Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Realize unloading operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

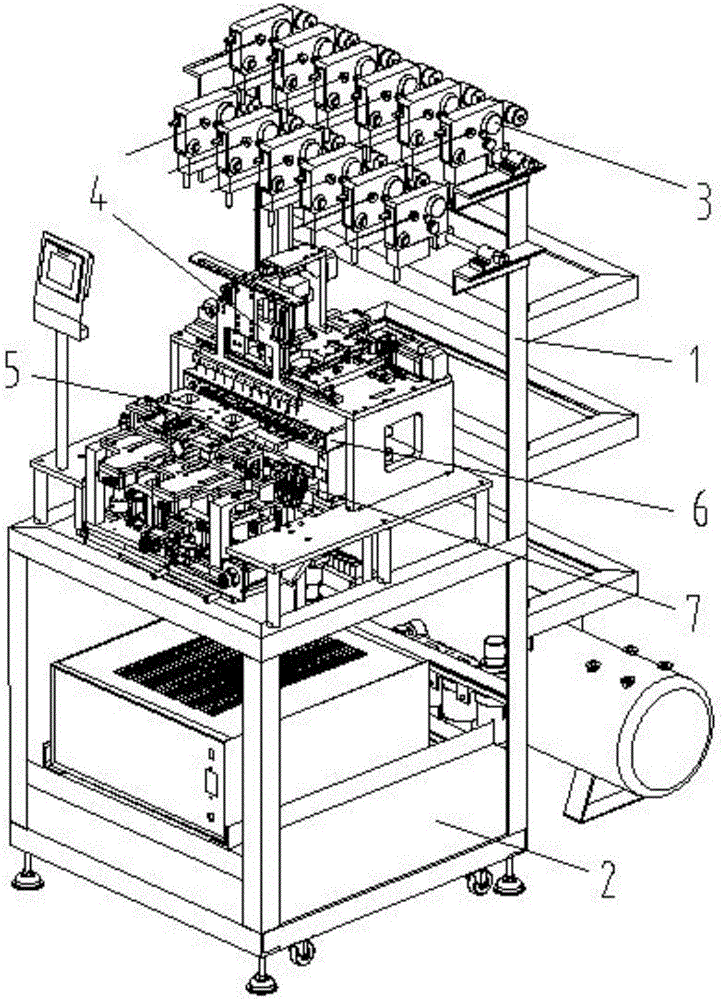

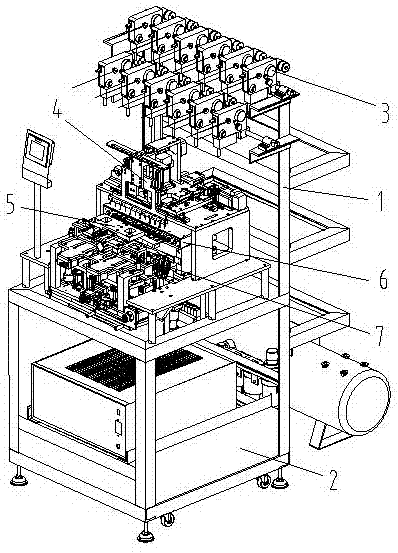

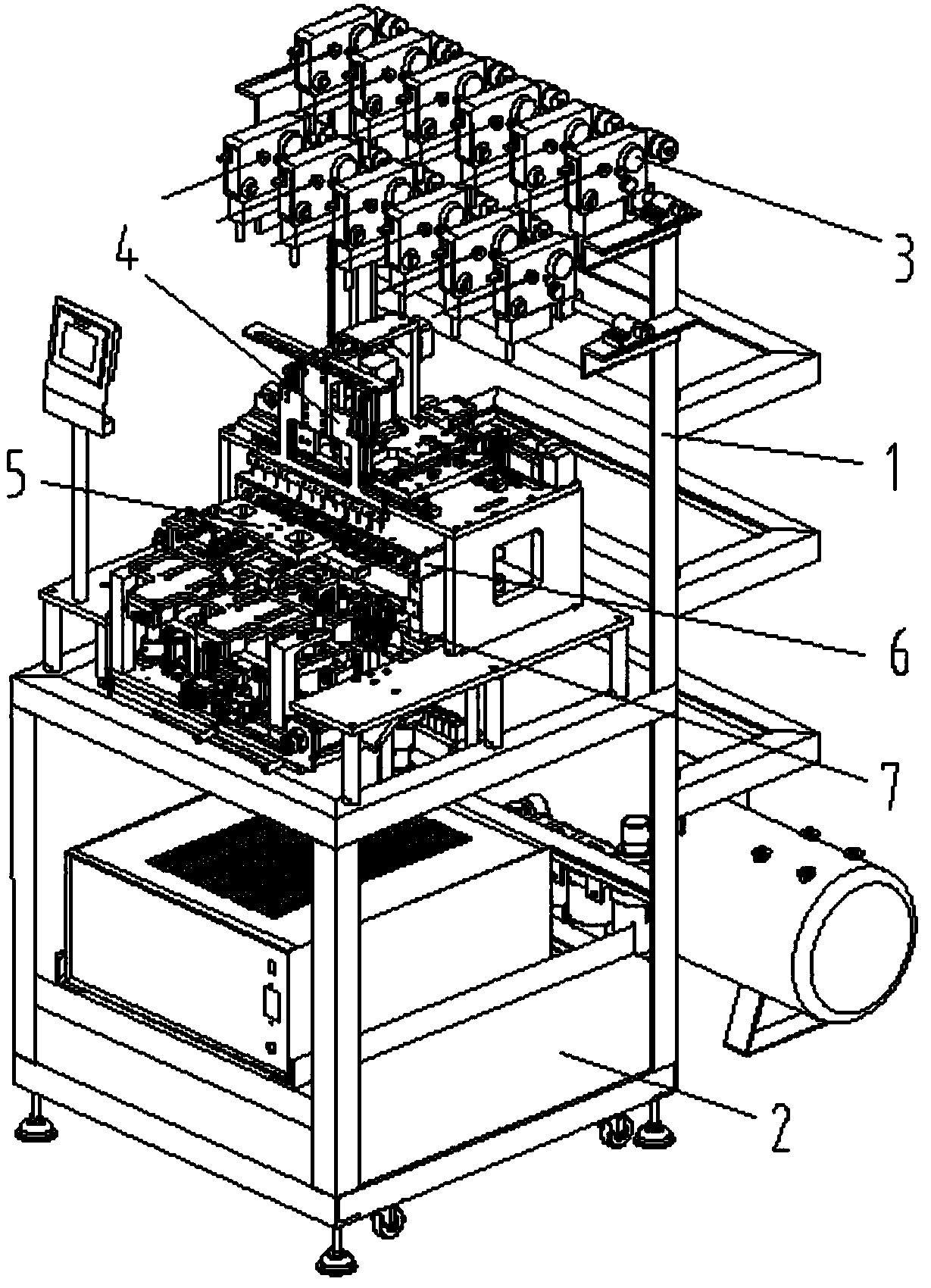

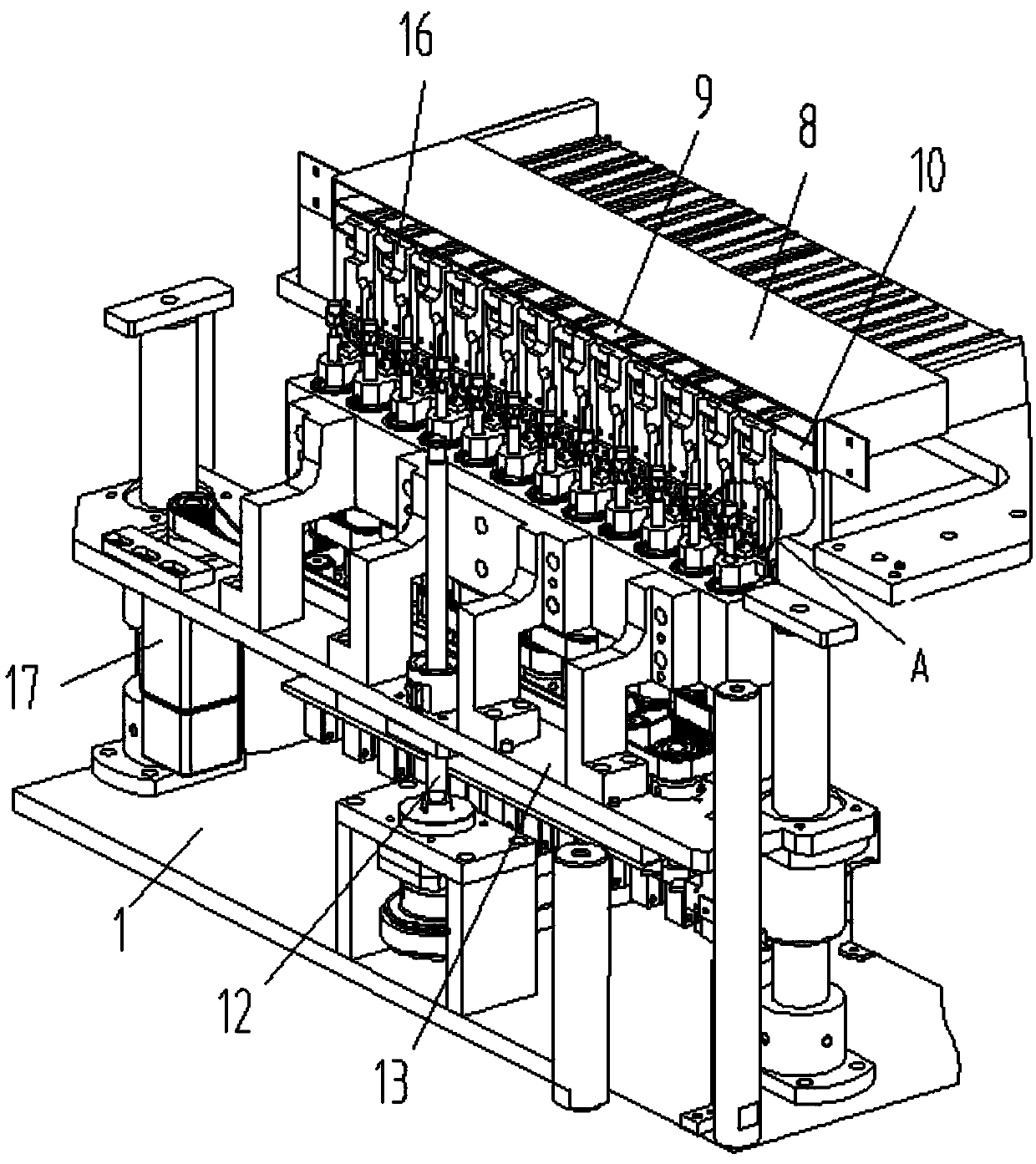

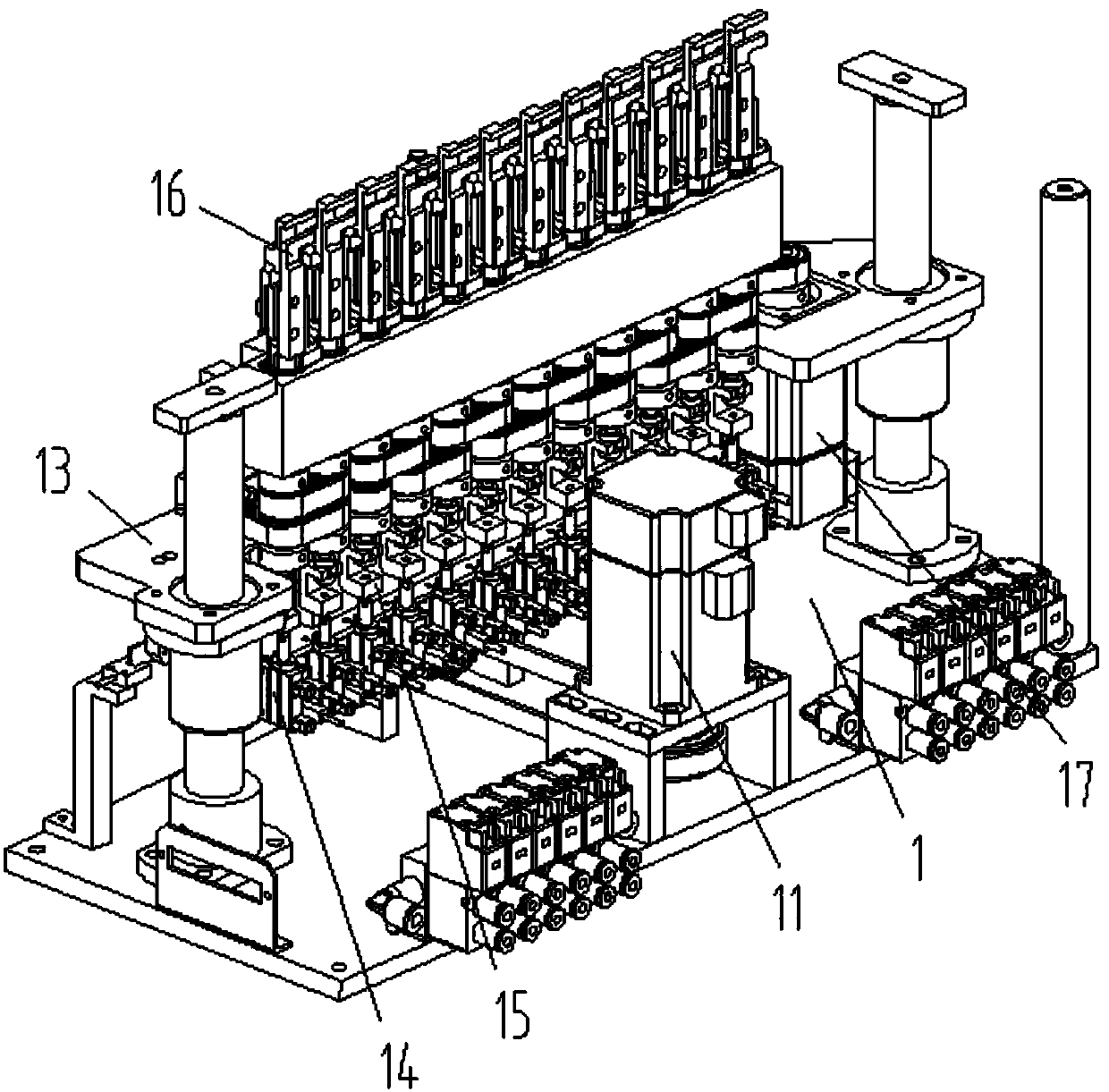

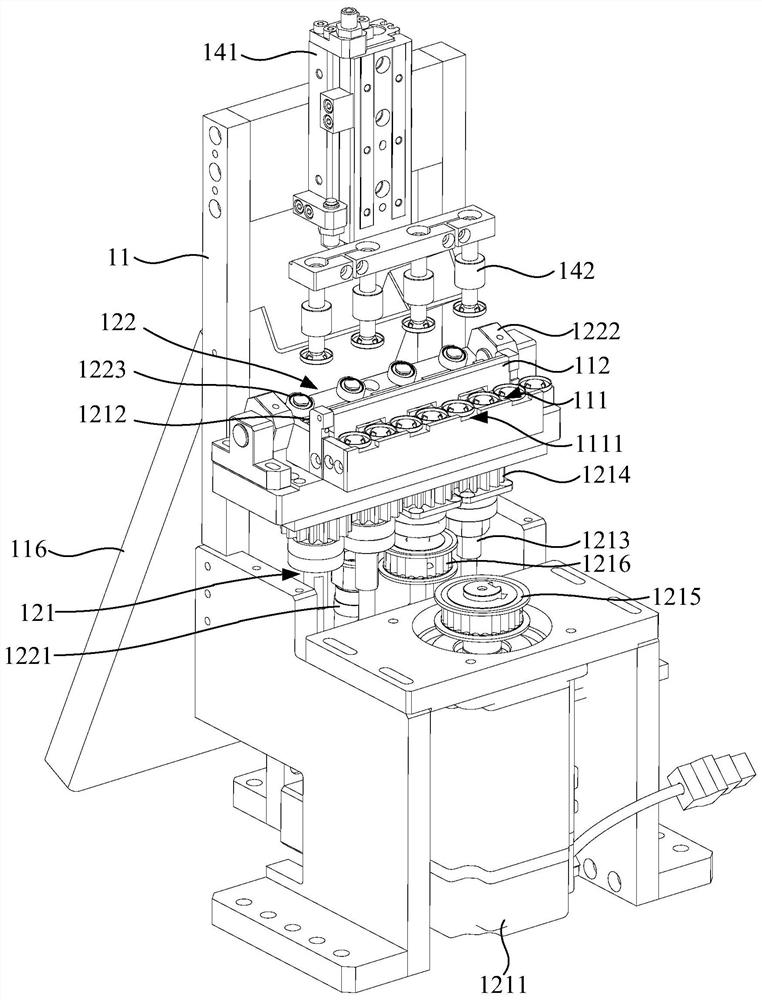

Automatic feed winding machine for inductance

ActiveCN106783143AQuality assuranceAvoid shakingInductances/transformers/magnets manufactureWinding machineDistribution control

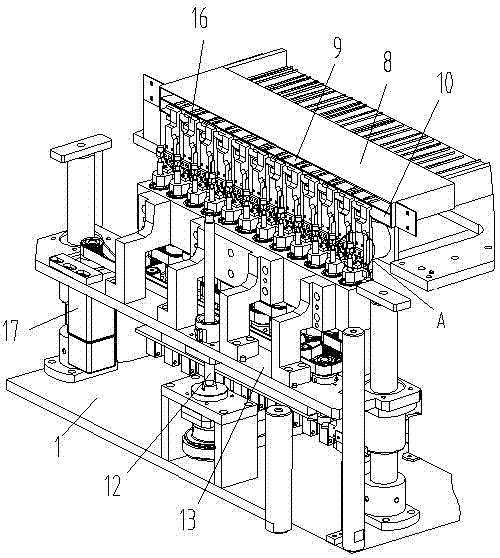

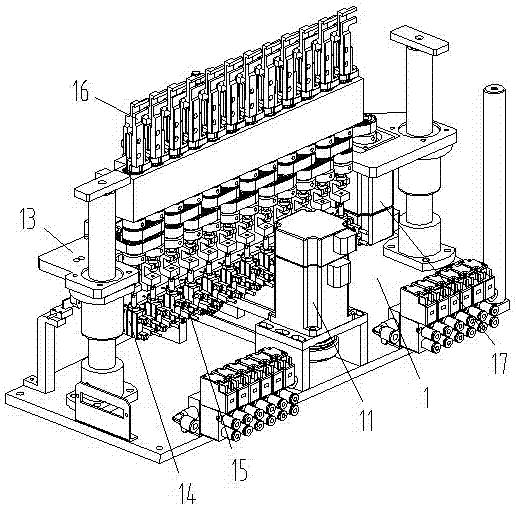

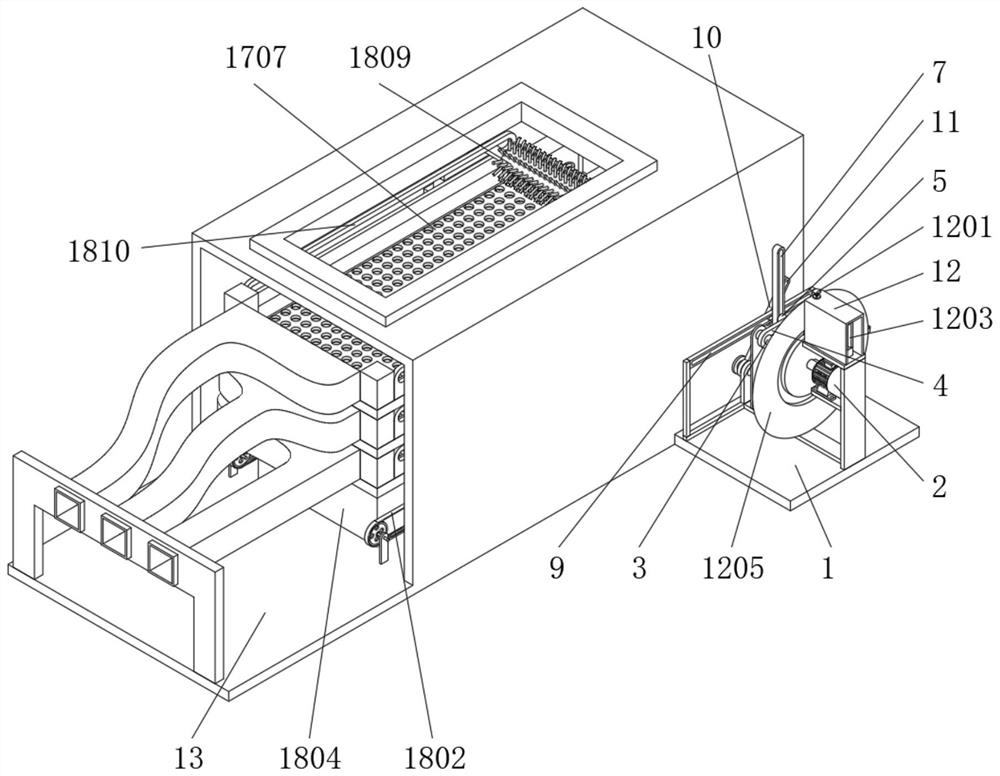

The invention relates to an automatic feed winding machine for inductance. The automatic feed winding machine comprises a rack and a distribution control box, a load rotating device is arranged in the middle of the rack, the upper portion of the load rotating device is matched with a wire plugging device and a wire conveying device, a feed docking device is fittingly arranged at the front portion of the load rotating device, the feed docking device is matched with a feeding device at the lower portion of the rack, the feed docking device comprises a docking seat arranged on the rack, a docking lifting cylinder is arranged on the docking seat and is connected with a docking lifting seat, a forward and backward receiving motion cylinder is arranged at the lower portion of the docking lifting seat and is connected with a receiving block made from electromagnet, receiving grooves matched with products are evenly formed in the receiving block, a forward and backward pushing motion cylinder is arranged at the upper portion of the docking lifting seat and is connected with a forward and backward pushing motion seat, and rotating pushing heads matched with the products are evenly arranged on the forward and backward pushing motion seat. By the arrangement, feeding efficiency is guaranteed, and meanwhile, quality in feeding and subsequent winding is guaranteed as well.

Owner:TONGXIANG YAORUN ELECTRONICS

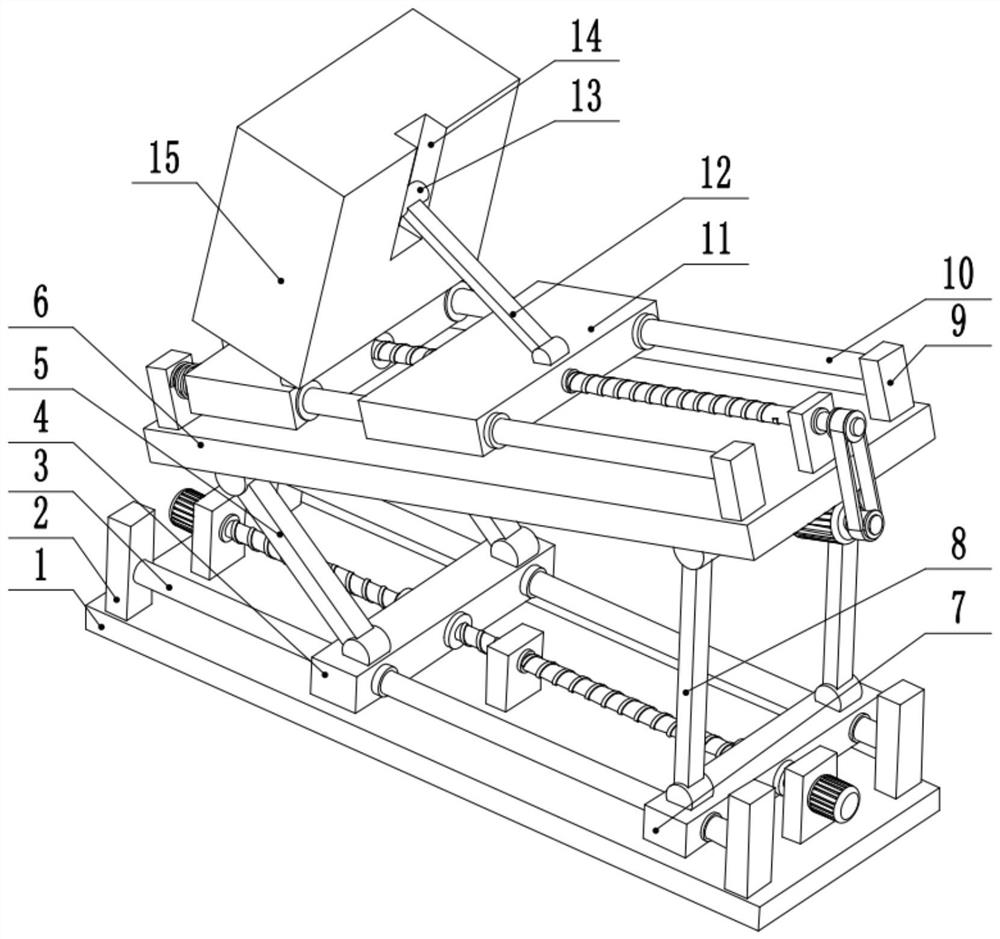

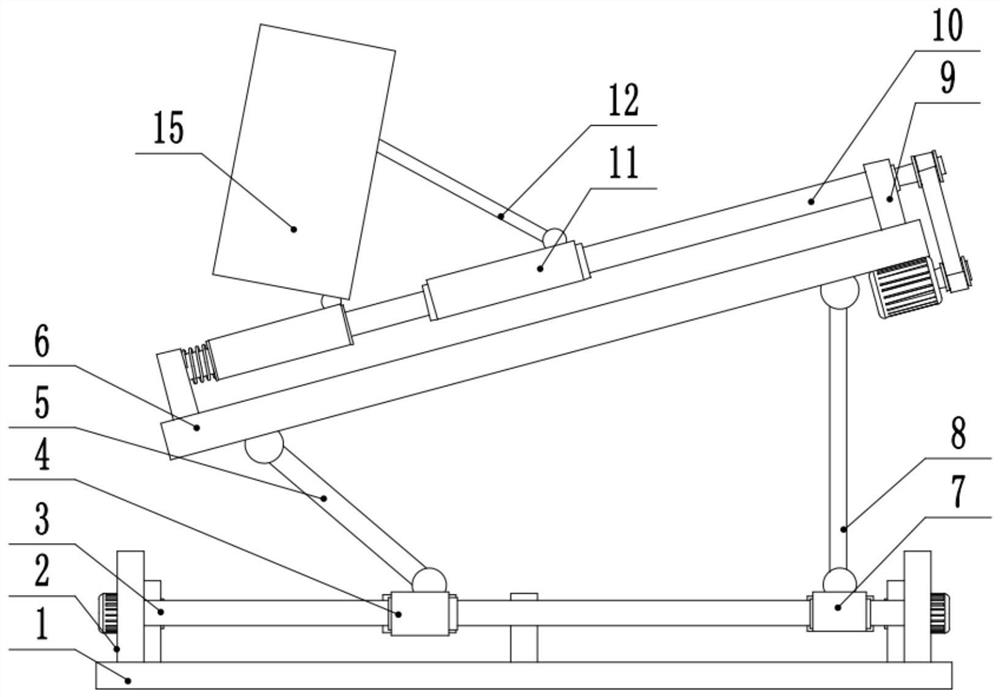

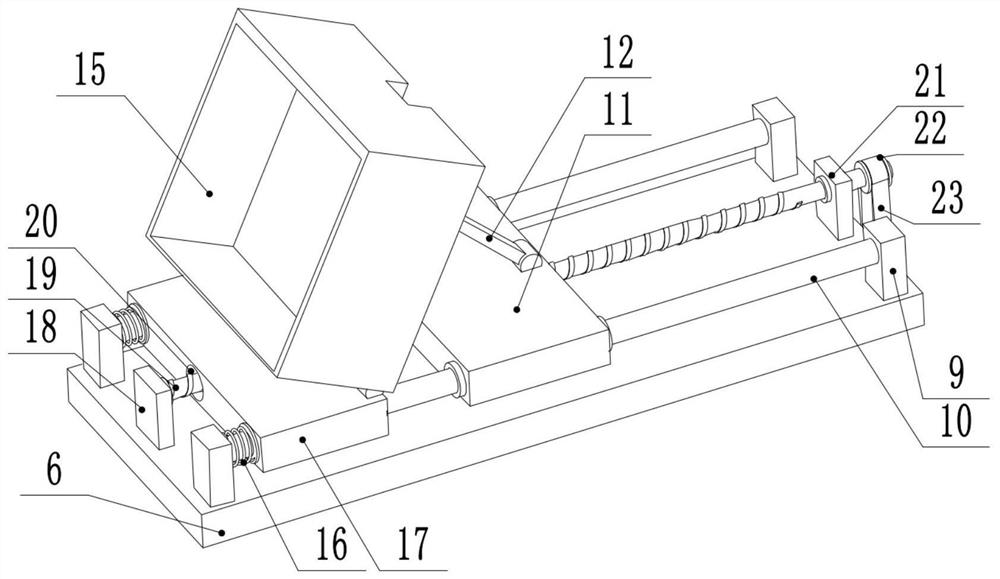

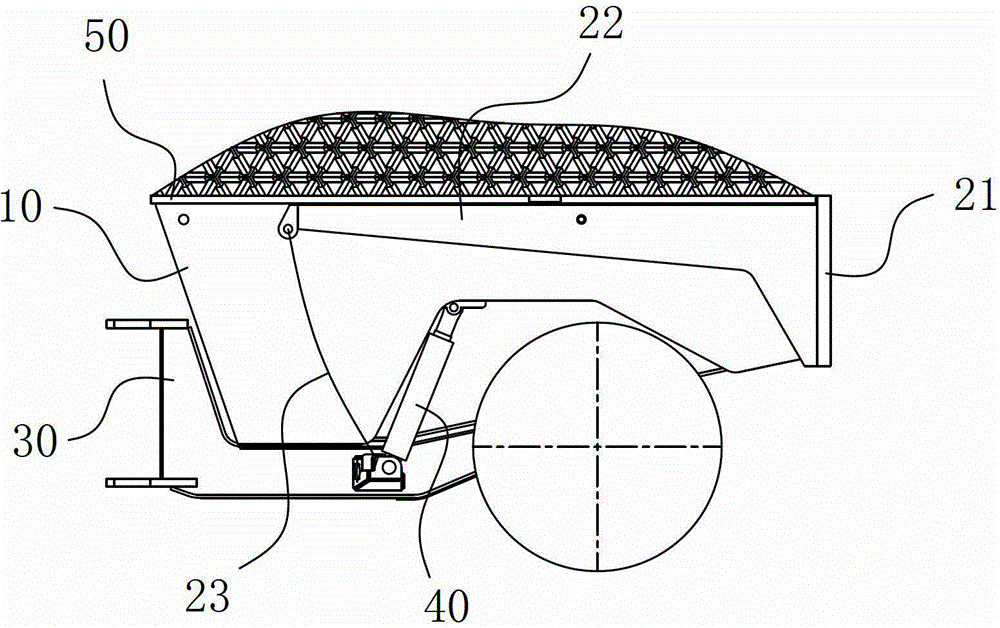

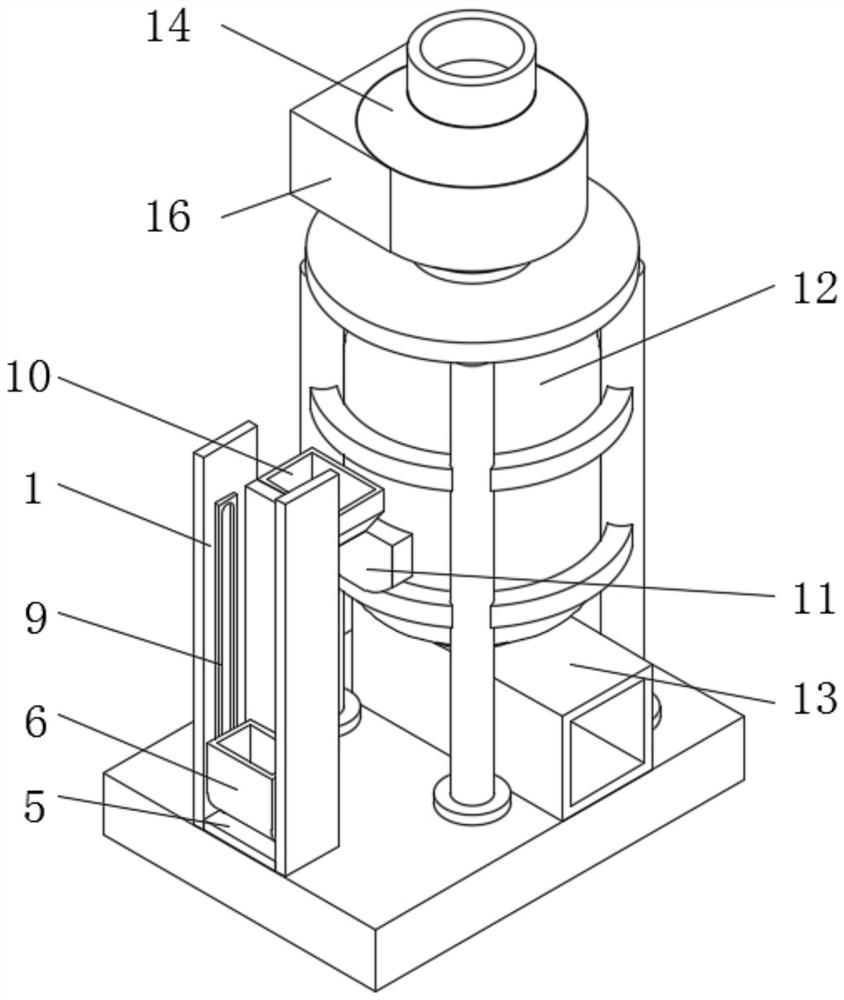

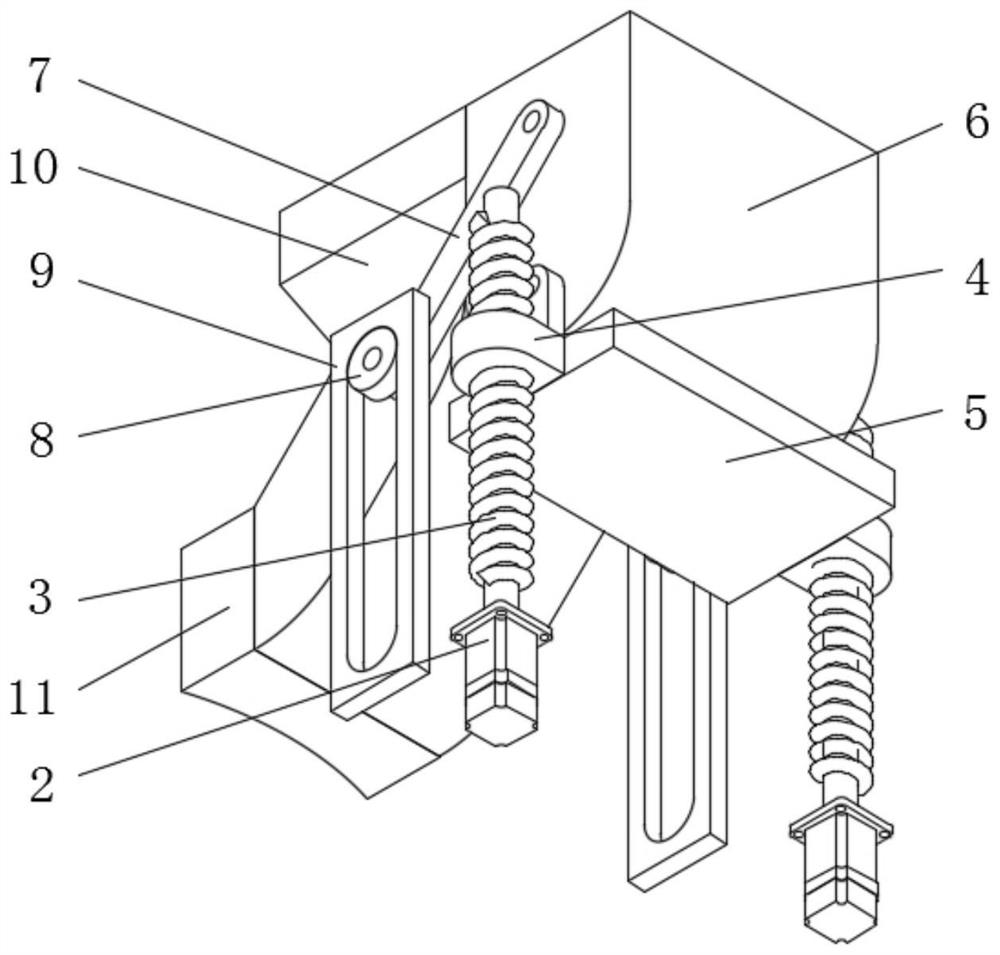

Building construction discharging platform device

InactiveCN112282385AFree to adjust the angleRealize unloading operationBuilding material handlingMechanical engineeringArchitectural engineering

The invention relates to the technical field of building construction, and discloses a building construction discharging platform device. The building construction discharging platform device comprises a rotating table, second fixing plates are arranged on the front side and the rear side of the upper surface of the rotating table, second guide rods are arranged in the middles of the second fixingplates, a fourth sliding base is slidably connected to the left sides of the second guide rods, the right side of the fourth sliding base is rotationally connected with the left side of a hopper, theleft side of the lower surface of the rotating table is rotationally connected with the upper ends of first supporting rods, the lower ends of the first supporting rods are rotationally connected with the front end and the rear end of the upper surface of a first sliding base, the front side and the rear side of the first sliding base are slidably connected with the left sides of first guide rods, the right sides of the first guide rods are slidably connected with the front side and the rear side of a second sliding base, and the front end and the rear end of the upper surface of the second sliding base are rotationally connected with the lower ends of second supporting rods. According to the building construction discharging platform device, by arranging the first sliding base and the second sliding base which can move left and right, the height and the angle of the hopper can be freely adjusted.

Owner:姚正平

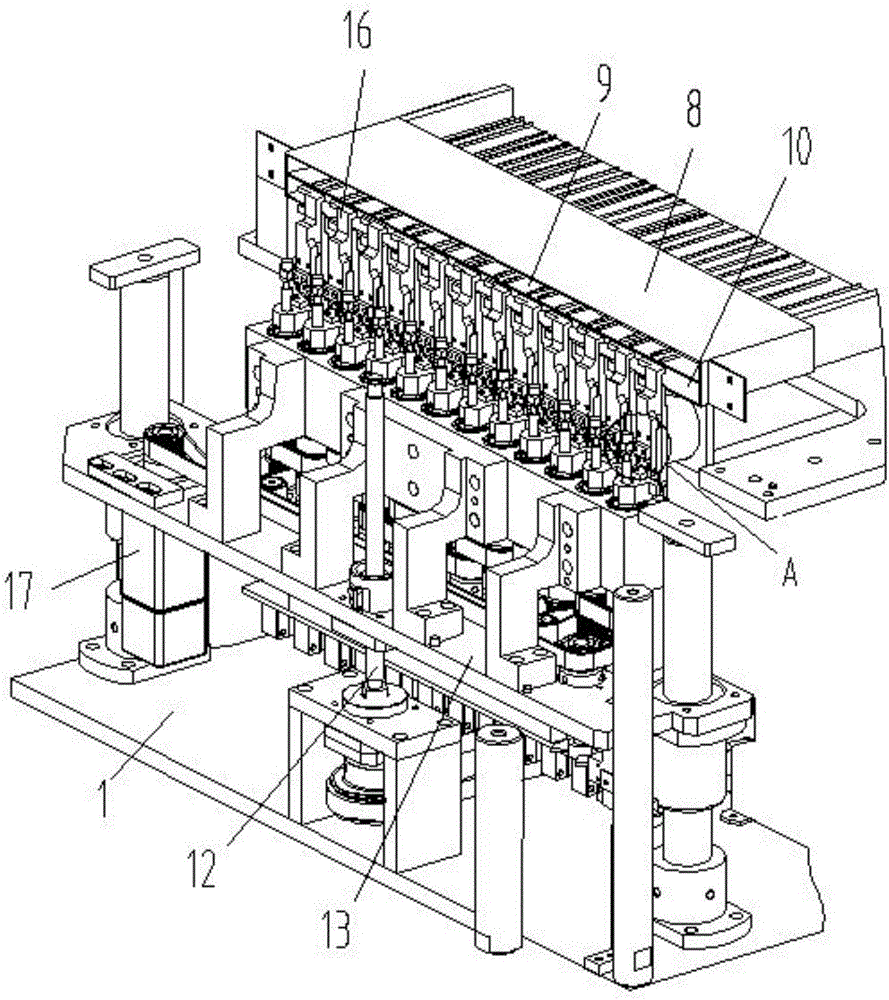

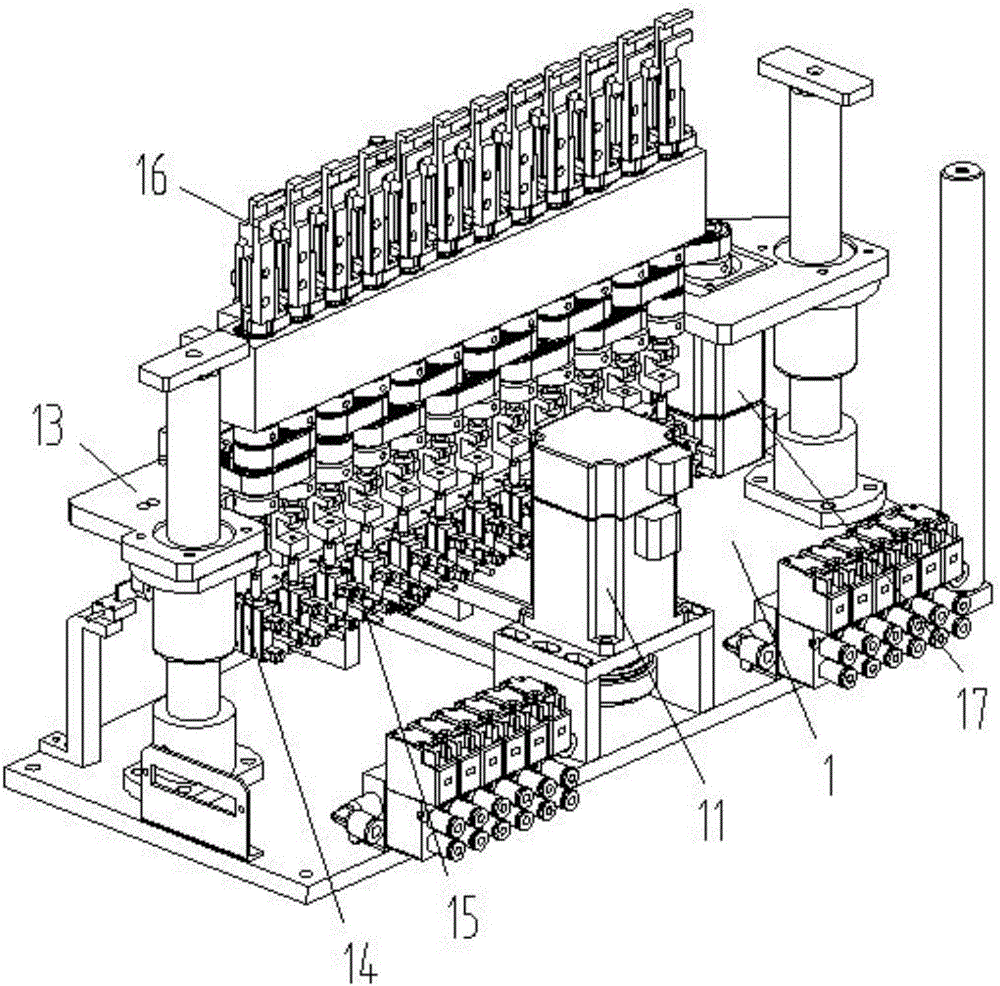

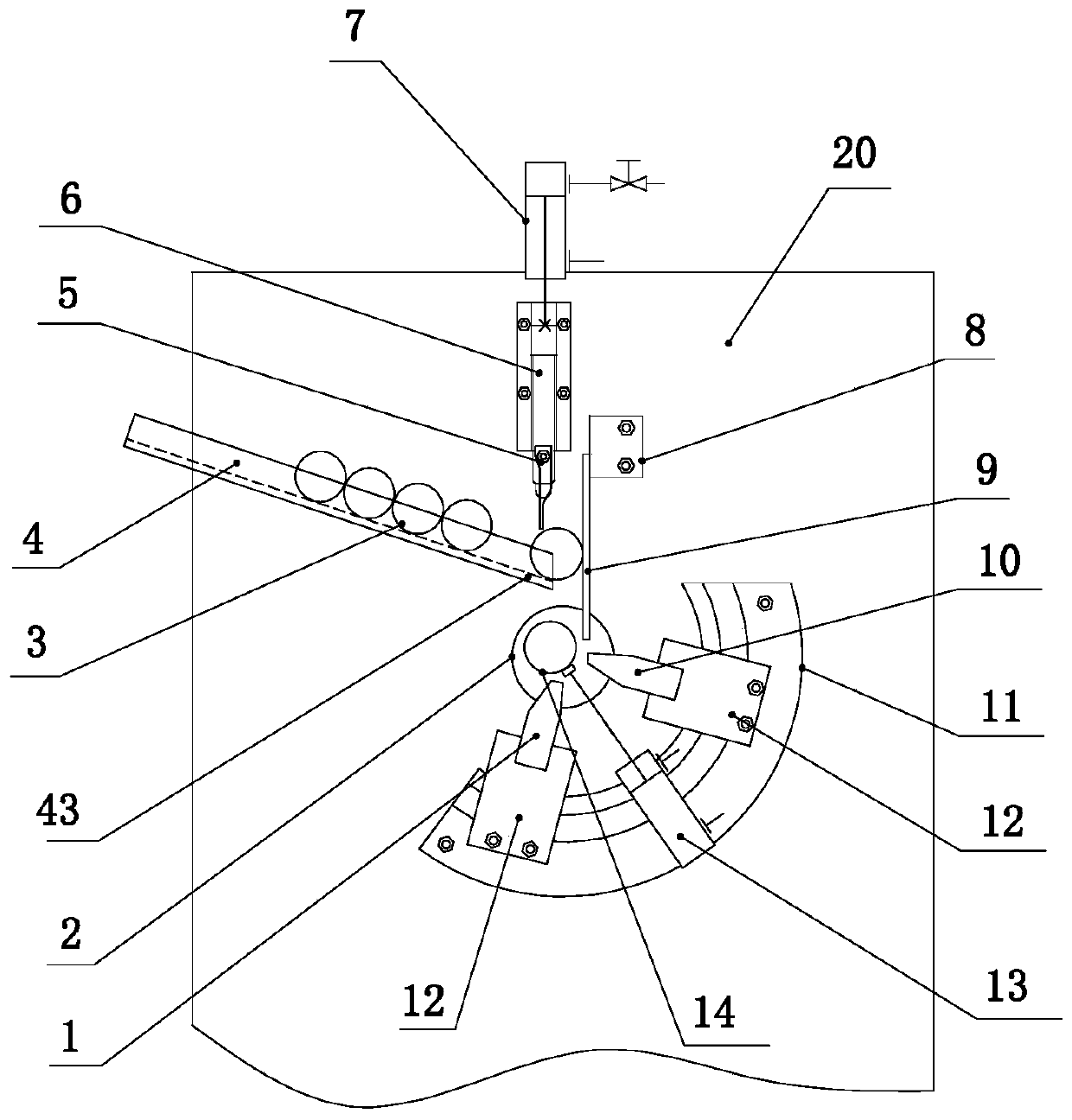

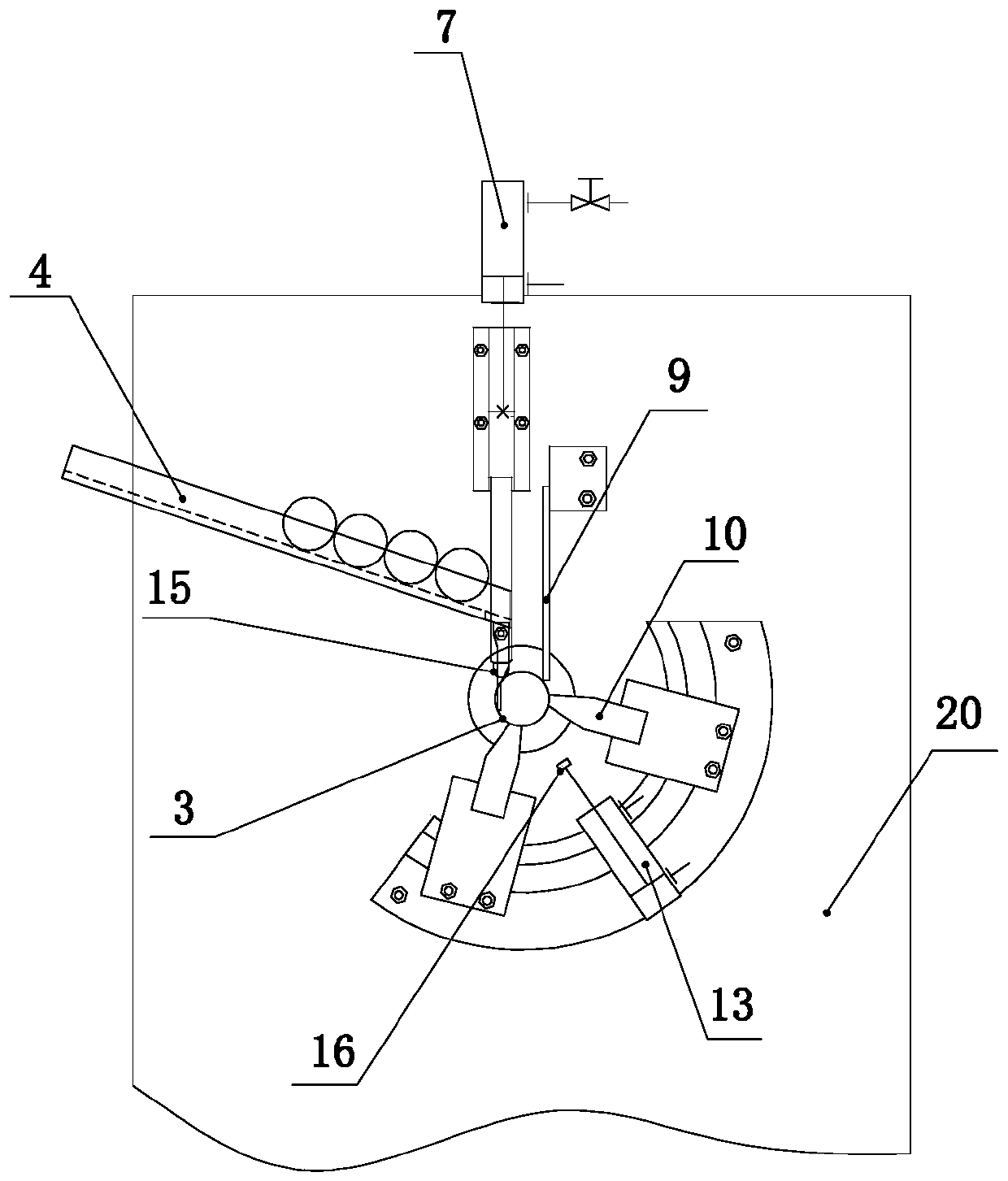

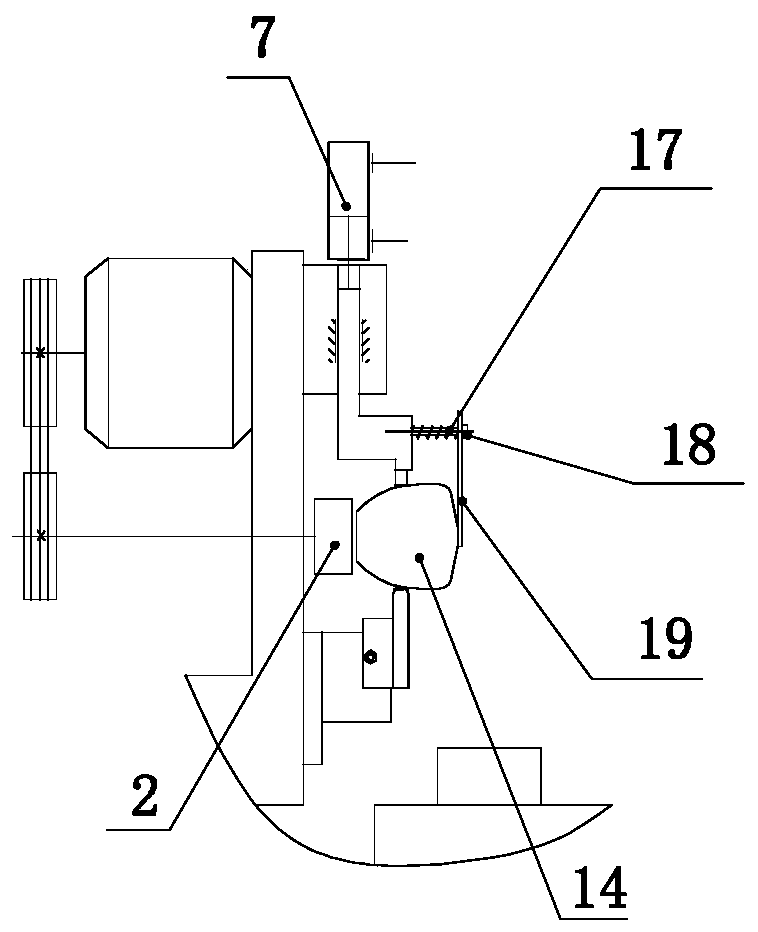

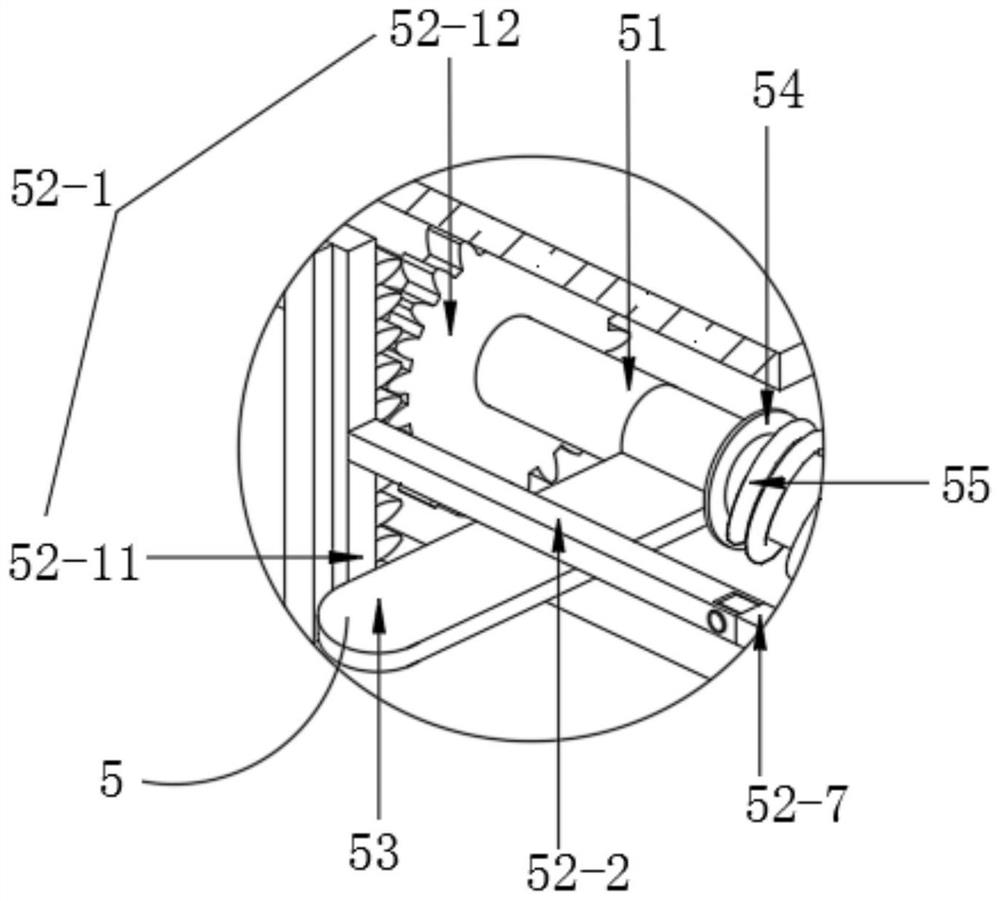

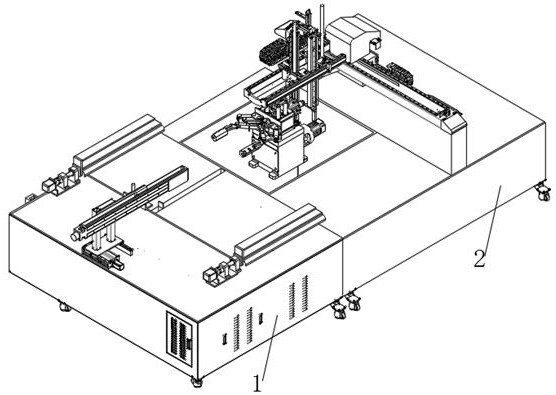

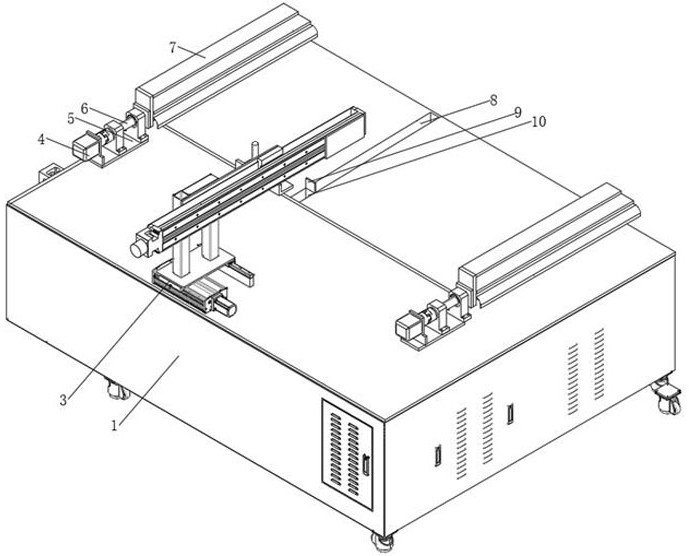

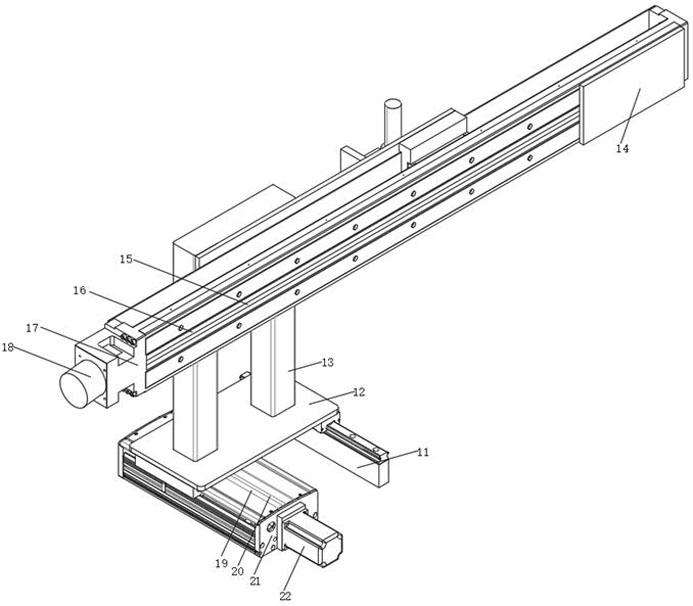

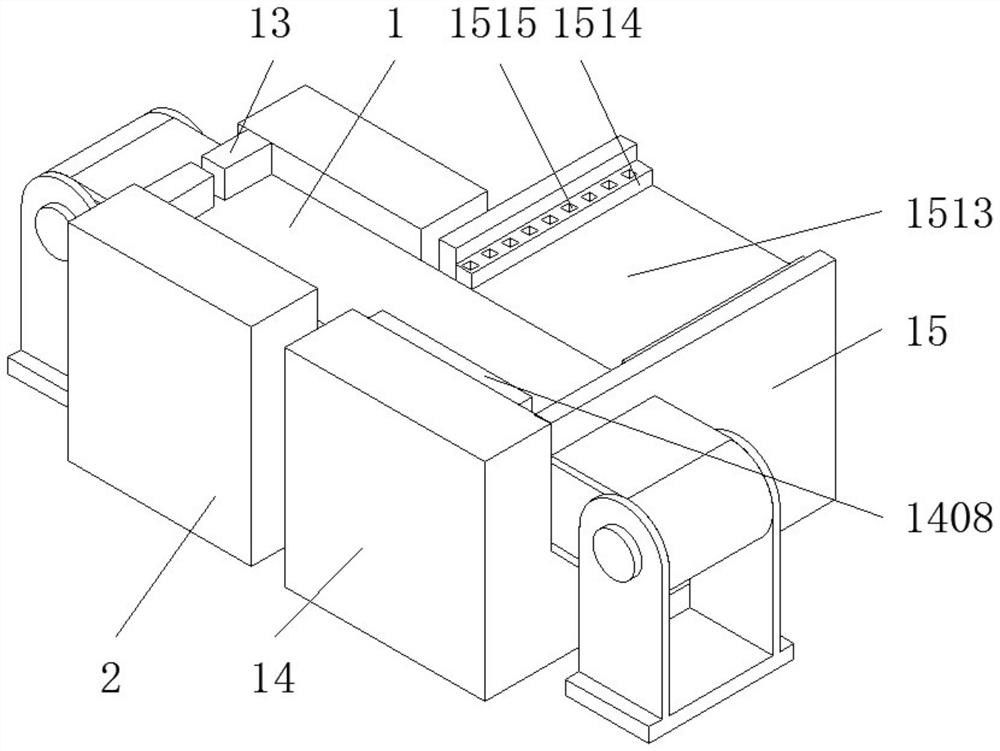

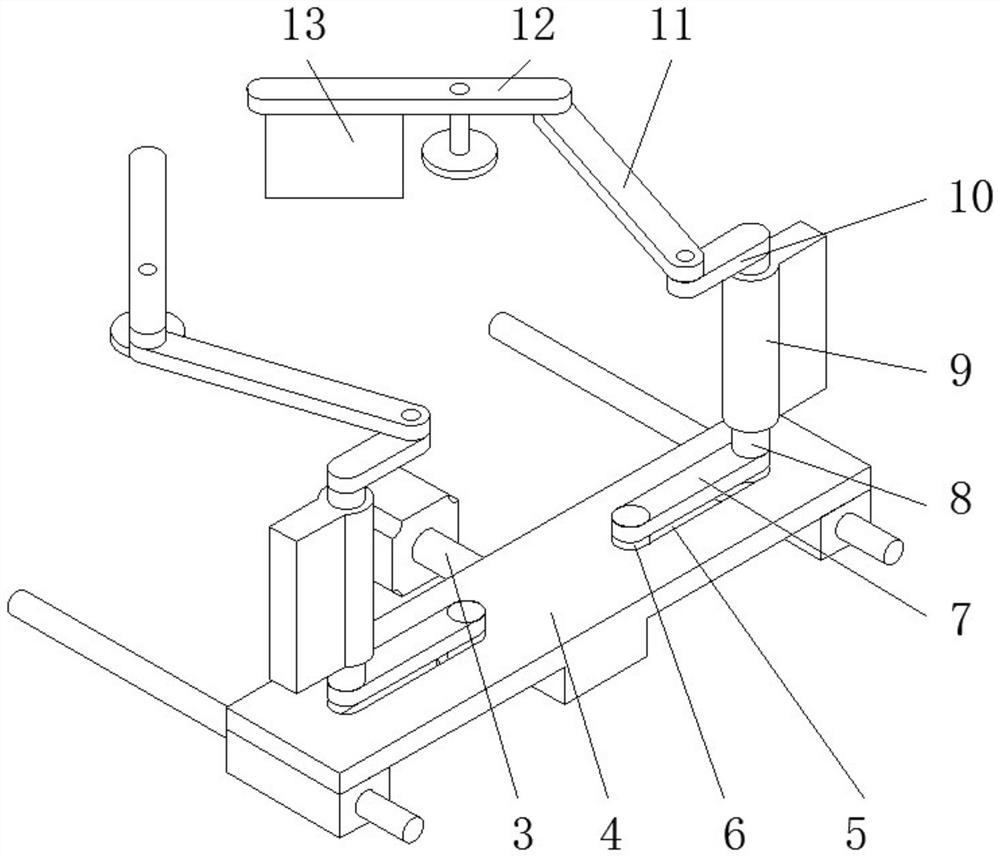

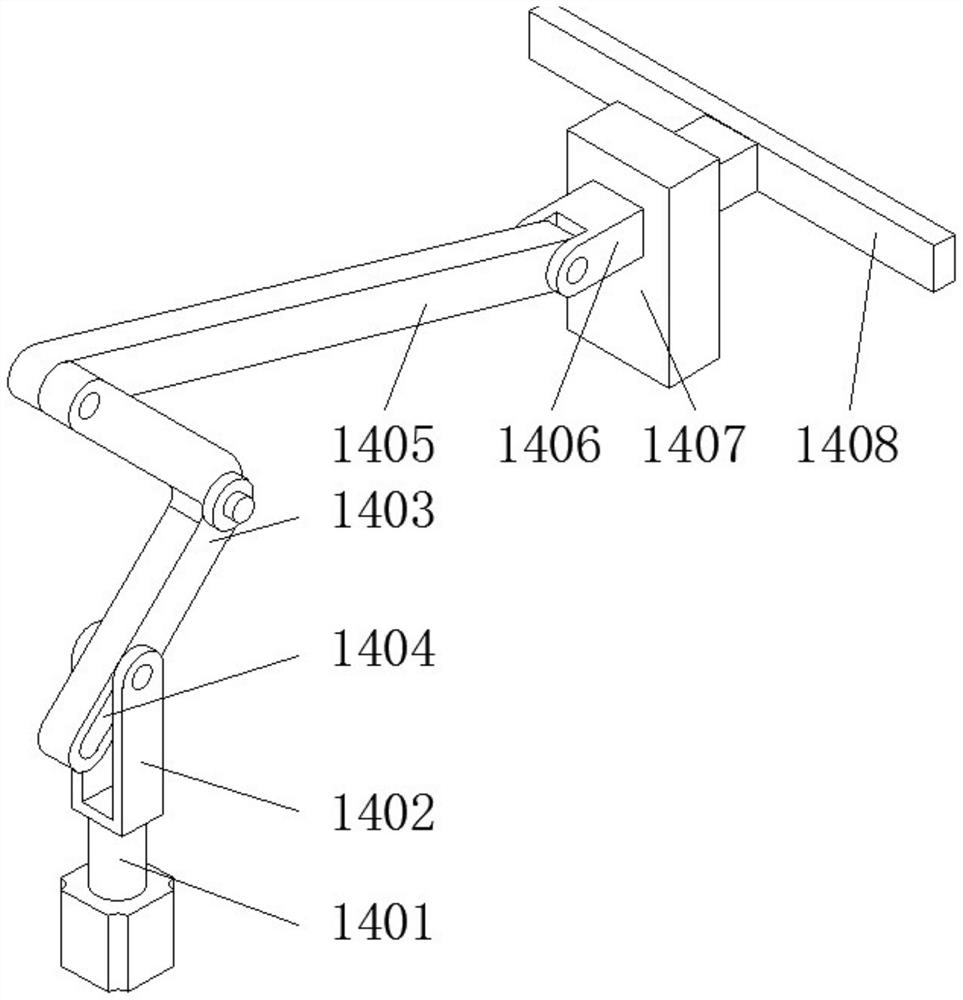

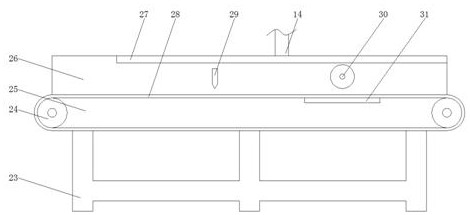

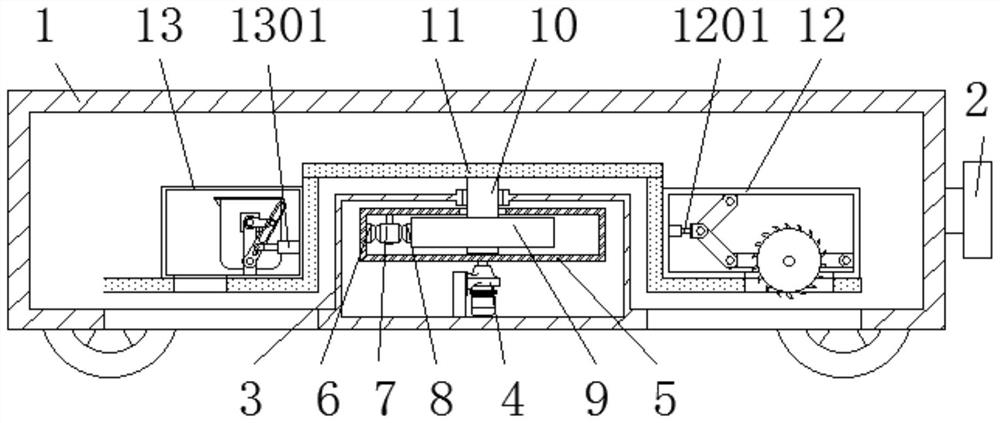

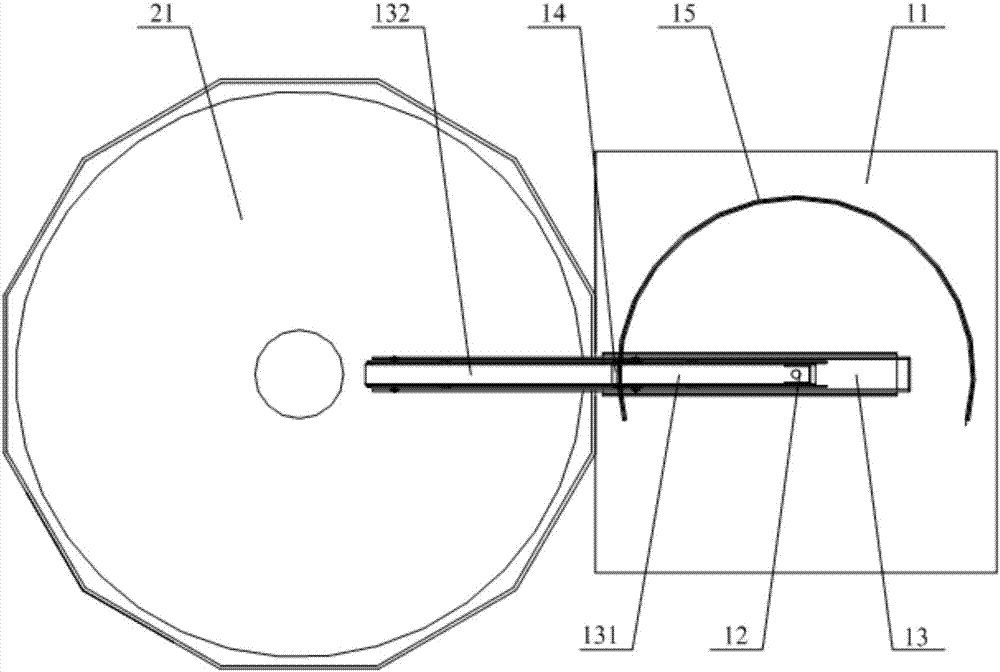

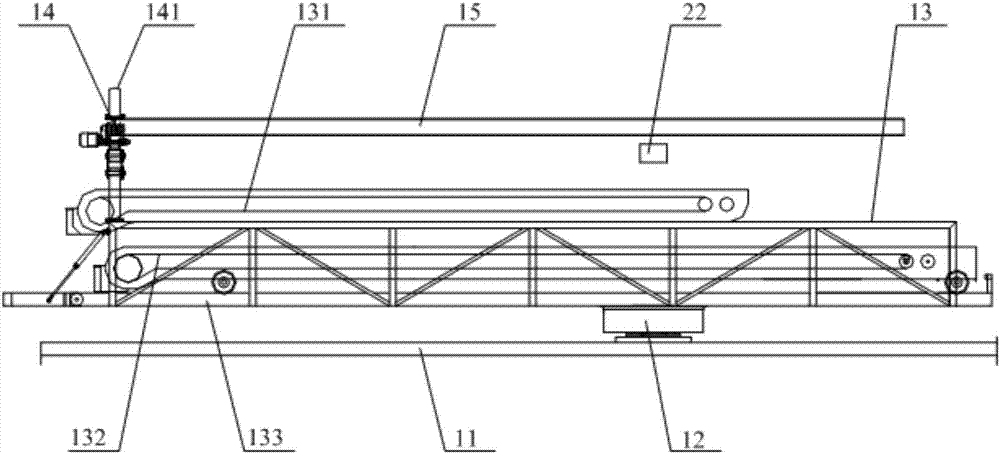

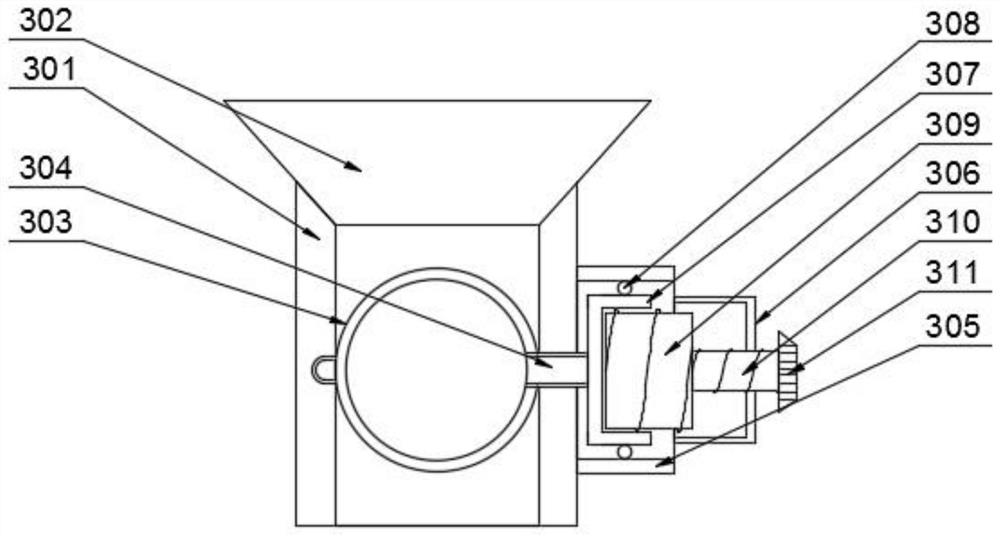

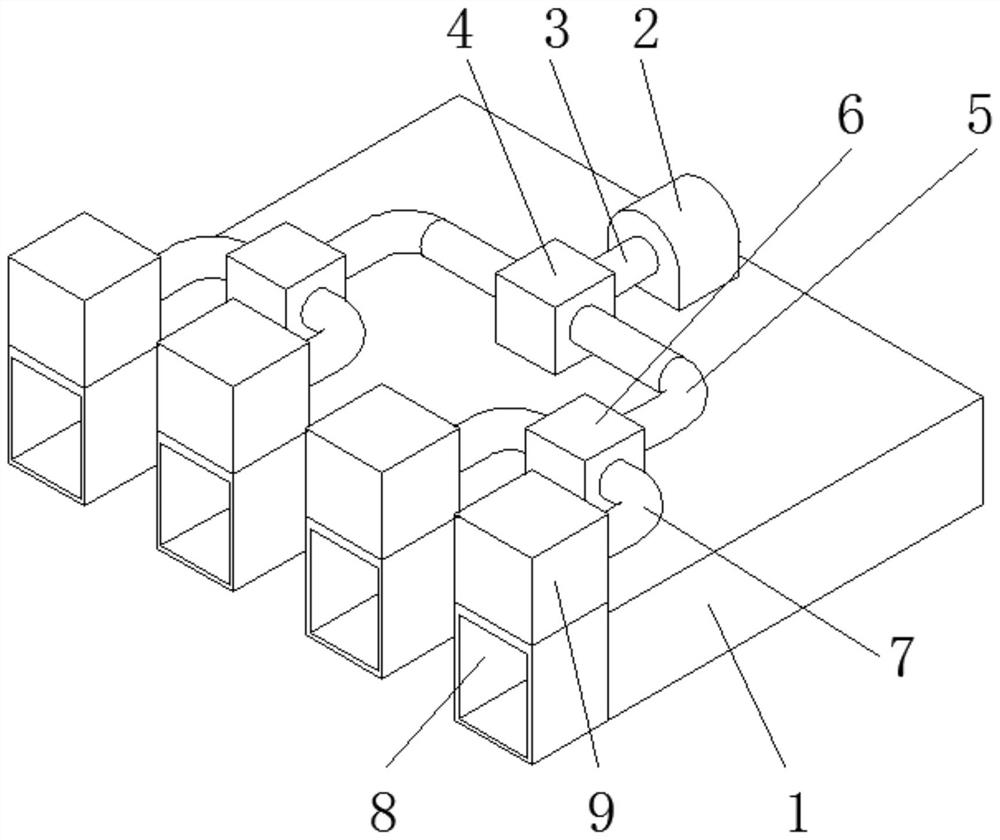

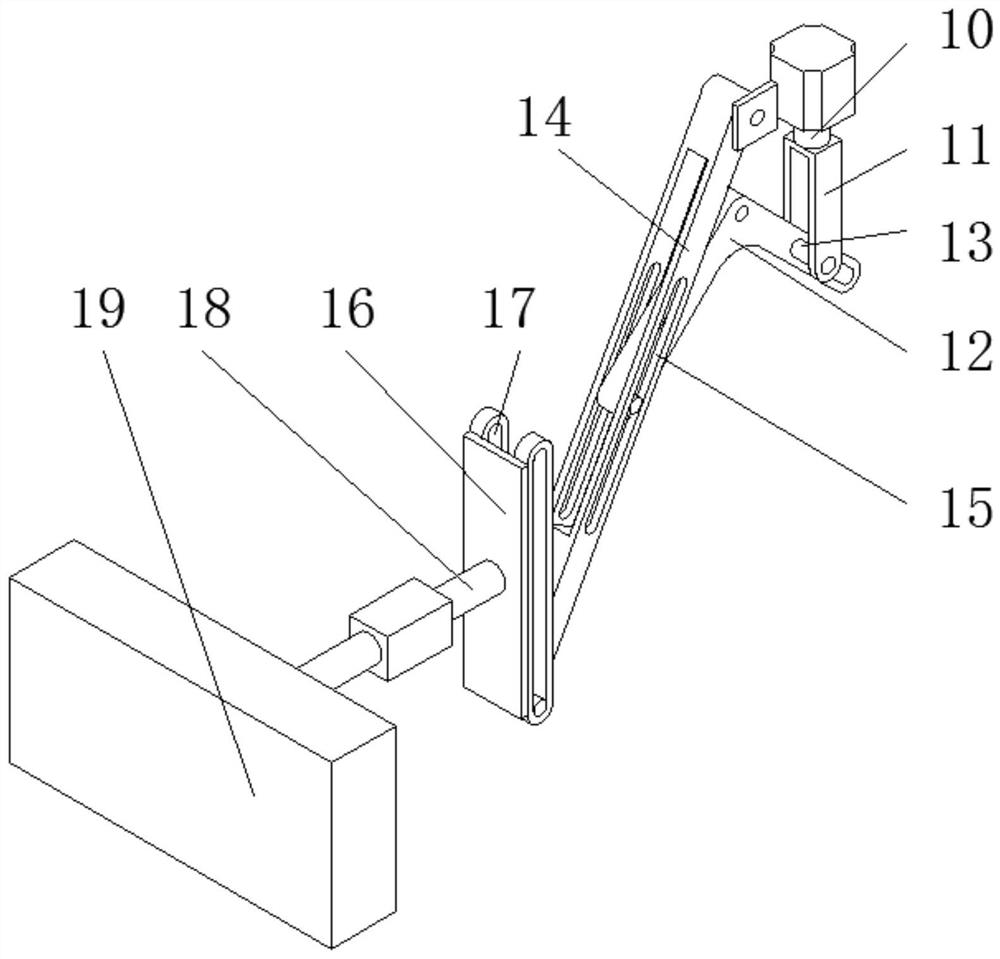

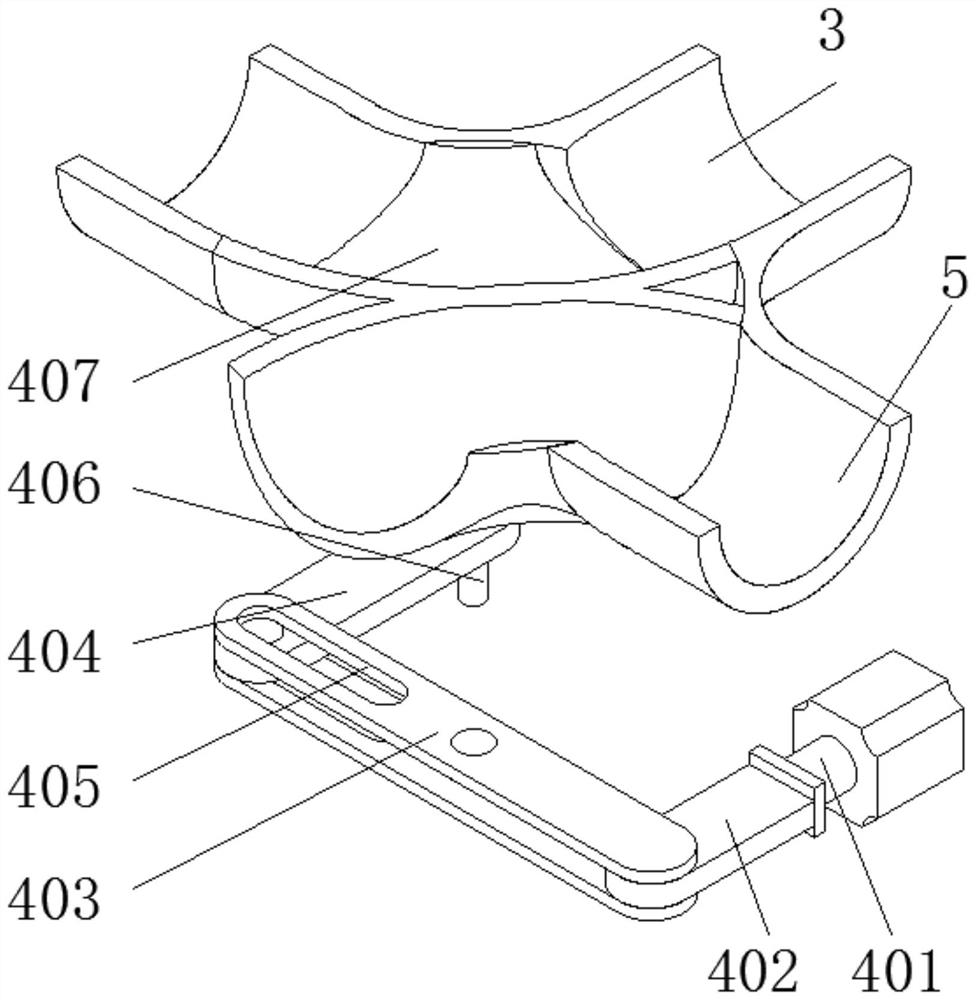

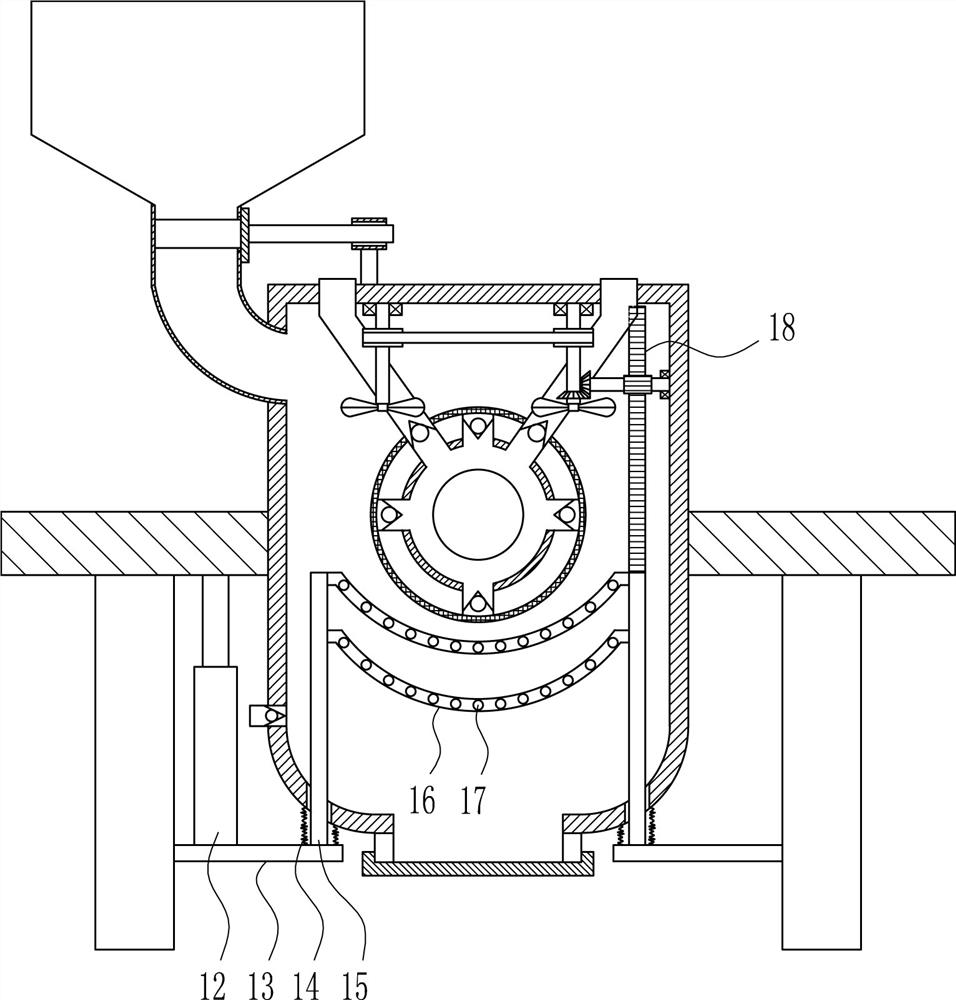

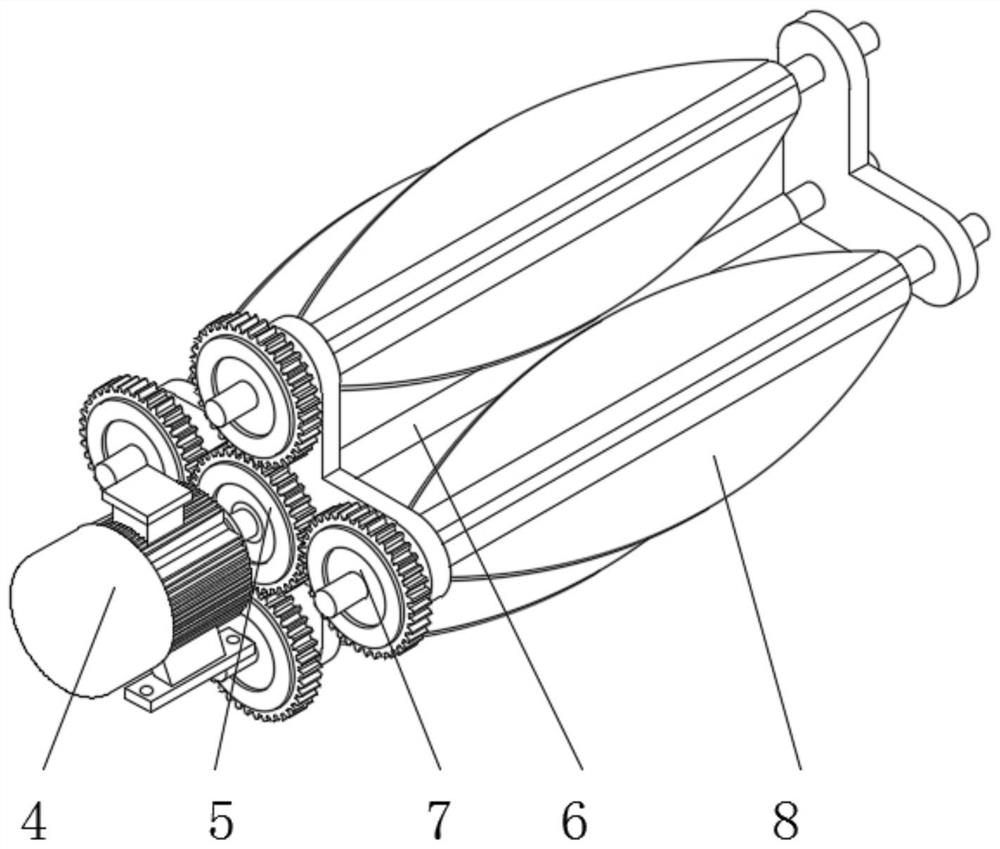

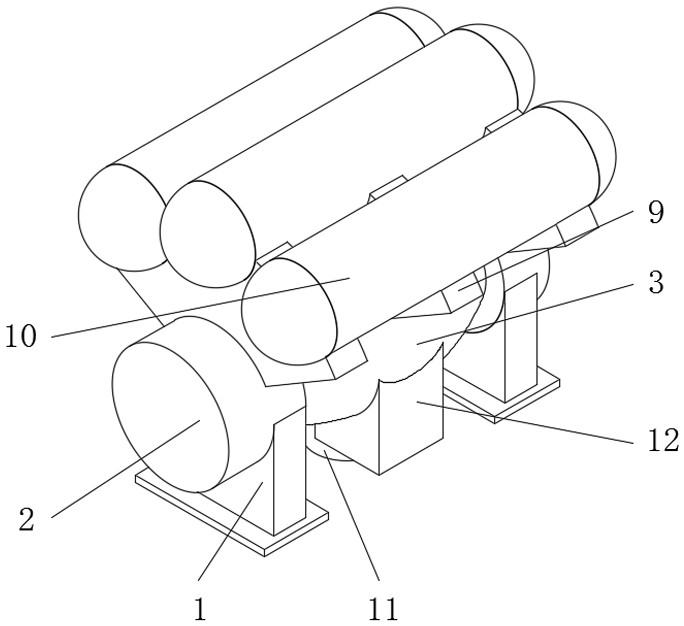

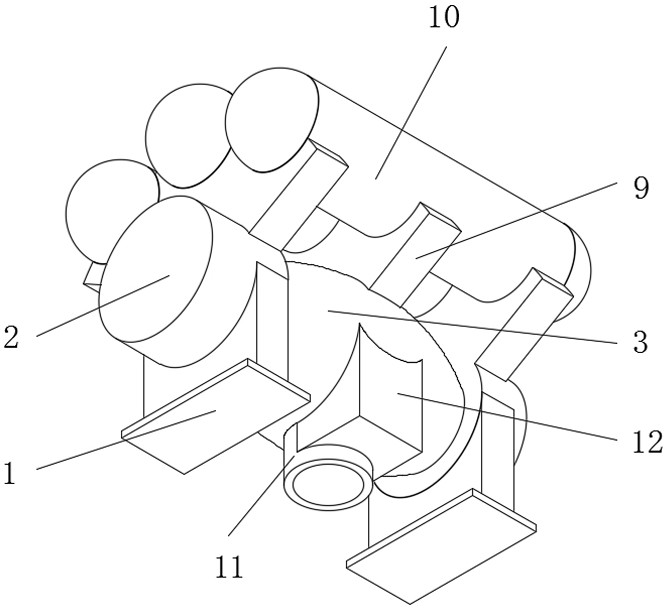

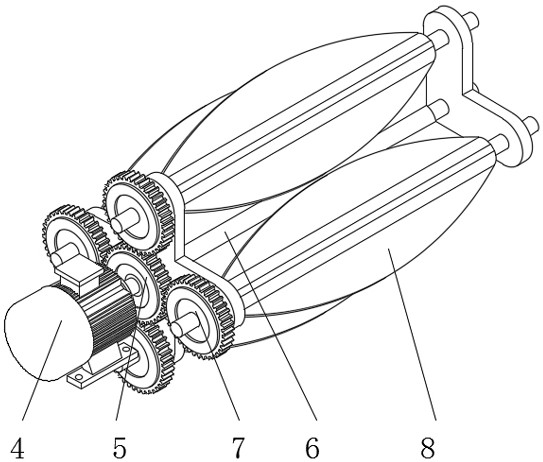

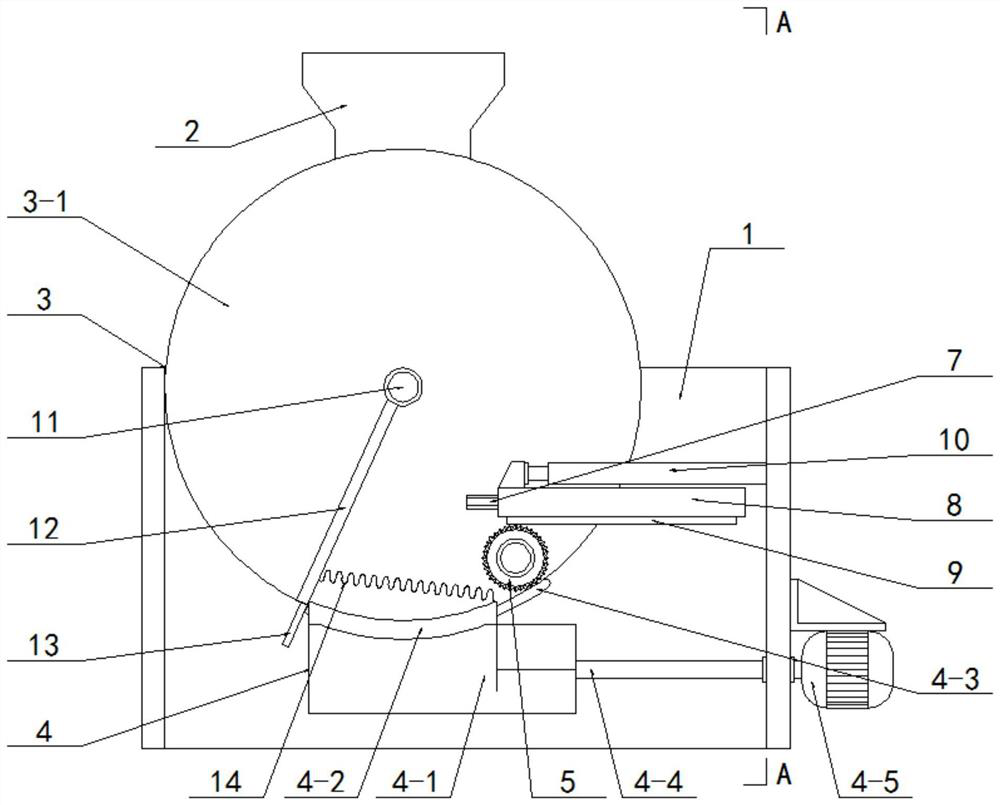

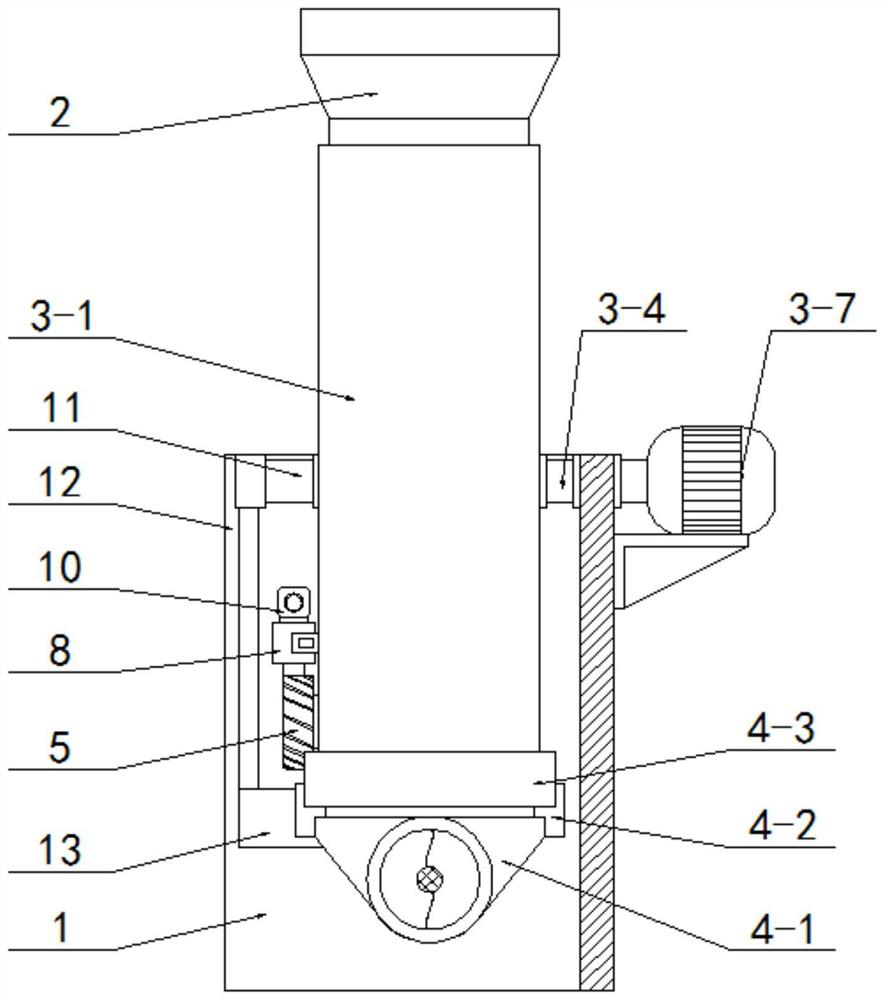

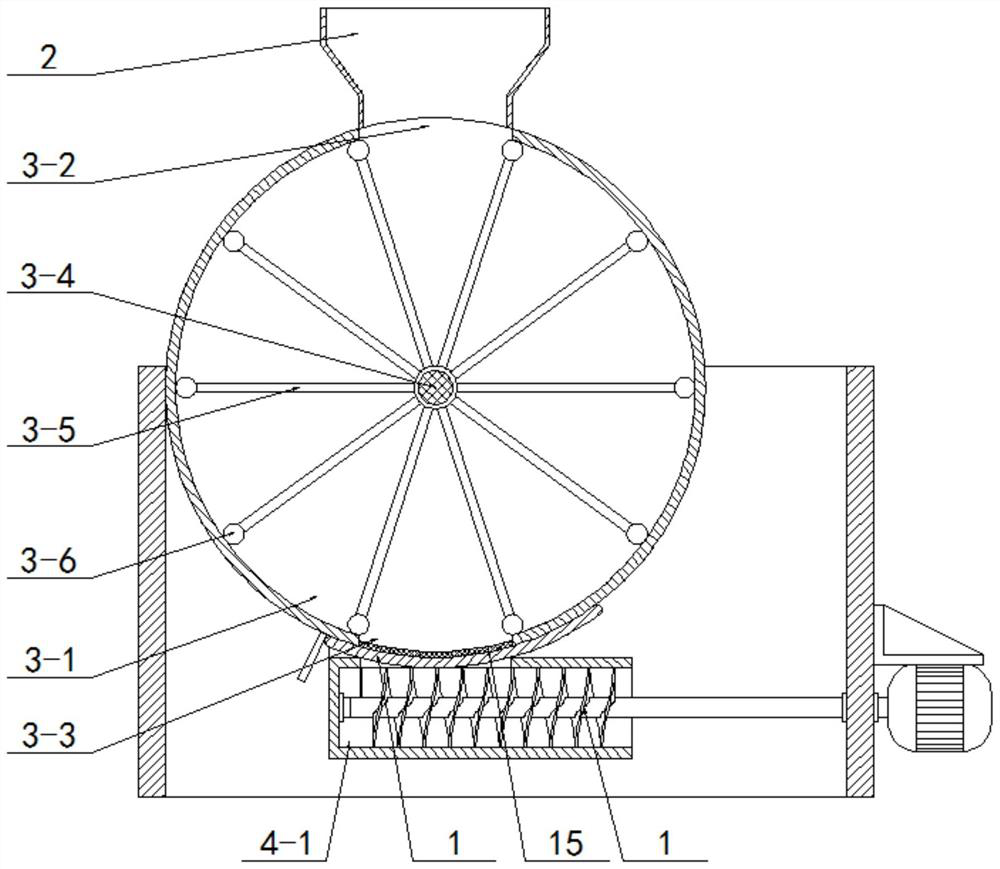

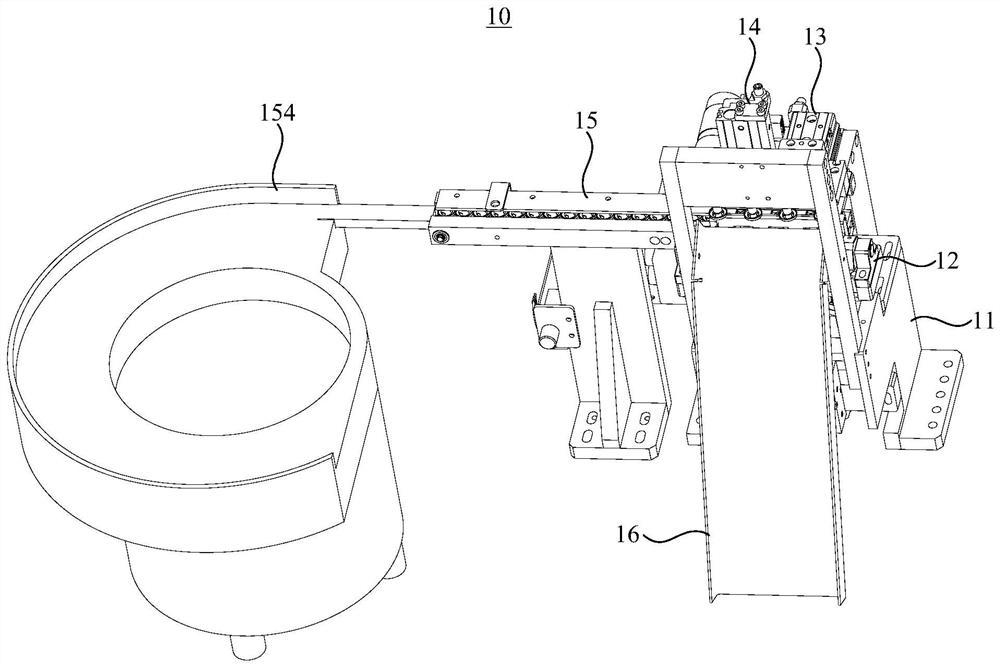

Automatic feeding and discharging system for spherical roller spherical base surface specialized grinding machine

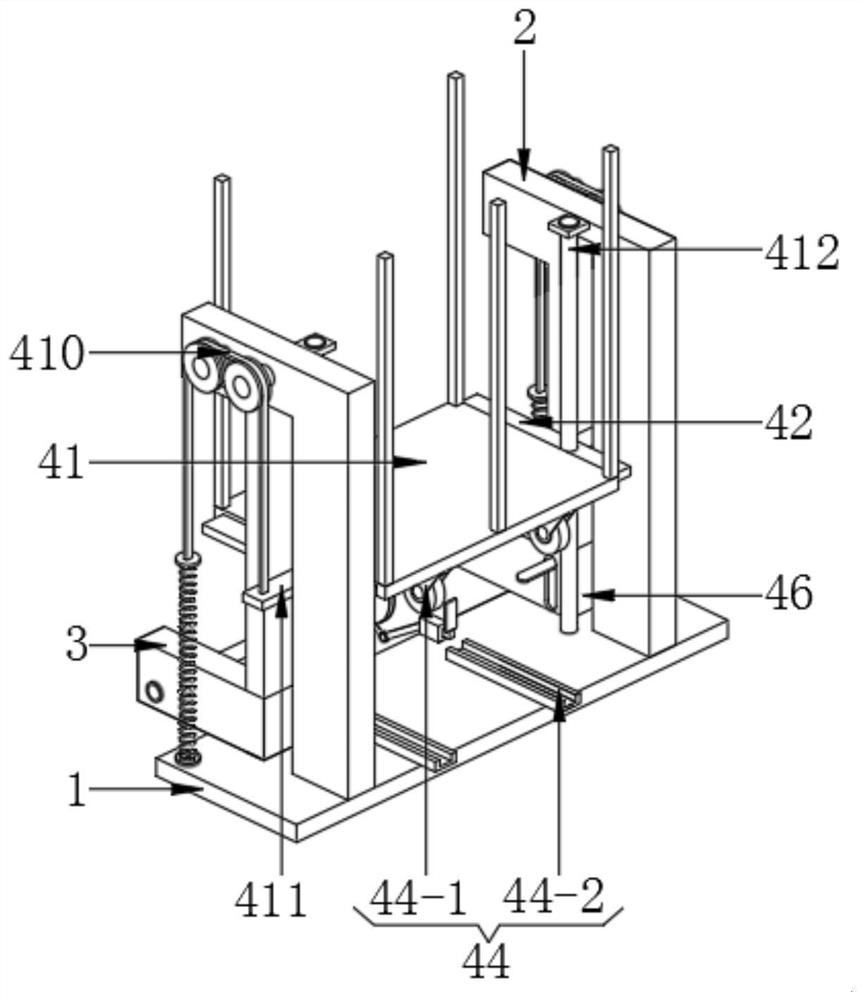

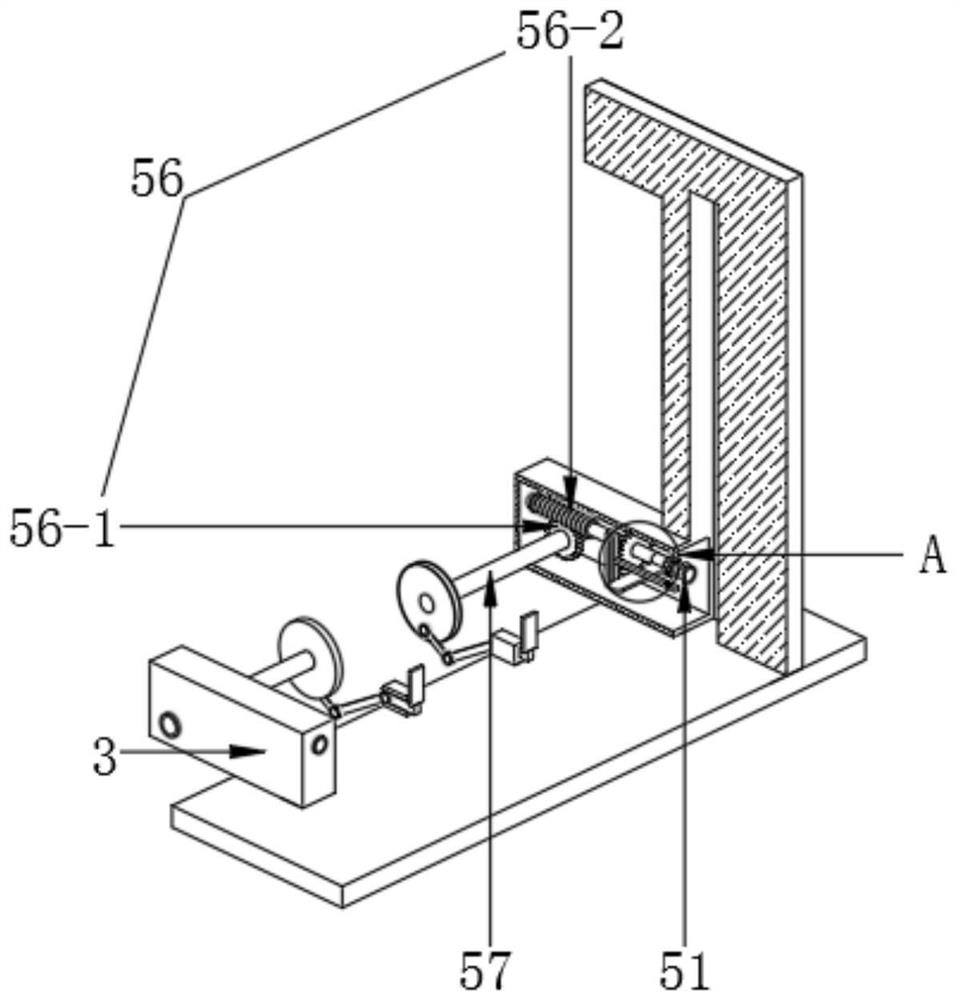

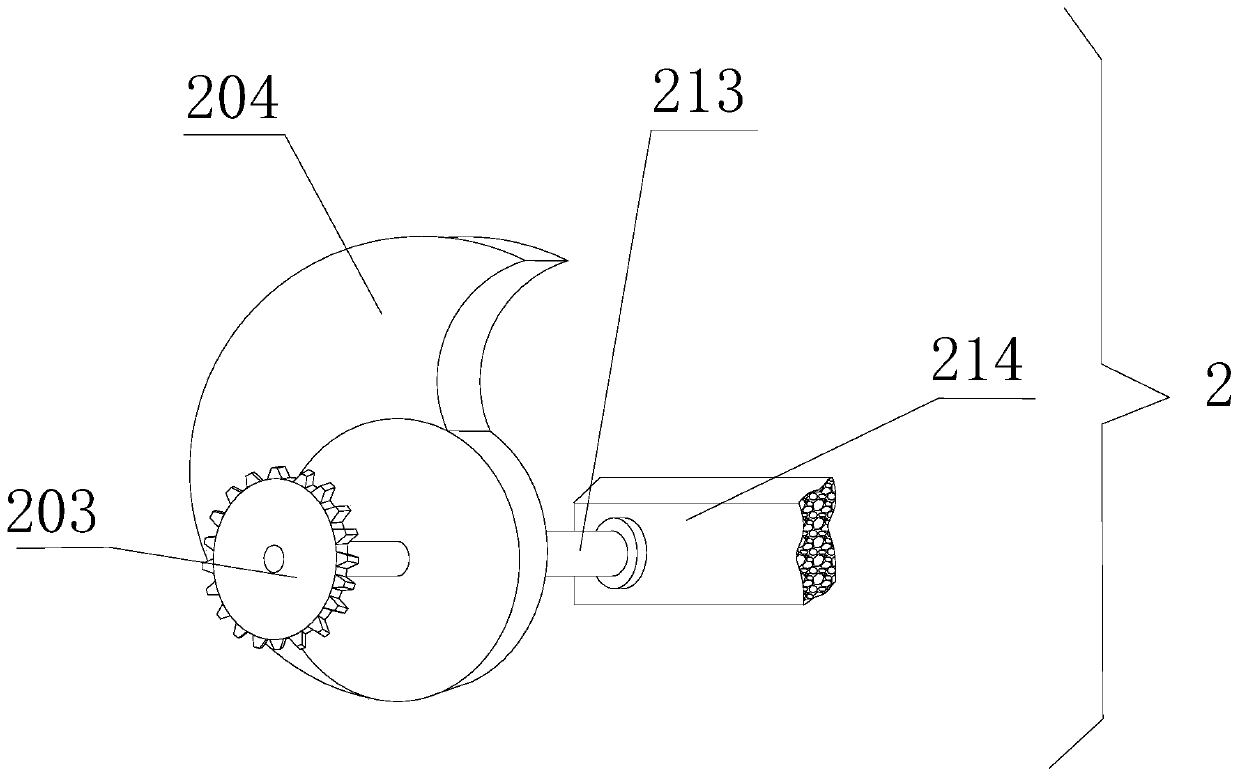

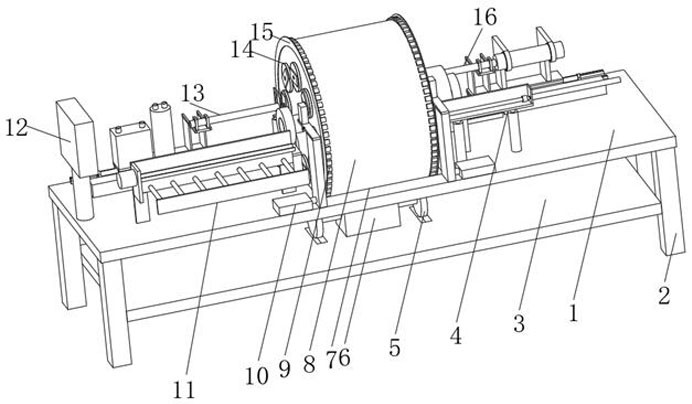

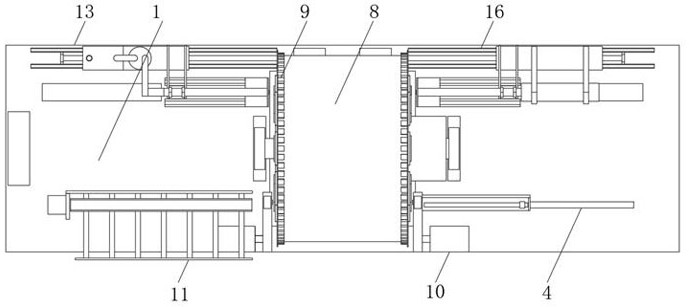

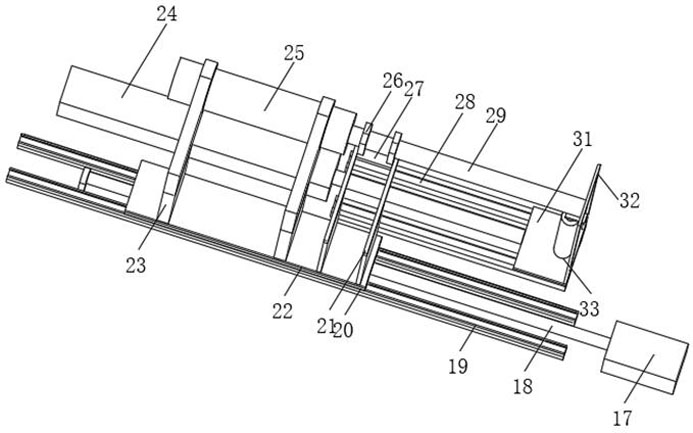

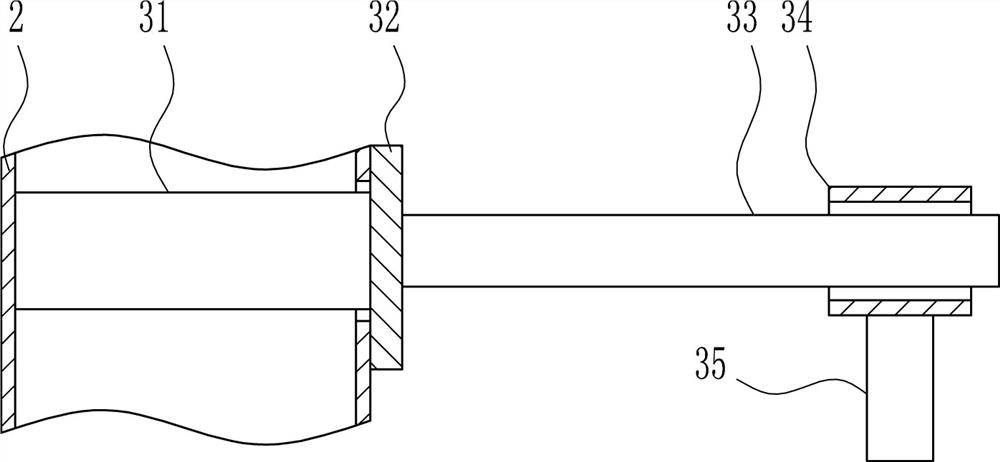

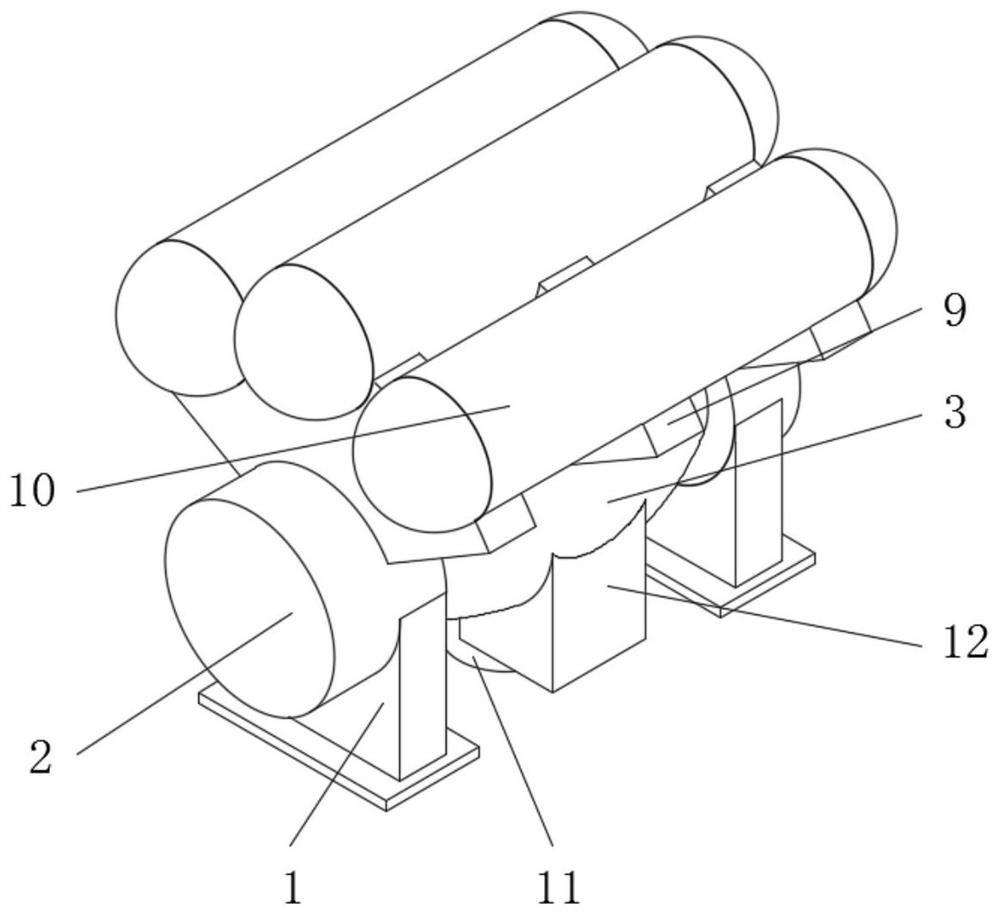

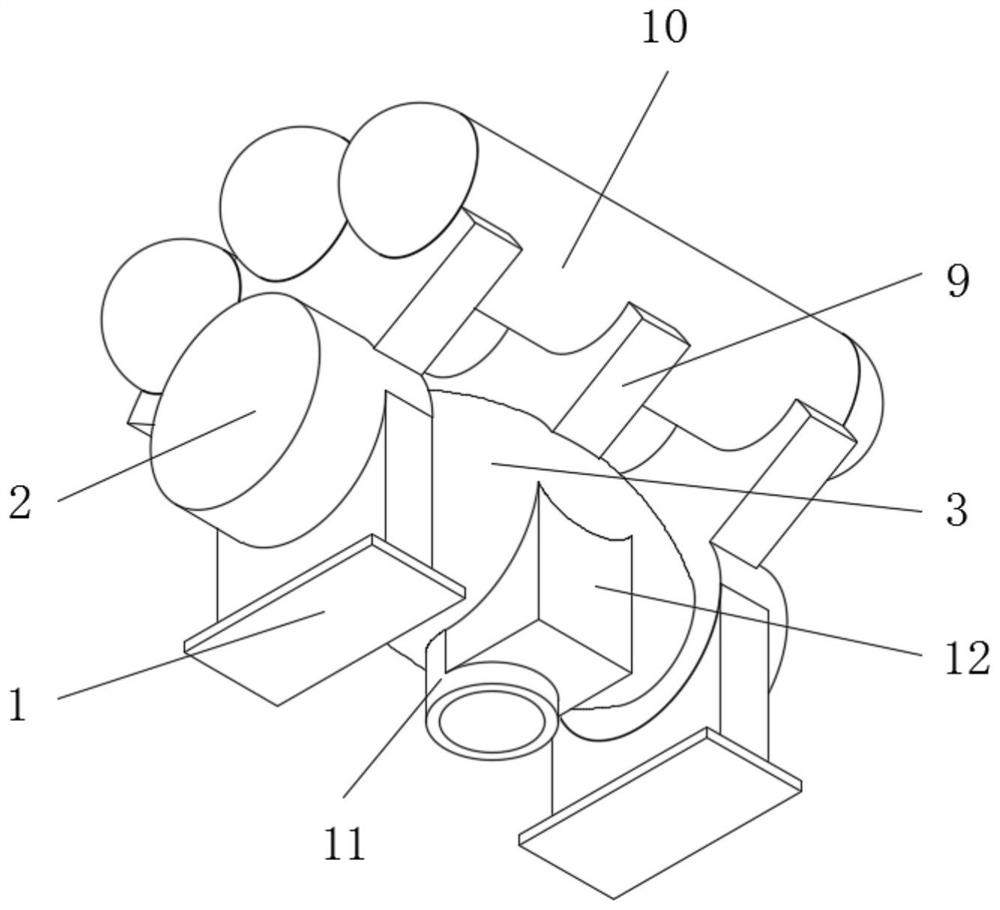

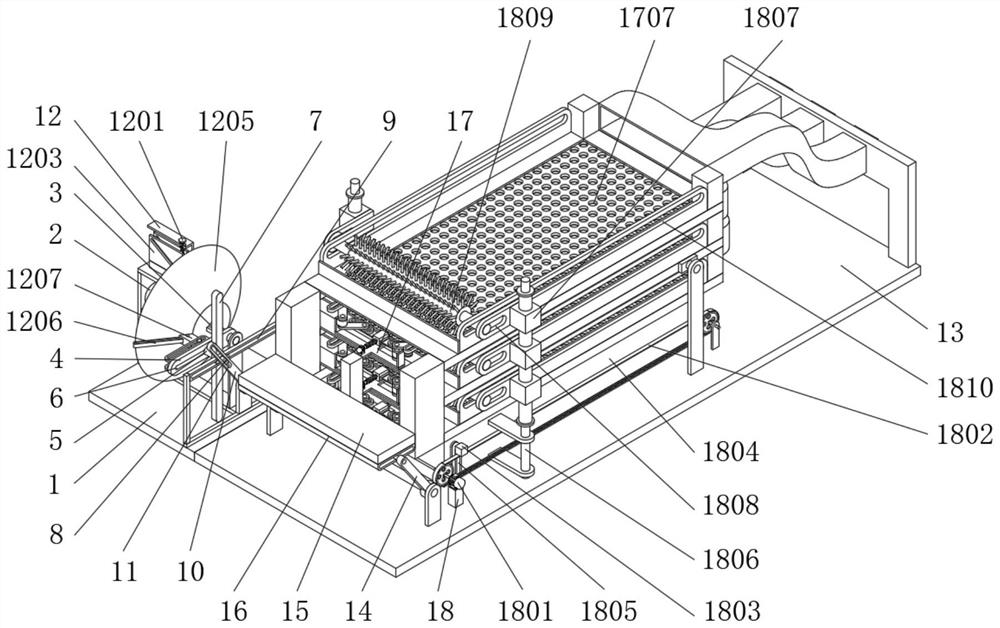

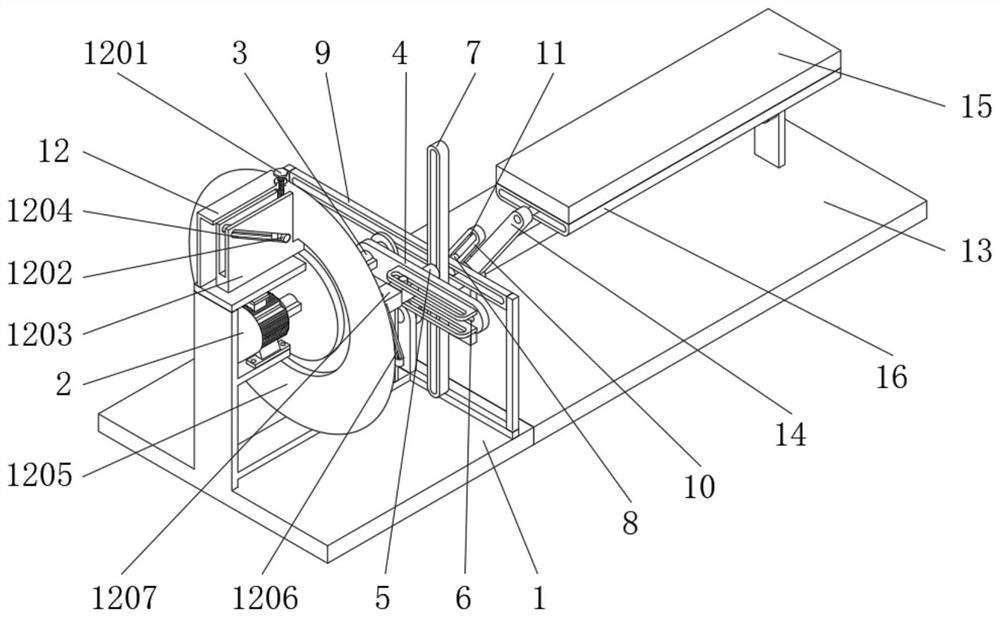

InactiveCN110465860ARealize loading operationRealize unloading operationGrinding machinesGrinding feedersReciprocating motionEngineering

The invention discloses an automatic feeding and discharging system for a spherical roller spherical base surface specialized grinding machine. The automatic feeding and discharging system for the spherical roller spherical base surface specialized grinding machine is used for achieving feeding and discharging of spherical rollers and comprises a rack, a crescent-moon-shaped plate, an electromagnetic chuck, a discharging channel, a conveying spring plate, a conveying movable plate and a material beating head; two support bases are slidably installed on the crescent-moon-shaped plate, locking structures are arranged between the support bases and the crescent-moon-shaped plate, a first support is fixed to the first support base, and a second support is fixed to the other support base; the electromagnetic chuck is arranged over the crescent-moon-shaped plate; the discharging channel is obliquely arranged, and roller blanks are arranged on the discharging channel; the upper end of the conveying spring plate is fixedly connected with the rack; the conveying movable plate is arranged on the left side of the conveying spring plate and arranged on the upper side of the lower end of the discharging channel, and a conveying driving mechanism used for driving the conveying movable plate to do vertical reciprocating motion is arranged on the rack; and the material beating head is movably arranged on the crescent-moon-shaped plate, and a material beating driving mechanism used for driving the material beating head is arranged on the crescent-moon-shaped plate. According to the system, feeding and discharging of the spherical rollers can be conveniently achieved.

Owner:临清市海滨轴承制造有限公司

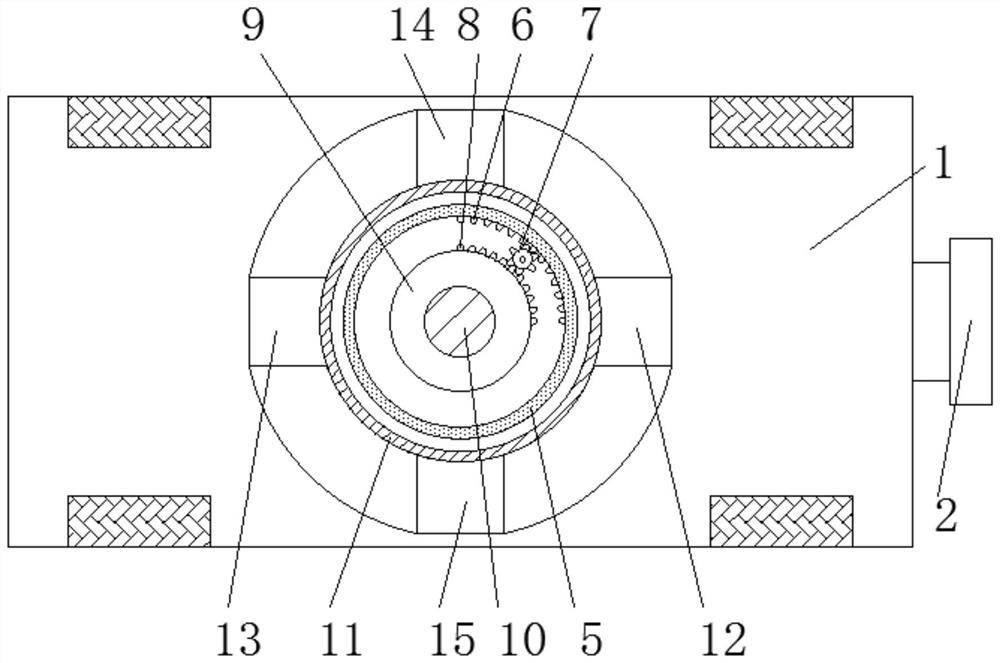

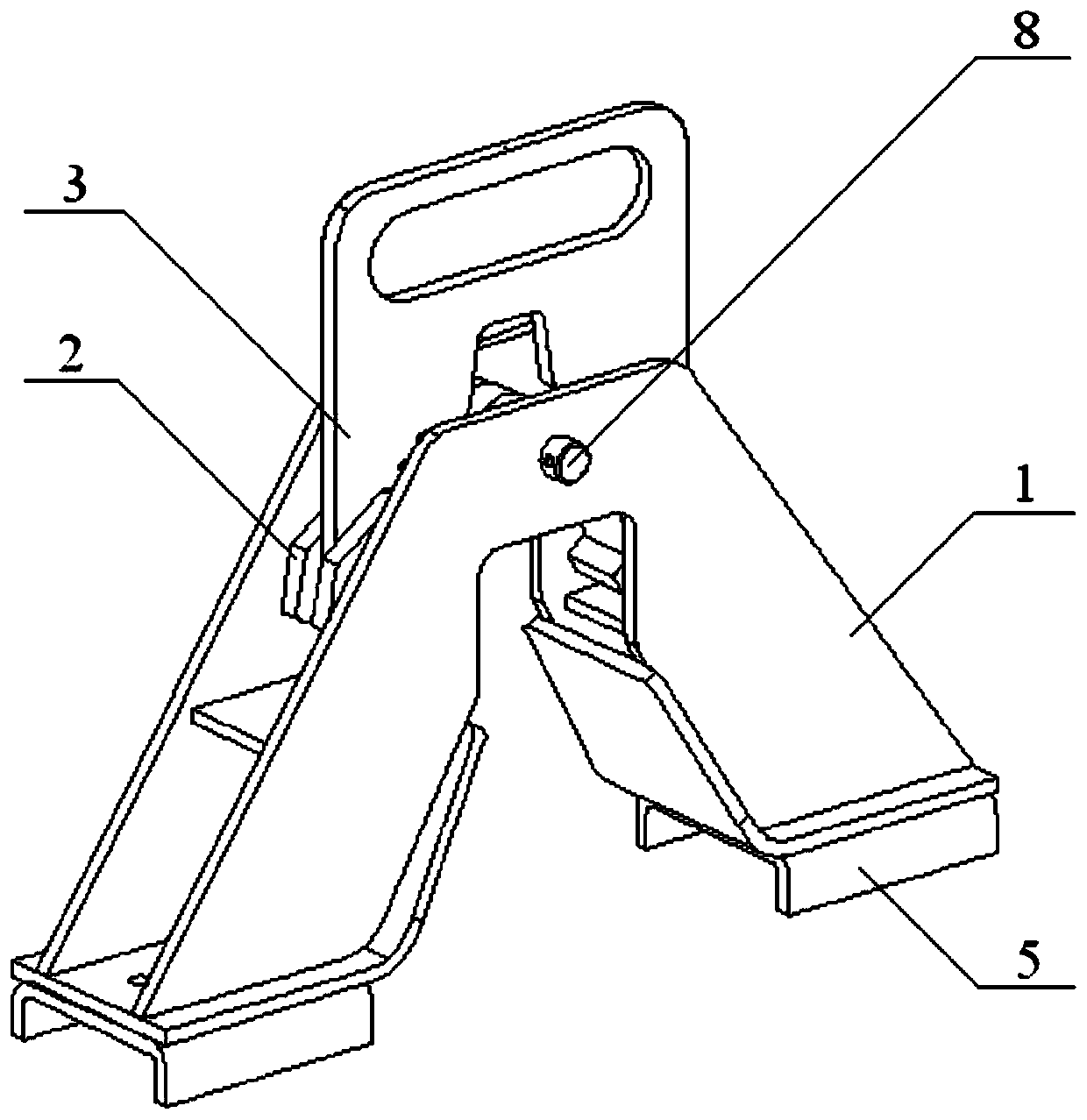

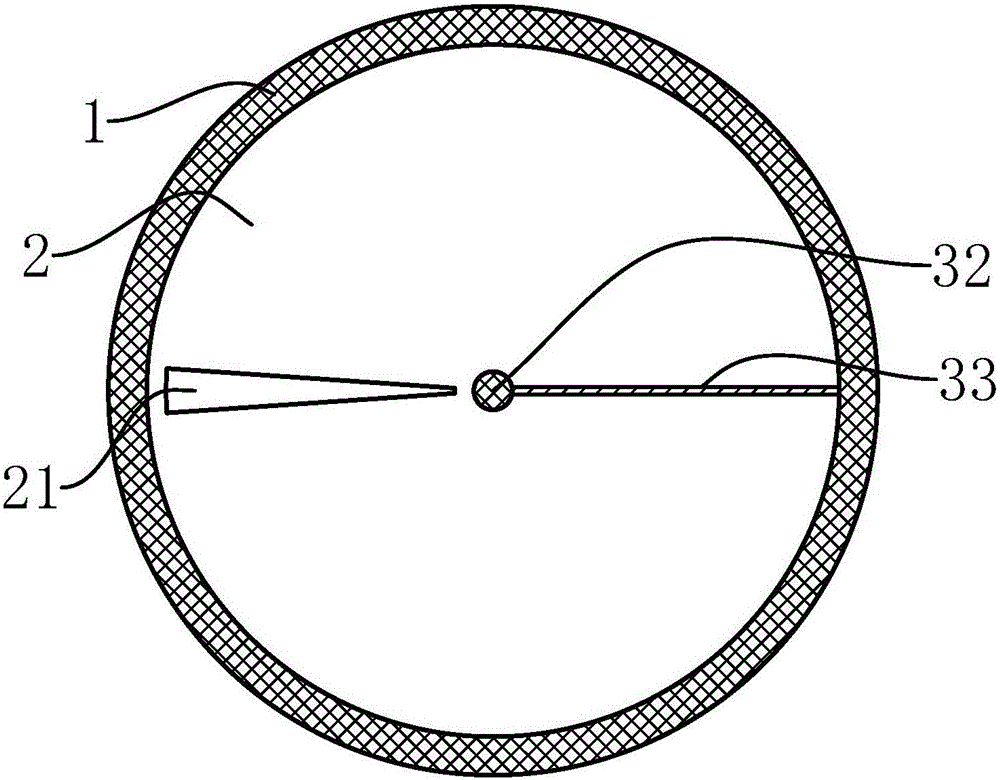

Bearing outer ring clamping device

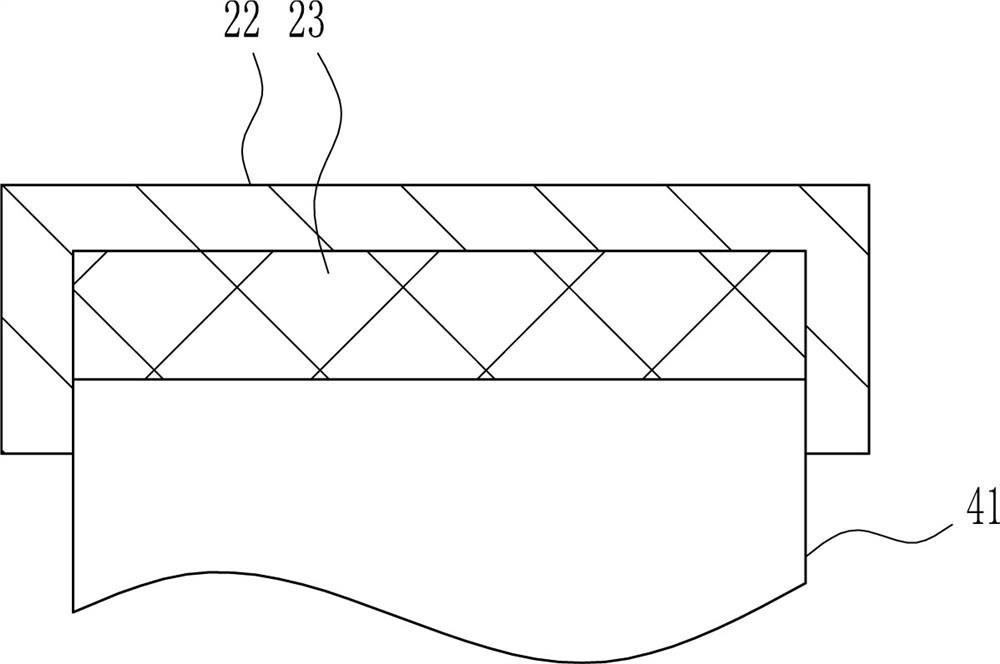

InactiveCN109748099AEffective implementation of clampingEasy to realize unloading operationConveyor partsMachiningIndustrial engineering

The invention relates to a bearing outer ring clamping device comprising a clamping pipe. The pipe length direction of the clamping pipe is horizontal, and clamping heads are arranged in the pipe wall. The clamping heads are connected with a clamping mechanism. When a turning head gets close to the inner wall of the clamping pipe, the clamping heads implement the clamping action for the clamping pipe. After a feeding mechanism progressively leads and sends a bearing outer ring into the clamping pipe, the clamping mechanism mentioned above is started, and the clamping operation of the outer wall of the bearing outer ring is implemented through the clamping heads; it is avoided that when a drive mechanism drives the clamping pipe to operate at a high speed, the turning head can effectively clamp the bearing outer ring; when the turning head gets close to a pipe opening of the clamping pipe, the clamping heads clamp the clamping pipe, and therefore turning machining of the inner ring faceof the bearing outer ring can be ensured; and after the turning head gets away from the pipe opening of the clamping pipe, the clamping mechanism resets, the clamping heads and the bearing outer ringcan be separated, or releasing of the bearing outer ring is implemented, and the discharge operation of the bearing outer ring is conveniently achieved.

Owner:合肥捷鑫轴承有限公司

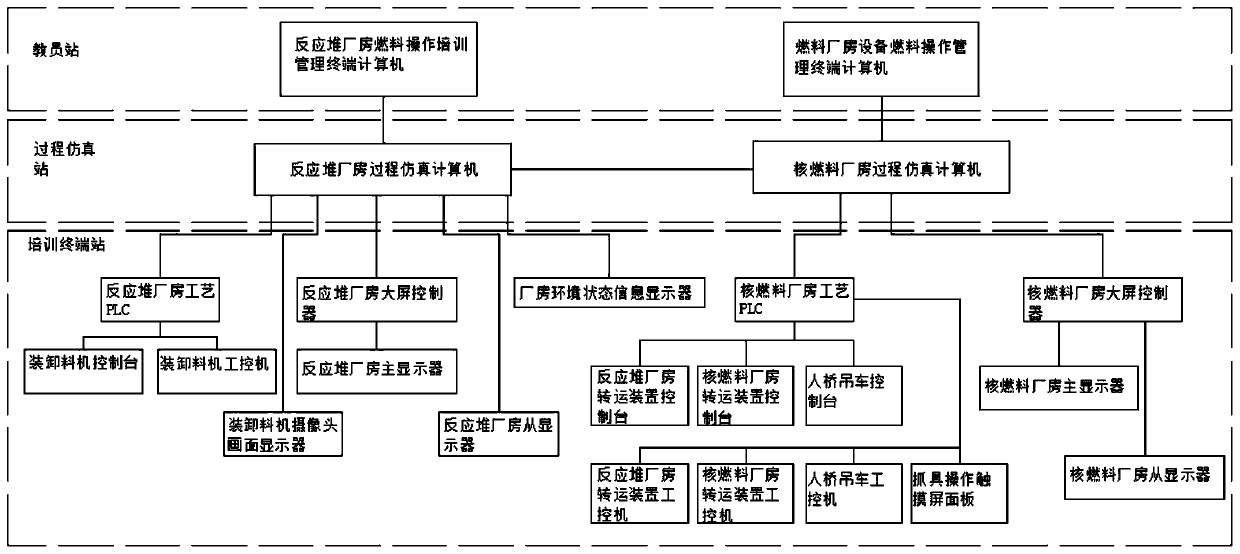

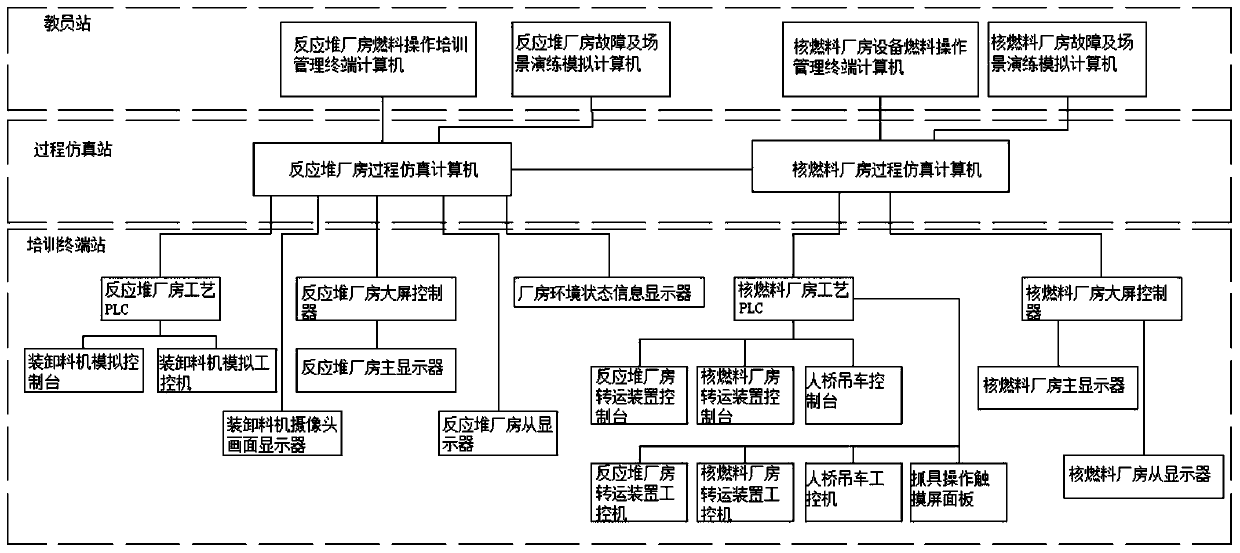

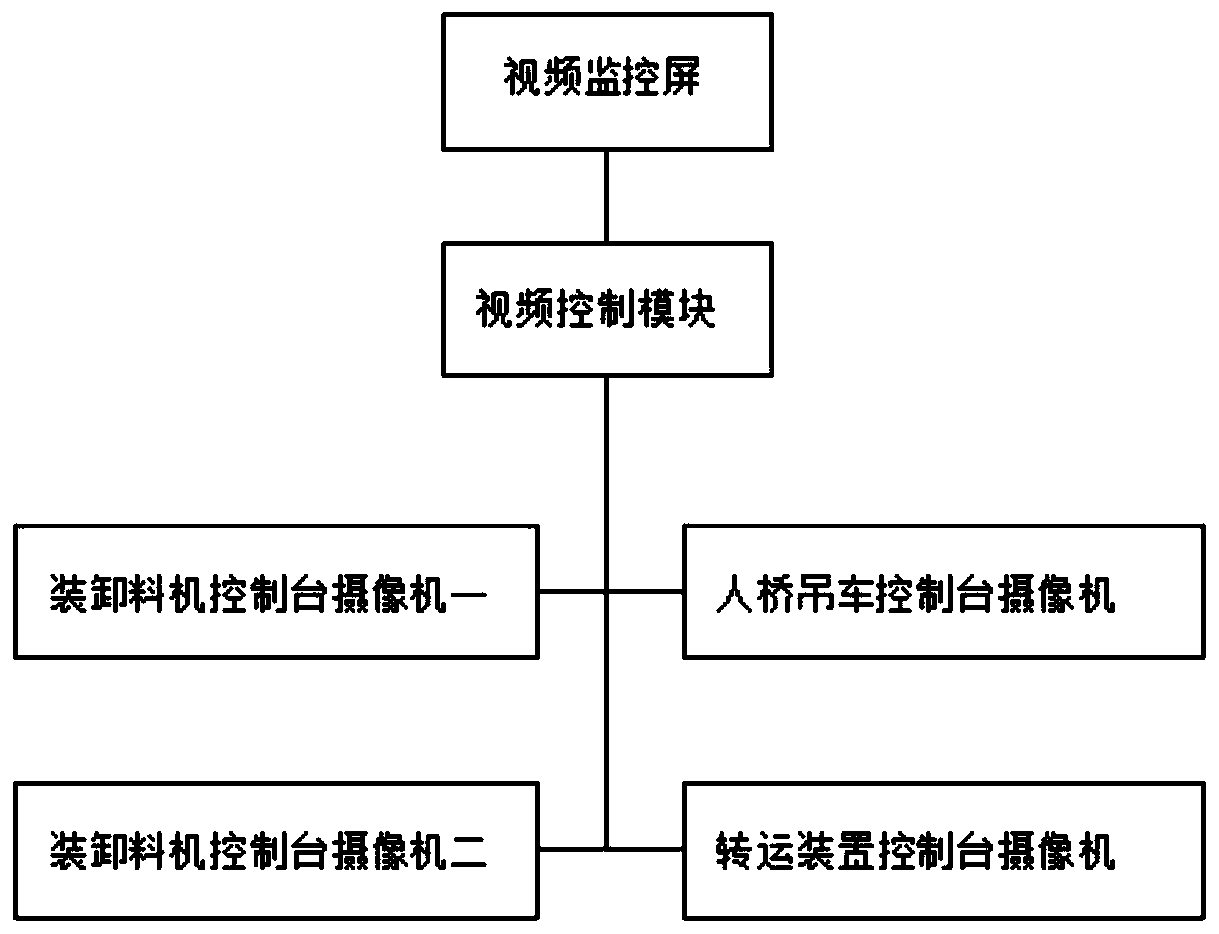

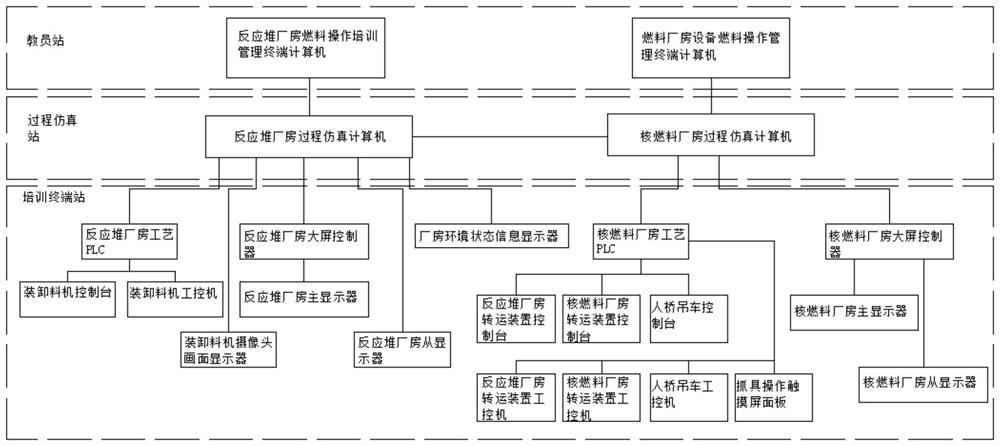

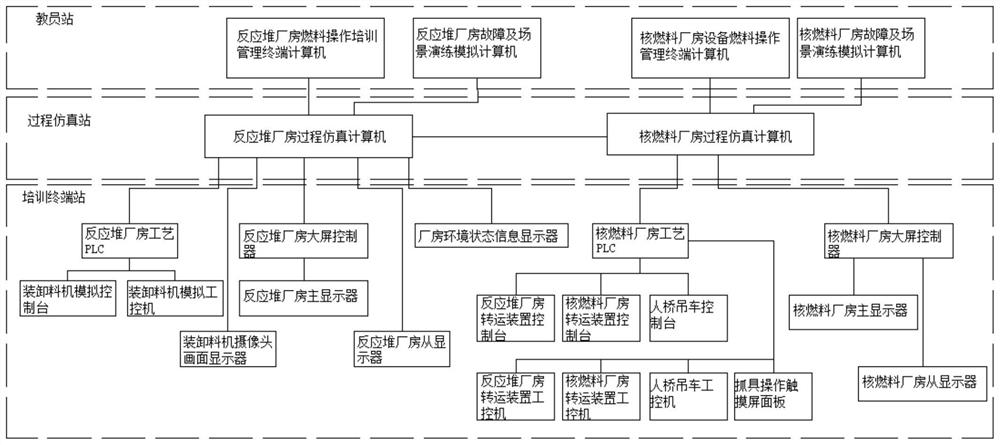

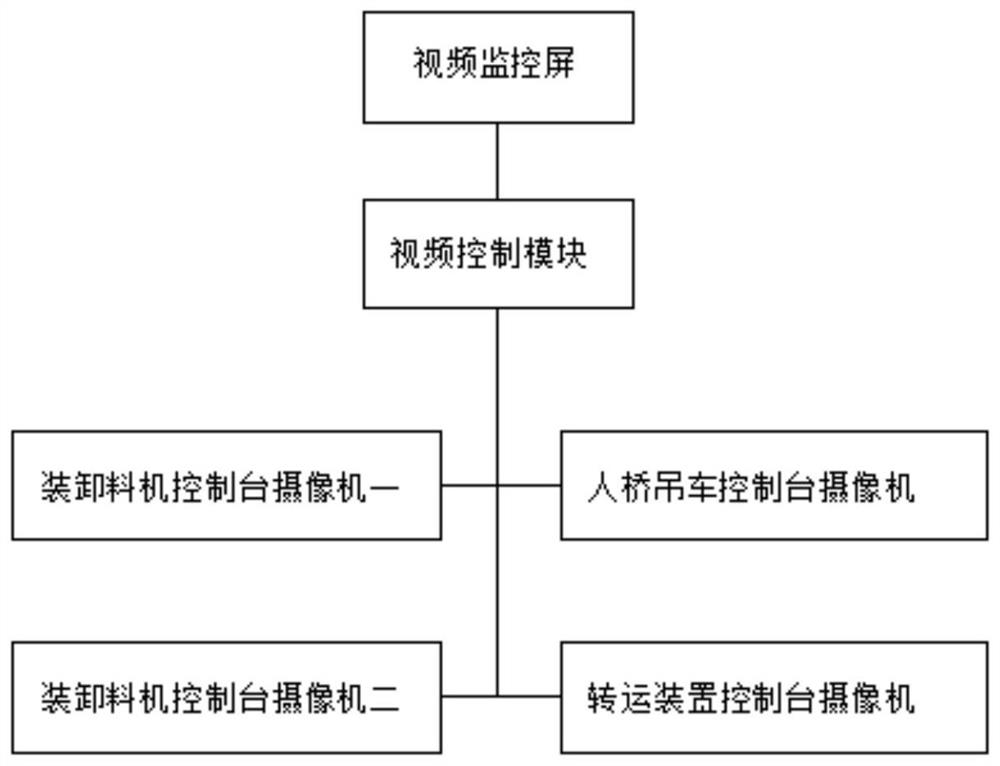

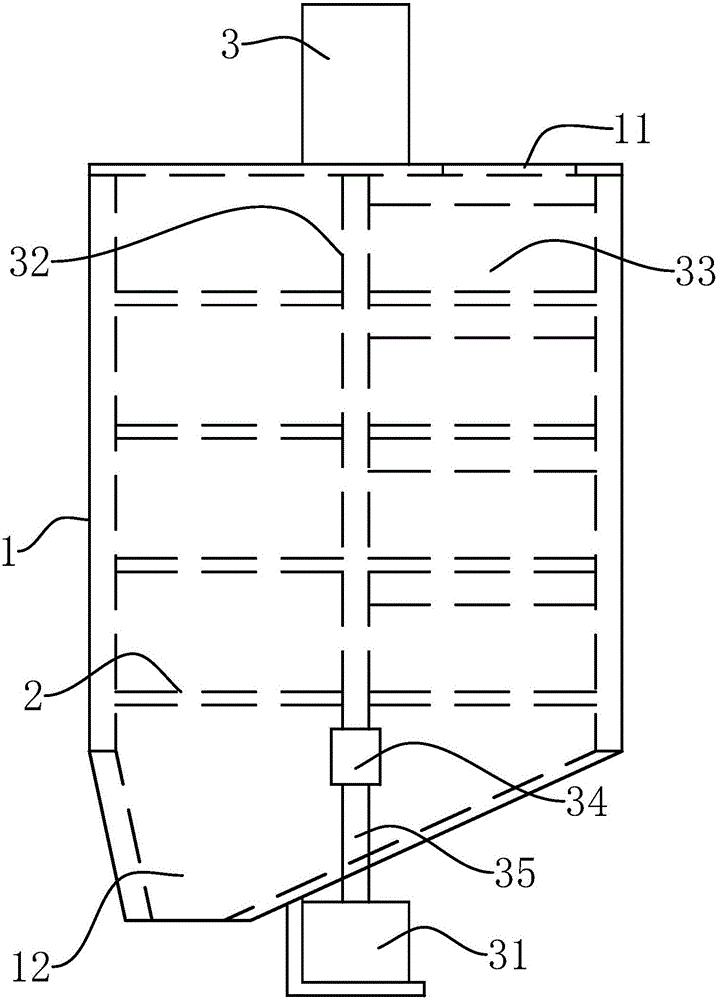

Simulation training system for nuclear fuel operation whole process

ActiveCN110264811AStrong sense of immersionRealize the operationCosmonautic condition simulationsSimulatorsCamera imageAnimation

The invention belongs to the technical field for nuclear fuel operation training, and specifically relates to a simulation training system of the nuclear fuel operation whole process. A control table of a loading and unloading machine, an industrial personal computer of the loading and unloading machine, and a camera image displayer of the loading and unloading machine of a training terminal station jointly constitute a control panel and console of the loading and unloading machine, a control table of a reactor plant transfer device and an industrial personal computer of the reactor plant transfer device jointly constitute a control panel and console of the reactor plant transfer device, a control table of a nuclear fuel plant transfer device and an industrial personal computer of the nuclear fuel plant transfer device jointly constitute a control panel and console of the reactor plant transfer device, a man-bridge crane rack, a man-bridge crane control table and a man-bridge crane industrial personal computer jointly constitute a man-bridge crane control panel and console, and a gripper operation touch screen panel integrates operational handles of a spent fuel assembly gripper and a choke plug assembly gripper through simulation animation and further integrates an old control bar assembly gripper. The simulation training system is used for training whole process loading and unloading of nuclear fuel and switching of related assemblies.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

Electrical inductance winding machine convenient for plugging wire

ActiveCN108010716AQuality assuranceAvoid shakingInductances/transformers/magnets manufactureWinding machineDistribution control

The invention relates to an electrical inductance winding machine convenient for plugging a wire. The winding machine comprises a rack and a power distribution control box, the middle of the rack is provided with a material loading rotation device, the upper part of the material loading rotation device is in cooperation with a wire transporting device through a wire plugging device, the front partof the material loading rotation device is cooperatively provided with a material loading butt joint device which is in cooperation with a material loading device arranged at the lower part of the rack, the material loading butt joint device comprises a butt joint seat arranged on the rack, the butt joint seat is provided with a butt joint lifting air cylinder, the butt joint lifting air cylinderis connected with a butt joint lifting seat, the lower part of the butt joint lifting seat is provided with a material-receiving front-back movement air cylinder which is connected with a material-receiving block made of an electromagnet, the material receiving block is uniformly provided with material-receiving grooves which are in cooperation with products, the upper part of the butt joint lifting seat is provided with a material butting front-back movement air cylinder which is connected with a material butting front-back movement seat, and the material butting front-back movement seat isuniformly provided with rotational material butting heads which cooperate with the products. The electrical inductance winding machine guarantees the quality of material loading and subsequent wire winding when guaranteeing the material loading efficiency simultaneously.

Owner:DONGKOU HUICHUANG ELECTRONICS CO LTD

Blanking and stacking method based on building insulation boards

InactiveCN114261778AAchieve separationEasy to useNon-rotating vibration suppressionStacking articlesArchitectural engineeringStructural engineering

The invention discloses a blanking and stacking method based on building heat preservation plates, in the second step, blanking and stacking equipment comprises a bottom plate and a supporting side plate, the rear side of the supporting side plate is fixedly connected with a transmission box, and the supporting side plate and the transmission box are both fixedly installed at the top of the bottom plate, and the invention relates to the technical field of building heat preservation materials. According to the discharging and stacking method based on the building heat preservation plates, a touch discharging mechanism is arranged, a lifting plate descends to drive a touch plate to rotate with a driving rotating shaft as the center, a push rod can be driven to push a bearing plate to move, and a fixing rod and a pressing plate can be driven to press a connecting plate; therefore, separation of a clamping assembly between the bearing plate and the lifting plate is achieved, products are pushed to be discharged for discharging transportation, the problem that the products fall off and are prone to damage in the discharging process is solved, meanwhile, the cost and use of a power source can be reduced, and use of workers is facilitated.

Owner:林雅

Welding surface detection device based on machine vision and detection method thereof

PendingCN112858316ARealize multi-directional movementEasy to moveOptically investigating flaws/contaminationMachine visionElectric machinery

The invention discloses a welding surface detection device based on machine vision and a detection method thereof. The welding surface detection device comprises a first bottom box, a second bottom box is fixedly connected to one side of the first bottom box, a welding structure is fixedly installed on one side of the top of the first bottom box, and three first sliding ways are formed in the other side of the top of the first bottom box; two motor mounting plates and two cover frames are fixedly mounted at the top of the first bottom box, a first driving motor is fixedly mounted at the top of each motor mounting plate, and a first threaded rod is fixedly connected to the driving end of each first driving motor. According to the welding surface detection device based on machine vision and the detection method thereof, automatic discharging of welded materials is achieved, welded workpieces are made to be away from a welding area, meanwhile, material clamping, namely welding surface detection of the workpieces is achieved, direct classified transportation is achieved after detection is completed, manual transfer is not needed, welding, unloading and detection are completed in one step, the process flow is reduced, and then the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Labeling machine with regular discharging assembly

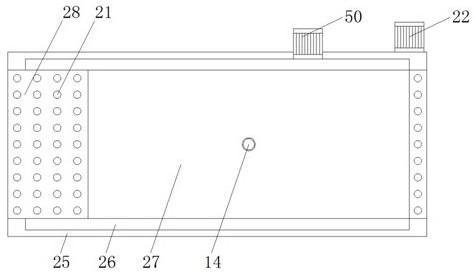

InactiveCN112660792AImplement transshipment operationsRealize unloading operationConveyor partsMachineControl theory

The invention discloses a labeling machine with a regular discharging assembly. The labeling machine comprises a conveying belt, and an adjusting work box is arranged below the conveying belt. According to the labeling machine with the regular discharging assembly, moving sliding grooves are arranged, in the adjusting work box, a first pneumatic push rod works to drive a pushing plate to slide along the inner wall of the adjusting work box, the pushing plate drives a guide block to rotate through the moving sliding grooves, two sets of the moving sliding grooves are arranged, the guide block drives a rotating shaft to rotate in a limiting sleeve through a swinging long plate, the rotating angle of the swinging long plate is 90 degrees, the rotating shaft drives a rotating rod to rotate through a swinging short plate, the swinging long plate, the rotating shaft and the swinging short plate are of an integrated structure, the rotating rod drives an adjusting plate to swing above the conveying belt through an adjusting rod, the rotating angle of the adjusting rod is 90 degrees, the length of the rotating rod is equal to the sum of the distances from the rotating centers of the short swing plate and the adjusting rod to the limiting sleeve, and therefore discharging operation is carried out on workpieces with different specifications.

Owner:东阳市君泽钓具有限公司

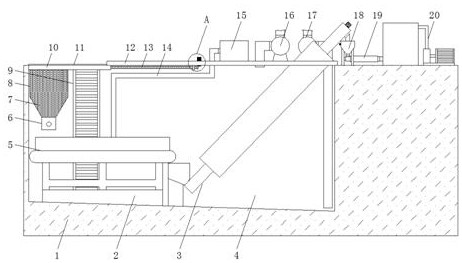

Garbage incineration power generation system for harmless treatment of garbage

InactiveCN112032729ARealize water filtration operationAvoid dropping large batches at onceMachines/enginesIncinerator apparatusElectric machineryProcess engineering

The invention discloses a garbage incineration power generation system for harmless treatment of garbage. The garbage incineration power generation system comprises a cement floor and a mounting groove formed in the cement floor, wherein a garbage can is fixedly connected to one side of the interior of the mounting groove. According to the garbage incineration power generation system for harmlesstreatment of garbage, through cooperative use of a crushing structure, a second feeding mechanism, a driving motor IV, crushing rollers and a crushing box, garbage entering the crushing box is crushed, small pieces of garbage are dried again through the second feeding mechanism, and large pieces of garbage are crushed into small pieces one by one, so that the contact area between the garbage and heat is further increased, and the garbage drying uniformity is further improved. Multiple drying measures are adopted for heating and drying the garbage, so that the garbage is dried more sufficientlyand thoroughly, and the garbage drying effect is good. The sufficiently-dried small pieces of garbage can be sufficiently combusted, so that smoke generated during garbage combustion can be reduced,and the garbage incineration power generation system is relatively environment-friendly.

Owner:(LONGYAN XINDONGYANG) SHENZHEN ENERGY ENVIRONMENT PURIFICATION CO LTD

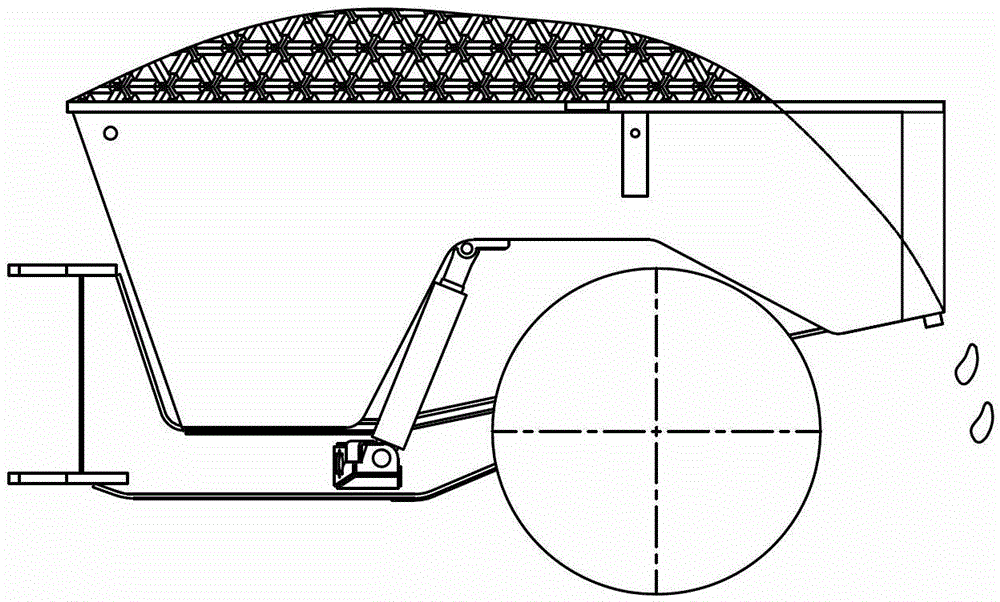

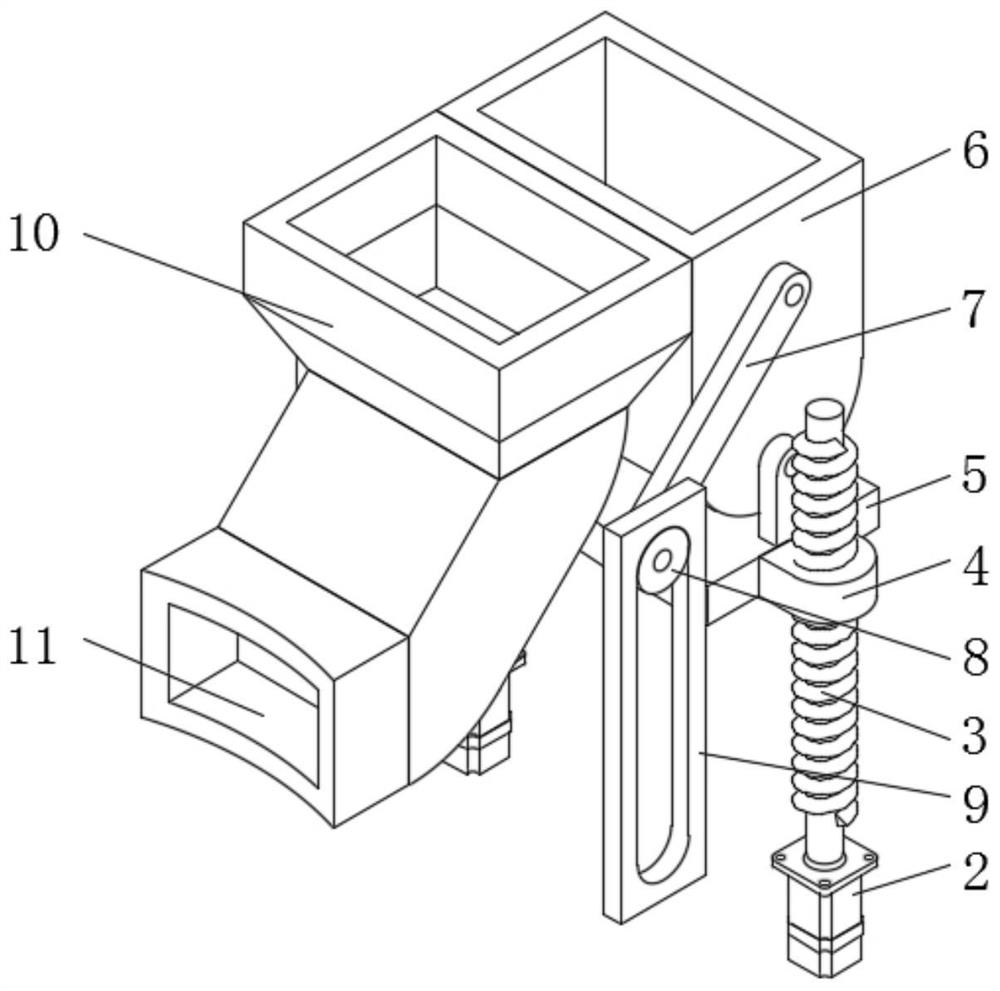

Hopper device for underground ore transfer cars

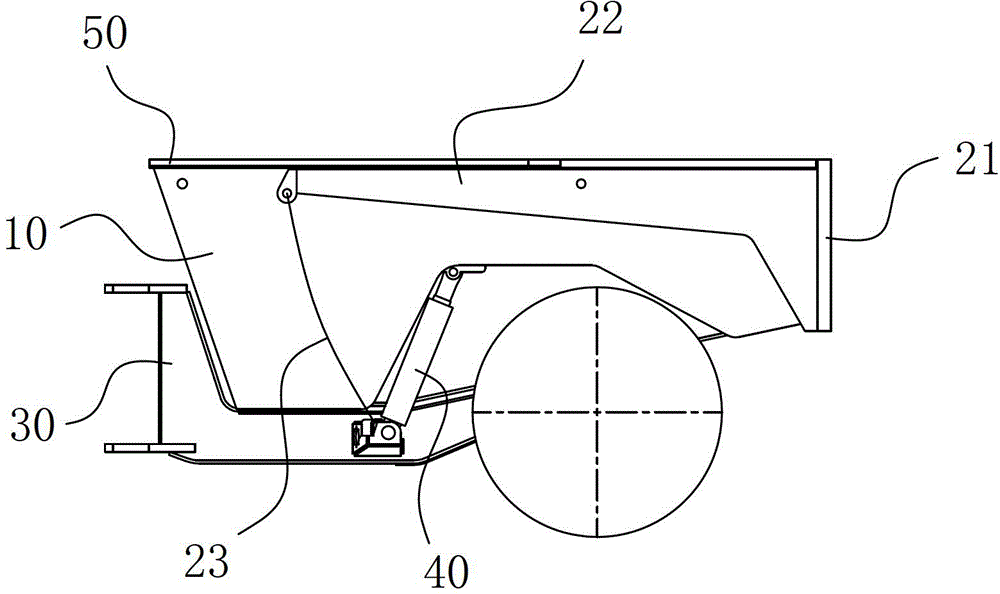

ActiveCN102795144BIncrease carrying capacityReduce bumps and slidesVehicle with tipping movementEngineeringHinge point

The invention belongs to the field of mine borehole operation machines, and specifically relates to a hopper device for underground ore transfer cars. The hopper device for underground ore transfer cars comprises a hopper which is fixed at the rear part of a car body and can carry out a pitching motion on the car body; and the hopper device also comprises an ore blocking unit, the ore blocking unit comprises an ore blocking plate and an extending end, the ore blocking plate is used for blocking an opening part of the hopper, the extending end is formed through extending to the direction of the front part of the car body along at least one end part of the ore blocking plate, a hinged running fit is formed between the extending end and the outer wall of the hopper, the extending end and the car body are hinged through a hinge, the hinge point on the extending end is located in a position between a hinged point on the extending end and the top of the extending end, when the hopper is in an initial state, the ore blocking plate is blocked at the opening part of the hopper, and when the hopper is in a pitch-up unloading state, the ore blocking plate is drawn by the hinge, so that an open mouth for enabling ores to fall is formed between the ore blocking plate and the opening of the hopper. The hopper device is high in conveying efficiency, and can effectively reduce and even avoid the occurrence of an ore falling phenomenon in the process of transportation.

Owner:ANHUI TONGGUAN MACHINERY

Organic acid tablet preparation method and production equipment

PendingCN111840077AImprove product qualityImprove processing qualityOrganic active ingredientsPharmaceutical product form changeHydraulic cylinderAnnular array

The invention discloses an organic acid tablet preparation method and production equipment, and relates to the technical field of organic acid tablet production. The equipment comprises a case body and a support frame, a feeding mechanism is arranged at the upper end of the case body; an upper turntable and a lower turntable are arranged in the case body; the upper turntable and the lower turntable are parallel to each other and are fixed on a driven rotating shaft; material pressing dies are arranged in the upper rotary disc in an annular array mode, a hydraulic cylinder is arranged above thematerial pressing dies and located on the inner wall of the top of the case body, an upper punching head is arranged at the output shaft end of the hydraulic cylinder, lower punching head assembliesare arranged in the material pressing dies, and discharging assemblies are arranged below the lower punching head assemblies and located on the lower rotary disc. The equipment is scientific in designand convenient to use, meets the production and processing requirements of enterprises for large-batch organic acid tablets, can prevent the punch sticking phenomenon, improves the processing qualityof the organic acid tablets, can prevent the processed organic acid tablets from being burnt yellow, reduces the rejection rate, and improves the appearance forming quality of products.

Owner:湖南康易达绿茵科技有限公司

Road construction inspection robot for asphalt pit filling

InactiveCN112482179AAutomate operationRealize crushing operationRoads maintainenceManipulatorGear wheelElectric machinery

The invention discloses a road construction inspection robot for asphalt pit filling. The road construction inspection robot comprises a main body frame, a detector is fixedly connected to the outer wall of the main body frame, an intermittent frame is fixedly connected to the bottom end of the inner wall of the main body frame, a first motor is fixedly installed on the inner wall of the intermittent frame, and a rotating box is installed at the output end of the first motor; and a first rack is welded to the inner wall of the rotating box, a gear is engaged with the position, located on the inner wall of the rotating box, of the first rack, a second rack is engaged with the side, away from the first rack, of the gear, and a rotating disc is welded to the side, away from the gear, of the second rack. According to the road construction inspection robot for asphalt pit filling, the rotating disc is adopted, the first motor rotates to drive the rotating box to rotate, the first rack in the rotating box drives the second rack through the gear, the second rack drives the rotating disc to rotate, when the first rack rotates by a circle, the second rack rotates by 90 degrees, and the rotating disc drives a station disc to rotate through a rotating shaft to achieve automatic operation of asphalt pit filling.

Owner:嘉兴惠韫智能科技有限公司

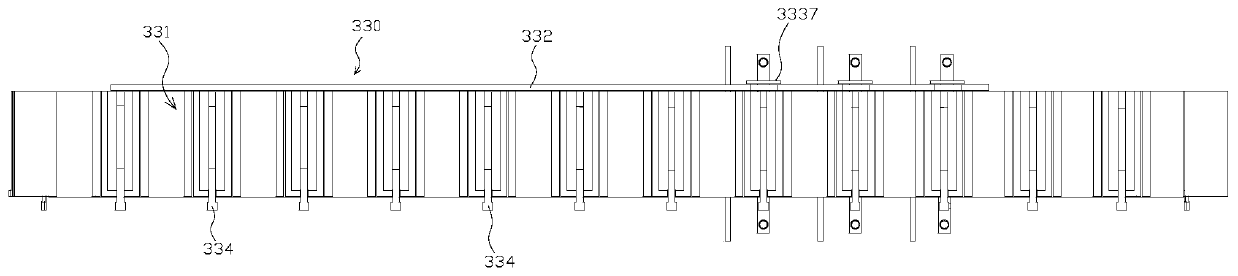

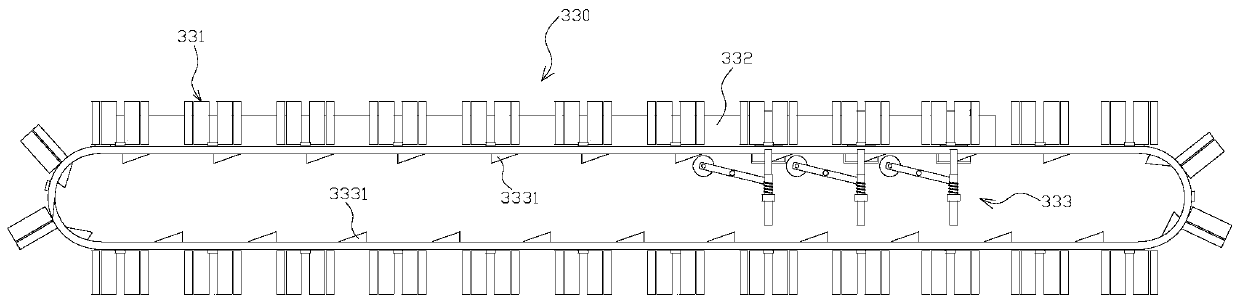

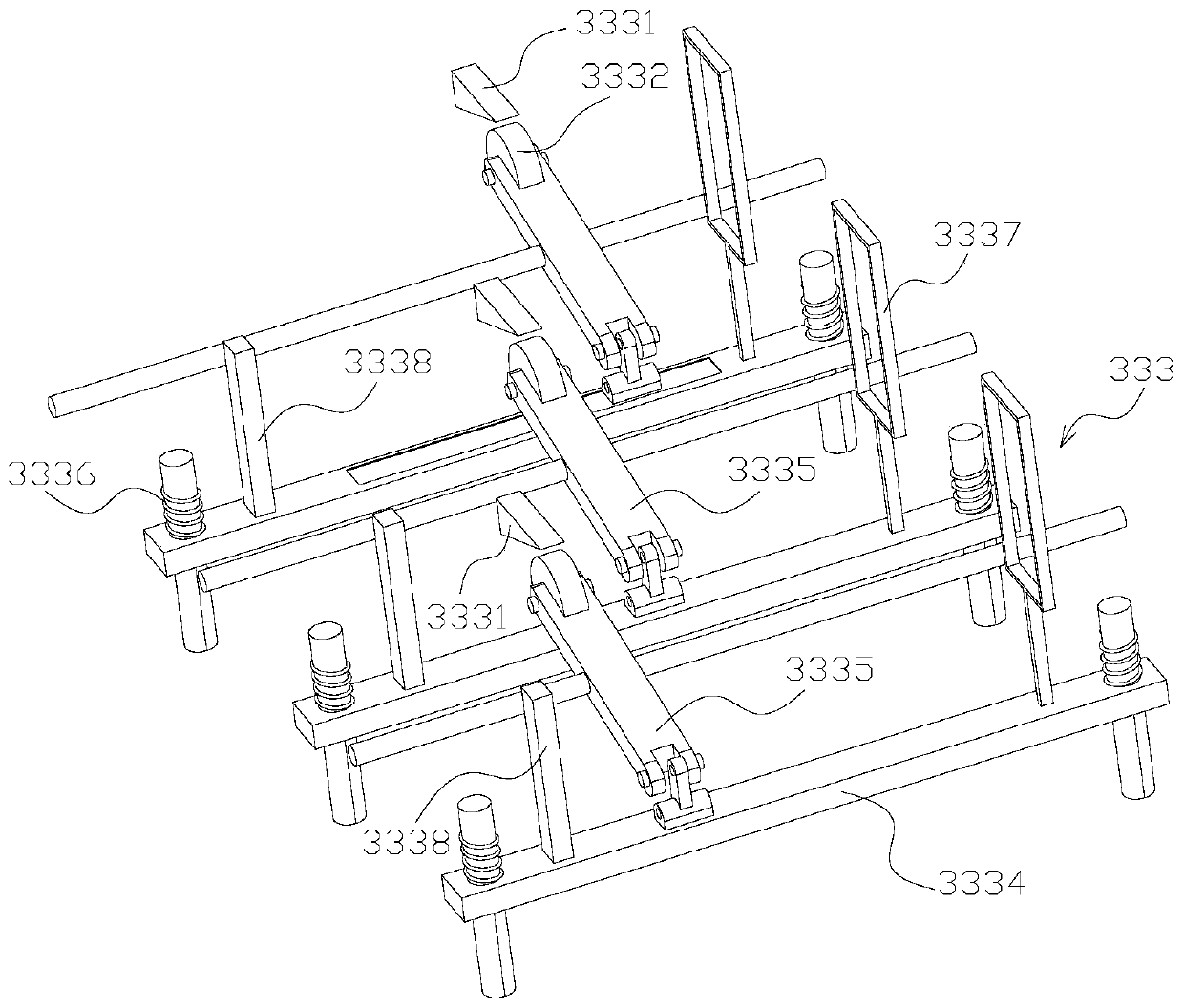

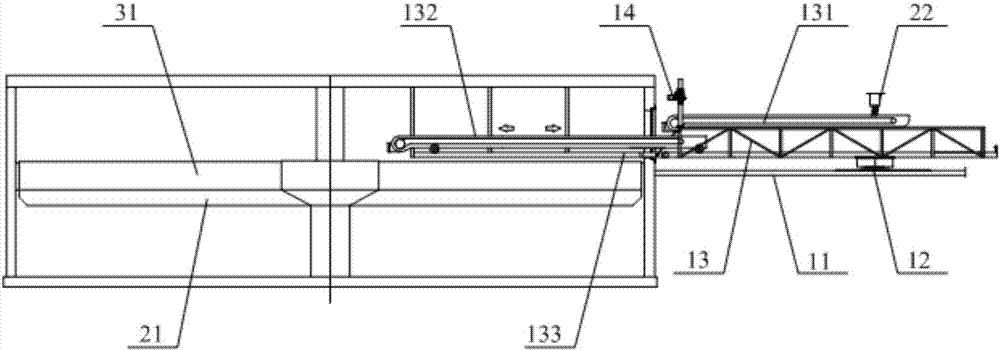

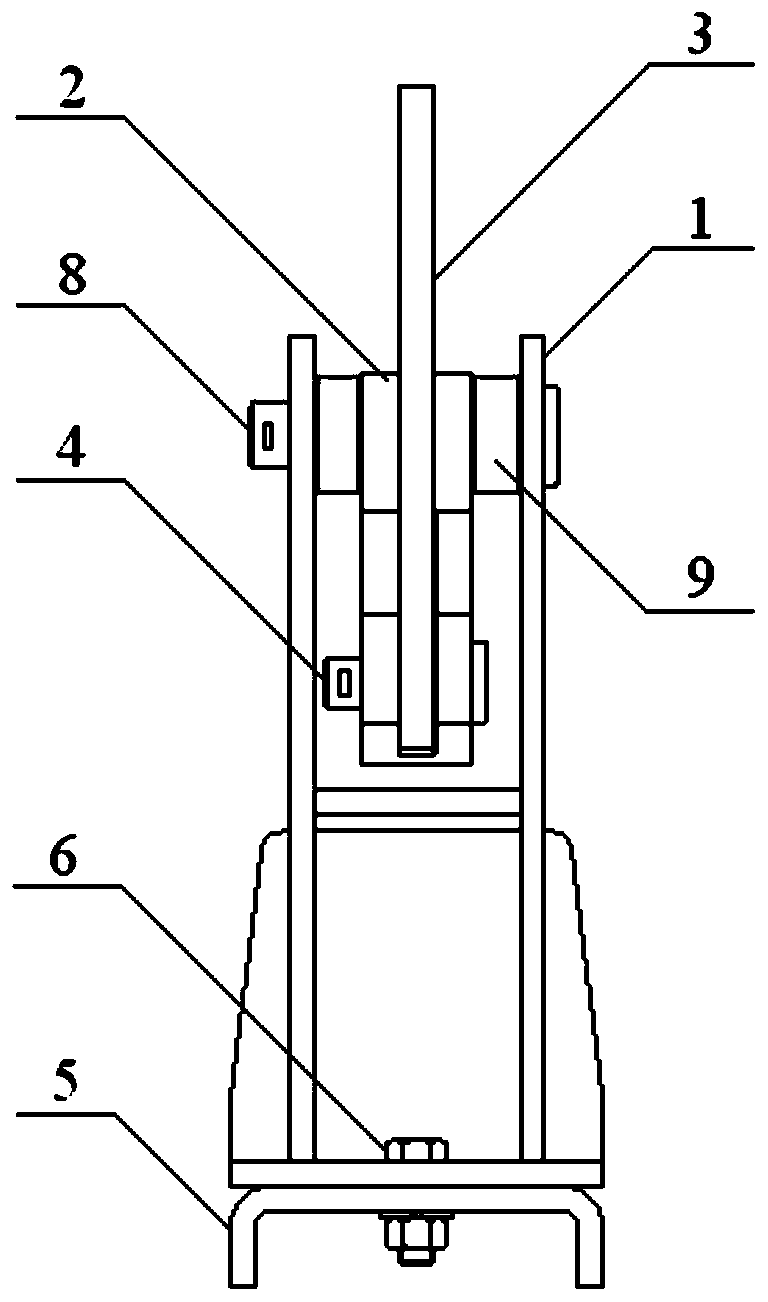

Discharging device of rotating disc solid culture equipment

PendingCN107472846ARealize unloading operationGuaranteed uptimePackagingSupporting framesCircular discBiochemical engineering

The invention discloses a discharging device of rotating disc solid culture equipment. The discharging device of the rotating disc solid culture equipment comprises an operating platform matched with a plurality of rotating discs. A rotating support is arranged on the operating platform; a rotating bracket is arranged on the rotating support in a fixed-axis rotation mode; a first-stage conveyor belt matched with a material-falling port is arranged on the rotating bracket; and a second-stage conveyor belt which is matched with the first-stage conveyor belt and the rotating discs is arranged on the rotating bracket in a retractable mode. The discharging device of the rotating disc solid culture equipment is simple in structure and low in cost.

Owner:NINGBO CHANGRONG BREWING EQUIP

Preparation method of high-purity polyferric chloride

InactiveCN112266025ARealize unloading operationAvoid affecting stirring efficiencyIron halidesWater/sewage treatment by flocculation/precipitationAcid dissolutionIron chloride

The invention discloses a preparation method of high-purity polyferric chloride. The high-purity polyferric chloride comprises the following raw materials: coal gangue, sulfuric acid, hydrochloric acid, a polymerizing agent and an oxidizing agent. The preparation method of the high-purity polyferric chloride comprises the following steps of S1, crushing: crushing coal gangue in a crusher, and sieving with a 250-mesh sieve to obtain coal gangue powder, S2, roasting: putting the coal gangue powder into a muffle furnace, and roasting at the temperature of 700-800 DEG C for the roasting time of 1-2 hours, S3, acid leaching: mixing the roasted coal gangue powder with sulfuric acid, adding hydrochloric acid, carrying out an acid dissolution reaction for 2-3 h at a temperature of 90-110 DEG C, and filtering the reaction liquid after the reaction to obtain a pickling solution, and S4, oxidation: mixing the pickling solution, a polymerizing agent and an oxidizing agent to obtain a mixture, putting the mixture into mixing and stirring equipment, and carrying out mixing and stirring reaction for 50-60 minutes to obtain the high-purity polyferric chloride.

Owner:马鞍山健鼎化工有限公司

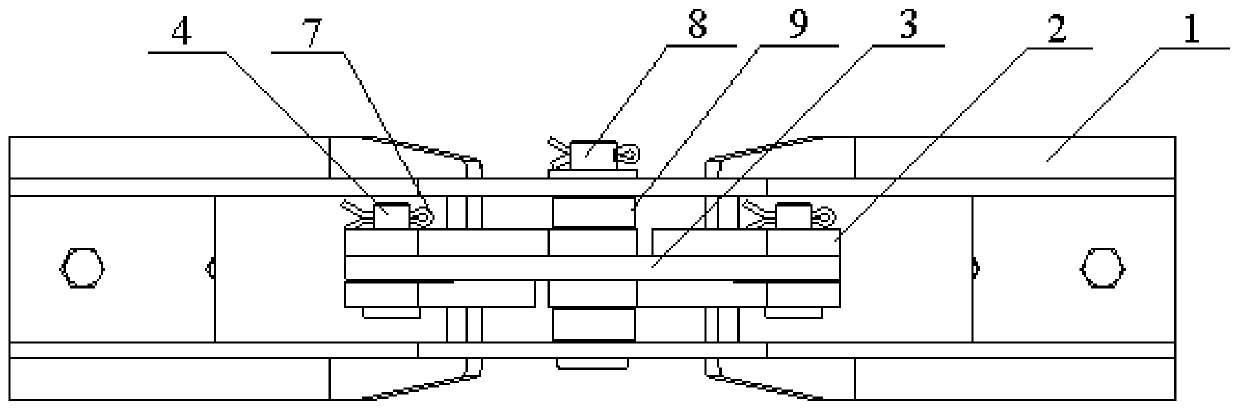

Rail overturning device

ActiveCN106758594BRealize unloading operationPrevent rolloverRailway track constructionRolloverEngineering

Owner:CRRC SHENYANG CO LTD

Plasma garbage treatment system with separated structure

InactiveCN113695363AImplement secondary classification operationsRealize unloading operationSolid waste disposalPressesPlasma technologyStructural engineering

The invention discloses a plasma garbage treatment system with a separated structure. The plasma garbage treatment system with the separated structure comprises a base, a push plate, a rotating bent rod, a rotating chute, a rotating plate, a push pore plate, a push chute and a push plate, so that the push plate moves to drive the rotating bent rod to vertically swing through the rotating chute. According to the plasma garbage treatment system with the separated structure, a first classification control box is arranged, garbage is treated through the plasma technology, the garbage passes through a first classification pipeline and is classified through the first classification control box, the classified garbage enters a second classification control box through second classification pipelines so as to be subjected to secondary classification, the two groups of second classification pipelines are arranged, the first classification control box and the second classification control box are of the same type, then the garbage enters a compression cylinder barrel through third classification pipelines, and the two groups of third classification pipelines are arranged, so that secondary classification operation of the garbage is achieved.

Owner:曾杰祥

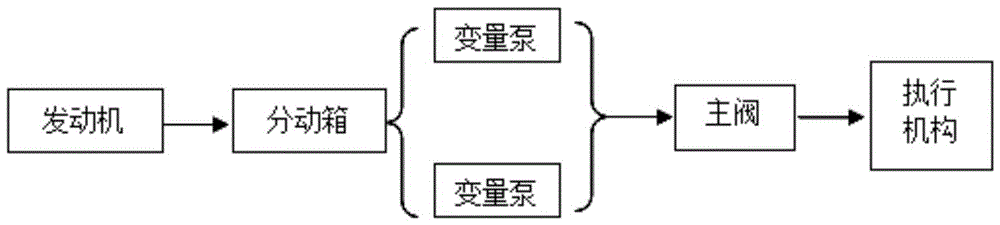

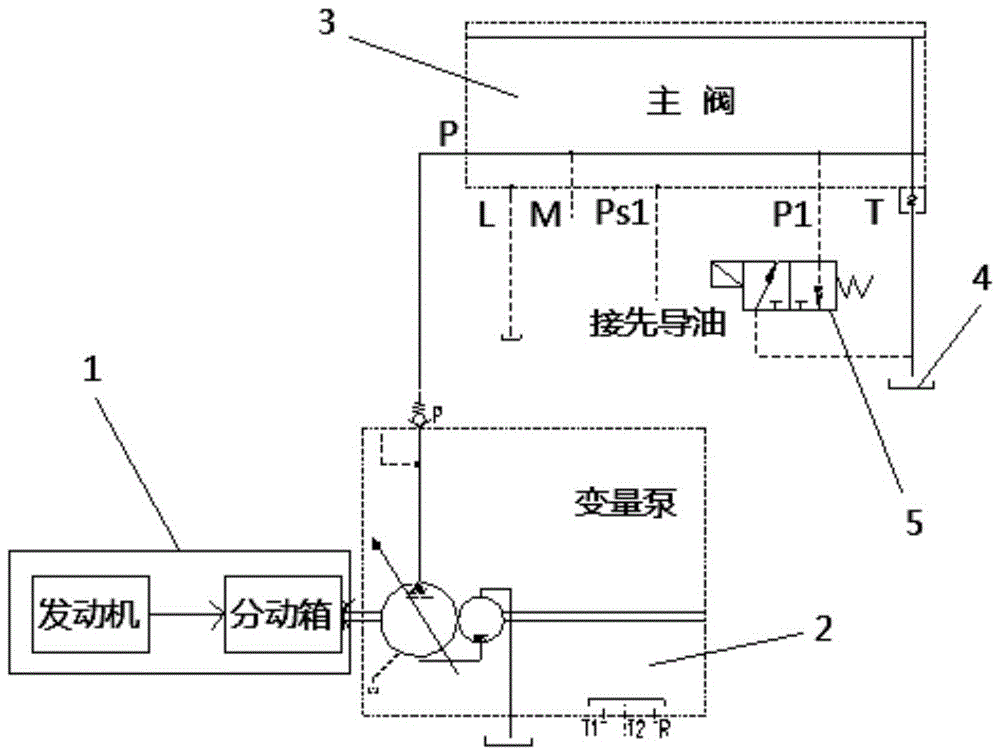

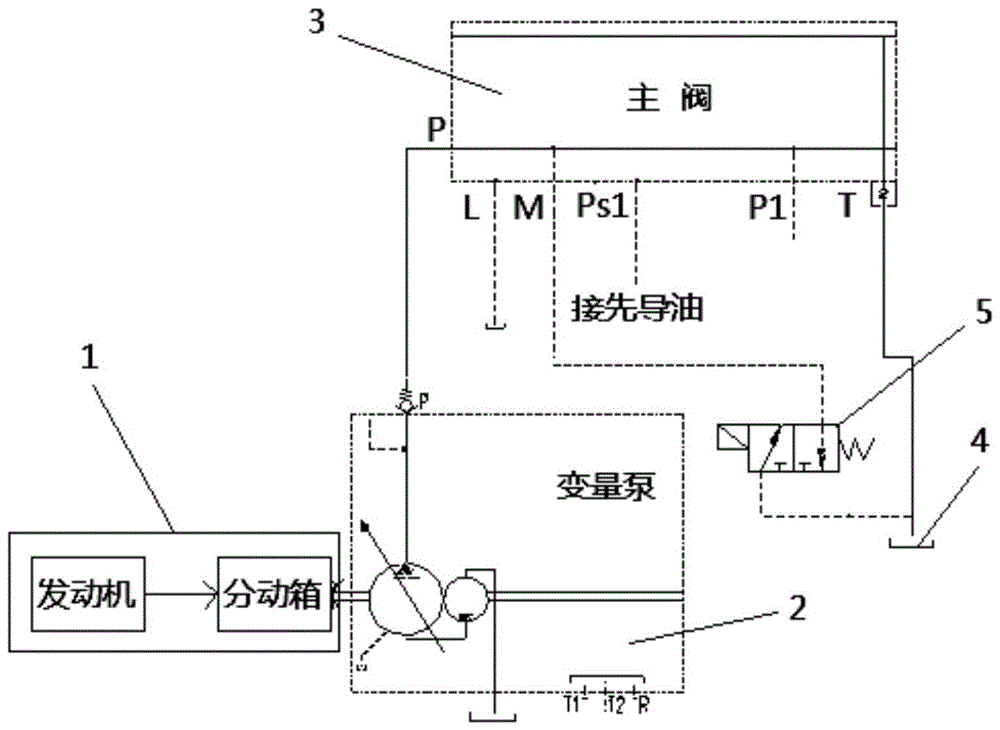

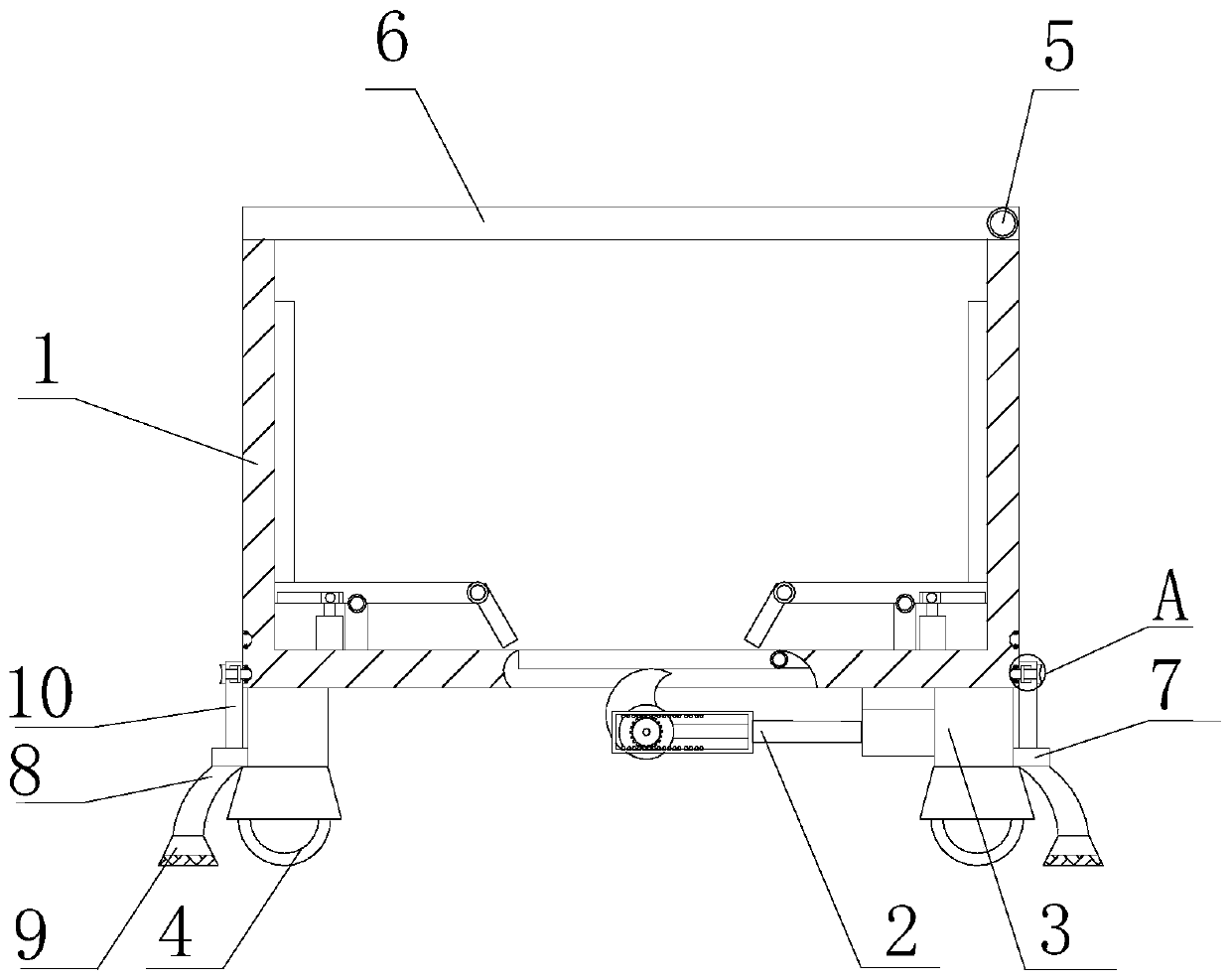

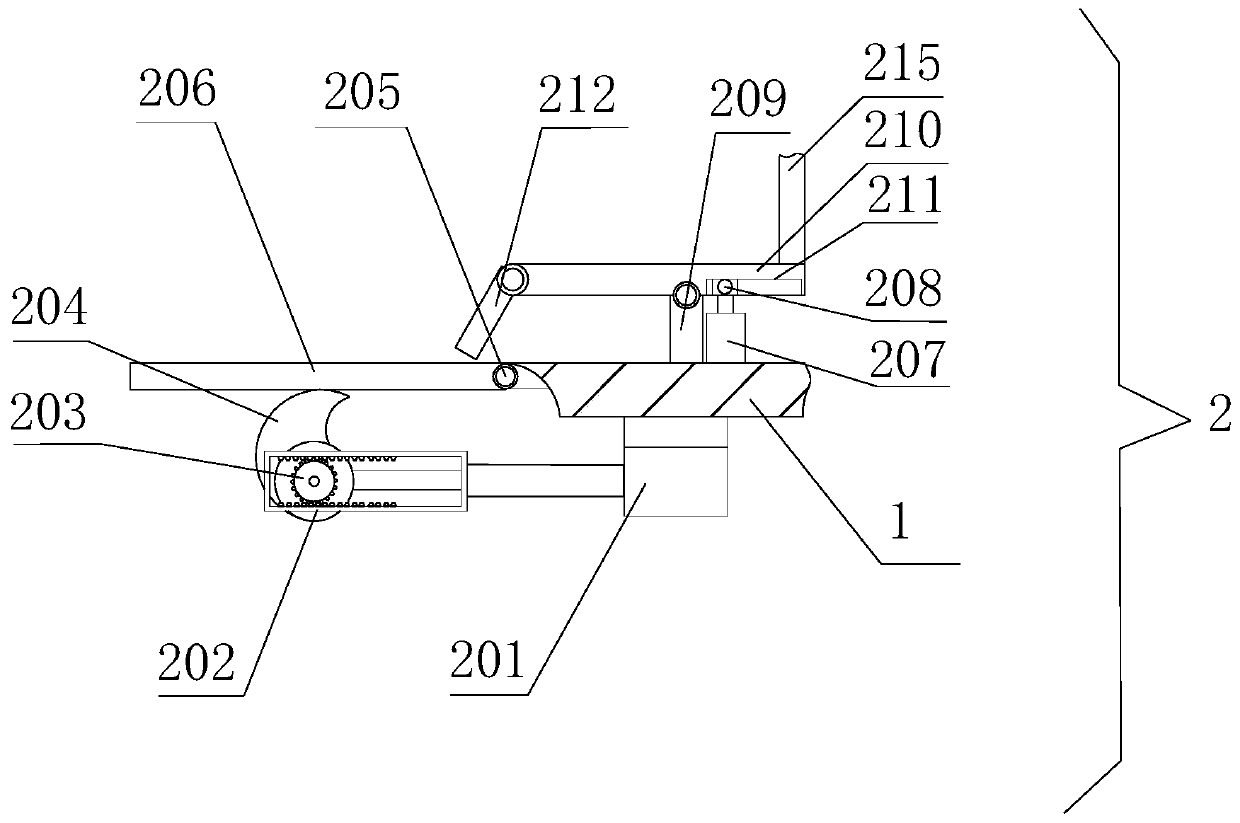

Hydraulic starting system, method and crane

ActiveCN104003306BRealize unloading operationSmooth startServomotor componentsServomotorsHigh resistanceSolenoid valve

The invention relates to a hydraulic starting system, a method and a crane. The hydraulic starting system comprises a power mechanism, a variable pump, a main valve and a hydraulic oil tank, wherein the power mechanism is used for providing driving power to the variable pump; the variable pump and the hydraulic oil tank are both communicated with the main valve through oil paths; the main valve is provided with an oil inlet which is communicated with an oil supply path of the variable pump; the main valve is further provided with a cold start oil drainage port; a solenoid valve for controlling the drainage load of the variable pump in cold start is further arranged between the cold start oil drainage port and the hydraulic oil tank. As the solenoid valve is arranged between the cold start oil drainage port and the hydraulic oil tank, and the oil supply path inside the main valve and the hydraulic oil tank are communicated through the solenoid valve in cold start, the unloading operation of the variable pump is achieved. By adopting the structure, the variable pump can be firstly unloaded when the power mechanism is in cold start, the hydraulic system is prevented from relatively high resistance moment, and thus smooth starting of the power mechanism in a low temperature environment is achieved.

Owner:XCMG CONSTR MACHINERY

Storage device for data line producing machining

InactiveCN110817085ARealize unloading operationEasy to useRigid containersExternal fittingsHydraulic cylinderGear wheel

The invention relates to the technical field of data line producing machining, and discloses a storage device for data line producing machining. The storage device comprises a main body and a discharging device. The discharging device is fixedly mounted on the bottom of the main body, supporting columns are fixedly connected to the bottom of the main body, universal wheels are fixedly connected tothe bottoms of the supporting columns, a rolling shaft is fixedly connected to the top of the main body, and a movable cover is movably connected to one side of the rolling shaft. According to the storage device for data line producing machining, a movable discharging plate is arranged on the bottom of the main body, when a hydraulic cylinder is started, a gear frame moves and drives a gear to rotate, at the moment, a rotating disc fixedly connected with one side of the gear rotates, an arc block on one side of the rotating disc rotates, a discharging plate on the top of the arc block rotatesaround a hinge support along with rotation of the arc block, discharging operation of a data line is achieved, materials on the top of the discharging plate can rapidly slide down, the materials in the middle of the discharging plate cannot be stacked, and the device practicability is effectively improved.

Owner:耒阳市浩鑫电子有限公司

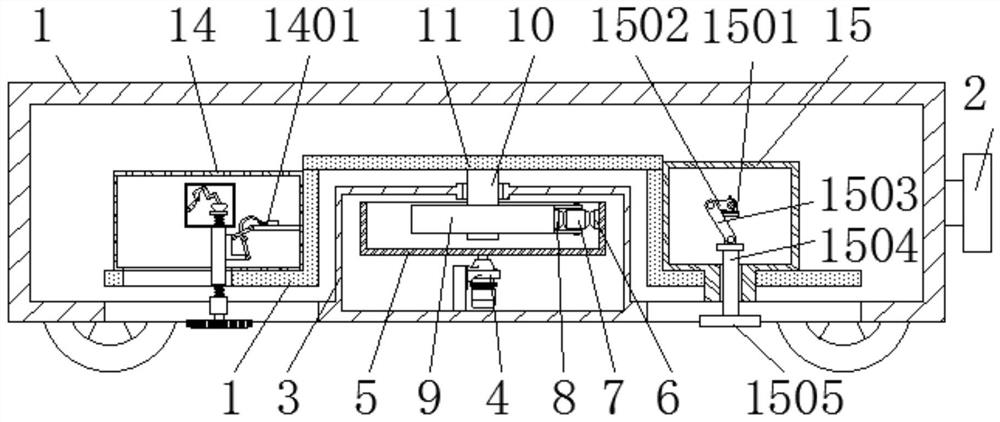

Intelligent nanometer silicon guide heating pipe production line based on automatic pipe spraying machine construction

PendingCN113973407APrecise thickness controlAutomatic adjustment of spray flowHeating element shapesEngineeringManufacturing line

The invention discloses an intelligent nanometer silicon guide heating pipe production line based on an automatic pipe spraying machine. The intelligent nanometer silicon guide heating pipe production line comprises a working table top, welding supporting legs are welded to the four corners of the bottom of the working table top, a mounting cavity groove is formed in the middle of the top of the working table top in a penetrating mode, a circular working bin is rotationally mounted at the top of the working table top through a bearing, and the bottom end of the circular working bin penetrates through an inner cavity of the mounting cavity groove. According to the intelligent nanometer silicon guide heating pipe production line built based on the automatic spraying pipe mechanism, material ejection from one end is achieved, material receiving from the other end is achieved, mechanical discharging operation is achieved, automatic and intelligent continuous production can be achieved, and the safety during discharging is improved; and the buffering step is adopted during workpiece receiving, and the workpieces are stopped in the arc-shaped seat at first and then are dumped, so that the situation that the workpieces are obliquely clamped at the discharging opening and cannot be discharged can be prevented, and the discharging stability is guaranteed.

Owner:DALIAN POLYTECHNIC UNIVERSITY

An Inductance Automatic Feeding and Winding Machine

ActiveCN106783143BQuality assuranceAvoid shakingInductances/transformers/magnets manufactureWinding machineDistribution control

The invention relates to an automatic feed winding machine for inductance. The automatic feed winding machine comprises a rack and a distribution control box, a load rotating device is arranged in the middle of the rack, the upper portion of the load rotating device is matched with a wire plugging device and a wire conveying device, a feed docking device is fittingly arranged at the front portion of the load rotating device, the feed docking device is matched with a feeding device at the lower portion of the rack, the feed docking device comprises a docking seat arranged on the rack, a docking lifting cylinder is arranged on the docking seat and is connected with a docking lifting seat, a forward and backward receiving motion cylinder is arranged at the lower portion of the docking lifting seat and is connected with a receiving block made from electromagnet, receiving grooves matched with products are evenly formed in the receiving block, a forward and backward pushing motion cylinder is arranged at the upper portion of the docking lifting seat and is connected with a forward and backward pushing motion seat, and rotating pushing heads matched with the products are evenly arranged on the forward and backward pushing motion seat. By the arrangement, feeding efficiency is guaranteed, and meanwhile, quality in feeding and subsequent winding is guaranteed as well.

Owner:TONGXIANG YAORUN ELECTRONICS

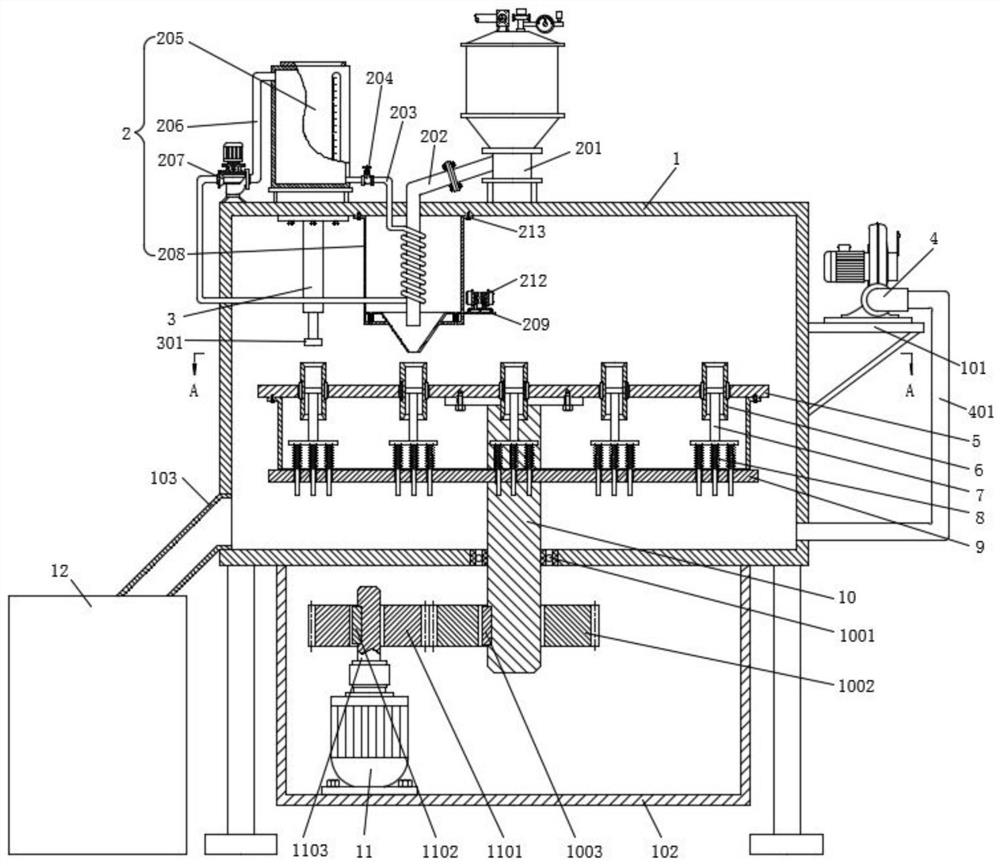

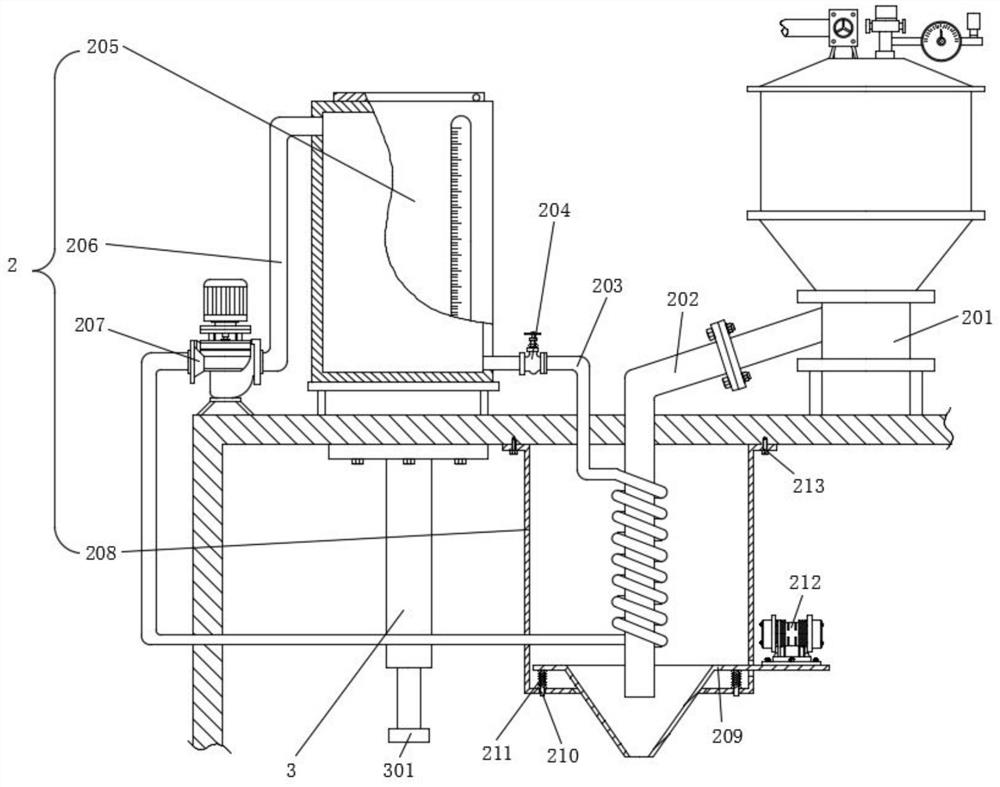

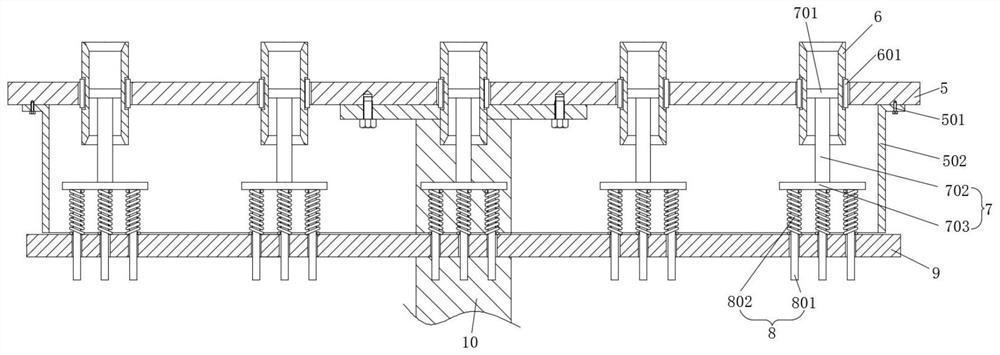

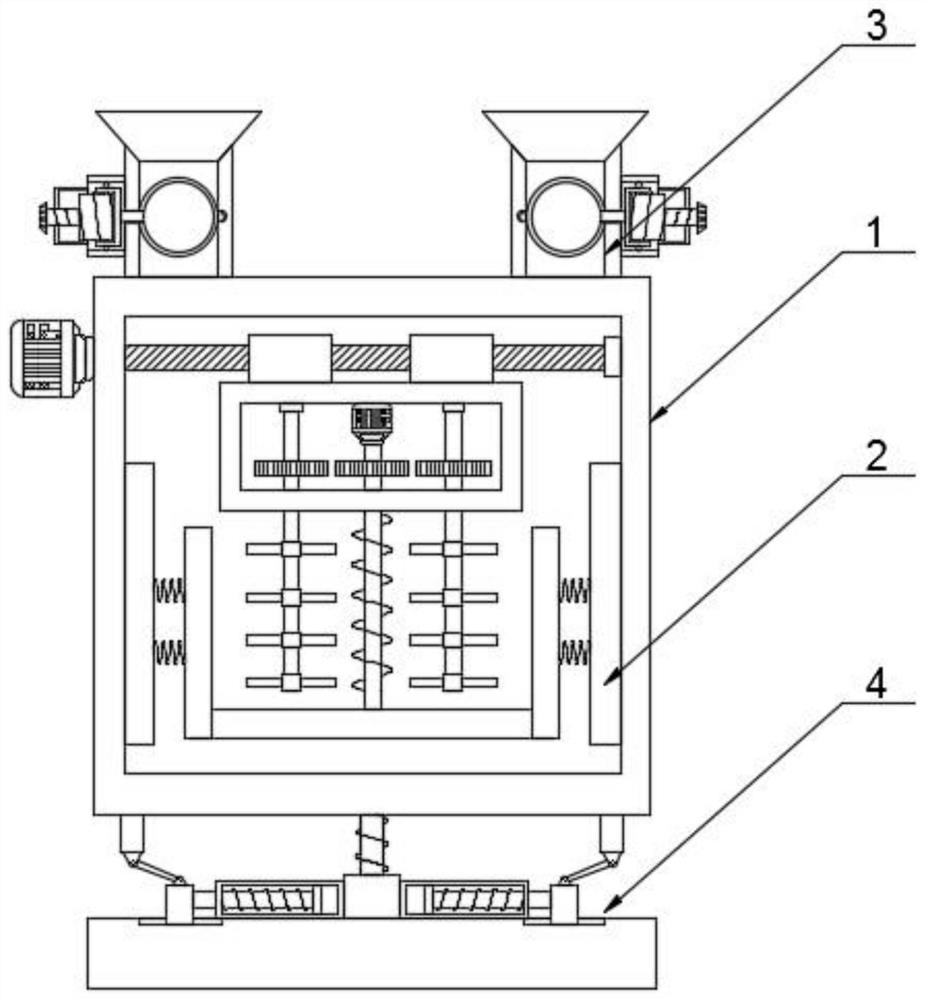

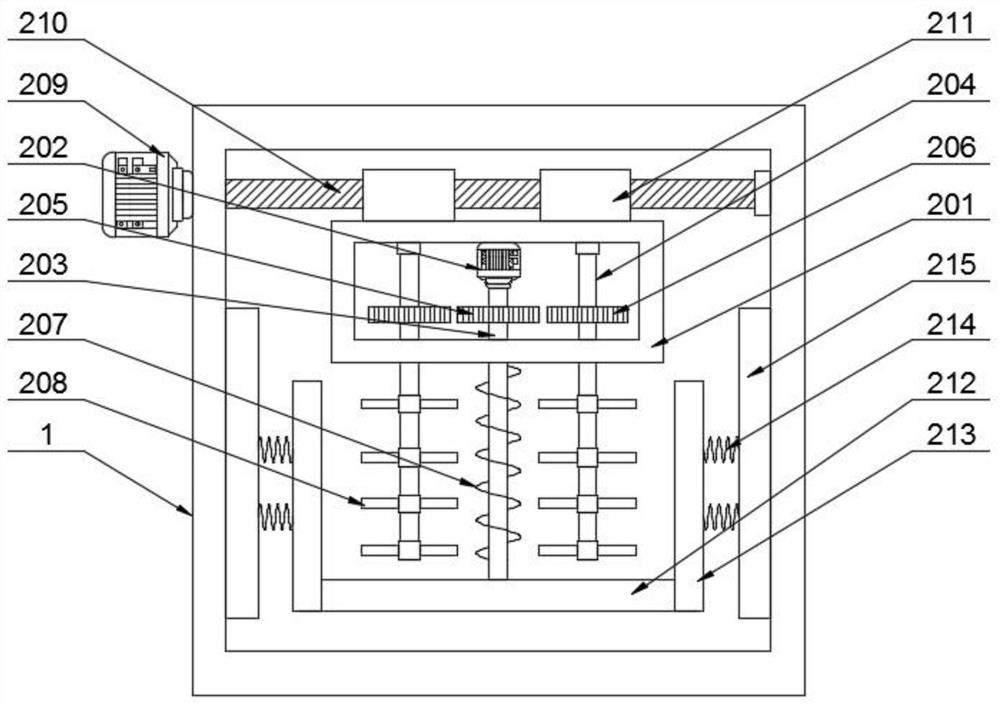

A lithium battery uniform dryer

ActiveCN109186198BDry evenlyBest dry conditionDrying gas arrangementsDrying machines with non-progressive movementsStructural engineeringProcess engineering

The invention relates to a drying machine, in particular to a lithium battery uniform drying machine. The lithium battery uniform drying machine is uniform in drying and high in efficiency. The lithium battery uniform drying machine comprises a quantitative slot, a feeding pipe, a switch mechanism, a drying mechanism, support plates, an exhaust pipe and the like. The support plates are arranged onthe tops of brackets on the left and right sides, a drying groove is installed in the middle of the supporting plates on the left and right sides, and the drying mechanism is arranged on the rear wall in the drying groove. The exhaust pipe is connected to the lower portion of the left wall of the drying groove, a third one-way valve is arranged on the exhaust pipe, and a discharge pipe is connected to the bottom of the drying groove. A screw cap is arranged on the discharge pipe in a matched mode, and the feeding pipe is connected to the upper portion of the left wall of the drying groove. The lithium battery uniform drying machine achieves the effects of uniform drying and high efficiency, and suitable and quantitative lithium batteries can enable the drying groove and the drying mechanism to achieve the optimal drying state, so that the battery drying is relatively uniform, and the lithium battery is continuously stirred by a mixing plate and a mixing strip, the drying rate is accelerated, and the uniformity of drying is greatly improved.

Owner:河北绿草地新能源股份有限公司

Application method of organic fertilizer mixing equipment

InactiveCN114177799AWell mixedThorough mixing operationRotary stirring mixersTransportation and packagingElectric machineGear wheel

The invention discloses a use method of organic fertilizer mixing equipment, the organic fertilizer mixing equipment comprises a base support, the top end of the base support is fixedly connected with a rotating frame, the side wall of the rotating frame is fixedly connected with a mixing roller, the inner wall of the rotating frame is fixedly connected with a rotating motor, and the rotating motor is fixedly connected with a rotating shaft. According to the organic fertilizer mixing equipment and the using method, the driving rotating wheel and the driven rotating wheel are arranged, in the rotating frame, the rotating motor rotates to drive the driving rotating wheel to rotate through the driving gear, and meanwhile, the driving gear rotates to drive the driven rotating wheel to rotate through the driven gear; and through simultaneous rotation of four groups of driven rotating wheels and driving rotating wheels, the organic fertilizer raw materials are fully mixed, so that the organic fertilizer raw materials in the mixing roller can be fully mixed.

Owner:宜兴市九香生态农业科技有限公司

Mountain tea garden organic fertilizer raw material manufacturing and mixing device and use method

ActiveCN113019251AWell mixedThorough mixing operationRotary stirring mixersMixer accessoriesAgricultural scienceElectric machine

The invention discloses a mountain tea garden organic fertilizer raw material manufacturing and mixing device and a use method. The mountain tea garden organic fertilizer raw material manufacturing and mixing device comprises a base support, the top end of the base support is fixedly connected with a rotating frame, and the side wall of the rotating frame is fixedly connected with a mixing roller; a rotating motor is fixedly connected to the inner wall of the rotating frame, and a driving gear is mounted at the output end of the rotating motor. According to the mountain tea garden organic fertilizer raw material manufacturing and mixing device and the use method, by arranging the driving rotating wheel and the driven rotating wheel, in the rotating frame, the rotating motor rotates to drive the driving rotating wheel to rotate through the driving gear, meanwhile, the driving gear rotates to drive the driven rotating wheels to rotate through the driven gears, and through simultaneous rotation of the four sets of driven rotating wheels and the driving rotating wheel, the organic fertilizer raw materials are fully mixed, so that the organic fertilizer raw materials in the mixing roller can be fully mixed.

Owner:宜兴市九香生态农业科技有限公司

Quantity-controllable anti-blocking device for plastic particle discharging

InactiveCN114803553AAvoid stickingAvoid cloggingControl devices for conveyorsLoading/unloadingMechanical engineeringPhysics

Owner:苏州市同发塑业有限公司

A simulation training system for the whole process of nuclear fuel operation

ActiveCN110264811BStrong sense of immersionRealize the operationCosmonautic condition simulationsSimulatorsDisplay deviceProcess engineering

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

Automatic pharmaceutical machinery drying device

InactiveCN105997511AImprove drying efficiencyRealize unloading operationPharmaceutical product form changeMotor shaftPiston rod

The invention provides an automatic pharmaceutical machinery drying equipment, which belongs to the field of pharmaceutical machinery. It solves the problems of troublesome operation and low drying efficiency of existing drying equipment. The automatic pharmaceutical machinery drying equipment includes a shell, the top and bottom of the shell are respectively provided with a material inlet and a material outlet, the inner wall of the shell is provided with a number of drying holes, and there are several partitions in the shell from top to bottom. There is a blanking hole on the partition plate, a cylinder and a motor are respectively fixed on the top and bottom of the casing, the piston rod of the cylinder is fixed on the movable rod arranged along the axial direction of the casing, the movable rod is provided with a pusher plate, and the movable rod The bottom end is fixed with a spline sleeve, and the motor shaft of the motor is connected with a spline shaft, and the movable rod can be pushed through the piston rod, so that the bottom of the pushing plate is placed against the top surface of the partition or is spaced apart from the top surface of the partition, and Through the rotation of the motor shaft, the spline shaft and the spline sleeve are matched, so that the movable rod rotates to drive the pusher plate to rotate. The drying equipment can be operated automatically, while improving the drying efficiency.

Owner:范素琴

Low-noise preparation equipment

PendingCN114146901AEnables vibratory screening operationsRealize adjustment operationSievingScreeningVibration amplitudeElectric machine

The low-noise preparation equipment comprises a vibration frame, a rotating pore plate, an adjusting column, a sliding pore plate, a guide column and a limiting pore plate, a vibration motor is installed on the outer wall of the vibration frame, and a rotating shaft used for driving the rotating pore plate rotationally connected with the outer wall of the vibration frame to vertically rotate is installed at the output end of the vibration motor; and an adjusting sliding groove movably connected with the adjusting column is formed in the inner wall of the rotating hole plate, so that the rotating hole plate rotates to drive the guide column fixedly connected with the outer wall of the sliding hole plate to horizontally slide along the limiting hole plate through the adjusting column. The lifting sliding column moves to drive the telescopic hole plate to horizontally slide through the moving chute, the telescopic hole plate moves to drive the circular table to slide along the rotating shaft, so that the circular table moves to drive the adjusting column connected with the telescopic abutting block to slide along the adjusting chute through the abutting hole plate, and the vibration amplitude of the screening net is adjusted.

Owner:程世荣

Battery cap manufacturing equipment

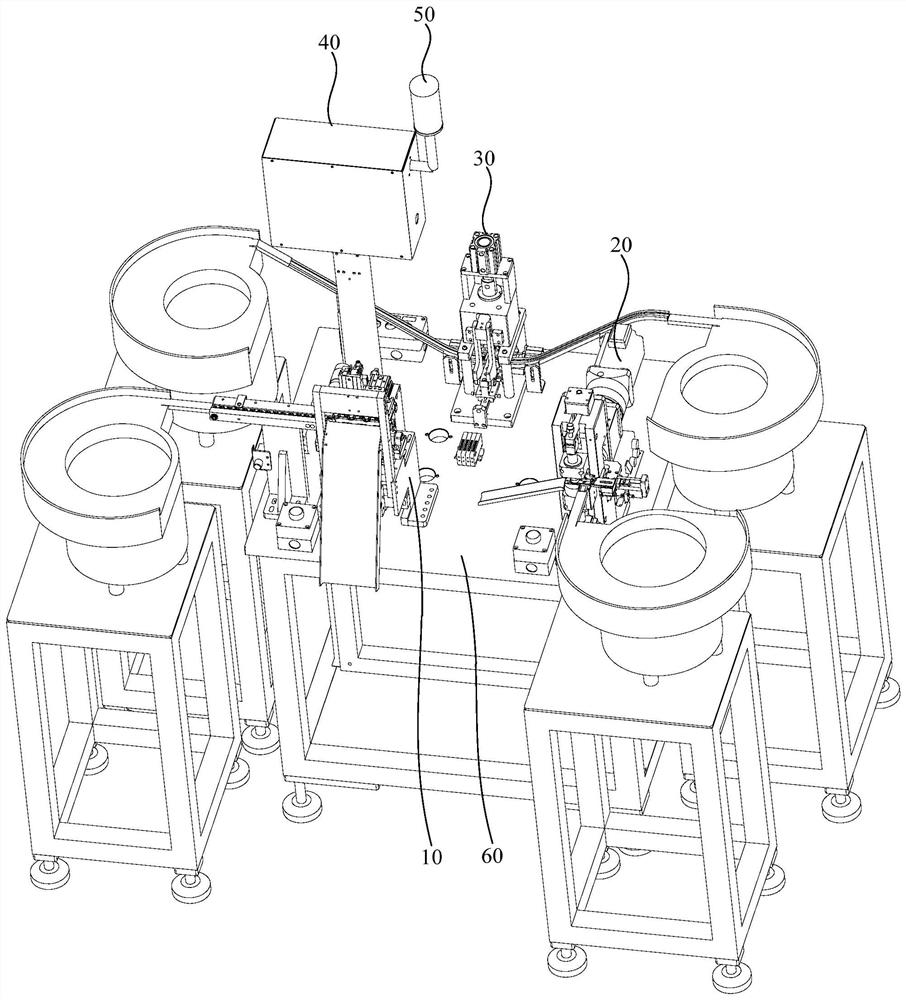

ActiveCN113206330ARealize unloading operationIncrease productivityAssembly machinesCell component detailsCell fabricationElectrical battery

The invention relates to the technical field of battery manufacturing, and provides battery cap manufacturing equipment. The equipment comprises an edge covering device, a leveling device, an assembling device and a controller, and the edge covering device comprises a first rack, an edge pressing mechanism and a pushing mechanism; the edge pressing mechanism comprises a rotating assembly and a side pressing assembly. The leveling device comprises a second rack, a driving mechanism, an upper pressing mechanism, a lower pressing mechanism and a discharging mechanism. A first positioning seat which is positioned between the upper pressing mechanism and the lower pressing mechanism and is used for placing a cover body is arranged on the second rack; the assembling device comprises a third rack, a press-fitting mechanism and a push rod; the third rack is provided with a second positioning seat for placing a cover body and a sealing ring; the controller is electrically connected with the rotating assembly, the side pressing assembly, the pushing mechanism, the driving mechanism and the press fitting mechanism, the battery cap manufacturing equipment can simultaneously realize automatic operation of an edge covering procedure, a leveling procedure and an assembling procedure, the production efficiency is high, standardized production can be carried out on battery caps, and the quality of finished products is uniform and good.

Owner:深圳市通则新能源科技有限公司

Medical hazardous waste incineration device and using method

InactiveCN113566206ARealize flip loading operationRealize lifting operationIncinerator apparatusElectric machineryMechanical engineering

The invention discloses a medical hazardous waste incineration device and a using method, and belongs to the technical field of medical hazardous waste incineration. The medical hazardous waste incineration device comprises a feeding frame, wherein the inner wall of the feeding frame is fixedly connected with feeding motors, a feeding screw rod is installed at the output end of each feeding motor, the outer wall of each feeding screw rod is in threaded connection with a lifting sliding block, the side walls of the lifting sliding blocks are fixedly connected with a lifting bottom plate, and the two ends of the lifting bottom plate are rotationally connected with a feeding box. According to the medical hazardous waste incineration device and the using method, by arranging the feeding box, in the feeding frame, the lifting sliding blocks move to drive the feeding box to slide along lifting sliding grooves through the lifting bottom plate, lifting operation of the feeding box is achieved, and when lifting rolling wheels slide to the top ends of the lifting sliding grooves, the lifting sliding blocks drive the lifting bottom plate to continuously slide so that the lifting bottom plate can drive the feeding box to rotate through guide rods and the top ends of the lifting sliding grooves, and overturning feeding operation of medical hazardous wastes is achieved.

Owner:江苏中科环宇环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com