Compressed liquefied gas charging system

A technology of liquefied gas and gas cylinders, applied in gas/liquid distribution and storage, container filling methods, equipment loaded into pressure vessels, etc., can solve the problem of not being able to get rid of the backward working mode of mechanical scales, the inability to distinguish and eliminate interference forces, and knife edges Susceptible to moisture, rust or corrosion, etc., to achieve the effect of reducing filling personnel, automatically adjusting filling flow, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

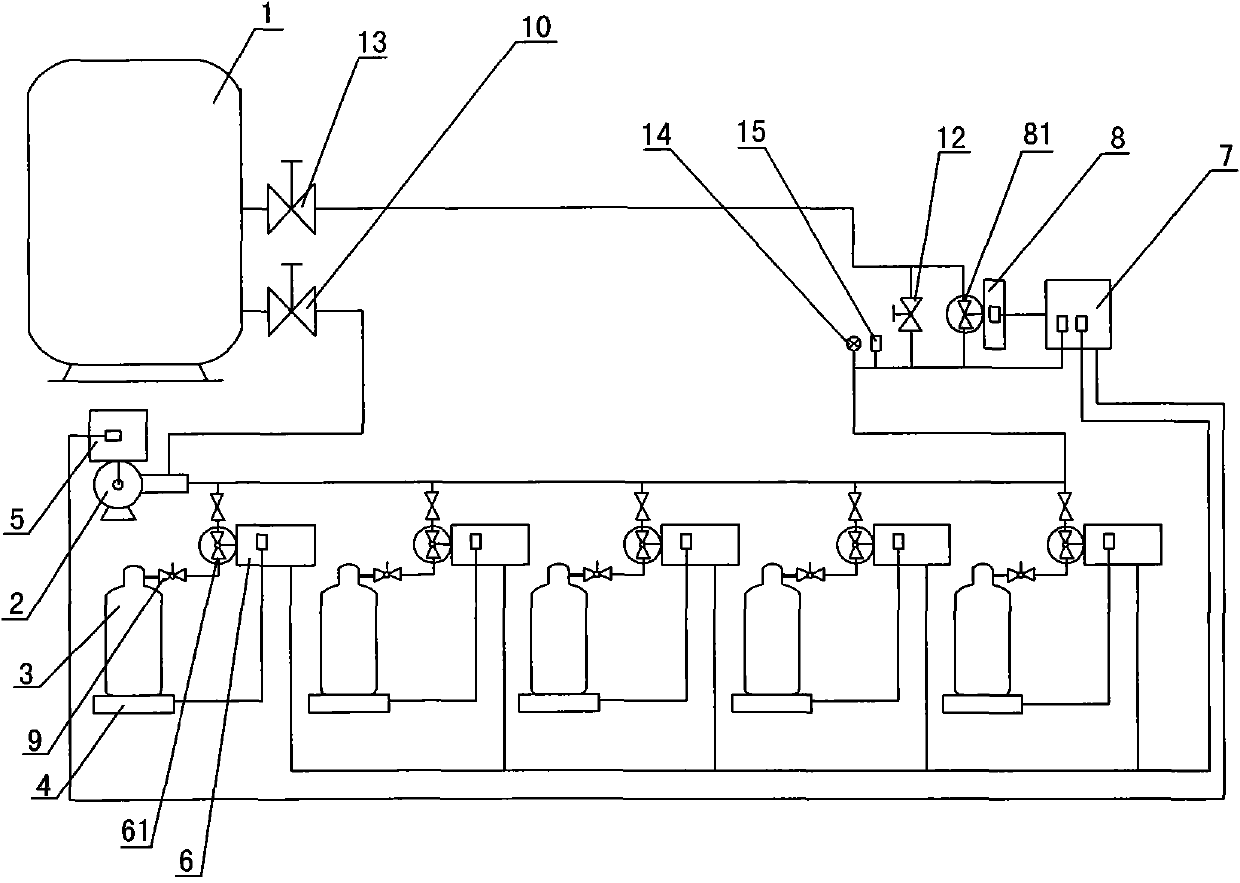

[0026] Such as Figure 1 to Figure 5 As shown, the compressed liquefied gas filling system of the present invention includes a liquid storage tank 1, a filling pump 2, a gas cylinder 3, a filling platform 4, an automatic flow adjustment device 5, an intelligent quantitative filling device 6, an adjustment control center device 7 and Automatic pressure regulator 8.

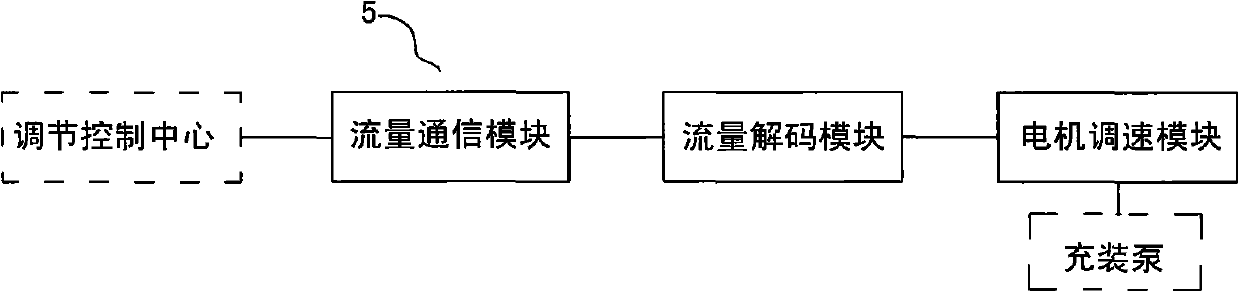

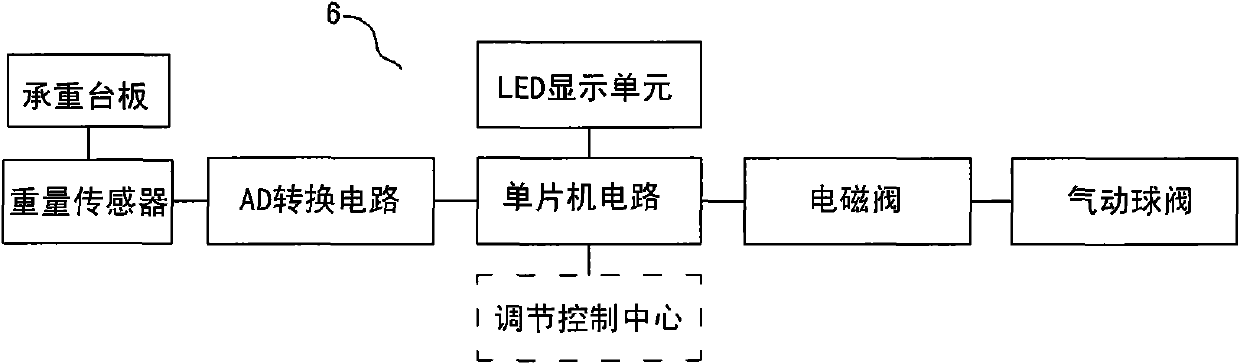

[0027] The filling pump 2 is connected to the liquid storage tank 1 through a pipeline, the gas cylinder 3 is placed on the filling platform 4, and the gas cylinder 3 is connected to the filling pump 2 through a pipeline. The filling pump 2 is connected with an automatic flow adjustment device 5 that can automatically control the flow of the filling pump. An intelligent quantitative filling device 6 is connected between the gas cylinder 3 and the filling pump 2. The automatic flow adjustment device 5 And the intelligent quantitative filling device 6 is also connected to the adjustment control center device 7 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com