A lithium battery uniform dryer

A dryer and lithium battery technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve problems such as low efficiency and uneven drying, and achieve the effect of improving uniformity and speeding up drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

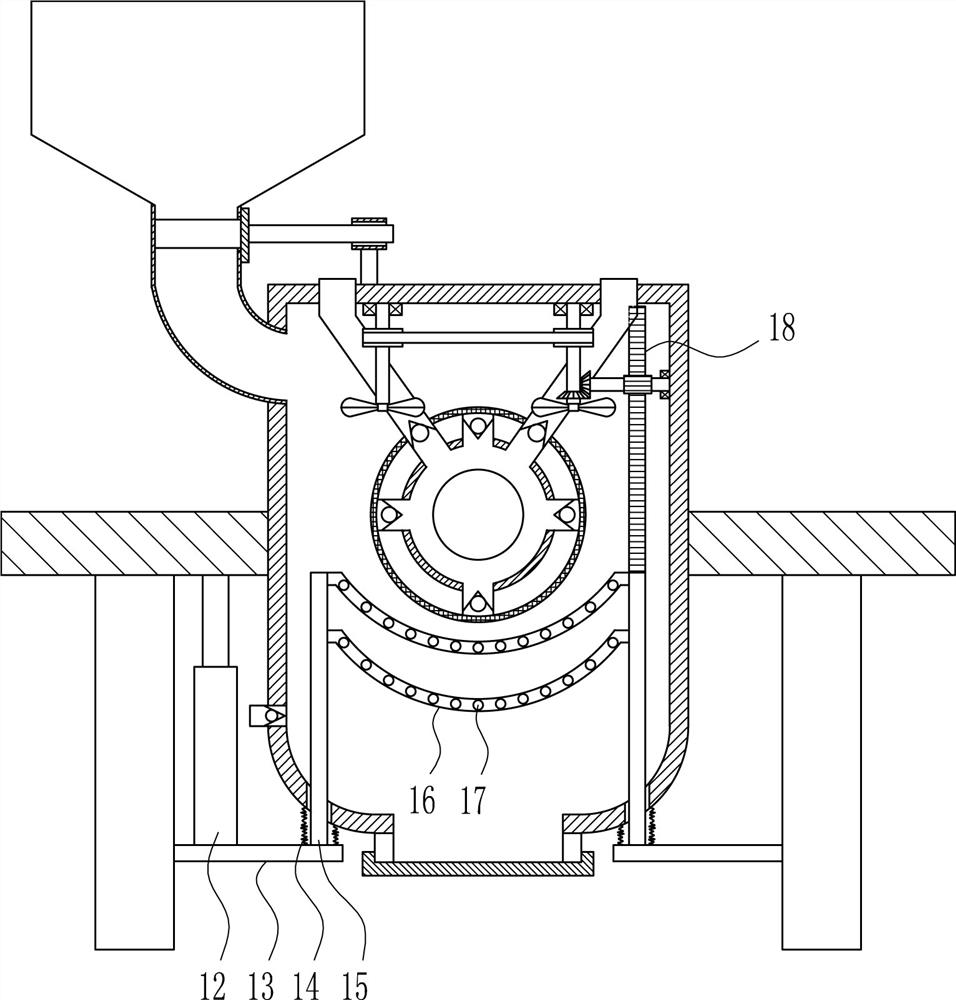

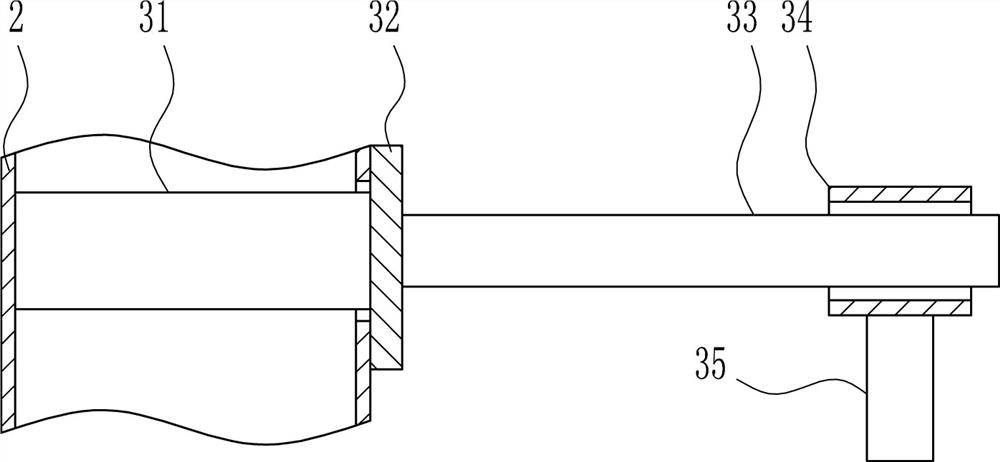

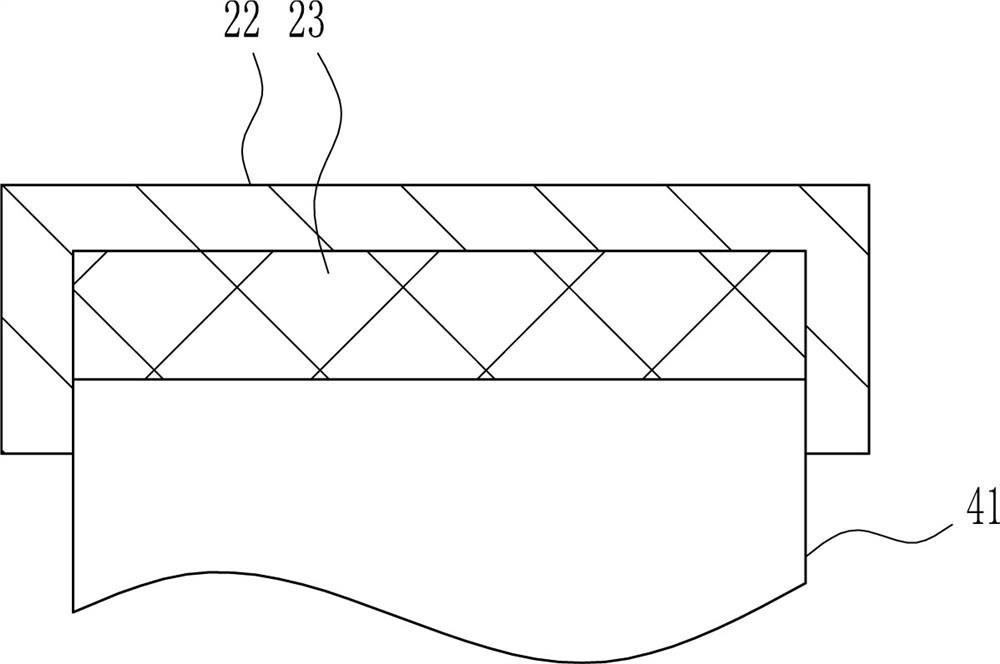

[0029] A uniform drying machine for lithium batteries, such as Figure 1-7 As shown, it includes a quantitative tank 1, a feeding pipe 2, a switch mechanism 3, a drying mechanism 4, a support plate 5, an exhaust pipe 6, a third one-way valve 7, a discharge pipe 8, a screw cap 9, and a drying tank 10 And support 11, support plate 5 is placed on the top of support 11 on left and right sides, and drying tank 10 is installed in the middle of support plate 5 on left and right sides, and drying tank 10 inner rear wall is provided with drying mechanism 4, and the left wall of drying tank 10 The lower part is connected with an exhaust pipe 6, the exhaust pipe 6 is provided with a third one-way valve 7, the bottom of the drying tank 10 is connected with a discharge pipe 8, the discharge pipe 8 is equipped with a screw cap 9, the left side of the drying tank 10 The upper part of the wall is connected with a feeding pipe 2, the feeding pipe 2 is provided with a switch mechanism 3, and th...

Embodiment 2

[0031] A uniform drying machine for lithium batteries, such as Figure 1-7 As shown, it includes a quantitative tank 1, a feeding pipe 2, a switch mechanism 3, a drying mechanism 4, a support plate 5, an exhaust pipe 6, a third one-way valve 7, a discharge pipe 8, a screw cap 9, and a drying tank 10 And support 11, support plate 5 is placed on the top of support 11 on left and right sides, and drying tank 10 is installed in the middle of support plate 5 on left and right sides, and drying tank 10 inner rear wall is provided with drying mechanism 4, and the left wall of drying tank 10 The lower part is connected with an exhaust pipe 6, the exhaust pipe 6 is provided with a third one-way valve 7, the bottom of the drying tank 10 is connected with a discharge pipe 8, the discharge pipe 8 is equipped with a screw cap 9, the left side of the drying tank 10 The upper part of the wall is connected with a feeding pipe 2, the feeding pipe 2 is provided with a switch mechanism 3, and th...

Embodiment 3

[0034] A uniform drying machine for lithium batteries, such as Figure 1-7 As shown, it includes a quantitative tank 1, a feeding pipe 2, a switch mechanism 3, a drying mechanism 4, a support plate 5, an exhaust pipe 6, a third one-way valve 7, a discharge pipe 8, a screw cap 9, and a drying tank 10 And support 11, support plate 5 is placed on the top of support 11 on left and right sides, and drying tank 10 is installed in the middle of support plate 5 on left and right sides, and drying tank 10 inner rear wall is provided with drying mechanism 4, and the left wall of drying tank 10 The lower part is connected with an exhaust pipe 6, the exhaust pipe 6 is provided with a third one-way valve 7, the bottom of the drying tank 10 is connected with a discharge pipe 8, the discharge pipe 8 is equipped with a screw cap 9, the left side of the drying tank 10 The upper part of the wall is connected with a feeding pipe 2, the feeding pipe 2 is provided with a switch mechanism 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com