Chemical water pump

A water pump and chemical technology, which is applied in the field of centrifugal chemical water pumps, can solve the problems of high energy consumption, the pump shaft is easily corroded by chemical liquid, and the centrifugal chemical water pump cannot achieve reasonable pressure and flow, so as to achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

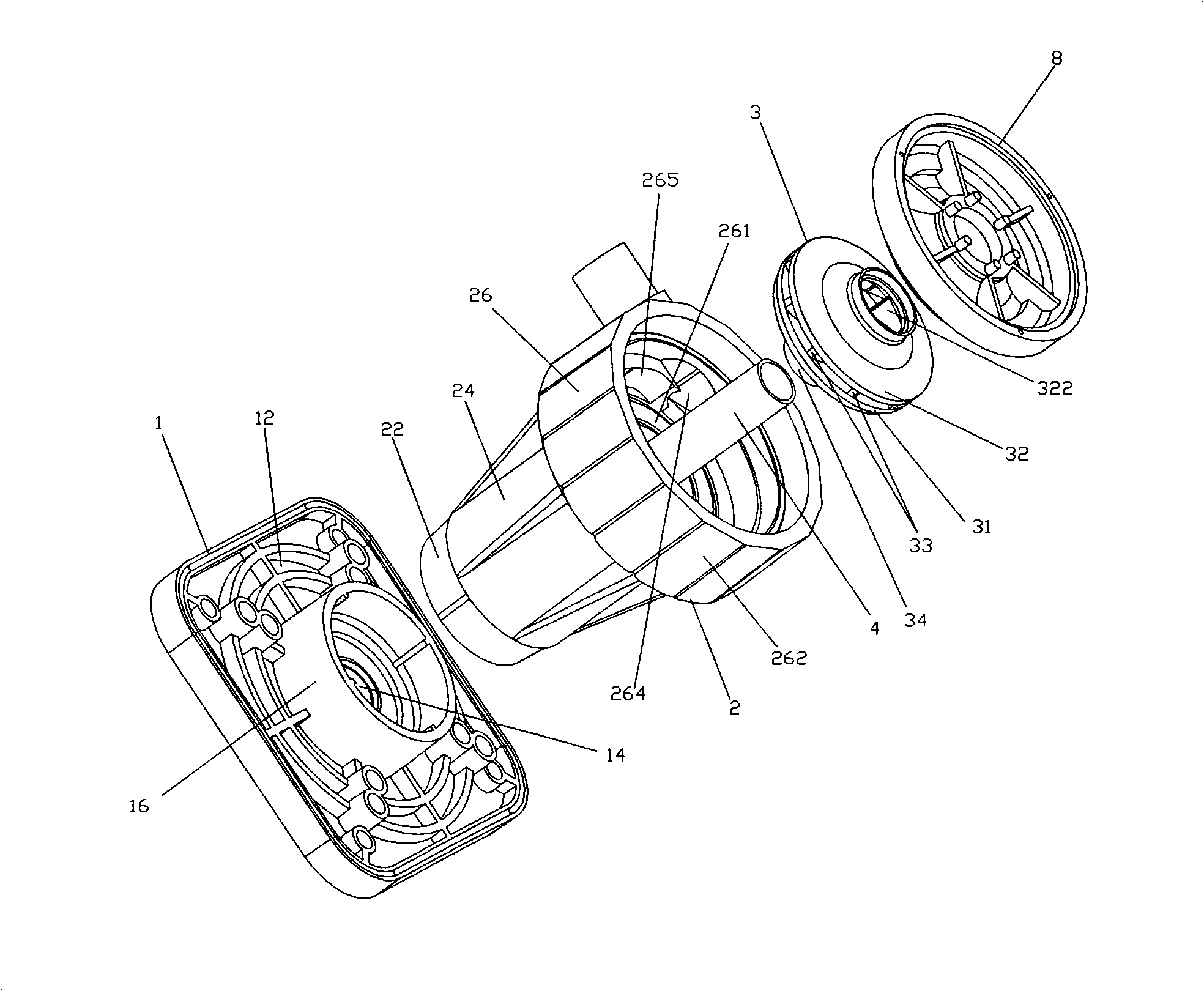

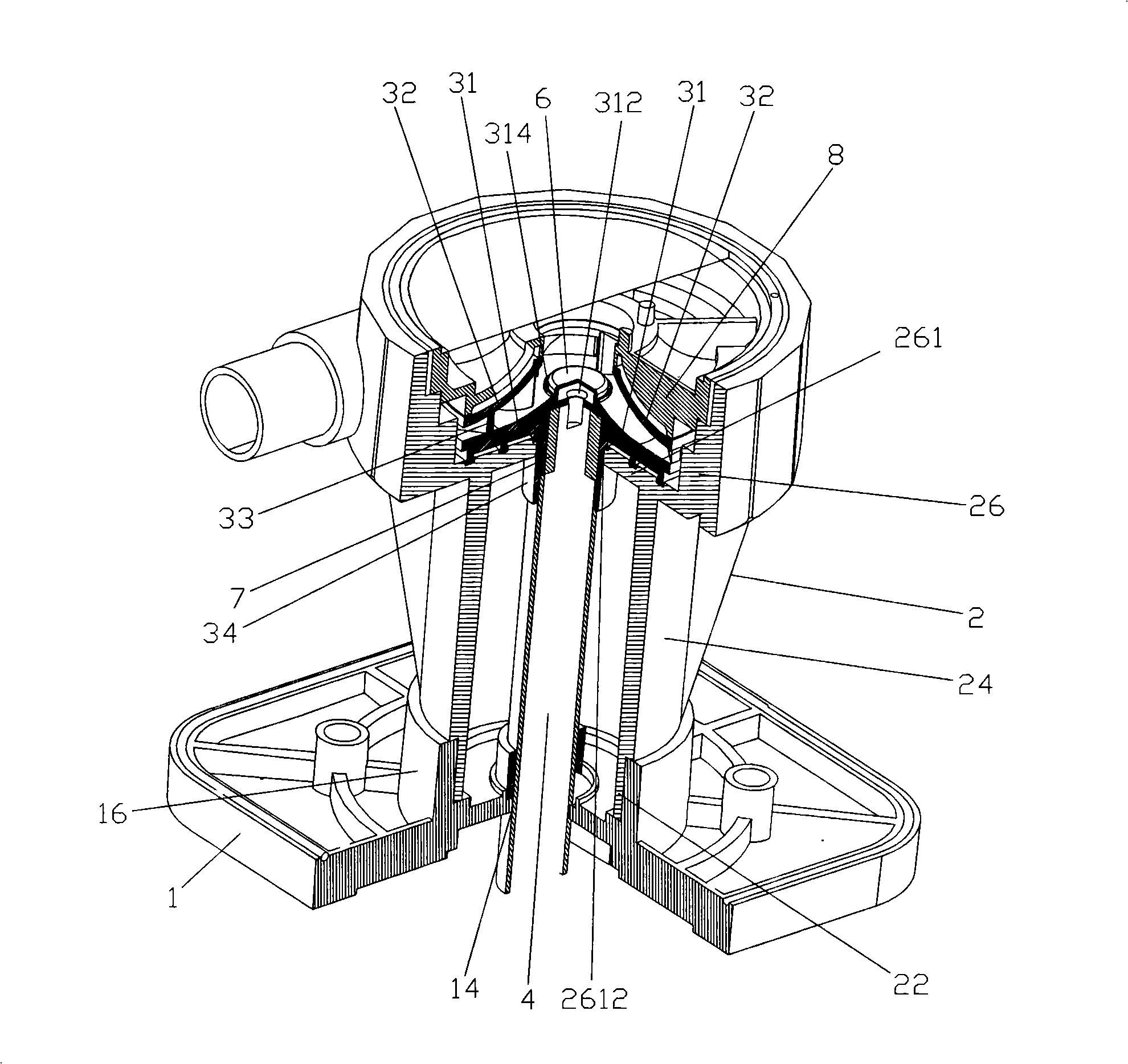

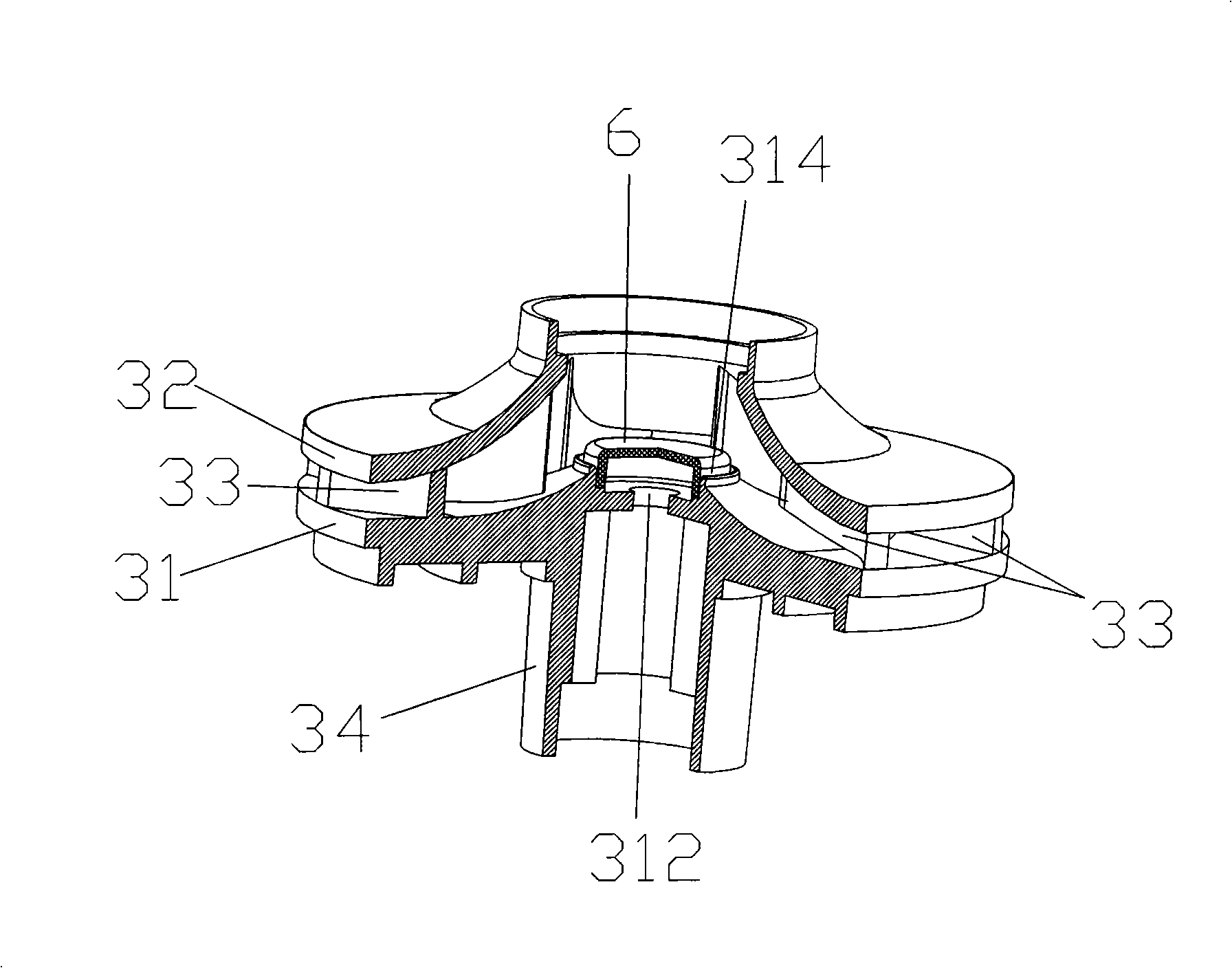

[0022] see Figure 1 to Figure 4 , a centrifugal chemical water pump, which includes a base 1, a pump body 2, an impeller 3, a pump shaft 4, a screw (not shown), a sealing cap 6, a sealing ring 7, a pump cover 8.

[0023] The base 1 includes a bottom plate 12 , a first through hole 14 , and a sleeve 16 . The first through hole 14 is defined in the middle of the bottom plate 12 . The sleeve 16 surrounds the first through hole 14 and protrudes outside the first through hole 14 .

[0024] The pump body 2 includes an annular lower shell 22 , a middle shell 24 , and an upper shell 26 .

[0025] The lower case 22 is inserted into the bushing 16 .

[0026] The middle shell 24 is connected between the lower shell 22 and the upper shell 26 .

[0027] The upper shell 26 includes a bottom plate 261 , an annular sidewall 262 , a water inlet (not labeled), a water outlet 264 , and a rib 265 .

[0028] A second through hole 2612 is defined in the center of the bottom plate 261 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com