Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reasonable pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique and equipment for processing reinforced thermoplastic plastic pipe

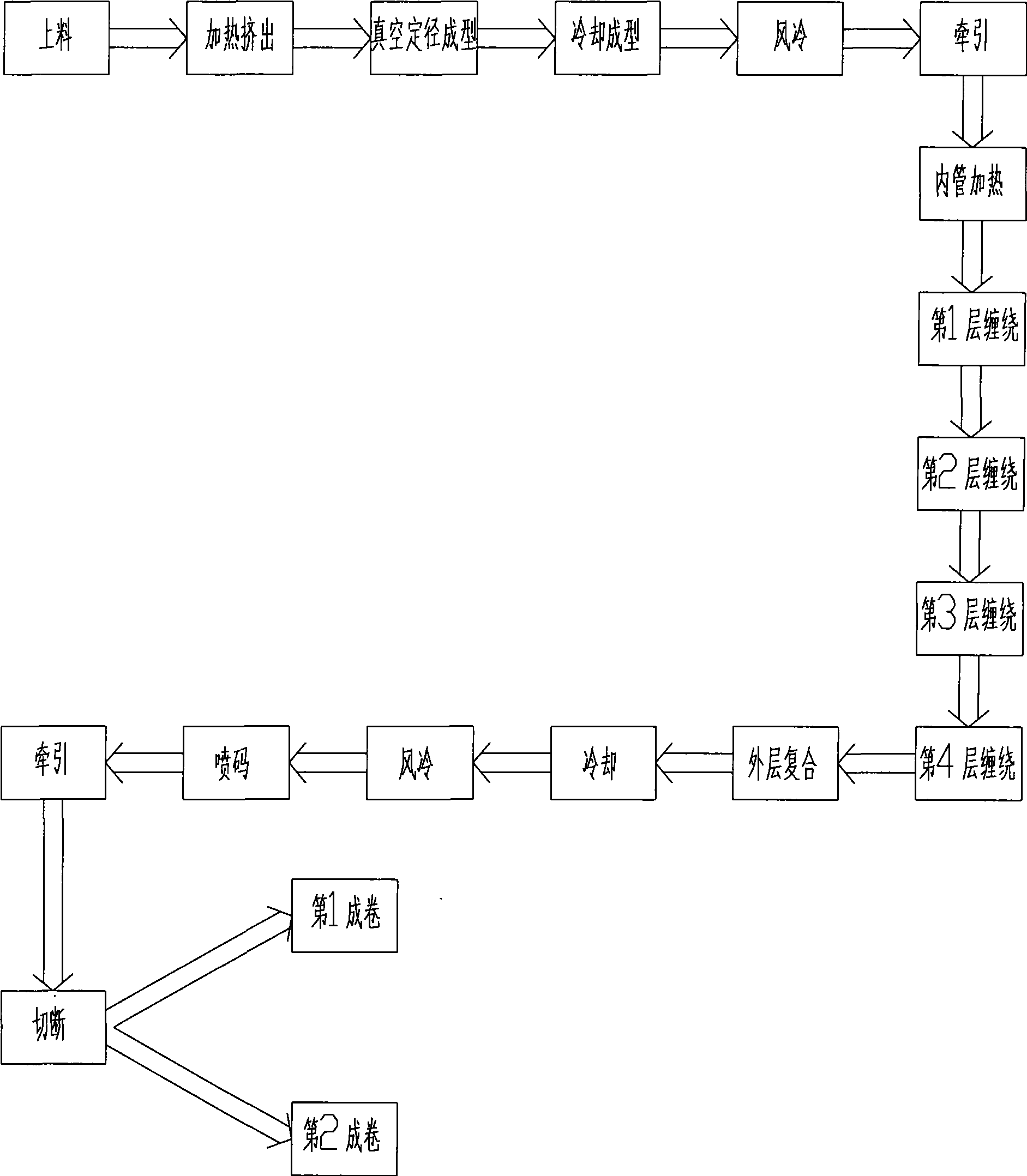

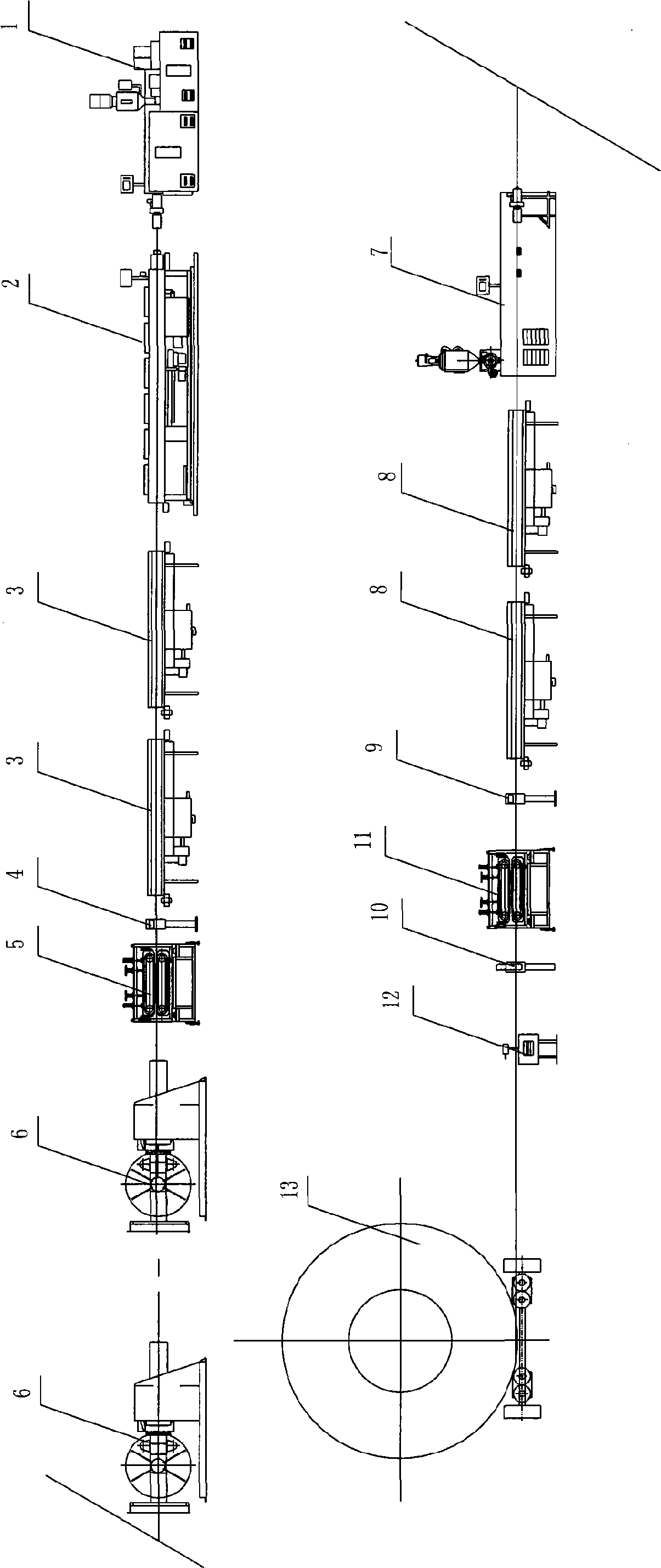

The invention provides a technique and an apparatus for producing a reinforced thermoplastic pipe. The technique comprises the following steps: 1) sending granular PE to a hopper of an extruding machine by negative pressure; 2) heating PE plastic by a first extruding machine, and continuously extruding the PE plastic by a die head with high pressure; 3) cooling the molten PE by water into a PE internal pipe under negative pressure through a vacuum calibrating sleeve of a vacuum water tank; 4) cooling and forming the PE internal pipe continuously in a spray water tank; 5) drying the surface of the PE internal pipe taken from the spray water tank by a first air cooler; 6) pulling the PE internal pipe continuously and stably by a hauling machine which provides power for forming the PE internal pipe; 7) winding a plastic covered reinforcing band made of steel wire or fiber yarn twisted ropes by a winding machine with constant tensile force in opposite directions respectively on the PE internal pipe or the outermost layer of the PE internal pipe; 8) wrapping the molten PE plastic on the outside of the wound reinforcing band through an external composite die head by a second extruding machine to form a wrapped RTP pipe; 9) spraying and cooling to form the wrapped RTP pipe in the water tank; and 10) drying the surface of the RTP pipe taken from the water tank by a second air cooler. The technique is simple and feasible. The apparatus has simple structure, good operating performance and stable and reliable operation.

Owner:李志雄

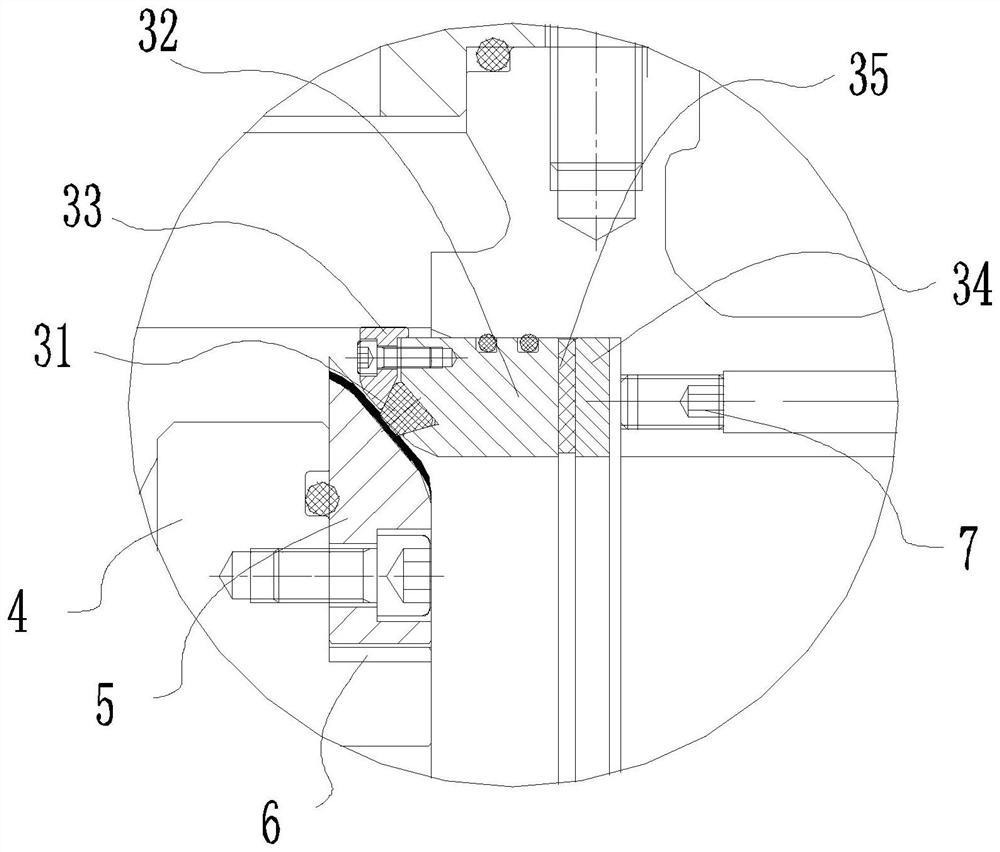

Crack-substrate coupling flow damage evaluating device and method by simulating formation conditions

ActiveCN105756674AIntuitive simulation of damage processSimulated damage process is clearBorehole/well accessoriesElectrical resistance and conductanceRock core

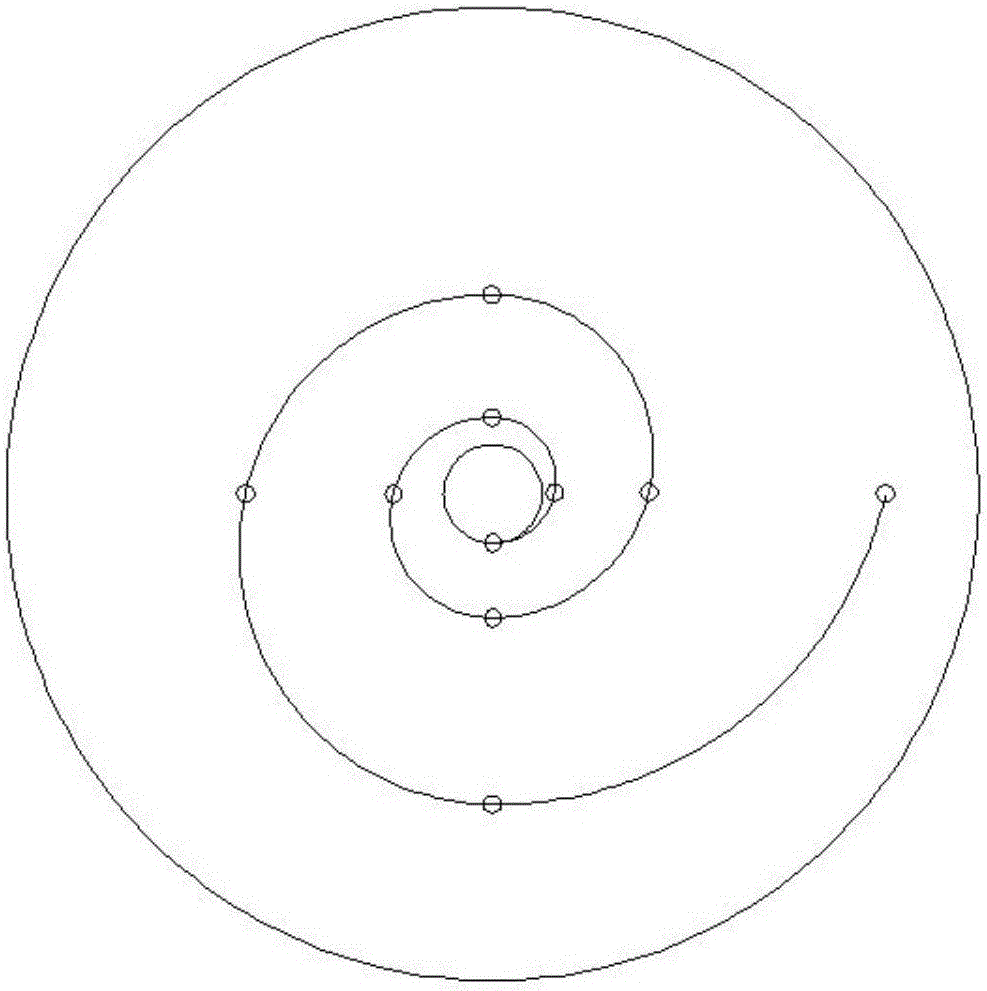

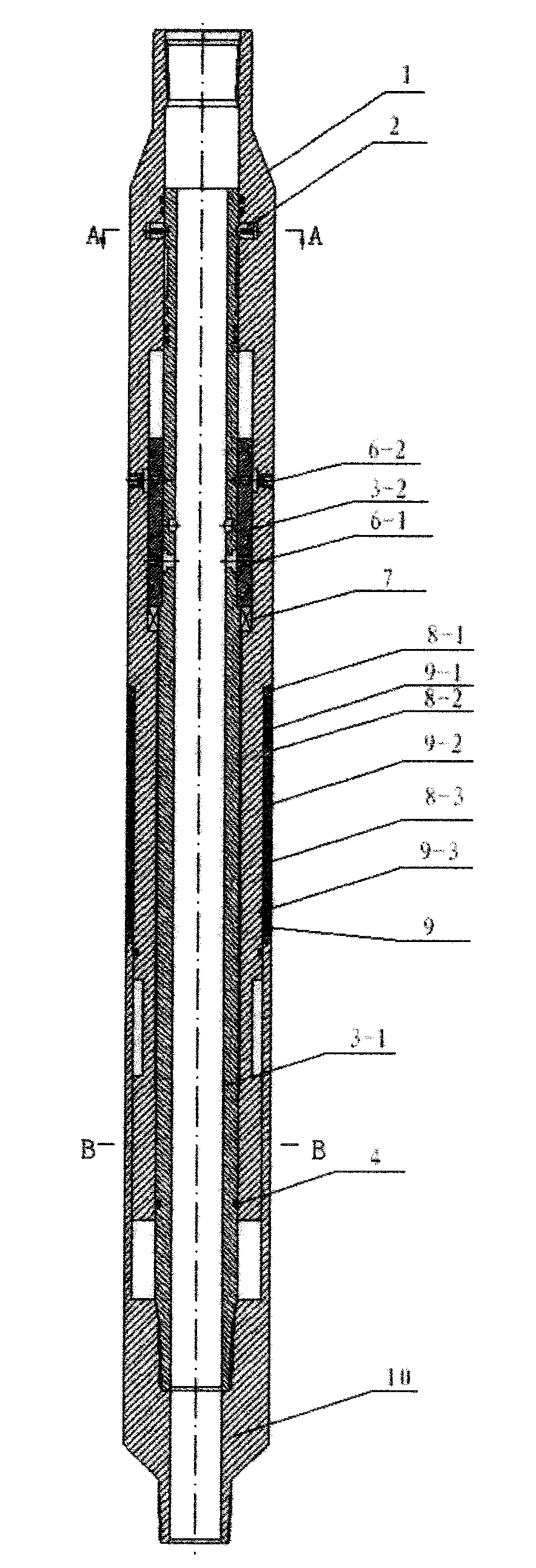

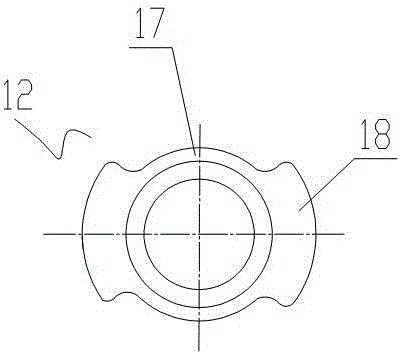

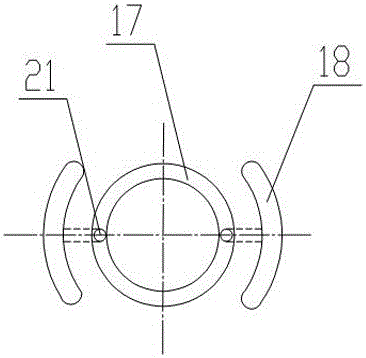

The invention discloses a crack-substrate coupling flow damage evaluating device and method by simulating formation conditions. The device mainly consists of a kettle body 4, a rock core 1, a crack 6, a simulated well 7, a pressurized capsule 3, a resistance probe 16, a pressure sensor 18, a data collecting system 17 and a work liquid circulation system, wherein the rock core 1 is arranged in the kettle body 4; the pressurized capsule 3 wraps the periphery of the rock core; the kettle body is provided with an axial pressure injecting opening, a peripheral pressure injecting opening and a gas inlet; the crack 6 and the simulated well 7 are arranged in the rock core; nine drilling holes extending into the rock core are distributed in the rock core; the resistance probe 16 is arranged in the drilling holes; the resistance probe 16 is connected with the pressure sensor 18; the resistance probe and the pressure sensor are connected with the data collecting system 17; the simulated well 7 is connected with the work liquid circulation system. The circum-well secondary stress condition and the formation radial flow of a crack-substrate system are simulated for determining the damage degree of the crack-substrate system by the device. The device and the method have the advantages that the principle is reliable; the operation is convenient; scientific and accurate quantitative reservoir damage evaluation can be made.

Owner:SOUTHWEST PETROLEUM UNIV +1

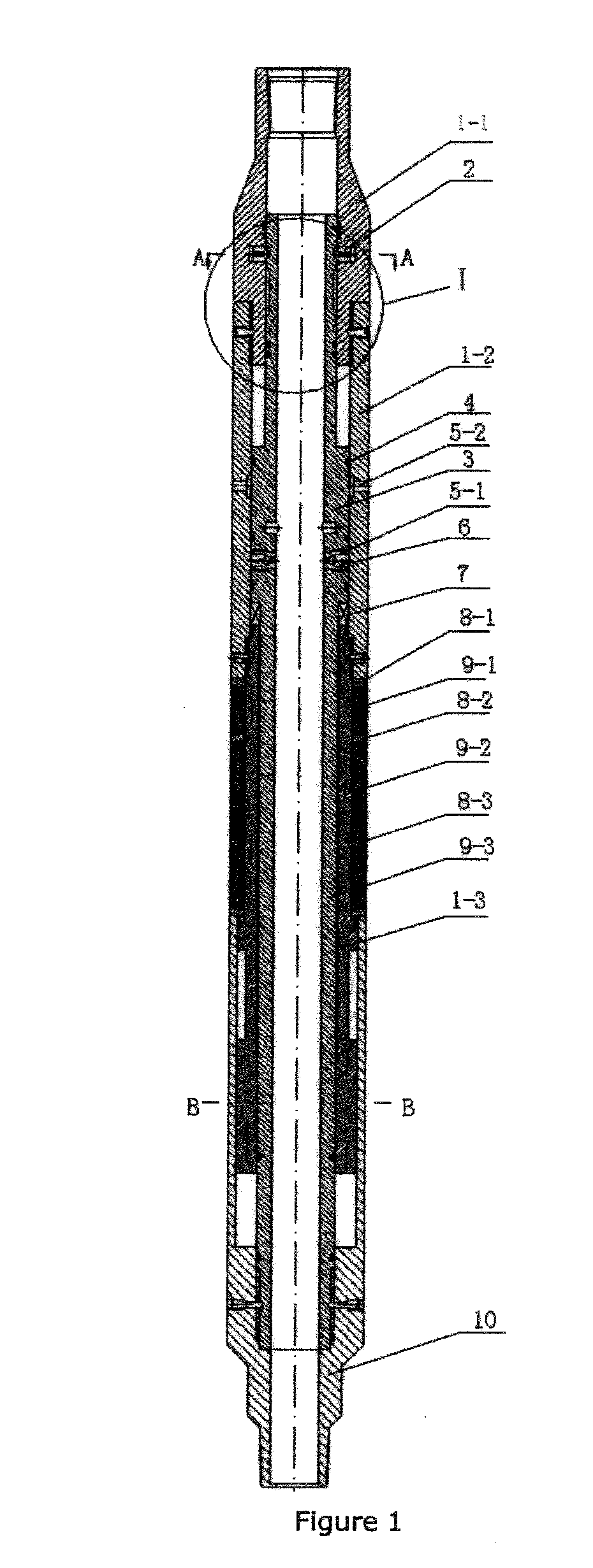

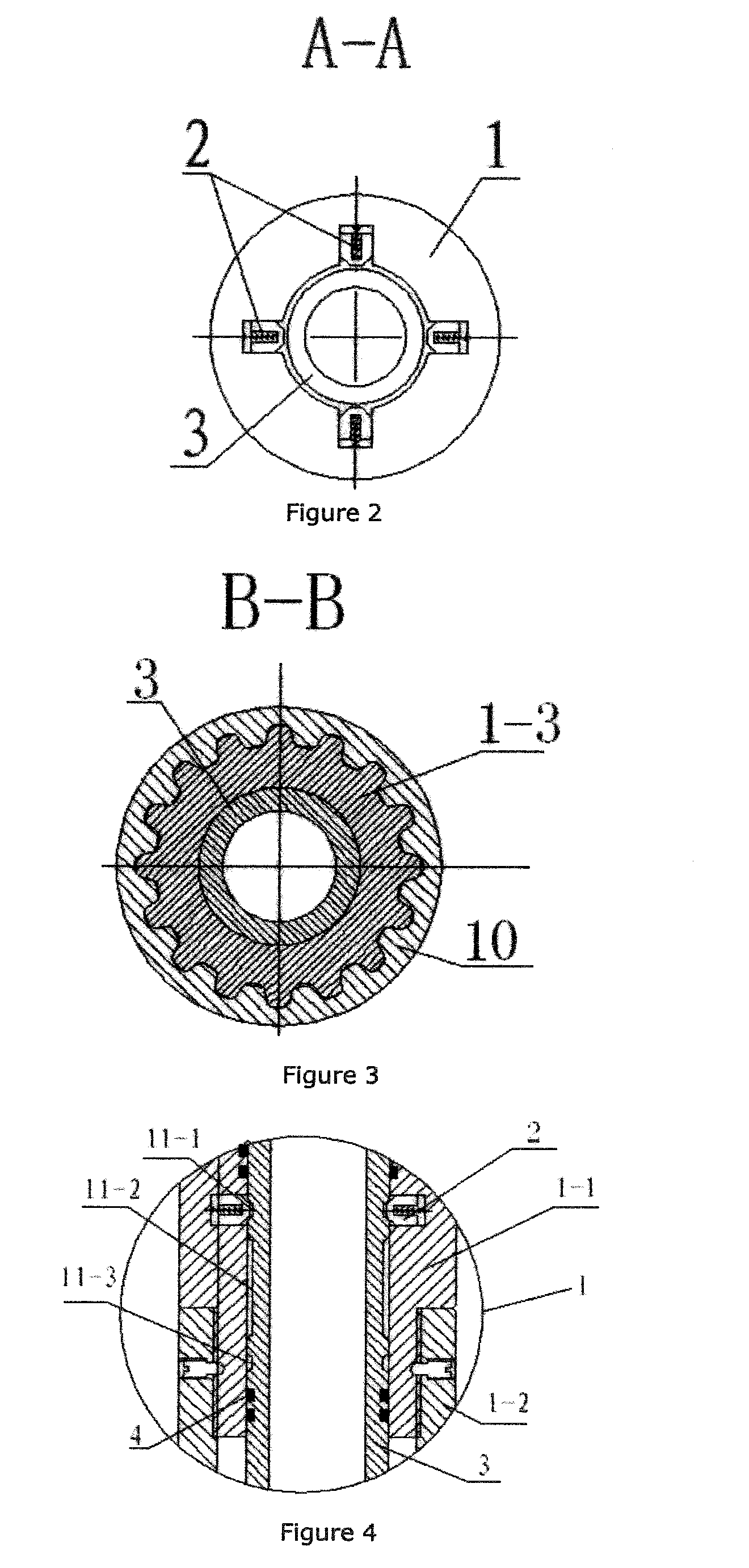

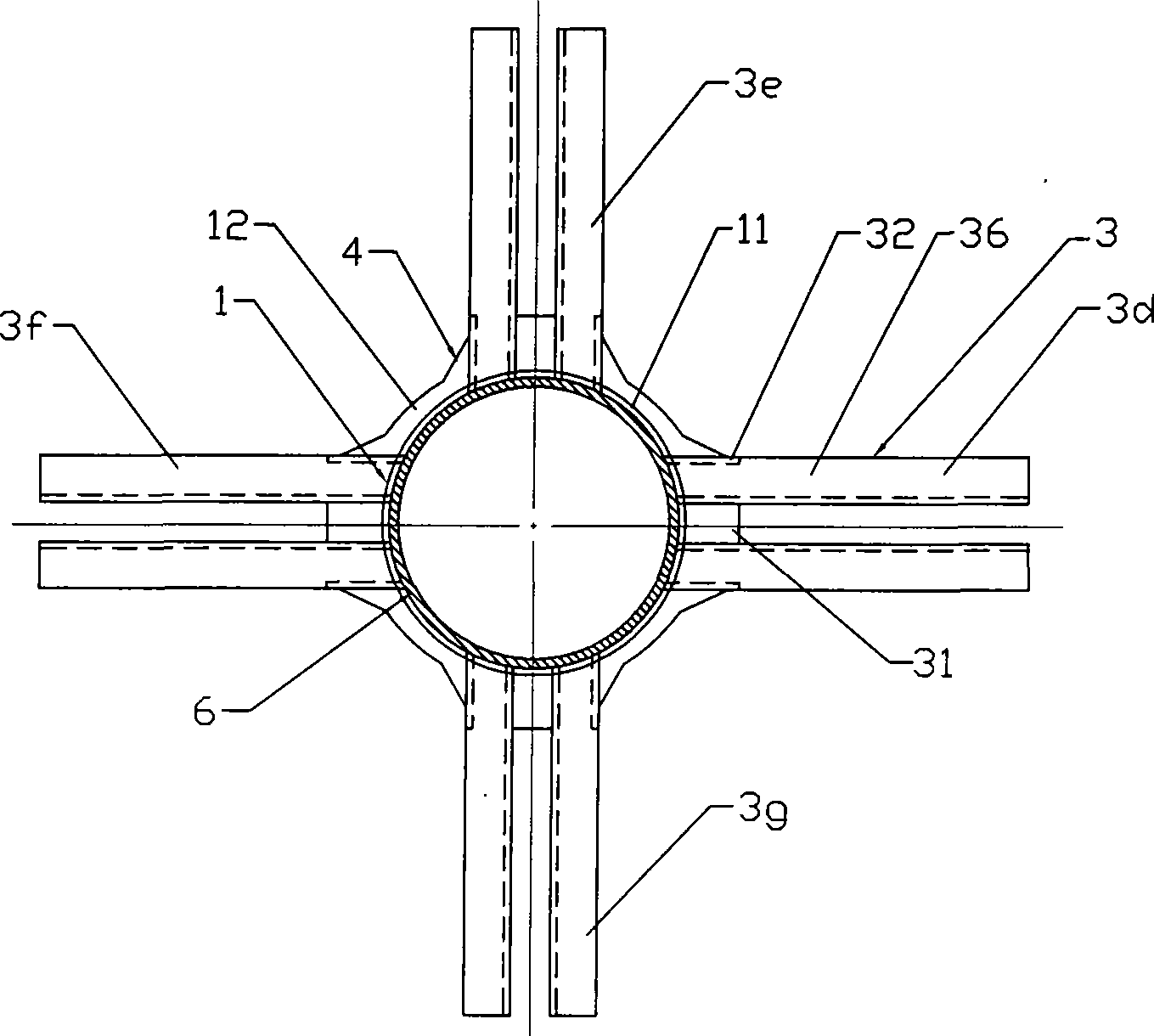

Underground Annular Blowout Preventer and Assembly Process Thereof

ActiveUS20130153796A1Simple structureDesign innovationValve arrangementsFlushingUpper jointWell drilling

An underground annular blowout preventer, which belongs to the technical field of underground blowout prevention, includes an upper joint and a lower joint are sleeved outside a central barrel. The lower end of the central barrel is fixedly connected with the lower joint. The lower end of the upper joint is sleeved on the inner side of the upper end of the lower joint. The upper joint is matched with the lower joint through a spline. The lower end of the upper joint can freely move relative to the lower joint along a spline pair. At least one rubber barrel is sleeved on the outer side of the upper joint. The rubber barrel can be extruded and expanded by the upper joint and the lower joint. The underground annular blowout preventer of the present invention can transmit large torque, has a simple structure, long service life, is convenient to use, and can be repeatedly used. The underground annular blowout preventer is used in coordination with a check valve of a near drill in the well drilling process, so that quick sealing of a well can be ensured, and well blowout accidents can be effectively prevented. A pipe column is lowered to seal the well and is lifted to open the well, and the inside of the drill rod is in communication with an annular space after the well is sealed, which facilitates replacement for heavy mud lubrication operations.

Owner:SOUTHWEST PETROLEUM UNIV

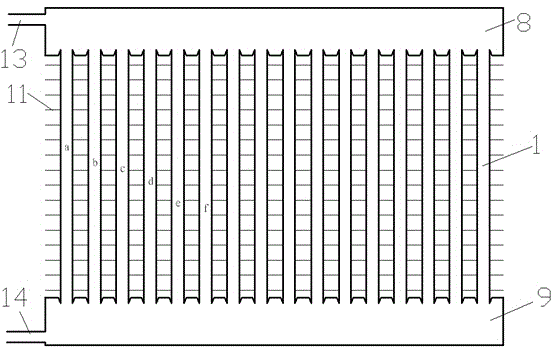

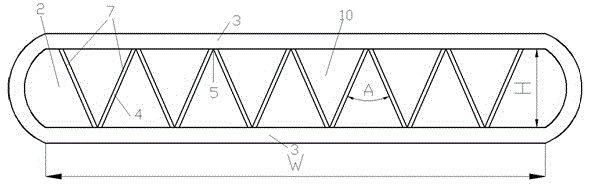

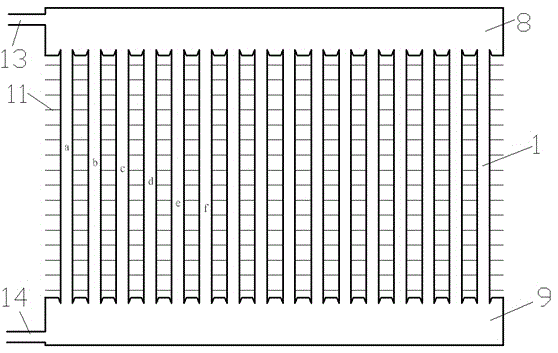

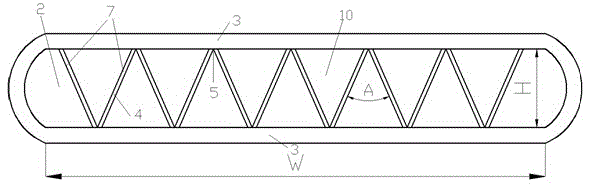

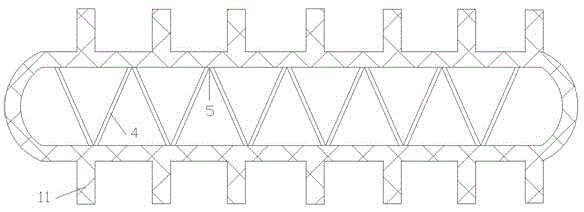

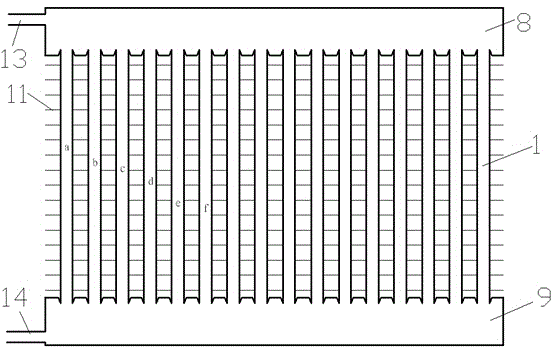

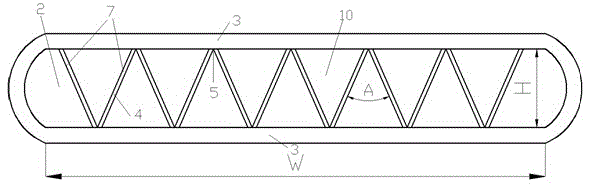

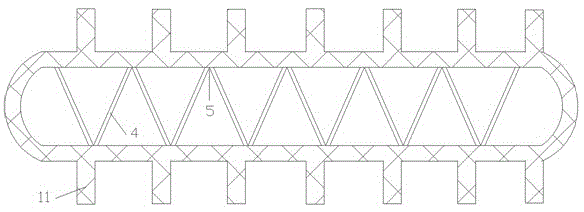

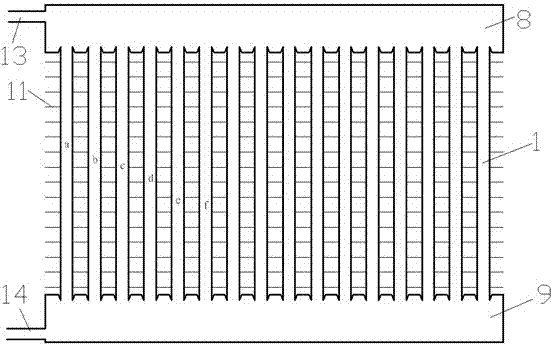

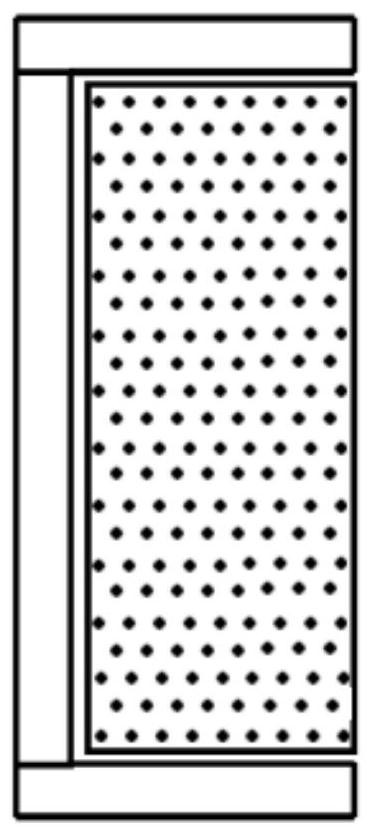

Heat exchanger with triangular through holes different in bottom side lengths

ActiveCN105605945AEvenly distributedSolve the problem of uneven internal pressureStationary conduit assembliesHeat exchanger casingsEngineeringMicro heat exchanger

The invention provides a heat exchanger which comprises two collecting boxes and heat exchange tubes, wherein the heat exchange tubes are arranged between the two collecting boxes; the heat exchange tubes are flat heat exchange tubes; fins are arranged in the flat tubes; the fins comprise inclined parts; a fluid channel is partitioned by the inclined parts into a plurality of small channels; the larger the distance between the flat tubes and an inlet tube is, the larger the lengths h of the bottom sides of the isosceles triangular communication holes in the flat heat exchange tubes are. According to the heat exchanger, as the lengths h of the bottom sides of the isosceles triangular communication holes are changed along with the distance between the flat heat exchange tubes and the inlet tube, fluid can be enabled to flow to the heat exchange tubes with small flow resistance and far away from the inlet tube, the fluid can be uniformly distributed inside the heat exchange tubes, the heat exchange efficiency can be improved, and the service life can be prolonged.

Owner:南京奥优美特压铸技术有限公司

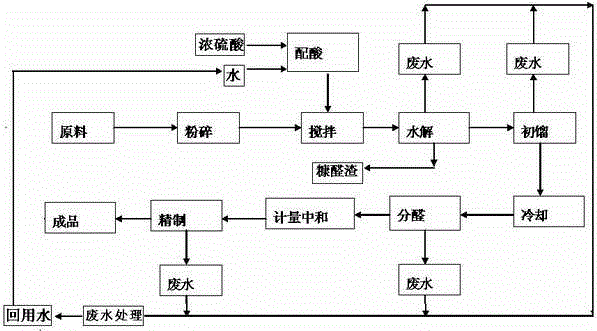

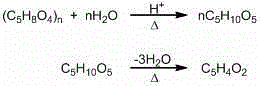

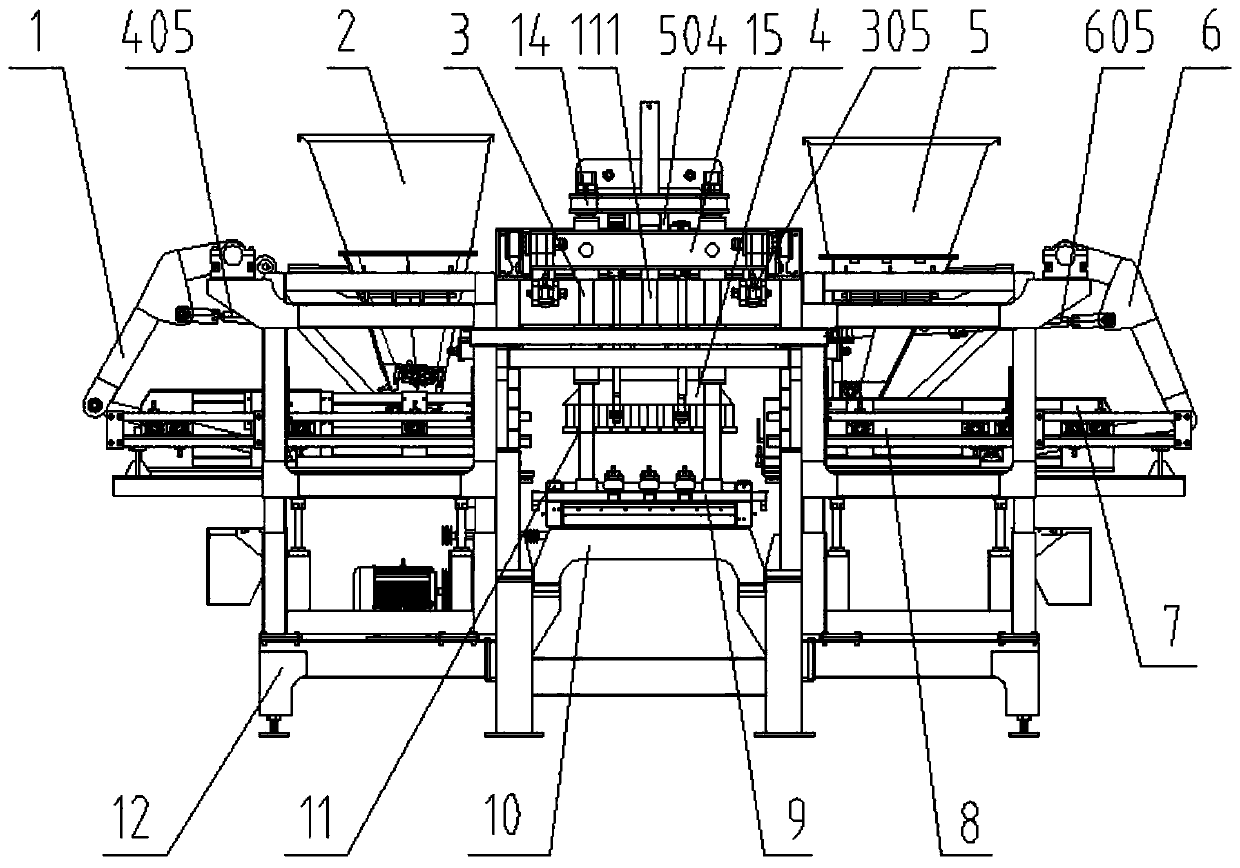

Clean production line for furfural and production method of furfural

The invention discloses a clean production line for furfural and a production method of the furfural. The clean production line comprises process facilities for sieving, crushing, acid preparation, hydrolysis, prefractionation, separation, rectification and the like and also further comprises treatment facilities for waste gas, wastewater and waste slag. The hydrolysis refers to charging corncobs mixed with acid to a hydrolysis pot at a charging density of 0.18 to 0.2t / m<3>, wherein the steam pressure is 0.5 to 1.0 MPa and the steam temperature is 140 to 180 DEG C in the hydrolysis pot; the tower top temperature is 94 to 97 DEG C and the tower bottom temperature is 98 to 108 DEG C in a prefractionation tower, furfural-containing water vapor is discharged from the tower top, and is condensed into liquid through a condenser, the liquid then enters a furfural separation tank to be subjected to water-furfural separation, and furfural liquid about 90 to 93% at the bottom automatically flows to a raw furfural tank. The clean production line disclosed by the invention can be used for scale processing of corncobs, and a separation effect of acetic acid and water can reach an international advanced level.

Owner:SHANGHAI YIZHI INDAL

Heat exchanger provided with area-varying communication holes

InactiveCN105571209AEvenly distributedSolve the problem of uneven internal pressureEvaporators/condensersTubular elementsEngineeringHeat exchanger

The invention provides a heat exchanger. The heat exchanger comprises two headers and heat exchanging tubes which are arranged between the two headers; each heat exchanging tube is a flat heat exchanging tube; fins are arranged in each flat tube; each fin comprises an inclined part; the inclined parts are used for isolating fluid passages to form a plurality of small passages; each inclined part is provided with communication holes; the communication holes in different flat heat exchanging tubes are different in area; the farther the distance from each communication hole to an inlet tube is, the larger the area of the communication hole in the flat tube is. According to the heat exchanger provided by the invention, the area of each communication hole is set to vary along with the distance away from the inlet tube, so that a fluid can flow into the heat exchanging tube which is small in flow resistance and far away from the inlet tube; therefore, the fluid can be uniformly distributed in the heat exchanging tubes, the heat exchange efficiency is improved, and the service life is prolonged.

Owner:青岛酒店管理职业技术学院

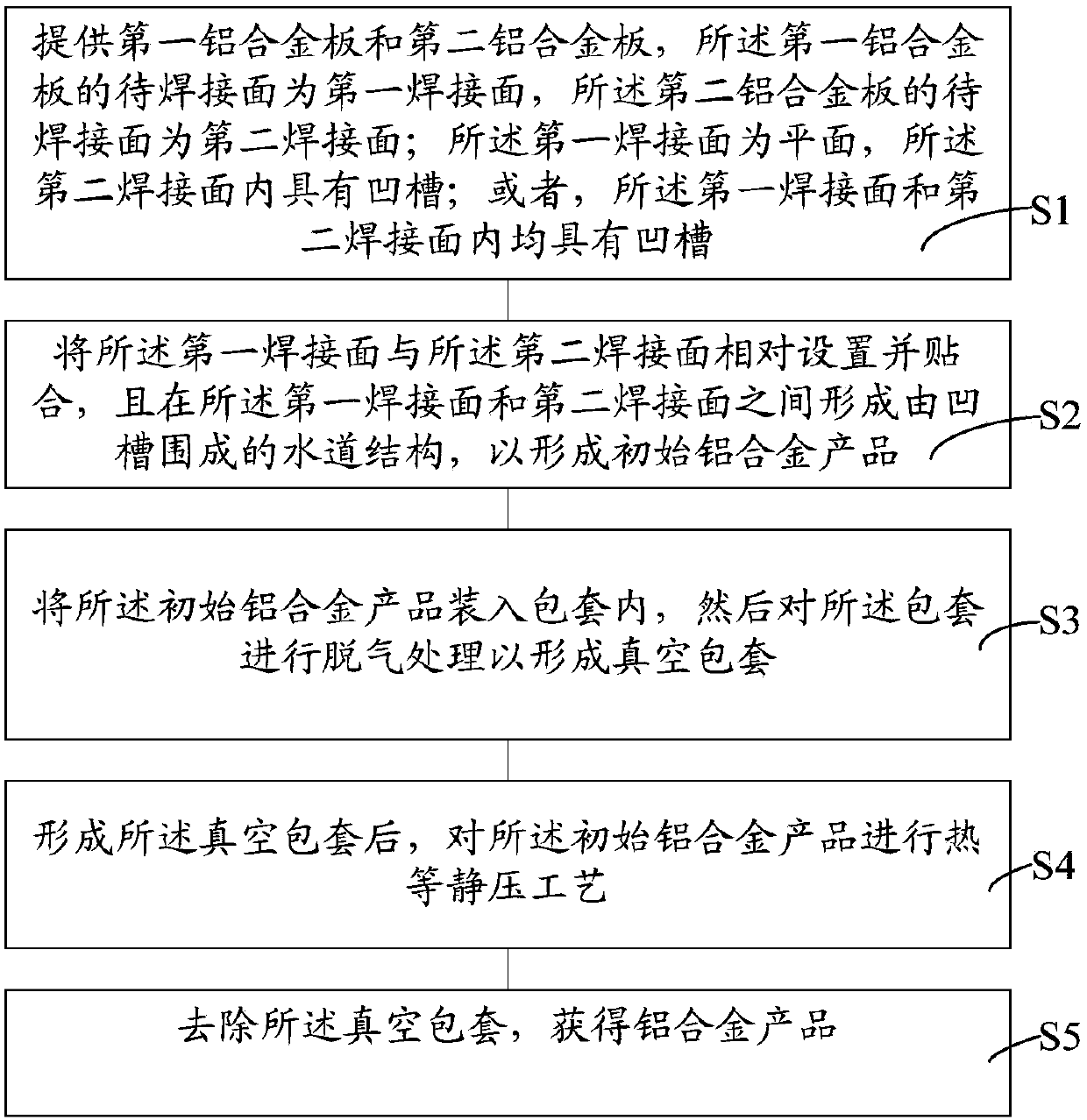

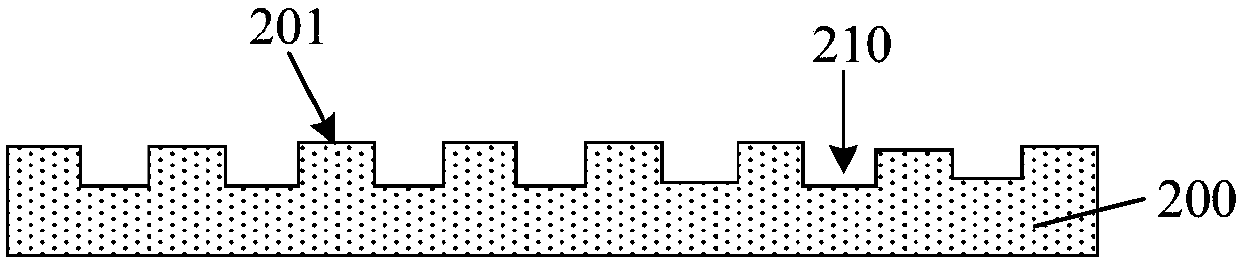

Manufacturing method of aluminum alloy product

InactiveCN107662045AImprove welding strengthAvoid deformation or even blockageNon-electric welding apparatusHot isostatic pressingWeld strength

The invention provides a manufacturing method of an aluminum alloy product. The manufacturing method of the aluminum alloy product comprises the following steps: a first aluminum alloy plate and a second aluminum alloy plate are provided, wherein a surface to be welded of the first aluminum alloy plate is a first welded surface, and a surface to be welded of the second aluminum alloy plate is a second welded surface; the first welded surface is a plane, and a groove is formed in the second welded surface; or grooves are formed in the first welded surface and the second welded surface; the first welded surface and the second welded surface are oppositely arranged and bonded, and a water way structure, surrounded by the grooves, is formed between the first welded surface and the second welded surface to form an initial aluminum alloy product; the initial aluminum alloy product is filled in a cover; the cover is degassed to form a vacuum cover; then, a hot isostatic pressing process is performed on the initial aluminum alloy product; and the vacuum cover is removed to obtain the aluminum alloy product. As the hot isostatic pressing process is applied on the initial aluminum alloy product, the welding strength of the formed aluminum alloy product is improved, and meanwhile, deformation or even blockage of the water way structure is prevented.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

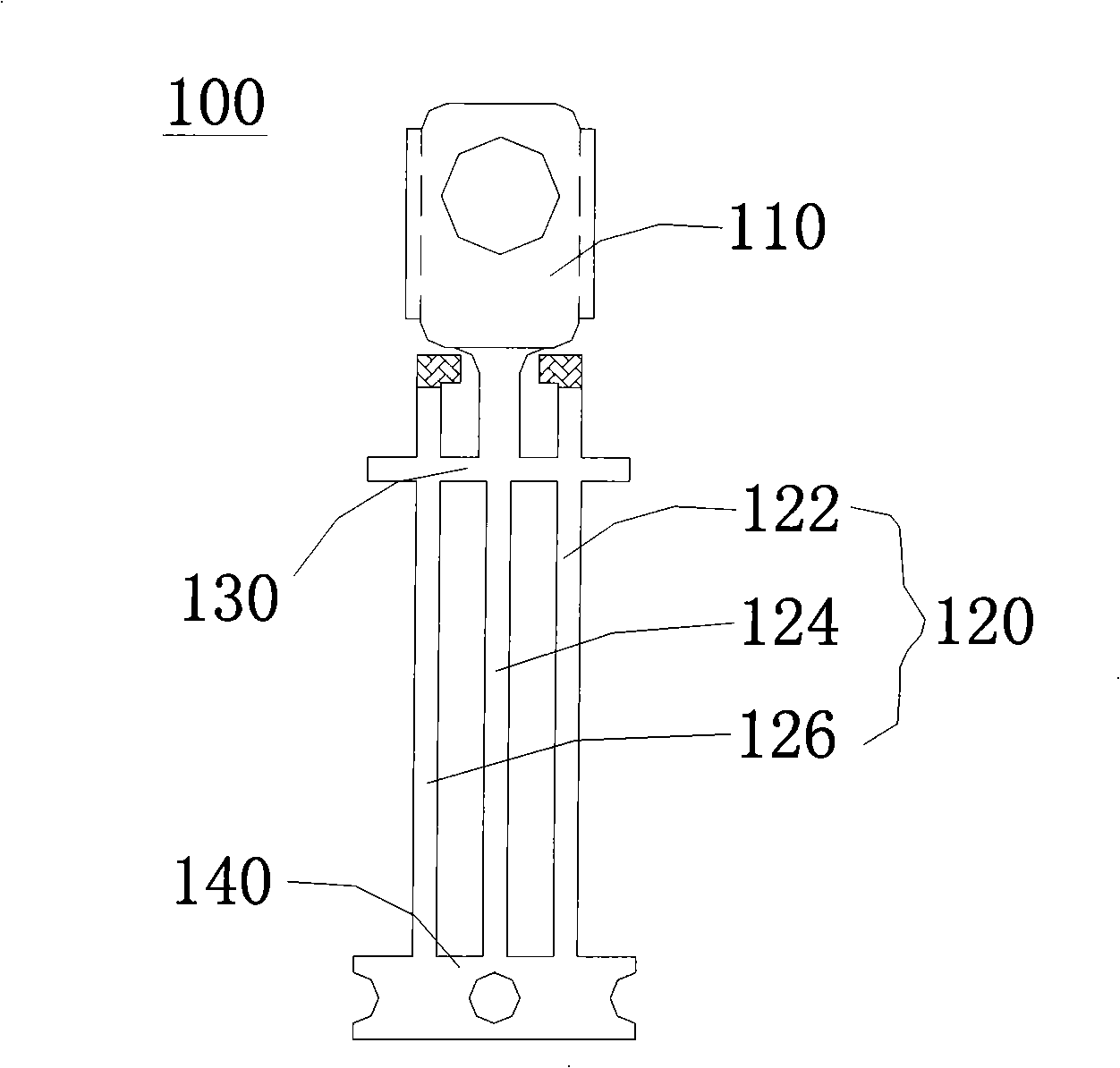

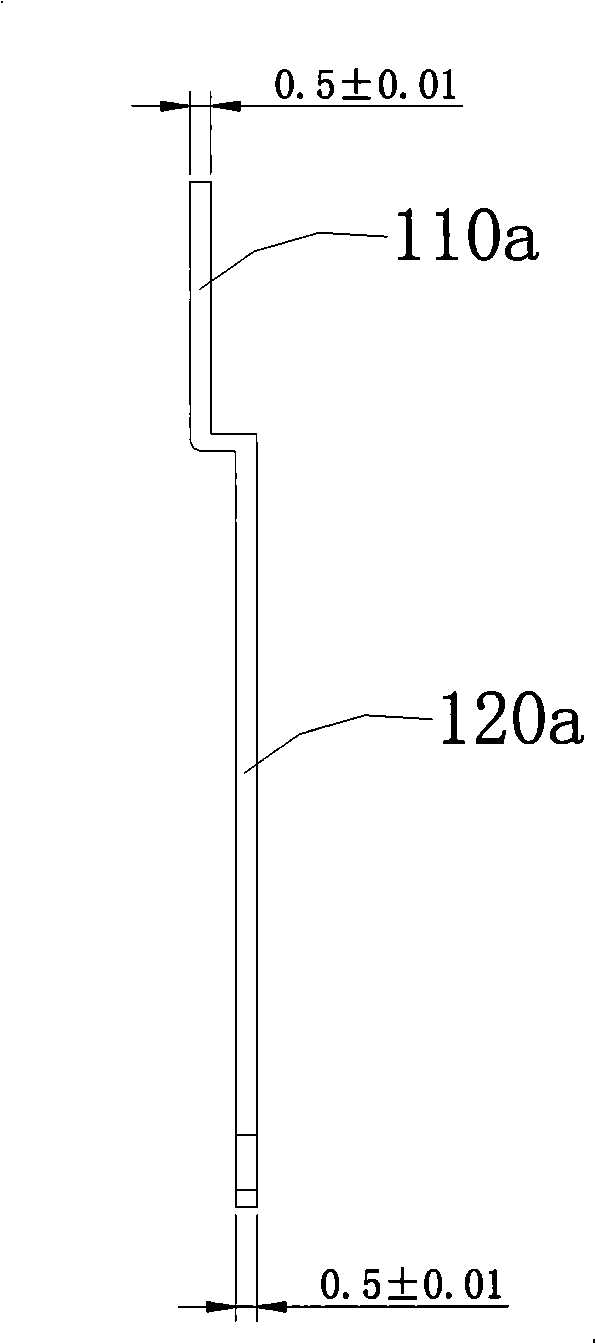

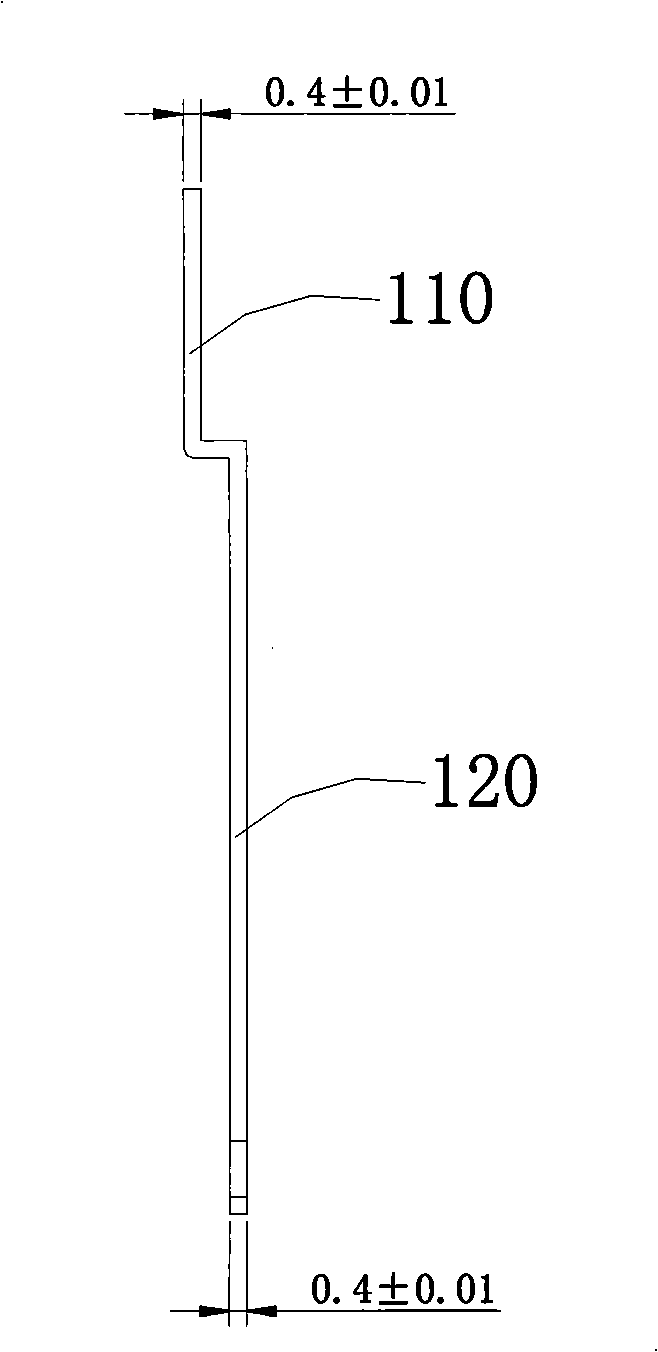

Triode and manufacturing method thereof

ActiveCN101404261ALow costSave materialSemiconductor/solid-state device detailsSolid-state devicesEngineeringSingle product

A manufacturing method of a triode comprises the following steps: a chip is welded on a frame the thickness of a pin of which is 0.36-0.44mm; bonding wires are bonded to connect the chip and the pin of the frame; and a plastic package material is used for protecting plastic package forming. The manufacturing method of the triode saves materials, reduces material cost, decreases the weight of products and reduces the transportation cost of a single product by reducing the thickness of the frame. In addition, a triode is provided by the invention.

Owner:SHENZHEN JINGDAO ELECTRONICS

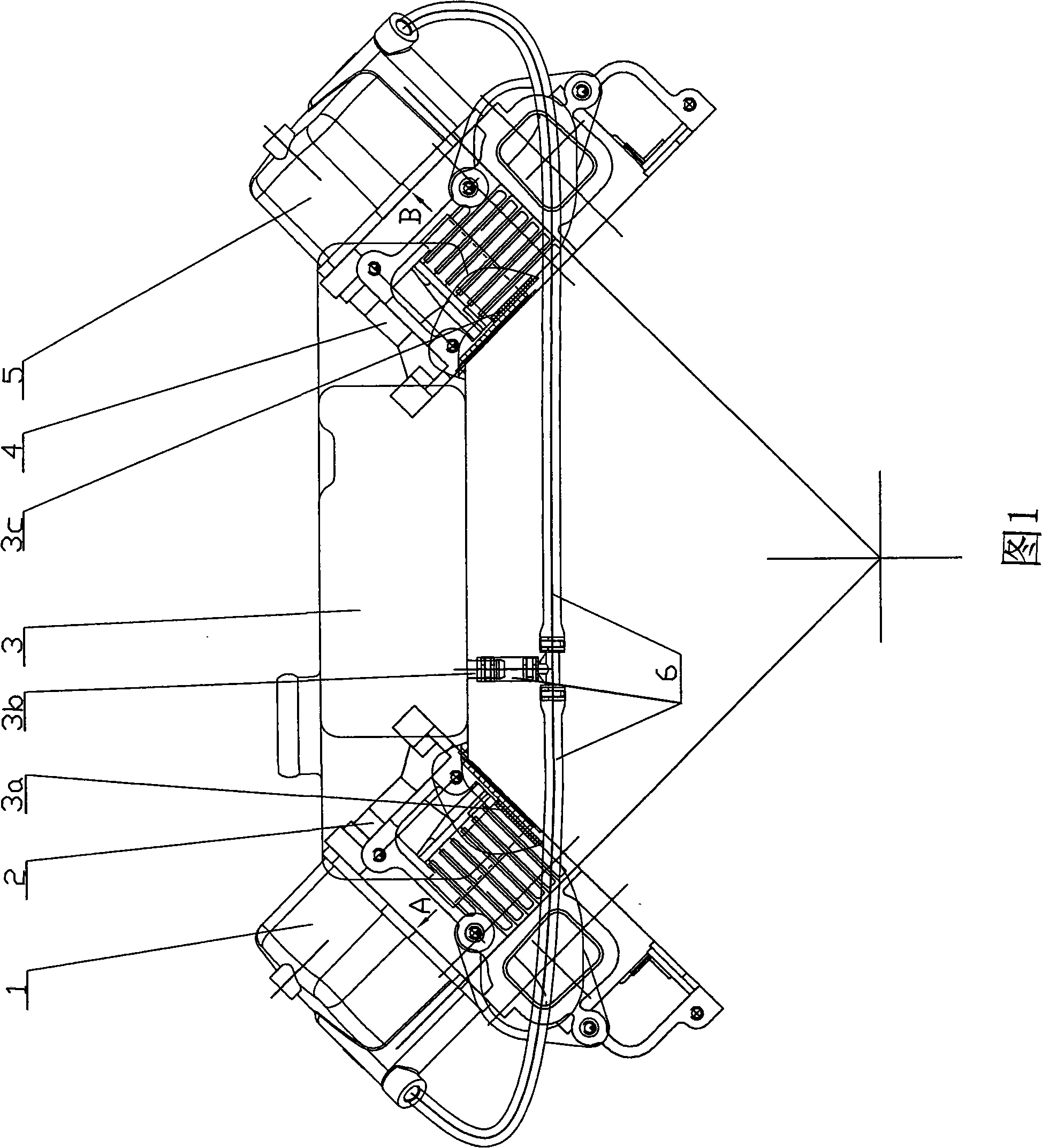

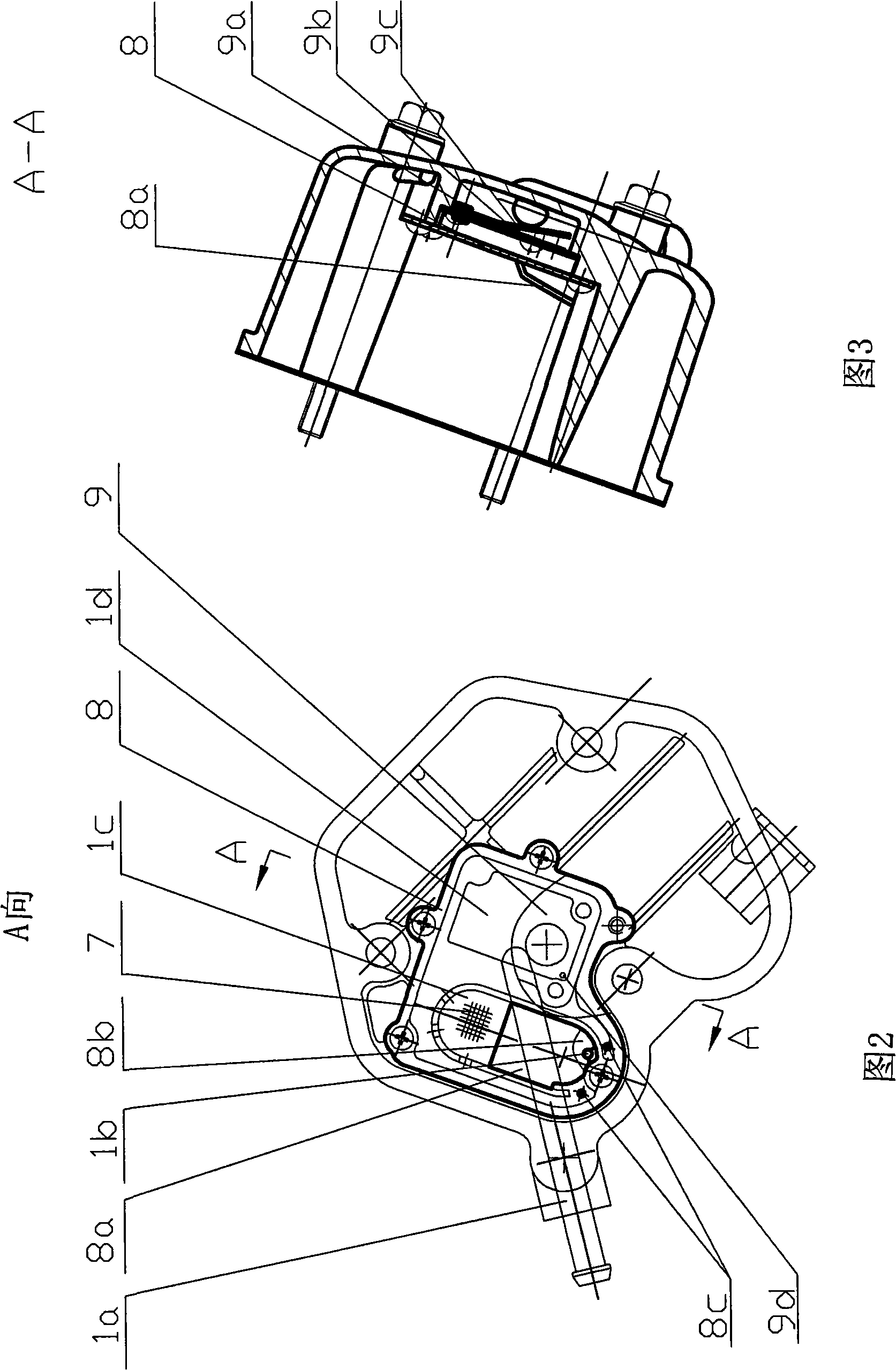

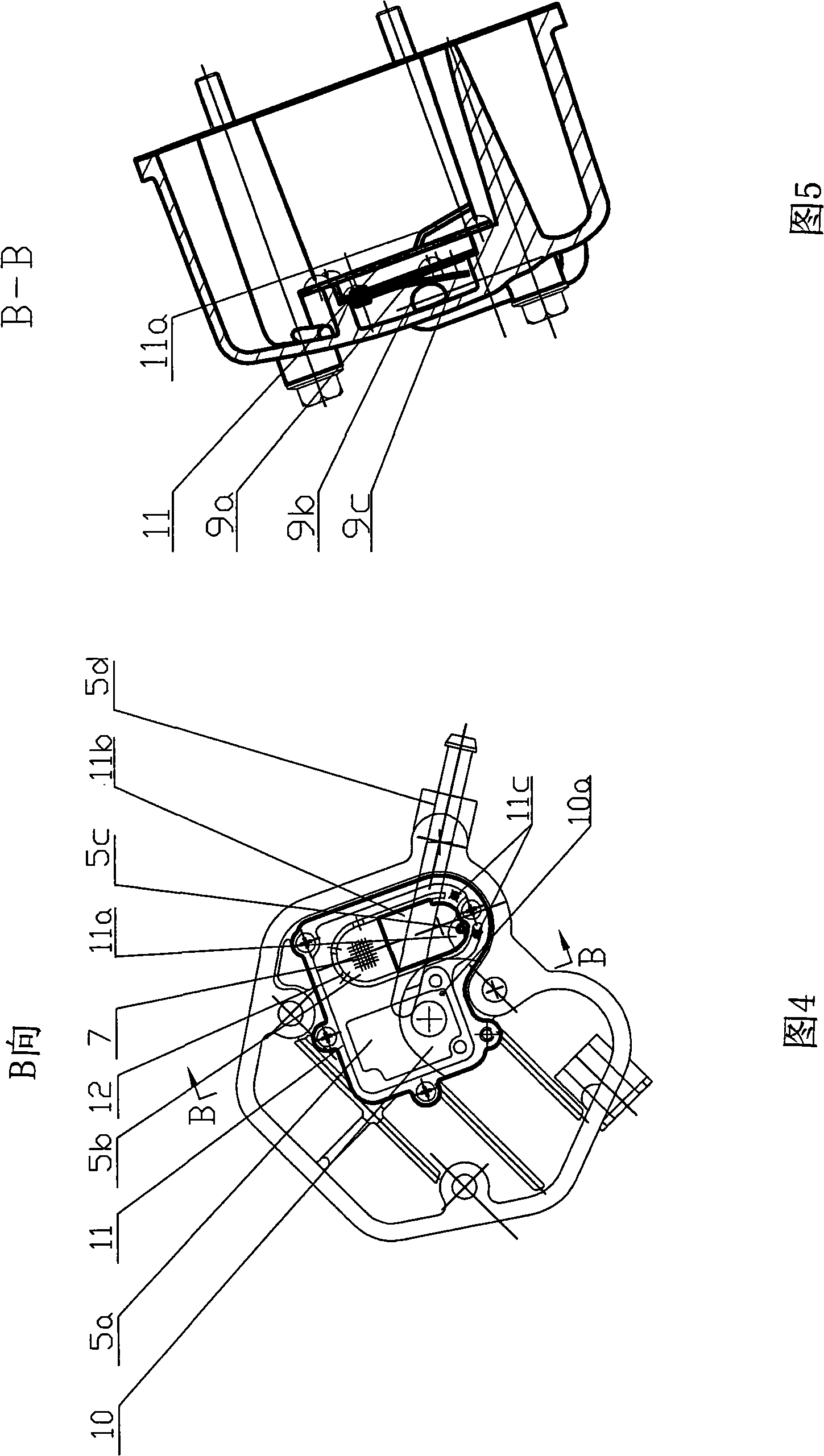

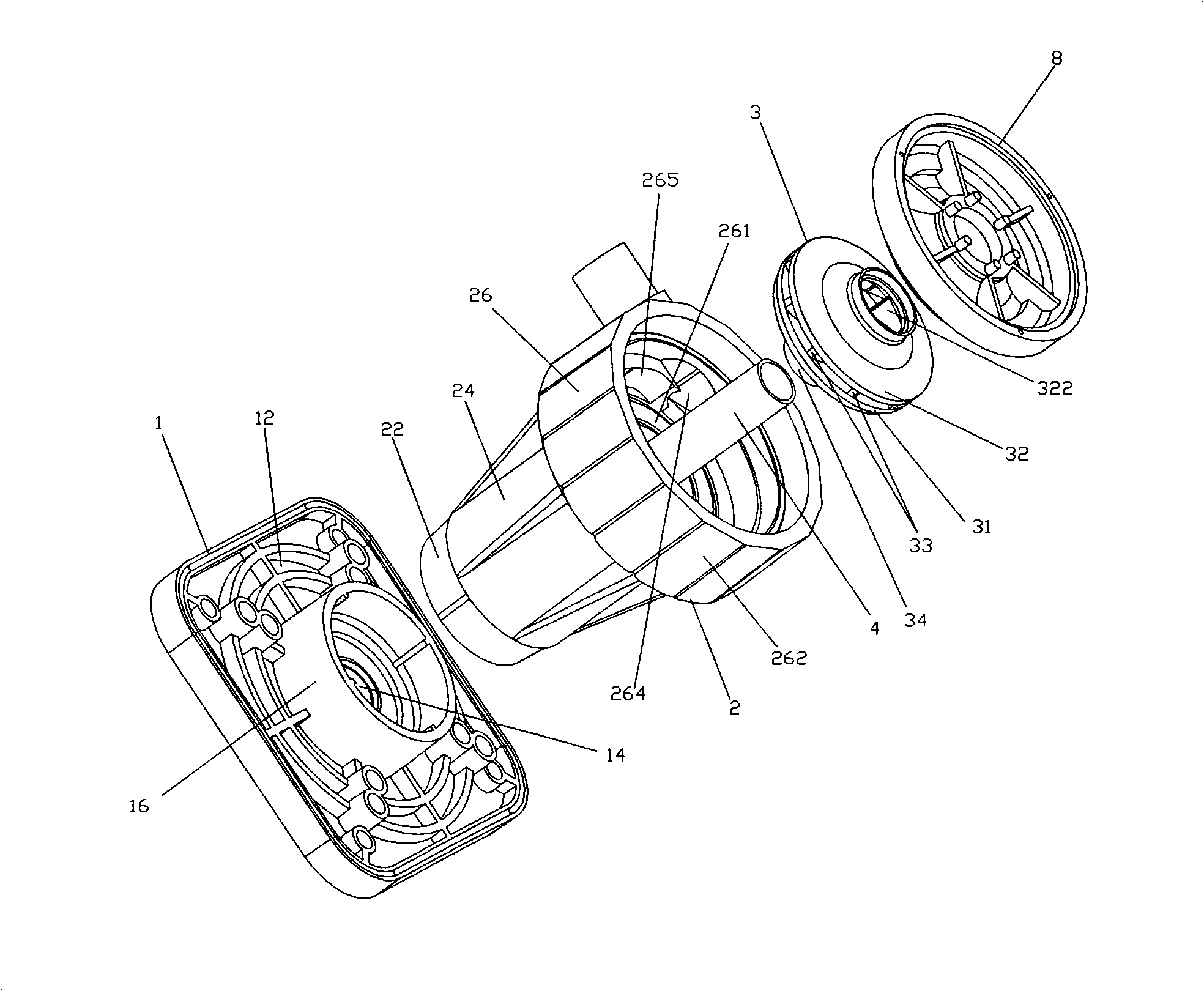

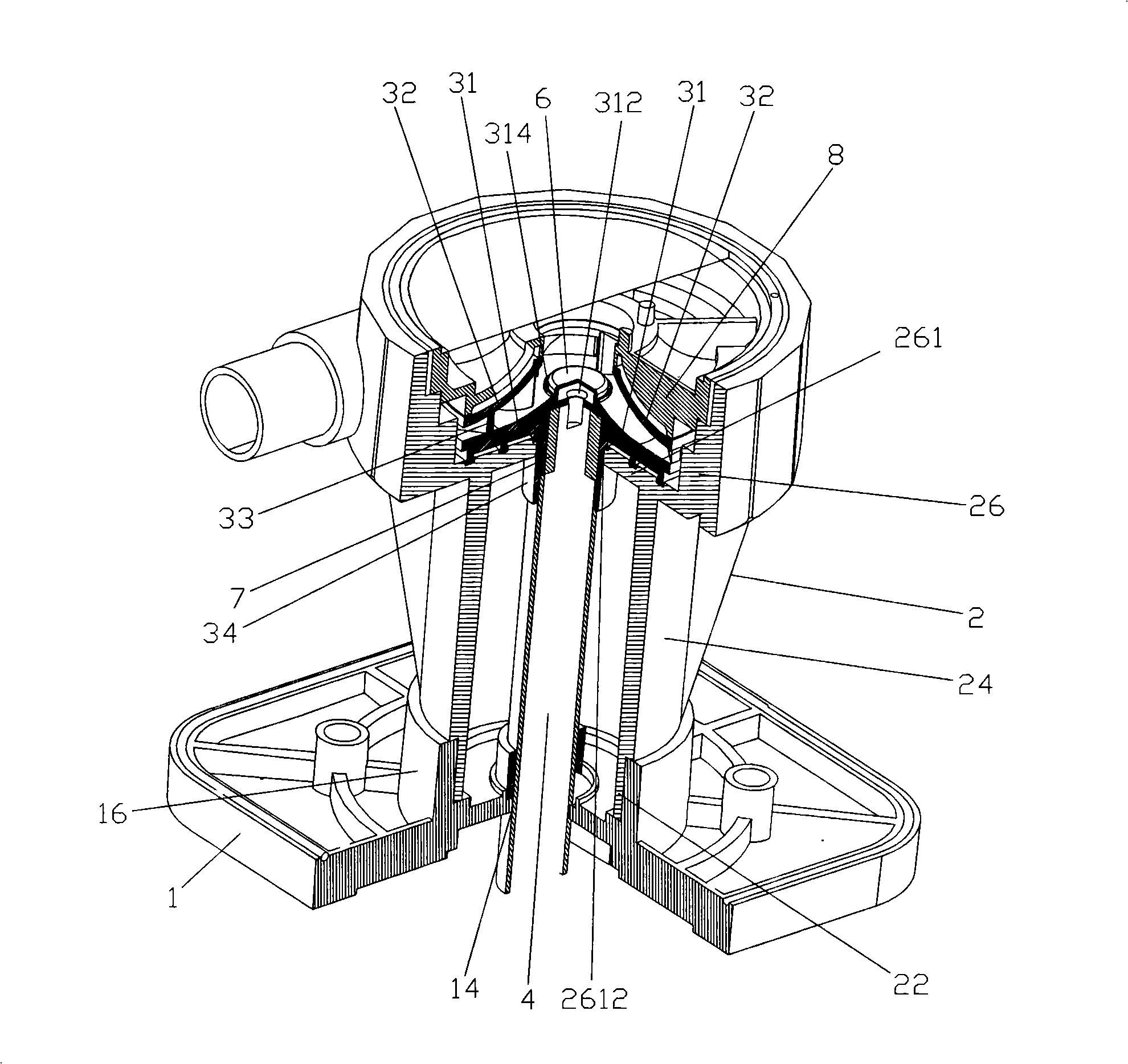

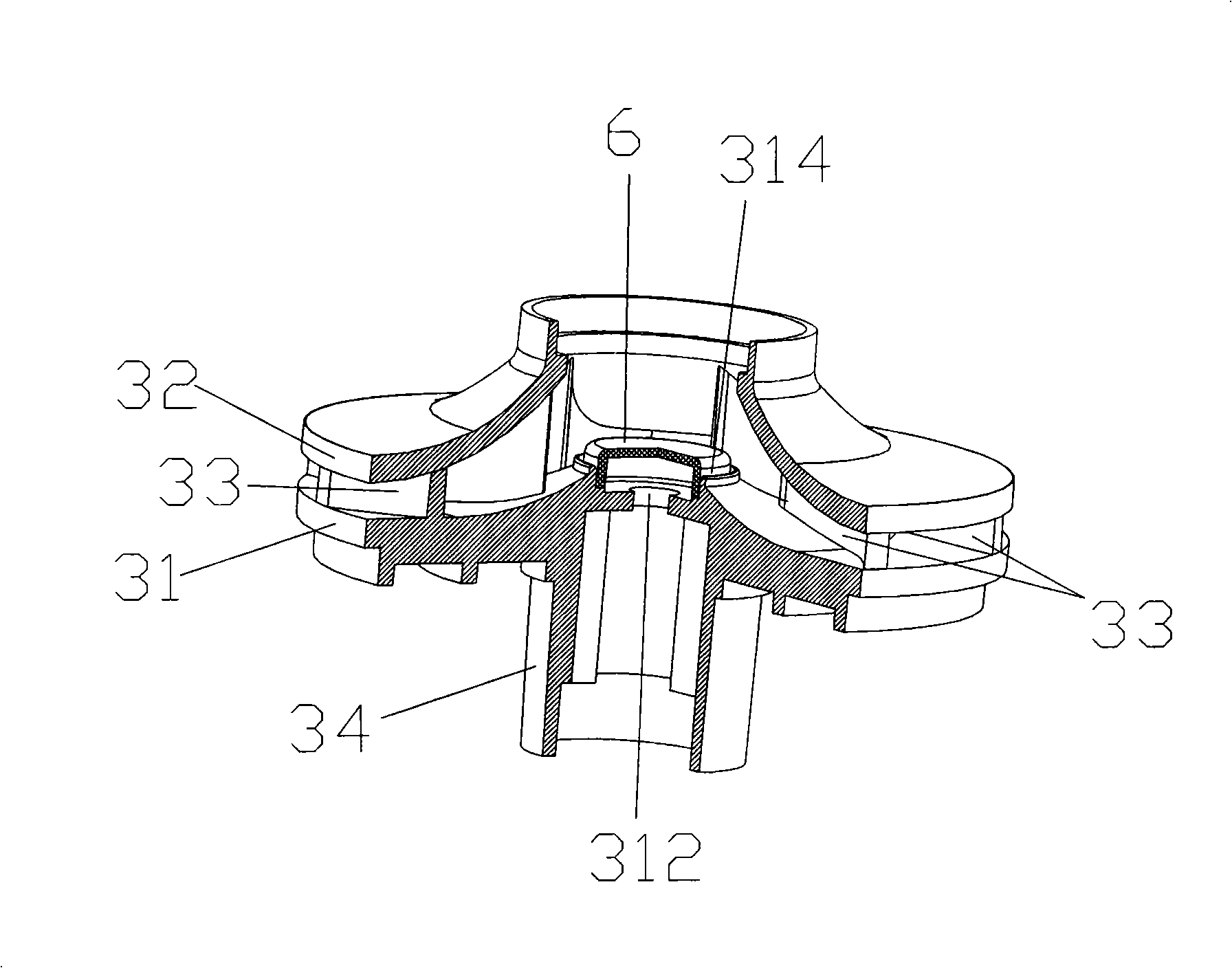

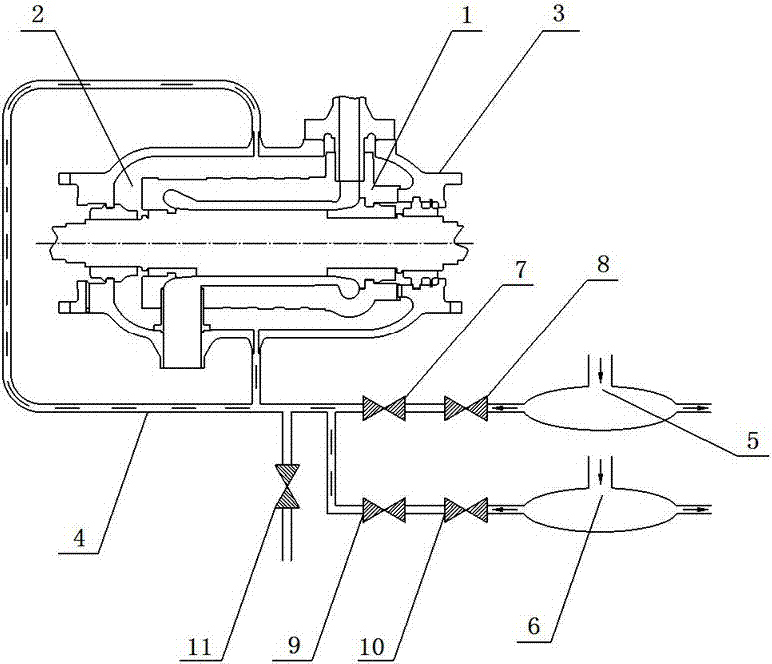

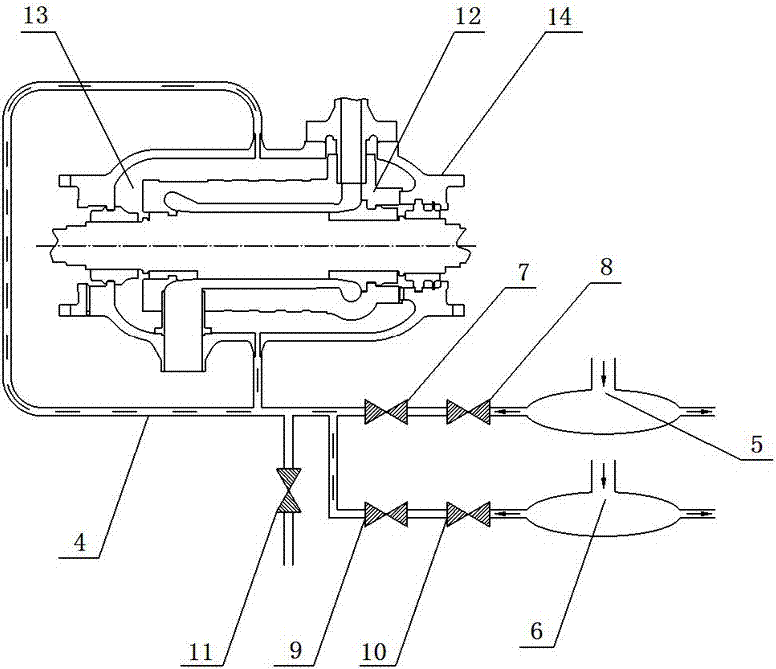

Crankcase ventilation apparatus of V type engine

ActiveCN101328824AReasonable pressurePrevent suctionMachines/enginesCrankcase ventillationCombustion chamberCylinder head

Owner:WUXI KIPOR POWER CO LTD

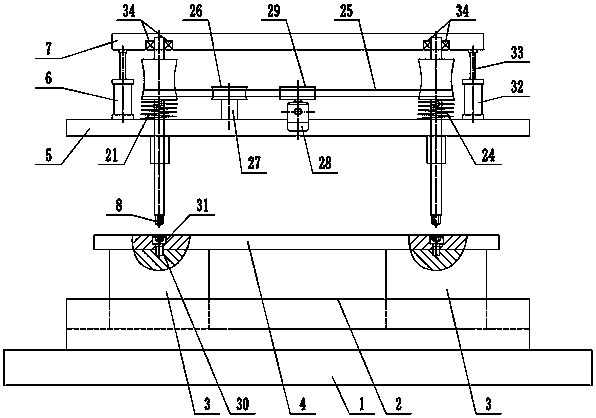

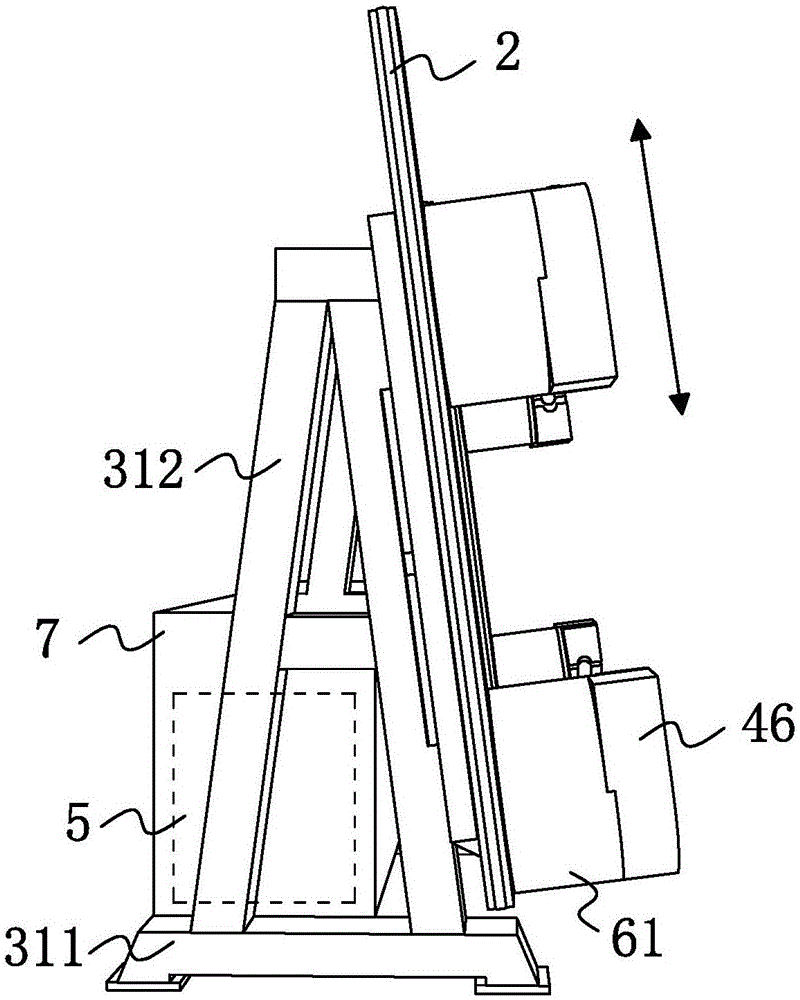

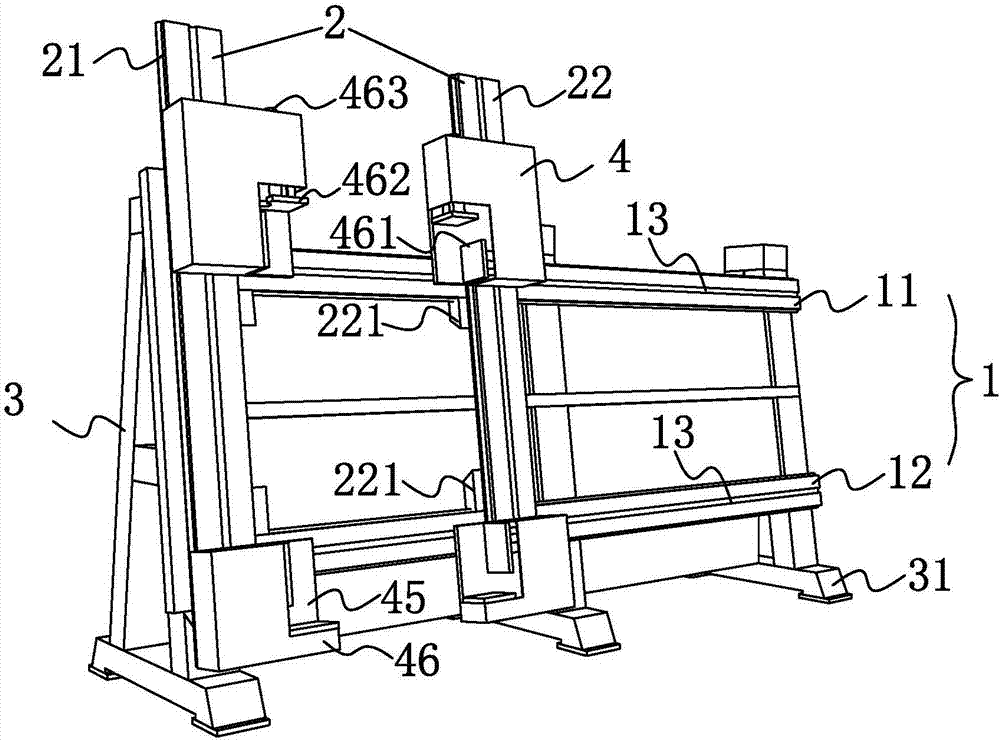

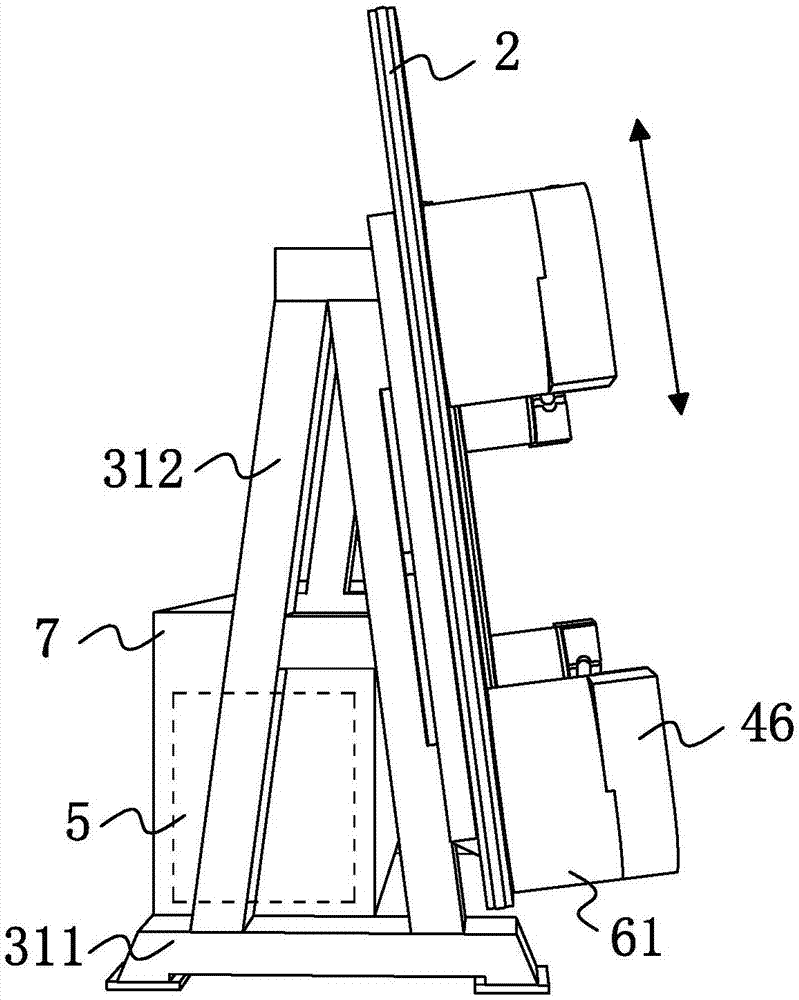

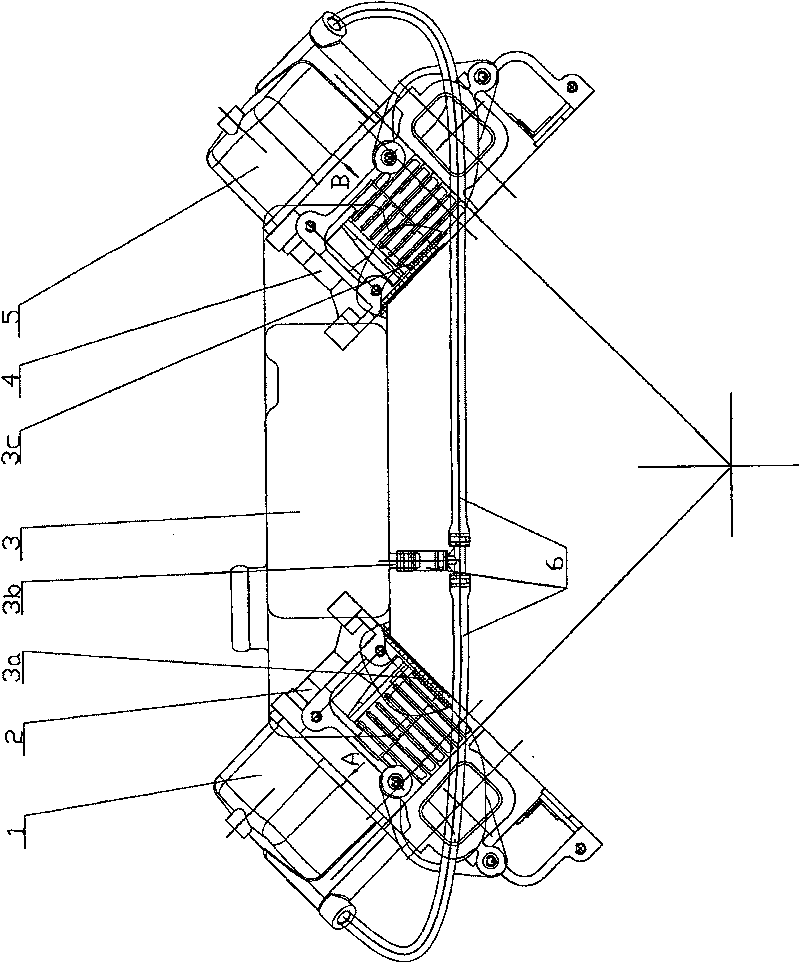

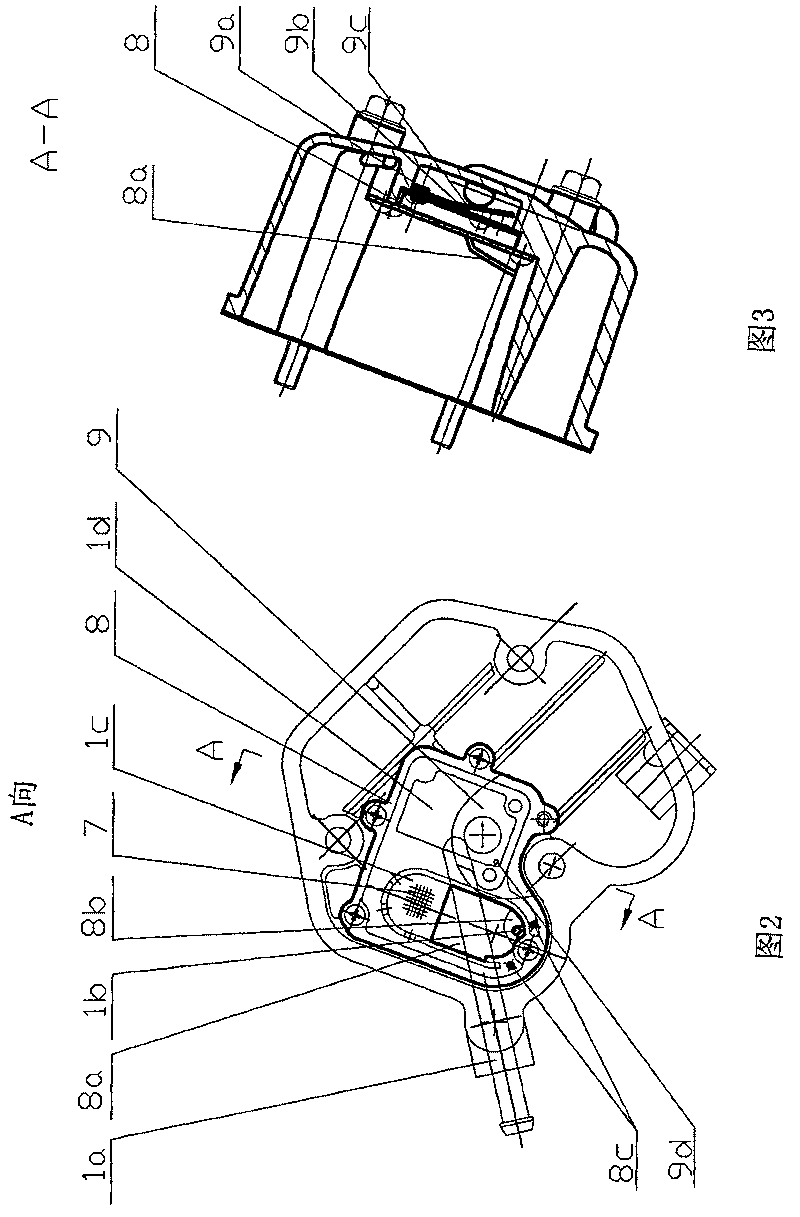

Dovetail groove slide block type guide rail automatic tightening device

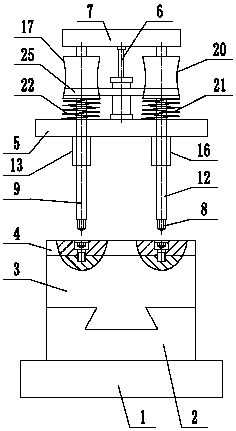

The invention provides an automatic tightening device for a dovetail slide block type guide rail, which belongs to the technical field of slide block type guide rails. It includes a hexagonal screw head, a connecting belt, a belt tensioner, a driving pulley, the upper end of the tightening drive piston rod of the tightening drive cylinder is connected to the tightening support plate, and the first screwing shaft is rotatably arranged on the first screwing shaft support seat and the tightening support On the board, the second screw shaft is rotatably arranged on the second screw shaft support seat and the tightening support plate, the third screw shaft is rotatably arranged on the third screw shaft support seat and the tighten support plate, and the fourth screw shaft is rotatably arranged on On the fourth screw shaft support seat and the tightening support plate, there are hexagonal screw heads under the first screw shaft, the second screw shaft, the third screw shaft and the fourth screw shaft, and the connecting belt is closed and surrounded by the driving pulley , Belt tensioner, first arc wheel, second arc wheel, third arc wheel and fourth arc wheel. The invention automatically tightens the hexagon socket head screw to realize the fast connection of the connecting plate and the sliding block of the dovetail groove.

Owner:桐乡市红旗塑料包装袋厂

Intravenous infusion anti-leakage device and method used for operating room nursing

ActiveCN105194758AFast calculation speedCalculation speedCatheterInfusion needlesSurface layerProgrammable logic controller

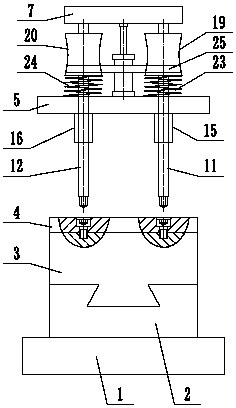

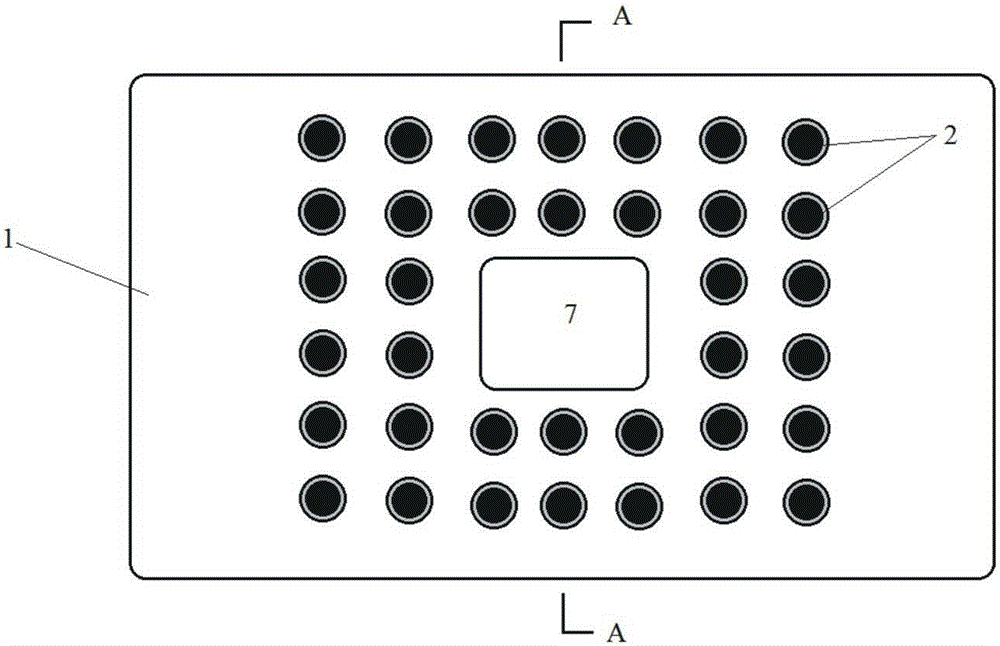

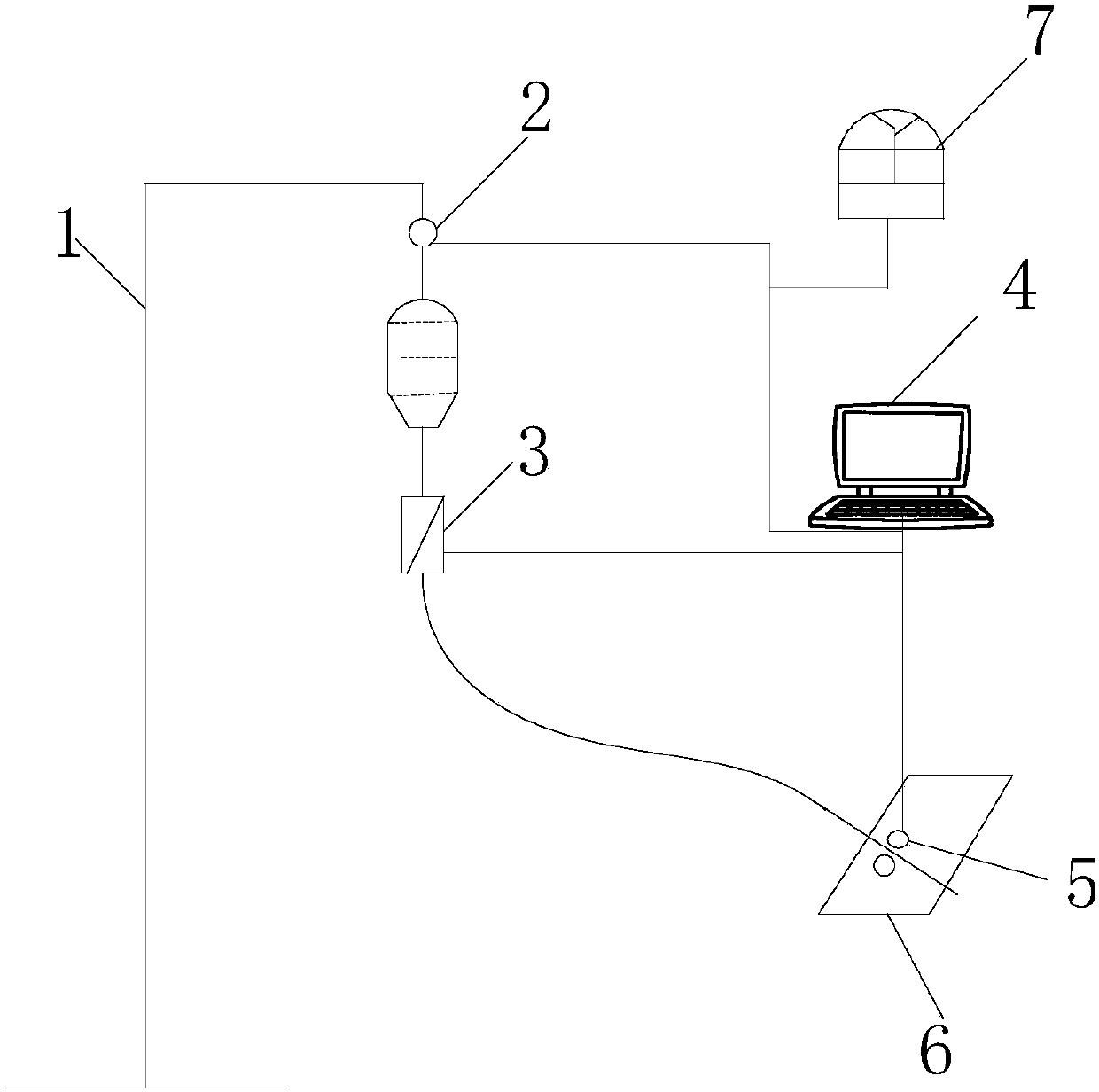

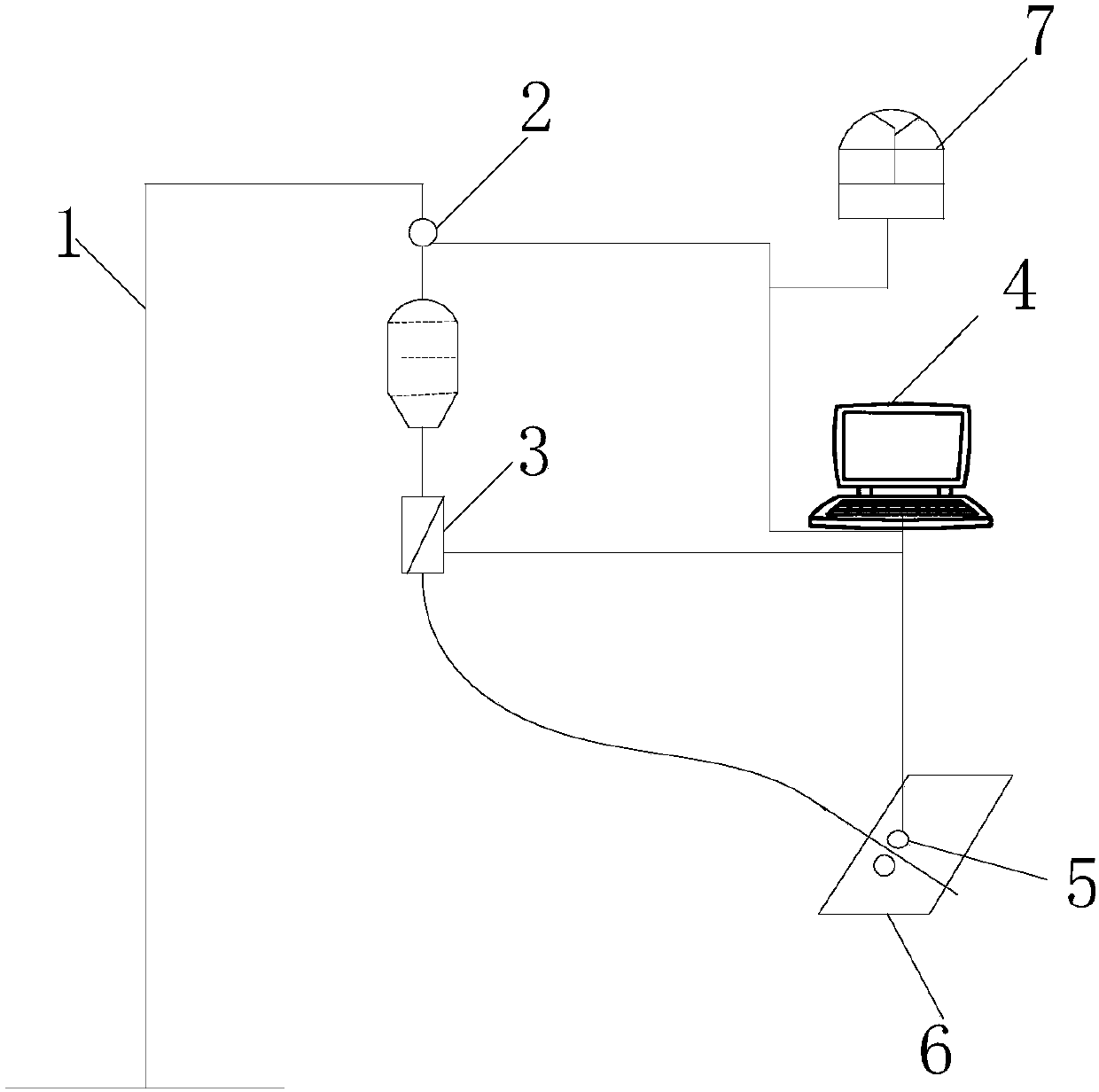

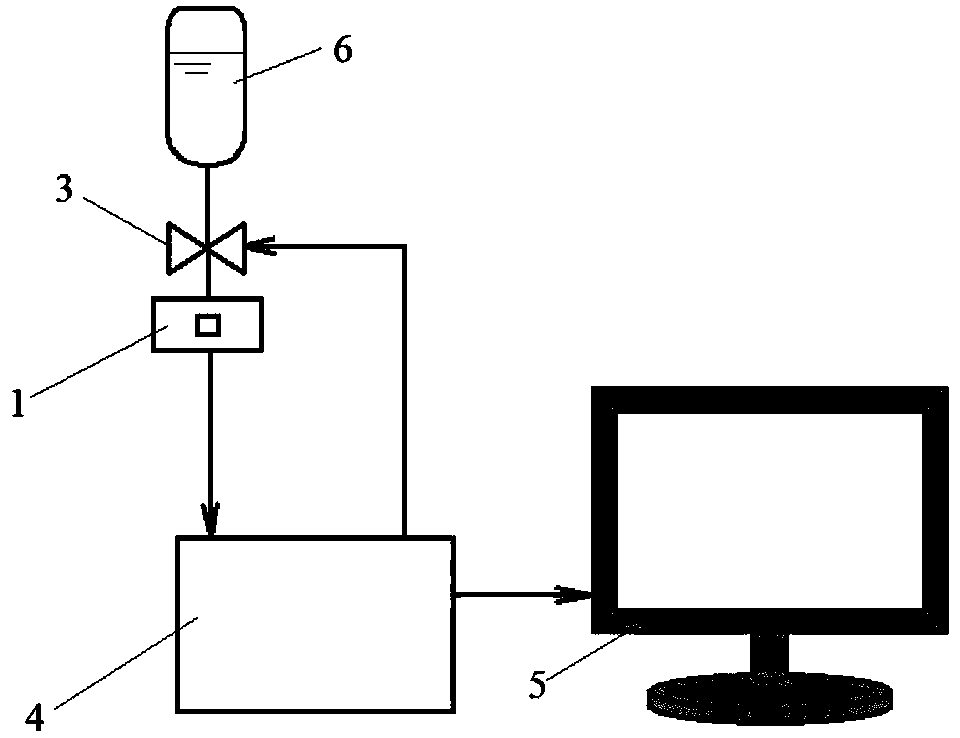

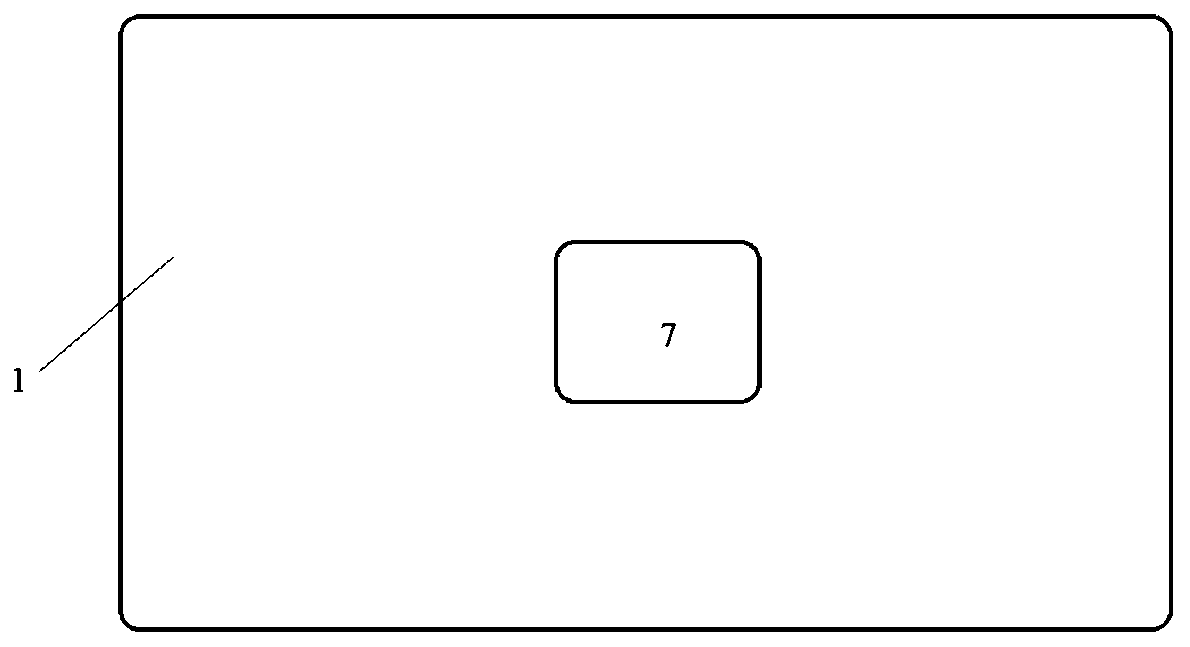

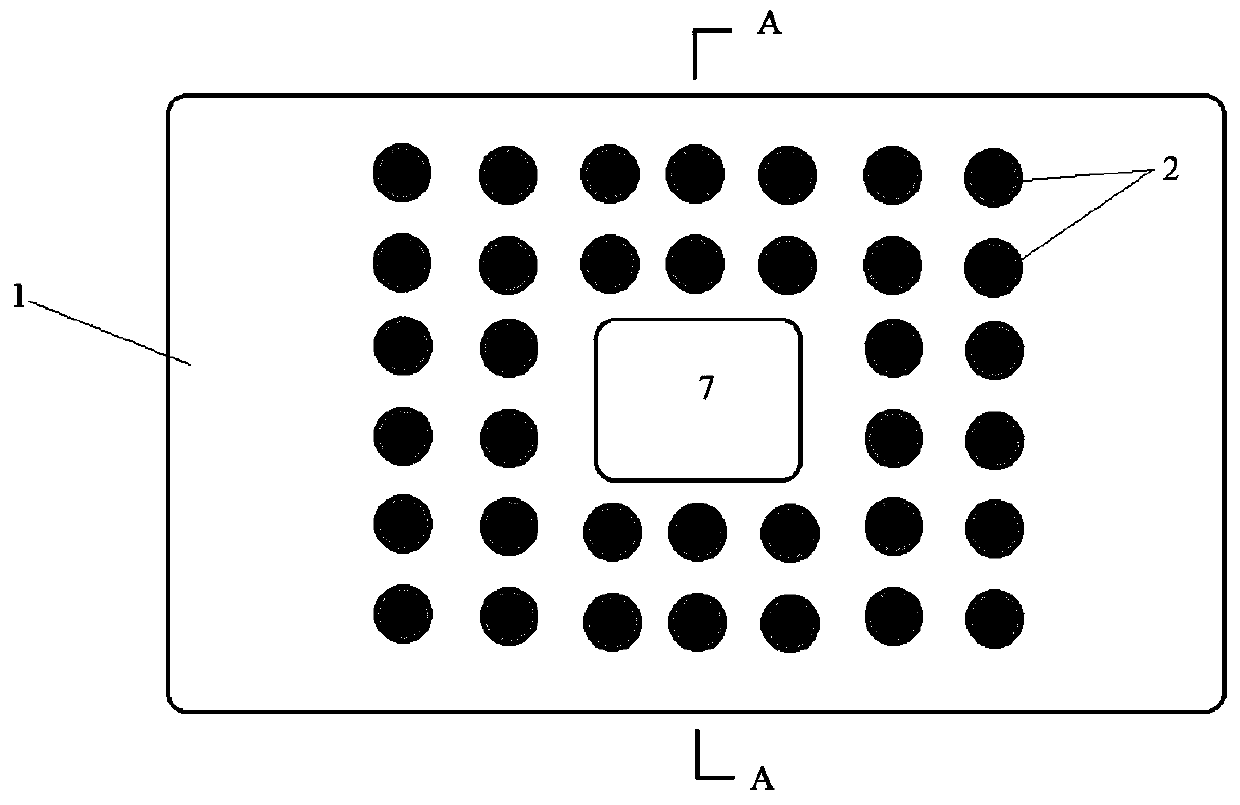

The invention provides an intravenous infusion anti-leakage device used for operating room nursing. The device comprises a rectangular dressing (1), pressure and temperature sensors (2), a liquid control valve (3), a PLC (programmable logic controller) (4), an interactive display terminal (5) and a control switch, wherein the dressing (1) comprises a surface layer (11) and a bottom layer (12); the surface layer (11) is made from breathable transparent materials; the bottom layer (12) is made from breathable self-adhesive materials; a hole is reserved in the middle of the bottom layer (12) and serves as an observation window (7); a plurality of pressure and temperature sensors (2) connected with the PLC (4) are arranged around the hole in the bottom layer (12); the liquid control valve (3) is arranged at a liquid outlet of an intravenous infusion device (6); the PLC (4) is connected with the liquid control valve (3) and controls the liquid control valve to open and close; the interactive display terminal (5) is connected with the PLC (4); the control switch controls the device to open and close. An intravenous infusion anti-leakage method used for operating room nursing is used for judging whether liquid leakage happens by using the device. By adopting the device and the method, whether leakage happens to intravenous infusion can be accurately judged and the infusion device can be timely closed, thus reducing harms caused to patients.

Owner:田桂菊

Operating room nursing venous transfusion leakproof device and control method thereof

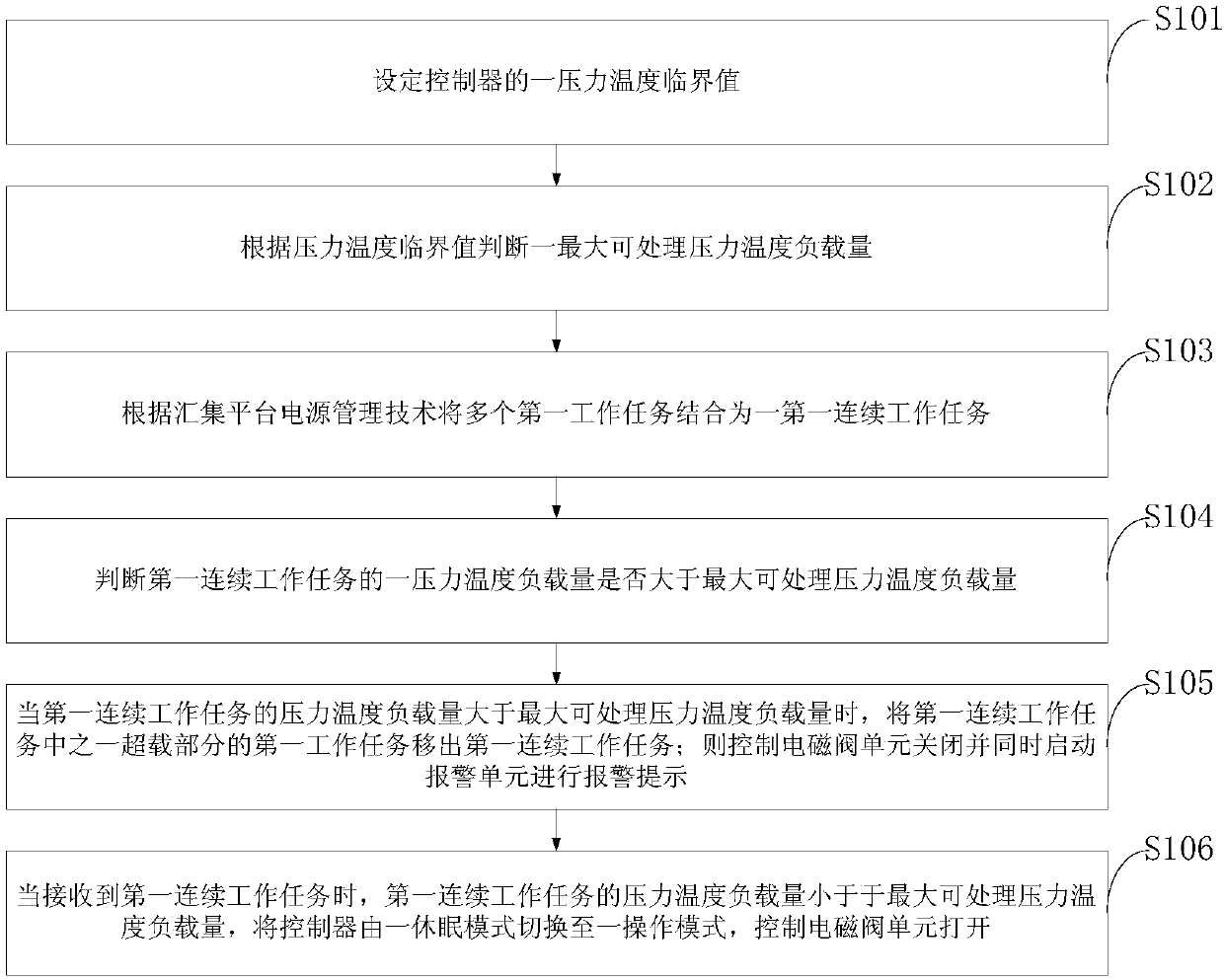

InactiveCN107050568AGuarantee the quality of nursing workAvoid medical malpracticeMedical devicesFlow monitorsIntensive care medicineIntravenous fluid

The invention discloses an operating room nursing venous transfusion leakproof device and a control method thereof. The operating room nursing venous transfusion leakproof device comprises a gravity sensor, an alarm unit, a sensor detecting unit, an electromagnetic valve unit and a controller. The control method of the operating room nursing venous transfusion leakproof device comprises setting a pressure and temperature critical value of the controller; according to the pressure and temperature critical value, determining a maximum processible pressure and temperature capacity; according to collecting platform power management technology, combining a plurality of first work tasks into a first continuous work task; determining whether the first pressure and temperature capacity of the first continuous work task is larger than the maximum processible pressure and temperature capacity to achieve control of the entire operating room nursing venous transfusion leakproof device. The operating room nursing venous transfusion leakproof device and the control method thereof can ensure the nursing operation quality and avoid medical negligence and are high in accuracy, simple in structure and convenient to operate.

Owner:李凤英

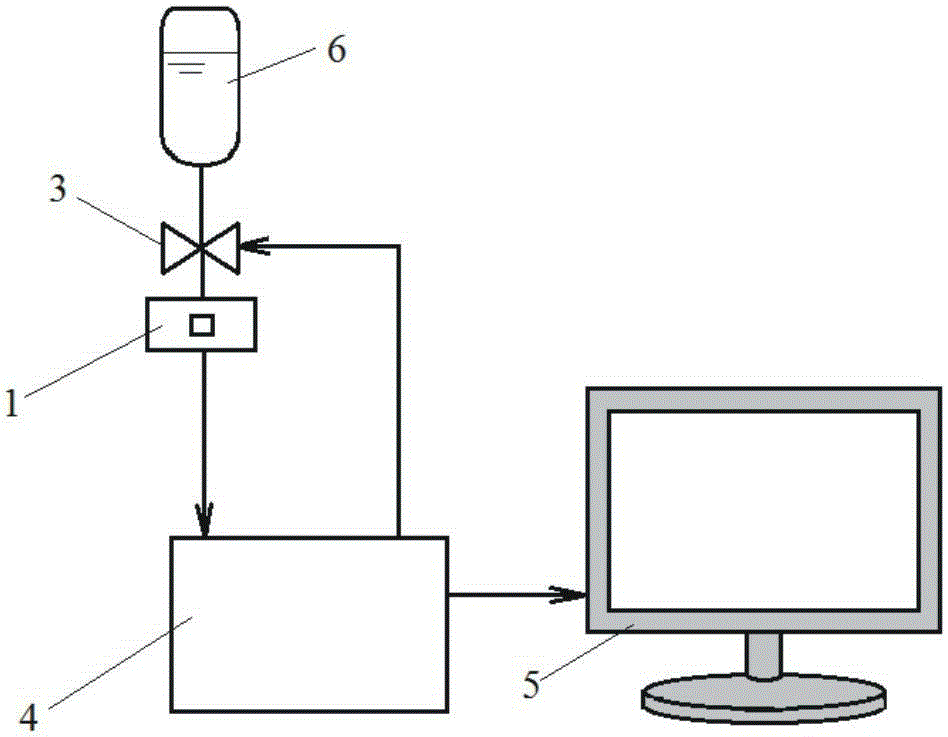

Gas tightness and sealing intensity test method for accumulator shell

InactiveCN102928184AQuickly find weak spotsQuick searchMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesWater leakageEngineering

The invention discloses a gas tightness and sealing intensity test method for an accumulator shell. The gas tightness and sealing intensity test method comprises the steps of filling water into the accumulator shell, sealing the shell, putting the shell into an observation box, adjusting air pressure to increasingly aerate the shell, taking the air pressure during the water leakage of the shell as the air tightness index of the shell, turning off a safety valve when the shell suddenly bursts, and recording the air pressure value as the sealing intensity index of the shell. According to the method, the sealing quality of the accumulator shell can be detected, the operation is simple and convenient, the investment is low, moreover, the sealing intensity of the accumulator shell and the pressure bearing value of the shell can be displayed in a digitalized manner.

Owner:SHUANGDENG GRP

Heat exchanger with variable numbers of communicating holes

ActiveCN105627789AEvenly distributedSolve the problem of uneven internal pressureHeat exhanger finsStationary conduit assembliesEngineeringMicro heat exchanger

The invention provides a heat exchanger. The heat exchanger comprises two headers and heat exchange pipes arranged between two headers. The heat exchange pipes are flat heat exchange pipes. Fins are arranged in the flat pipes. The fins include inclined parts. A fluid channel is divided into a plurality of small channels through the inclined parts. The numbers of the communicating holes distributed in the different flat heat exchange pipes are different, and the longer the distances of the flat heat exchange pipes away from an inlet pipe are, the larger the numbers of the communicating holes distributed in the flat heat exchange pipes are. By means of the heat exchanger with the variable numbers of the communicating holes, due to the fact that the numbers of the communicating holes are set to be changed along with the distances of the heat exchange pipes away from the inlet pipe, fluid flows into the heat exchange pipes which are low in flowing resistance and is away from the inlet pipe, the fluid is evenly distributed in the heat exchange pipes, the heat exchange efficiency is improved, and the service life is prolonged.

Owner:南通市通州区宏峰机械有限公司

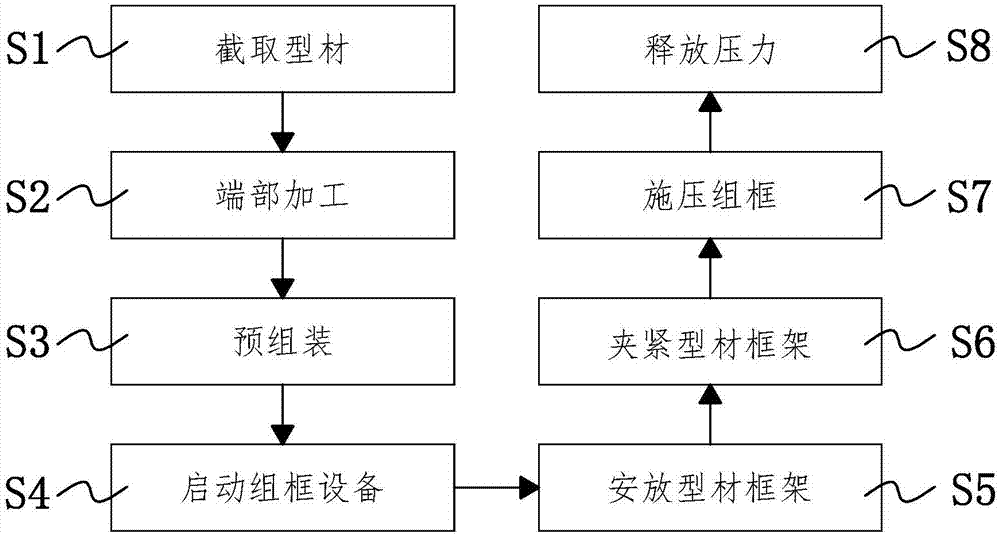

Framing machining method of core-shell structure door and window profiles

InactiveCN106801568AAchieve clampingApply pressure evenlyDoors/windowsEngineeringUltimate tensile strength

The invention discloses a framing machining method of core-shell structure door and window profiles, relates to the field of building decoration engineering, and aims to solve the problems that existing door and window profiles are not reasonable in assembly process, and door and window profile corners are not high in bonding strength and accuracy, close in sealing, attractive and durable. The framing machining method includes the steps: S1 cutting the profiles; S2 machining the ends of the profiles; S3 preassembling the machined profiles; S4 starting a framing device; S5 mounting a profile frame; S6 clamping the profile frame; S7 applying pressure to the frame; S8 releasing the pressure. By the aid of the steps, longitudinal parallel rods and transverse parallel rods relatively motion through hydraulic transmission, the assembled door and window profiles can be effectively assembled in the device, and the method solves the quality problems that in a traditional assembly process, force is unequally applied, errors are large, the ends of the profiles are easily damaged, connectors have biased and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

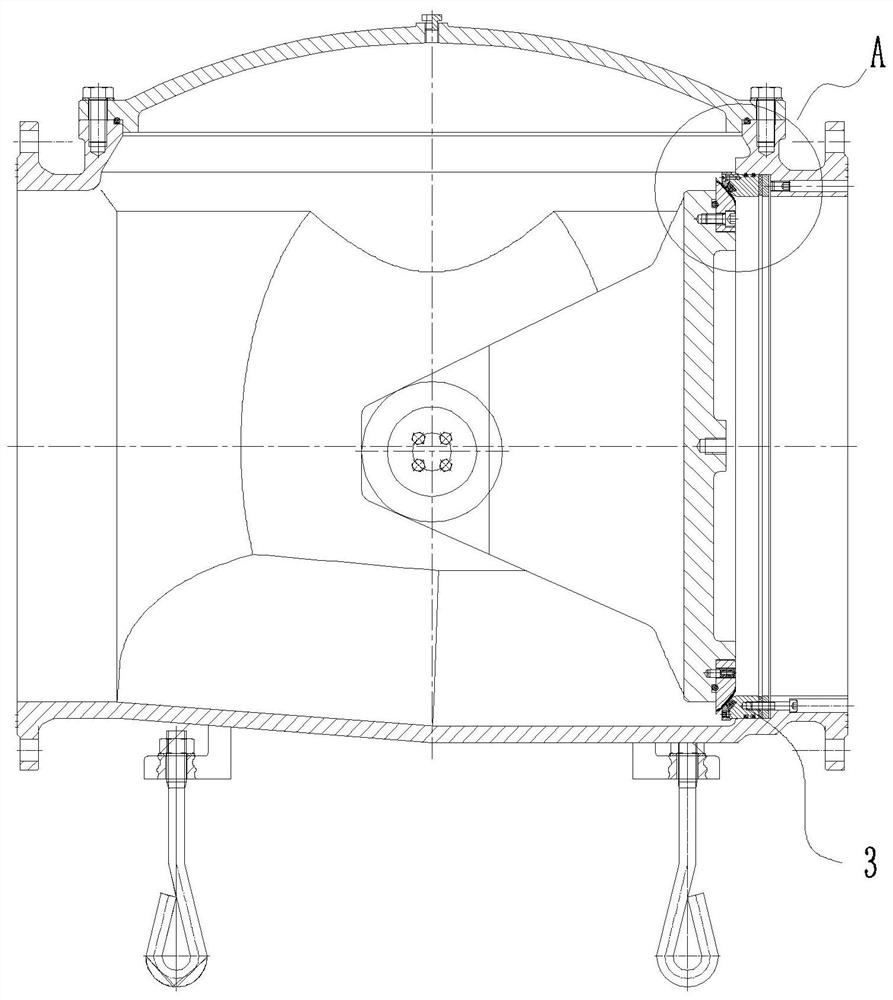

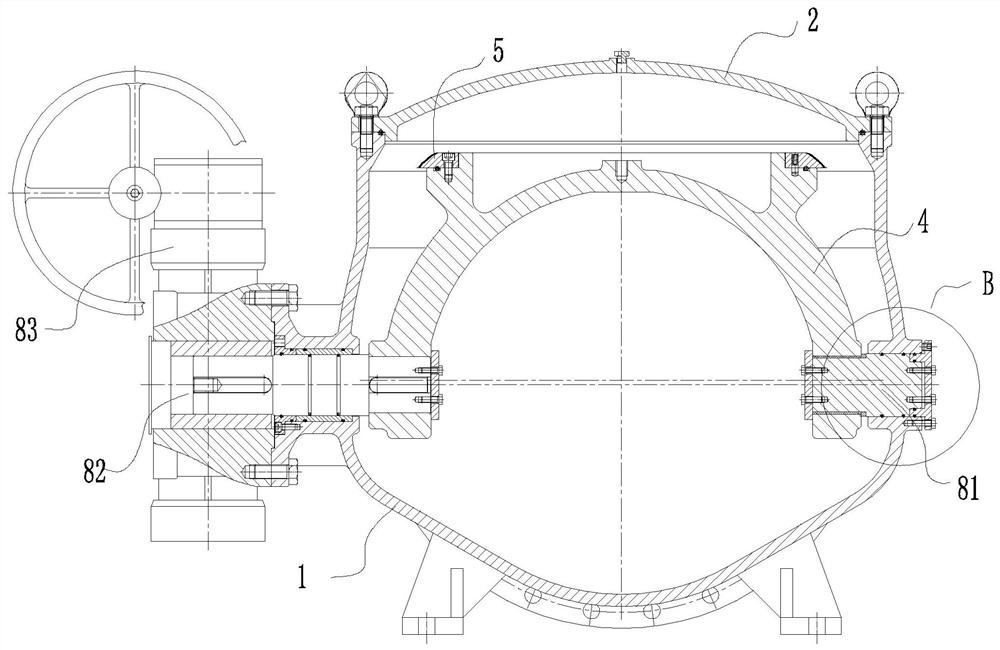

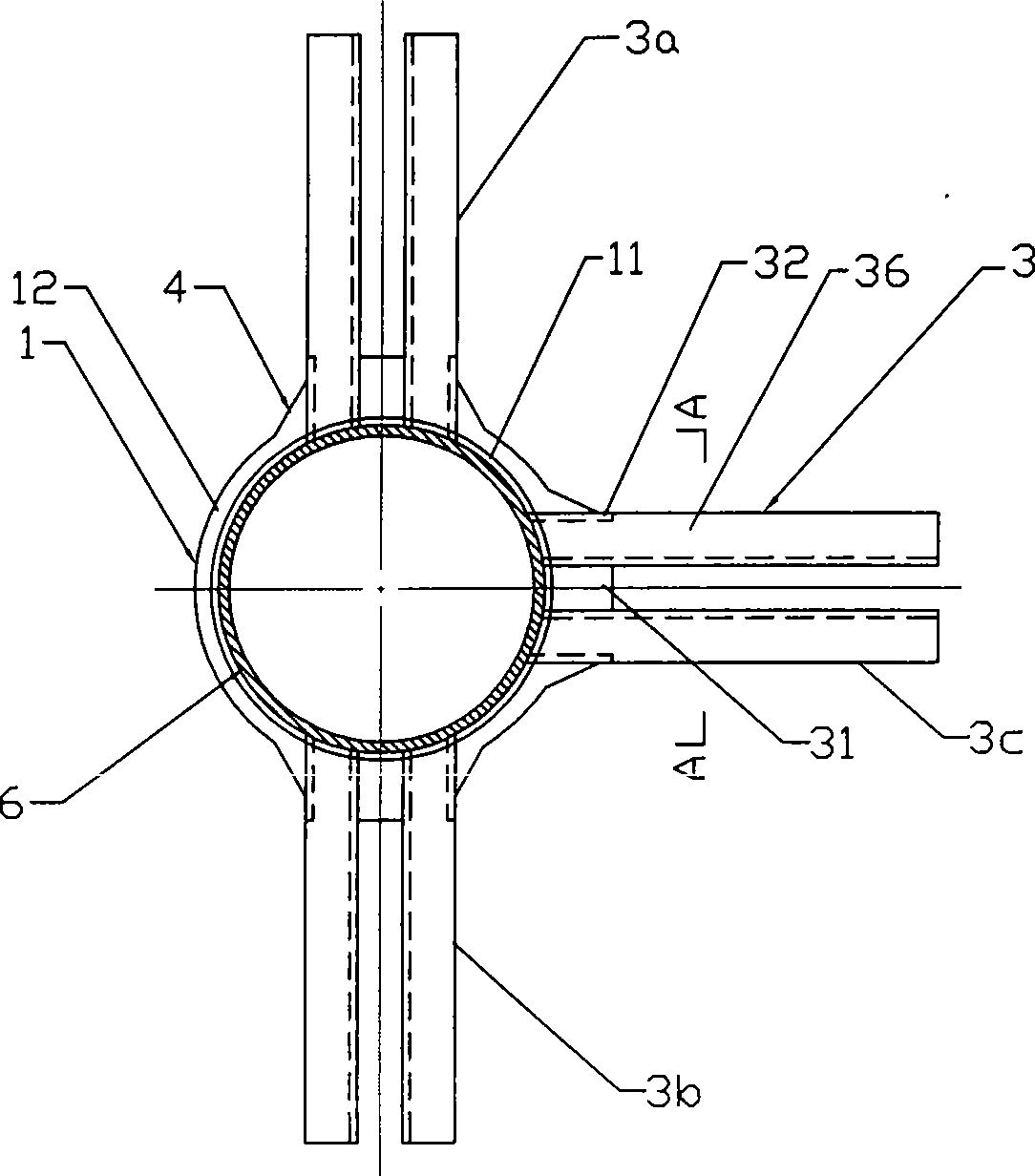

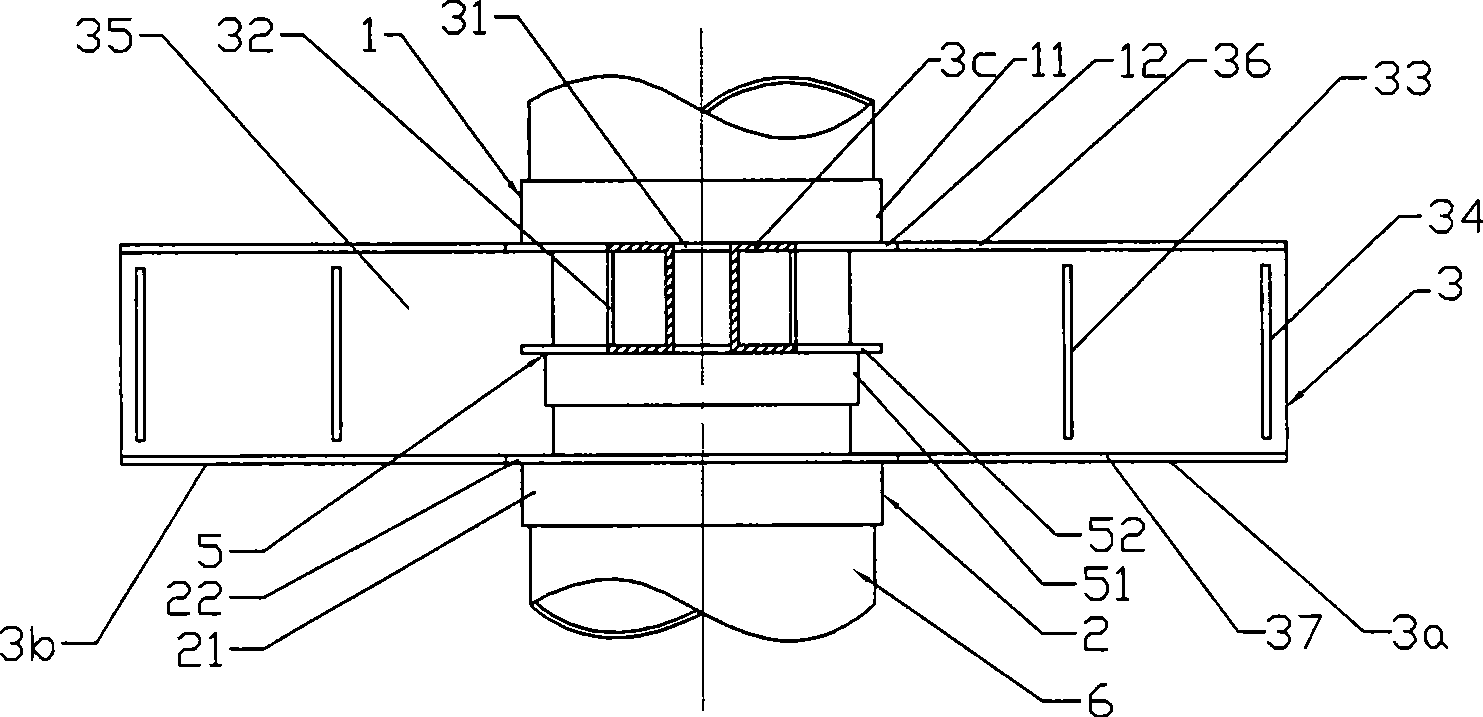

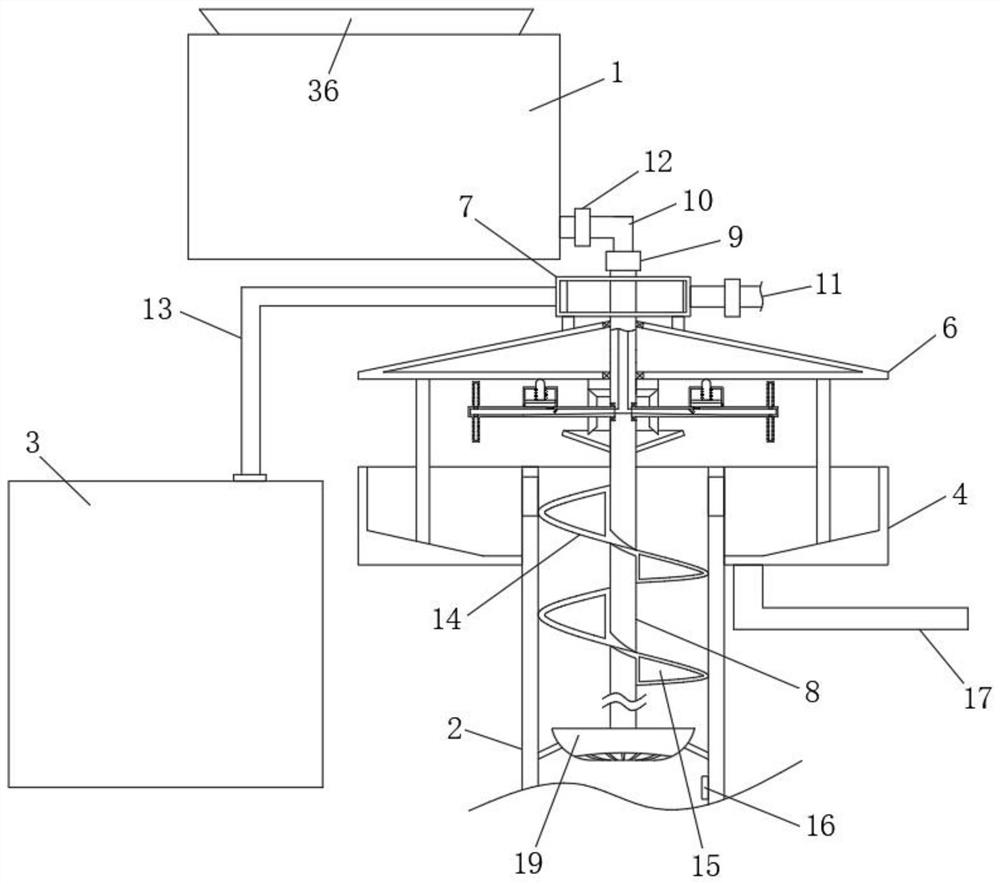

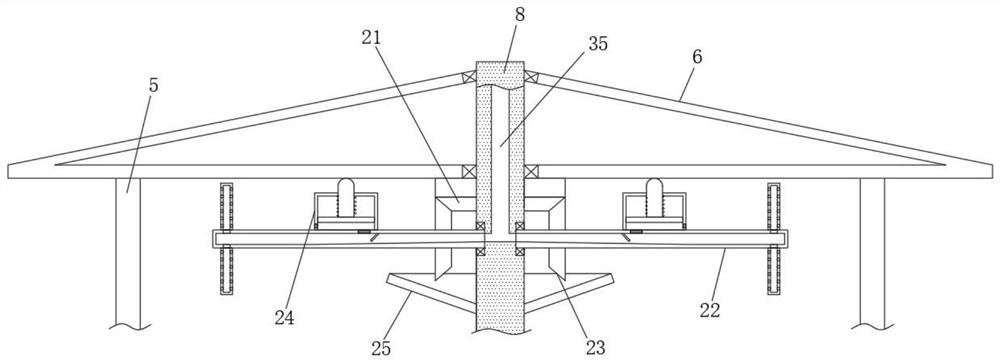

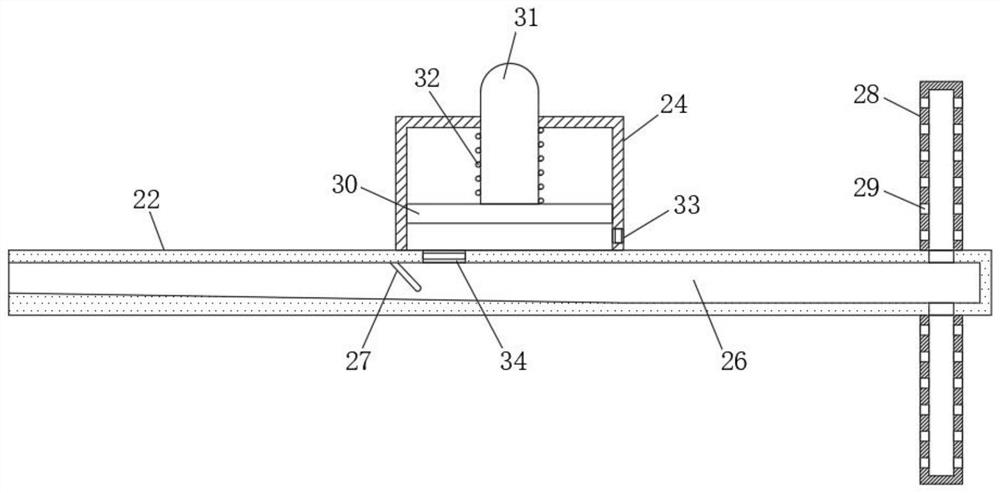

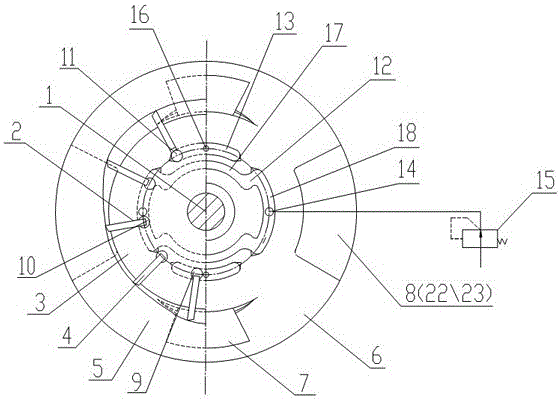

Chemical water pump

InactiveCN101294574AReasonable pressureReasonable trafficSpecific fluid pumpsPump componentsImpellerCompound (substance)

The invention relates to a centrifugal chemical pump which comprises a pump body, an impeller and a pump shaft driving the impeller to rotate; wherein the pump body comprises an upper shell; the upper shell comprises a bottom plate, a ring-shaped lateral wall, a water inlet, a water outlet and a cog; the lateral wall is arranged on the edge of the bottom plate in a winding manner, the water inlet is arranged at the top end of the upper shell, the water outlet is arranged in the position of the lateral wall near the bottom plate, the cog is involute-structured, namely, the cog is arranged in the intersection position of the bottom plate and the lateral wall in a winding manner, both ends of the cog are respectively arranged at the both ends of the water outlet, and the thickness of the cog gradually turns smaller; the impeller arranged on the upper shell of the pump body comprises a rib wheel, a cover wheel and a plurality of main blades; wherein, the cover wheel is arranged above the rib wheel in an overlapping manner, the arc-shaped main blades are arranged between the rib wheel and the cover wheel. The centrifugal chemical pump can achieve reasonable pressure and flow rate, ensure low energy consumption and effectively prevent the pump shaft from being corroded.

Owner:杨军 +1

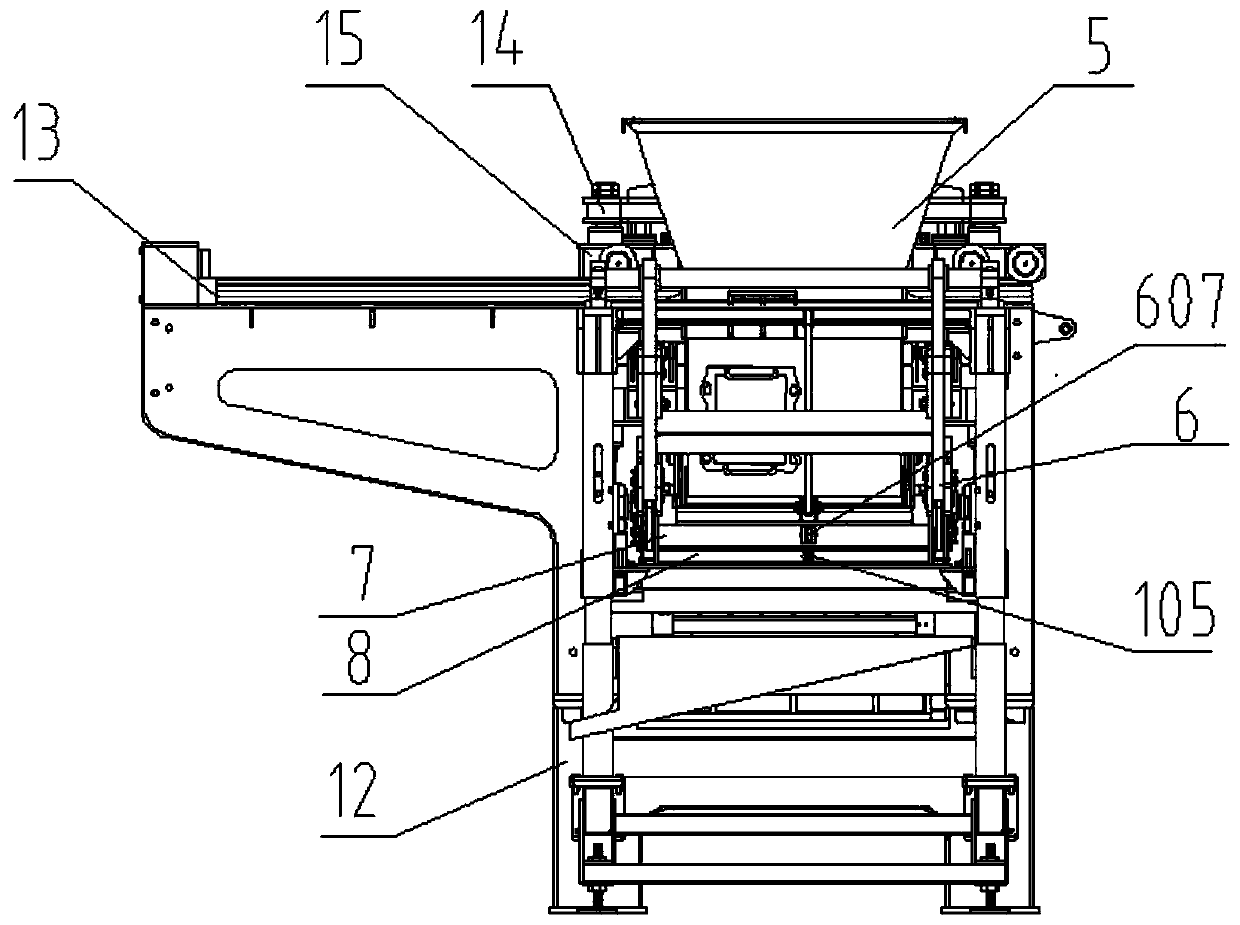

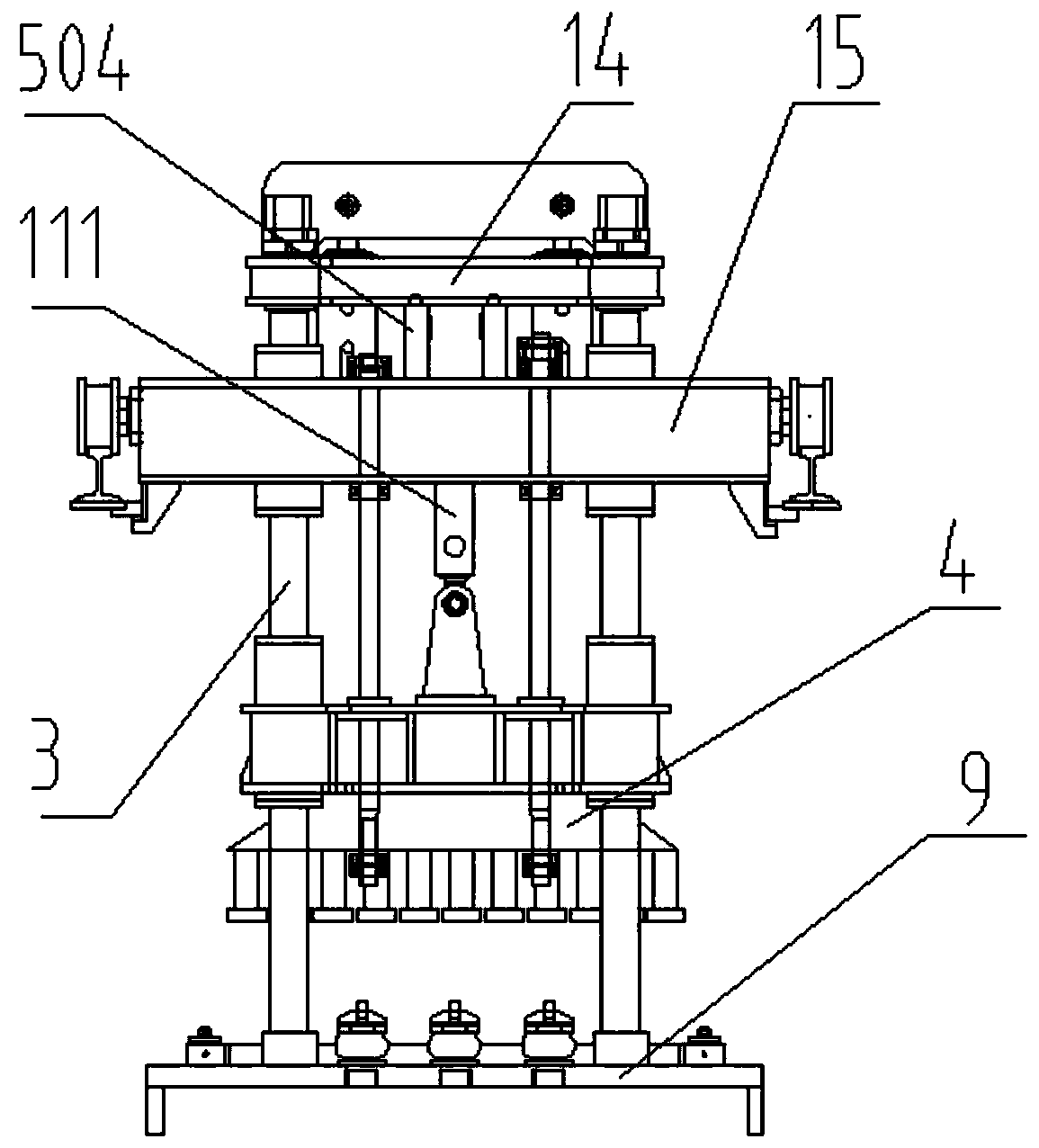

Hydraulic control system of building block forming machine

ActiveCN110116453AImprove matching abilitySave layout spaceDischarging arrangementFeeding arrangmentsTransfer systemFuel tank

The invention discloses a hydraulic control system of a building block forming machine. The hydraulic control system is capable of realizing process pressurizing control over a forming mechanism in abuilding block production process and can be combined with a main building block forming machine to realize the production of building blocks. The system specifically comprises a first power system, asecond power system, a die transferring system, a surface material distributing system, a die releasing and propping-out system, a bottom material distributing system, an oil returning system and anoil tank, wherein the first power system is connected to the second power system; the first power system internally comprises a part for supplying power to a pressing head pressing part and a materialhomogenizing part; the second power system is correspondingly connected to the die transferring system, the surface material distributing system, the die releasing and propping-out system and the bottom material distributing system; an inlet of the oil returning system is correspondingly connected to the first power system, the bottom material distributing system, the surface material distributing system, the die transferring system and the die releasing and propping-out system; and an outlet of the oil returning system is connected to the oil tank. The system is capable of realizing safety sequence action under different technology demands of the building block forming machine, and high quality building blocks can be produced, and moreover, the system utilization rate can be increased; and the system is efficient and stable.

Owner:NANJING UNIV OF SCI & TECH +1

Horizontal shaft eccentric semi-ball valve

PendingCN112460283ALow flow resistanceEasy maintenancePlug valvesValve housingsEngineeringValve seat

The invention discloses a horizontal shaft eccentric semi-ball valve. A valve element is installed through a horizontal shaft structure, the axis of a valve rod of the horizontal shaft eccentric semi-ball valve is perpendicular to the flowing direction of media in a valve body and is horizontally arranged, the lower end of a flow channel is not occupied, the lower end of the flow channel can be designed to be smoother than a vertical eccentric semi-ball valve, and flowing resistance is reduced. A cylindrical boss concentric with the valve element is arranged on the valve element, a sealing ring is arranged on the boss in a sleeving manner at an interval, the sealing ring is provided with a spherical-crown-shaped sealing face, an air bag ring is arranged in a clamping gap formed by the bossand the sealing ring, and the sealing ring and the valve element are fixed through a fixing assembly. The center of a valve element sealing spherical crown and the center of a valve seat can be adjusted to be concentric in the assembling process, machining errors are overcome, and effective sealing is guaranteed.

Owner:YUANDA VALVE GRP CO LTD

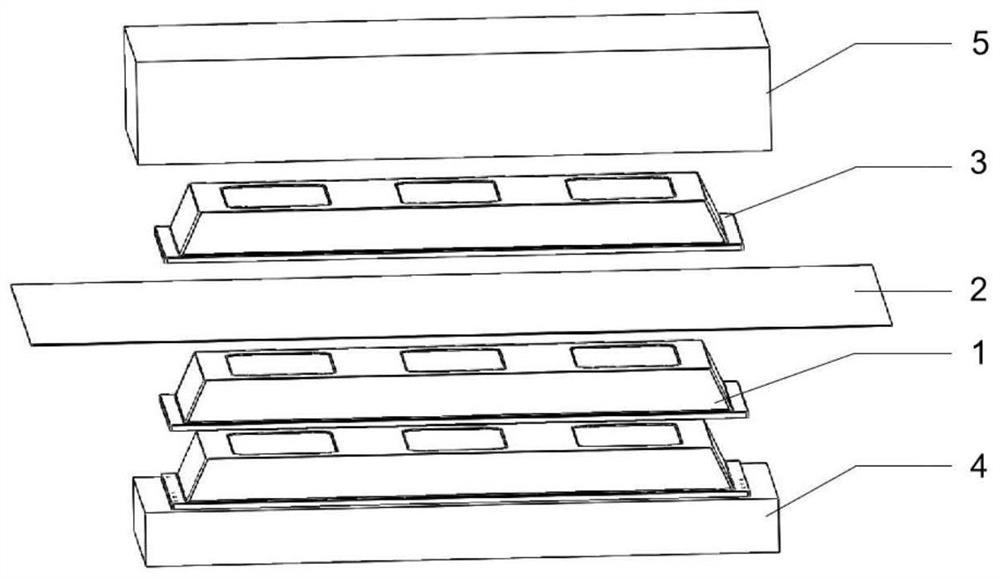

Super-hybrid composite material battery box and preparation method thereof

PendingCN114512753AShieldingFlame retardantMagnetic/electric field screeningBattery isolationElectrophoresesElectrical battery

The invention relates to a super-hybrid composite material battery box and a preparation method thereof, the super-hybrid composite material battery box comprises an inner-layer metal shell, an outer-layer metal shell and a sheet molding compound, the inner-layer metal shell is sleeved in the outer-layer metal shell, and the sheet molding compound is connected between the inner-layer metal shell and the outer-layer metal shell. According to the battery box disclosed by the invention, a metal-sheet molding compound (SMC)-metal laminated structure is adopted, and the metal shell with the two layers of outer surfaces has electromagnetic shielding and flame-retardant effects while providing certain strength, and can be directly subjected to electrophoretic coating at the same time. The sheet molding compound composite material in the middle reduces the weight of the battery box, provides higher strength and rigidity, is easy to form, and has higher bonding strength with metal.

Owner:义乌协同创新研究院 +1

A method for adjusting and operating steam turbine interlayer steam parameters

ActiveCN106194284BReasonable temperatureReasonable pressureMachines/enginesEngine controlSteam pressureEngineering

The invention discloses a method for adjusting and operating the interlayer steam parameters of a steam turbine. For a reheating unit, the steps include: 1) adopting a structure of directly exhausting steam in the high-pressure inner cylinder of the high-pressure cylinder; 2) using a pressure balance pipe to connect the parallel Steam source 1 and steam source 2 are connected to the interlayer between high-pressure inner and outer cylinders; 3) When the steam turbine starts up in a cold state, open the first stop valve and adjust the opening of the first throttle valve to control the steam flow in the pipeline to warm up ;4) When the steam turbine is running normally, close the first cut-off valve and the first throttle valve, open the second cut-off valve and the second throttle valve, use steam source 2 to build up the interlayer steam pressure, and have high-pressure front and rear end steam Seal leakage steam leaks into the interlayer between the high-pressure inner and outer cylinders; adjust during the process of increasing load and changing load, and properly adjust the steam source and valve to establish a suitable temperature field and pressure field for the interlayer between the high-pressure inner and outer cylinders, adapting to the high-pressure inner and outer cylinders Changes in pressure and temperature fields. This method is also applicable to the ultra-high pressure cylinder of the double reheat unit.

Owner:DONGFANG TURBINE CO LTD

Node component used for connecting steel tube concrete column with building roof beam

The invention a juncture structure used in connecting the steel pipe concrete post and the building coping, comprising a steel and fixed arranged juncture structure, all the juncture structure comprising an annual board structure and a steel cow leg component, the annual board component comprises more than one upper annual board and one lower annual board that the longitudinal cross-section are Lshaped, composed by the vertical annual board and the horizontal annual board turned outside, the upper annual board and the lower annual board is fixed connected with the outer wall of the steel pipe, the steel cow leg component is horizontally placed, comprising more than one steel cow leg, one end of the steel cow leg is fixed connected with the annual board component and the outer wall of thesteel pipe, another end of the steel cow leg is extended outside. The invention has a novel structure with a reasonable shearing force and torque-transmitting mechanism, the produce and assembly of the injecting concrete is easy, the juncture area is small, the device tunnel is not influenced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE +1

A connected hole fin heat exchanger with different row spacing

InactiveCN105571347BEvenly distributedSolve the problem of uneven internal pressureHeat exhanger finsStationary conduit assembliesMechanical engineeringMechanics

The invention provides a heat exchanger. The heat exchanger comprises two headers and heat exchanging tubes which are arranged between the two headers; each heat exchanging tube is a flat heat exchanging tube; fins are arranged in each flat tube; each fin comprises an inclined part; the inclined parts are used for isolating fluid passages to form a plurality of small passages; the same inclined part is provided with a plurality of rows of communication holes; the distance between every two adjacent rows of communication holes are represented by S2; the S2s in different flat heat exchanging tubes are different in value; the farther the distances away from an inlet tube are, the smaller the S2s are. According to the heat exchanger provided by the invention, the distances between every two adjacent rows of communication holes are set to vary along with the distances away from the inlet tube, so that a fluid can flow into the heat exchanging tube which is small in flow resistance and far away from the inlet tube; therefore, the fluid can be uniformly distributed in the heat exchanging tubes, the heat exchange efficiency is improved, and the service life is prolonged.

Owner:青岛酒店管理职业技术学院

Environment-friendly building smoke exhaust pipe

InactiveCN113187199APromote absorptionEasy to handleGas treatmentUsing liquid separation agentDaily livingWater storage tank

The invention discloses an environment-friendly building smoke exhaust pipe. The environment-friendly building smoke exhaust pipe comprises a waste water tank, a smoke exhaust pipe body and a water storage tank, wherein the waste water tank is used for collecting domestic waste water, a storage box is arranged at the outer top of the smoke exhaust pipe body, a supporting rod is fixedly connected to the top of the storage box, a top plate is arranged at the top of the supporting rod, a water drainage tank is fixedly connected to the top of the top plate, and a rotating shaft extending to the top of the water drainage tank is arranged in the smoke exhaust pipe body. According to the environment-friendly building smoke exhaust pipe, pressure in a household tap water pipeline is reasonably and effectively utilized, driving of any driving electric appliance is not needed, water in the tap water pipeline can enter the water storage tank, the requirements of people for daily life can be met, waste of water resources in the tap water pipeline is not caused, the energy-saving and environment-friendly effects are achieved, and meanwhile, waste water in the waste water tank can be used for water sprayed out of a rotating plate without additional water resources, the water resources are effectively and reasonably recycled, and the national call of saving energy is responded.

Owner:绍兴明楷机械有限公司

Improved vane hydraulic pump and motor

ActiveCN104100521BReduce fluid pressureReliable contact workRotary piston pumpsRotary piston liquid enginesVolume variationDrive shaft

Owner:胡凯

Anti-leakage device and method for intravenous transfusion for nursing in operating room

ActiveCN105194758BImprove accuracyFast calculation speedCatheterInfusion needlesSurface layerProgrammable logic controller

The invention provides an intravenous infusion anti-leakage device used for operating room nursing. The device comprises a rectangular dressing (1), pressure and temperature sensors (2), a liquid control valve (3), a PLC (programmable logic controller) (4), an interactive display terminal (5) and a control switch, wherein the dressing (1) comprises a surface layer (11) and a bottom layer (12); the surface layer (11) is made from breathable transparent materials; the bottom layer (12) is made from breathable self-adhesive materials; a hole is reserved in the middle of the bottom layer (12) and serves as an observation window (7); a plurality of pressure and temperature sensors (2) connected with the PLC (4) are arranged around the hole in the bottom layer (12); the liquid control valve (3) is arranged at a liquid outlet of an intravenous infusion device (6); the PLC (4) is connected with the liquid control valve (3) and controls the liquid control valve to open and close; the interactive display terminal (5) is connected with the PLC (4); the control switch controls the device to open and close. An intravenous infusion anti-leakage method used for operating room nursing is used for judging whether liquid leakage happens by using the device. By adopting the device and the method, whether leakage happens to intravenous infusion can be accurately judged and the infusion device can be timely closed, thus reducing harms caused to patients.

Owner:田桂菊

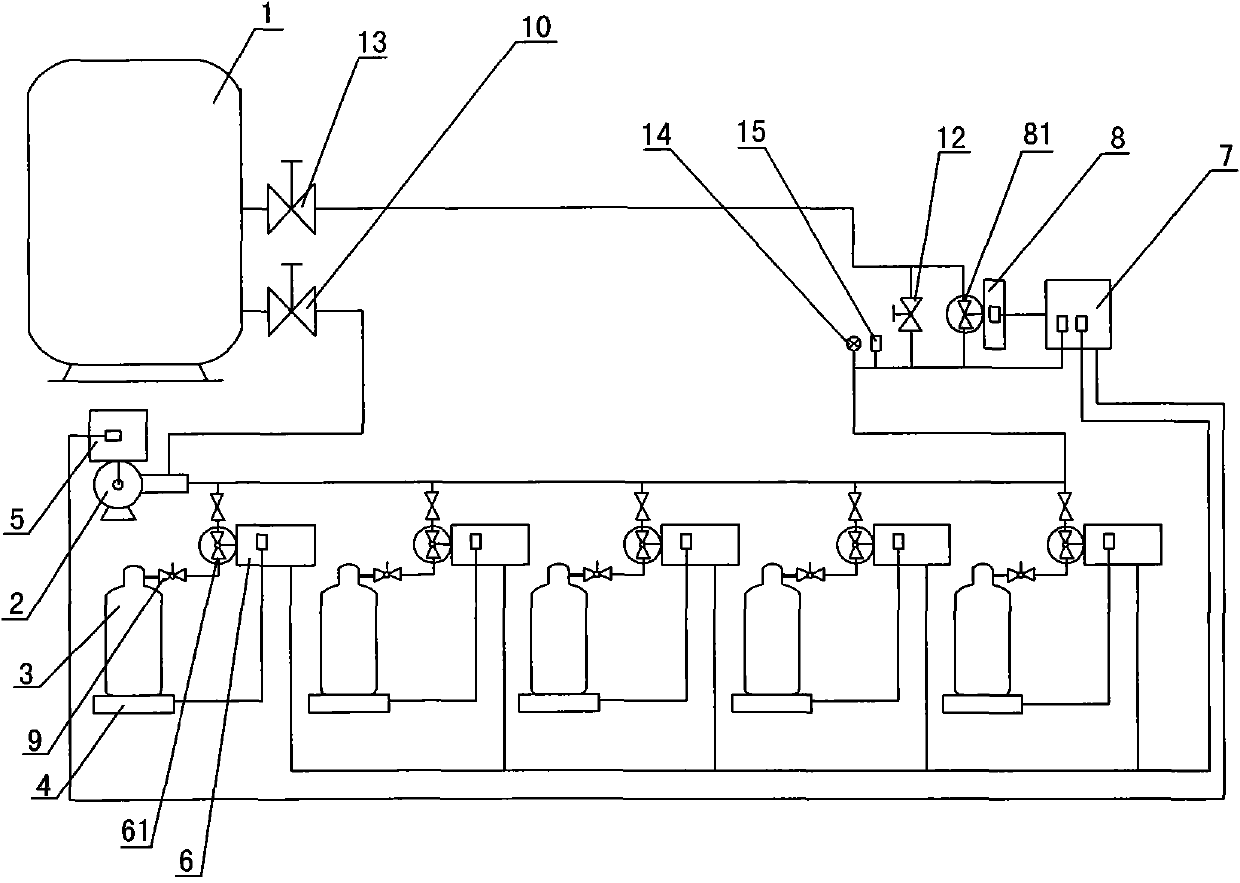

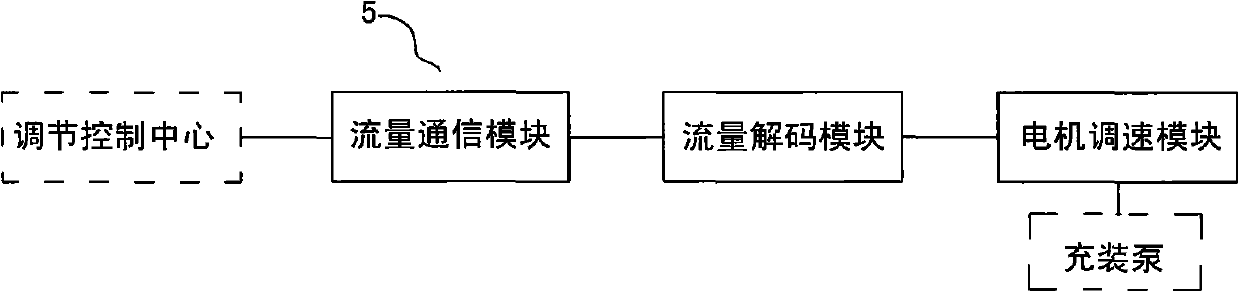

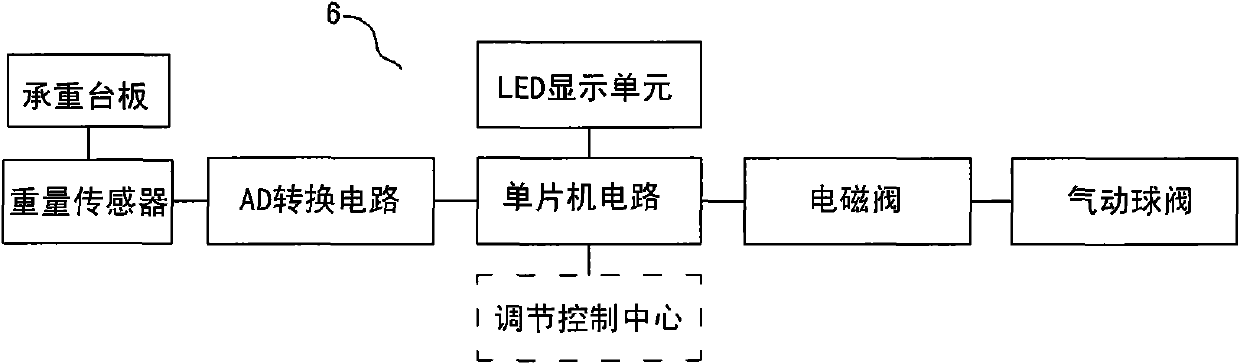

Compressed liquefied gas charging system

InactiveCN101761772BAccurate fillingLow costContainer discharging methodsContainer filling under pressureAutomatic controlLiquid storage tank

The invention relates to a compressed liquefied gas charging system, belonging to the liquefied gas charging field. The compressed liquefied gas charging system comprises a liquid storage tank, a charging pump, a gas bottle and a charging platform, wherein the charging pump is connected with the liquid storage tank by a pipeline; the gas bottle is arranged on the charging platform and is connected with the charging pump by the pipeline; the charging pump is connected with an automatic flow rate adjusting device used for automatically controlling the flow rate of the charging pump; an intelligent quantifying charging device used for automatically controlling the charging quantity is arranged between the gas bottle and the charging pump; the compressed liquefied gas charging system also comprises an adjusting control center device and an automatic pressure adjusting device; the automatic flow rate adjusting device and the intelligent quantifying charging device are also respectively connected with the adjusting control center device by a control circuit; and one end of the automatic pressure adjusting device is connected with the adjusting control center device, and the other end thereof is connected with the liquid storage tank. By adopting the structure, the compressed liquefied gas charging system has the advantages of full-automatic control, accurate charging quantity, low cost, safety, long service life and the like.

Owner:广西柳州海湾恒日化工气体有限公司

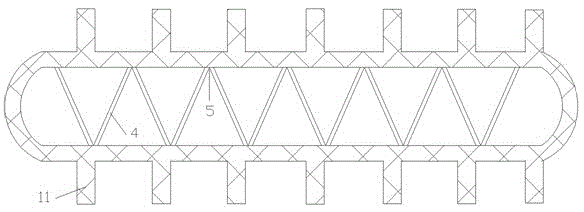

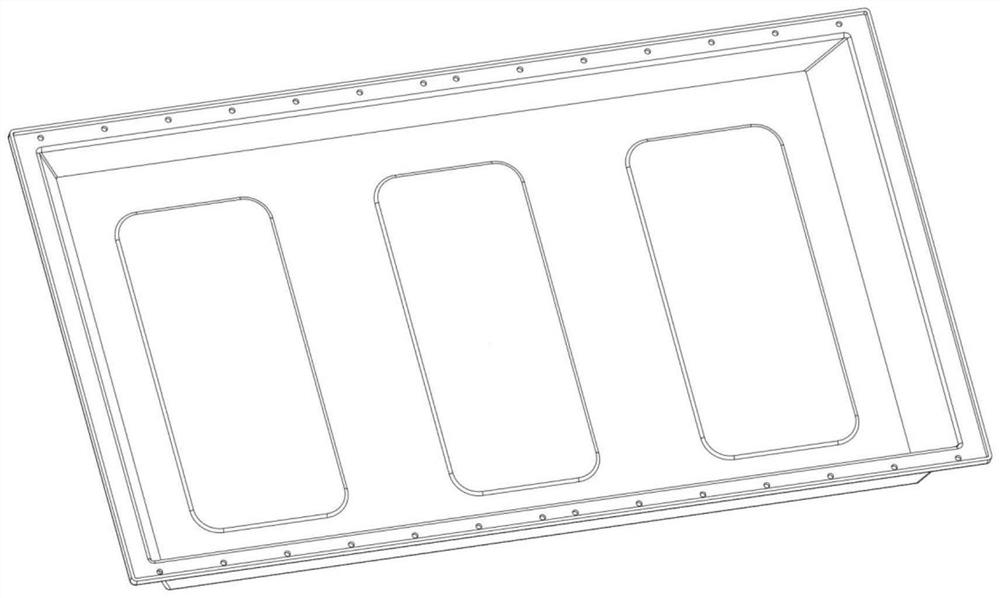

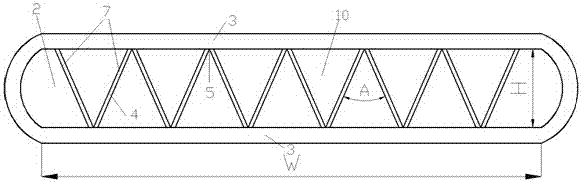

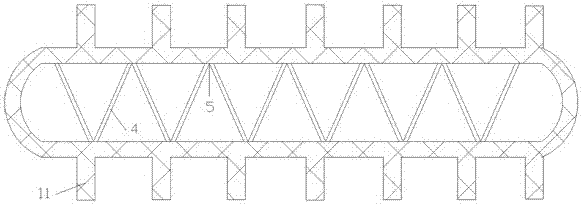

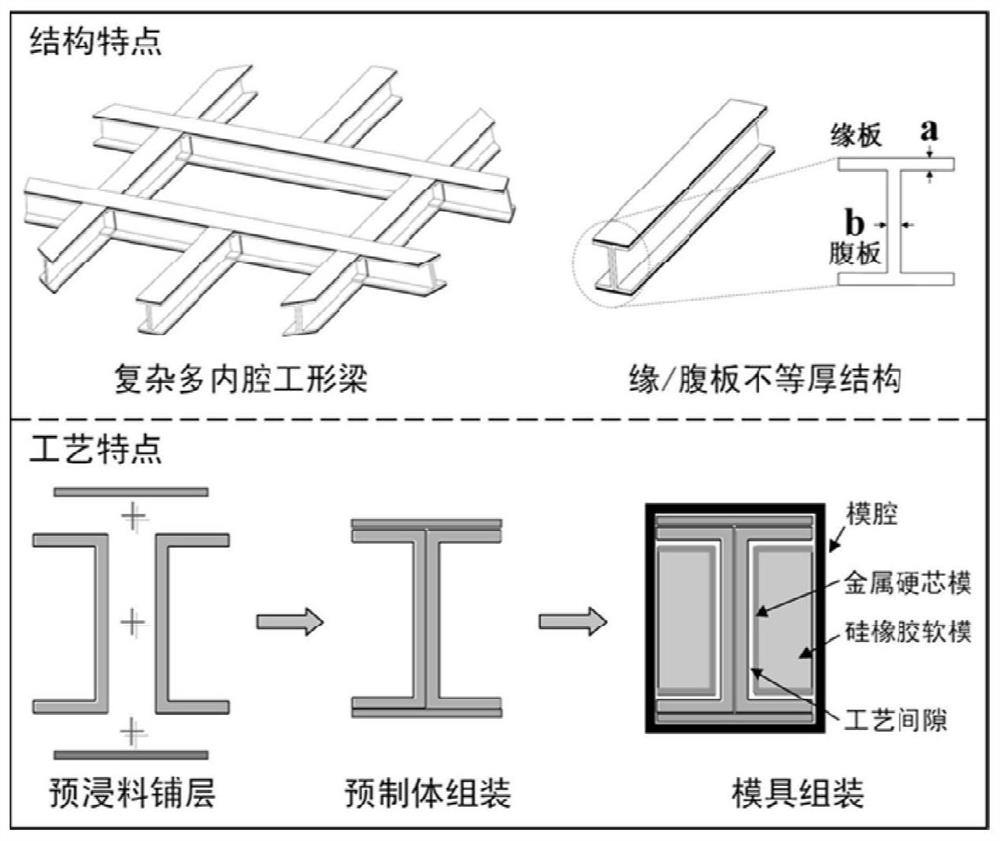

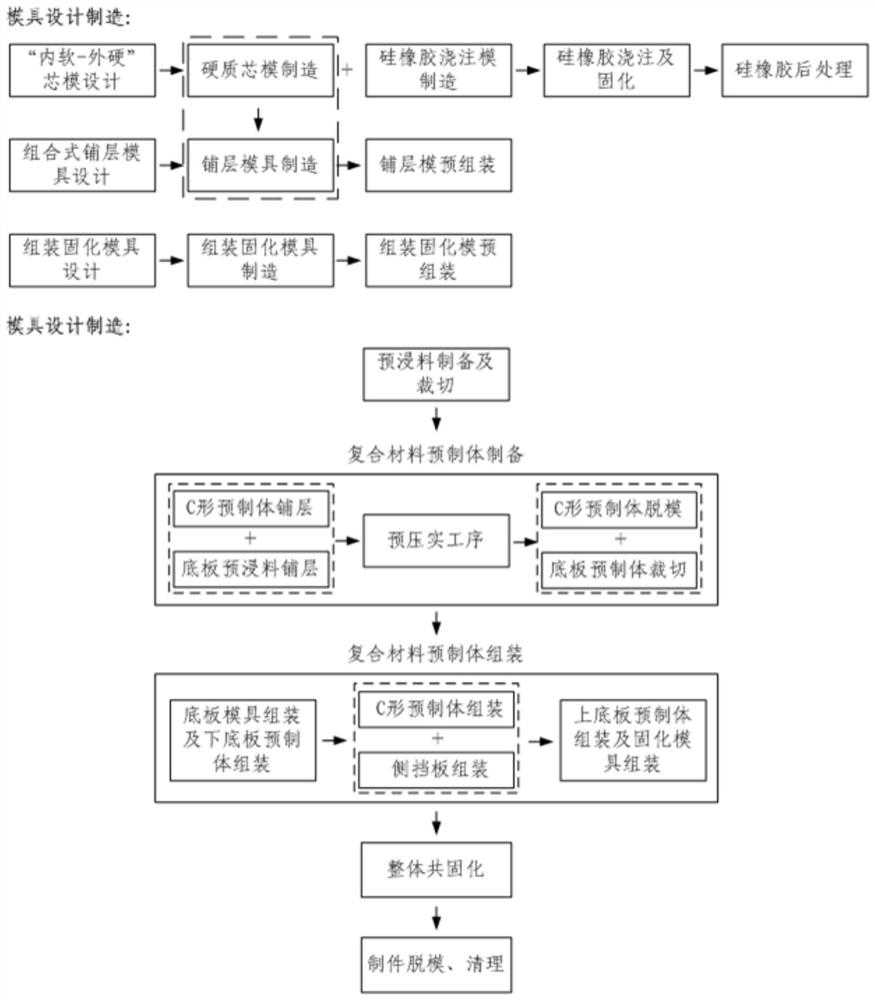

A multi-cavity I-shaped beam and its high-precision soft mold forming and defect control process method

The invention provides a multi-cavity I-beam and a high-precision soft mold forming and defect control method thereof. Aiming at structural features of multiple cavities, multiple molded surfaces, unequal thickness of marginal / web plates and high precision of molded surfaces inside cavities, silicone rubber soft mold pressurization is adopted to achieve the overall co-curing molding of the I-beamwith a complex structure. The multi-cavity I-beam comprises at least two main beams and at least six secondary beams, the main beams and the secondary beams are in the same plane, the main beams are not intersected with each other, the secondary beams located between the main beams are used for connecting the main beams, and the secondary beams located outside the main beams are used for connecting with the outside; equitable distribution of pressure in the X / Y / Z direction is achieved by adopting silicone rubber soft mold process gap compensation design, and the problem of unequal thickness pressurization of the marginal / web plates is solved; an internal soft-external hard pressure equalization design method is utilized to avoid the pressure deviation caused by uneven expansion of a soft mold, and the dimensional accuracy and internal defects of the molded surfaces inside the cavities are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A frame processing method of core-shell structure door and window profiles

The invention discloses a framing machining method of core-shell structure door and window profiles, relates to the field of building decoration engineering, and aims to solve the problems that existing door and window profiles are not reasonable in assembly process, and door and window profile corners are not high in bonding strength and accuracy, close in sealing, attractive and durable. The framing machining method includes the steps: S1 cutting the profiles; S2 machining the ends of the profiles; S3 preassembling the machined profiles; S4 starting a framing device; S5 mounting a profile frame; S6 clamping the profile frame; S7 applying pressure to the frame; S8 releasing the pressure. By the aid of the steps, longitudinal parallel rods and transverse parallel rods relatively motion through hydraulic transmission, the assembled door and window profiles can be effectively assembled in the device, and the method solves the quality problems that in a traditional assembly process, force is unequally applied, errors are large, the ends of the profiles are easily damaged, connectors have biased and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

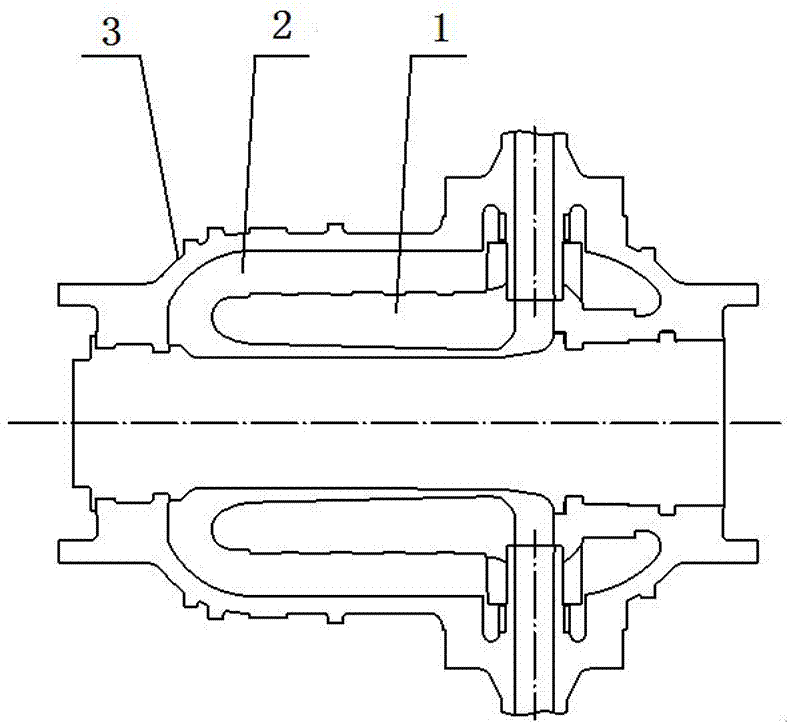

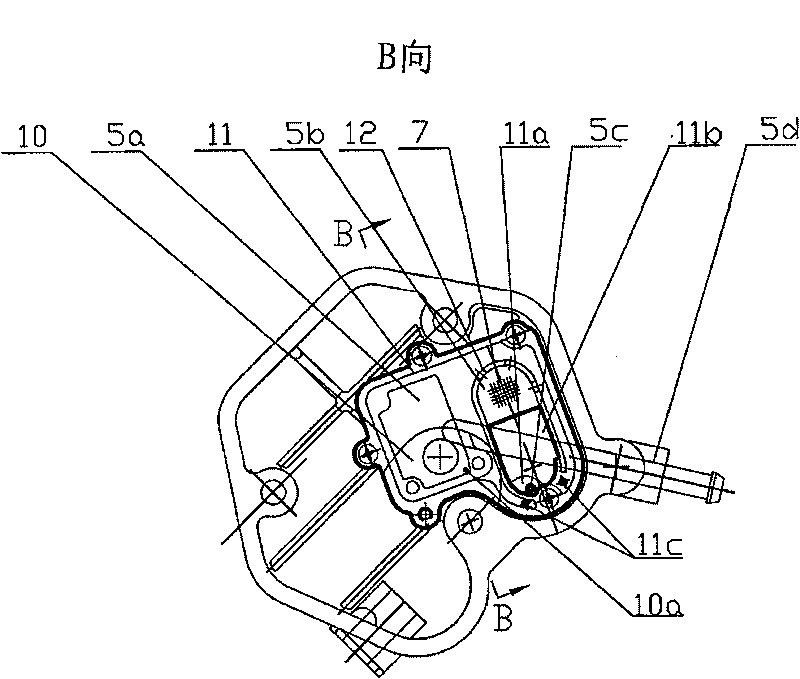

Crankcase ventilation apparatus of V-type engine

ActiveCN101328824BReasonable pressurePrevent suctionMachines/enginesCrankcase ventillationCombustion chamberCylinder head

The invention relates to a device for ventilating a crankcase of a V-type engine belonging to the power device technical field. The device mainly comprises a left cylinder head, a right cylinder head, a left cylinder head cover, a right cylinder head, and an air inlet pressure stabilizing chamber. The device is characterized in that the insides of the left cylinder head cover and the right cylinder head cover are provided with oil baffle plates, and oil-gas separation chambers and control switch chambers are formed by isolating the oil baffle plates, the insides of the control switch chambersare provided with one-way valves, the pipe passages are arranged inside the control switch chambers; after the pipe passages of the two head covers are communicated with each other, the pipe passagesof the two head covers are connected to the bottom of the air inlet pressure stabilizing chamber, template one-way valves are respectively arranged inside the two head covers, and the pipe passages of the two head covers are connected to the bottom of the air inlet pressure stabilizing chamber after the pipe passages of the two head covers are communicated with each other. The device can guarantypressure in the crankcase to be reasonable and stable and a passing route of an oil mist is long when removing the surplus gas in the crankcase, thereby improving removal effect for the oil mist, preventing the overmuch oil mist from entering the combustion chamber, reducing engine oil consumption, and improving safety performance of the whole engine.

Owner:WUXI KIPOR POWER CO LTD

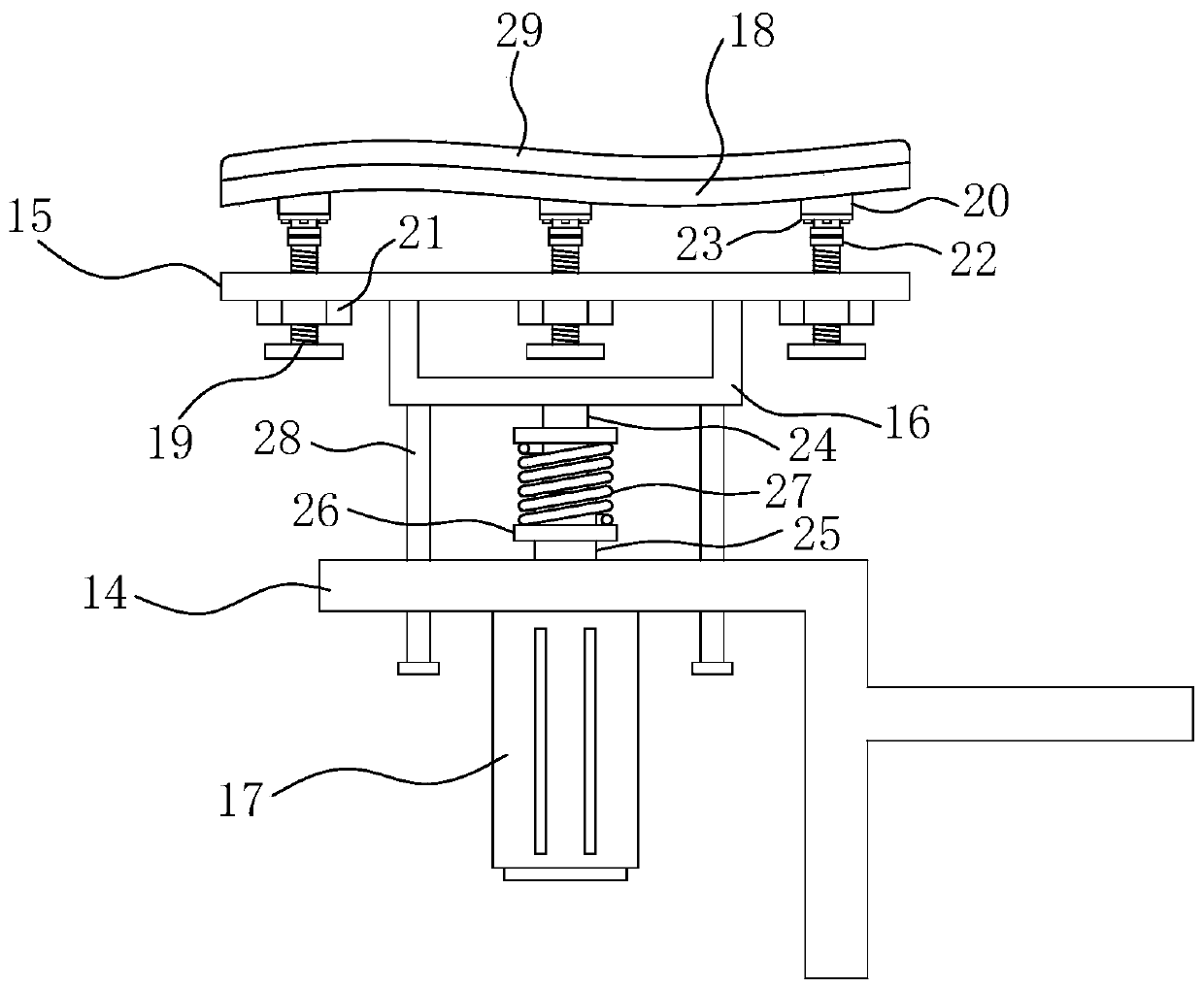

Novel scoliosis correction head

ActiveCN110464594AImprove rehabilitation effectConforms to deformed shapeChiropractic devicesScoliosisMechanical equipment

The invention relates to medical mechanical equipment and aims at providing a novel scoliosis correction head with a linear correction function. By adopting the technical scheme, the novel scoliosis correction head comprises a horizontal mounting plate and a horizontal lifting plate which is arranged above the mounting plate and has a strip shape, wherein a U-shaped connecting rack is fixedly arranged on the lower surface of the lifting plate; a push-press motor is arranged at the bottom of the mounting plate, and the output end of the push-press motor is fixedly connected with the connectingrack through a connecting rod; a strip-type elastic contact plate is arranged above the lifting plate, and is connected with the mounting plate through adjusting components; and the adjusting components are uniformly distributed along the length direction of the elastic contact plate. The novel scoliosis correction head can be used for performing linear push-press on a deformed part, and the rehabilitation effect for scoliosis deformation is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com