A rotor core and an electric machine having the same

A rotor core and rotor body technology, applied in the direction of synchronous machines, electric components, electrical components, etc., can solve the problems that the main magnetic flux cannot be adjusted according to needs, the operating range of the motor is narrow, and the speed regulation range is limited, so as to reduce the Effects of vibration and noise, reduced field weakening requirements, and increased adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

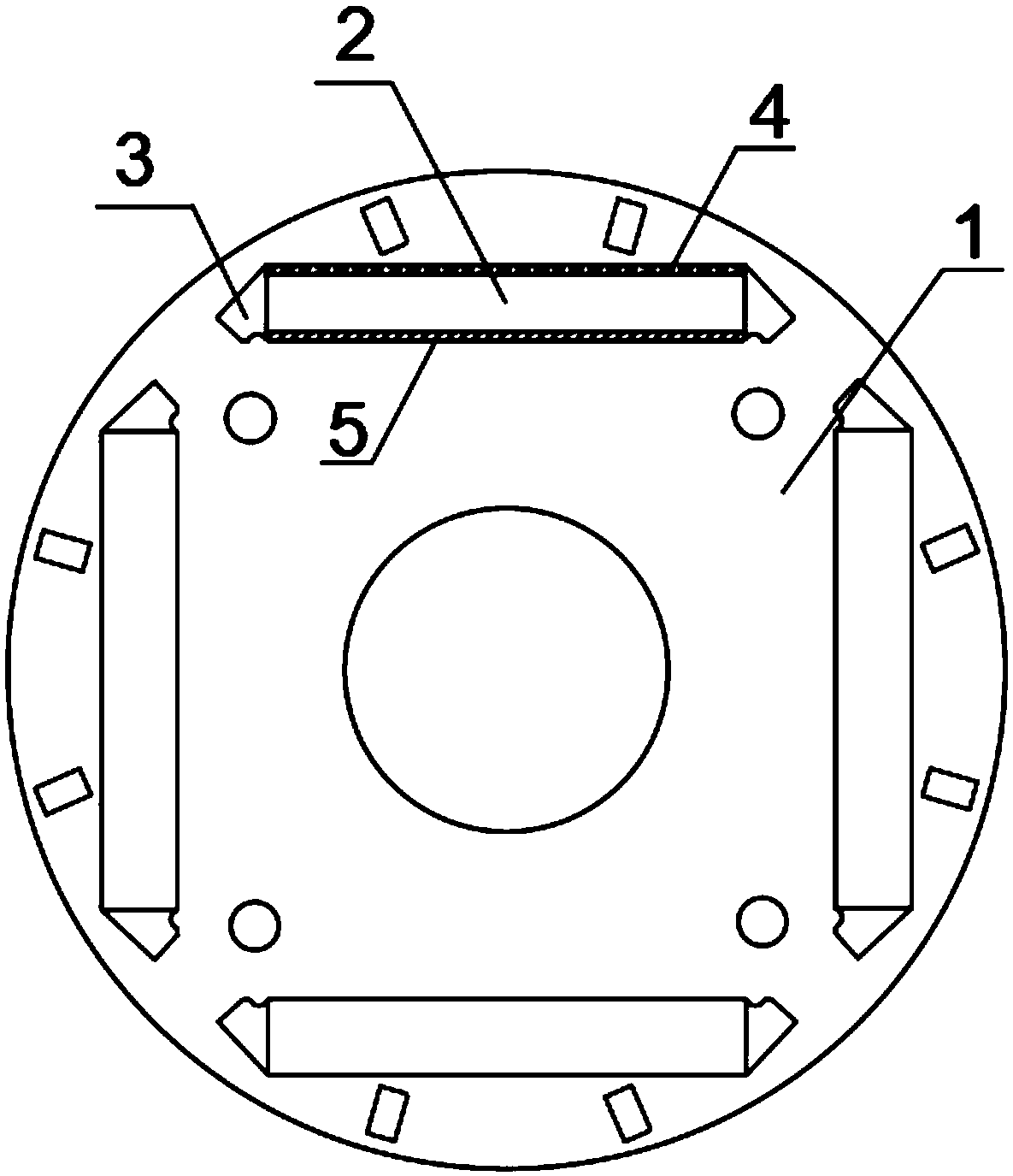

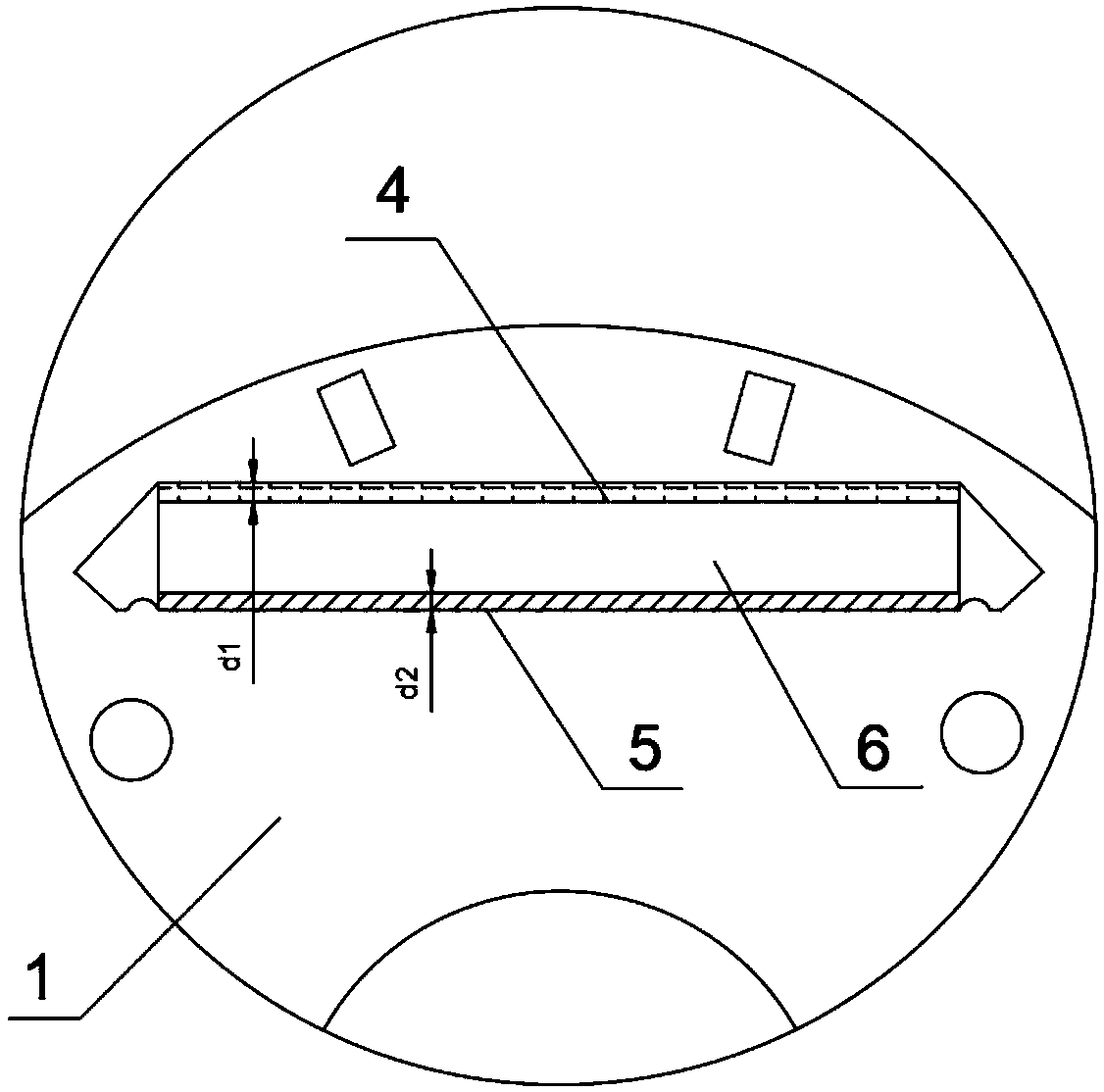

[0034] Please refer to figure 1 , figure 2 and image 3 As shown, this embodiment provides a rotor core, including a rotor body 1, the rotor body 1 is provided with at least one magnetic steel groove 2, the magnetic steel groove 2 is provided with a magnetically conductive elastic member 5 and a nonmagnetically conductive elastic member 4, and the magnetic steel The surface near the outer side of the rotor body 1 between the two ends of the slot 2 is the outer wall surface, the surface corresponding to the outer wall of the magnetic steel slot 2 is the inner wall surface, the non-magnetic conductive elastic part 4 is arranged on the outer wall surface, and the magnetic conductive elastic part 5 is arranged on the inner wall surface Above, the magnetic steel groove 2 is provided with a magnetic steel 6, and the non-magnetic conductive elastic and magnetic conductive elastic parts 5 respectively squeeze the magnetic steel 6, and the magnetic steel groove 2 is arranged on the a...

Embodiment 2

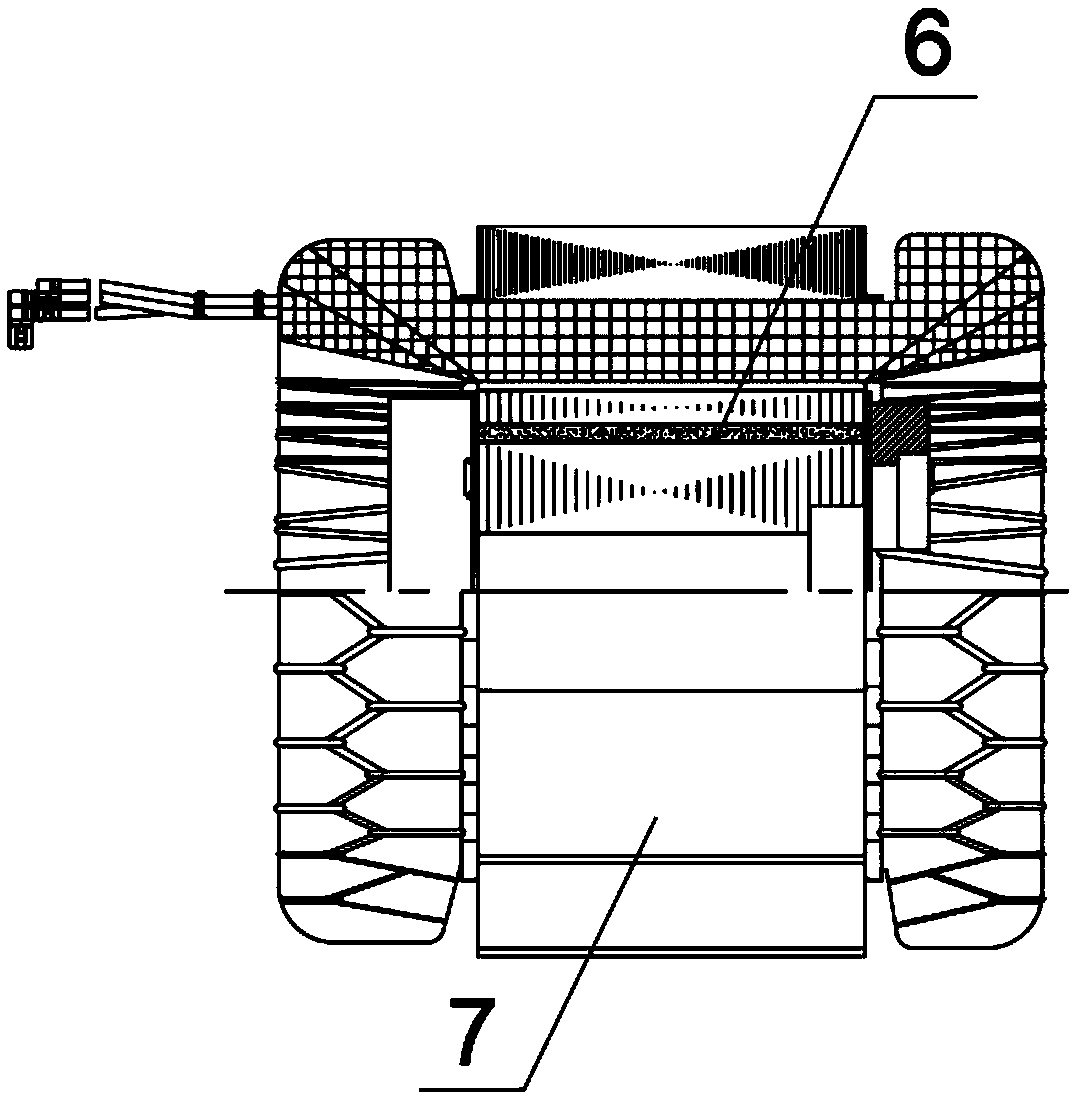

[0039] combine figure 1 , figure 2 and image 3 As shown, the present embodiment provides a motor, the motor includes a rotor core, the motor also includes a stator 7, the stator 7 is provided with a winding coil and a rotor shaft hole, the rotor core is rotatably arranged in the inner ring of the stator 7, the rotor iron The core includes a rotor body 1, four rectangular magnetic steel grooves 2 are arranged on the axial end face of the rotor body 1, and the two ends of the magnetic steel groove 2 are provided with magnetic isolation grooves 3 communicating with the magnetic steel groove 2. The surface of the groove 2 near the outer side of the rotor body 1 is the outer wall surface, the side of the magnetic steel groove 2 opposite to the outer wall surface is the inner wall surface, the non-magnetic conductive elastic part 4 is pasted on the outer wall surface, and the magnetic conductive elastic part 5 is pasted on the inner wall surface , the magnetic steel 6 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com