Rotor, electric machine including same, and method for producing rotor

A rotor and rotor shaft technology, applied in the field of rotors, can solve the problems of wire loosening and breakage, and achieve the effect of high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

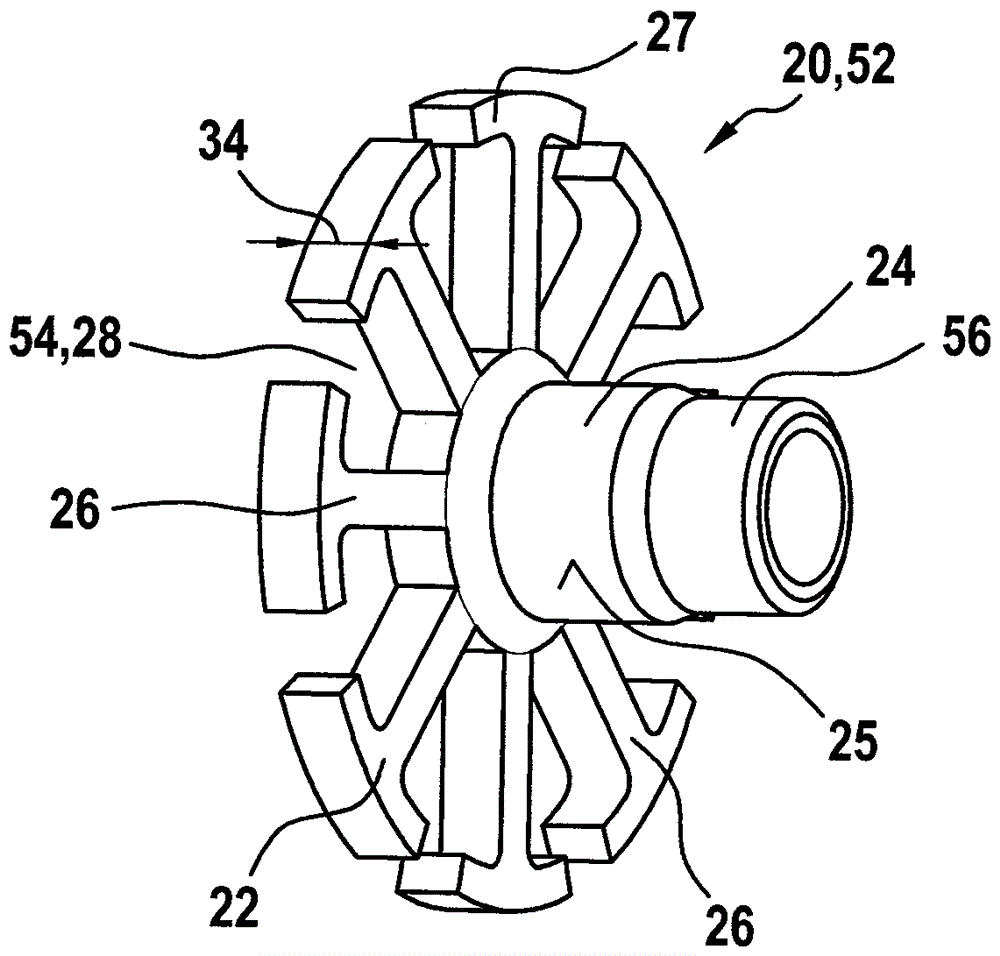

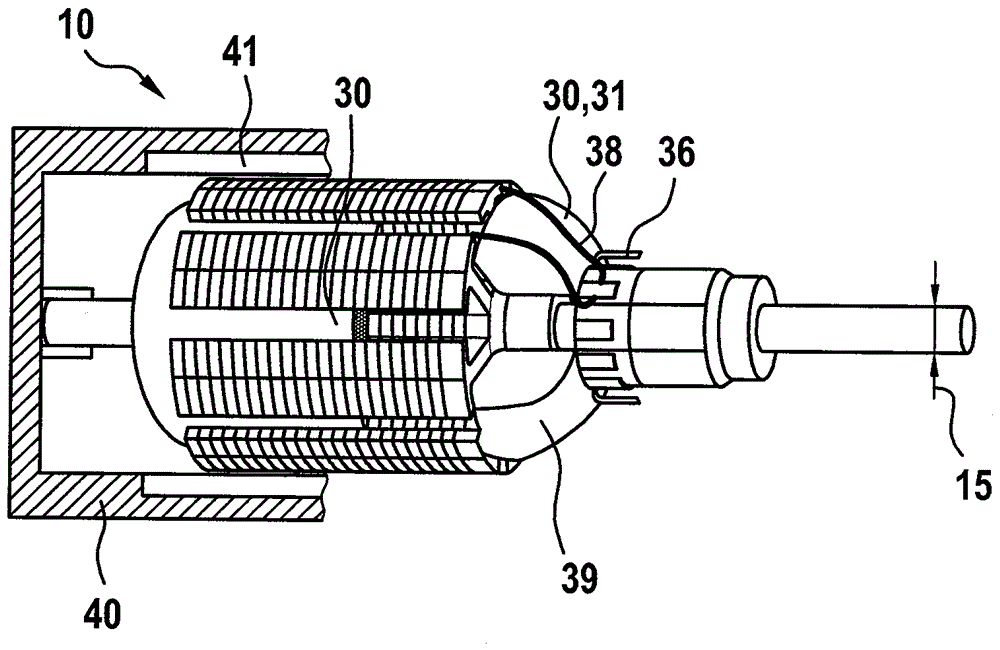

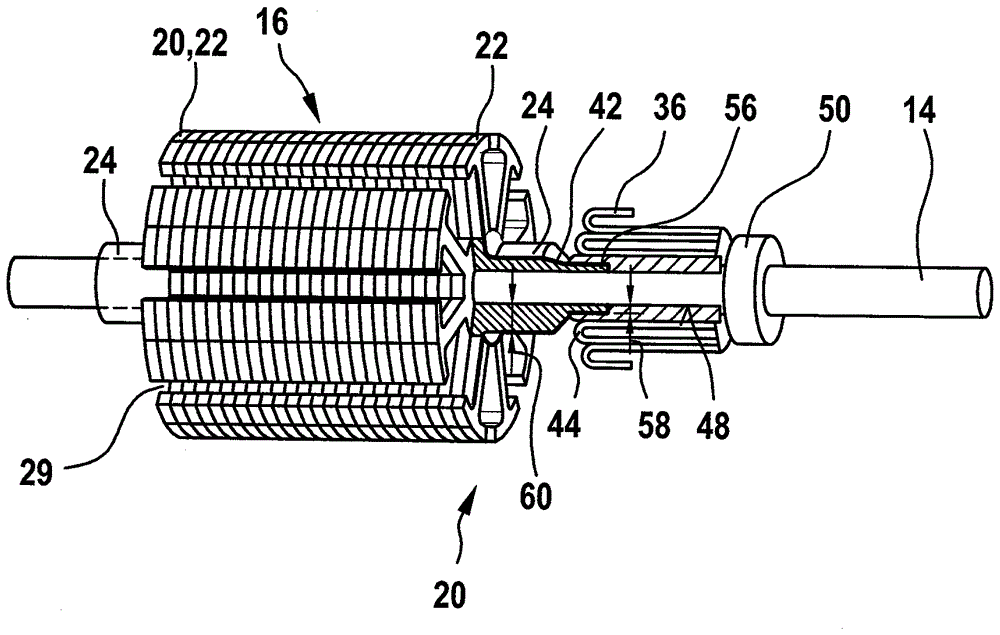

[0024] exist figure 1 A rotor 12 of an electric machine 10 is shown in , wherein a rotor set 16 is arranged on a rotor shaft 14 . The rotor group 16 consists of individual metal plates 18 stacked one above the other, which each have an end piece 20 at the axial ends of the rotor group 16 . The metal plates 18 are usually punched out of electrical sheet steel and have radial rotor teeth 26 with slots 28 in between. A tooth head 27 is formed on the radially outer end of the rotor tooth 26 , which radially covers part of the groove 28 . The plates 18 stacked one above the other together with the end pieces 20 have longitudinal grooves 29 according to figure 2 The rotor winding 30 shown in the figure is accommodated in the longitudinal slots. The end plate 20 is likewise produced from a magnetically conductive metal and has a plate body 22 to which a sleeve 24 is connected in the axial direction. In this exemplary embodiment, the sleeve 24 is formed together with the laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com