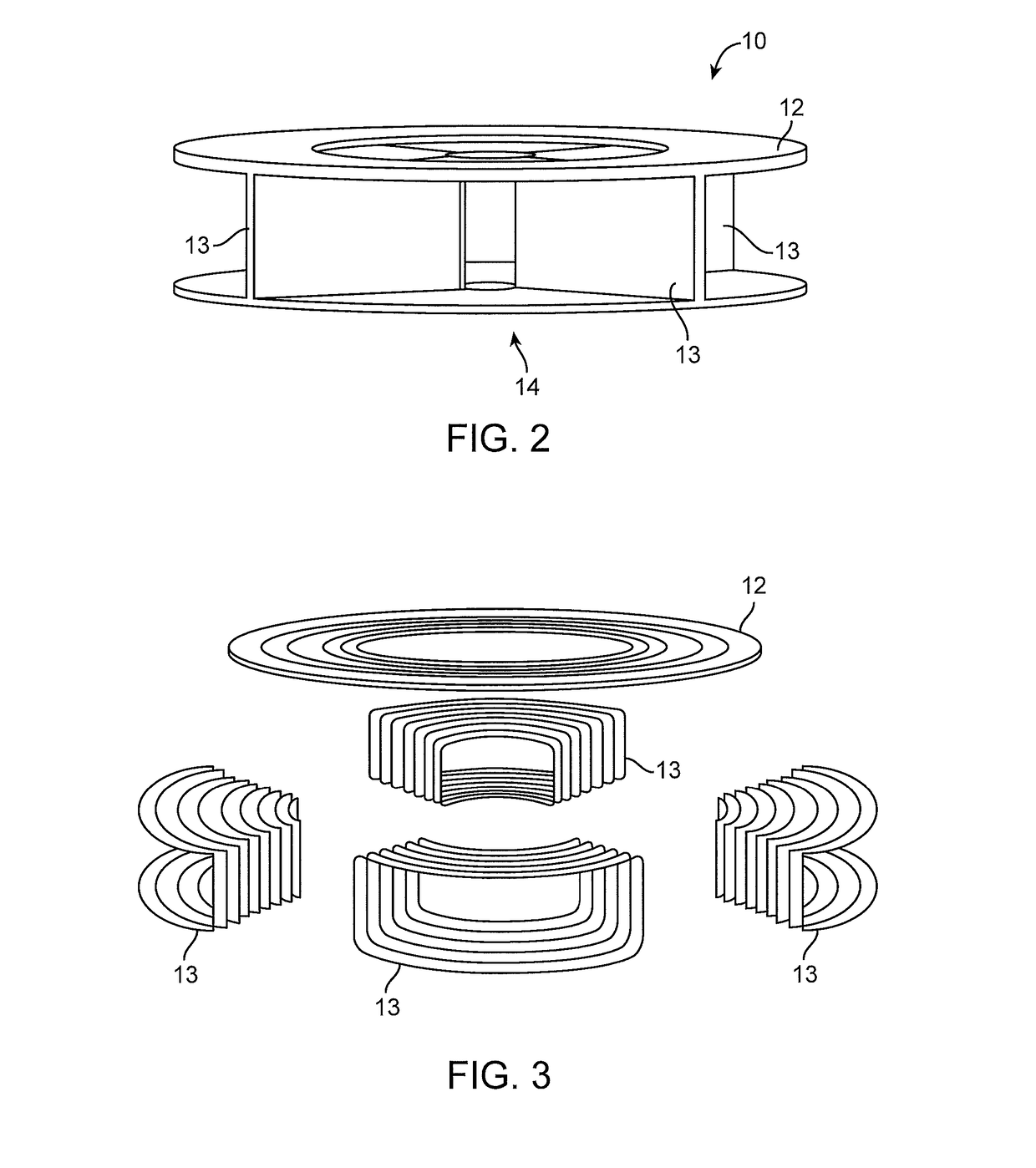

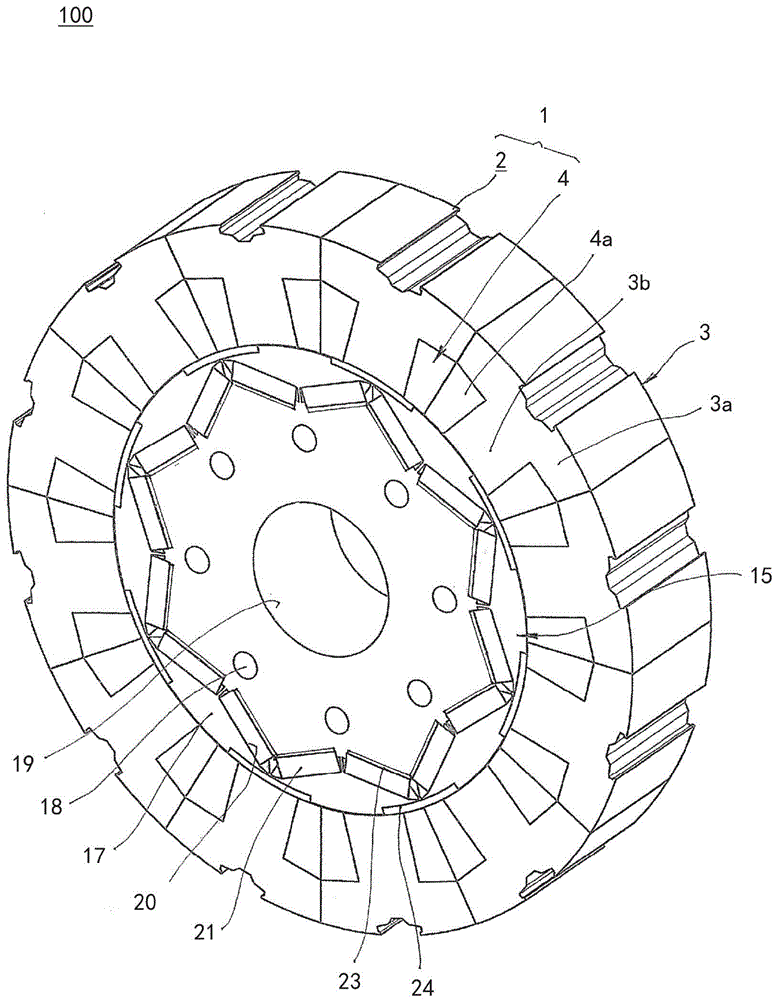

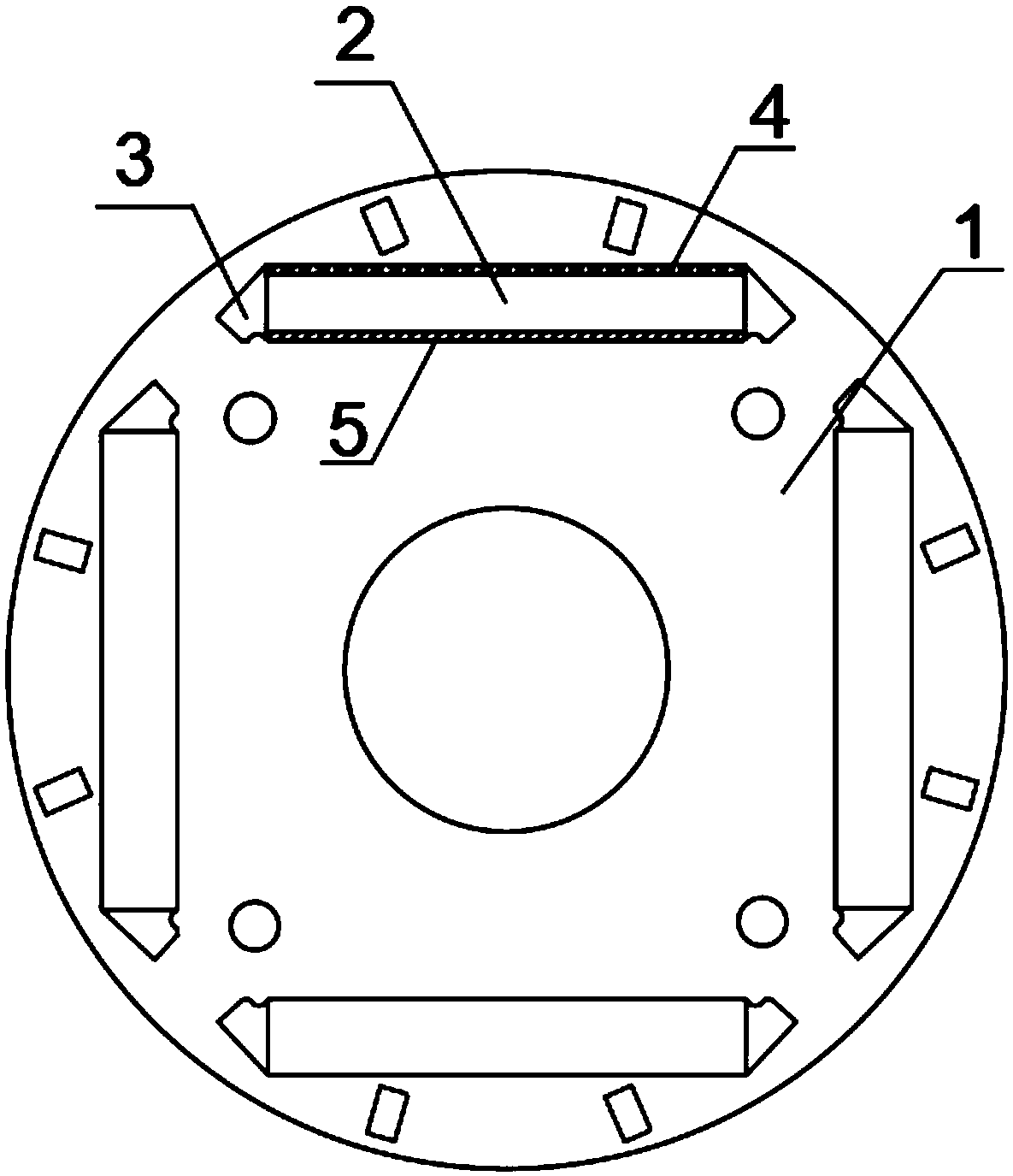

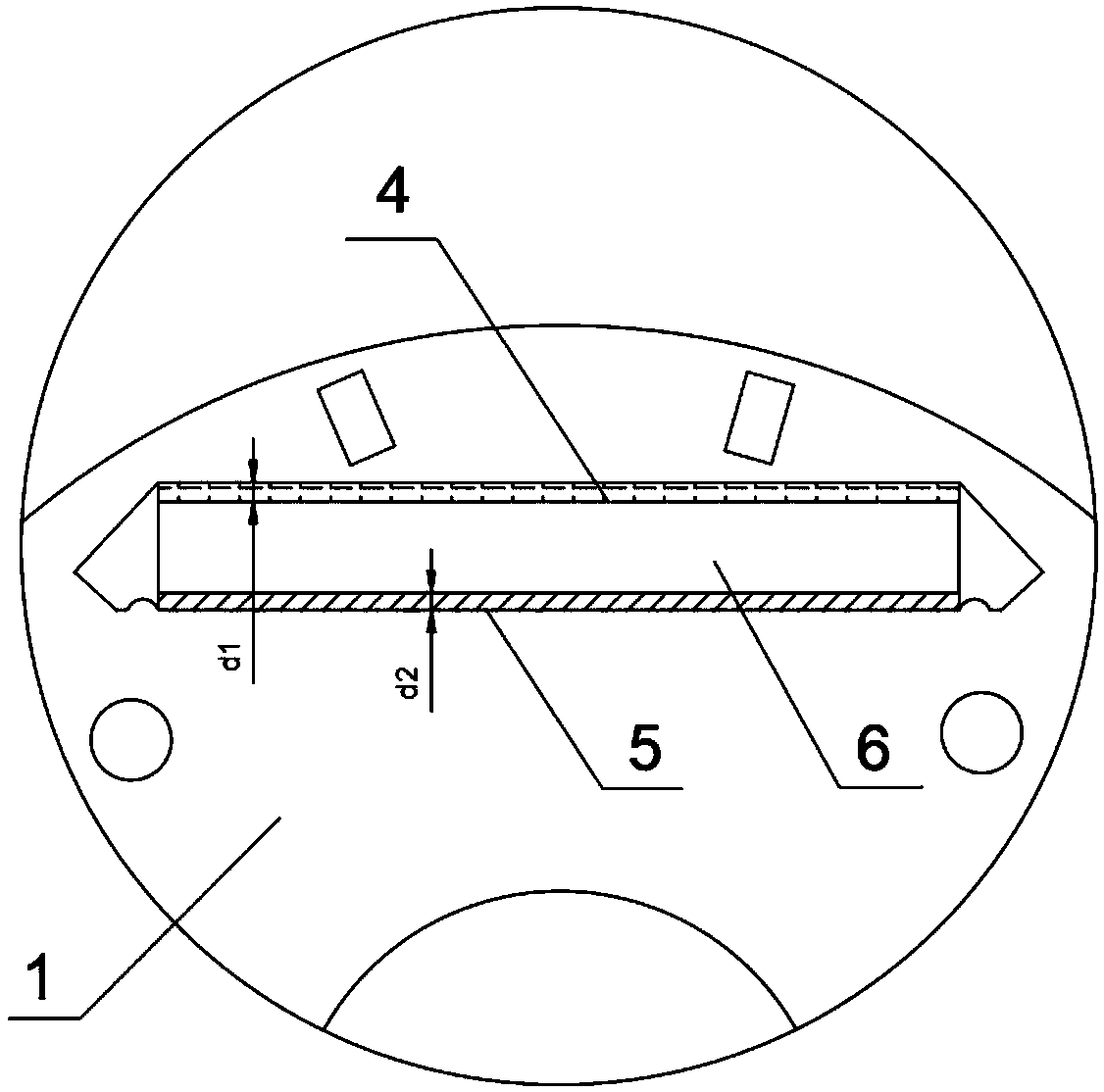

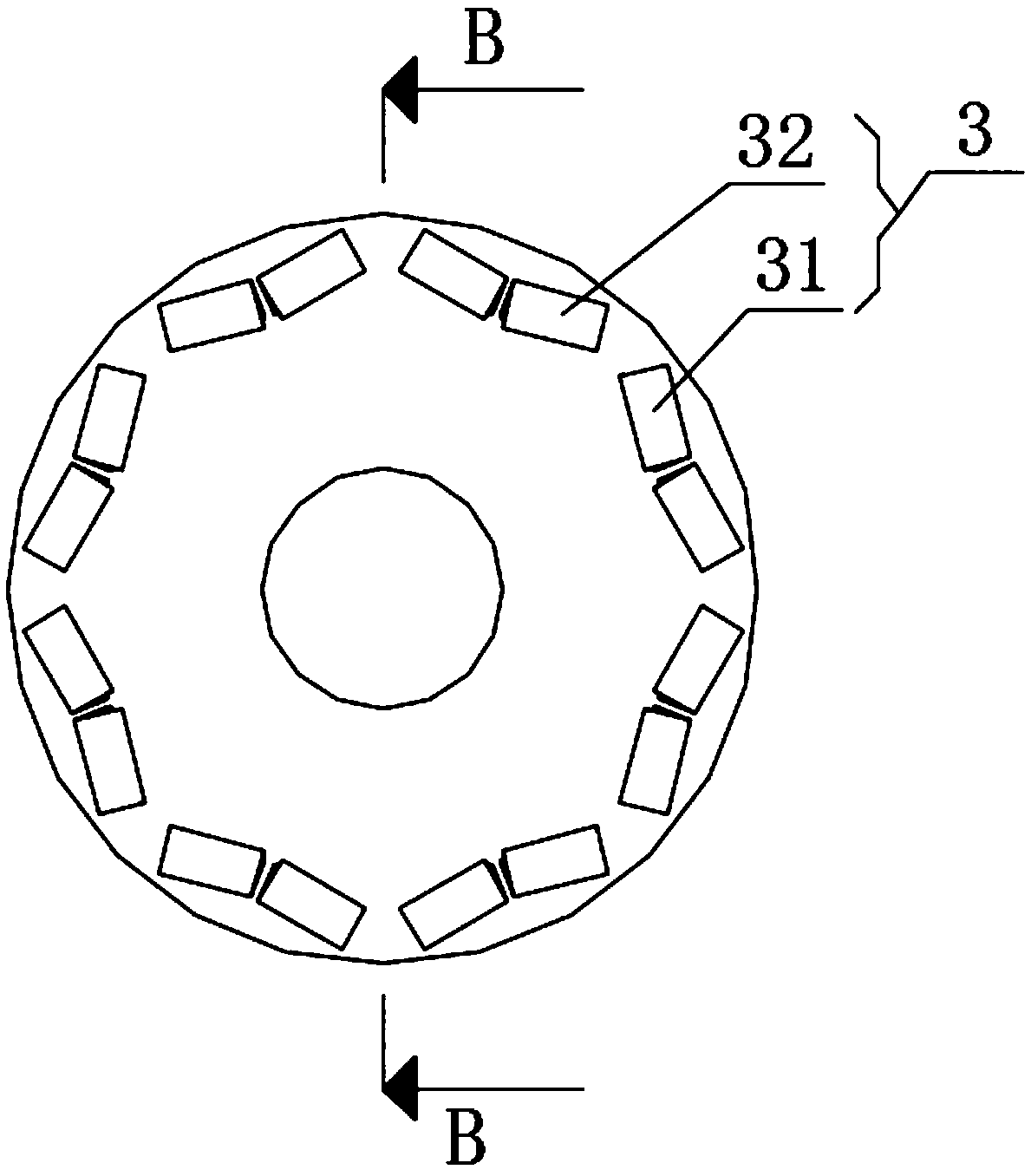

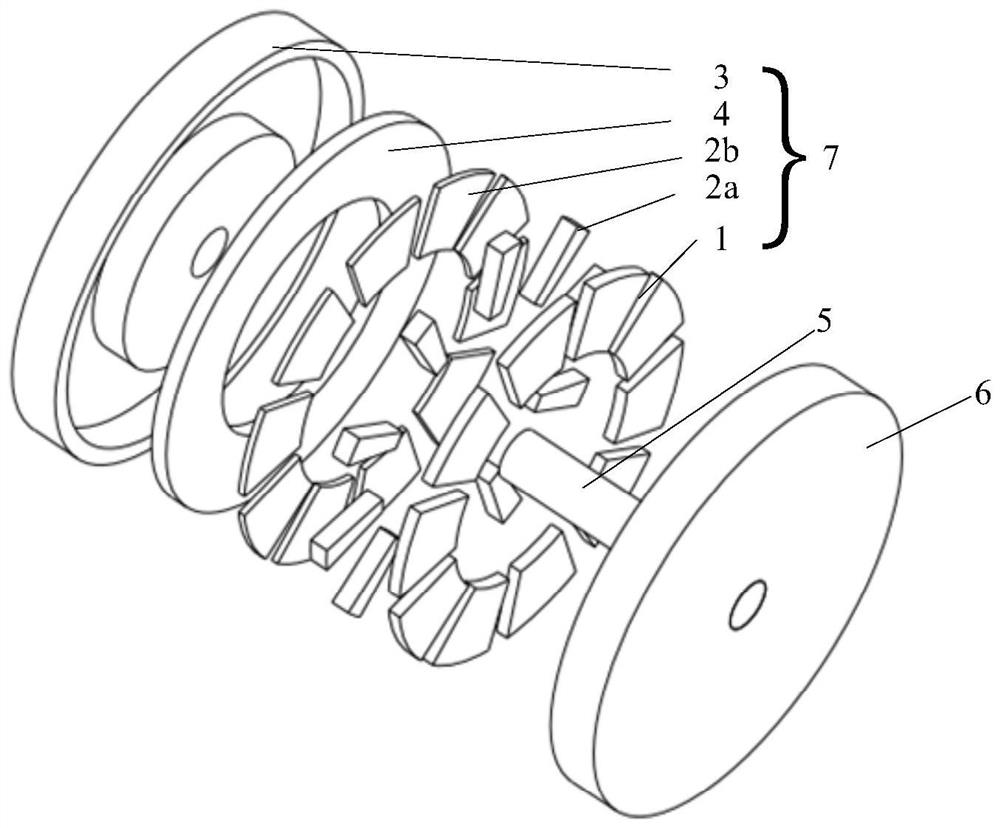

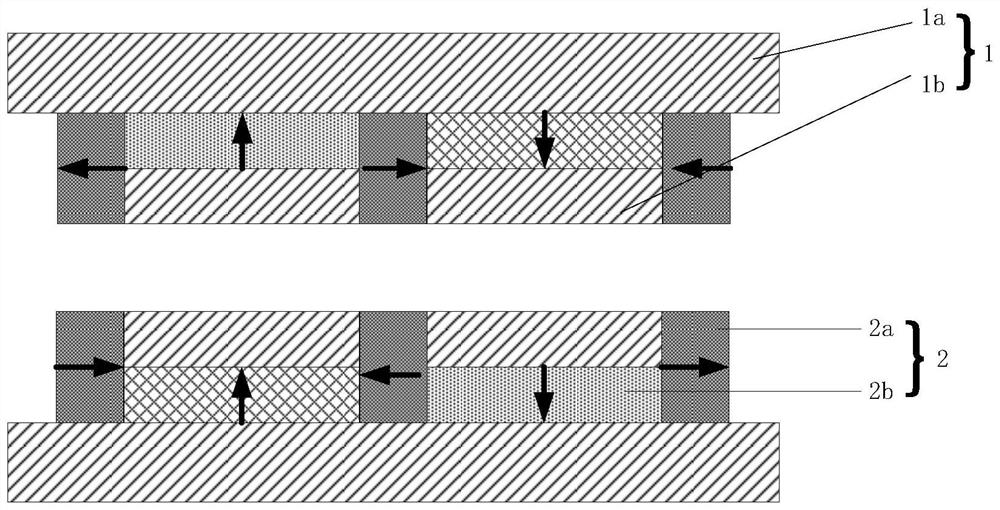

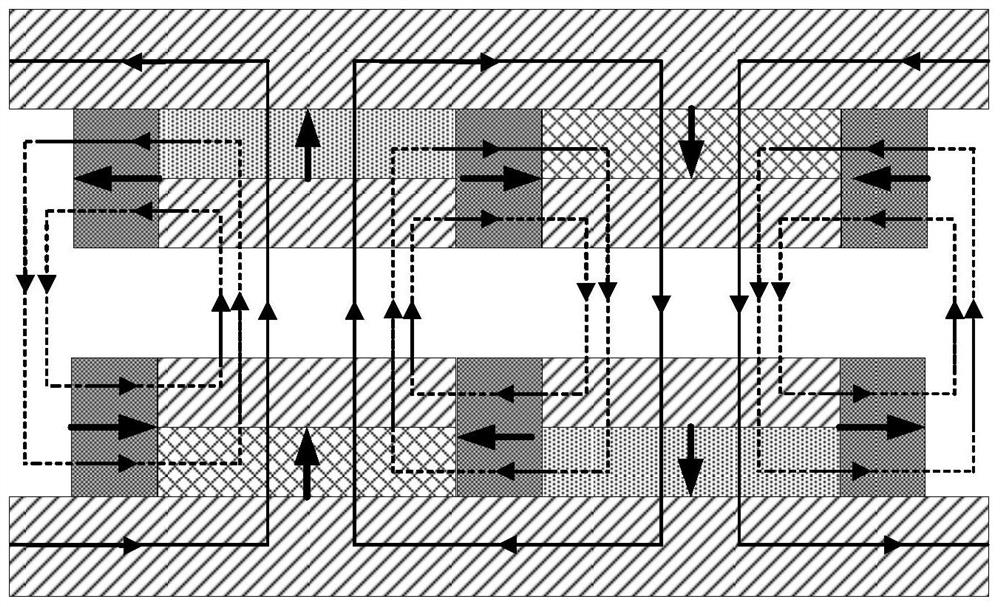

Combined magnetizing type permanent magnet built-in rotor of axial magnetic field permanent magnet motor

ActiveCN111541325AIncrease the main fluxReduce Flux LeakageMagnetic circuit rotating partsElectric machineryMagneto

The invention discloses combined magnetizing permanent magnet built-in rotor of an axial magnetic field permanent magnet motor. The rotor structurally comprises two rotor discs installed on a rotatingshaft, the first rotor disc comprises a rotor iron core, permanent magnets, a rotor supporting shell and a rotor back yoke, the permanent magnets comprise the first permanent magnet and the second permanent magnet, and the rotor iron core comprises a rotor outer iron core and a rotor inner iron core; the rotor back yoke is installed on the rotor supporting shell, and the first permanent magnets and the second permanent magnets are alternately and evenly arranged on the rotor back yoke in the circumferential direction. The rotor core is fixed to the second permanent magnets arranged on the rotor back yoke together so as to keep the permanent magnets fixed in the radial direction and the axial direction; the rotor iron core, the permanent magnets, the rotor supporting shell and the rotor back yoke are fixed together to form the first rotor disc which is installed on the rotating shaft, and then the first rotor disc is connected with the second rotor disc through the rotating shaft to fix the position of the second rotor disc in the axial direction to form a double-rotor structure. The permanent magnet rotor is good in magnetism gathering effect, high in air gap flux density and large in reluctance torque.

Owner:NANJING UNIV OF SCI & TECH

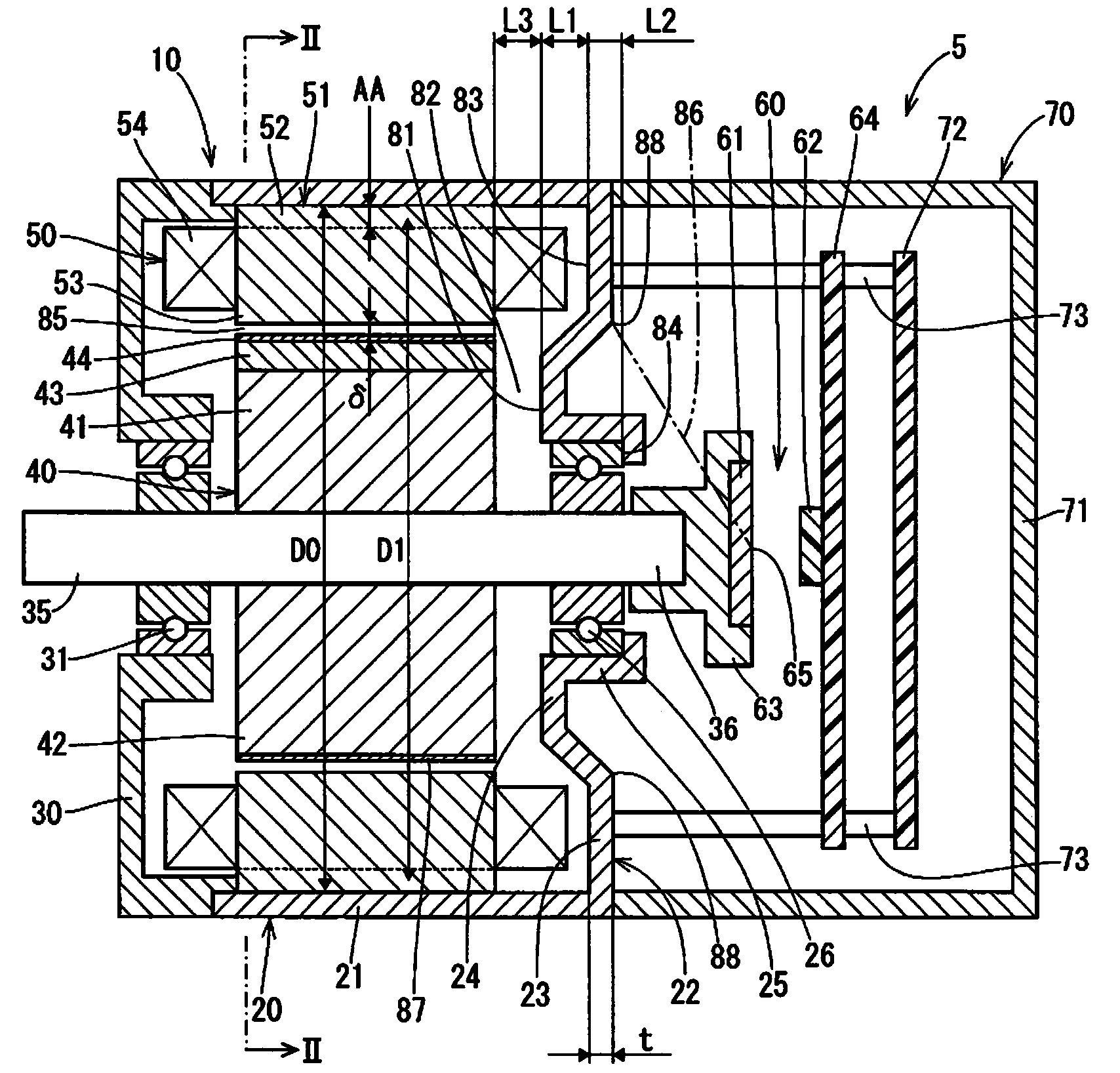

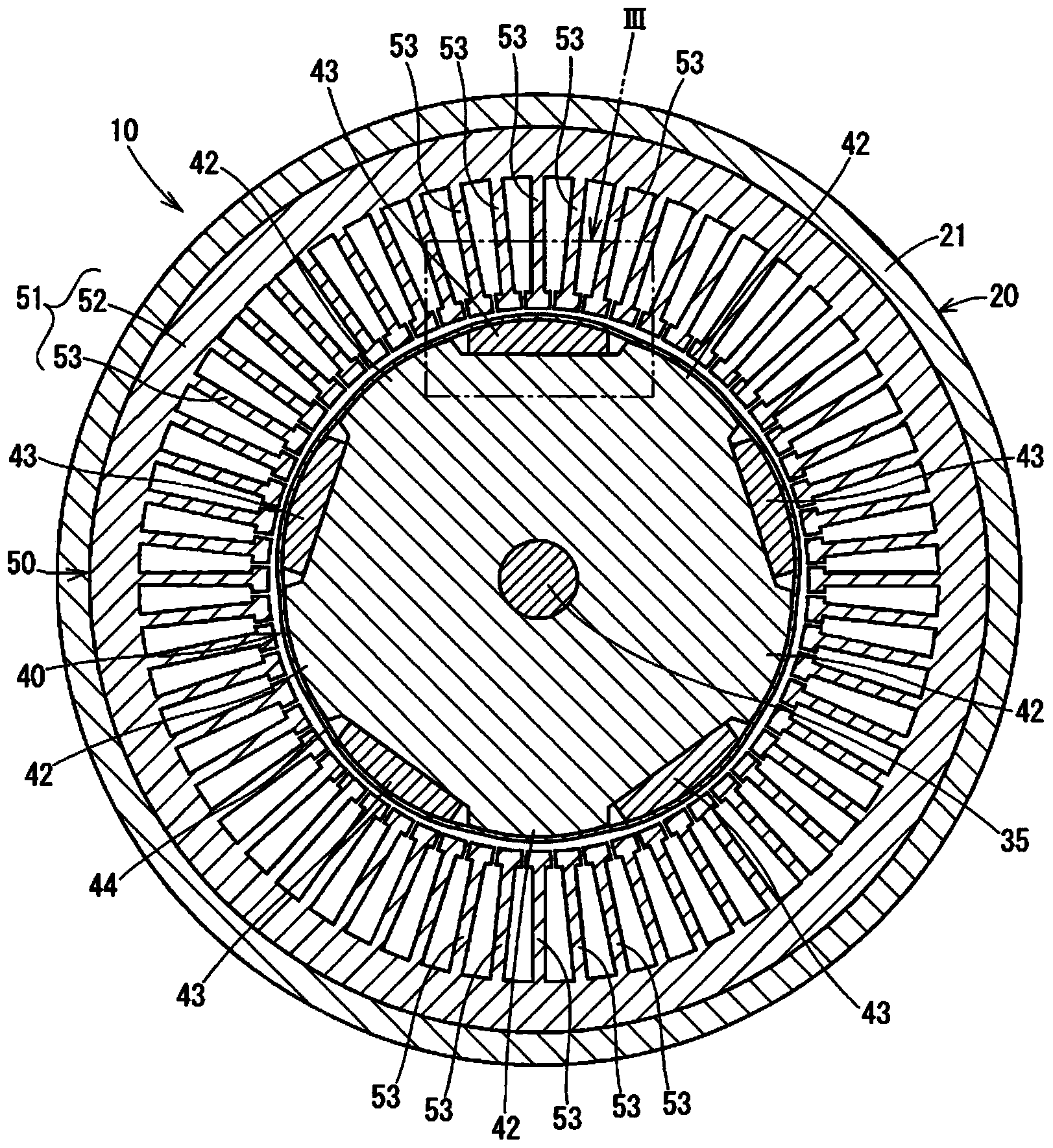

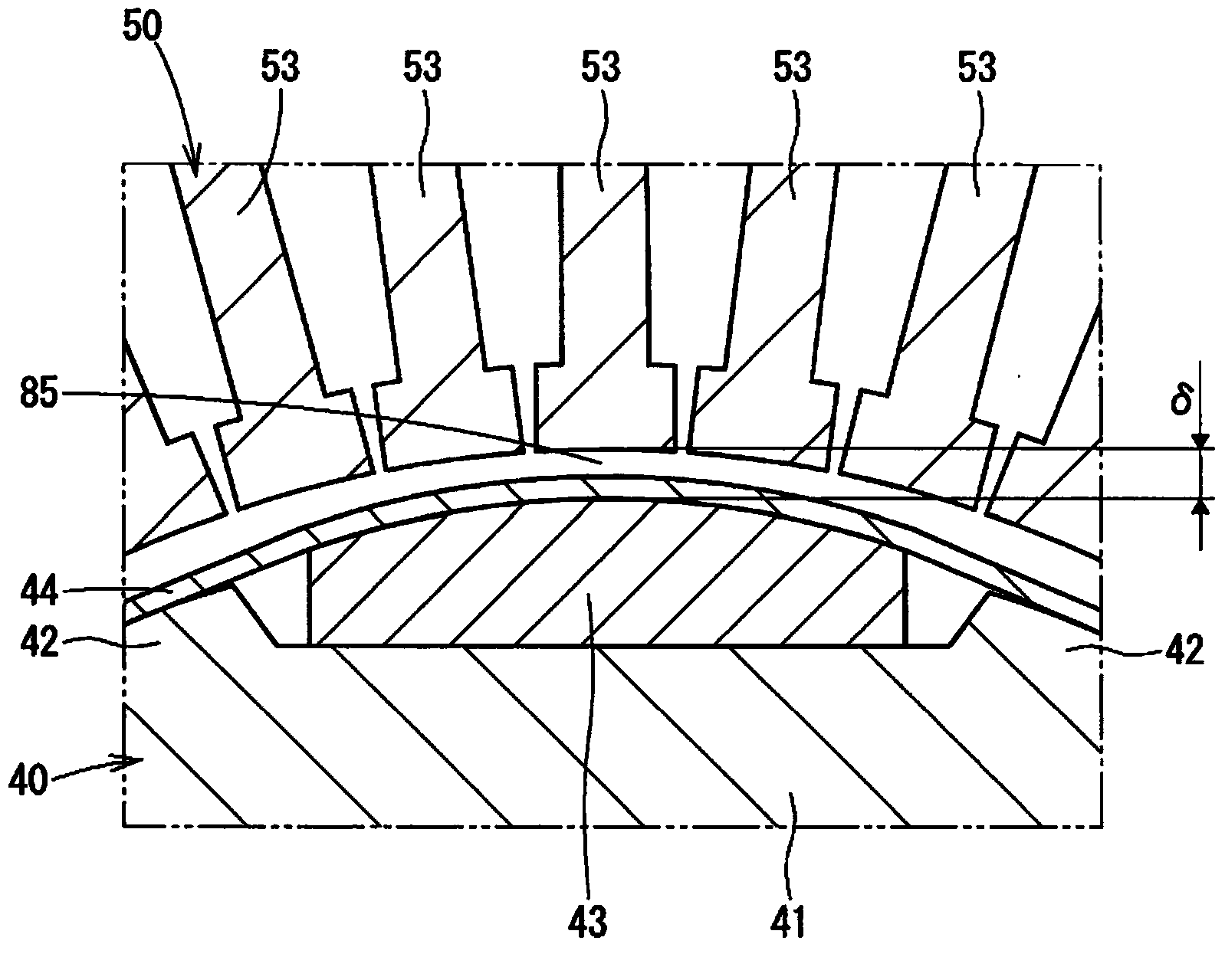

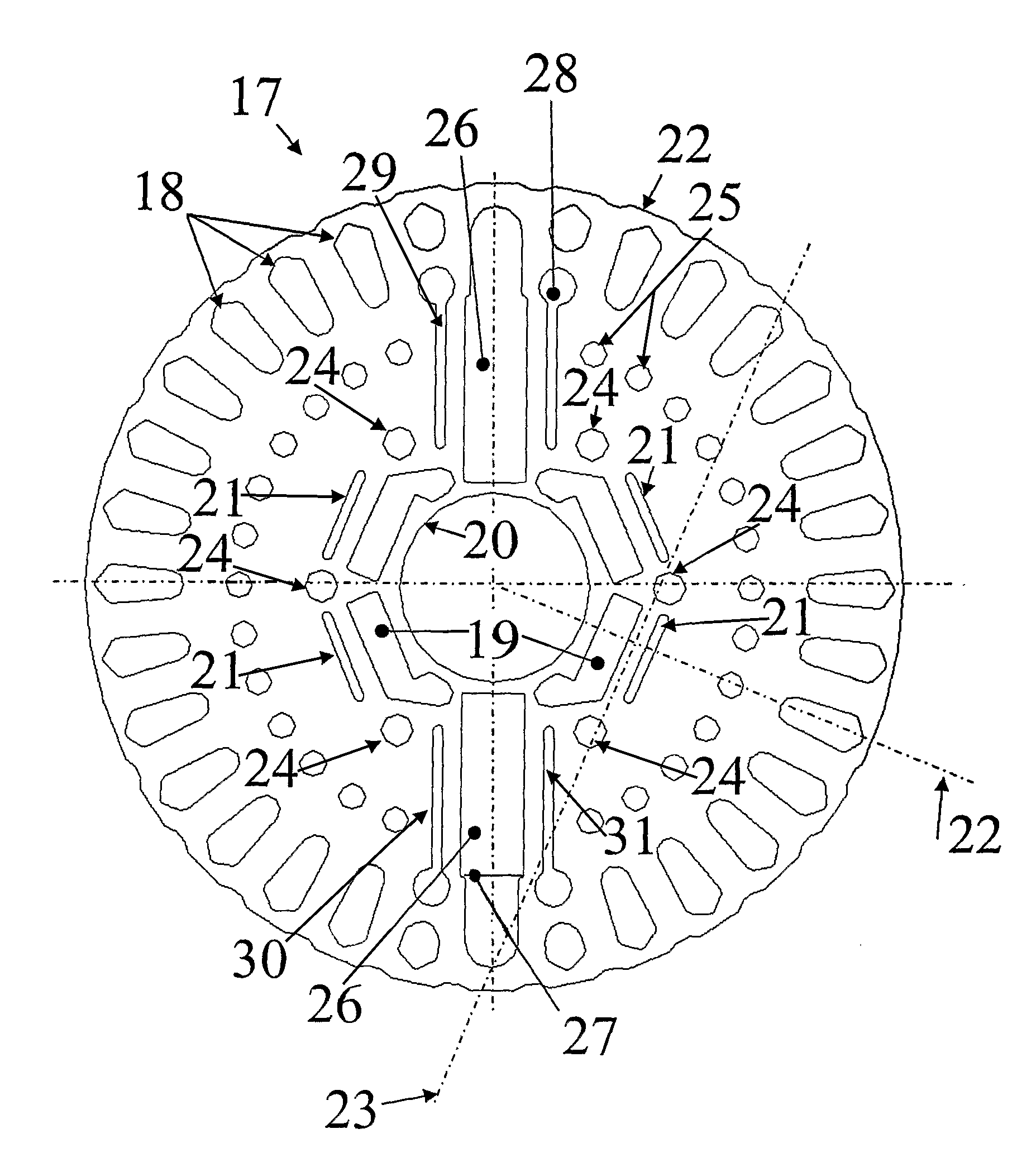

Rotary electric machine and driving apparatus using the same

ActiveCN104124827ADetection accuracy dropsReduce magnetic fluxMagnetic circuitStructural associationElectric machineMagnetic poles

A motor includes a stator core fitted to a cylindrical portion of a case, a rotor core being rotatable in the stator core, soft magnetic poles radially extending from the rotor core, and magnet poles disposed between the soft magnetic poles. The case includes a bottom portion having a ring-shaped plate portion, a protrusion portion, and a bearing-supporting portion extending from the protrusion portion. A condition that L2≧t and a condition that L1≧L2 are met, wherein t represents a thickness of the bottom portion, L1 represents a distance in an axial direction between a side surface of the ring-shaped plate portion close to the stator core and a protrusion end of the protrusion portion close to the rotor core, and L2 represents a distance in the axial direction between the side surface and an end surface of a bearing opposite to the rotor core.

Owner:DENSO CORP

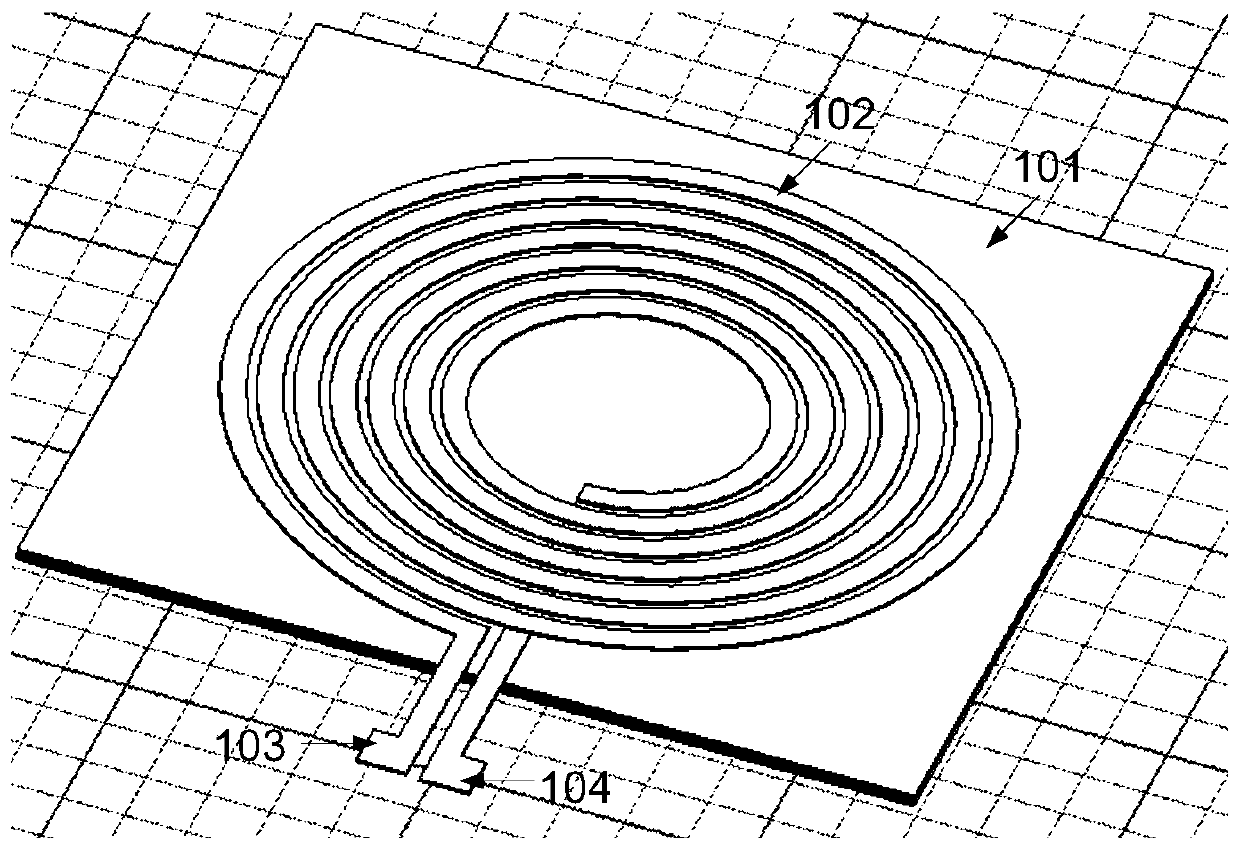

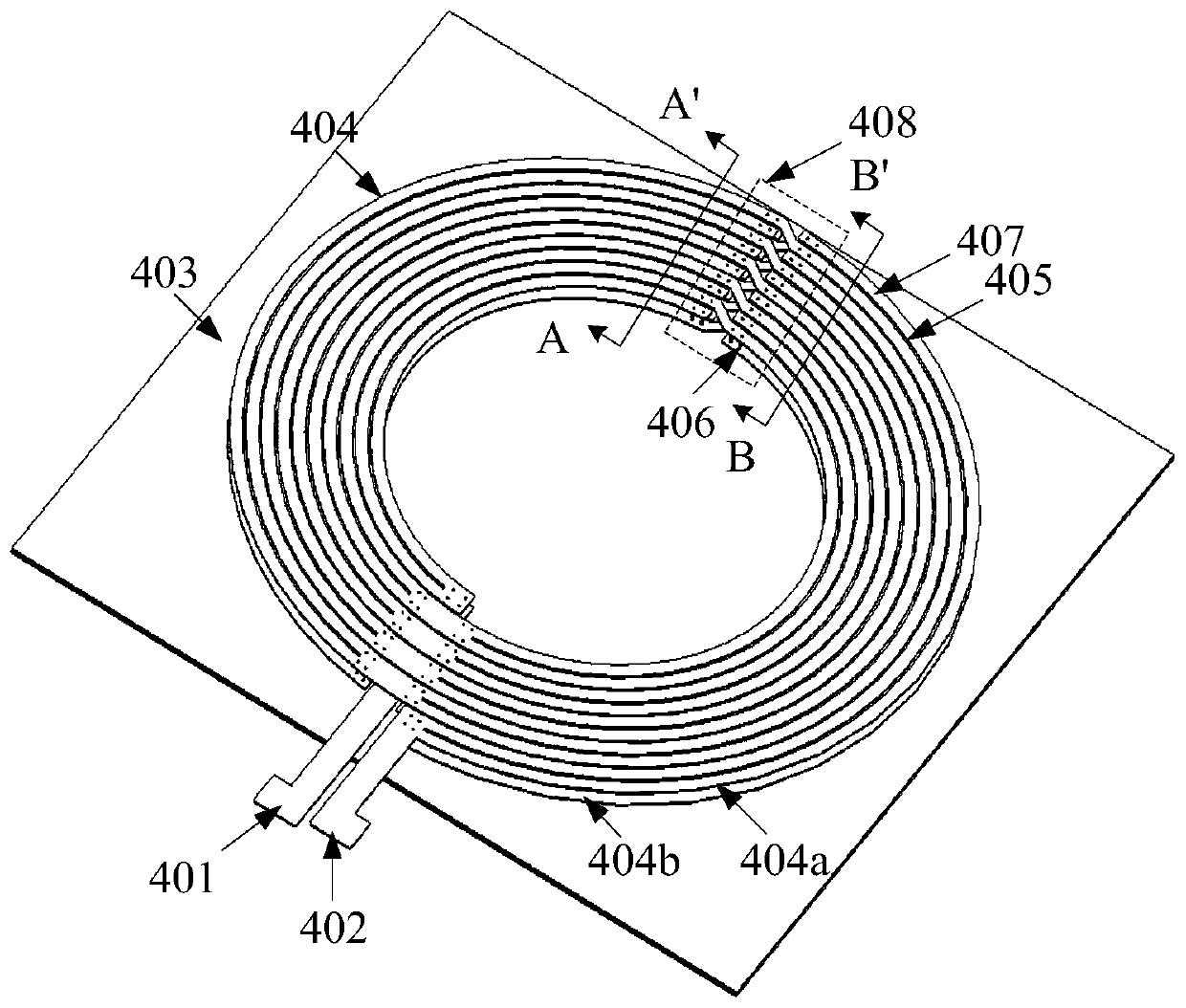

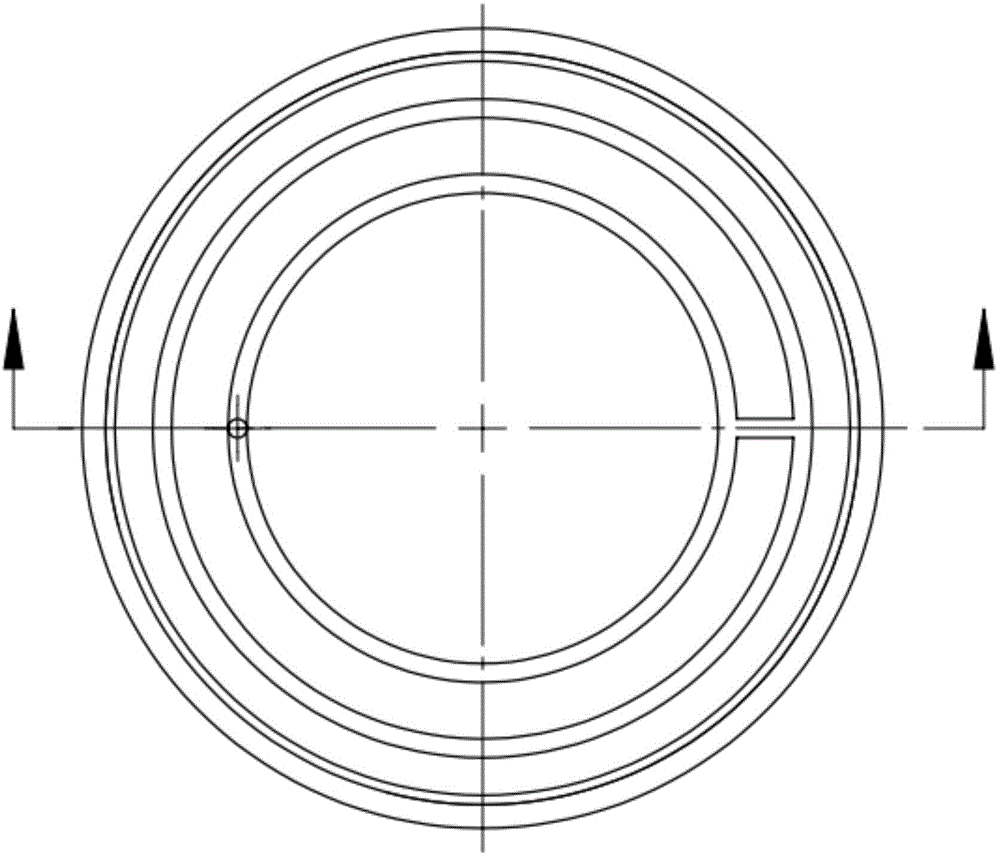

Coil module, wireless charging transmitting device, wireless charging receiving device, wireless charging system and mobile terminal

ActiveCN109887724AReduce eddy current lossImprove charging efficiencyBatteries circuit arrangementsTransformersEddy currentCirculating current

The invention discloses a coil module, a wireless charging transmitting device, a wireless charging receiving device, a wireless charging system and a mobile terminal. The coil module comprises a first plane coil winding, wherein the first plane coil winding comprises multiple turns of coils and a target side part; at least one turn of a first coil of the multiple turns of coils of the first planecoil winding comprises at least one first cutting opening; the first cutting opening divides the first coil into a first outer side part and a first inner side part in the extending direction of thecoil; the first outer side part is provided with a first connecting end, and the first inner side part is provided with a second connecting end; the first target side part comprises a first cutting groove, wherein the first target side part is at least one of the first outer side part and the first inner side part; the extending direction of the first cutting groove is the same as that of the first target side part; and the width of the single first cutting groove is smaller than or equal to that of the single first cutting opening. The vortex path of the first target side part is cut off, thepassing area of the magnetic flux is reduced, the magnetic flux is reduced, the eddy current loss and the circulating current loss are reduced, and the charging efficiency is improved.

Owner:HUAWEI TECH CO LTD

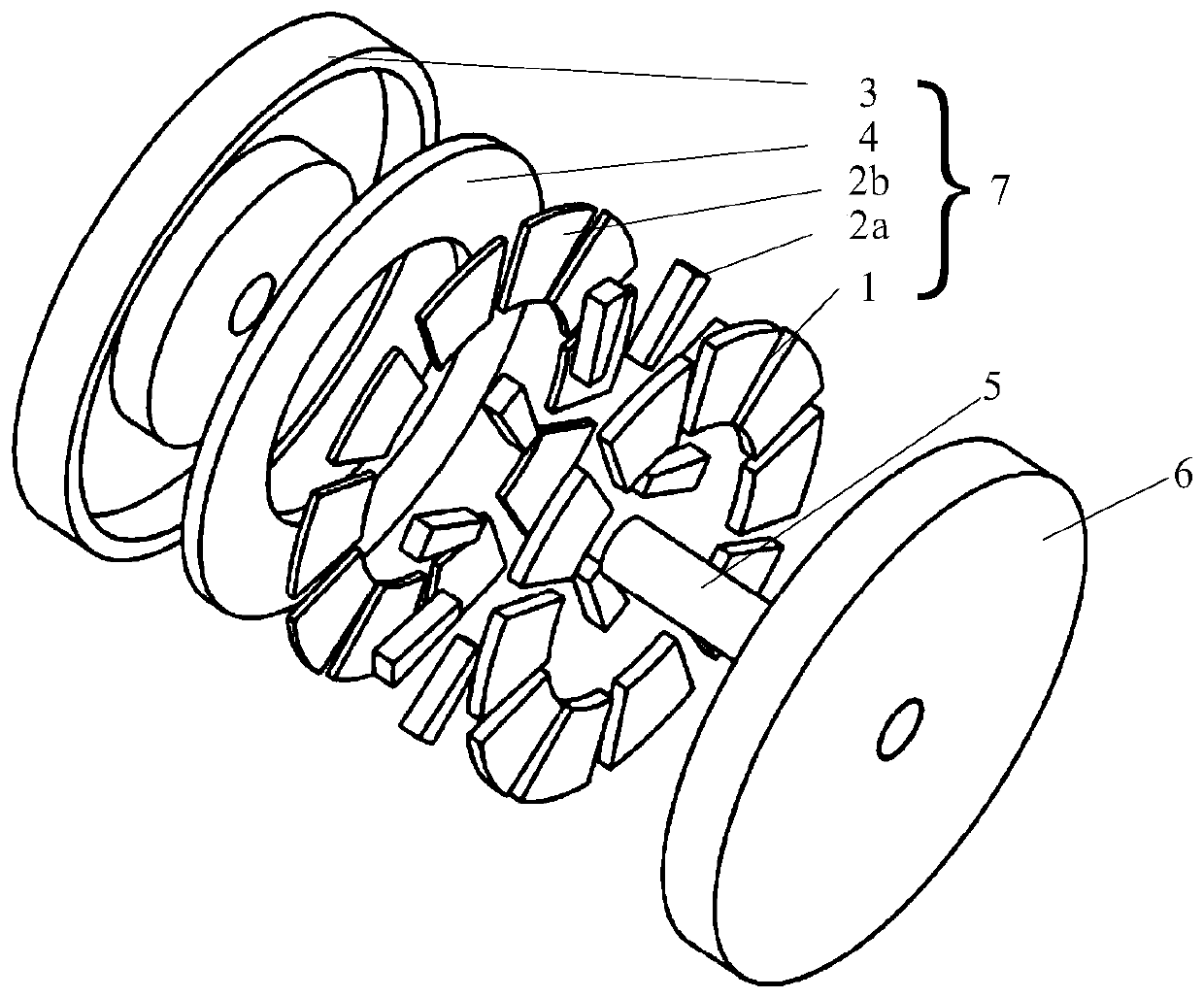

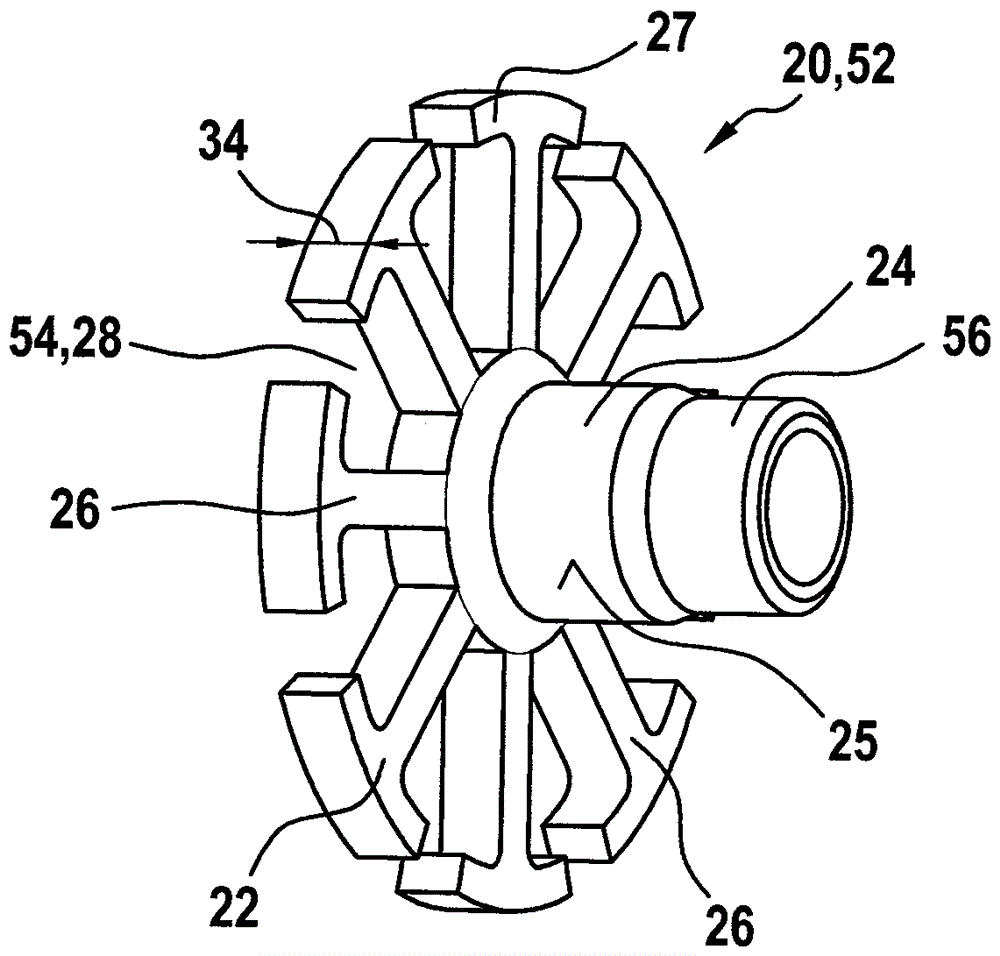

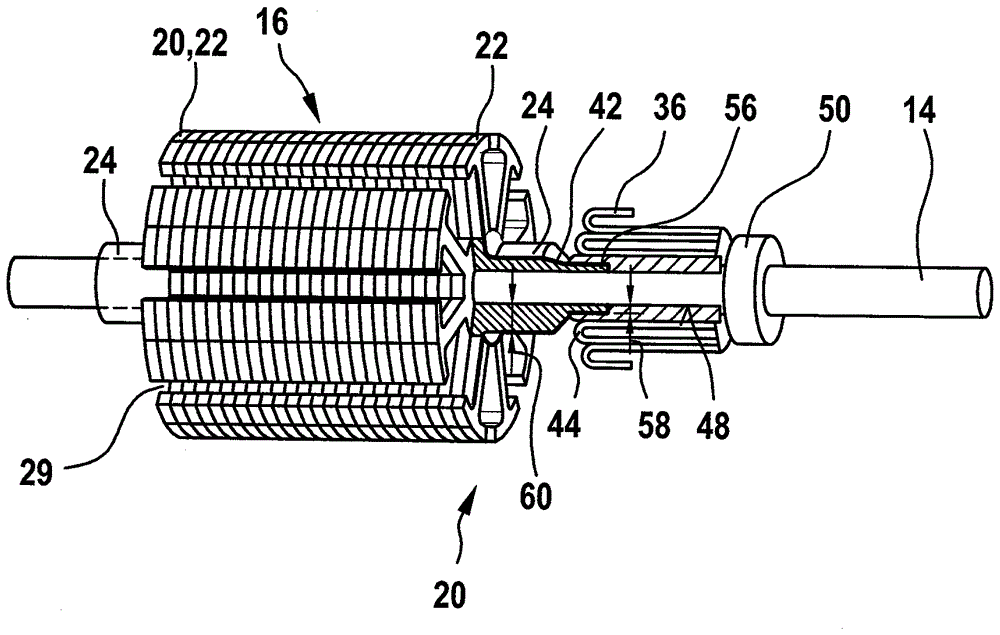

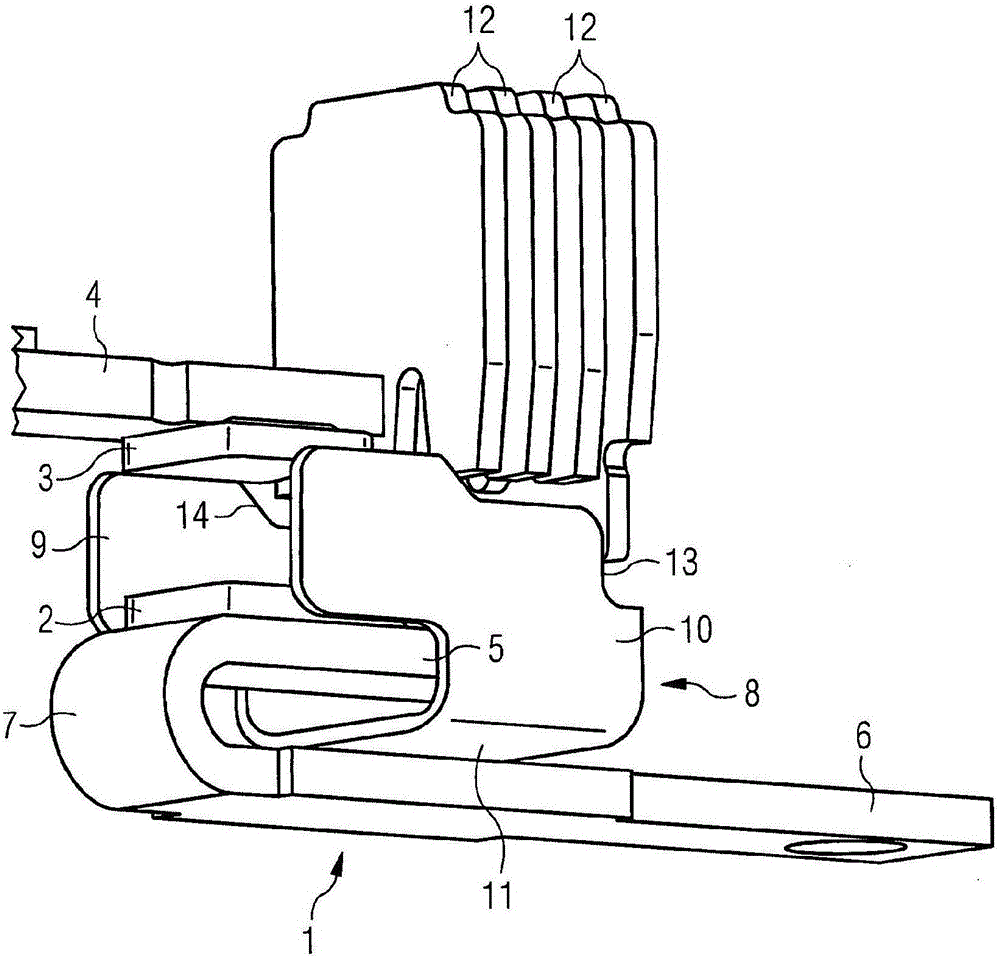

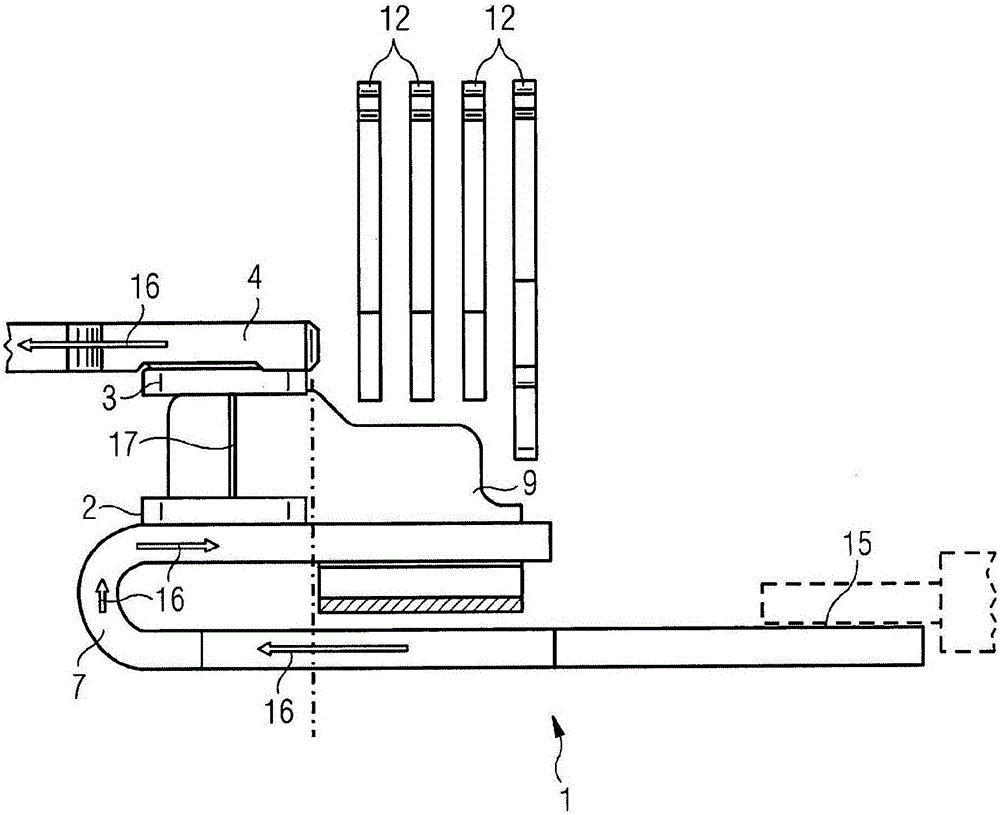

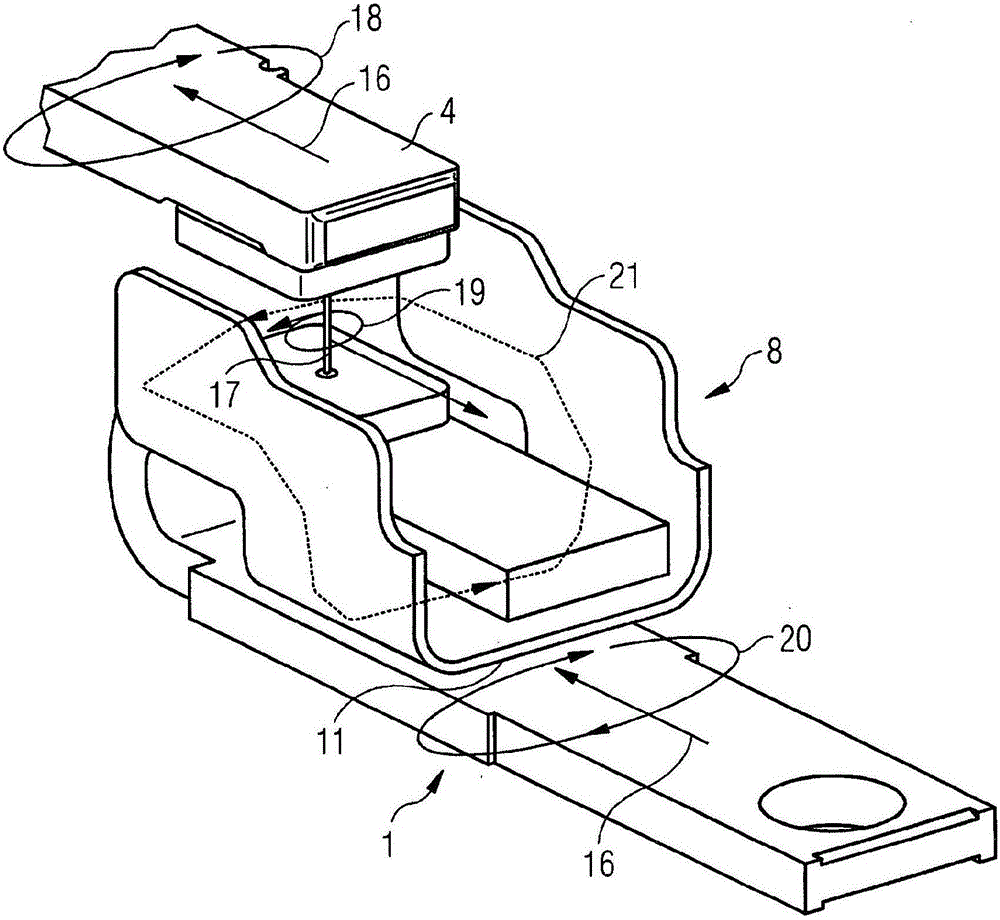

Rotor, electric machine including same, and method for producing rotor

ActiveCN106849526AImprove mechanical stabilityAvoid bendingMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringConductor Coil

The invention relates to a rotor and an electric machine (10) in particular for the motorized adjustment of a movable part in a motor vehicle, and a method for producing such the rotor. The rotor comprises a rotor shaft (14), a rotor assembly (16) for containing a rotor winding (30) is fixed to the rotor, and the rotor assembly (16) comprises an end plate (20) made of metal. The rotor is characterized in that at least one end plate (20) comprises a sleeve (24) made of metal, and the sleeve extends along the axial direction from a disk-shaped plate body (22) of the end plate (20) and encloses the rotor shaft (14).

Owner:ROBERT BOSCH GMBH

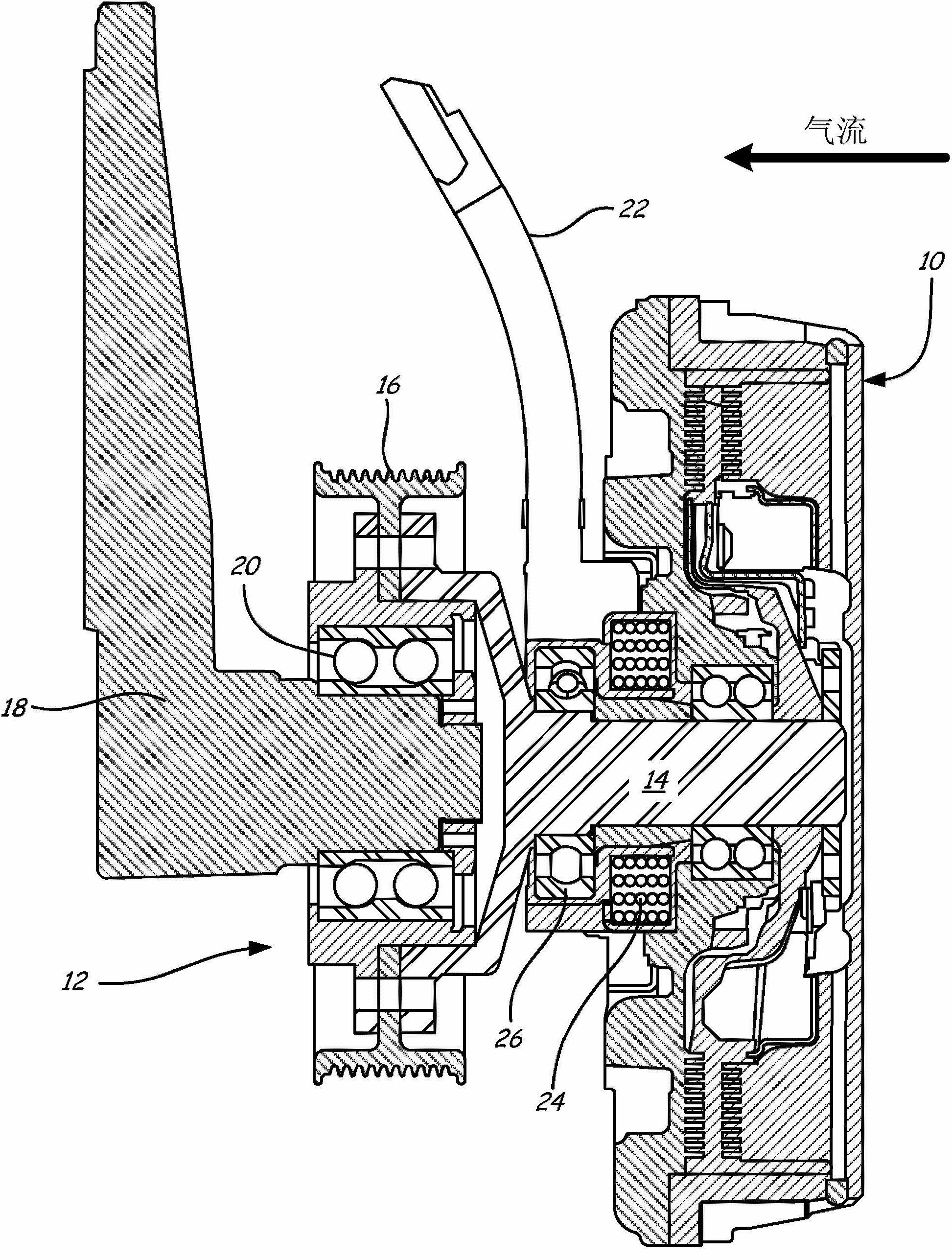

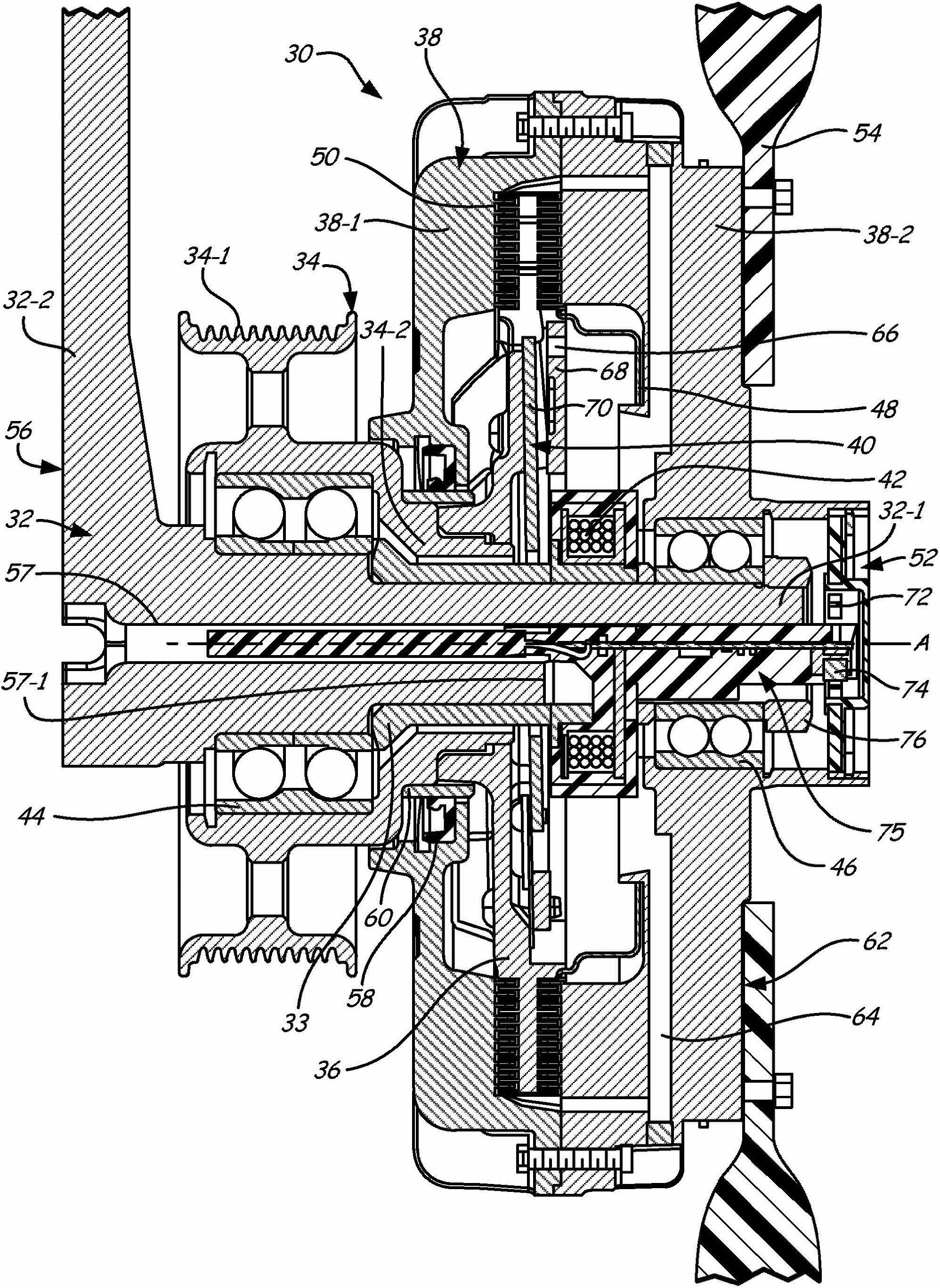

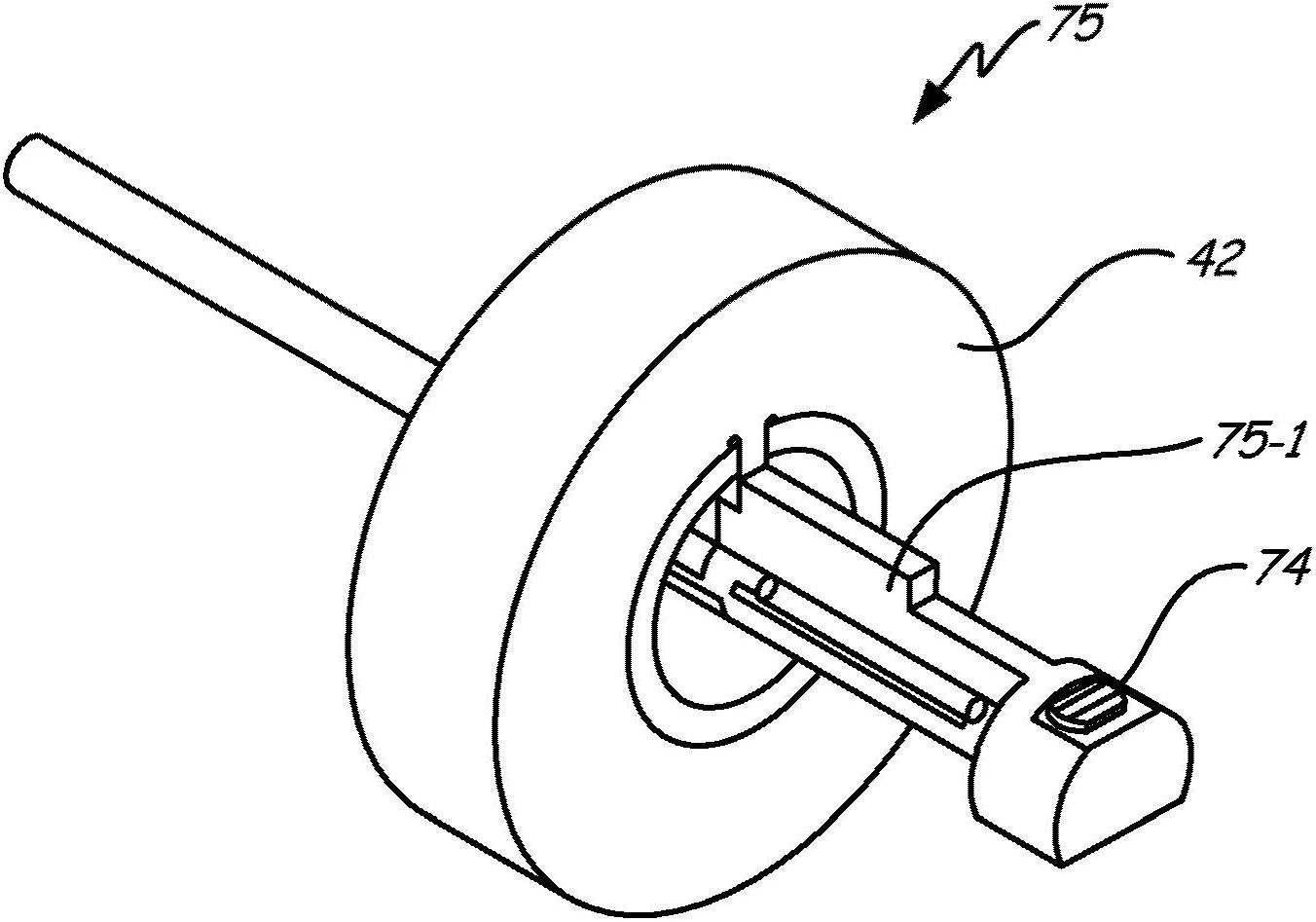

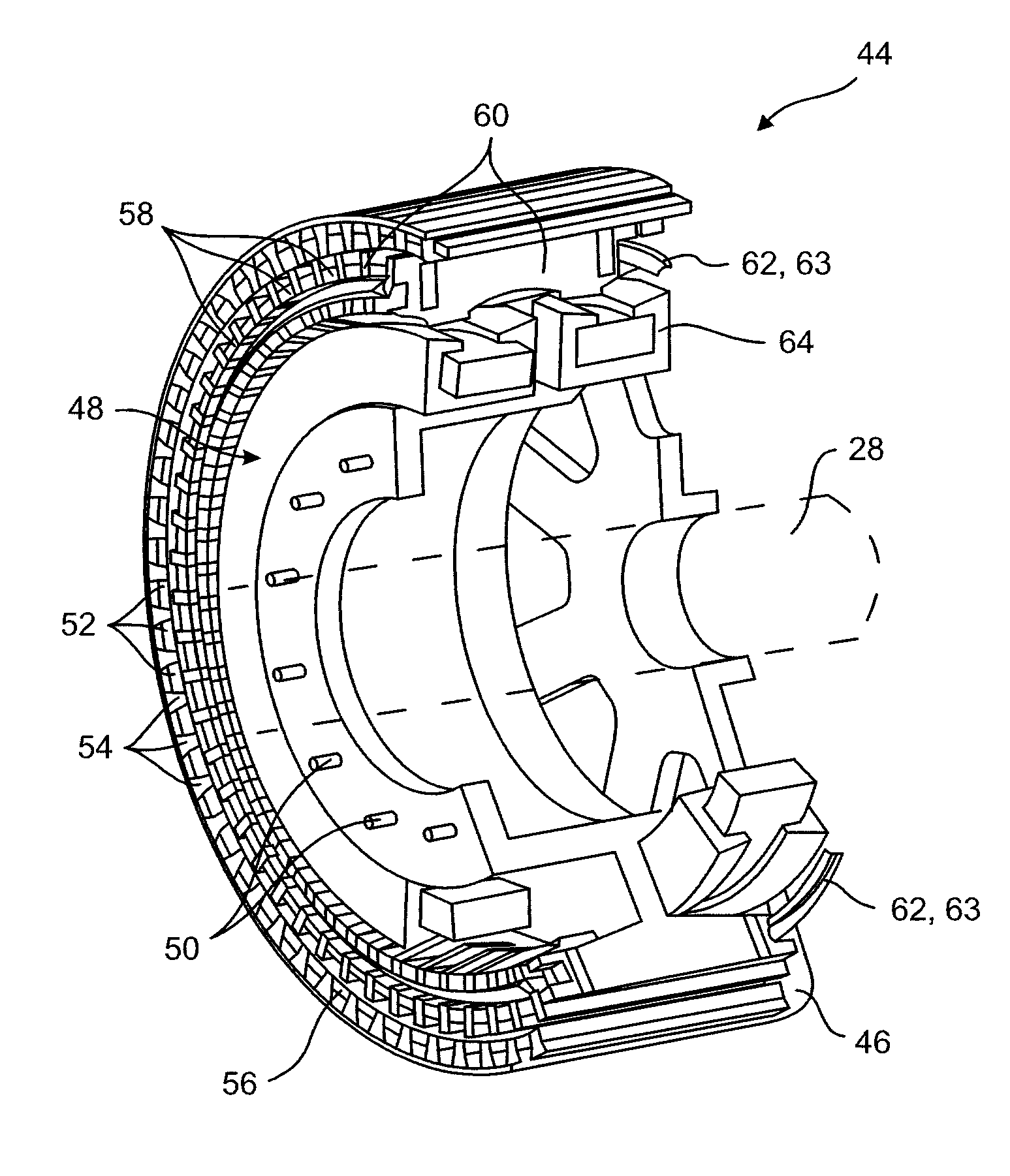

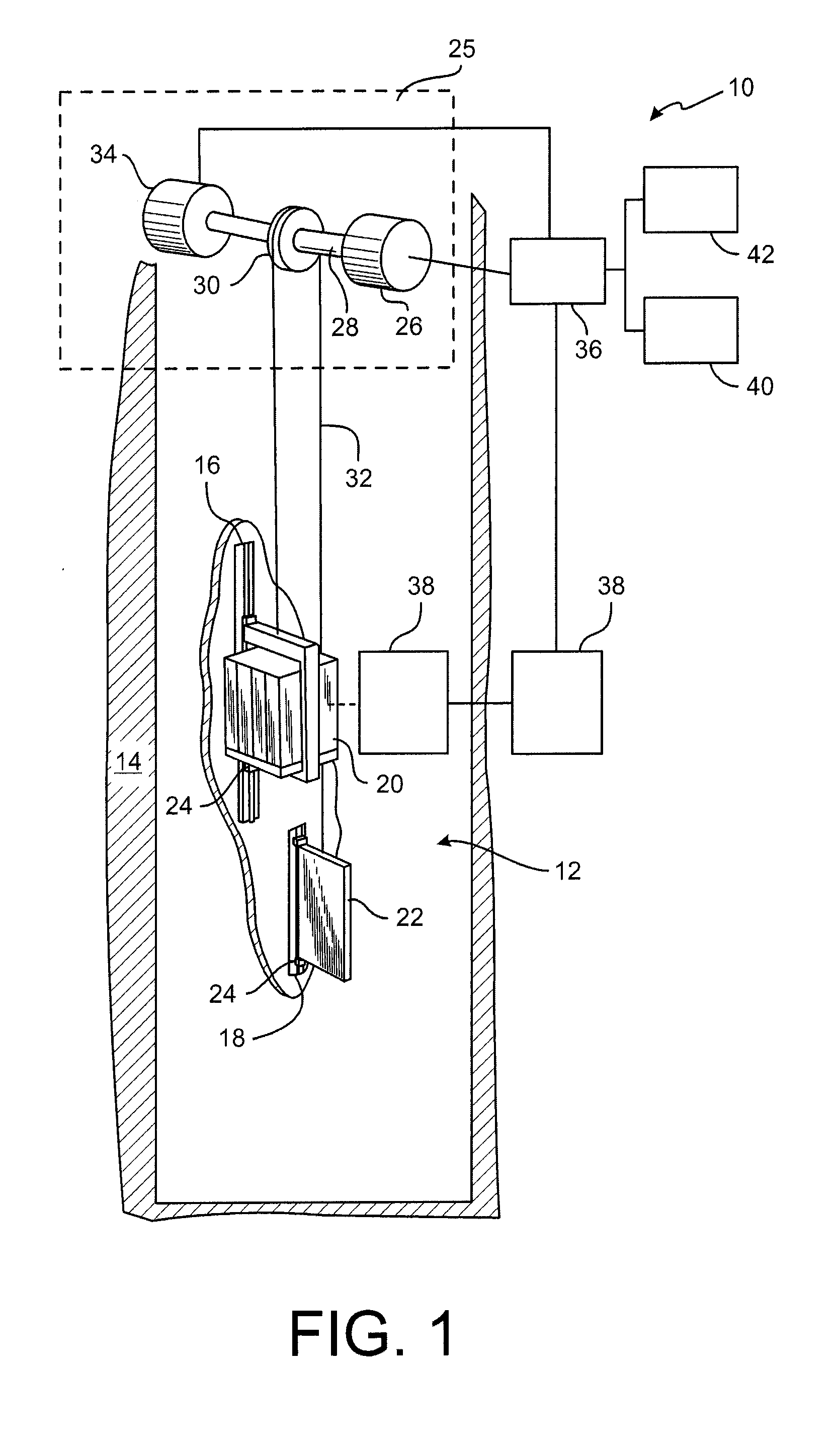

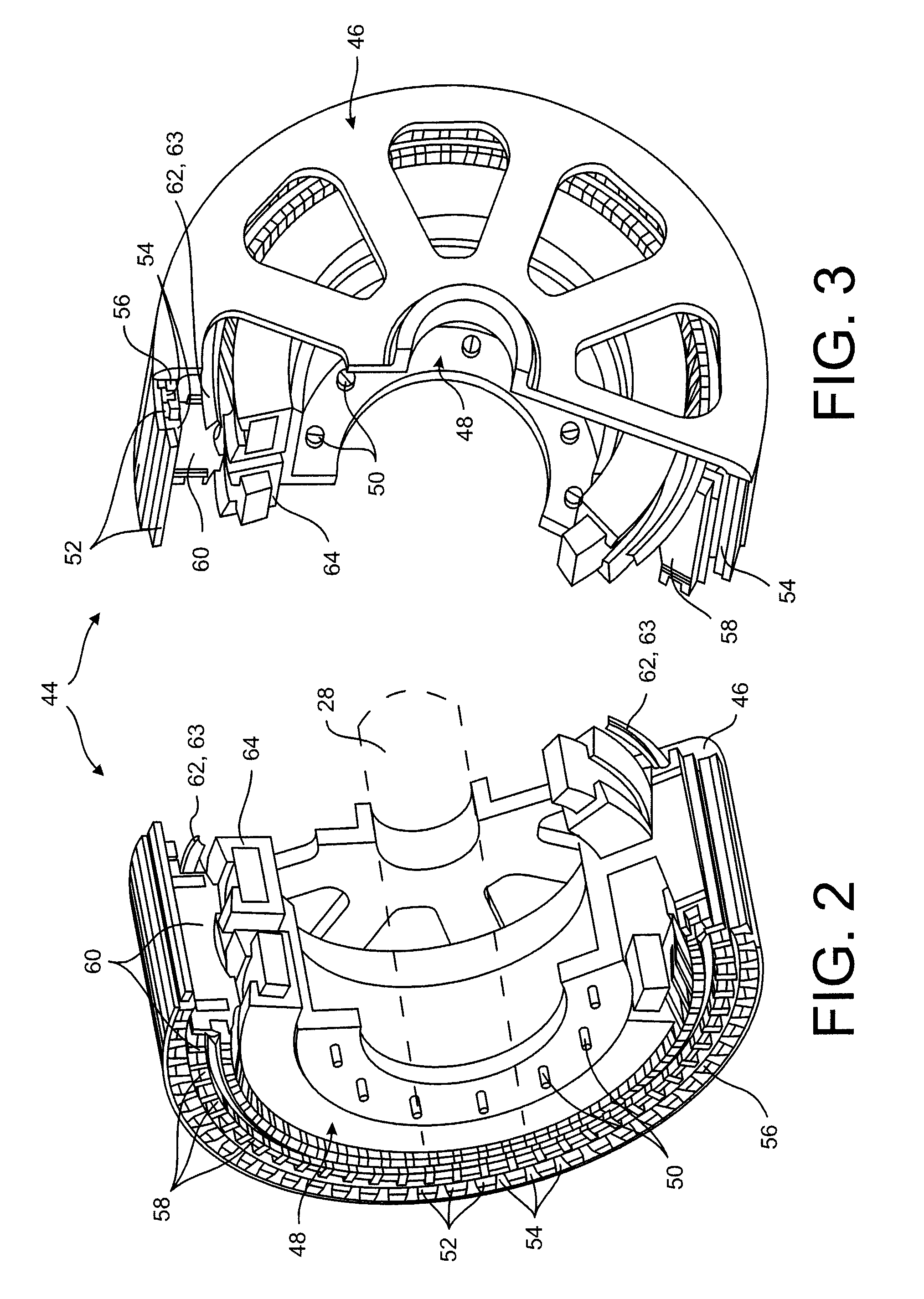

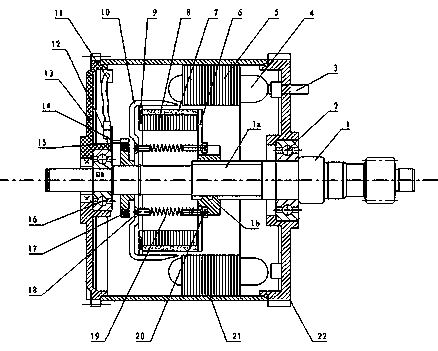

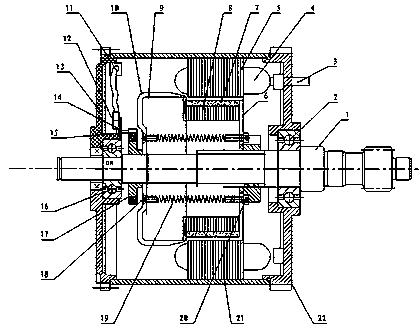

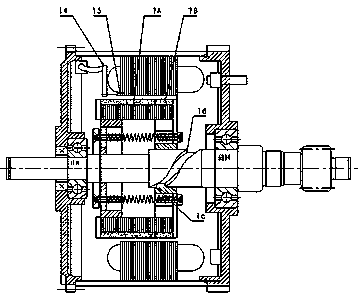

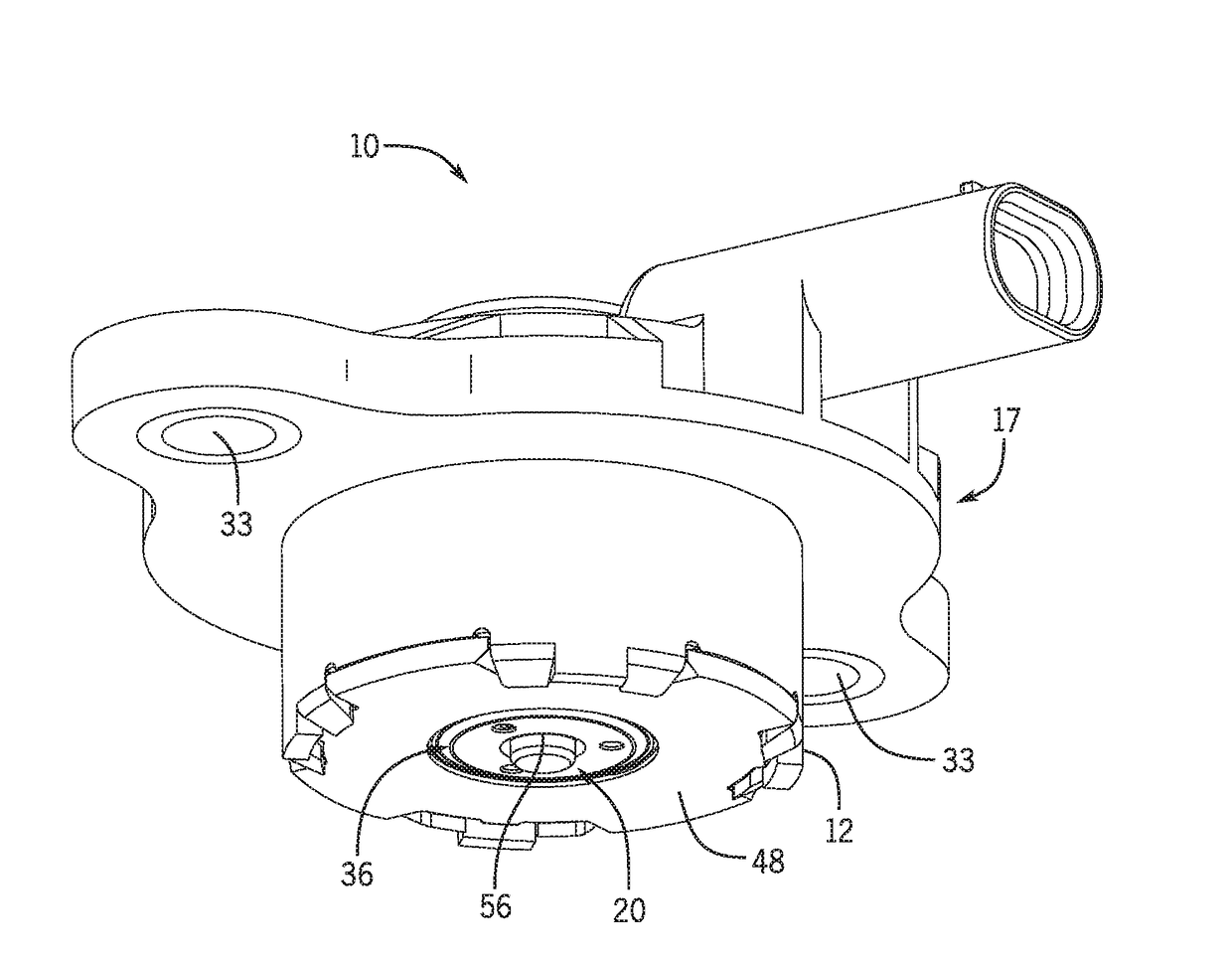

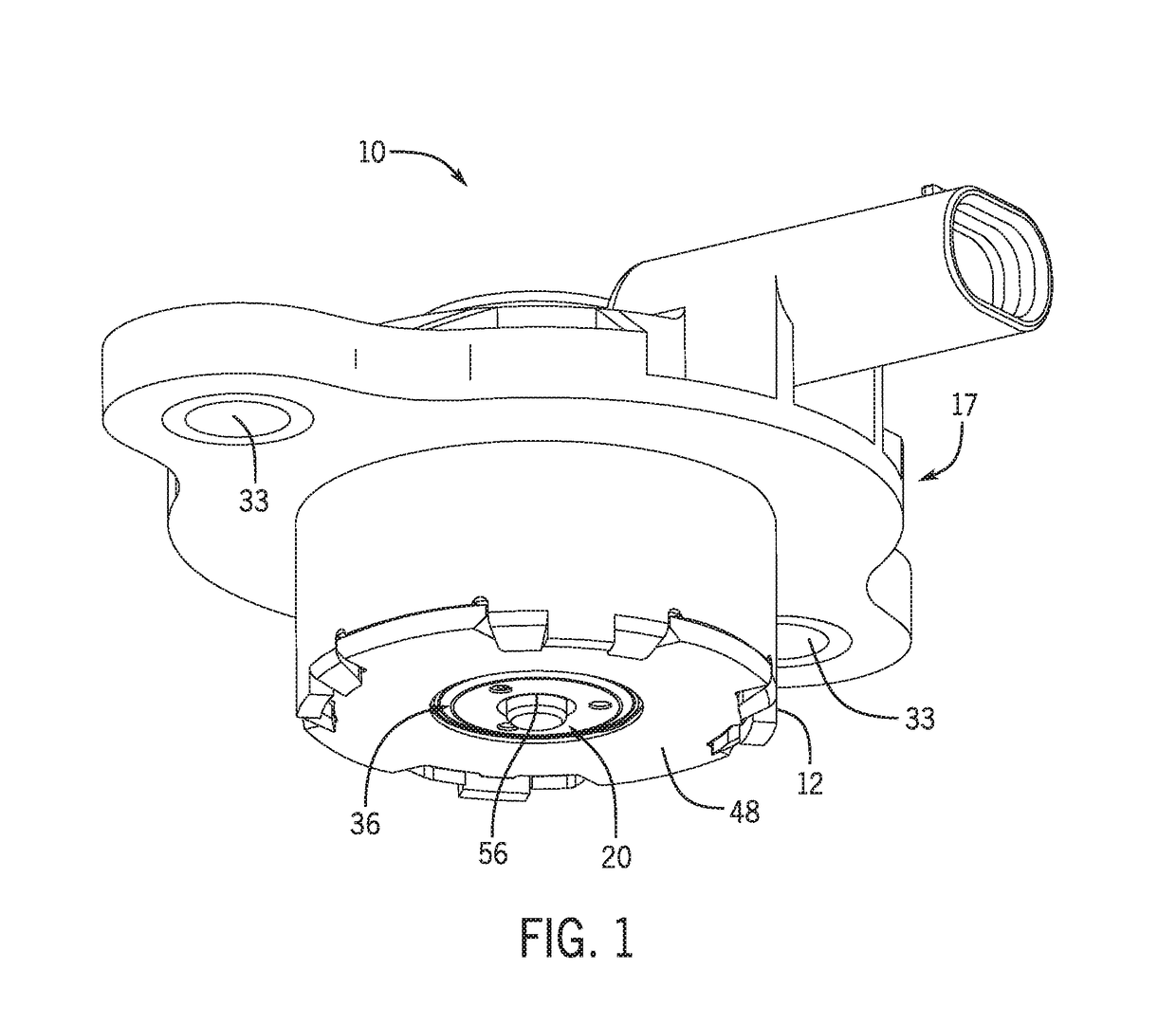

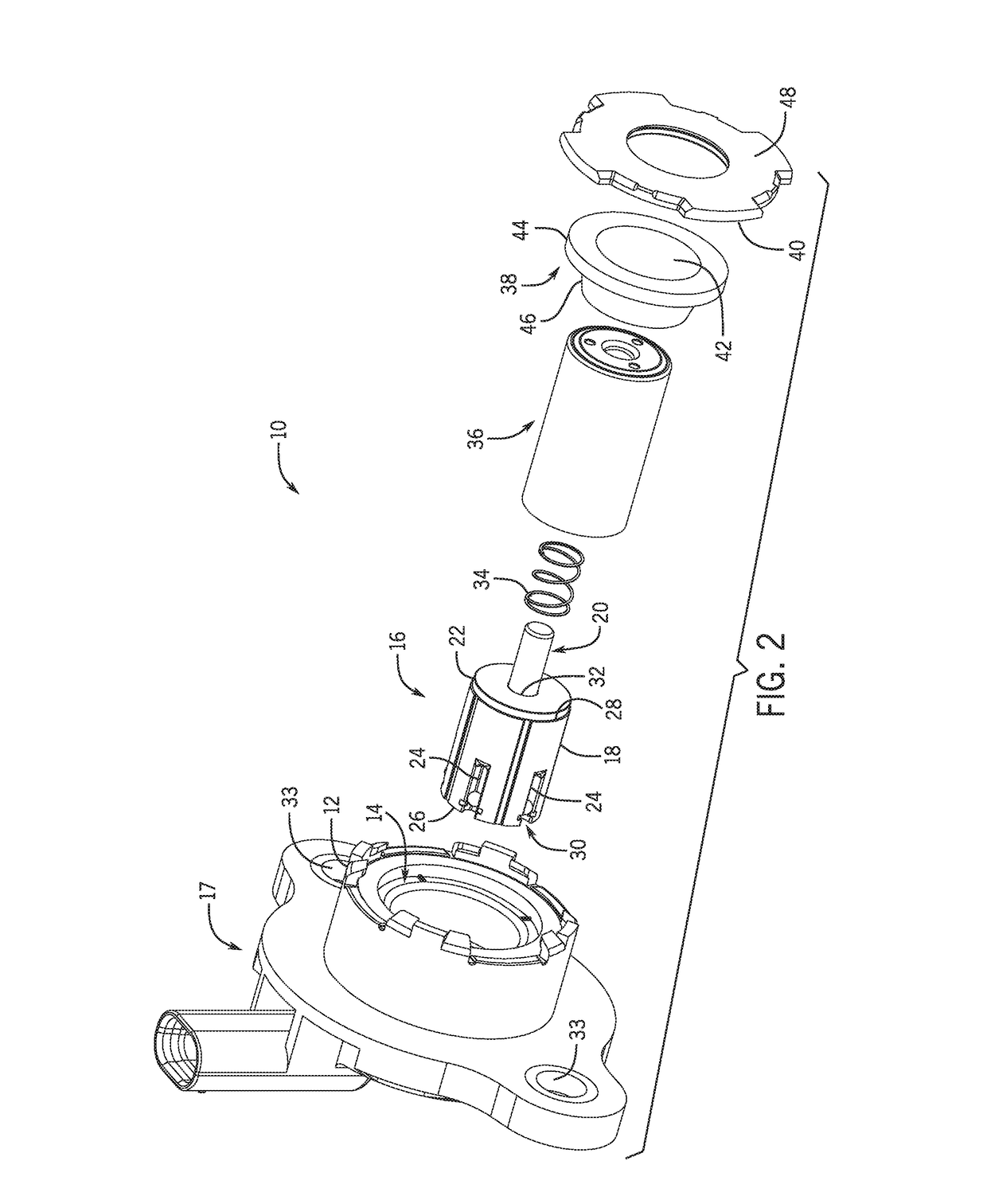

Integrated viscous clutch

InactiveCN102667213AIncrease the number of turnsLight in massFluid actuated clutchesCouplingsEngineeringClutch

A viscous clutch (30; 30') includes a stationary journal bracket (32; 32') defining a mounting shaft (32-1; 32-1'), an output member (34; 34') rotatably supported on the mounting shaft about an axis (A), an input member (34; 34') rotatably supported on the mounting shaft about the axis, and a working chamber (50; 50') defined between the input member and the output member to selectively transmit torque there between when a shear fluid is present. The mounting shaft extends axially through the viscous clutch from a front face (62; 62') of the viscous clutch to a rear face (56; 56') of the viscous clutch, with the rear face defining a mounting surface for mounting the viscous clutch at a mounting location. The front and rear faces are located at opposite sides of the viscous clutch and face in opposite directions.

Owner:HORTON

Rotor with a thermal barrier and a motor with such a rotor

InactiveUS20090091200A1Improve cooling effectInhibit exchangeMagnetic circuit rotating partsSynchronous machinesConductor CoilThermal conductivity

The invention provides an electrical line-start motor comprising with a stator and a squirrel cage rotor adapted for rotation around a centre axis. The rotor comprises a squirrel cage winding in which a current is induced by corresponding windings of the stator, and a set of permanent magnets. To protect the magnets from excessive heat, the rotor comprises thermal barriers e.g. in the form of cavities located between the squirrel cage winding of the rotor and the magnets. Due to the thermal barriers, the thermal conductivity in a path between the windings and the magnets are reduced and the magnets are protected.

Owner:DANFOSS COMPRESSORS

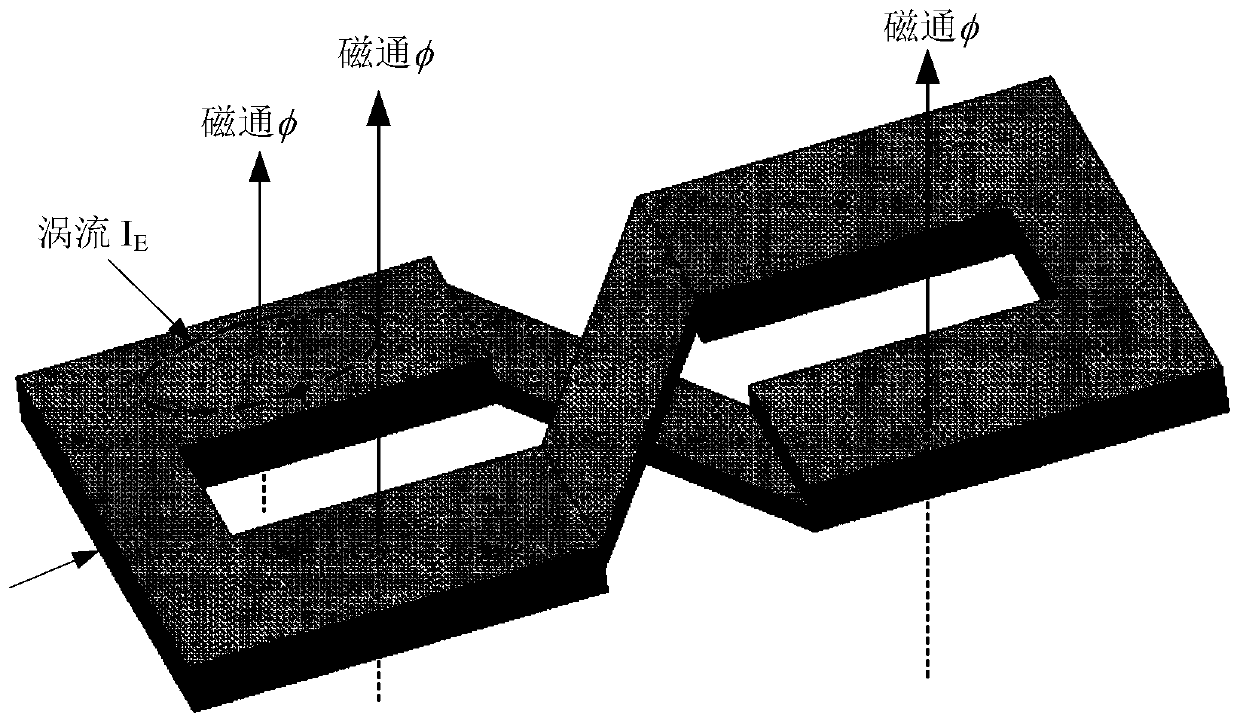

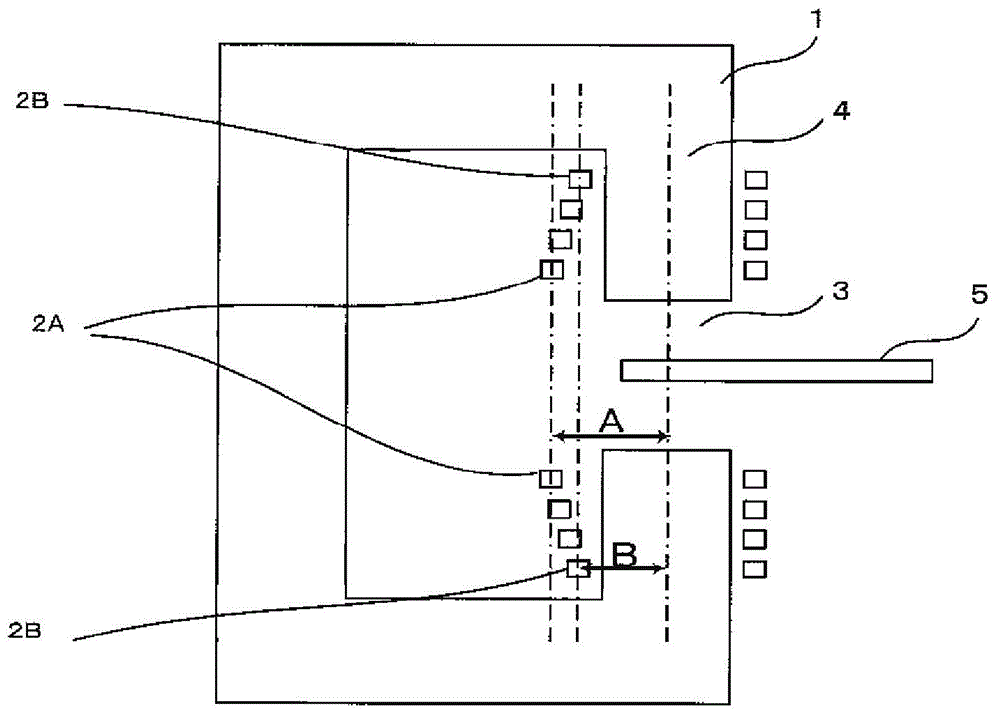

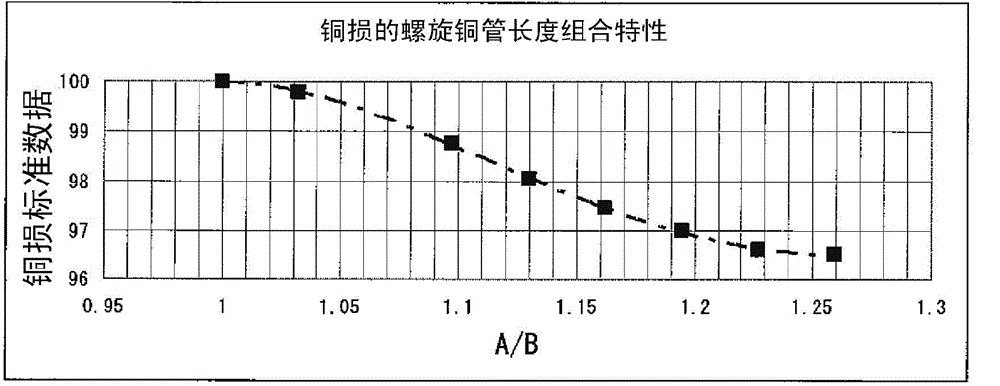

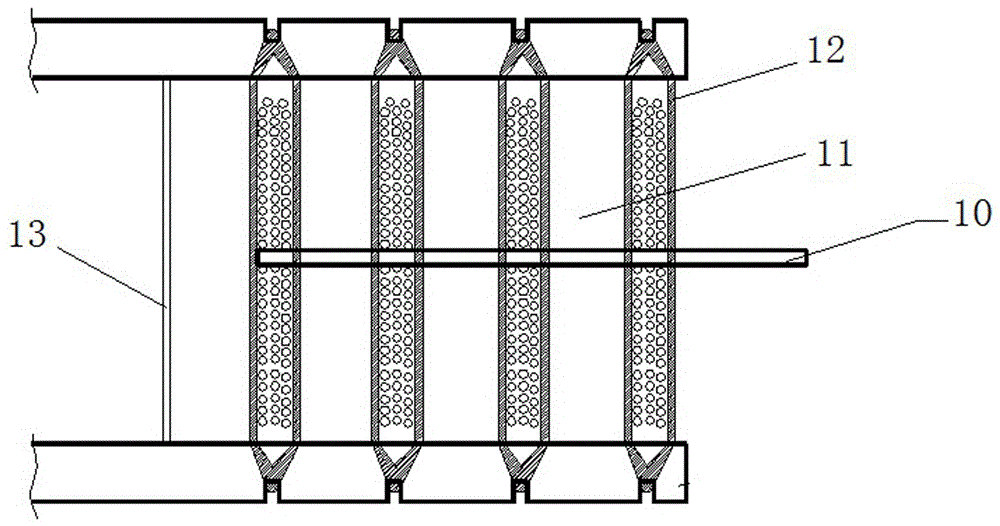

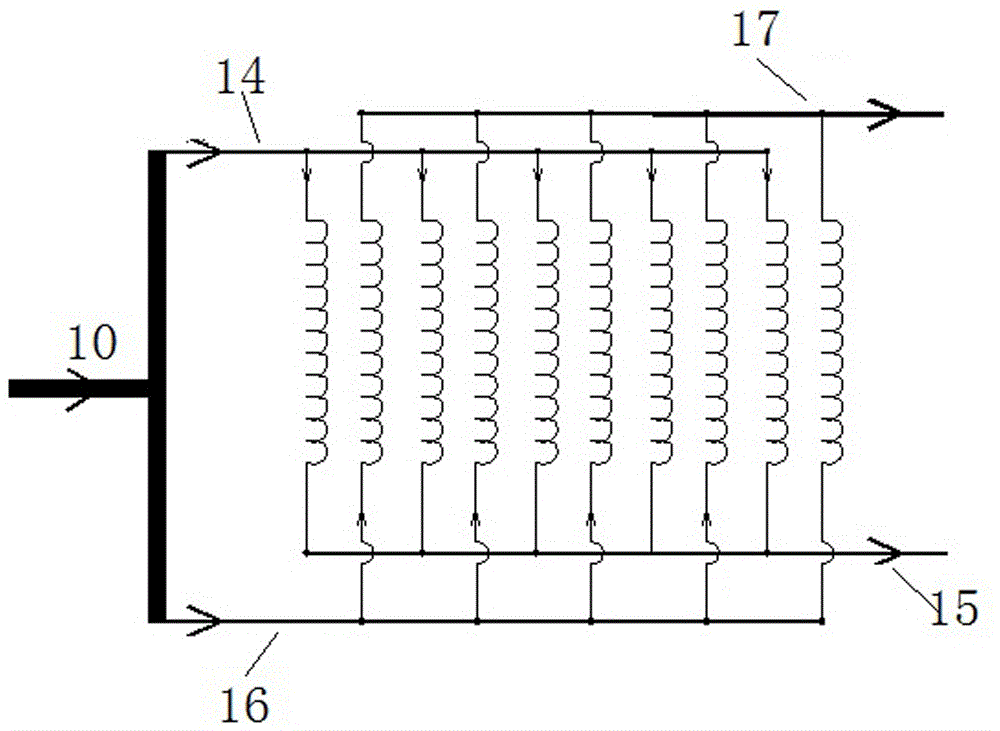

Induction heating apparatus

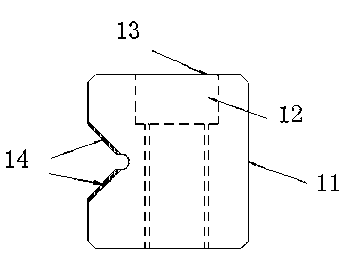

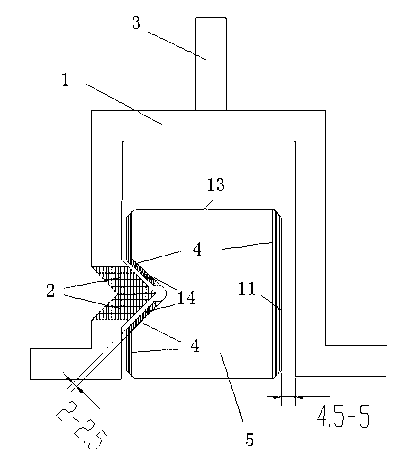

ActiveCN104918343AAvoid heatingReduce magnetic fluxIncreasing energy efficiencyInduction heating apparatusInductorCopper

Provided is an induction heating apparatus of a C-shaped inductor, which can restrain spiral copper pipe heating, and magnetic flux reduction which is the reason of copper loss, and can not reduce the heating efficiency of the end portion of a heated piece. The induction heating apparatus is in pairs provided with fixed C-shaped inductors formed by C-shaped iron core structures at two end portions of a heat piece in the width direction, characterized in that the C-shaped inductor is composed of a main body iron core portion which is provided with an opening used for passing through a heated piece along the conveying direction of the heated piece; an iron core leg portion in connection with the opening portion and formed in a mode of clamping the opening portion up and down; and a heating coil which clamps the opening portion and winds the up and down iron core leg portion, allows linkage between the heated piece and magnetic flow so as to heat a piece to be heated, and is winded in a mode in which the winding diameter of the heating coil gradually expands towards the end portion of the surface opposite to the opening portion.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

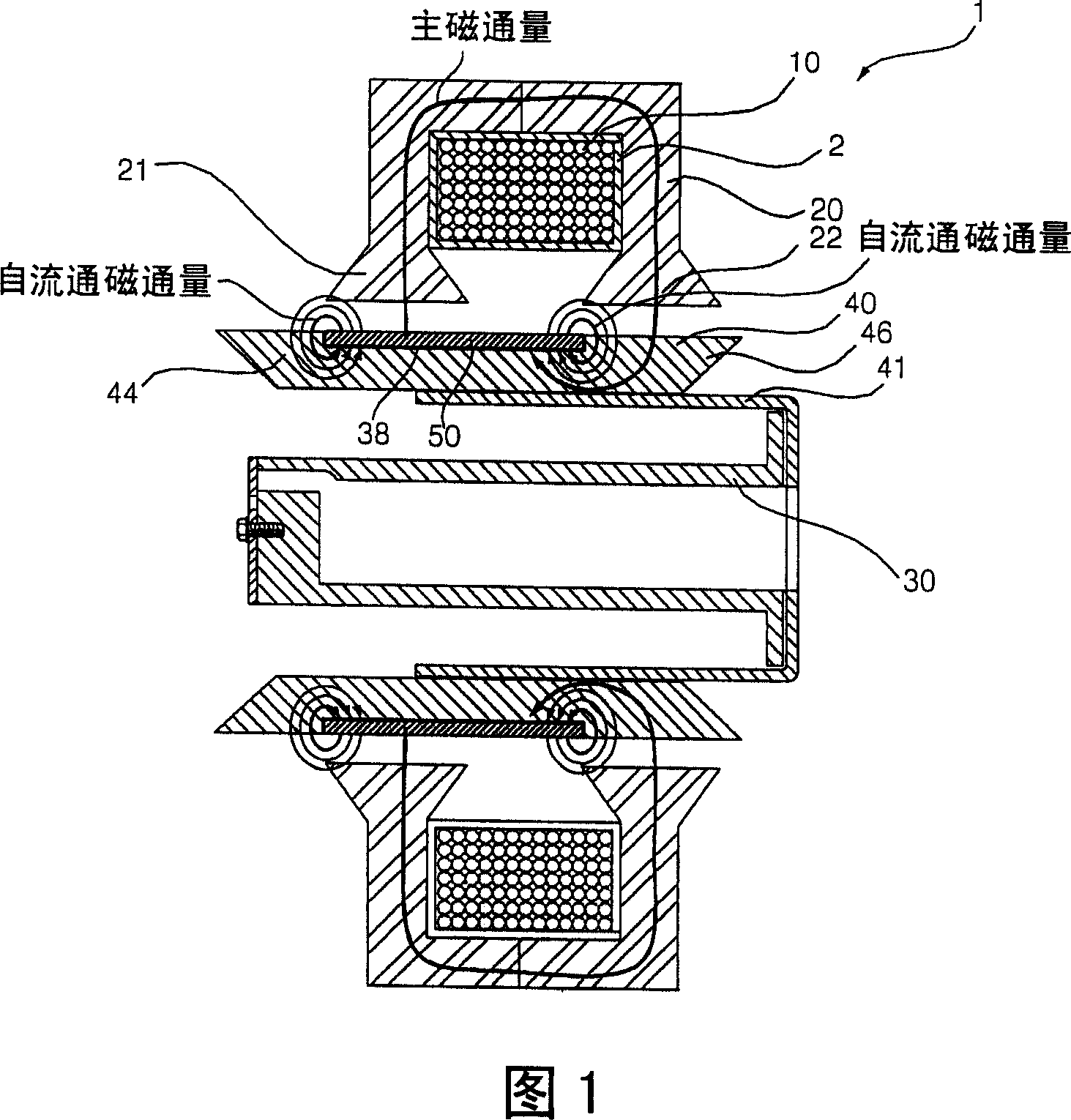

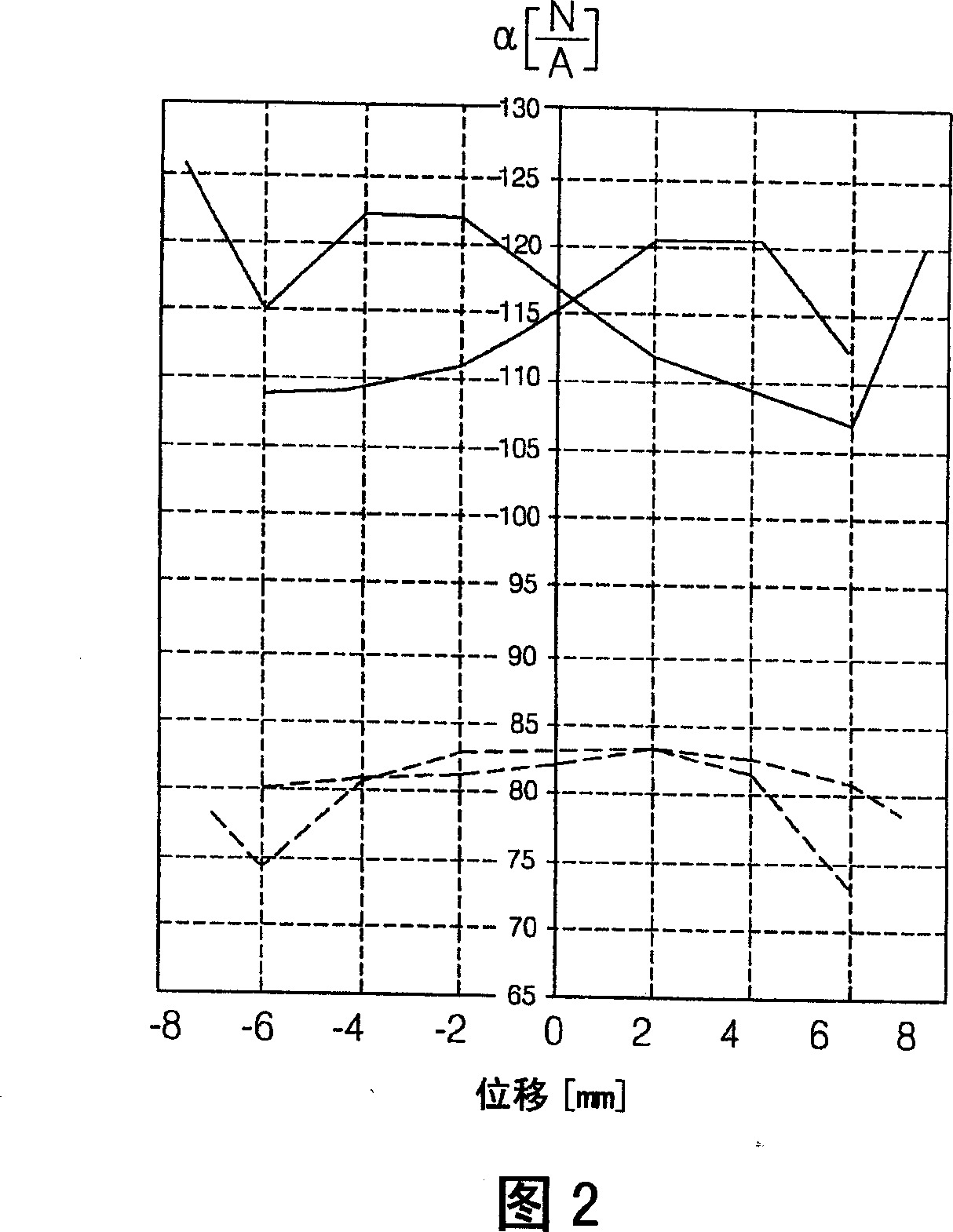

Linear motor and linear compressor using the same

InactiveCN1976183AReduce dosageEffective controlCompressorMagnetic circuit rotating partsReciprocating motionLinear compressor

A linear motor and a linear compressor using the linear motor are provided. Since an inner core is linearly and reciprocally moved together with a target movement body and a magnet insertion recess is formed on an outer circumferential surface thereof, the forward / backward vibration movement of a magnet can be effectively controlled. In addition, since a gap is minimized, self-resistance that interferes with a force exerted by the magnet can be minimized, and accordingly, the size of the magnet necessary for outputting the same force can be minimized.

Owner:LG ELECTRONICS INC

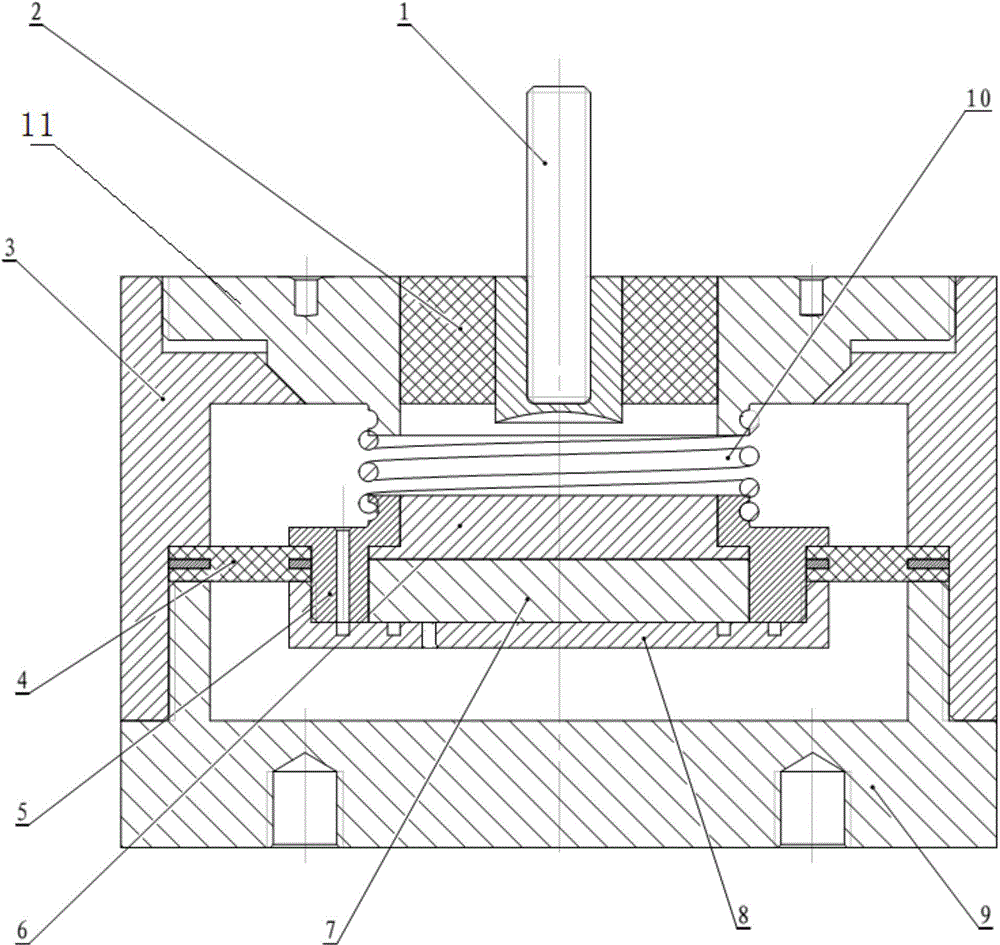

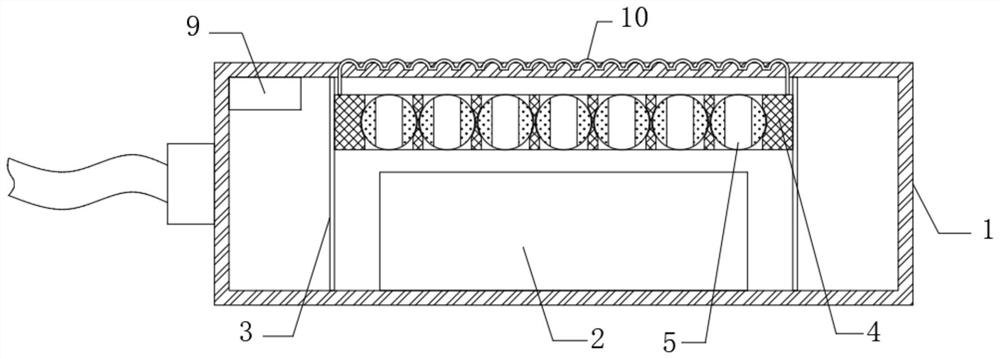

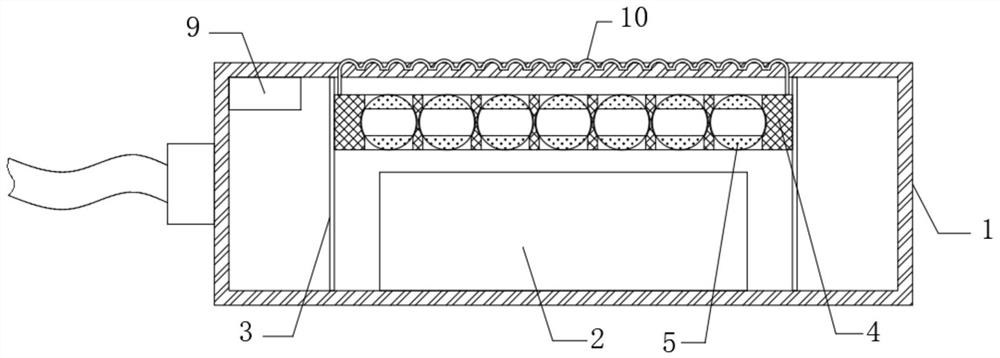

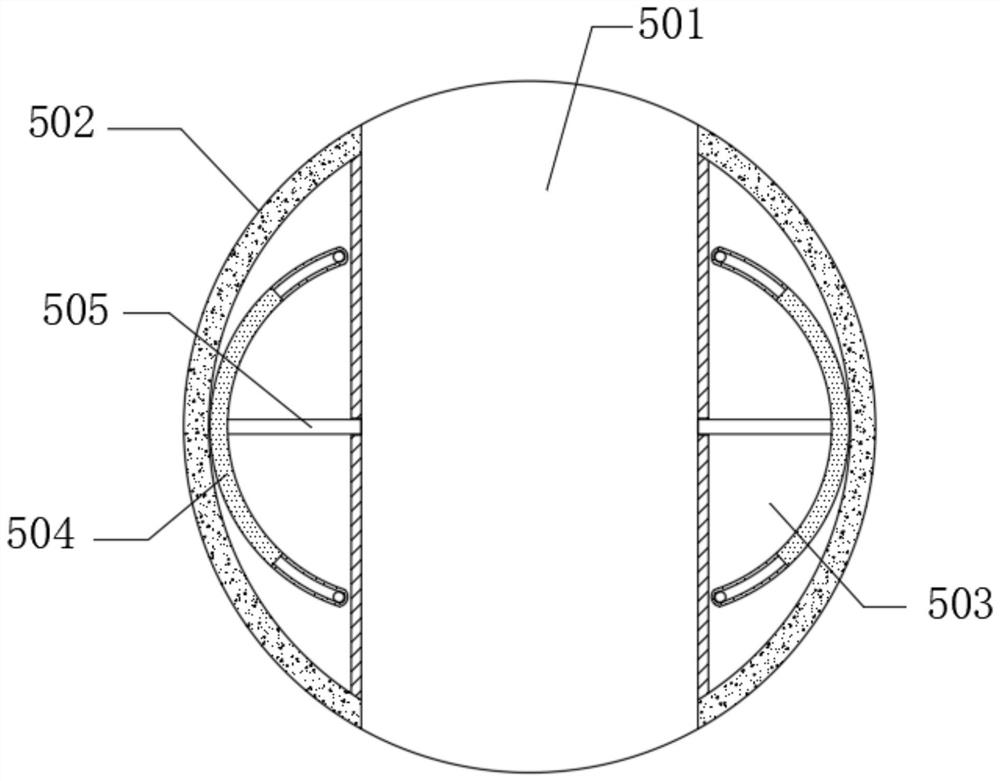

Shear mode magnetorheological elastomer frequency conversion vibration isolator

ActiveCN104895986ARealize frequency conversion vibration isolationIncrease stiffnessSpringsShock absorbersMagnetic currentElastomer

The invention discloses a shear mode magnetorheological elastomer frequency conversion vibration isolator comprising a bolt, magnetorheological elastomer, a shell, an upper cover plate, a lower cover plate, a sealing ring, a magnet, a magnet outer cover, a magnet cover plate and a spring. The bolt is fixed in the middle of the magnetorheological elastomer via a connecting nut; the magnetorheological elastomer and the shell form a magnetorheological elastomer assembly; the two ends of the shell are matched with the upper cover plate; the upper cover plate, the lower cover plate and the magnetorheological elastomer assembly form a closed space; the sealing ring, the magnet outer cover and the magnet cover plate divide the closed space into an upper cavity and a lower cavity; the magnet is installed between the magnet outer cover and the magnet cover plate; the magnet outer cover and the magnetorheological elastomer assembly are connected through the spring. Through the movement of the magnetorheological elastomer, the positions of the magnet and the magnetorheological elastomer change relatively, so that the frequency conversion and the vibration isolation under multi-frequency working state are realized.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

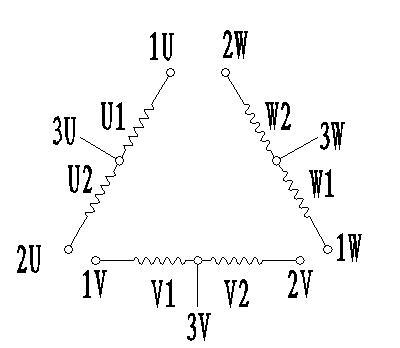

Variable frequency motor for electric vehicle and connection method for conversion windings of variable frequency motor

ActiveCN102142728AAvoid excitationIncrease the number of turnsElectric machinesWindings conductor shape/form/constructionElectric machineStator coil

The invention relates to a variable frequency motor for an electric vehicle and a connection method for conversion windings of the variable frequency motor. The variable frequency motor comprises six groups of stator coils U1, U2, V1, V2, W1 and W2, wherein an end head of the U1 is a connection terminal 1U; an end tail of the U1 is connected in series with the end head of the U2 to lead out a connection terminal 3U; the end tail of the U2 is a connection terminal 2U; the end head of the V1 is a connection terminal 1V; the end tail of the V1 is connected in series with the end head of the V2 to lead out a connection terminal 3V; the end tail of the V2 is a connection terminal 2V; the end head of the W1 is a connection terminal 1W; the end tail of the W1 is connected in series with the end head of the W2 to lead out a connection terminal 3W; the end tail of the W2 is a connection terminal 2W; when the variable frequency motor operates in a low frequency region, the stator coils are in star-like connection; when the variable frequency motor operates in a low-high transition region, the stator coils are in edge-extension triangular connection; and when the variable frequency motor operates in a high-frequency region, the stator coils are in triangular connection. By the invention, the phenomena of over-excitation in a low-frequency working condition and insufficient exertion in a high-frequency working condition are avoided.

Owner:CHANGZHOU YUCHENG FUTONG MOTOR CO LTD

Brake for Electric Motor

ActiveUS20140060980A1Reduce magnetic fluxPromote variable magnetic fluxNon-rotating vibration suppressionFilament handlingBrake torqueControl theory

A brake is provided. The brake may include a rotor having a plurality of magnets and a plurality of ferromagnetic poles radially disposed thereabout, and a stator having a plurality of shunts and a plurality of teeth radially disposed thereabout. At least one of the plurality of shunts and the plurality of teeth may be configured to selectively move between an engagement state and a free engagement state. The teeth may be configured to generate magnetic flux with the ferromagnetic poles so as to generate a braking torque during the engagement state. The shunts may be configured to redirect the magnetic flux therethrough and reduce the braking torque between the teeth and the ferromagnetic poles during the free engagement state.

Owner:OTIS ELEVATOR CO

A rotor core and an electric machine having the same

PendingCN109038897AChange fluxIncrease magnetic fluxSynchronous machine detailsMagnetic circuit rotating partsElectric machineArchitectural engineering

The invention relates to the field of electric machines, in particular to a rotor iron core and an electric machine having the same, comprising a rotor body, wherein the rotor body is provided with atleast one magnetic steel groove; The magnetic steel groove is provided with a magnetically conductive elastic member and a non-magnetically conductive elastic member; The surface between the two endsof the magnetic steel groove close to the outer side of the rotor body is an outer wall surface; The surface of the magnetic steel groove corresponding to the outer wall is an inner wall surface, thenon-magnetically conductive elastic member is arranged on the outer wall surface, and the magnetically conductive elastic member is arranged on the inner wall surface. When the rotor core rotates, the magnetically conductive elastic member and the non-magnetically conductive elastic member can change the position of the magnetic steel in the magnetic steel groove, thereby regulating the magneticflux of the rotor core.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Deceleration buffer magnetic shield rotating shaft

InactiveCN104235167AReduce weightIncreased ventilation issuesShaftsFluid actuated drum brakesEngineeringMagnetic shield

The invention relates to a deceleration buffer magnetic shield rotating shaft which comprises a rotating shaft body arranged at the axis position of a rotor, narrow iron plates, wide iron plates, a casing and a buffer seat, wherein the narrow iron plates and the wide iron plates are uniformly distributed on the surface of the rotating shaft body in the axial direction of the rotating shaft body at equal intervals; a magnetic shield bushing and a fixing sleeve are arranged between every two adjacent iron plates; a wind flowing plate is arranged on the outer side of each fixing sleeve; a key groove is formed in the tail end of each wide iron plate; a through hole and a through groove are respectively formed in the side face of each iron plate; a bump is arranged on the rotating shaft body; the casing is arranged on the outer side of the bump; the buffer seat is arranged at an inlet of the casing; symmetrical springs are arranged between an elastic sleeve between the buffer seat and the bump and the buffer seat; a friction piece is arranged on the elastic sleeve; a buffer tube is arranged in the buffer seat. A motor rotating shaft disclosed by the invention has the advantages of reduced integral weight, low energy consumption, good heat radiating performance and low work load; the rotating shaft is not easy to damage, so the maintenance cost is low and the service life is long.

Owner:NINGBO JIECHENG AXLE TRADE

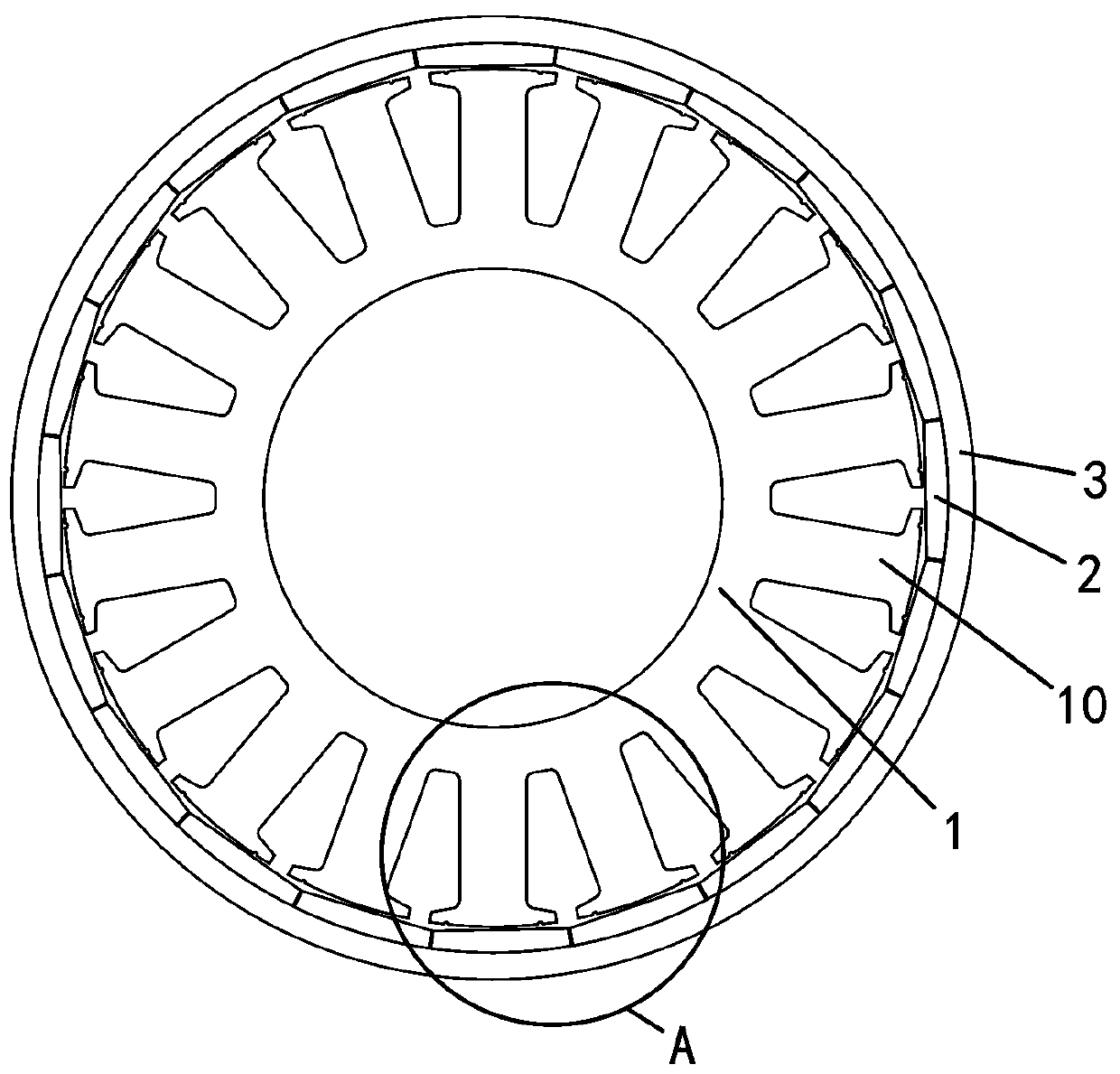

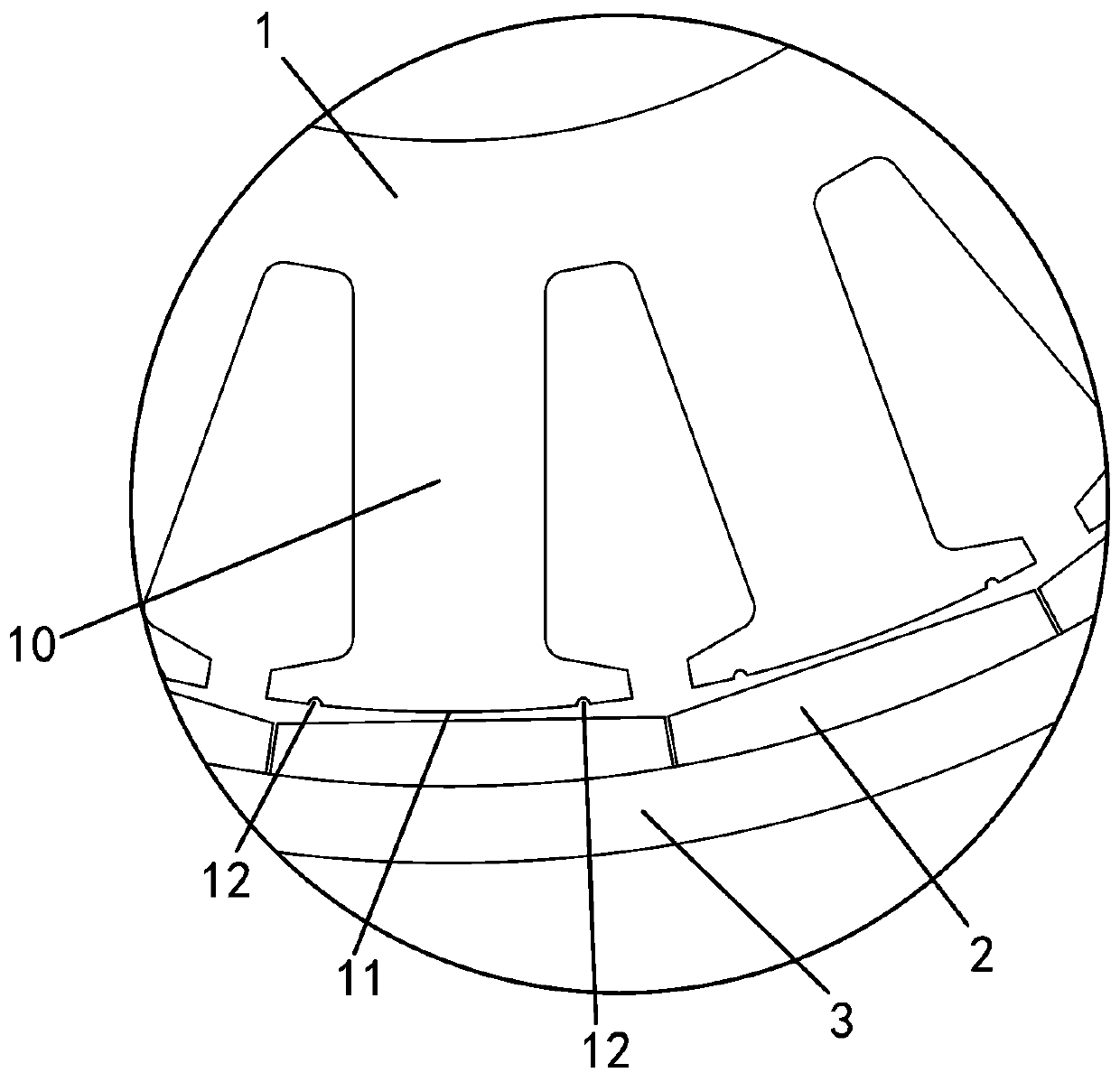

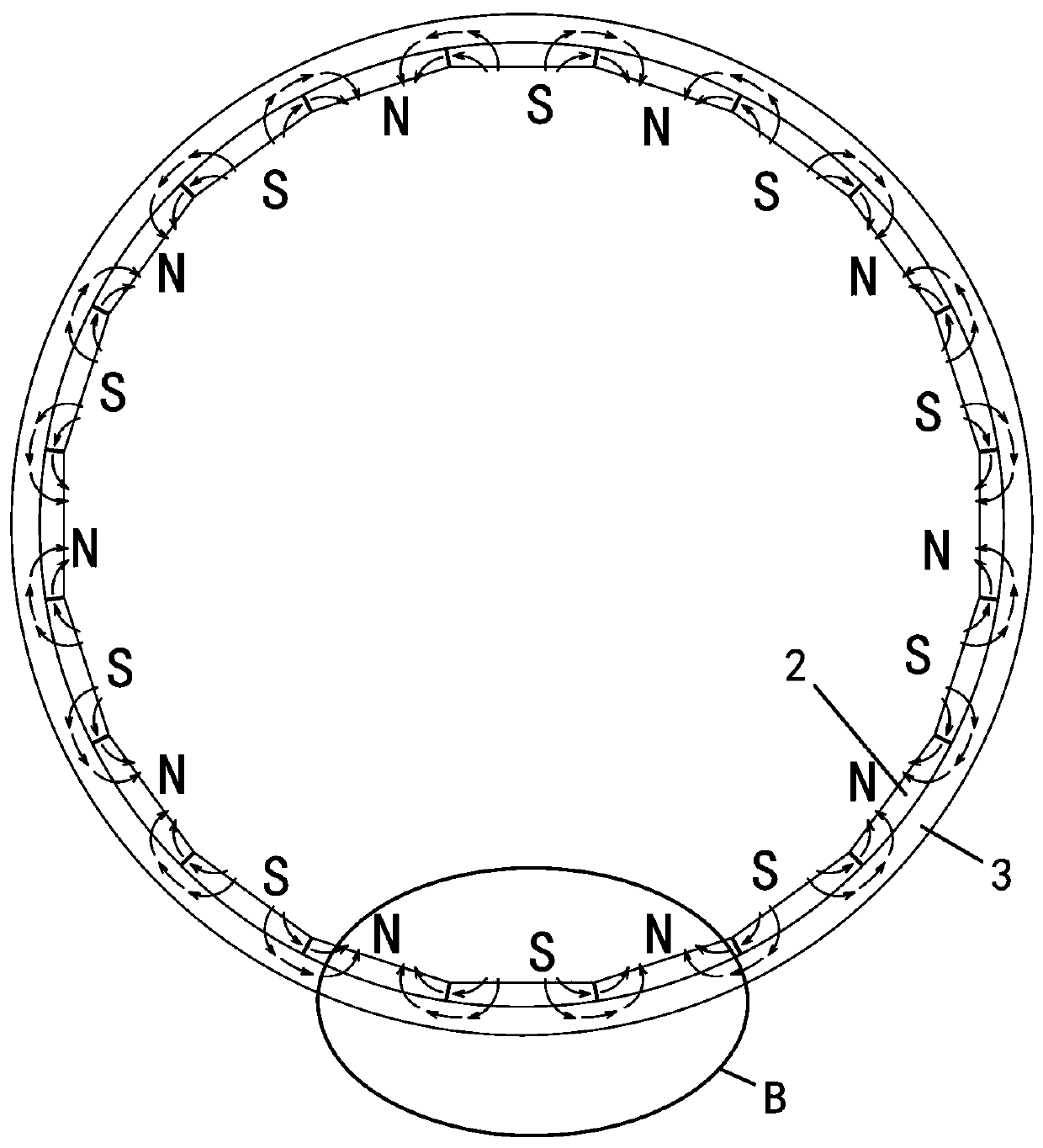

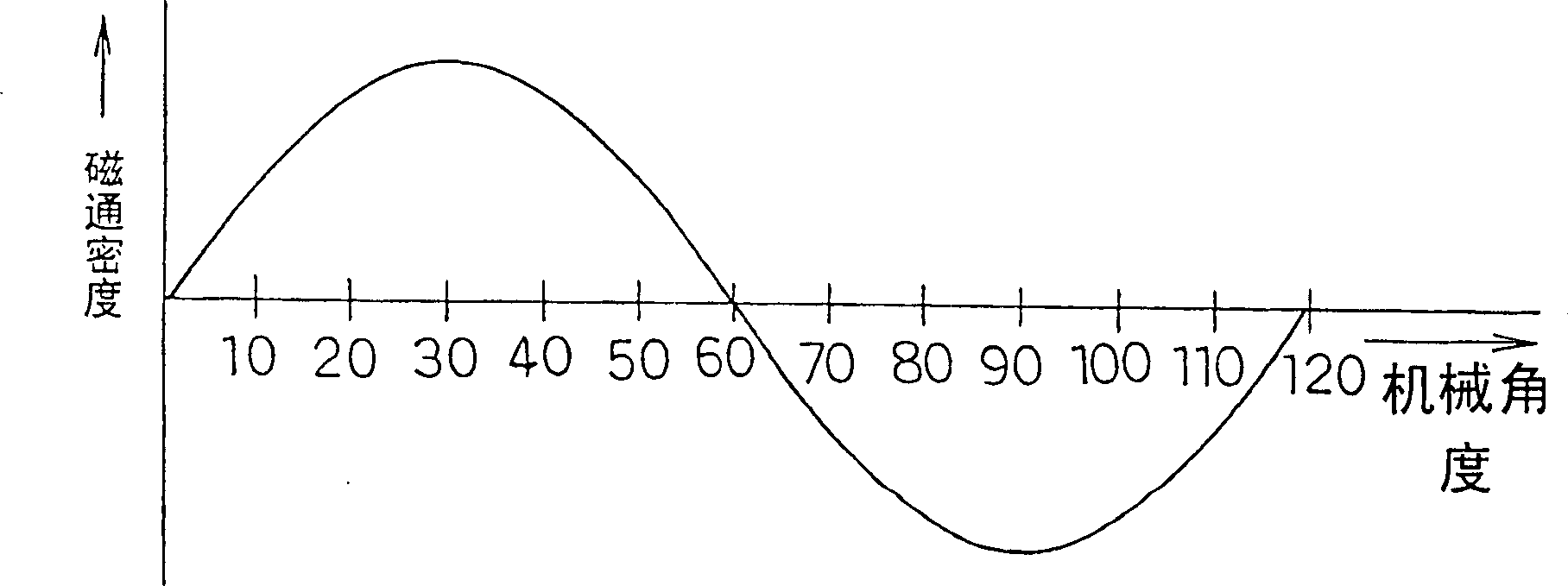

External rotor motor and permanent magnet magnetizing method

PendingCN110445337AReduce material requirementsImprove power densityMagnetic bodiesMagnetic circuit stationary partsRotor magnetsPunching

The invention discloses an external rotor motor. The external rotor motor comprises a stator formed by stacking stator punching sheets, permanent magnets and a rotor magnet yoke, wherein the permanentmagnets are the ones with non-uniform thickness; the plurality of permanent magnets are uniformly annularly arranged on the inner side surface of the rotor magnet yoke; the stator punching sheets areplaced on the inner sides of the permanent magnets; the permanent magnets with non-uniform thickness are magnetized in an unequal-diameter magnetizing manner; the permanent magnets with non-uniform thickness provides magnetic flows as well as magnetic circuits. The external rotor motor is reasonable in design; the permanent magnets with non-uniform thickness are magnetized in the unequal-diametermagnetizing manner, so that the magnetic flows are concentrated at the center of magnetic poles, the closed magnetic circuit is formed between the adjacent permanent magnets with non-uniform thickness, the magnetic flux passing through the closed rotor magnet yoke is reduced, and thus higher power can be output under a same size, the power density of the motor is improved, and the requirement onthe material of the rotor magnet yoke is also reduced.

Owner:KINETEK DE SHENG SHUNDE MOTOR CO LTD

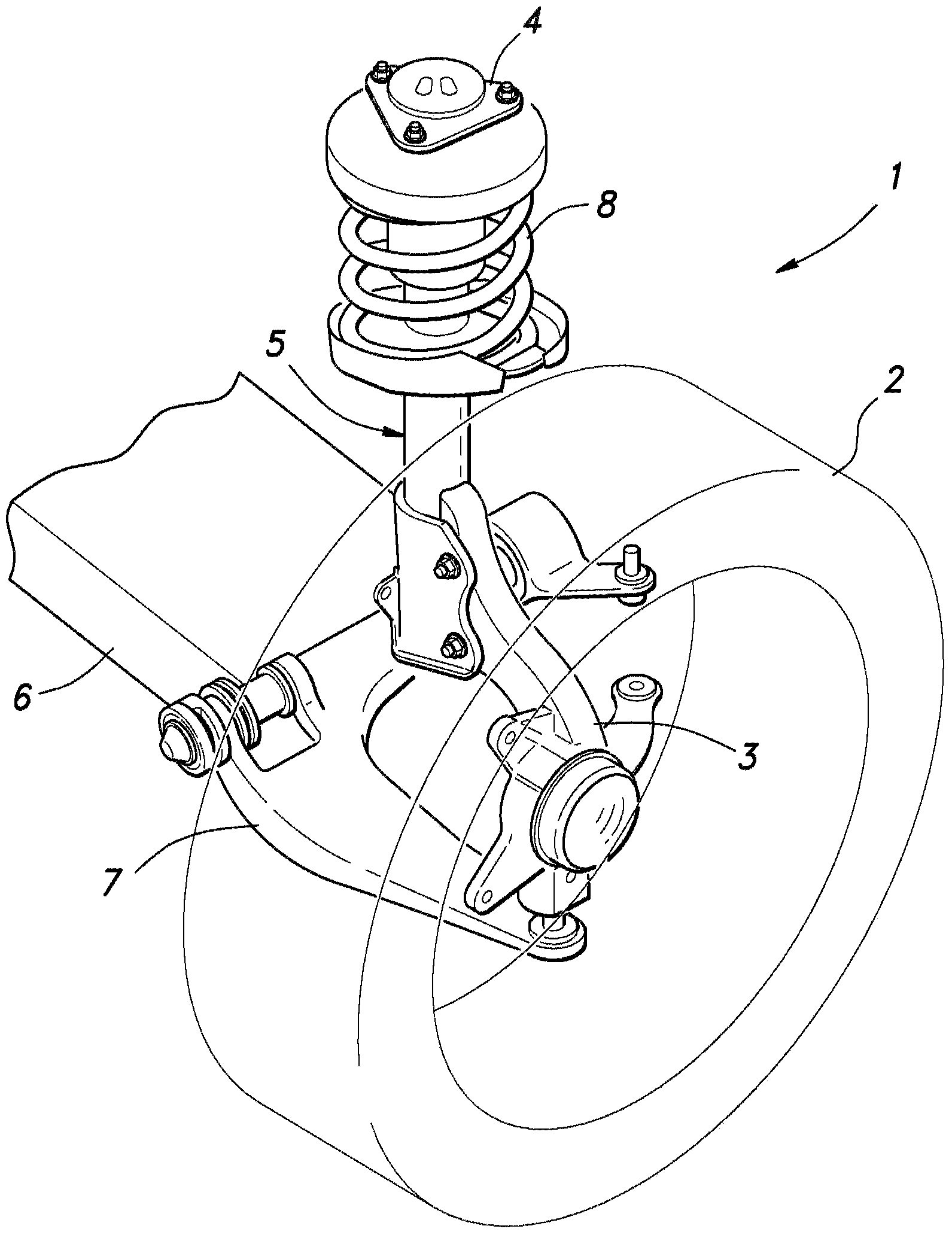

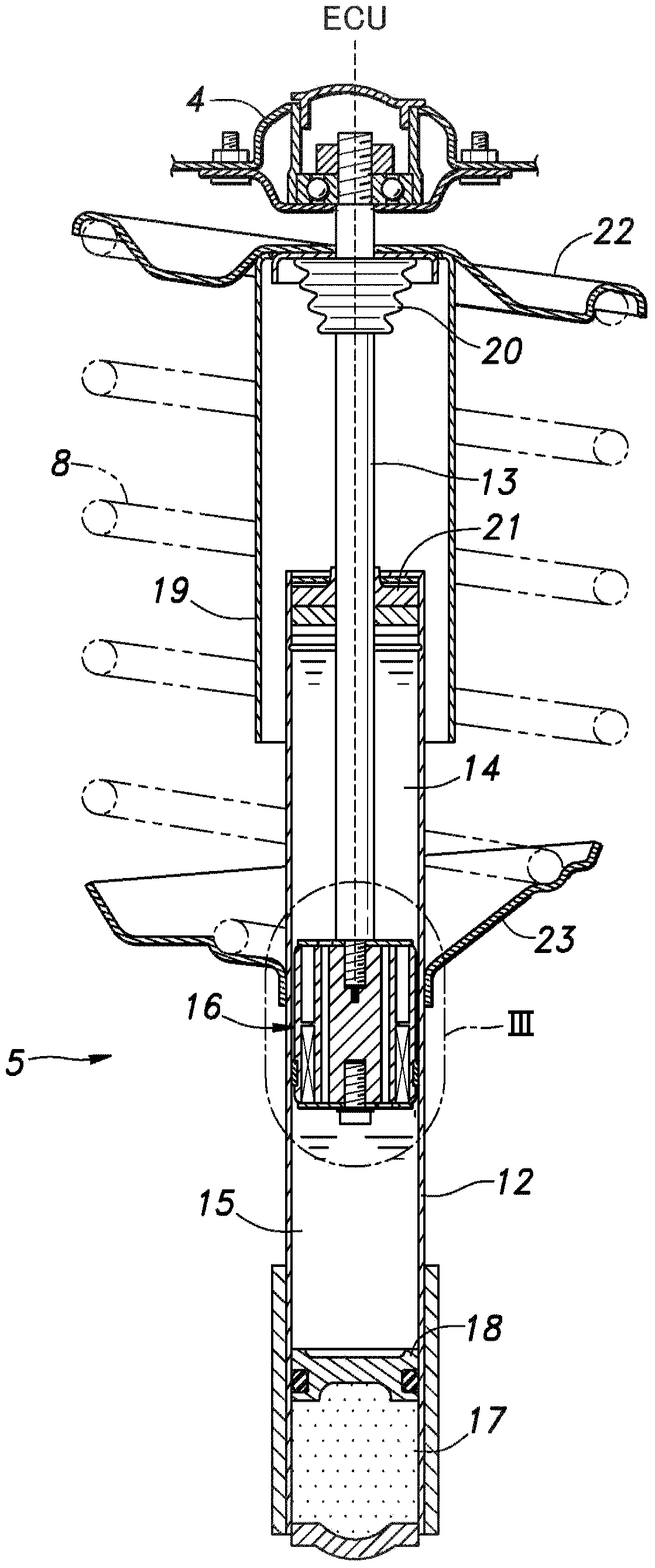

Variable damper

InactiveCN103765036AAvoid deformationConstrained Relative DisplacementSpringsLiquid based dampersDie castingEngineering

[Problem] To provide a solenoid-type variable damper that improves piston strength and prevents disconnection of the electromagnetic coil, and the like. [Solution] A piston (16) comprises a piston body (30), an expansion-side valve plate (41), a contraction-side valve plate (42), an electromagnetic coil (43), and a bolt (44). The piston body (30) is cast as a single piece and is manufactured through a powder metallurgy method, a die casting method, or the like, using a ferrite-based or other ferromagnetic material as a raw material, and comprises a cylindrical outer yoke (31) that is in slidable contact with the inner periphery of a cylinder (12); a columnar inner yoke (34), the outer periphery of which faces the inner periphery of the outer yoke (31) across first and second gaps (32, 33); and a connecting section (35) in the central part in the axial direction of the piston (16), which connects the outer yoke (31) and the inner yoke (34) and divides the first and second gaps (32, 33) from each other. The electromagnetic coil (43) is fit into the second gap (33) of the piston body (30).

Owner:HONDA MOTOR CO LTD

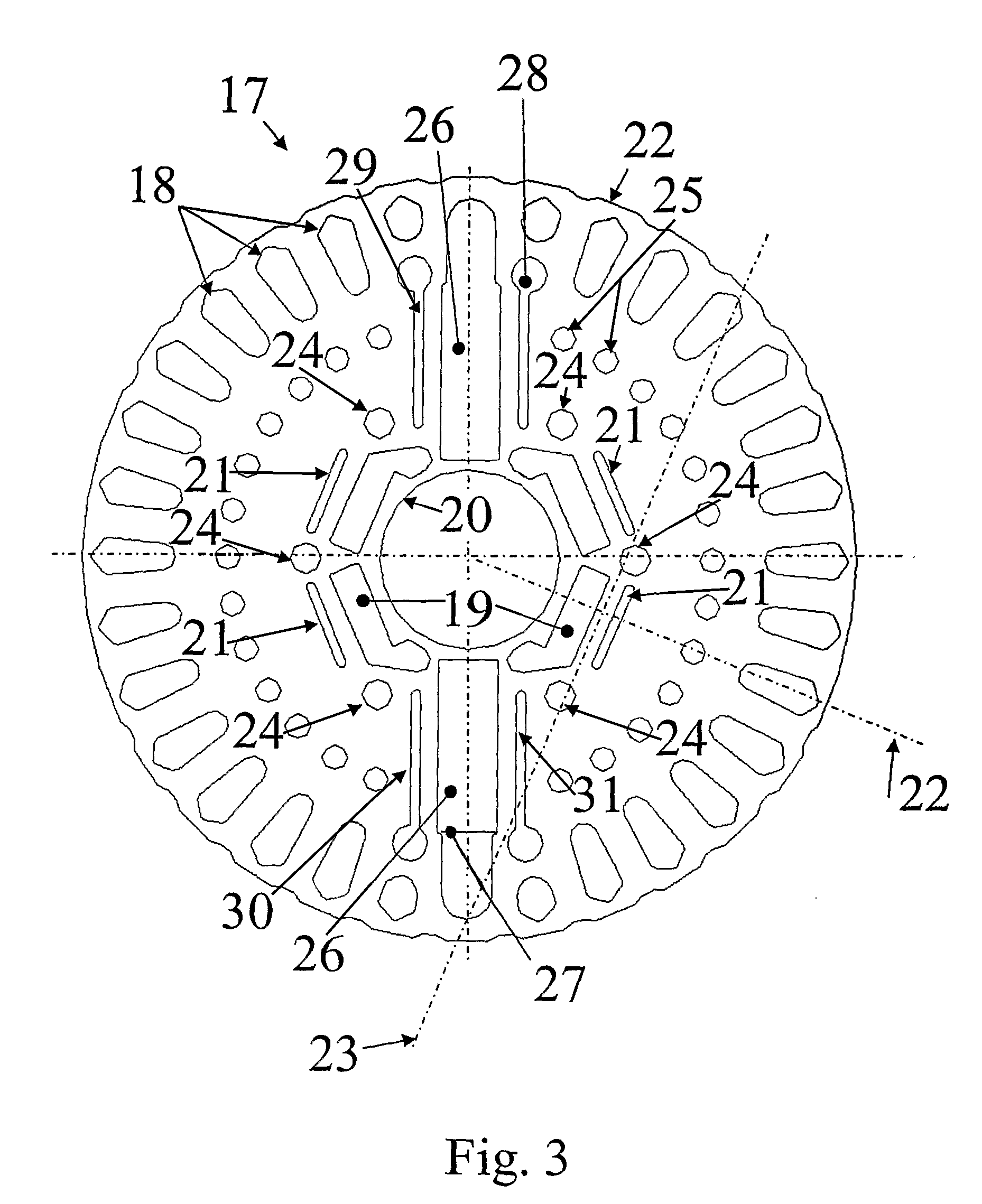

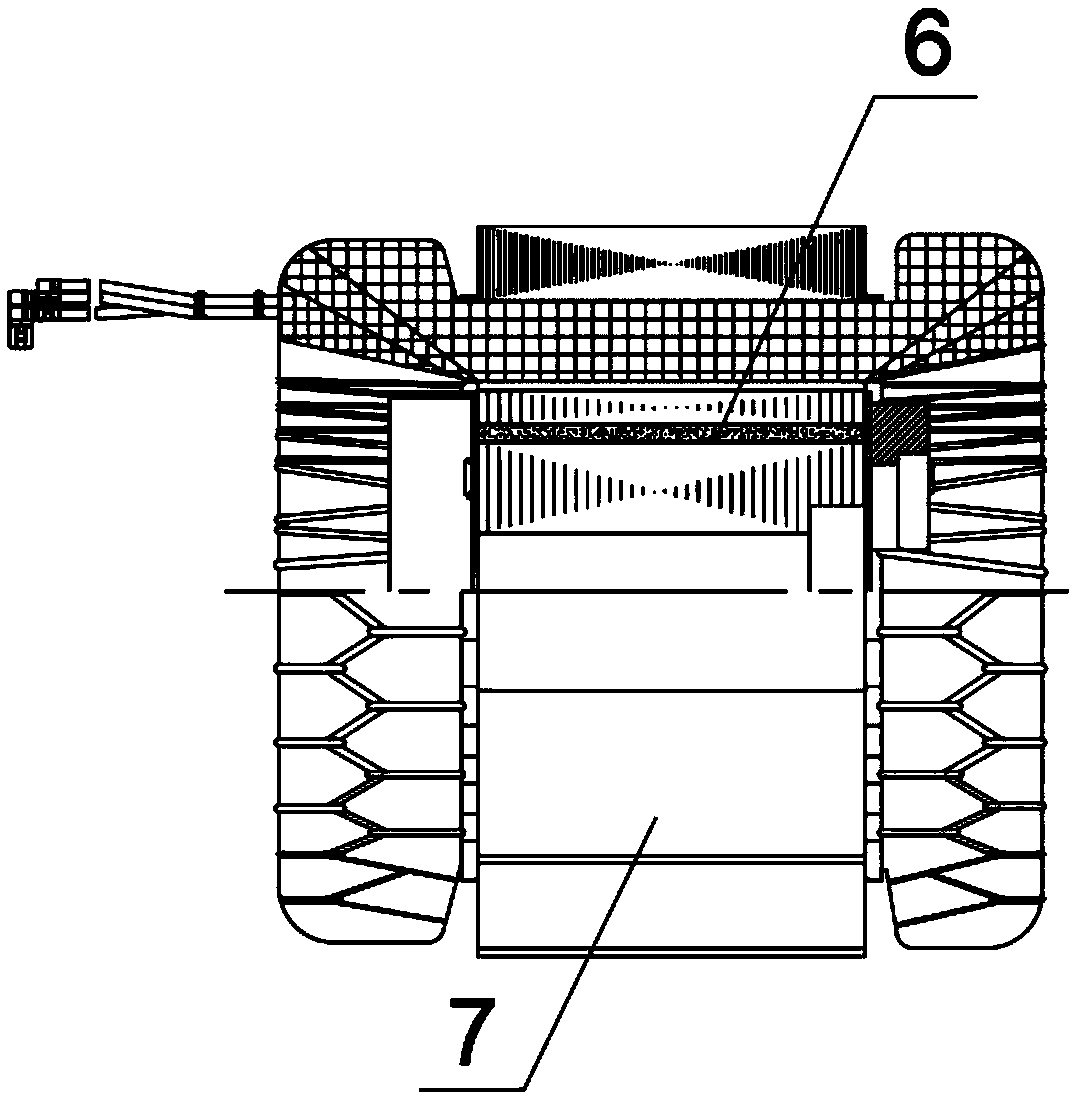

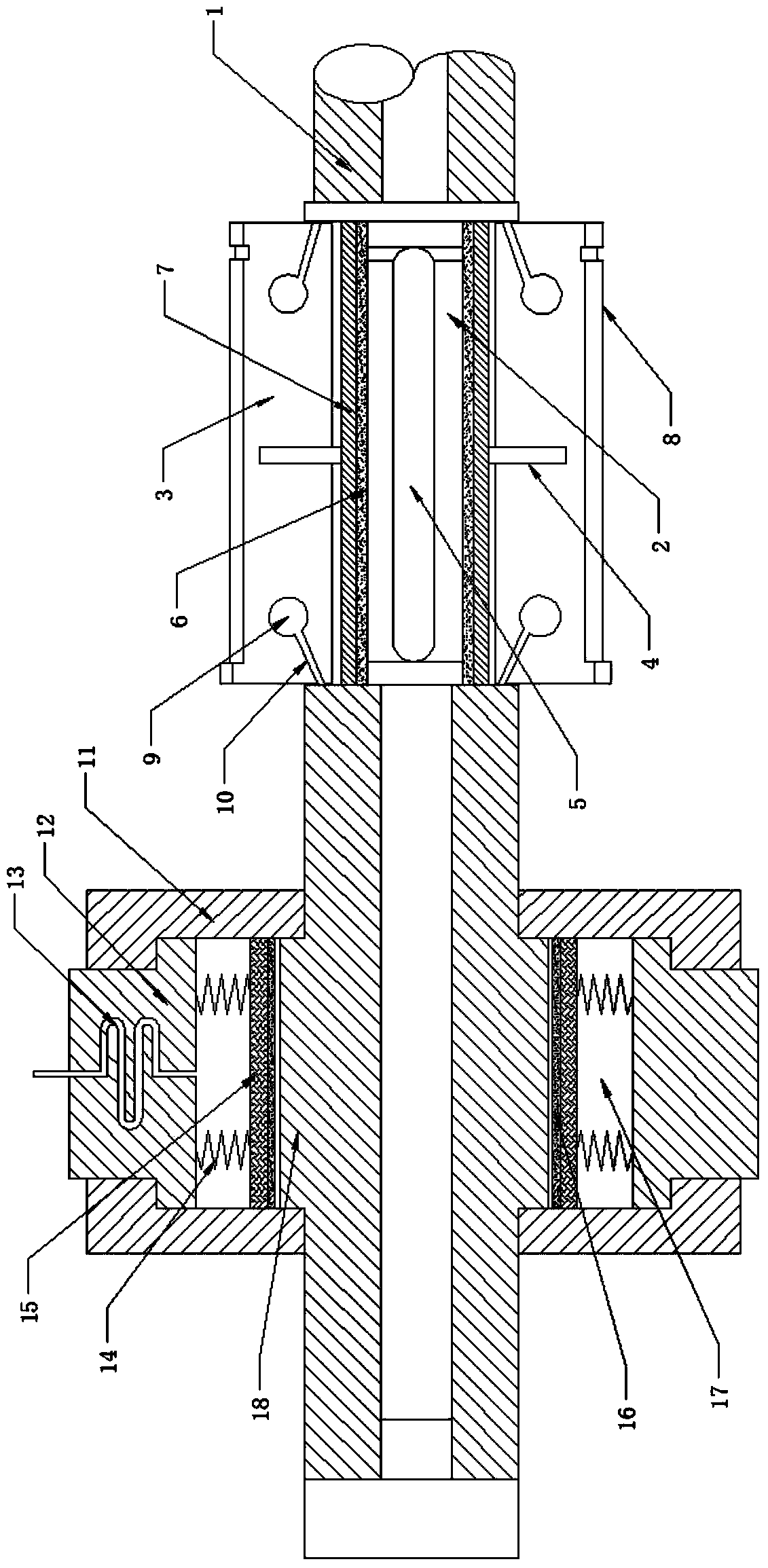

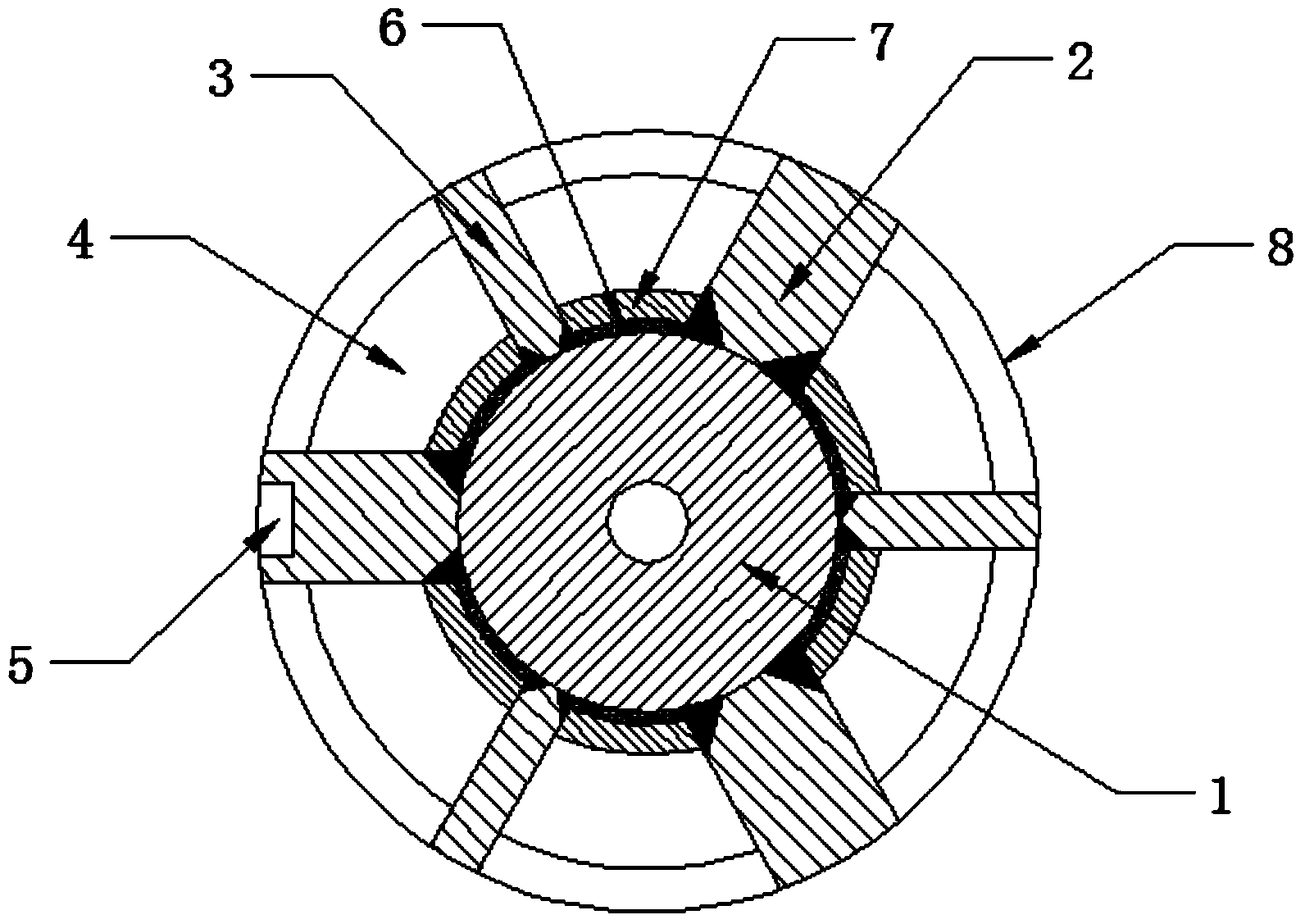

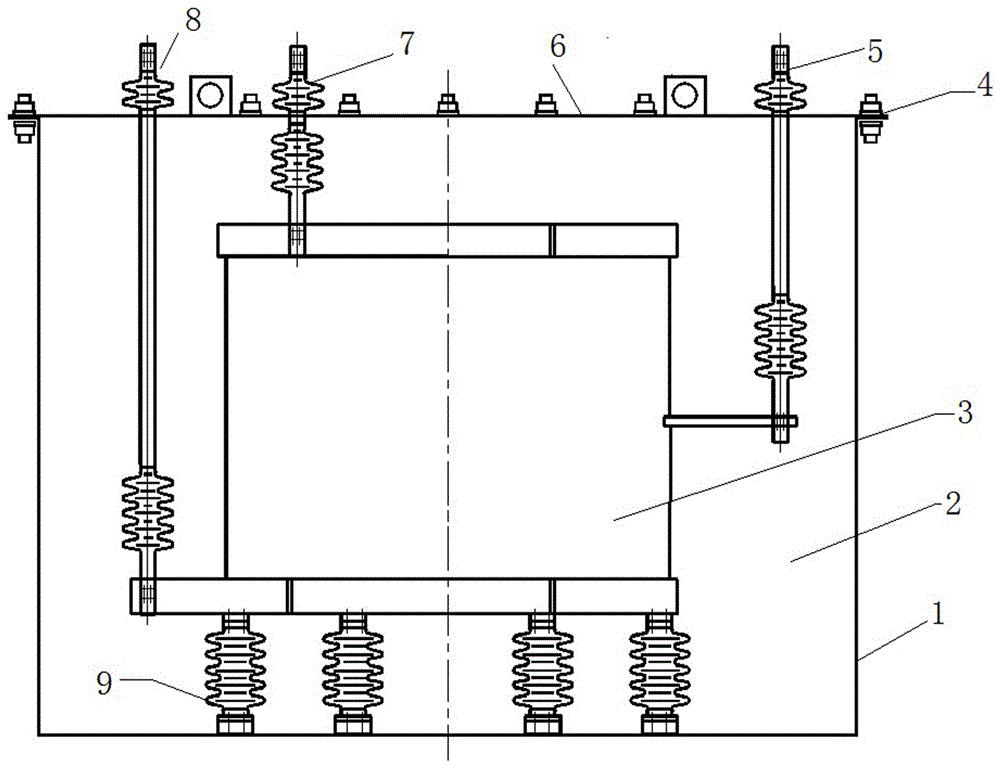

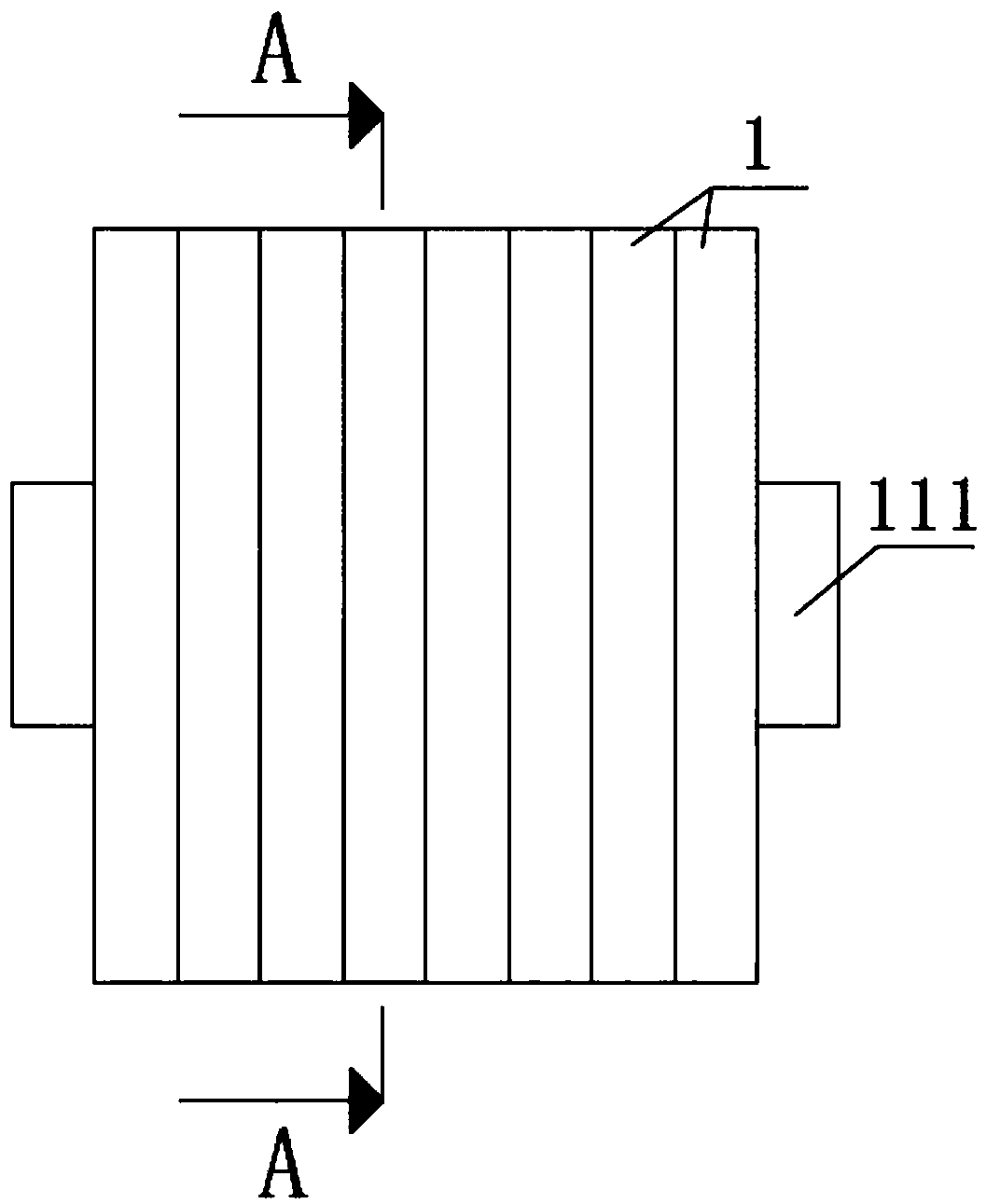

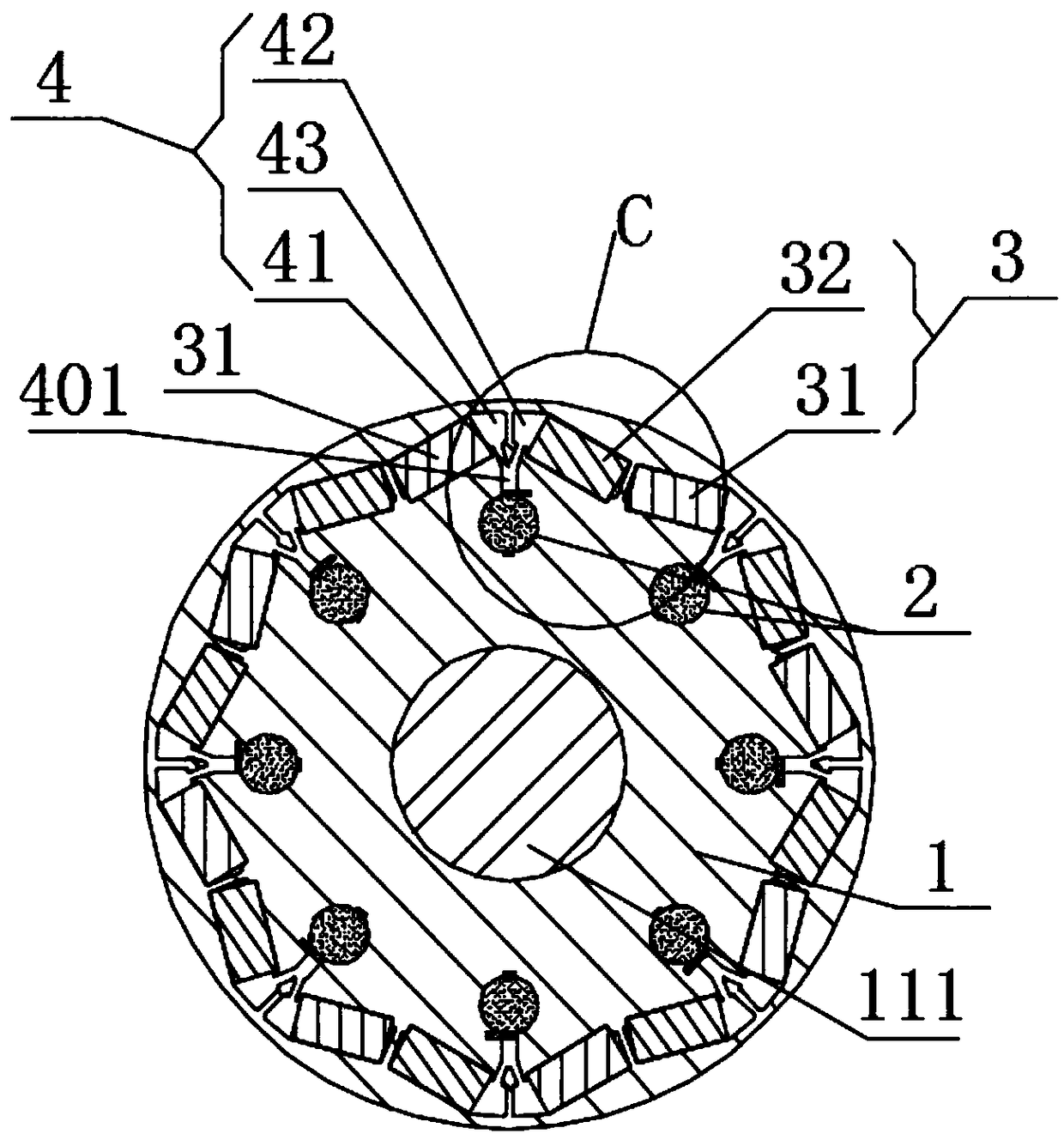

A torque adaptive continuously variable permanent magnet inner rotor brushless motor

ActiveCN104979991BLow costReduce magnetic fluxMagnetic circuit rotating partsStructural associationBrushless motorsElectric machine

The invention discloses a permanent magnet inner rotor brushless motor capable of continuously changing speed adaptively according to torque changes. The permanent magnet inner rotor brushless motor comprises an electric motor shaft, a rotor, a stator, a machine enclosure, an end cap and the like. The permanent magnet inner rotor brushless motor is characterized in that a mechanism capable of automatically adapting to torque changes to regulate magnetic flux size is arranged on the inner part of the rotor, wherein the mechanism is mainly composed of a spring measurement and control system and a spiral transmission pair; torque generated by stator current in rotator magnetic fields can be converted into axial component force in proportion, so that the stator carries out screw-feeding motion on the motor shaft, and therefore, the axial position, relative to the rotor, of the stator is changed; air gap magnetic flux is changed into a torque function from the original constant, so that the rotation speed is changed in an inversely proportional mode with the torque; and the output power is kept unchanged all the time, so that the brushless motor has self-adapted equal-power infinite variable speed characteristics according to multiple gear ratios. The permanent magnet inner rotor brushless motor realizes direct torque control effect by virtue of a simple and reliable method.

Owner:重庆西伟迪磁电动力科技有限公司

Switching device comprising an electromagnetic arc driving mechanism

ActiveCN105745728AEnhanced magnetic forceGrow fastElectric switchesEngineeringElectrical and Electronics engineering

The invention relates to a switching device comprising an electromagnetic arc driving mechanism and an arcing chamber that includes a stationary switching piece (1) and an opposite movable switching piece (4). The invention is characterized in that the electromagnetic arc driving mechanism is embodied in the form of a metal sheet (8) that is placed around the stationary switching piece (1).

Owner:SIEMENS AG

A mobile phone wireless charger with an overcharge protection device

ActiveCN112350447BSmall currentAvoid feverCircuit arrangementsModifications by conduction heat transferMobile phoneBattery cell

The invention discloses a mobile phone wireless charger with an overcharge protection device, which belongs to the field of mobile phone chargers. A mobile phone wireless charger with an overcharge protection device includes a wireless charger body, and a wireless charger body is installed on the bottom of the wireless charger body. Coil, the inner wall of the wireless charger body is fixedly connected with a support plate, and the coil is located inside the support plate, and the inner wall of the support plate above the coil is fixedly connected with a mounting plate, which sends signals to the wireless charger through the mobile phone battery overcharge protection board , so that the gear rotates 90°, and then the through hole rotates to block the magnetic induction line, so that the mobile phone will not generate current, thereby protecting the battery of the mobile phone. At the same time, if the mobile phone is seriously heated during charging, the heat will make the memory metal The sheet changes from a curved phase state to a vertical phase state, so that the control board is pushed into the through hole to reduce the magnetic flux, which can reduce the current in the mobile phone, slow down the charging speed, and protect the overcharge at the same time. Realized overheating protection.

Owner:SHENZHEN WIRELESS TECH CO LTD

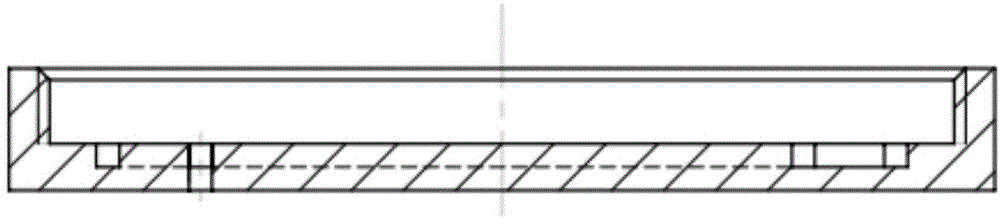

Oil-immersed type split reactor

InactiveCN106449067ASpecific heatReduce generationTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringTransformer oil

The invention discloses an oil-immersed type split reactor. The oil-immersed type split reactor comprises a coil which is formed by a first winding and a second winding which are arranged coaxially, all envelopes of the first winding and all envelopes of the second winding are sequentially arranged in a crossed mode from inside to outside, the odd layers of the envelopes of the coil form the first winding, and the even layers of the envelopes of the coil form the second winding; the oil-immersed type split reactor further comprises a closed shell which is provided with an oil cavity used for containing transformer oil, and the coil is located in the oil cavity. According to the oil-immersed type split reactor, the transformer oil replaces air to serve as a magnetic flux medium, the insulating strength of the transformer oil is much higher than that of air, magnetic flux can be effectively reduced, and higher voltage can be borne. The transformer oil is high in specific heat, often serves as a cooling agent and is beneficial to heat dissipation of the coil.

Owner:XUJI GRP +2

Rotor with automatic flux weakening structure and permanent magnet motor

PendingCN109450137AEasy to controlImprove efficiencyMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention relates to the technical field of a permanent magnet motor, and particularly relates to a rotor with an automatic flux weakening structure and a permanent magnet motor. The rotor comprises a plurality of permanent magnet installation rotary table units overlaid sequentially; each permanent magnet installation rotary table unit is provided with a plurality of permanent magnet insertion through holes and a magnetic conductive powder accommodation cavity; each two adjacent permanent magnet insertion through holes are communicated by a magnetic conductive powder compensation passage;each magnetic conductive powder compensation passage is communicated with the magnetic conductive powder accommodation cavity and a critical switching valve is arranged at the joint; when the rotor rotates at a high speed, the magnetic conductive powder compensation passages are communicated with the magnetic conductive powder accommodation cavity, a leakage magnetic flux is increased, and a magnetic flux passing through an air gap is reduced, so as to implement flux weakening; the rotating speed is reduced, a centrifugal force applying to magnetic conductive powder is gradually reduced, andwhen the magnetic conductive powder compensation passages move to the highest point, the magnetic conductive powder is returned to the magnetic conductive powder accommodation cavity and a value of the magnetic flux passing through the air gap is returned to a normal state; and the automatic flux weakening and speed expansion are implemented, the rotor and the permanent magnet motor are easy for motor control, and meanwhile, motor efficiency and a power density can be improved.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

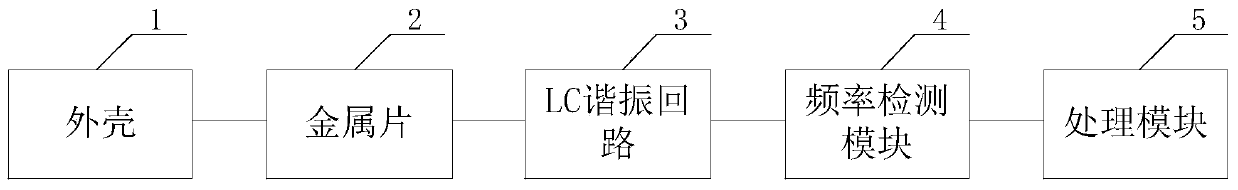

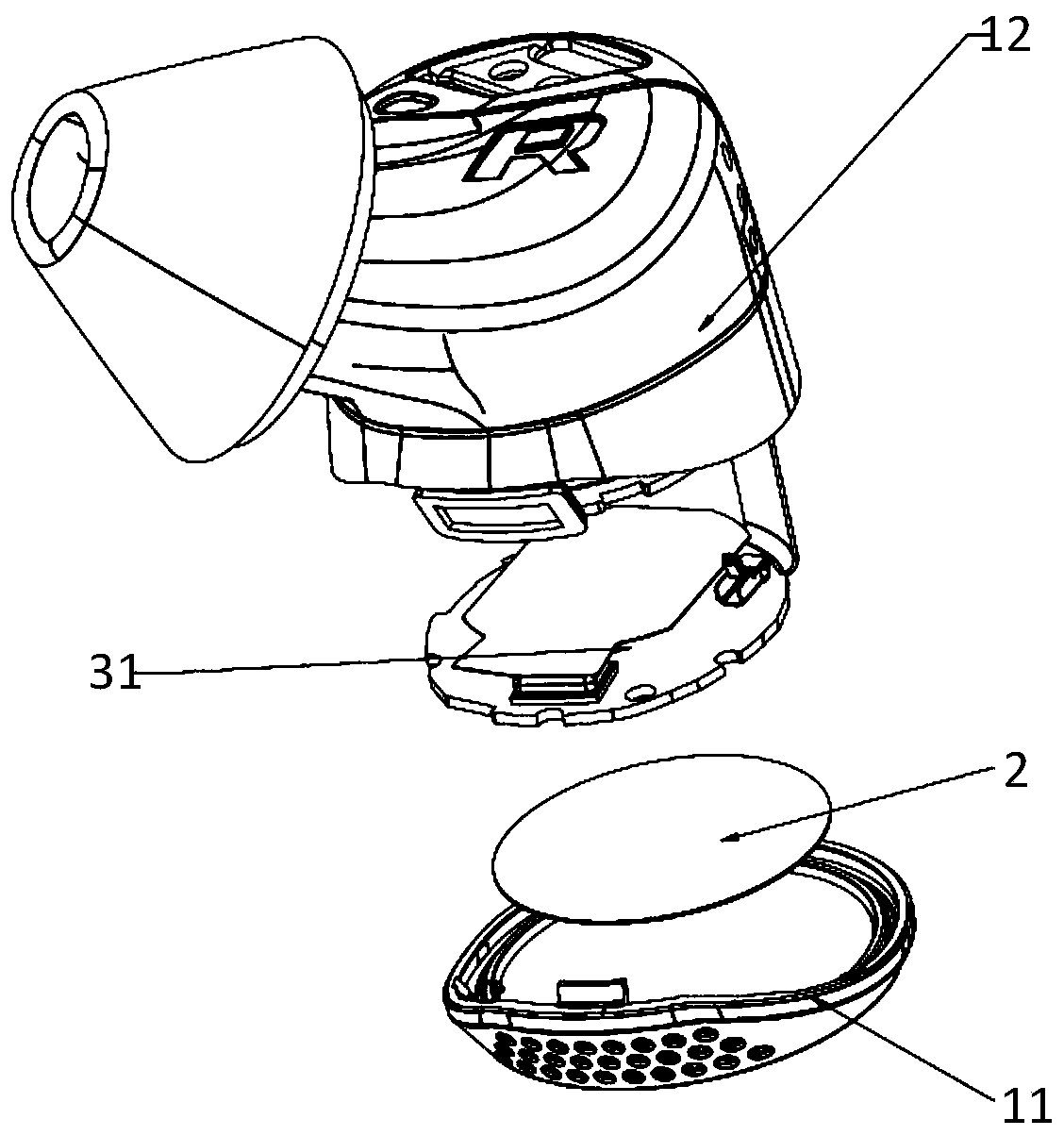

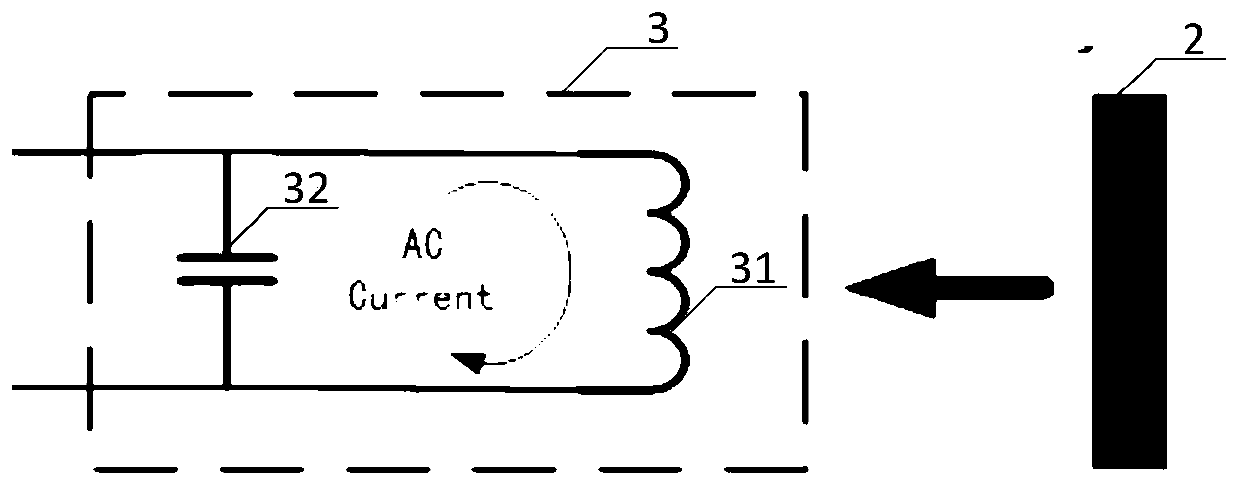

Electronic equipment

The invention discloses electronic equipment. Electromagnetic induction principle, the LC resonance circuit resonates at a fixed resonance frequency and generates a magnetic field when the key is notpressed; press key, the metal sheet generates a magnetic field which is mutually exclusive to the magnetic field under the action of the magnetic field; when the key is pressed, the magnetic flux of the magnetic field of the LC resonance circuit passing through the inductance coil is equivalently reduced, the inductance value of the inductor is reduced, the resonance frequency of the LC resonancecircuit is increased finally, and finally, whether the key is pressed or not can be determined based on the resonance frequency of the LC resonance circuit. Compared with a mechanical key in the priorart, the key is simple in structure, the metal sheet can deform through the key with small force, key pressing is further detected, the key provides the hand feeling of the mechanical key, and in addition, the situation of false triggering is not likely to happen.

Owner:GEER TECH CO LTD

Systems and methods for an electromagnetic actuator

ActiveUS20170271115A1Reduce magnetic fluxLess amp-turnsRelay bases/casings/coversMagnetsEngineeringPole piece

An electromagnetic actuator having a permanent magnet coupled to an armature of the electromagnetic actuator is provided. The electromagnetic actuator includes a housing, a pole piece arranged within the housing and secured by an end plate, and an armature assembly having an armature and a permanent magnet coupled to the armature. The armature is movable between a first position and a second position. The electromagnetic actuator further includes a wire coil positioned around the armature assembly and arranged within the housing. An actuation position of the armature between the first position and the second position is proportional to a magnitude of current applied to the wire coil.

Owner:HUSCO AUTOMOTIVE HLDG

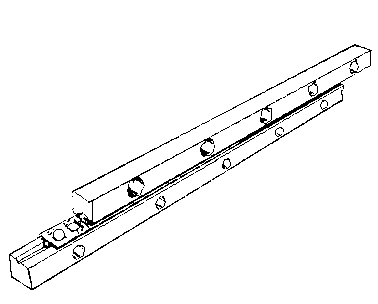

Surface induction hardening inductor for V-shaped roller cross linear guide rail

ActiveCN102560016BReduce hardnessReduced processing performanceFurnace typesIncreasing energy efficiencyElectrical conductorEngineering

The invention discloses a surface induction hardening inductor for a V-shaped roller cross linear guide rail, which comprises an inducing conductor, a magnetizer and a fixing piece, wherein the inducing conductor made of a hollow copper tube adopts a door-type structure adapting to the cross section of the V-shaped roller cross linear guide rail; the magnetizer adapting to a V-shaped raceway surface of the V-shaped roller cross linear guide rail is arranged on the inducing conductor; and the fixing piece is arranged on the inducing conductor. The surface induction hardening inductor can achieve surface induction heating on the raceway surface and the bottom surface of the guide rail at the same time under different temperatures, different surface hardness and different hardening layer depths, ensures that a hardening layer with high hardness and high strength is formed on the raceway surface and the hardening layer has the bottom surface with certain hardness at the same time, and satisfies the requirements of quenching deformation of the guiding rail and the mounting hole processing.

Owner:NANJING TECHN EQUIP MFG

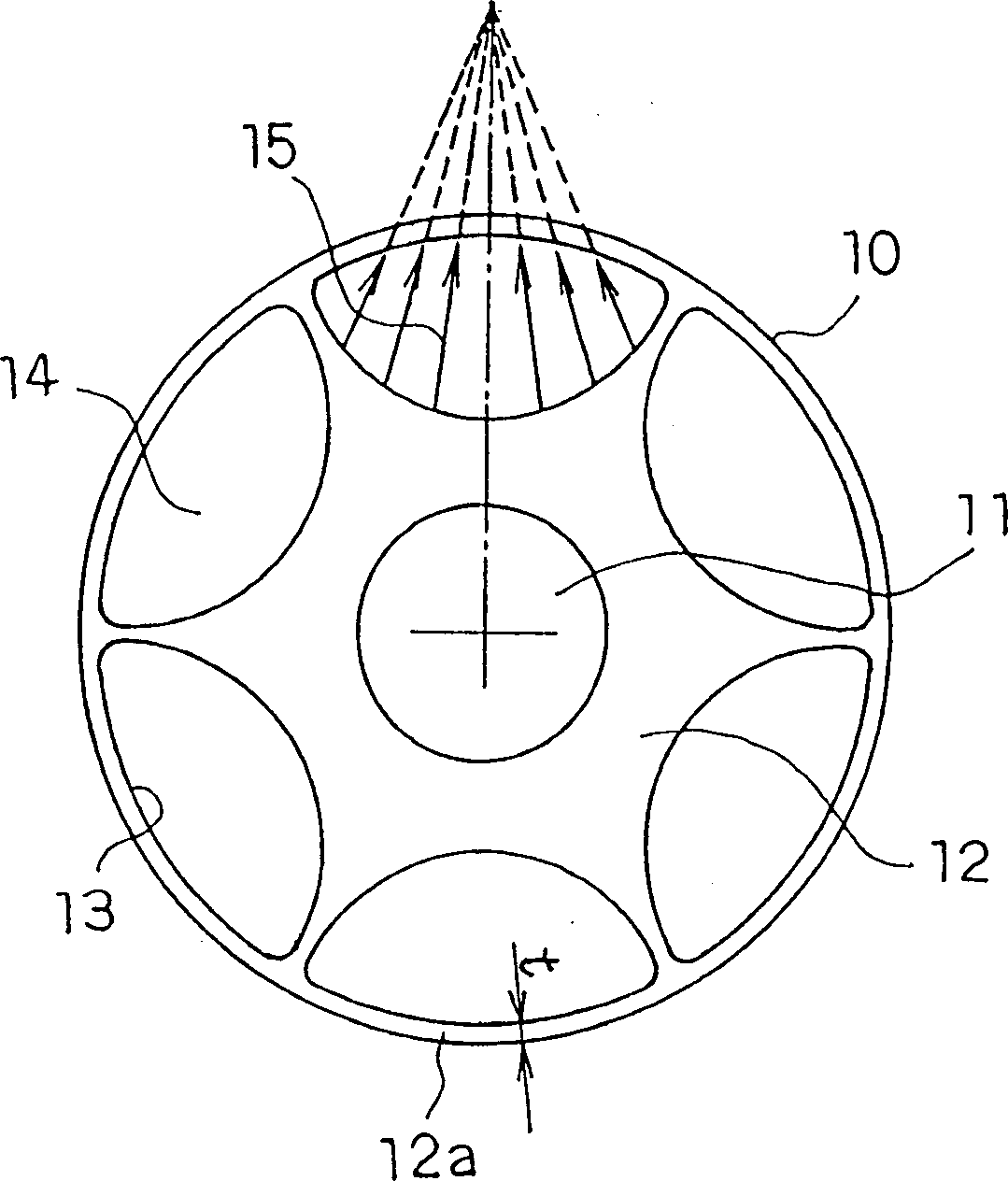

Permanent magnet type motor and method of producing permanent magnetic type motor

InactiveCN1251382CTorque variation does not increaseLow elimination efficiencyMagnetic circuit rotating partsMagnetic polesMulti phase

A permanent magnet type motor with a permanent magnet, capable of reducing vibration and noise without lowering the motor efficiency, which comprises a stator (1) having multi-phase stator windings, and a rotor (10) disposed inside the stator in opposed relation through air gaps, and having a stator core (12) and permanent magnets (14) installed in the stator core, wherein the permanent magnets (14) are so shaped that their section at right angles with the axis of rotation is convexed on both inner and outer diameter sides and that the focus of magnetism orientation in each magnet pole of the permanent magnet (14) is disposed outside the rotor (10).

Owner:MITSUBISHI ELECTRIC CORP

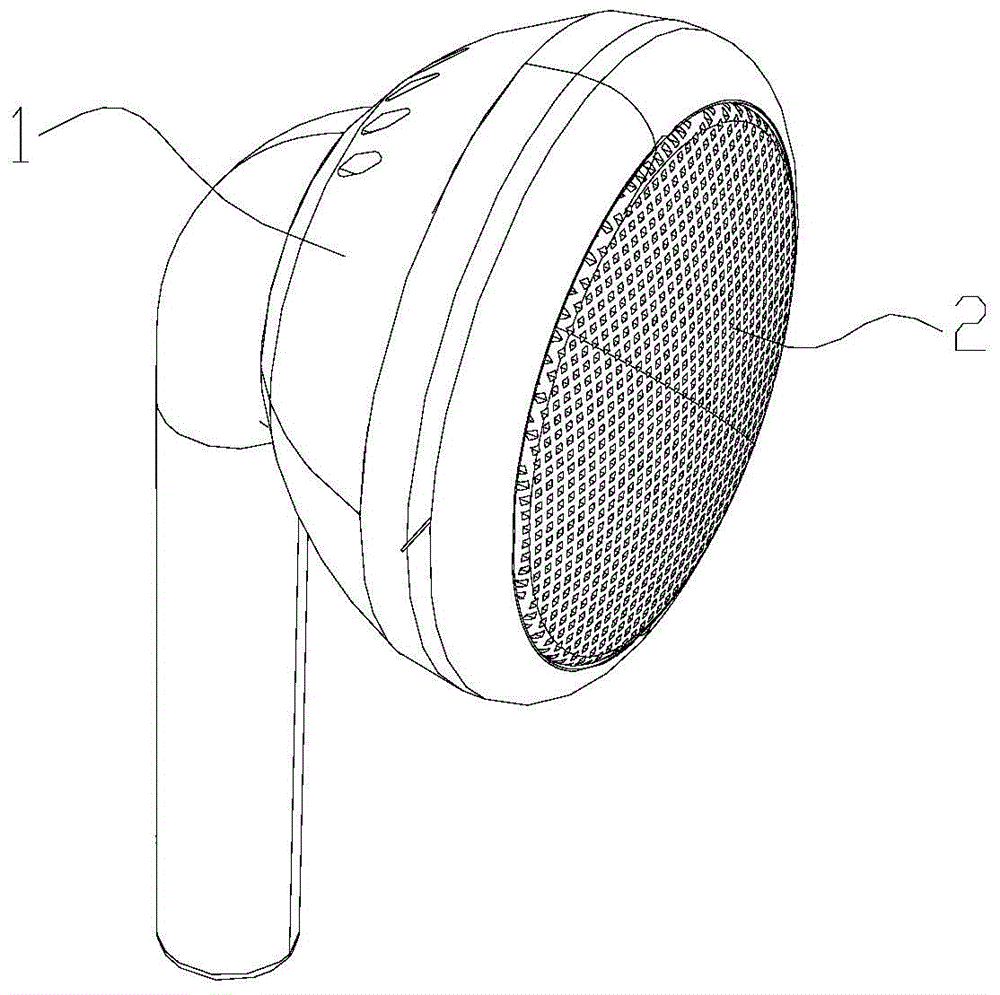

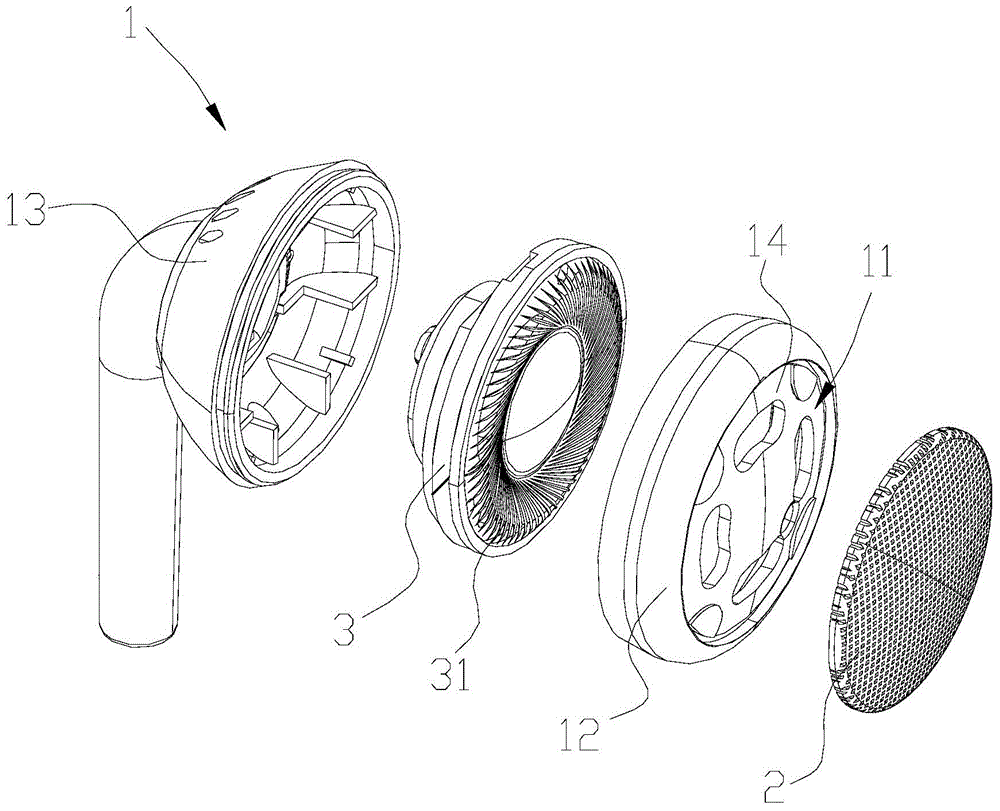

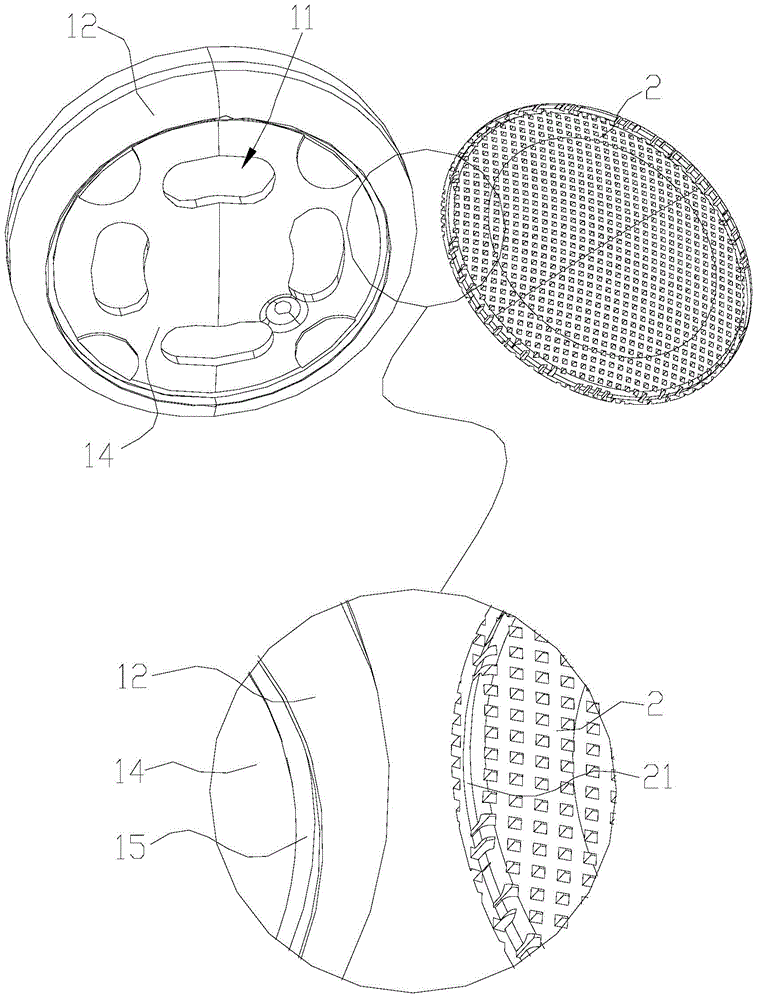

Headset

InactiveCN105208481AReduce magnetic fluxLess attractiveEarpiece/earphone attachmentsSound qualityEngineering

The embodiment of the invention provides a headset and belongs to the field of electronic equipment. The headset comprises a shell and a net cover which are arranged in a split mode. A sound outlet is formed in the shell. The net cover covers the sound outlet. The net cover is made of magnetic shielding materials. A loudspeaker assembly is arranged in the shell and provided with a magnetic circuit unit. According to the headset, the net cover and the shell are arranged in the split mode, and the net cover covers the sound outlet of the shell; due to the fact that the net cover is made of the magnetic shielding materials, the outward-radiation magnetic flux of the magnetic circuit unit of the loudspeaker assembly can be reduced, the magnetic flux on the periphery of the net cover is greatly reduced, the attraction force of the magnetic circuit unit to external ferromagnetic substances is effectively weakened, the phenomenon that the ferromagnetic substances are attracted into a vibration film of the loudspeaker assembly through the net cover and the sound outlet is avoided, and it is ensured that the sound quality effect of the headset is not affected and the service life of the headset is prolonged.

Owner:VIVO MOBILE COMM CO LTD

An axial magnetic field permanent magnet motor combined magnetization type permanent magnet built-in rotor

ActiveCN111541325BNot easy to demagnetizeThe salient pole effect is obviousMagnetic circuit rotating partsPermanent magnet rotorElectric machinery

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com