Automatic feeding and discharging system for spherical roller spherical base surface specialized grinding machine

A technology of automatic loading and unloading and spherical rollers, which is applied in the direction of grinding machines, grinding feed movement, and grinding machine parts, etc., which can solve the problems of low feeding speed, complex structure, and long relative motion trajectory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

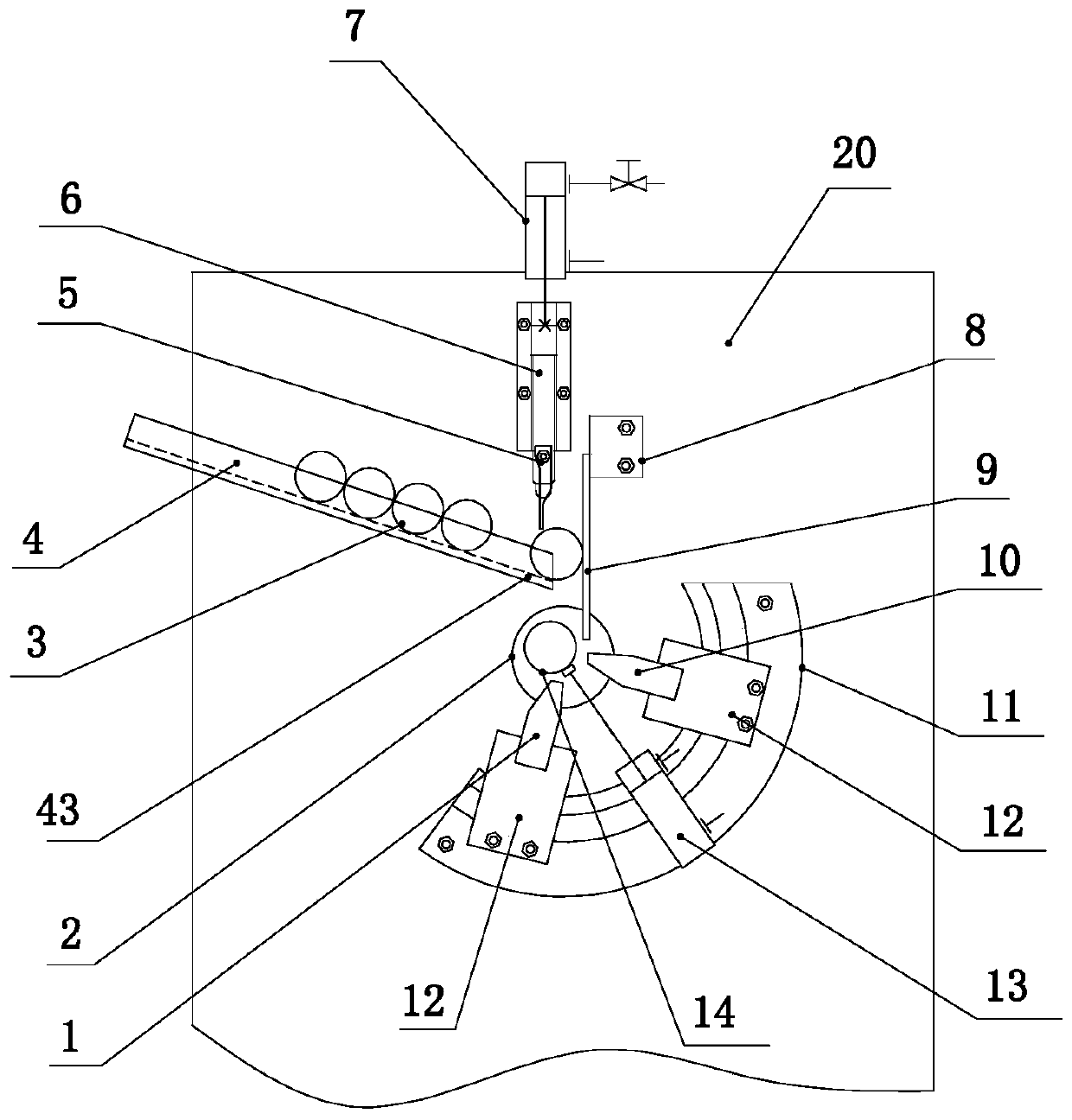

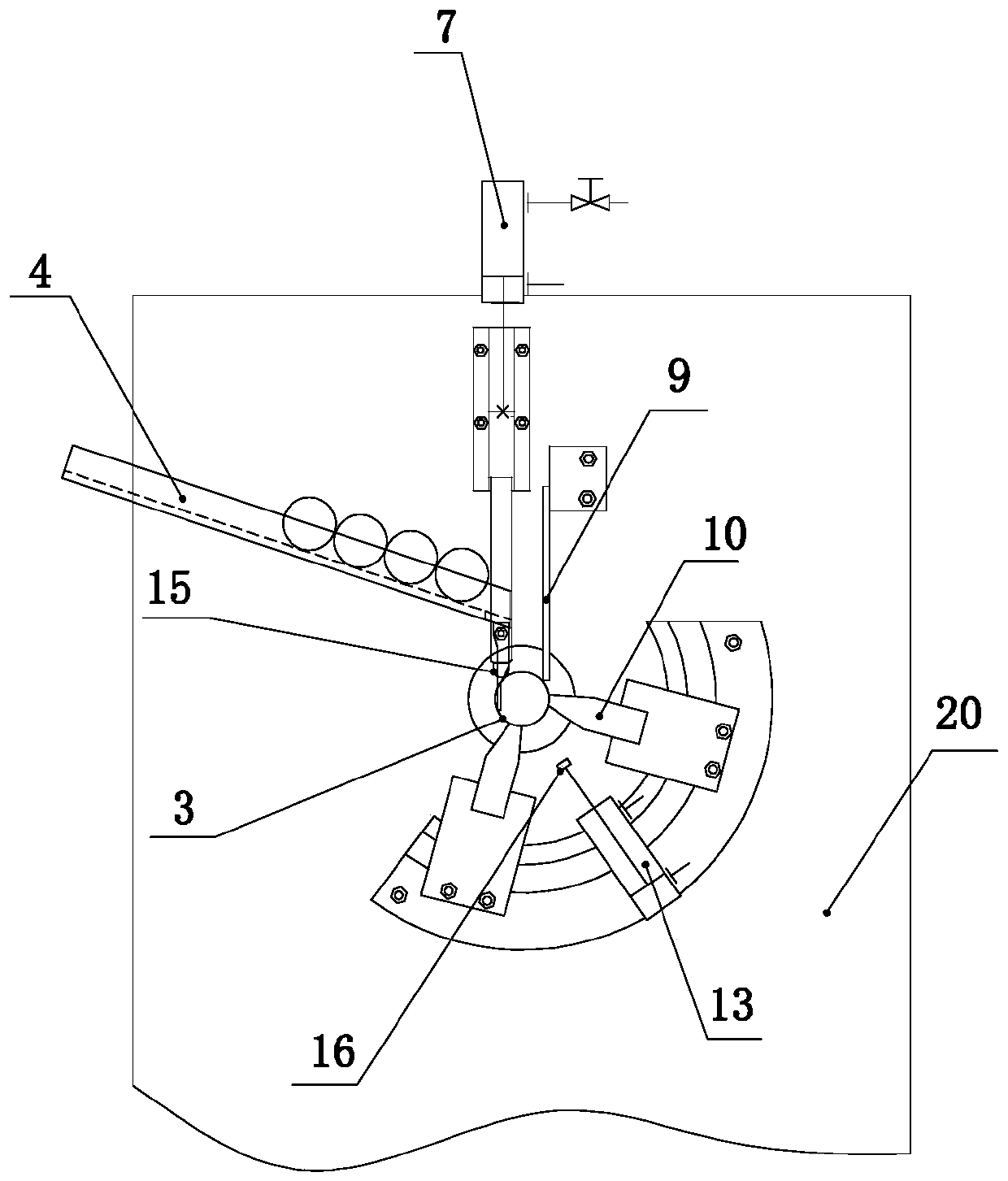

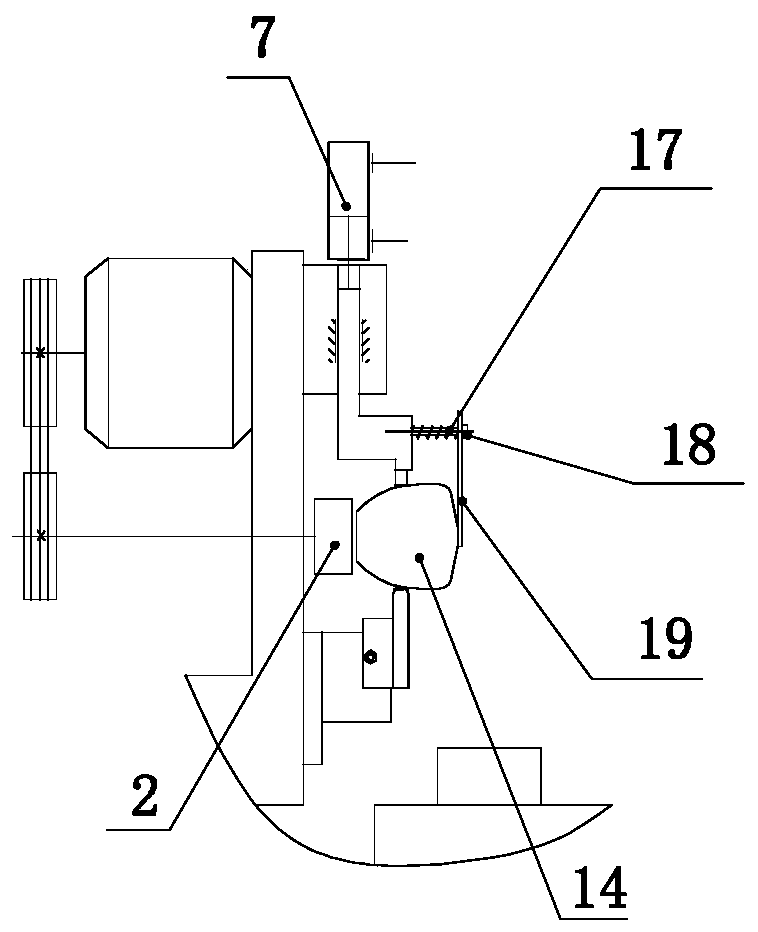

[0025] Such as Figure 1 to Figure 4 As shown, the present invention mainly includes a first support 1, an electromagnetic chuck 2, a discharge channel 4, a moving plate for feeding 5, a feeding slider 6, a feeding cylinder 7, a spring plate seat 8, a feeding spring plate 9, a second support 10, Crescent plate 11, support seat 12, blowing material cylinder 13, the 3rd support 15, blowing head 16, spring 17, bearing pin 18, small spring plate 19 and frame 20, the present invention is described in detail below in conjunction with accompanying drawing.

[0026] Such as Figure 1 to Figure 3 As shown, the first support 1 and the second support 10 are fixed on the support seat 12 by bolts, and the support seat is slidably arranged on the crescent plate 12. The connection mode between the support seat and the crescent plate is convenient for debugging the support seat on the crescent plate. After debugging the position of the support seat, lock the support seat and the crescent pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com