External rotor motor and permanent magnet magnetizing method

An external rotor motor, permanent magnet technology, applied to magnetic objects, synchronous motors with stationary armatures and rotating magnets, magnetic circuits, etc. It can improve the output power, improve the noise and vibration characteristics, and reduce the cogging torque and torque ripple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

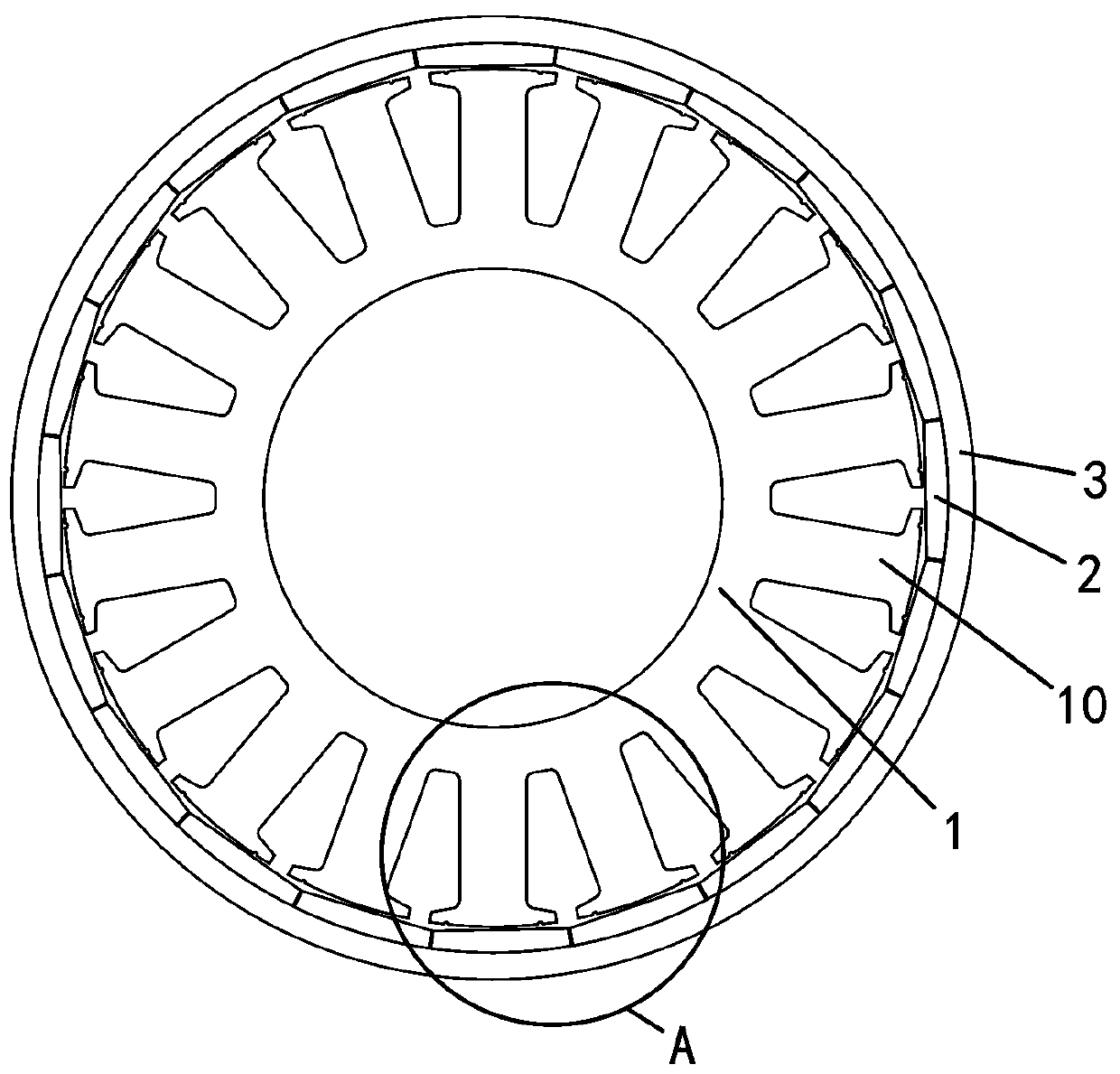

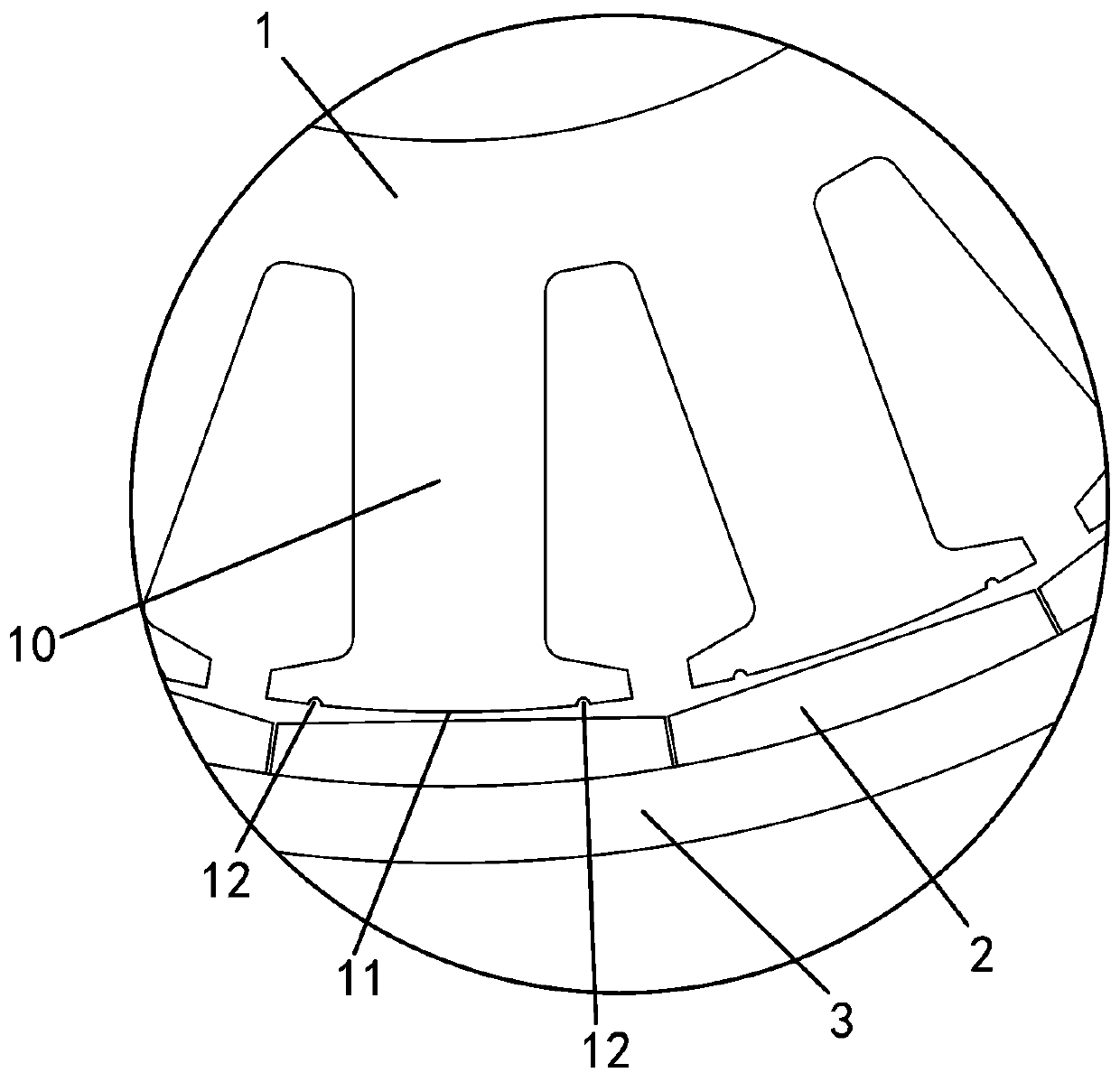

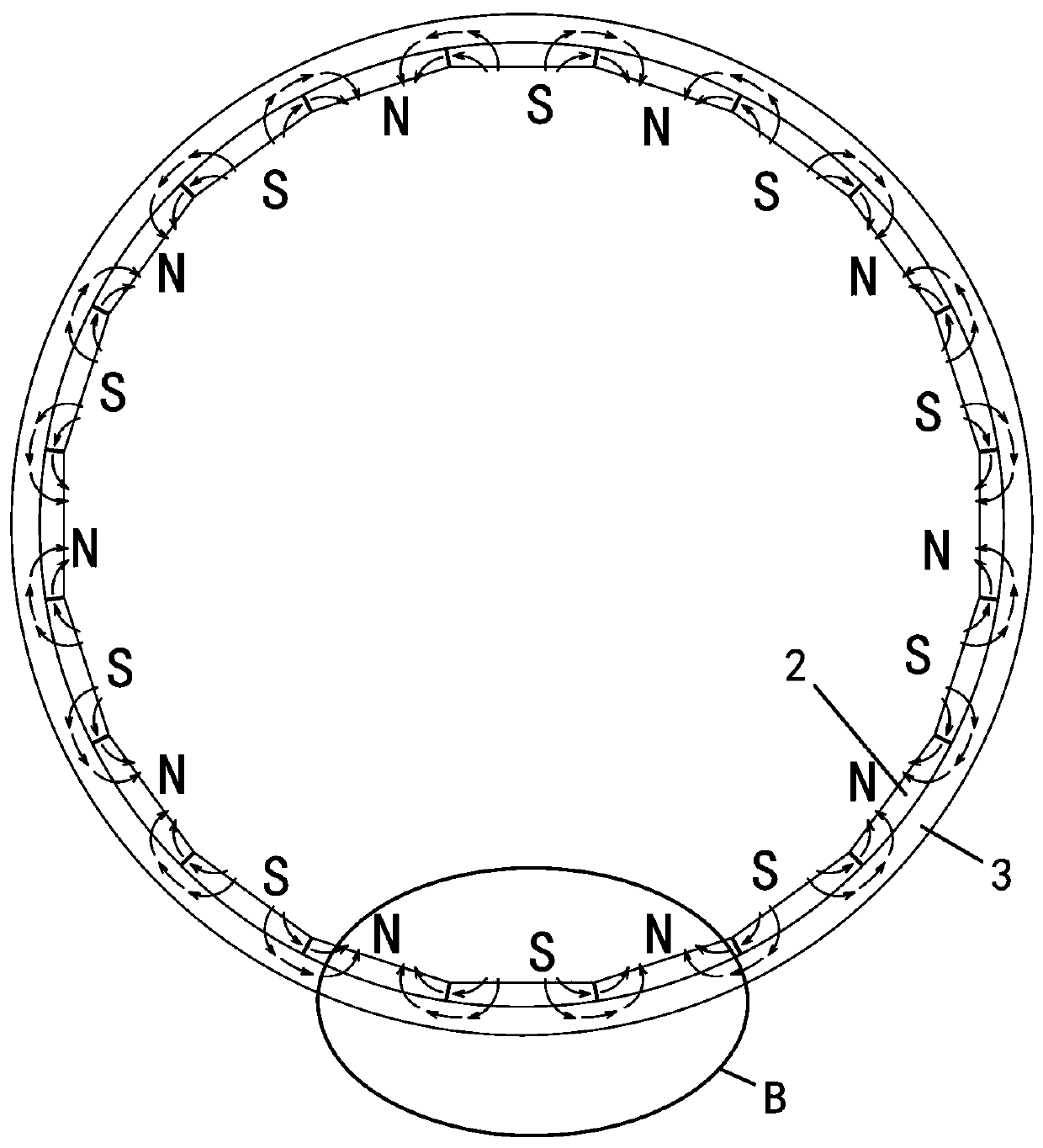

[0023] Embodiment one, see Figure 1 to Figure 7 As shown, an external rotor motor includes a stator, a permanent magnet and a rotor yoke 3 stacked by stator punches 1. The permanent magnets are permanent magnets 2 with unequal thicknesses. The unequal-thickness permanent magnets 2, the unequal-thickness permanent magnets are magnetized by unequal-diameter magnetization, the unequal-thickness permanent magnets provide magnetic flux, and provide magnetic circuits. A closed magnetic circuit is formed between them, and a closed magnetic circuit is formed between adjacent permanent magnets 2 of unequal thickness through the rotor yoke 3 .

[0024] Wherein, the unequal thickness permanent magnet 2 refers to the permanent magnet whose middle thickness of the permanent magnet is greater than the edge thickness, as referring to Image 6 Another unequal thickness permanent magnet 2 is shown, the middle thickness d1 is greater than the edge thickness d2.

[0025] The stator punch 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com