Discharging device of rotating disc solid culture equipment

A rotating disc and solid culture technology, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of complex and bulky overall structure, inconvenient production and processing operations, and high manufacturing costs, so as to simplify the equipment structure and reduce equipment manufacturing. and operating costs, and the effect of simple and efficient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a rotating disc solid culture equipment discharging device, which has a simple structure and low cost.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

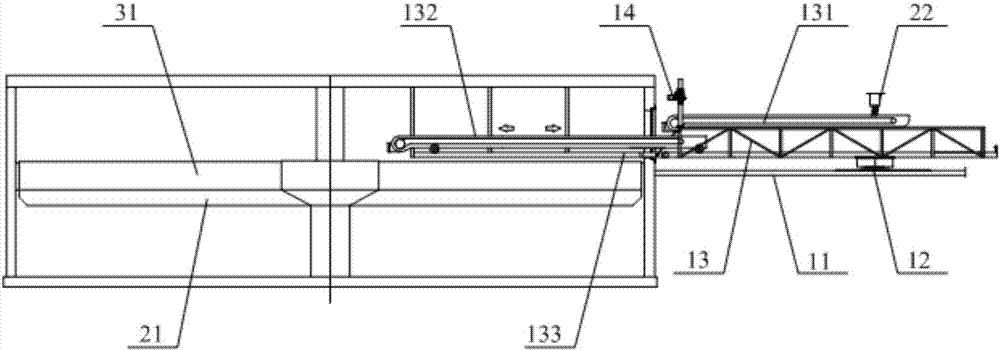

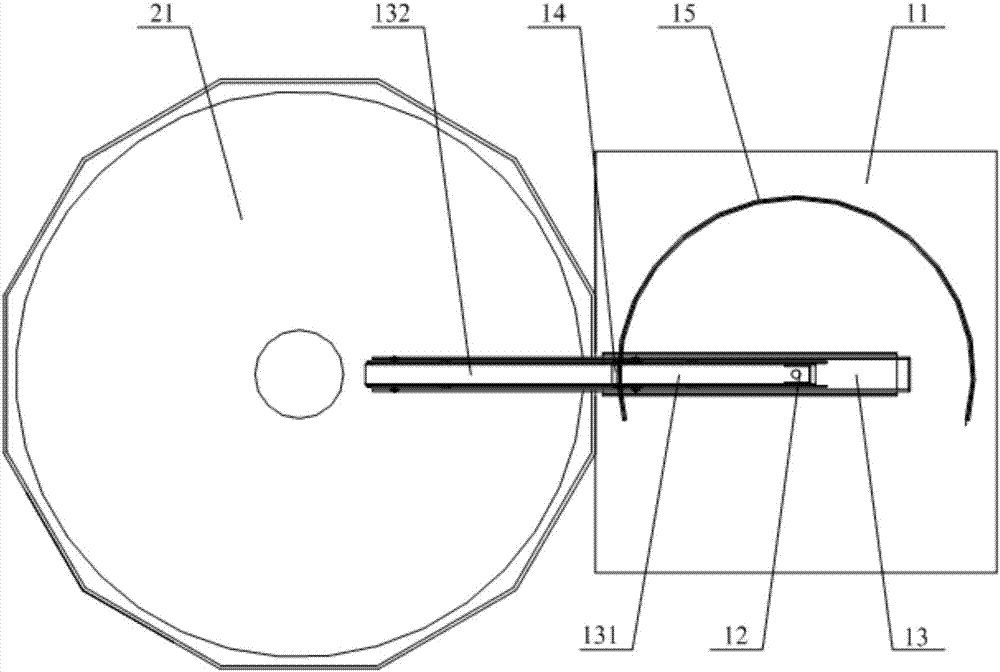

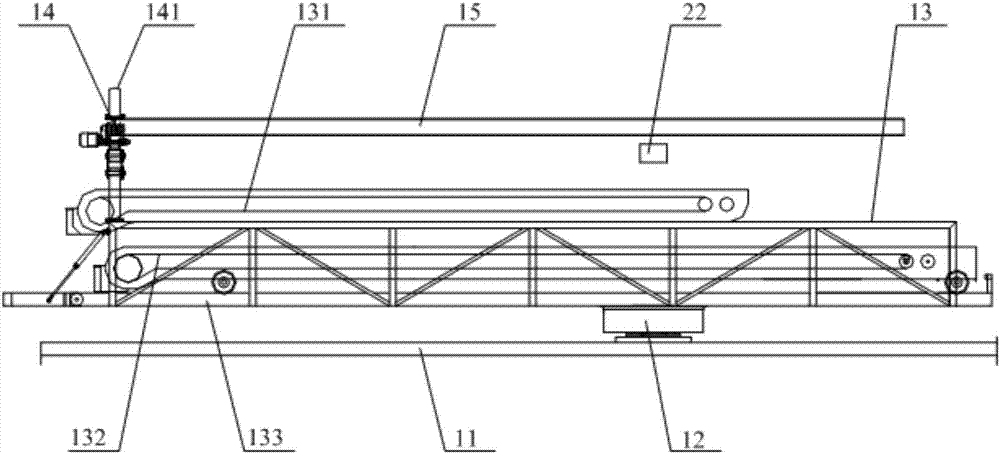

[0024] Please refer to Figure 1 to Figure 5 , figure 1 It is a front view of the cooperation structure between the rotating disk solid culture equipment discharge device and the rotating disk provided by a specific embodiment of the present invention; figure 2 for figure 1 top view of image 3 for figure 1 Front view of the structure of the feeding device part of the rotating disk solid culture equipment; Figure 4 for image 3 side view of the structure; Figure 5 for figure 1 A top view of the cooperation structure between the discharging device of the middle rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com