Clean production line for furfural and production method of furfural

A clean production and assembly line technology, applied in the direction of organic chemistry, can solve problems such as poor recycling of wastewater, insufficient disclosure of treatment process parameters, and difficulty in guiding practice, achieving high yield, high purity, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

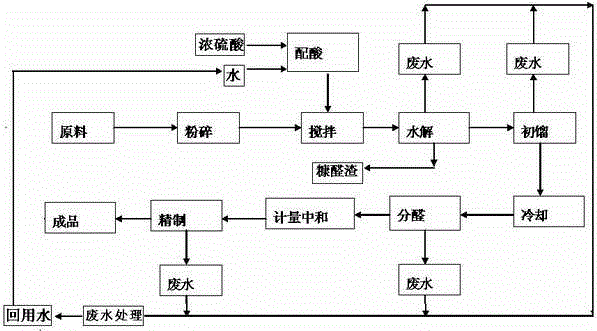

[0027] as attached figure 1 The furfural cleaning production line shown has process facilities for screening, crushing, acid mixing, hydrolysis, initial distillation, separation and rectification, and post-treatment facilities for waste gas, waste water and waste residue.

[0028] In the mixed acid process step, the concentrated sulfuric acid is made into 3~5% dilute sulfuric acid, which is evenly mixed with the raw material corn cob, and the raw material and dilute acid are added at the same time;

[0029] In the hydrolysis process step: according to the charging density of 0.18-0.2t / m3, put the corncobs mixed with acid into the hydrolysis pot, the whole hydrolysis time is 4-6 hours, the steam pressure in the hydrolysis pot is 0.5-1.0MPa, steam The temperature is 150-170°C, the azeotrope of aldehyde gas generated after the hydrolysis reaction is discharged from the top pipe, and the hydrolysis slag is discharged from the bottom of the hydrolysis pot for post-treatment.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com